Enhanced Supercapacitor Performance Using Electropolymerization of Self-Doped Polyaniline on Carbon Film

Abstract

:1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of CNP Substrates

2.3. Preparation of SPANI−CNP Composite Electrodes

2.4. Characterization Techniques

2.5. Electrochemical Characterization

3. Results and Discussion

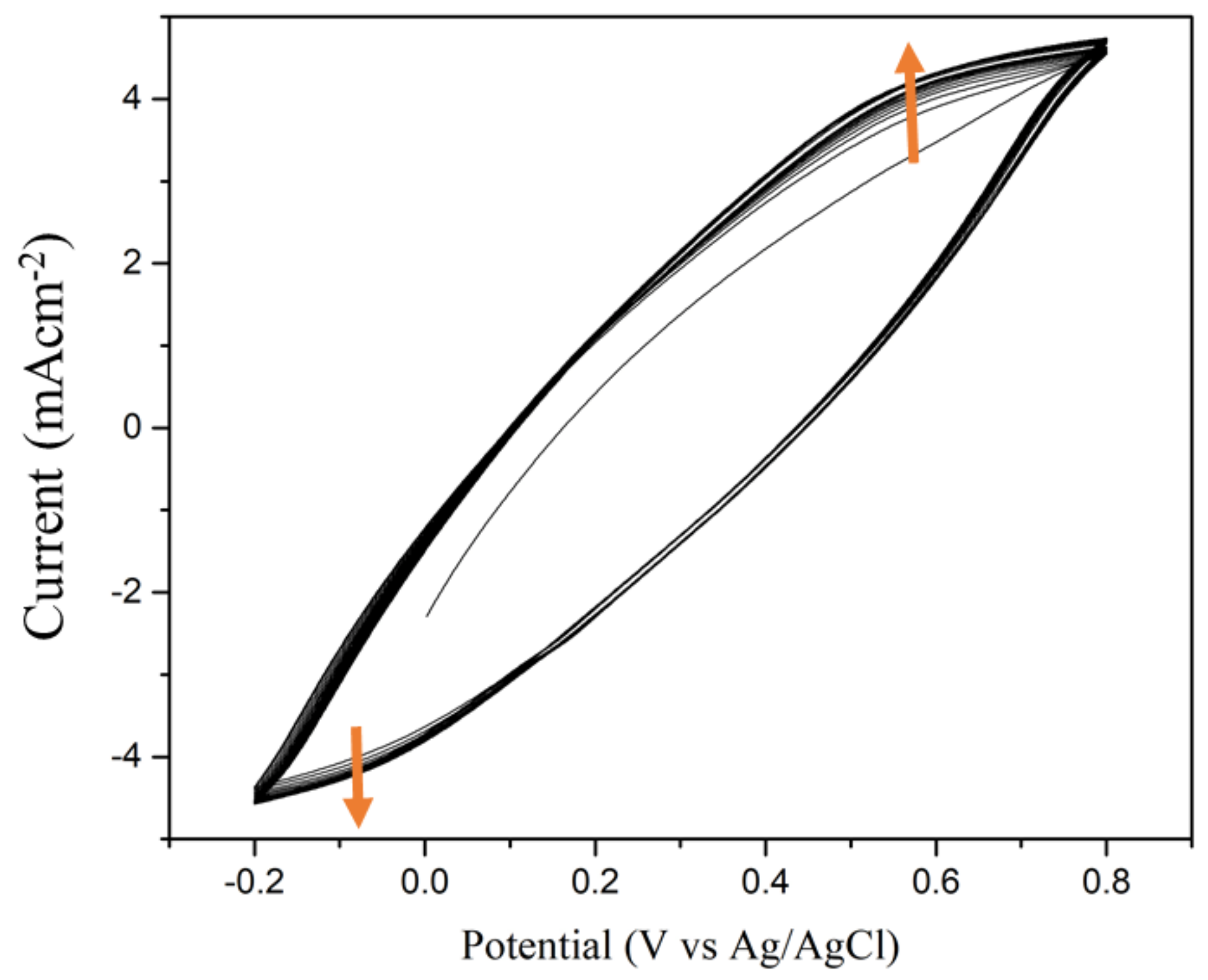

3.1. Cyclic Voltammograms of SPANI Electropolymerization on CNP Substrate

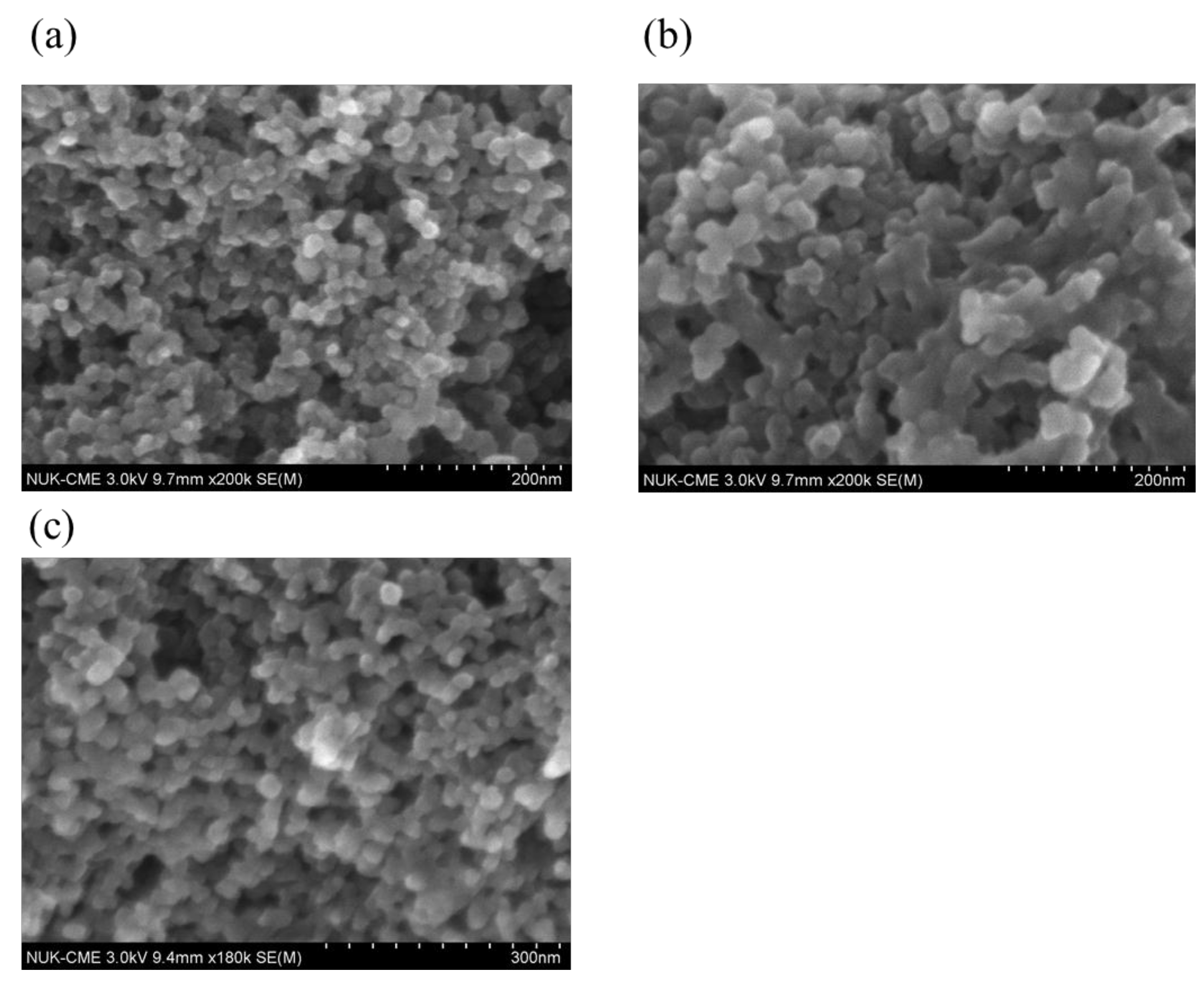

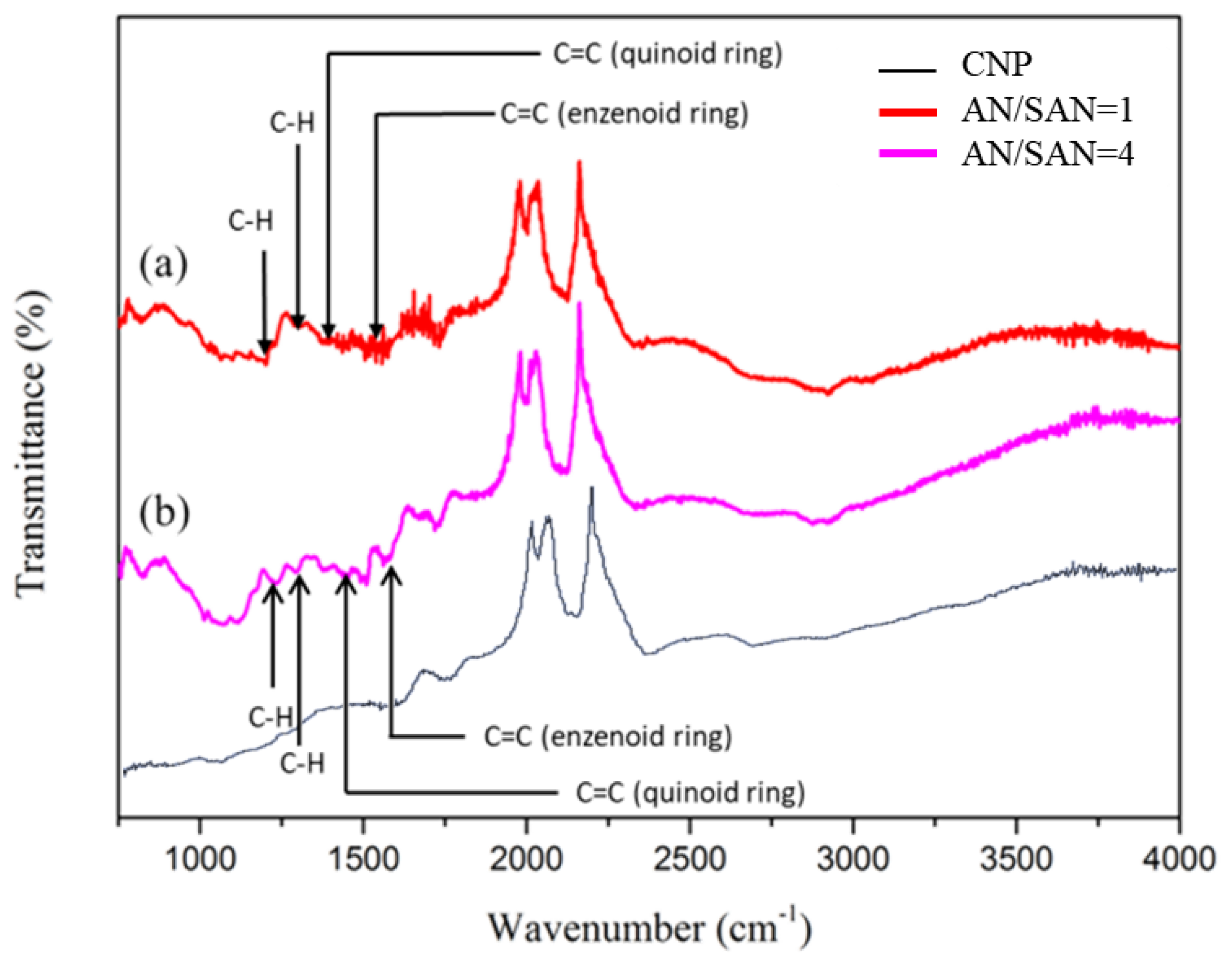

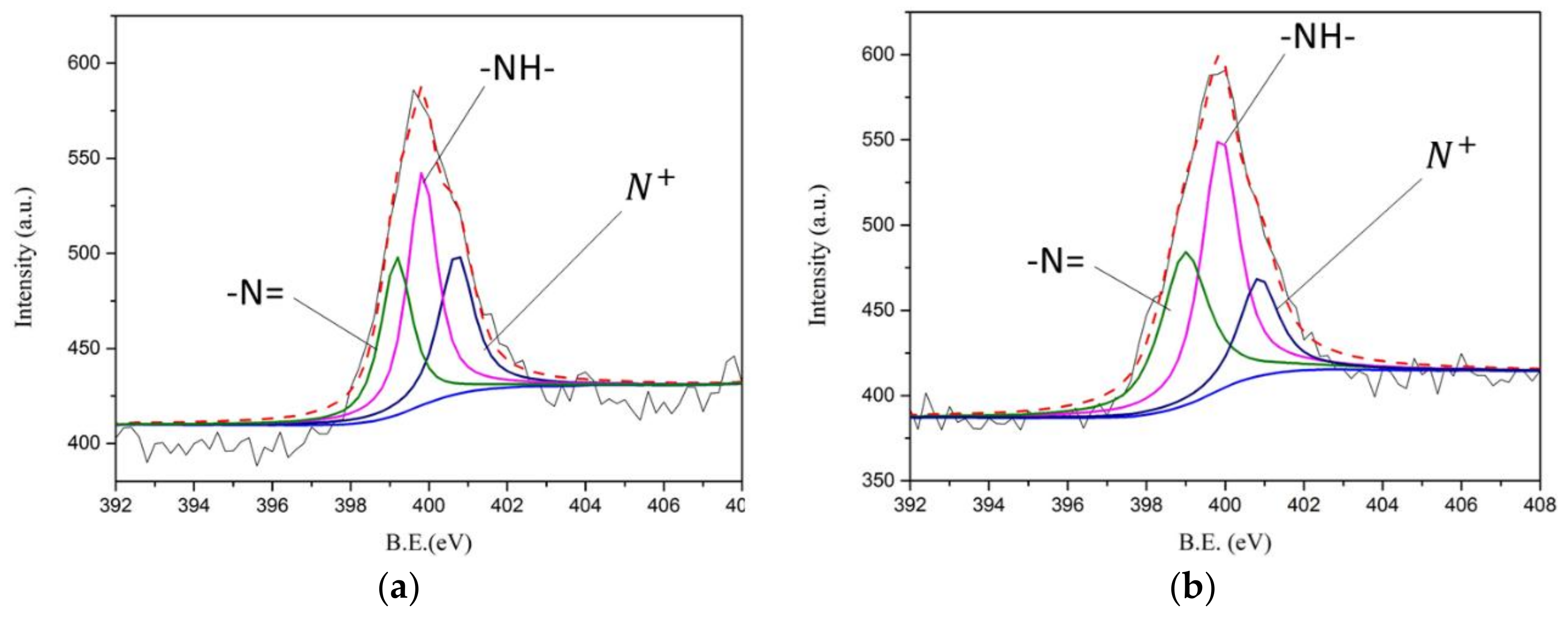

3.2. Material Analysis

3.3. Electrochemical Studies

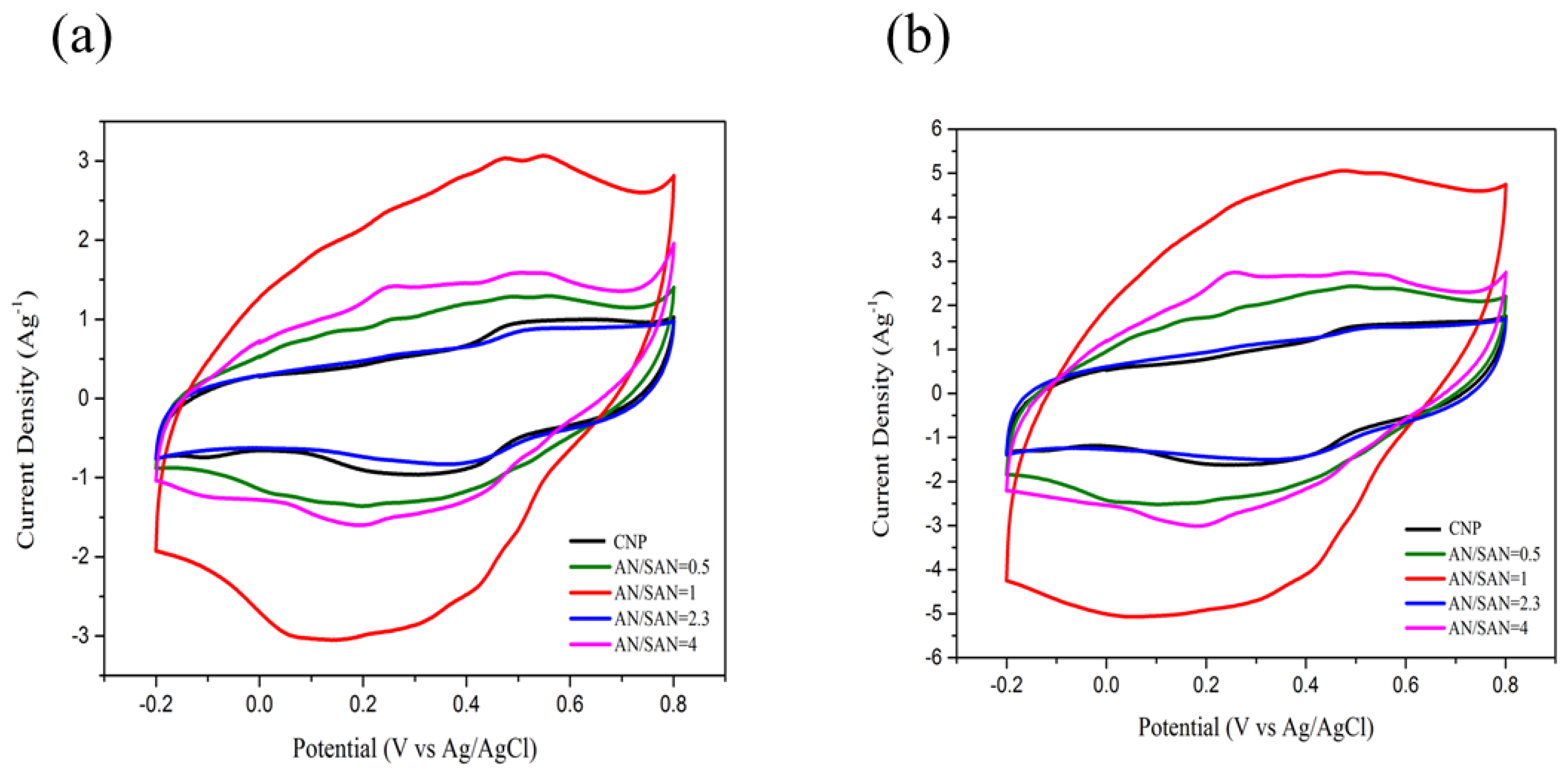

