Effects of Atomization Injection on Nanoparticle Processing in Suspension Plasma Spray

Abstract

:1. Introduction

2. Mathematic Model

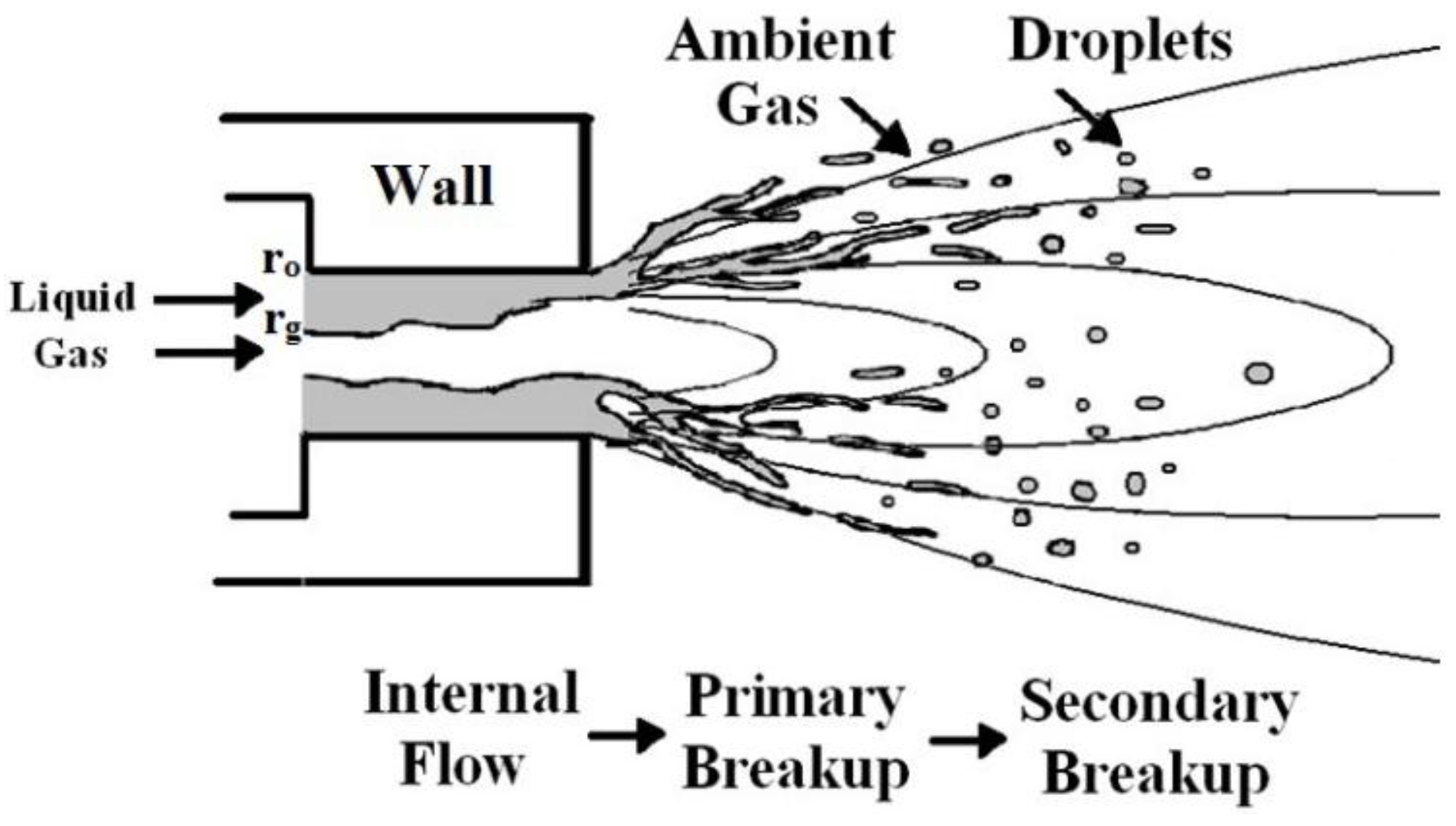

