The Role of Cu Length on the Magnetic Behaviour of Fe/Cu Multi-Segmented Nanowires

Abstract

:1. Introduction

2. Materials and Methods

3. Results

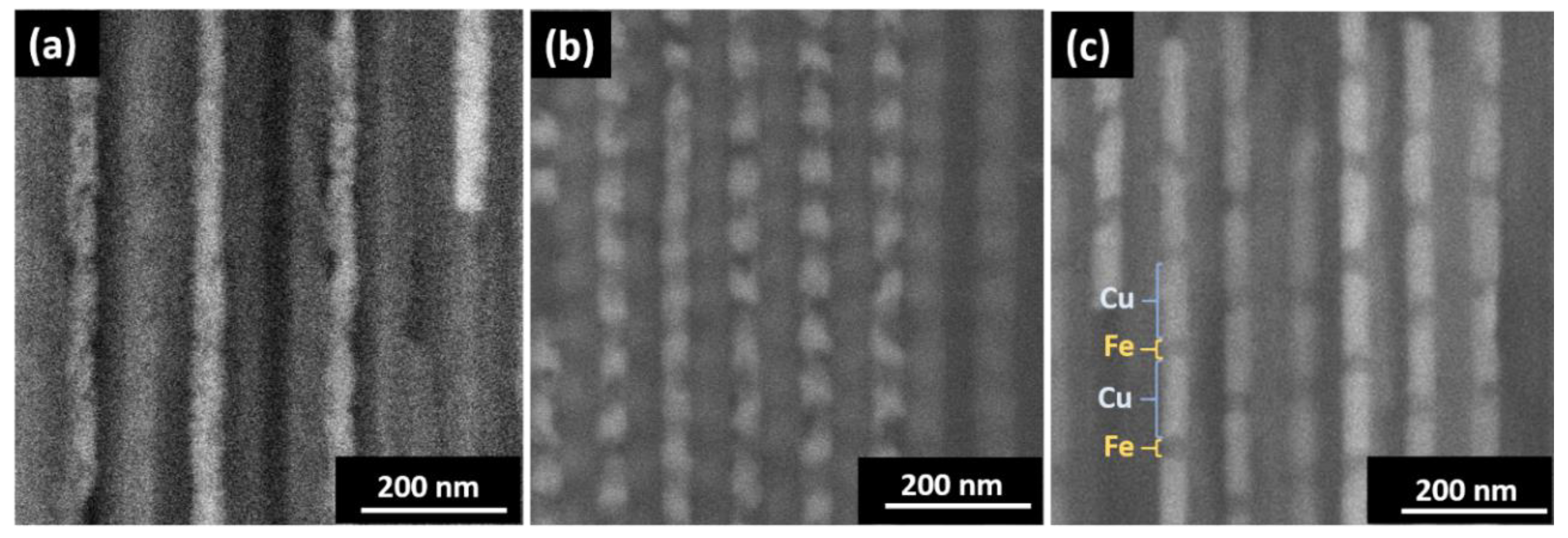

3.1. Morphological Characterization

3.2. Structural Characterization

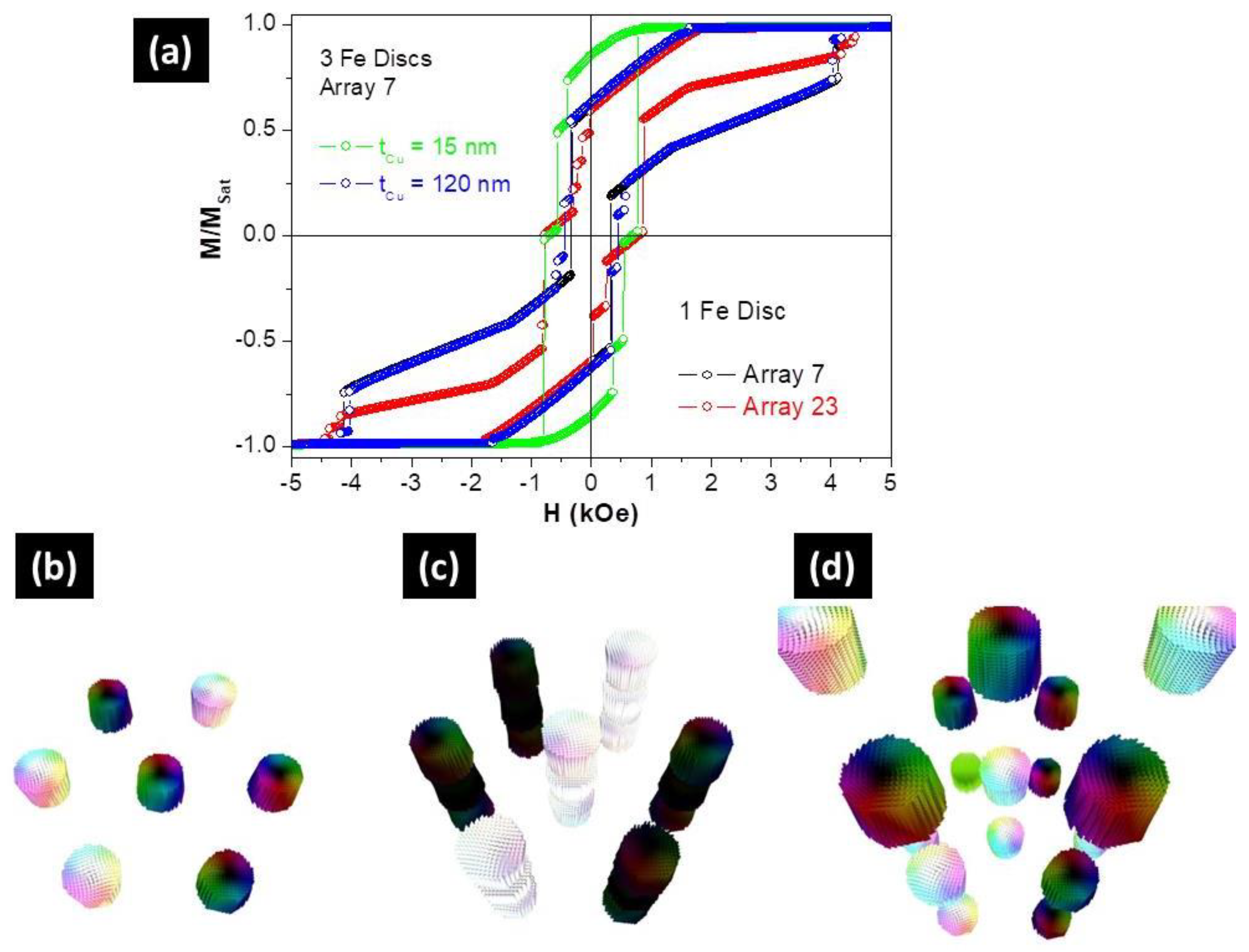

3.3. Magnetic Characterization

3.4. Micromagnetic Simulations

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fernández-Pacheco, A.; Streubel, R.; Fruchart, O.; Hertel, R.; Fischer, P.; Cowburn, R.P. Three-dimensional nanomagnetism. Nat. Commun. 2017, 8, 15756. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paulus, P.M.; Luis, F.; Kröll, M.; Schmid, G.; de Jongh, L.J. Low-temperature study of the magnetization reversal and magnetic anisotropy of Fe, Ni, and Co nanowires. J. Magnetism Magn. Mater. 2001, 224, 180–196. [Google Scholar] [CrossRef]

- Ross, C.A.; Hwang, M.; Shima, M.; Cheng, J.Y.; Farhoud, M.; Savas, T.A.; Smith, H.I.; Schwarzacher, W.; Ross, F.M.; Redjdal, M. Micromagnetic behavior of electrodeposited cylinder arrays. Phys. Rev. B 2002, 65, 144417. [Google Scholar] [CrossRef]

- Walter, E.C.; Ng, K.; Zach, M.P.; Penner, R.M.; Favier, F. Electronic devices from electrodeposited metal nanowires. Microelectron. Eng. 2002, 61–62, 555–561. [Google Scholar] [CrossRef]

- Skomski, R. Nanomagnetics. J. Phys. Condens. Matter. 2003, 15, R841. [Google Scholar] [CrossRef]

