Nano-Photonic Structures for Light Trapping in Ultra-Thin Crystalline Silicon Solar Cells

Abstract

:1. Introduction

2. Results

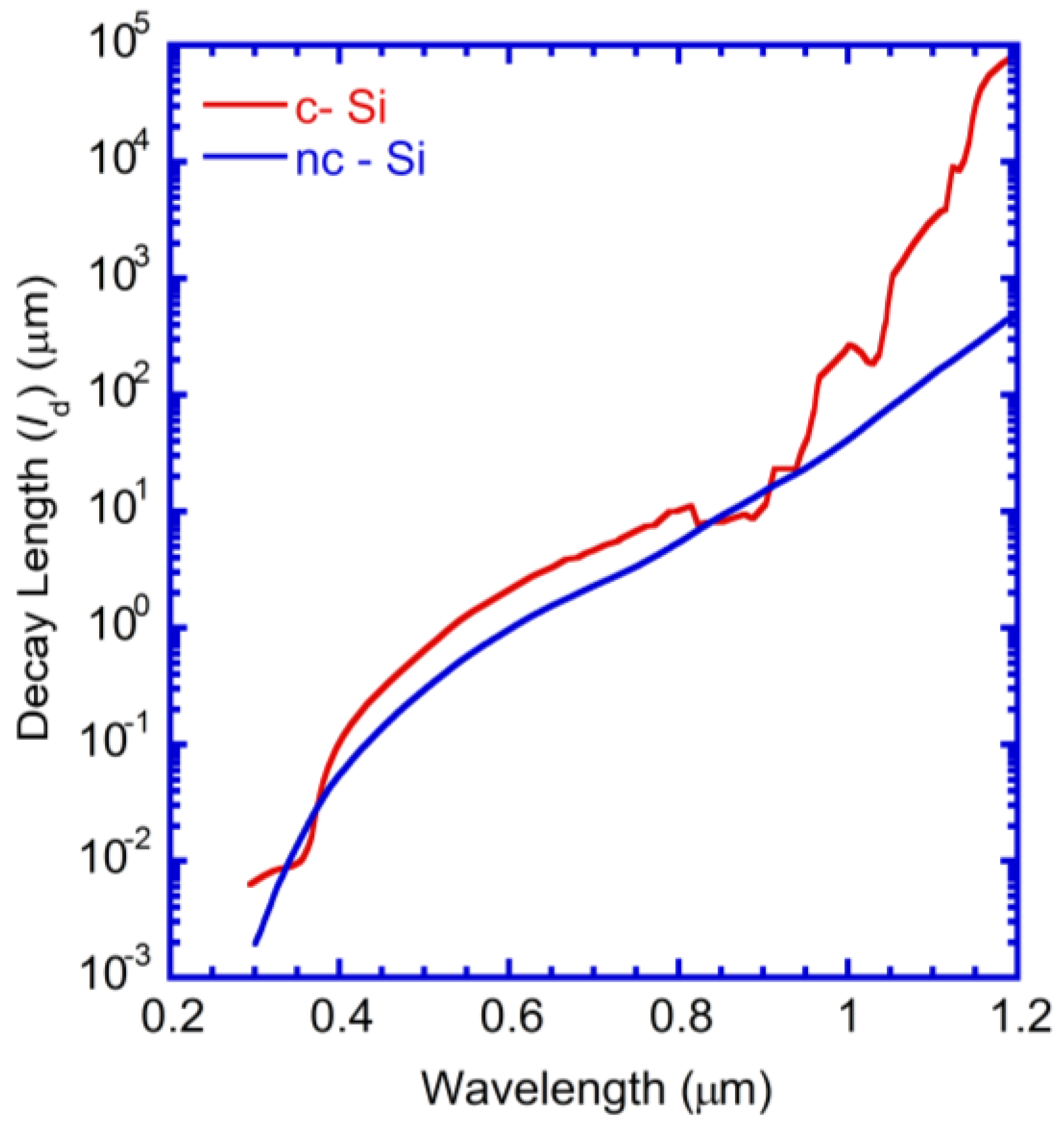

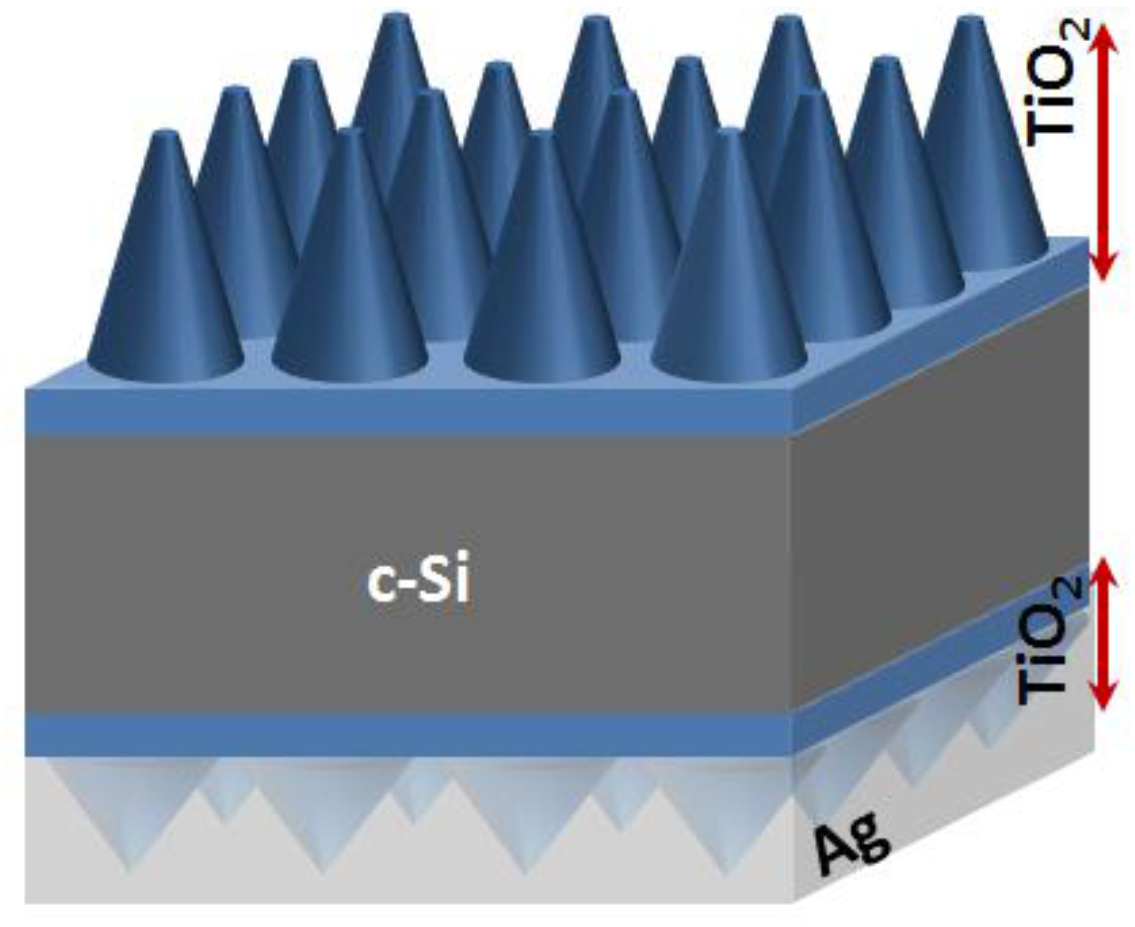

2.1. Approach and Structure

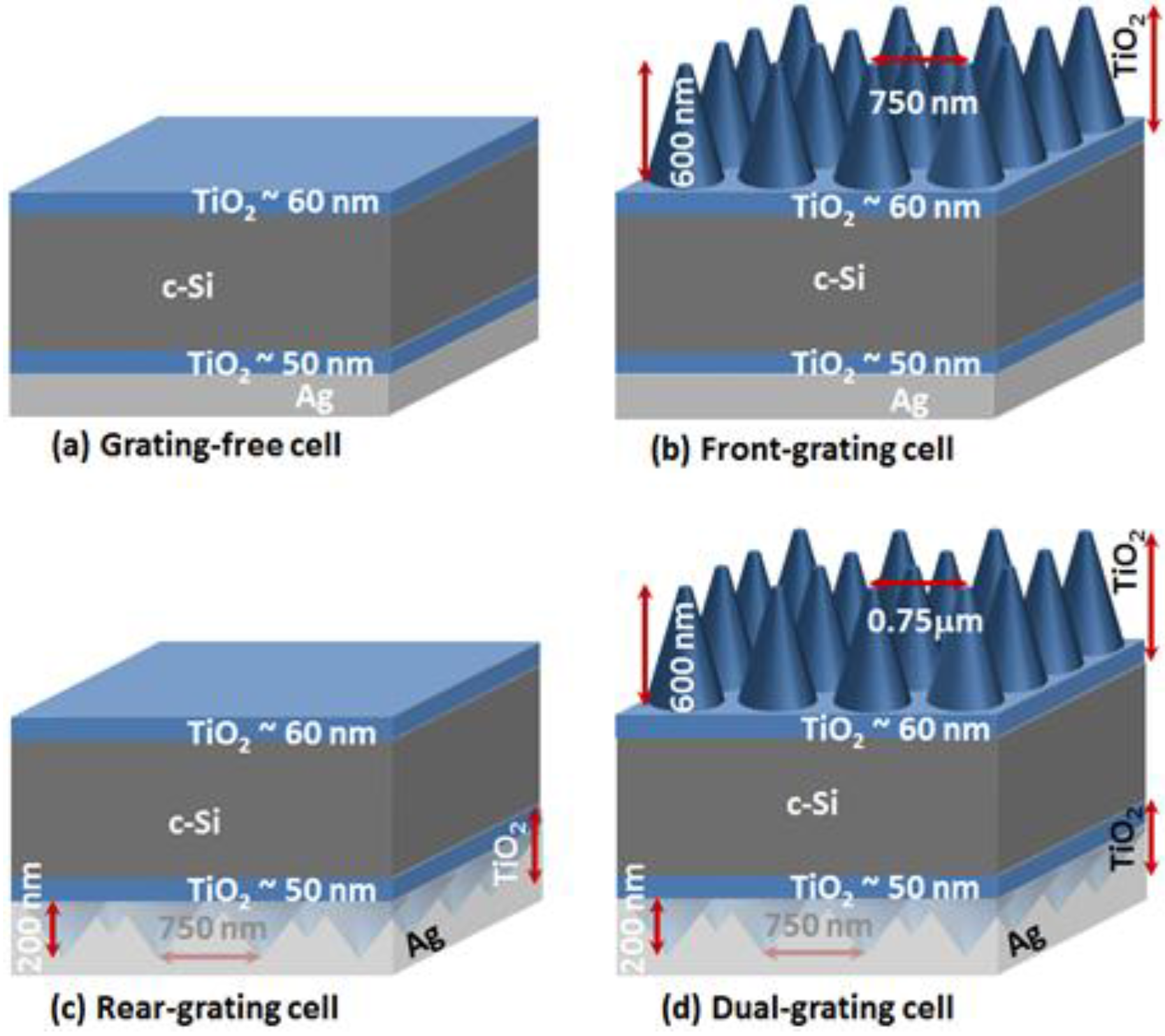

2.2. Design of Light Trapping Architecture Methods and Structure

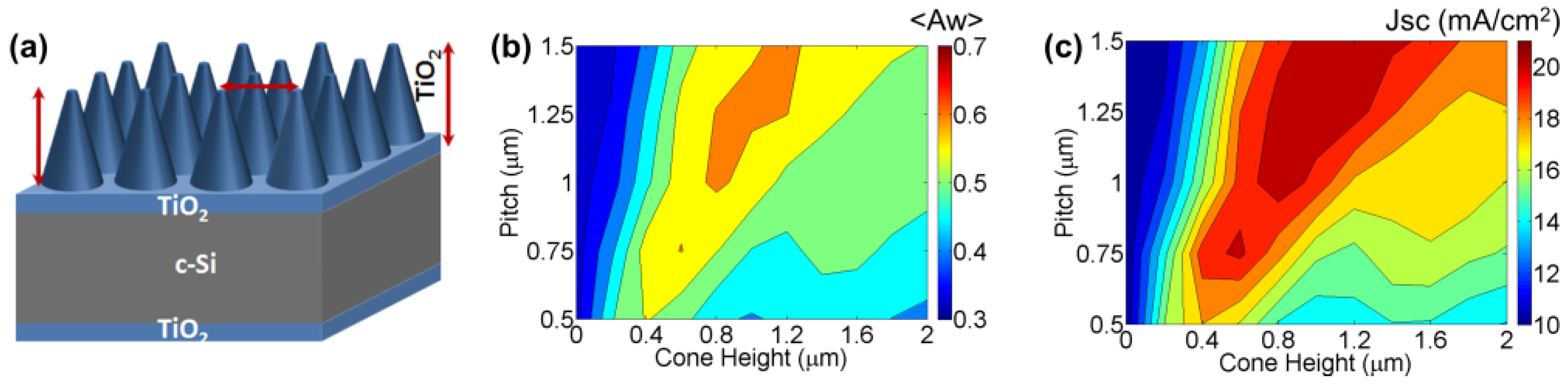

2.2.1. Front Nanocone Array

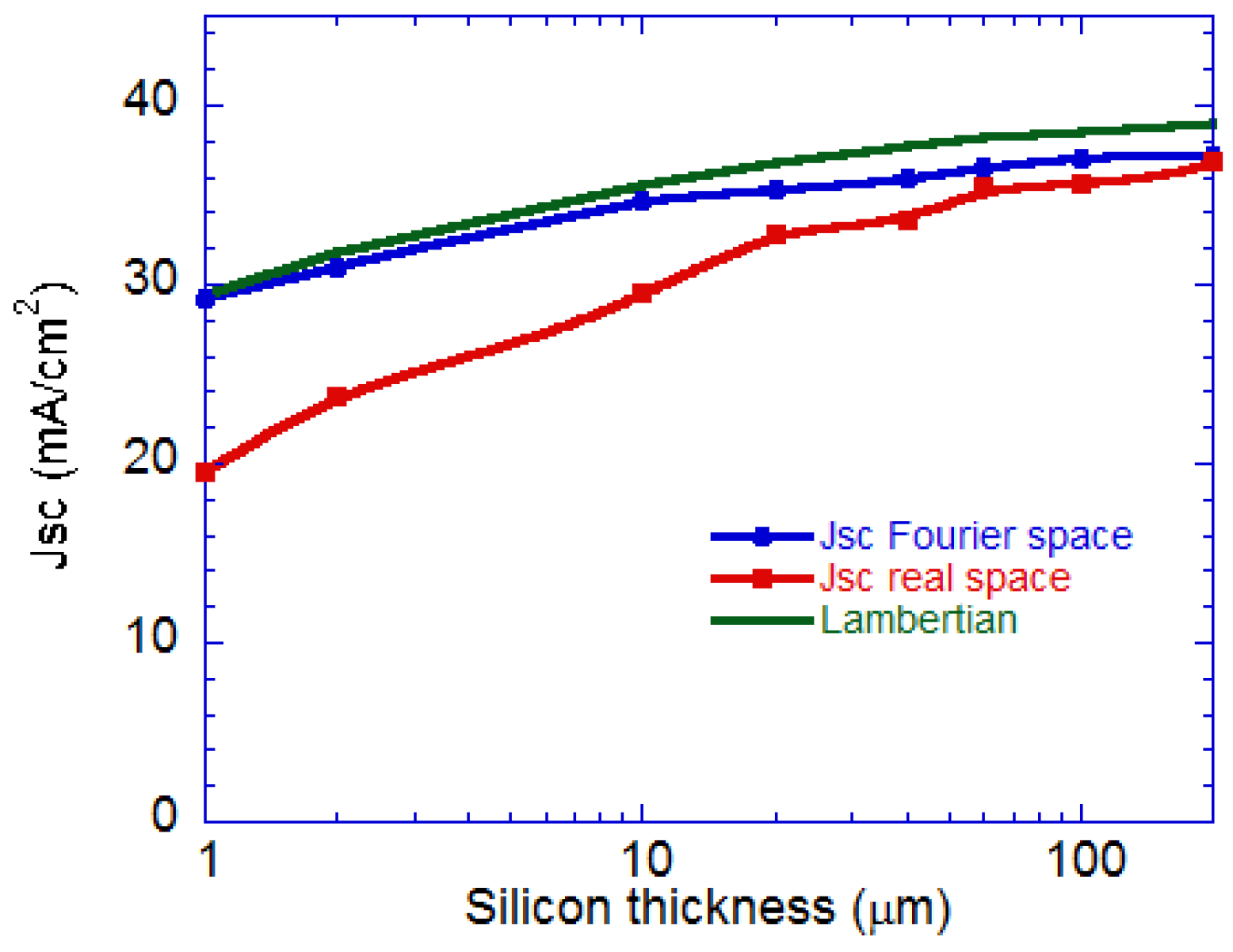

2.2.2. Absorption Enhancement

2.2.3. Variation with Angle of Incidence

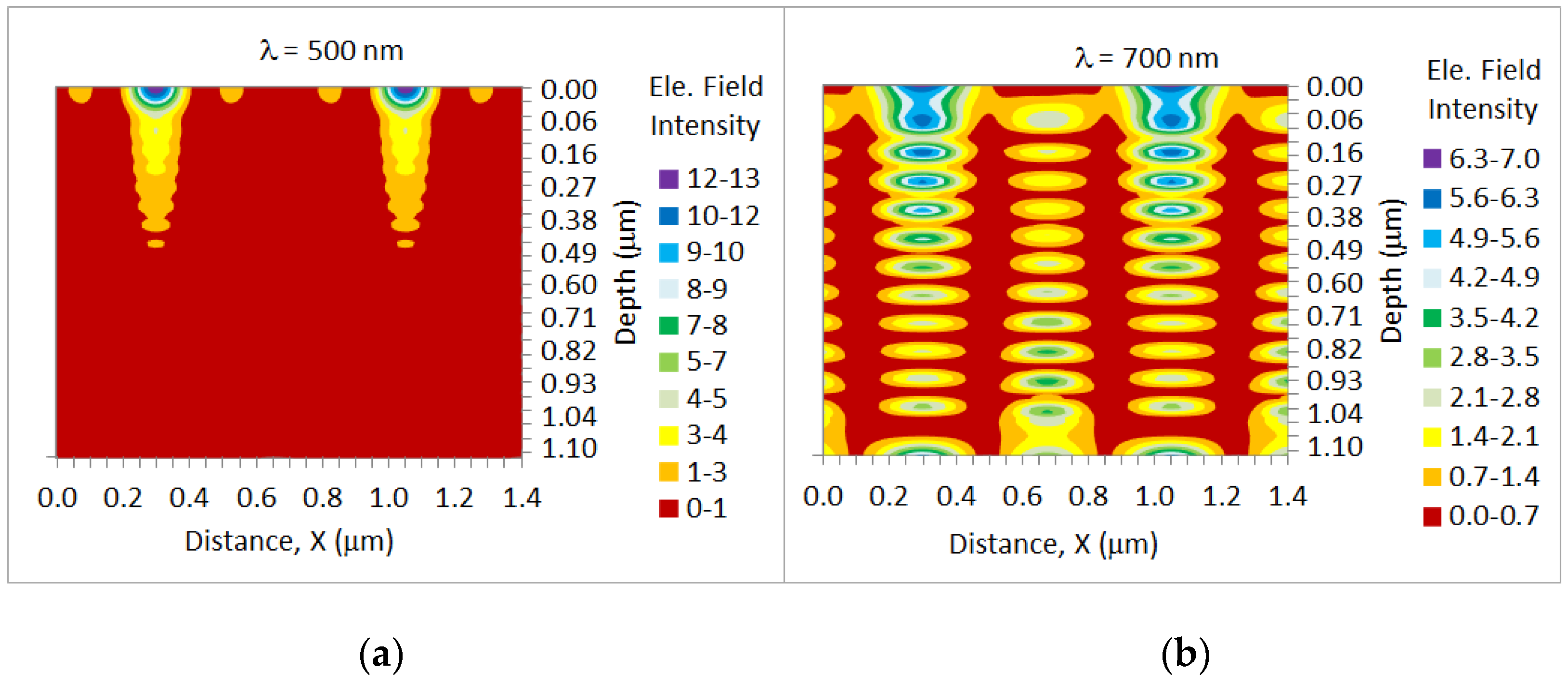

2.2.4. Field Distribution