2.1. Modeling Liquid Primary Breakup to Estimate Droplet Mean Size

2.2. Eulerian/Lagrangian Model of Droplets or Particles in Plasma Jet

3. Experimental and Numerical Setup

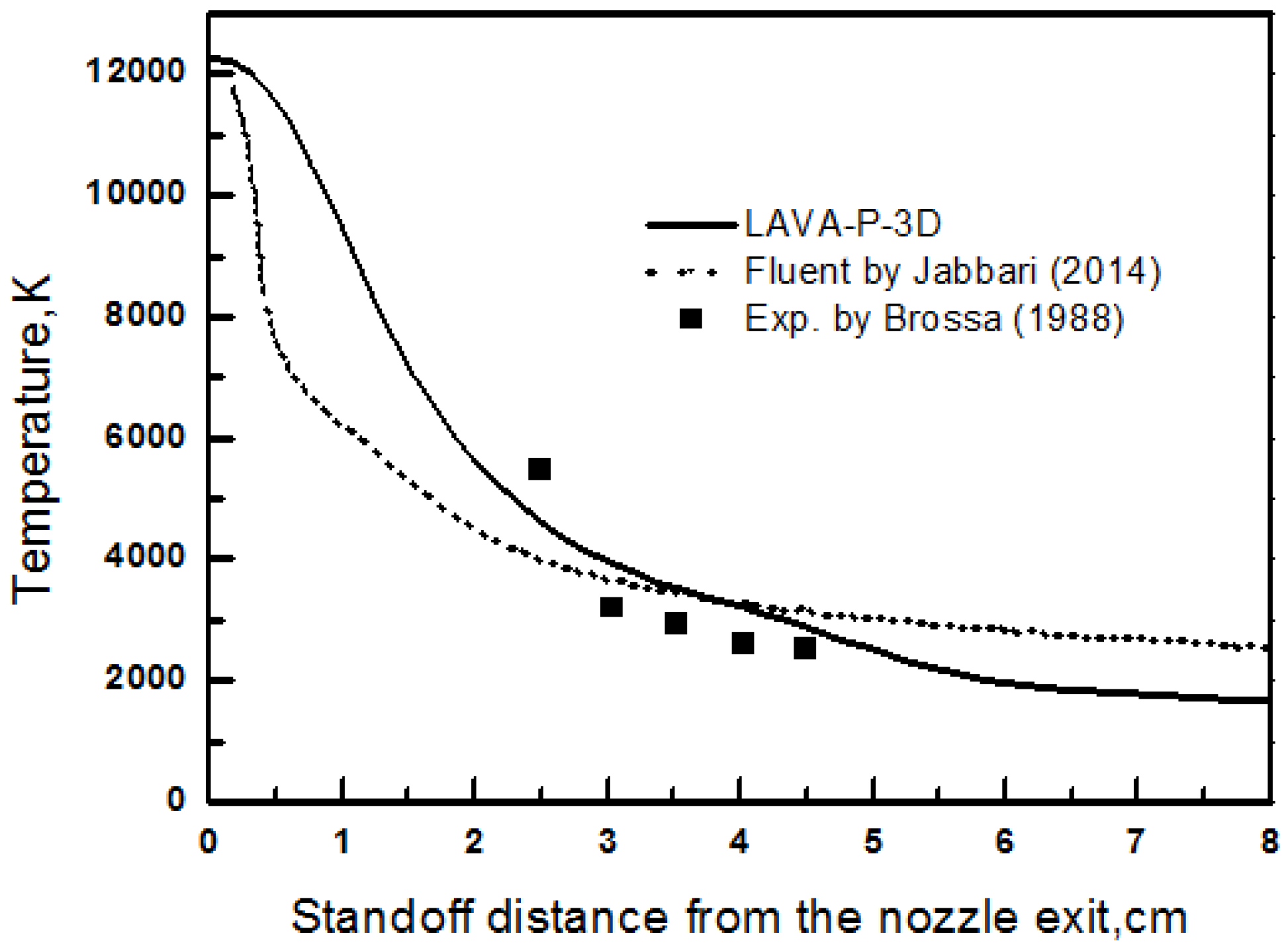

4. Validation of Model Predictions