- Fennell, J.F.; Liu, S.F.; Azzarelli, J.M.; Weis, J.G.; Rochat, S.; Mirica, K.A.; Ravnsbæk, J.B.; Swager, T.M. Nanowire Chemical/Biological Sensors: Status and a Roadmap for the Future. Angew. Chem. Int. Ed. 2016, 55, 1266–1281. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.-S.; Lin, H.-M.; Hwu, Y.-K.; Chiou, Y.-J. Synthesis and Characterization of Functionalied Iron Nanowires. Procedia Eng. 2014, 92, 42–45. [Google Scholar] [CrossRef]

- Kumeria, T.; Maher, S.; Wang, Y.; Kaur, G.; Wang, L.; Erkelens, M.; Forward, P.; Lambert, M.F.; Evdokiou, A.; Losic, D. Naturally Derived Iron Oxide Nanowires from Bacteria for Magnetically Triggered Drug Release and Cancer Hyperthermia in 2D and 3D Culture Environments: Bacteria Biofilm to Potent Cancer Therapeutic. Biomacromolecules 2016, 17, 2726–2736. [Google Scholar] [CrossRef] [PubMed]

- Sousa, C.T.; Leitao, D.C.; Proenca, M.P.; Ventura, J.; Pereira, A.M.; Araujo, J.P. Nanoporous alumina as templates for multifunctional applications. Appl. Phys. Rev. 2014, 1, 031102. [Google Scholar] [CrossRef] [Green Version]

- Nielsch, K.; Müller, F.; Li, A.-P.; Gösele, U. Uniform Nickel Deposition into Ordered Alumina Pores by Pulsed Electrodeposition. Adv. Mater. 2000, 12, 582–586. [Google Scholar] [CrossRef]

- Vázquez, M.; Pirota, K.; Hernández-Vélez, M.; Prida, V.M.; Navas, D.; Sanz, R.; Batallán, F.; Velázquez, J. Magnetic properties of densely packed arrays of Ni nanowires as a function of their diameter and lattice parameter. J. Appl. Phys. 2004, 95, 6642–6644. [Google Scholar] [CrossRef] [Green Version]

- Whitney, T.M.; Searson, P.C.; Jiang, J.S.; Chien, C.L. Fabrication and Magnetic Properties of Arrays of Metallic Nanowires. Science 1993, 261, 1316. [Google Scholar] [CrossRef] [PubMed]

- Susano, M.; Proenca, M.P.; Moraes, S.; Sousa, C.T.; Araújo, J.P. Tuning the magnetic properties of multisegmented Ni/Cu electrodeposited nanowires with controllable Ni lengths. Nanotechnology 2016, 27, 335301. [Google Scholar] [CrossRef] [PubMed]

- Böhnert, T.; Niemann, A.C.; Michel, A.-K.; Bäßler, S.; Gooth, J.; Tóth, B.G.; Neuróhr, K.; Péter, L.; Bakonyi, I.; Vega, V.; et al. Magnetothermopower and magnetoresistance of single Co-Ni/Cu multilayered nanowires. Phys. Rev. 2014, 90, 165416. [Google Scholar] [CrossRef] [Green Version]

- Kuo, Q.; Xinghua, L.; Hong, Z.; Li, W.; Desheng, X.; Haoli, Z.; Baofan, Z.; Nigel, J.M.; Yong, P. Nanoscale characterization and magnetic property of NiCoCu/Cu multilayer nanowires. Nanotechnology 2012, 23, 505707. [Google Scholar]

- Park, J.J.; Reddy, M.; Stadler, B.J.H.; Flatau, A.B. Hysteresis measurement of individual multilayered Fe-Ga/Cu nanowires using magnetic force microscopy. J. Appl. Phys. 2013, 113, 17A331. [Google Scholar] [CrossRef]

- Reddy, S.M.; Park, J.J.; Maqableh, M.M.; Flatau, A.B.; Stadler, B.J.H. Magnetization reversal mechanisms in 35-nm diameter Fe1-xGax/Cu multilayered nanowires. J. Appl. Phys. 2012, 111, 07A920. [Google Scholar] [CrossRef]

- Ishrat, S.; Maaz, K.; Lee, K.-J.; Jung, M.-H.; Kim, G.-H. Fabrication and temperature-dependent magnetic properties of one-dimensional multilayer Au–Ni–Au–Ni–Au nanowires. J. Solid State Chem. 2014, 210, 116–120. [Google Scholar] [CrossRef]