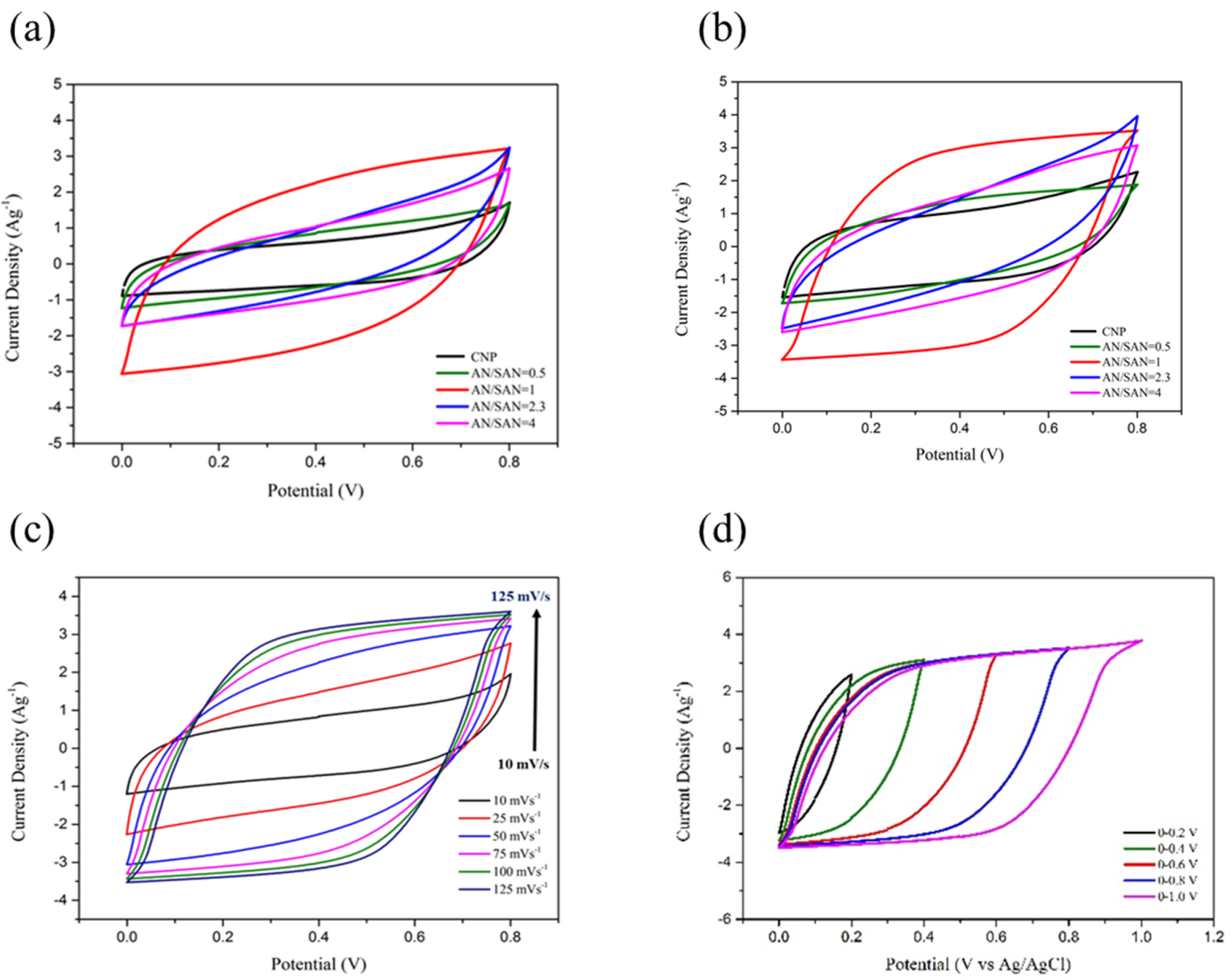

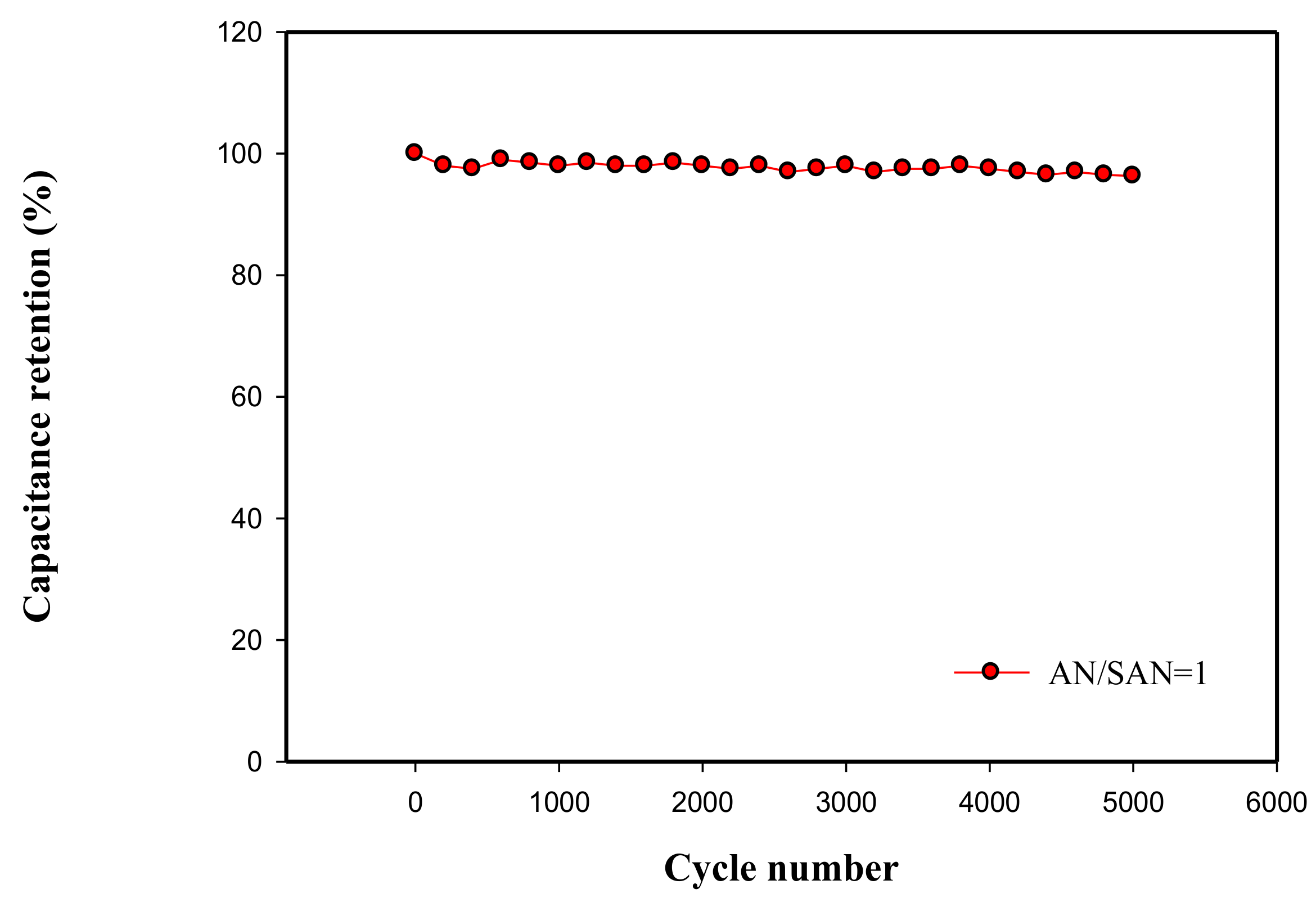

3.4. Electrochemical Impedance Spectroscopy

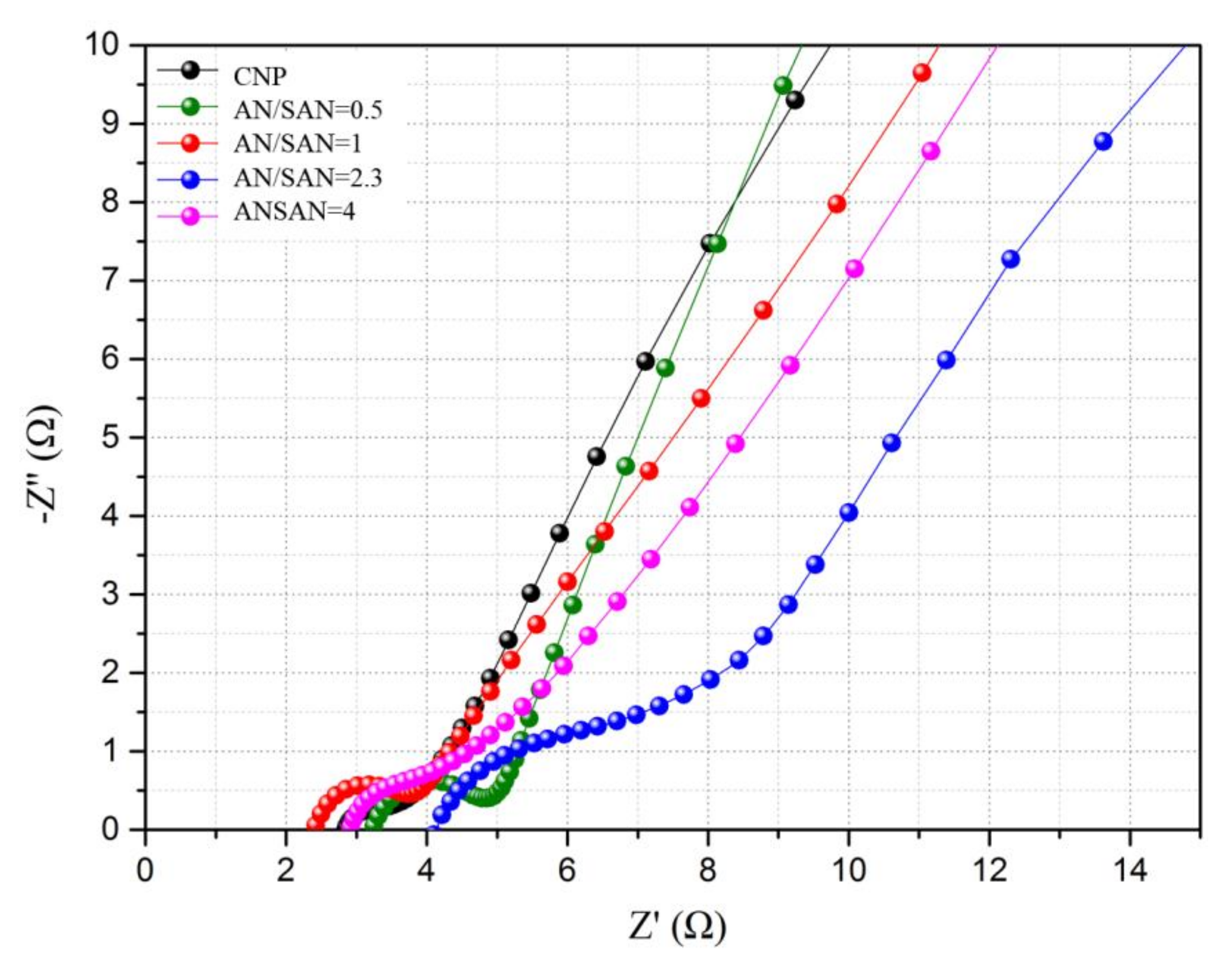

3.5. Galvanostatic Charge−Discharge

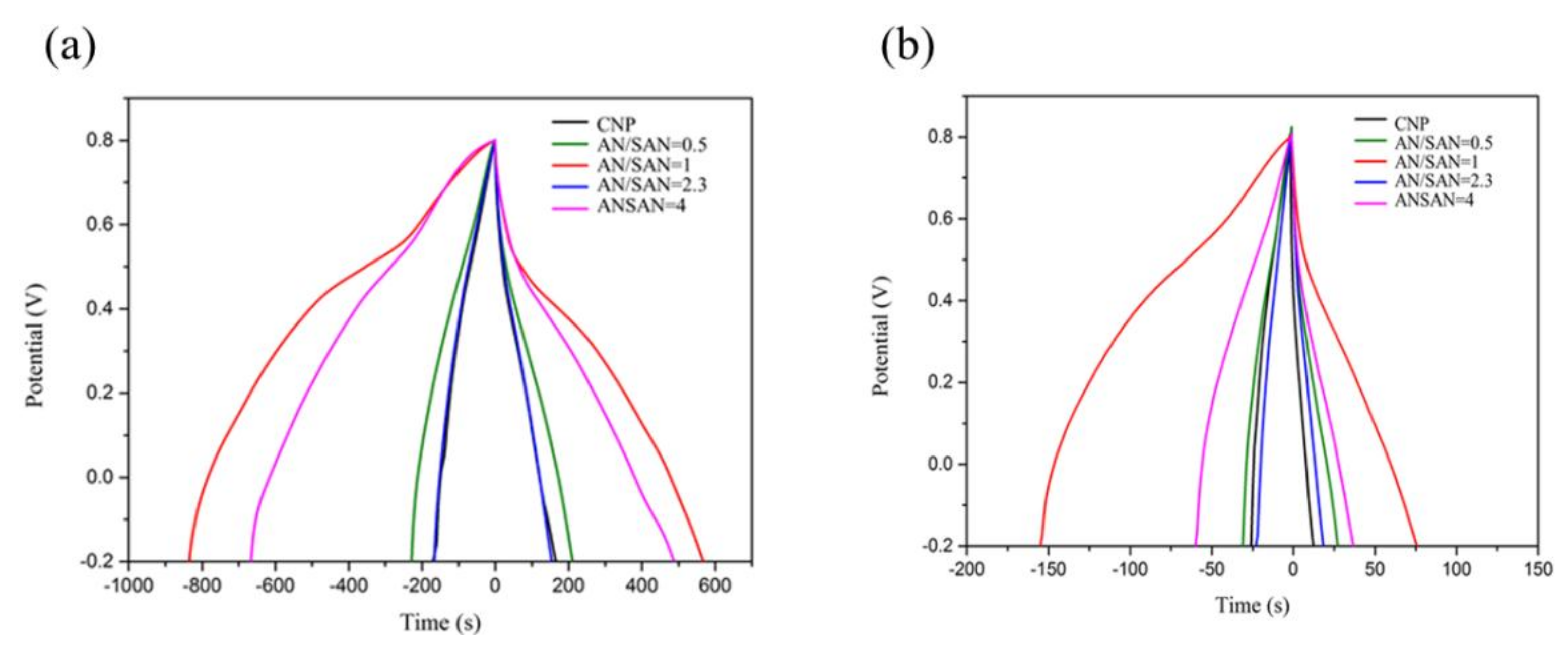

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Burke, A. Ultracapacitors: Why, how, and where