2.2.5. Parasitic Losses

3. Discussion

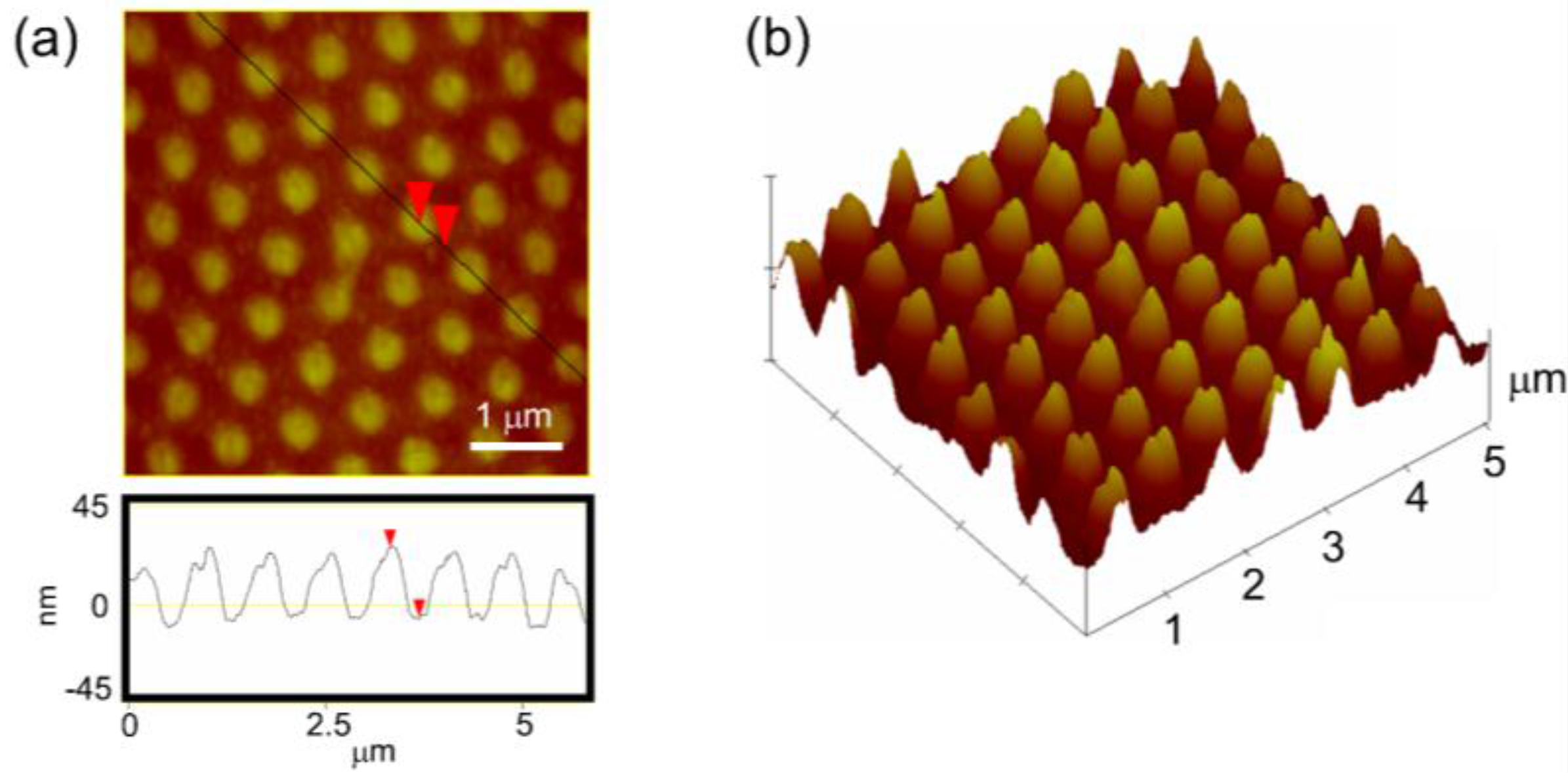

Proof of Concept Demonstration of TiO2 Nanocone Array Fabrication

4. Materials and Methods

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- National Renewable Energy Laboratory (NREL). National Center for Photovoltaics Solar Efficiency Chart. Available online: http://www.nrel.gov/pv/assets/images/efficiency_chart.jpg (accessed on 30 December 2016).

- Green, M.A.; Emery, K.; Hishikawa, Y.; Warta, W.; Dunlop, E.D. Solar Efficiency Tables (version 47). Prog. Photovolt. 2016, 24, 3–11. [Google Scholar] [CrossRef]