- Clime, L.; Zhao, S.Y.; Chen, P.; Normandin, F.; Roberge, H.; Veres, T. The interaction field in arrays of ferromagnetic barcode nanowires. Nanotechnology 2007, 18, 435709. [Google Scholar] [CrossRef] [Green Version]

- Chen, M.; Chien, C.-L.; Searson, P.C. Potential Modulated Multilayer Deposition of Multisegment Cu/Ni Nanowires with Tunable Magnetic Properties. Chem. Mater. 2006, 18, 1595–1601. [Google Scholar] [CrossRef]

- Carignan, L.-P.; Lacroix, C.; Ouimet, A.; Ciureanu, M.; Yelon, A.; Ménard, D. Magnetic anisotropy in arrays of Ni, CoFeB, and Ni/Cu nanowires. J. Appl. Phys. 2007, 102, 023905. [Google Scholar] [CrossRef]

- Chen, M.; Searson, P.C.; Chien, C.L. Micromagnetic behavior of electrodeposited Ni/Cu multilayer nanowires. J. Appl. Phys. 2003, 93, 8253–8255. [Google Scholar] [CrossRef]

- Maleak, N.; Potpattanapol, P.; Bao, N.N.; Ding, J.; Wongkokuo, W.; Tang, I.M.; Thongmee, S. Fabrication and magnetic properties of electrodeposited Ni/Cu nanowires using the double bath method. J. Magn. Magn. Mater. 2014, 354, 262–266. [Google Scholar] [CrossRef]

- Béron, F.; Carignan, L.P.; MÉnard, D. Yelon Magnetic Behavior of Ni/Cu Multilayer Nanowire Arrays Studied by First-Order Reversal Curve Diagrams. IEEE Trans. Magn. 2008, 44, 2745–2748. [Google Scholar] [CrossRef]

- Shirazi Tehrani, A.; Almasi Kashi, M.; Ramazani, A.; Montazer, A.H. Axially adjustable magnetic properties in arrays of multilayered Ni/Cu nanowires with variable segment sizes. Superlattices Microstruct. 2016, 95, 38–47. [Google Scholar] [CrossRef]

- Xu, S.H.; Fei, G.T.; Zhu, X.G.; Zhang, L.D. Orientation-dependent growth rate of crystalline plane study in electrodeposited Ni/Cu superlattice nanowires. CrystEngComm 2013, 15, 4070–4076. [Google Scholar] [CrossRef]

- Tang, X.-T.; Wang, G.-C.; Shima, M. Magnetic layer thickness dependence of magnetization reversal in electrodeposited CoNi/Cu multilayer nanowires. J. Magn. Magn. Mater. 2007, 309, 188–196. [Google Scholar] [CrossRef]

- Krimpalis, S.; Dragos, O.-G.; Moga, A.-E.; Lupu, N.; Chiriac, H. Magnetization processes in electrodeposited NiFe/Cu multilayered nanowires. J. Mater. Res. 2011, 26, 1081–1090. [Google Scholar] [CrossRef]

- Blondel, A.; Doudin, B.; Ansermet, J.P. Comparative study of the magnetoresistance of electrodeposited Co/Cu multilayered nanowires made by single and dual bath techniques. J. Magn. Magn. Mater. 1997, 165, 34–37. [Google Scholar] [CrossRef]

- Medina, J.D.L.T.; Darques, M.; Encinas, A.; Piraux, L. Dipolar interactions in multilayered Co0.96Cu0.04/Cu nanowire arrays. Phys. Status Solidi (A) 2008, 205, 1813–1816. [Google Scholar] [CrossRef]

- Wong, J.; Greene, P.; Dumas, R.K.; Liu, K. Probing magnetic configurations in Co/Cu multilayered nanowires. Appl. Phys. Lett. 2009, 94, 032504. [Google Scholar] [CrossRef] [Green Version]

- Piraux, L.; George, J.M.; Despres, J.F.; Leroy, C.; Ferain, E.; Legras, R.; Ounadjela, K.; Fert, A. Giant magnetoresistance in magnetic multilayered nanowires. Appl. Phys. Lett. 1994, 65, 2484–2486. [Google Scholar] [CrossRef]