is the technology. J. Power Sources 2000, 91, 37–50. [Google Scholar] [CrossRef]

- Arico, A.S.; Bruce, P.; Scrosati, P.B.; Tarascon, J.M.; Van Schalkwijk, W. Nanostructured materials for advanced energy conversion and storage devices. Nat. Mater. 2005, 4, 366–377. [Google Scholar] [CrossRef] [PubMed]

- Soudan, P.; Gaudet, J.; Guay, D.; Bélanger, D.; Schulz, R. Electrochemical properties of ruthenium-based nanocrystalline materials as electrodes for supercapacitors. Chem. Mater. 2002, 14, 1210–1215. [Google Scholar] [CrossRef]

- Choi, B.Y.; Chung, I.J.; Chun, J.H.; Ko, J.M. Electrochemical characteristics of dodecylbenzene sulfonic acid-doped polyaniline in aqueous solutions. Synth. Met. 1999, 99, 253–256. [Google Scholar] [CrossRef]

- Izadi-Najafabadi, A.; Yasuda, S.; Kobashi, K.; Yamada, T.; Futaba, D.N.; Hatori, H.; Yumura, M.; Iijima, S.; Hata, K. Extracting the full potential of single-walled carbon nanotubes as durable supercapacitor electrodes operable at 4 V with high power and energy density. Adv. Mater. 2010, 22, E235–E241. [Google Scholar] [CrossRef] [PubMed]

- Nishihara, H.; Simura, T.; Kobayashi, S.; Nomura, K.; Berenguer, R.; Ito, M.; Uchimura, M.; Iden, H.; Arihara, K.; Ohma, A.; et al. Oxidation-resistant and elastic mesoporous carbon with single-layer graphene walls. Adv. Funct. Mater. 2016, 26, 6418–6427. [Google Scholar] [CrossRef]

