Liquid-Assisted Femtosecond Laser Precision-Machining of Silica

Abstract

:1. Introduction

2. Materials and Methods

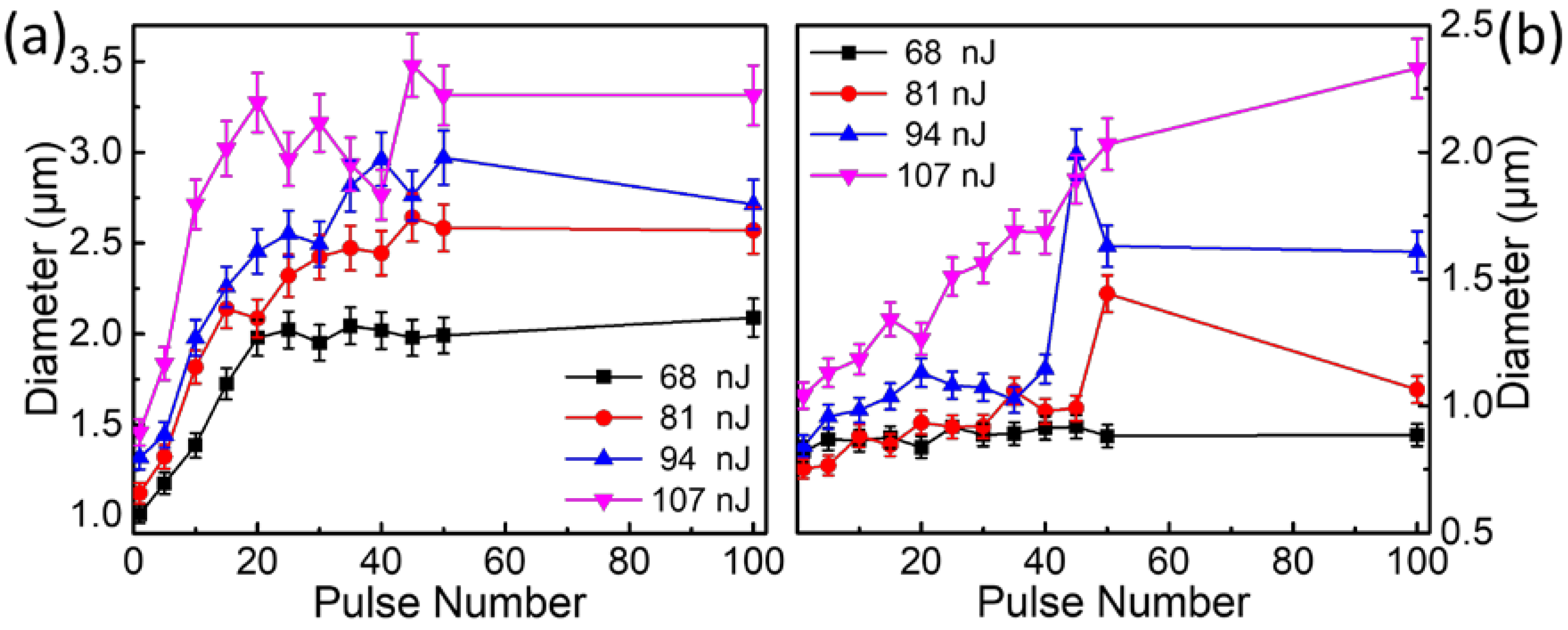

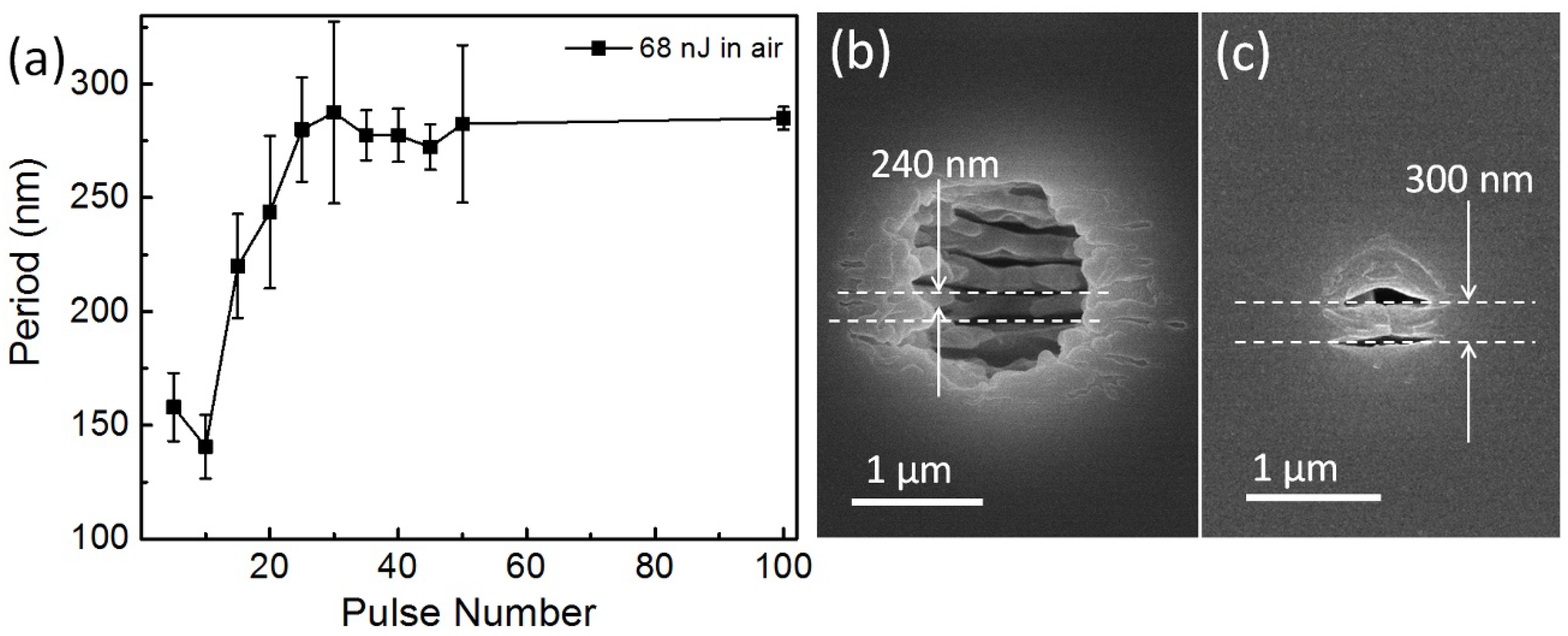

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Malinauskas, M.; Žukauskas, A.; Hasegawa, S.; Hayasaki, Y.; Mizeikis, V.; Buividas, R.; Juodkazis, S. Ultrafast Laser Processing of Materials: From Science to Industry. Light Sci. Appl. 2016, 5, e16133. [Google Scholar] [CrossRef]

- Ni, J.; Wang, C.; Zhang, C.; Hu, Y.; Yang, L.; Lao, Z.; Xu, B.; Li, J.; Wu, D.; Chu, J. Three-Dimensional Chiral Microstructures Fabricated by Structured Optical Vortices in Isotropic Material. Light Sci. Appl. 2017, 6, e17011. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Chen, Q.D.; Xia, H.; Sun, H.B. Designable 3D Nanofabrication by Femtosecond Laser Direct Writing. Nano Today 2010, 5, 435–448. [Google Scholar] [CrossRef]