- Jang, B.; Pellicer, E.; Guerrero, M.; Chen, X.; Choi, H.; Nelson, B.J.; Sort, J.; Pané, S. Fabrication of Segmented Au/Co/Au Nanowires: Insights in the Quality of Co/Au Junctions. ACS Appl. Mater. Interfaces 2014, 6, 14583–14589. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Cui, C.; Yang, W.; Hu, B.; Sun, J.-B. Electrochemical fabrication and magnetic properties of Fe7Co3 alloy nanowire array. J. Mater. Sci. 2011, 46, 2379–2383. [Google Scholar] [CrossRef]

- Park, B.C.; Kim, B.G.; Seo, H.W.; Kim, Y.K. Magnetic Anisotropy Evolution in CoFe/Au Barcode Nanowire Arrays. IEEE Trans. Magn. 2014, 50, 1–4. [Google Scholar] [CrossRef]

- Akhtari-Zavareh, A.; Carignan, L.P.; Yelon, A.; Ménard, D.; Kasama, T.; Herring, R.; Dunin-Borkowski, R.E.; McCartney, M.R.; Kavanagh, K.L. Off-axis electron holography of ferromagnetic multilayer nanowires. J. Appl. Phys. 2014, 116, 023902. [Google Scholar] [CrossRef] [Green Version]

- Núñez, A.; Pérez, L.; Abuín, M.; Araujo, J.P.; Proenca, M.P. Magnetic behaviour of multisegmented FeCoCu/Cu electrodeposited nanowires. J. Phys. D Appl. Phys. 2017, 50, 155003. [Google Scholar] [CrossRef] [Green Version]

- Özkale, B.; Shamsudhin, N.; Chatzipirpiridis, G.; Hoop, M.; Gramm, F.; Chen, X.; Martí, X.; Sort, J.; Pellicer, E.; Pané, S. Multisegmented FeCo/Cu Nanowires: Electrosynthesis, Characterization, and Magnetic Control of Biomolecule Desorption. ACS Appl. Mater. Interfaces 2015, 7, 7389–7396. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ester, M.P.; Fanny, B.; Cristina, B.; Rafael, P.D.R.; Manuel, V. Magnetic interactions in compositionally modulated nanowire arrays. Nanotechnology 2016, 27, 435705. [Google Scholar]

- Sahin, T.; Kockar, H.; Alper, M. Properties of electrodeposited CoFe/Cu multilayers: The effect of Cu layer thickness. J. Magn. Magn. Mater. 2015, 373, 128–131. [Google Scholar] [CrossRef]

- Ramazani, A.; Kashi, M.A.; Eghbal, F.; Jafari-Khamse, E. The effect of deposition parameters on the magnetic behavior of CoFe/Cu multilayer nanowires. Eur. Phys. J. Plus 2015, 130, 2. [Google Scholar] [CrossRef]

- Ramazani, A.; Ghaffari, M.; Kashi, M.A.; Kheiry, F.; Eghbal, F. A new approach to fabricating magnetic multilayer nanowires by modifying the ac pulse electrodeposition in a single bath. J. Phys. D Appl. Phys. 2014, 47, 355003. [Google Scholar] [CrossRef]

- Almasi-Kashi, M.; Ramazani, A.; Kheyri, F.; Jafari-Khamse, E. The effect of magnetic layer thickness on magnetic properties of Fe/Cu multilayer nanowires. Mater. Chem. Phys. 2014, 144, 230–234. [Google Scholar] [CrossRef]

- Masuda, H.; Fukuda, K. Ordered Metal Nanohole Arrays Made by a Two-Step Replication of Honeycomb Structures of Anodic Alumina. Science 1995, 268, 1466–1468. [Google Scholar] [CrossRef] [PubMed]

- Leitao, D.C.; Apolinario, A.; Sousa, C.T.; Ventura, J.; Sousa, J.B.; Vazquez, M.; Araujo, J.P. Nanoscale Topography: A Tool to Enhance Pore Order and Pore Size Distribution in Anodic Aluminum Oxide. J. Phys. Chem. C 2011, 115, 8567–8572. [Google Scholar] [CrossRef]

- Mayergoyz, I.D. Mathematical Models of Hysteresis. Phys. Rev. Lett. 1986, 56, 1518–1521. [Google Scholar] [CrossRef] [PubMed]

- Béron, F.; Clime, L.; Ciureanu, M.; Ménard, D.; Cochrane, R.W.; Yelon, A. Magnetostatic Interactions and Coercivities of Ferromagnetic Soft Nanowires in Uniform Length Arrays. J. Nanosci. Nanotechnol. 2008, 8, 2944–2954. [Google Scholar] [CrossRef]