- Frackowiak, E.; Khomenko, V.; Jurewicz, K.; Lota, K.; Beguin, F. Supercapacitors based on conducting polymers/nanotubes composites. J. Power Sources 2006, 153, 413–418. [Google Scholar] [CrossRef]

- Liu, W.; Yan, X.; Xue, Q. Multilayer hybrid films consisting of alternating graphene and titanium dioxide for high performance supercapacitors. J. Mater. Chem. C 2013, 1, 1413–1422. [Google Scholar] [CrossRef]

- Peng, H.; Ma, G.; Sun, K.; Zhang, Z.; Yang, Q.; Rana, F.; Lei, Z. A facile and rapid preparation of highly crumpled nitrogen-doped graphene-like nanosheets for high-performance supercapacitors. J. Mater. Chem. A 2015, 3, 13210–13214. [Google Scholar] [CrossRef]

- Wang, J.; Gao, Z.; Li, Z.; Wang, B.; Yan, Y.; Liu, Q. Green synthesis of graphene nanosheets/ZnO composites and electrochemical properties. J. Solid State Chem. 2011, 184, 1421–1427. [Google Scholar] [CrossRef]

- Ryu, K.S.; Lee, Y.; Han, K.S.; Parka, Y.J.; Kang, M.G.; Park, N.G.; Chang, S.H. Electrochemical supercapacitor based on polyaniline doped with lithium salt and active carbon electrodes. Solid State Ion. 2004, 175, 765–768. [Google Scholar] [CrossRef]

- Yan, J.; Liu, J.; Fan, Z.; Wei, T.; Zhang, L. High-performance supercapacitor electrodes based on highly corrugated graphene sheets. Carbon 2012, 50, 2179–2188. [Google Scholar] [CrossRef]

- Ramadoss, A.; Ki, S. Improved activity of a grapheme–TiO2 hybrid electrode in an electrochemical supercapacitor. Carbon 2013, 63, 434–445. [Google Scholar] [CrossRef]

- Grover, S.; Goel, S.; Sahu, V.; Singh, G.; Sharma, R.K. Asymmetric supercapacitive characteristics of PANI embedded holey graphene nanoribbons. ACS Sustain. Chem. Eng. 2015, 3, 1460–1469. [Google Scholar] [CrossRef]

- Winokur, M.J.; Mattes, B.R. Polyaniline as viewed from a structural perspective. J. Reinf. Plast. Compos. 1999, 18, 875–884. [Google Scholar] [CrossRef]

- Yang, C.H.; Chih, Y.K.; Cheng, H.E.; Chen, C.H. Nanofibers of self-doped polyaniline. Polymer 2005, 46, 10688–10698. [Google Scholar] [CrossRef]

- Wei, Y.; Focke, W.W.; Wnek, G.E.; Ray, A.; MacDiarmid, A.G. Synthesis and electrochemistry of alkyl ring-substituted polyanilines. J. Phys. Chem. 1989, 93, 495–499. [Google Scholar] [CrossRef]

- Yang, C.H.; Wen, T.C. Polyaniline derivative with external and internal doping via electrochemical copolymerization of aniline and 2,5-diaminobenzenesulfonic acid on IrO2-coated titanium electrode. J. Electrochem. Soc. 1994, 141, 2624–2632. [Google Scholar] [CrossRef]

| AN/SAN | –N = (eV/%) | –NH– (eV/%) | (eV/%) |

|---|---|---|---|

| 1 | 399.2 (28.5%) | 399.8 (39%) | 400.8 (32.4%) |

| 4 | 399 (31.6%) | 399.8 (42.1%) | 401 (26.2%) |

| Sample | ESR (Ω) | Rct (Ω) |

|---|---|---|

| CNP | 2.83 | 1.0 |

| AN/SAN = 0.5 | 3.23 | 1.89 |

| AN/SAN = 1 | 2.39 | 1.63 |

| AN/SAN = 2.3 | 4.1 | 4.0 |

| AN/SAN = 4 | 2.9 | 1.97 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, P.-H.; Wang, T.-L.; Lin, W.-C.; Lin, H.-Y.; Lee, M.-H.; Yang, C.-H. Enhanced Supercapacitor Performance Using Electropolymerization of Self-Doped Polyaniline on Carbon Film. Nanomaterials 2018, 8, 214. https://doi.org/10.3390/nano8040214

Wang P-H, Wang T-L, Lin W-C, Lin H-Y, Lee M-H, Yang C-H. Enhanced Supercapacitor Performance Using Electropolymerization of Self-Doped Polyaniline on Carbon Film. Nanomaterials. 2018; 8(4):214. https://doi.org/10.3390/nano8040214

Chicago/Turabian StyleWang, Po-Hsin, Tzong-Liu Wang, Wen-Churng Lin, Hung-Yin Lin, Mei-Hwa Lee, and Chien-Hsin Yang. 2018. "Enhanced Supercapacitor Performance Using Electropolymerization of Self-Doped Polyaniline on Carbon Film" Nanomaterials 8, no. 4: 214. https://doi.org/10.3390/nano8040214