- Atwater, H.; Polman, A. Plasmonics for improved photonic devices. Nat. Photonics 2010, 9, 9–16. [Google Scholar]

- Palik, E. Handbook of the Optical constants of Solids; Academic Press: San Diego, CA, USA, 1998. [Google Scholar]

- Biswas, R.; Xu, C. Nano-crystalline silicon solar cell architecture with absorption at the classical 4n2 limit. Opt. Exp. 2011, 19, A672. [Google Scholar] [CrossRef] [PubMed]

- Bhattacharya, J.; Chakravarty, N.; Pattnaik, S.; Slafer, W.D.; Biswas, R.; Dalal, V. A Novel photonic-plasmonic Structure for Enhancing Light Absorption in Thin Film Solar Cells. Appl. Phys. Lett. 2011, 99, 131114. [Google Scholar] [CrossRef]

- Ferry, V.E.; Verschuuren, M.A.; Li, H.B.T.; Schropp, R.E.I.; Atwater, H.A.; Polman, A. Improved red-response in thin film a-Si:H solar cells with soft-imprinted plasmonic back reflectors. Appl. Phys. Lett. 2009, 95, 183503. [Google Scholar] [CrossRef]

- Sai, H.; Saito, K.; Hozuki, N.; Kondo, M. Relationship between the cell thickness and the optimum period of textured back reflectors in thin-film microcrystalline silicon solar cells. Appl. Phys. Lett. 2013, 102, 053509. [Google Scholar]

- Han, S.E.; Chen, G. Toward the Lambertian limit of light trapping in thin nanostructured silicon solar cells. Nano Lett. 2010, 10, 4692–4696. [Google Scholar] [CrossRef] [PubMed]