- Juodkazis, S.; Mizeikis, V.; Matsuo, S.; Ueno, K.; Misawa, H. Three-Dimensional Micro- and Nano-Structuring of Materials by Tightly Focused Laser Radiation. Bull. Chem. Soc. Jpn. 2008, 81, 411–448. [Google Scholar] [CrossRef]

- Guo, F.; Karl, A.; Xue, Q.-F.; Tam, K.C.; Forberich, K.; Brabec, C.J. The Fabrication of Color-Tunable Organic Light-Emitting Diode Displays via Solution Processing. Light Sci. Appl. 2017, 6, e17094. [Google Scholar] [CrossRef]

- Guo, L.; Xia, H.; Fan, H.T.; Zhang, Y.L.; Chen, Q.D.; Zhang, T.; Sun, H.B. Femtosecond Laser Direct Patterning of Sensing Materials toward Flexible Integration of Micronanosensors. Opt. Lett. 2010, 35, 1695–1697. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, T.; Sun, H.B.; Kawata, S. Rapid Sub-Diffraction-Limit Laser Micro/Nanoprocessing in a Threshold Material System. Appl. Phys. Lett. 2002, 80, 312–314. [Google Scholar] [CrossRef]

- Sugioka, K.; Cheng, Y. Ultrafast Lasers—Reliable Tools for Advanced Materials Processing. Light Sci. Appl. 2014, 3, e149. [Google Scholar] [CrossRef]