- Fanny, B.; Luiz, A.S.D.O.; Marcelo, K.; Kleber, R.P. A novel method for identifying the local magnetic viscosity process of heterogeneous magnetic nanostructures. J. Phys. D Appl. Phys. 2013, 46, 045003. [Google Scholar]

- Béron, F.; Ménard, D.; Yelon, A. First-order reversal curve diagrams of magnetic entities with mean interaction field: A physical analysis perspective. J. Appl. Phys. 2008, 103, 07D908. [Google Scholar] [CrossRef]

- Dobrotă, C.-I.; Stancu, A. Tracking the individual magnetic wires' switchings in ferromagnetic nanowire arrays using the first-order reversal curves (FORC) diagram method. Phys. B Condens. Matter 2015, 457, 280–286. [Google Scholar] [CrossRef]

- Vansteenkiste, A.; Leliaert, J.; Dvornik, M.; Helsen, M.; Garcia-Sanchez, F.; Van Waeyenberge, B. The design and verification of MuMax3. AIP Adv. 2014, 4, 107133. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.-P.; Zhao, S.-J. The energetic and structural properties of bcc NiCu, FeCu alloys: A first-principles study. Comput. Mater. Sci. 2011, 50, 2586–2591. [Google Scholar] [CrossRef]

- Reyes, D.; Biziere, N.; Warot-Fonrose, B.; Wade, T.; Gatel, C. Magnetic Configurations in Co/Cu Multilayered Nanowires: Evidence of Structural and Magnetic Interplay. Nano Lett. 2016, 16, 1230–1236. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palma, J.L.; Morales-Concha, C.; Leighton, B.; Altbir, D.; Escrig, J. Micromagnetic simulation of Fe asymmetric nanorings. J. Magn. Magn. Mater. 2012, 324, 637–641. [Google Scholar] [CrossRef]

- Igor, V.R.; Chang-Peng, L.; Harry, S.; Xavier, B.; Roy, S.; Sunil, K.S.; Park, S.; Roger, P.; Fitzsimmons, M.R.; Jose, M.-L.; et al. Measurement of the vortex core in sub-100 nm Fe dots using polarized neutron scattering. EPL (Europhys. Lett.) 2009, 86, 67008. [Google Scholar]

- Yu, P.I.; Vázquez, M.; Chubykalo-Fesenko, O. Magnetic reversal modes in cylindrical nanowires. J. Phys. D Appl. Phys. 2013, 46, 485001. [Google Scholar] [Green Version]

| Systems | (Oe) | (Oe) | ||

|---|---|---|---|---|

| (Fe(30nm)/Cu(15nm))15 | 650 ± 50 | 190 ± 30 | 0.70 ± 0.03 | 0.04 ± 0.01 |

| (Fe(30nm)/Cu(60nm))15 | 480 ± 30 | 240 ± 40 | 0.45 ± 0.02 | 0.07 ± 0.02 |

| (Fe(30nm)/Cu(120nm))15 | 430 ± 30 | 280 ± 40 | 0.37 ± 0.02 | 0.20 ± 0.02 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moraes, S.; Navas, D.; Béron, F.; Proenca, M.P.; Pirota, K.R.; Sousa, C.T.; Araújo, J.P. The Role of Cu Length on the Magnetic Behaviour of Fe/Cu Multi-Segmented Nanowires. Nanomaterials 2018, 8, 490. https://doi.org/10.3390/nano8070490

Moraes S, Navas D, Béron F, Proenca MP, Pirota KR, Sousa CT, Araújo JP. The Role of Cu Length on the Magnetic Behaviour of Fe/Cu Multi-Segmented Nanowires. Nanomaterials. 2018; 8(7):490. https://doi.org/10.3390/nano8070490

Chicago/Turabian StyleMoraes, Suellen, David Navas, Fanny Béron, Mariana P. Proenca, Kleber R. Pirota, Célia T. Sousa, and João P. Araújo. 2018. "The Role of Cu Length on the Magnetic Behaviour of Fe/Cu Multi-Segmented Nanowires" Nanomaterials 8, no. 7: 490. https://doi.org/10.3390/nano8070490