- Zhao, H.; Ozturk, B.; Schiff, E.A.; Sivec, L.; Yan, B.; Yang, J.; Guha, S. Back reflector morphology effects and thermodynamic light-trapping in thin-film silicon solar cells. Sol. Energy Mater. Sol. Cells 2014, 129, 104–114. [Google Scholar] [CrossRef]

- Battaglia, C.; Escarre, J.; Soderstrom, K.; Charriere, M.; Despeisse, M.; Haug, F.-J.; Ballif, C. Nanomoulding of transparent zinc oxide electrodes for efficient light trapping in solar cells. Nat. Photonics 2011, 5, 535–538. [Google Scholar] [CrossRef]

- Soderstrom, T.; Haug, F.J.; Daudrix, V.T.; Ballif, C. Flexible micromorph tandem a-Si/μc-Si solar cells. J. Appl. Phys. 2010, 107, 014507. [Google Scholar] [CrossRef]

- Wang, K.X.; Yu, Z.; Liu, V.; Cui, Y.; Fan, S. Absorption enhancement in ultrathin crystalline silicon solar cells with antireflection and light-trapping nanocone gratings. Nano Lett. 2012, 2012, 1616–1619. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Weil, B.D.; Li, Y.; Wang, K.X.; Garnett, E.; Fan, S.; Cui, Y. Large-area free-standing ultrathin single-crystal silicon as processable materials. Nano Lett. 2013, 13, 4393–4398. [Google Scholar] [CrossRef] [PubMed]