- Shaheen, M.E.; Gagnon, J.E.; Fryer, B.J. Femtosecond Laser Ablation Behavior of Gold, Crystalline Silicon, and Fused Silica: A Comparative Study. Laser Phys. 2014, 24, 106102. [Google Scholar] [CrossRef]

- Juodkazis, S.; Nishi, Y.; Misawa, H. Femtosecond Laser-Assisted Formation of Channels in Sapphire Using Koh Solution. Phys. Status Solidi RRL 2008, 2, 275–277. [Google Scholar] [CrossRef]

- Ahsan, M.S.; Lee, M.S.; Hasan, M.K.; Noh, Y.-C.; Sohn, I.-B.; Ahmed, F.; Jun, M.B.G. Formation Mechanism of Self-Organized Nano-Ripples on Quartz Surface Using Femtosecond Laser Pulses. Optik 2015, 126, 5979–5983. [Google Scholar] [CrossRef]

- Huang, M.; Zhao, F.; Cheng, Y.; Xu, N.; Xu, Z. Origin of Laser-Induced near-Subwavelength Ripples: Interference between Surface Plasmons and Incident Laser. Acs Nano 2009, 3, 4062–4070. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Chen, Q.-D.; Yang, R.; Xu, B.-B.; Wang, H.-Y.; Yang, H.; Huo, C.-S.; Sun, H.-B.; Tu, H.-L. Rapid Production of Large-Area Deep Sub-Wavelength Hybrid Structures by Femtosecond Laser Light-Field Tailoring. Appl. Phys. Lett. 2014, 104, 031904. [Google Scholar] [CrossRef]

- Li, Q.K.; Yu, Y.H.; Wang, L.; Cao, X.W.; Liu, X.Q.; Sun, Y.L.; Chen, Q.D.; Duan, J.A.; Sun, H.B. Sapphire-Based Fresnel Zone Plate Fabricated by Femtosecond Laser Direct Writing and Wet Etching. IEEE Photonics Technol. Lett. 2016, 28, 1290–1293. [Google Scholar] [CrossRef]

- Richter, S.; Heinrich, M.; Döring, S.; Tünnermann, A.; Nolte, S. Formation of Femtosecond Laser-Induced Nanogratings at High Repetition Rates. Appl. Phys. A 2011, 104, 503–507. [Google Scholar] [CrossRef]

- Varkentina, N.; Dussauze, M.; Royon, A.; Ramme, M.; Petit, Y.; Canioni, L. High Repetition Rate Femtosecond Laser Irradiation of Fused Silica Studied by Raman Spectroscopy. Opt. Mater. Express 2015, 6, 79–90. [Google Scholar] [CrossRef]

- Li, Q.K.; Cao, J.J.; Yu, Y.H.; Wang, L.; Sun, Y.L.; Chen, Q.D.; Sun, H.B. Fabrication of an Anti-Reflective Microstructure on Sapphire by Femtosecond Laser Direct Writing. Opt. Lett. 2017, 42, 543–546. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.Q.; Chen, Q.D.; Guan, K.M.; Ma, Z.C.; Yu, Y.H.; Li, Q.K.; Tian, Z.N.; Sun, H.B. Dry-Etching-Assisted Femtosecond Laser Machining. Laser Photonics Rev. 2017, 11, 1600115. [Google Scholar] [CrossRef]

- Kaakkunen, J.J.J.; Silvennoinen, M.; Paivasaari, K.; Vahimaa, P. Water-Assisted Femtosecond Laser Pulse Ablation of High Aspect Ratio Holes. Phys. Procedia 2011, 12, 89–93. [Google Scholar] [CrossRef]

- Li, Y.; Qu, S.L. Water-Assisted Femtosecond Laser Ablation for Fabricating Three-Dimensional Microfluidic Chips. Curr. Appl. Phys. 2013, 13, 1292–1295. [Google Scholar] [CrossRef]

- Wang, J.; Niino, H.; Yabe, A. One-Step Microfabrication of Fused Silica by Laser Ablation of an Organic Solution. Appl. Phys. A Mater. 1999, 68, 111–113. [Google Scholar] [CrossRef]

- Böhme, R.; Braun, A.; Zimmer, K. Backside Etching of UV-Transparent Materials at the Interface to Liquids. Appl. Surf. Sci. 2002, 186, 276–281. [Google Scholar] [CrossRef]