- Zhang, R.; Shao, B.; Dong, J.R.; Zhang, J.C.; Yang, H. Absorption enhancement analysis of crystalline Si thin film solar cells based on broadband antireflection nanocone grating. J. Appl. Phys. 2011, 110, 113105. [Google Scholar]

- Yablonovitch, E. Statistical ray optics. J. Opt. Soc. Am. 1982, 72, 899–907. [Google Scholar] [CrossRef]

- Tiedje, T.; Yablonovitch, E.; Cody, G.D.; Brooks, B. Limiting efficiency of silicon solar cells. IEEE Trans. Electron Devices 1984, 31, 711–716. [Google Scholar] [CrossRef]

- Xu, Q.; Johnson, C.; Disney, C.; Pillai, S. Enhanced broadband light trapping in c-Si colar cells using Nanosphere-Embedded Metallic Grating Structure. IEEE J. Photovolt. 2016, 6, 61–67. [Google Scholar] [CrossRef]

- Eisenlohr, J.; Benick, J.; Peters, M.; Bläsi, B.; Goldschmidt, J.C.; Hermle, M. Hexagonal sphere gratings for enhanced light trapping in crystalline silicon solar cells. Opt. Exp. 2014, 22, A111–A119. [Google Scholar] [CrossRef] [PubMed]

- Ingenito, A.; Isabella, O.; Zeman, M. Experimental demonstration of 4n2 classical absorption limit in nanotextured ultrathin solar cells with dielectric omnidirectional back reflector. ACS Photonics 2014, 1, 270–278. [Google Scholar] [CrossRef]

- Ouyang, Z.; Pillai, S.; Beck, F.; Kunz, O.; Varalmov, S.; Catchpole, K.R.; Campbell, P.; Green, M.A. Effective light trapping in polycrystalline silicon thin film solar cells with localized surface plasmons. Appl. Phys. Lett. 2010, 96, 261109. [Google Scholar] [CrossRef]

- Pillai, S.; Catchpole, K.R.; Trupke, T.; Green, M.A. Surface plasmon enhanced solar cells. J. Appl. Phys. 2007, 101, 093107. [Google Scholar] [CrossRef]

- Varlamov, S.; Dore, J.; Evans, R.; Ong, D.; Eggleston, B.; Kunz, O.; Schubert, H.; Young, T.; Huang, J.; Soderstron, T.; et al. Polycrystalline silicon on glass thin film solar cells: A transition from solid-phase to liquid-phase crystallized silicon. Sol. Energy Mater. Sol. Cells 2013, 119, 246–255. [Google Scholar] [CrossRef]

- Peer, A.; Biswas, R. Nano-photonic Organic Solar Cell Architecture for Advanced Light Trapping with Dual Photonic Crystals. ACS Photonics 2014, 1, 840–847. [Google Scholar] [CrossRef]

- Chen, Y.; Elshobaki, M.; Gebhardt, R.; Bergeson, S.; Noack, M.; Park, J.-M.; Hillier, A.C.; Ho, K.-M.; Biswas, R.; Chaudhary, S. Reducing optical losses in organic solar cells using microlens arrays: Theoretical-experimental investigation of microlens dimensions. Phys. Chem. Chem. Phys. 2015, 17, 3723–3730. [Google Scholar] [CrossRef] [PubMed]

- Shah, A.V.; Schade, H.; Vanecek, M.; Meier, J.; Vallat-Sauvain, E.; Wyrsch, N.; Kroll, U.; Droz, C.; Bailat, J. Thin-film silicon solar cell technology. Prog. Photovolt. 2004, 12, 113–142. [Google Scholar] [CrossRef]

- Li, Z.Y.; Lin, L.L. Photonic band structures solved by a plane-wave based transfer matrix method. Phys. Rev. E 2003, 67, 046607. [Google Scholar] [CrossRef] [PubMed]

- Biswas, R.; Neginhal, S.; Ding, C.G.; Puscasu, I.; Johnson, E. Mechanisms underlying extraordinary transmission in sub-wavelength hole arrays. J. Opt. Soc. Am. B 2007, 24, 2489–2495. [Google Scholar] [CrossRef]

- Zhou, D.Y.; Biswas, R. Photonic crystal enhanced light-trapping in thin film solar cells. J. Appl. Phys. 2008, 103, 093102. [Google Scholar] [CrossRef]

- Yu, Z.; Raman, A.; Fan, S. Fundamental limit of light trapping in grating structures. Opt. Exp. 2010, 18, A366–A380. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Raman, A.; Fan, S. Fundamental limit of nanophotonic light trapping in solar cells. Proc. Natl. Acad. Sci. USA 2010, 107, 17491–17496. [Google Scholar] [CrossRef] [PubMed]

- Schiff, E.A. Thermodynamic limit to photonic-plasmonic light trapping in thin films on metals. J. Appl. Phys. 2011, 110, 104501. [Google Scholar] [CrossRef]

- Van Lare, M.; Lenzmann, F.; Verschuuren, M.A.; Polman, A. Mode coupling by plasmonic surface scatterers in thin-film silicon solar cell. Appl. Phys. Lett. 2012, 101, 221110. [Google Scholar] [CrossRef]

- Ferry, V.E.; Munday, J.N.; Atwater, H.A. The design considerations for plasmonic photovoltaics. Adv. Mater. 2010, 22, 4794–4808. [Google Scholar] [CrossRef] [PubMed]

- Bermel, P.; Luo, C.; Zeng, L.; Kimerling, L.C.; Joannopoulos, J.D. Improving thin-film crystalline silicon solar cell efficiencies with photonic crystals. Opt. Exp. 2007, 15, 16986–17000. [Google Scholar] [CrossRef]

- Zanotto, S.; Liscidini, M.; Andreani, L.C. Light trapping regimes in thin film silicon cells with a photonic pattern. Opt. Exp. 2010, 18, 4260–4274. [Google Scholar] [CrossRef] [PubMed]

- Heine, C.; Morf, R.H. Sub-micrometer gratings for solar energy applications. Appl. Opt. 1995, 34, 2476–2482. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Chattopadhyay, S.; Jen, Y.; Peng, C.; Liu, T.; Hsu, Y.; Pan, C.; Lo, H.; Hsu, C.; Chang, Y.; et al. Improved broadband and quasi-omnidirectional anti-reflection properties with biomimetic silicon nanostructures. Nat. Nanotechnol. 2007, 2, 770–774. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yu, H.; Li, Y.; Wang, F.; Yang, M.; Wong, S.M. Low aspect-ratio hemispherical nanopit surface texturing for enhancing light absorption in crystalline Si thin film-based solar cells. Appl. Phys. Lett. 2011, 98, 021905. [Google Scholar] [CrossRef]

- Ok, J.G.; Youn, H.S.; Kwak, M.K.; Lee, K.; Shin, Y.J.; Guo, L.J.; Greenwald, A.; Liu, Y. Continuous and scalable fabrication of flexible metamaterial films via roll-to-roll nanoimprint process for broadband plasmonic infrared filters. Appl. Phys. Lett. 2012, 101, 223102. [Google Scholar] [CrossRef]

- Masuko, K.; Shigematsu, M.; Hashiguchi, T.; Fujishima, D.; Kai, M.; Yoshimura, N.; Yamaguchi, T.; Ichihashi, Y.; Yamanishi, T.; Takahama, T.; et al. Achievement of more than 25% conversion efficiency with crystalline silicon heterojunction solar cell. IEEE J. Photovolt. 2014, 4, 1433–1435. [Google Scholar] [CrossRef]

- Peer, A.; Biswas, R. Extraordinary optical transmission in nanopatterned ultrathin metal films without holes. Nanoscale 2016, 8, 4657–4666. [Google Scholar] [CrossRef] [PubMed]

- Chen, Q.; Zhou, H.; Hong, Z.; Luo, S.; Duan, H.S.; Wang, H.H.; Liu, Y.; Li, G.; Yang, Y. Planar heterojunction perovskite solar cells via vapor-assisted solution process. J. Am. Chem. Soc. 2013, 136, 622–625. [Google Scholar] [CrossRef] [PubMed]

- Peer, A.; Dhakal, R.; Biswas, R.; Kim, J. Nanoscale patterning of biopolymers for functional biosurfaces and controlled drug release. Nanoscale 2016, 8, 18654–18664. [Google Scholar] [CrossRef] [PubMed]

- Kooy, N.; Mohamme, K.; Pin, L.T.; Guan, O.S. A review of roll-to-roll nanoimprint lithography. Nanoscale Res. Lett. 2014, 9, 320. [Google Scholar] [CrossRef] [PubMed]

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pathi, P.; Peer, A.; Biswas, R. Nano-Photonic Structures for Light Trapping in Ultra-Thin Crystalline Silicon Solar Cells. Nanomaterials 2017, 7, 17. https://doi.org/10.3390/nano7010017

Pathi P, Peer A, Biswas R. Nano-Photonic Structures for Light Trapping in Ultra-Thin Crystalline Silicon Solar Cells. Nanomaterials. 2017; 7(1):17. https://doi.org/10.3390/nano7010017

Chicago/Turabian StylePathi, Prathap, Akshit Peer, and Rana Biswas. 2017. "Nano-Photonic Structures for Light Trapping in Ultra-Thin Crystalline Silicon Solar Cells" Nanomaterials 7, no. 1: 17. https://doi.org/10.3390/nano7010017