- Ameer-Beg, S.; Perrie, W.; Rathbone, S.; Wright, J.; Weaver, W.; Champoux, H. Femtosecond Laser Microstructuring of Materials. Appl. Surf. Sci. 1998, 127, 875–880. [Google Scholar] [CrossRef]

- Buividas, R.; Mikutis, M.; Juodkazis, S. Surface and Bulk Structuring of Materials by Ripples with Long and Short Laser Pulses: Recent Advances. Prog. Quantum Electron. 2014, 38, 119–156. [Google Scholar] [CrossRef]

- Yan, Z.J.; Chrisey, D.B. Pulsed Laser Ablation in Liquid for Micro-/Nanostructure Generation. J. Photochem. Photobiol. C 2012, 13, 204–223. [Google Scholar] [CrossRef]

- Baudach, S.; Bonse, J.; Krüger, J.; Kautek, W. Ultrashort Pulse Laser Ablation of Polycarbonate and Polymethylmethacrylate. Appl. Surf. Sci. 2000, 154, 555–560. [Google Scholar] [CrossRef]

- Wang, L.; Xu, B.-B.; Cao, X.-W.; Li, Q.-K.; Tian, W.-J.; Chen, Q.-D.; Juodkazis, S.; Sun, H.-B. Competition between Subwavelength and Deep-Subwavelength Structures Ablated by Ultrashort Laser Pulses. Optica 2017, 4, 637–642. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Q.-D.; Cao, X.-W.; Buividas, R.; Wang, X.; Juodkazis, S.; Sun, H.-B. Plasmonic Nano-Printing: Large-Area Nanoscale Energy Deposition for Efficient Surface Texturing. Light Sci. Appl. 2017, 6, e17112. [Google Scholar] [CrossRef]

- Chen, C.; Sun, H.B.; Guo, J.C.; Wang, L.; Chen, Q.D.; Yang, R.; Yu, Y.S. Monitoring Thermal Effect in Femtosecond Laser Interaction with Glass by Fiber Bragg Grating. J. Lightw. Technol. 2011, 29, 2126–2130. [Google Scholar] [CrossRef]

- Juodkazis, S.; Yamasaki, K.; Mizeikis, V.; Matsuo, S.; Misawa, H. Formation of Embedded Patterns in Glasses Using Femtosecond Irradiation. Appl. Phys. A Mater. 2004, 79, 1549–1553. [Google Scholar] [CrossRef]

- Rekštytė, S.; Jonavičius, T.; Gailevičius, D.; Malinauskas, M.; Mizeikis, V.; Gamaly, E.G.; Juodkazis, S. Nanoscale Precision of 3D Polymerization via Polarization Control. Adv. Opt. Mater. 2016, 4, 1209–1214. [Google Scholar] [CrossRef]

- Louchev, O.A.; Juodkazis, S.; Murazawa, N.; Wada, S.; Misawa, H. Coupled Laser Molecular Trapping, Cluster Assembly, and Deposition Fed by Laser-Induced Marangoni Convection. Opt. Express 2008, 16, 5673–5680. [Google Scholar] [CrossRef] [PubMed]

- Joglekar, A.P.; Liu, H.-H.; Meyhöfer, E.; Mourou, G.; Hunt, A.J. Optics at Critical Intensity: Applications to Nanomorphing. Proc. Natl. Acad. Sci. USA 2004, 101, 5856–5861. [Google Scholar] [CrossRef] [PubMed]

- Gamaly, E.G.; Rode, A.V. Ultrafast Re-Structuring of the Electronic Landscape of Transparent Dielectrics: New Material States (Die-Met). Appl. Phys. A 2018, 124, 278. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, X.-W.; Chen, Q.-D.; Fan, H.; Zhang, L.; Juodkazis, S.; Sun, H.-B. Liquid-Assisted Femtosecond Laser Precision-Machining of Silica. Nanomaterials 2018, 8, 287. https://doi.org/10.3390/nano8050287

Cao X-W, Chen Q-D, Fan H, Zhang L, Juodkazis S, Sun H-B. Liquid-Assisted Femtosecond Laser Precision-Machining of Silica. Nanomaterials. 2018; 8(5):287. https://doi.org/10.3390/nano8050287

Chicago/Turabian StyleCao, Xiao-Wen, Qi-Dai Chen, Hua Fan, Lei Zhang, Saulius Juodkazis, and Hong-Bo Sun. 2018. "Liquid-Assisted Femtosecond Laser Precision-Machining of Silica" Nanomaterials 8, no. 5: 287. https://doi.org/10.3390/nano8050287