5. Discussion

5.1. Flow Field of the Plasma Jet

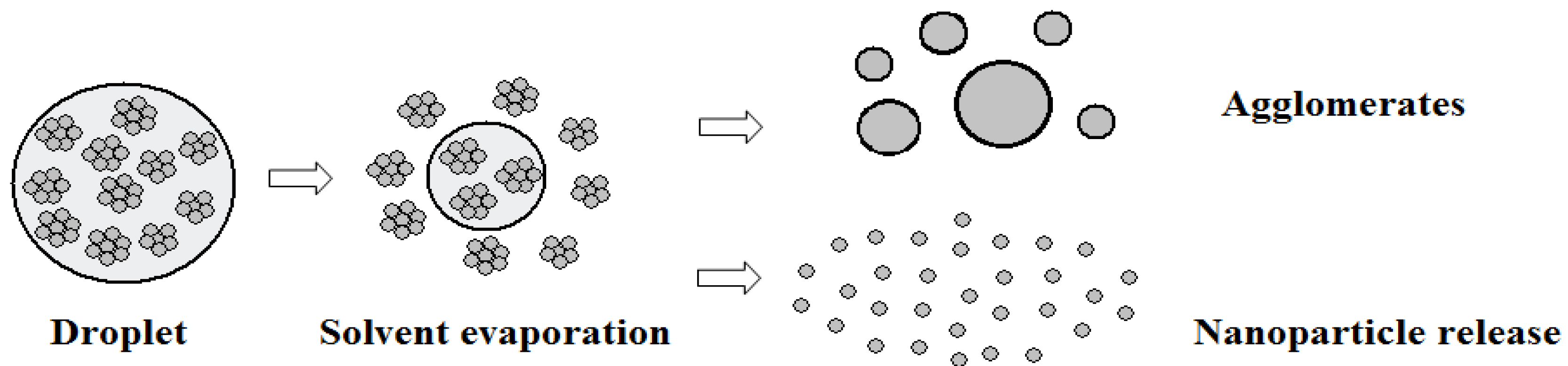

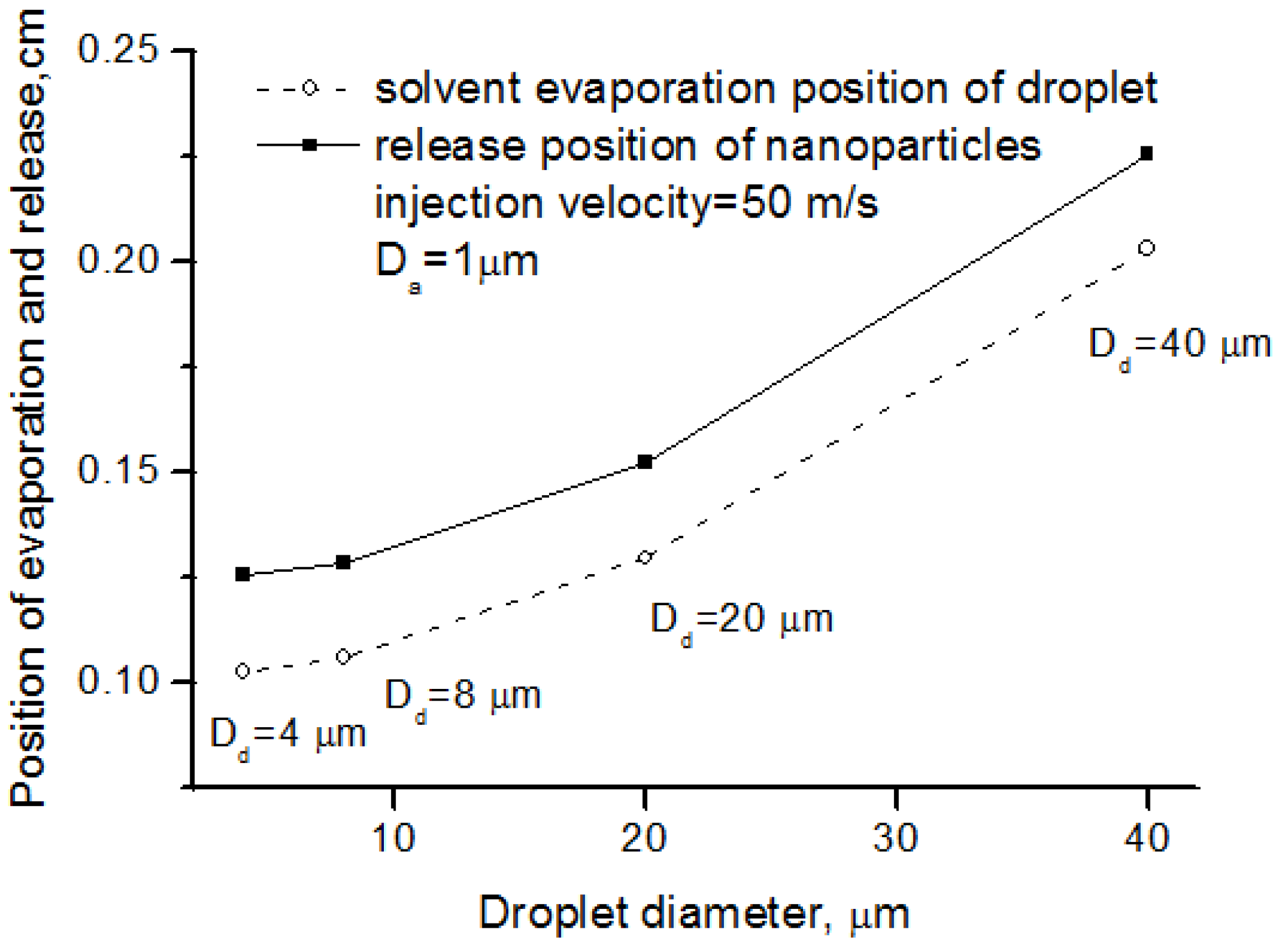

5.2. Effects of Droplet Diameter on Nanoparticle Release

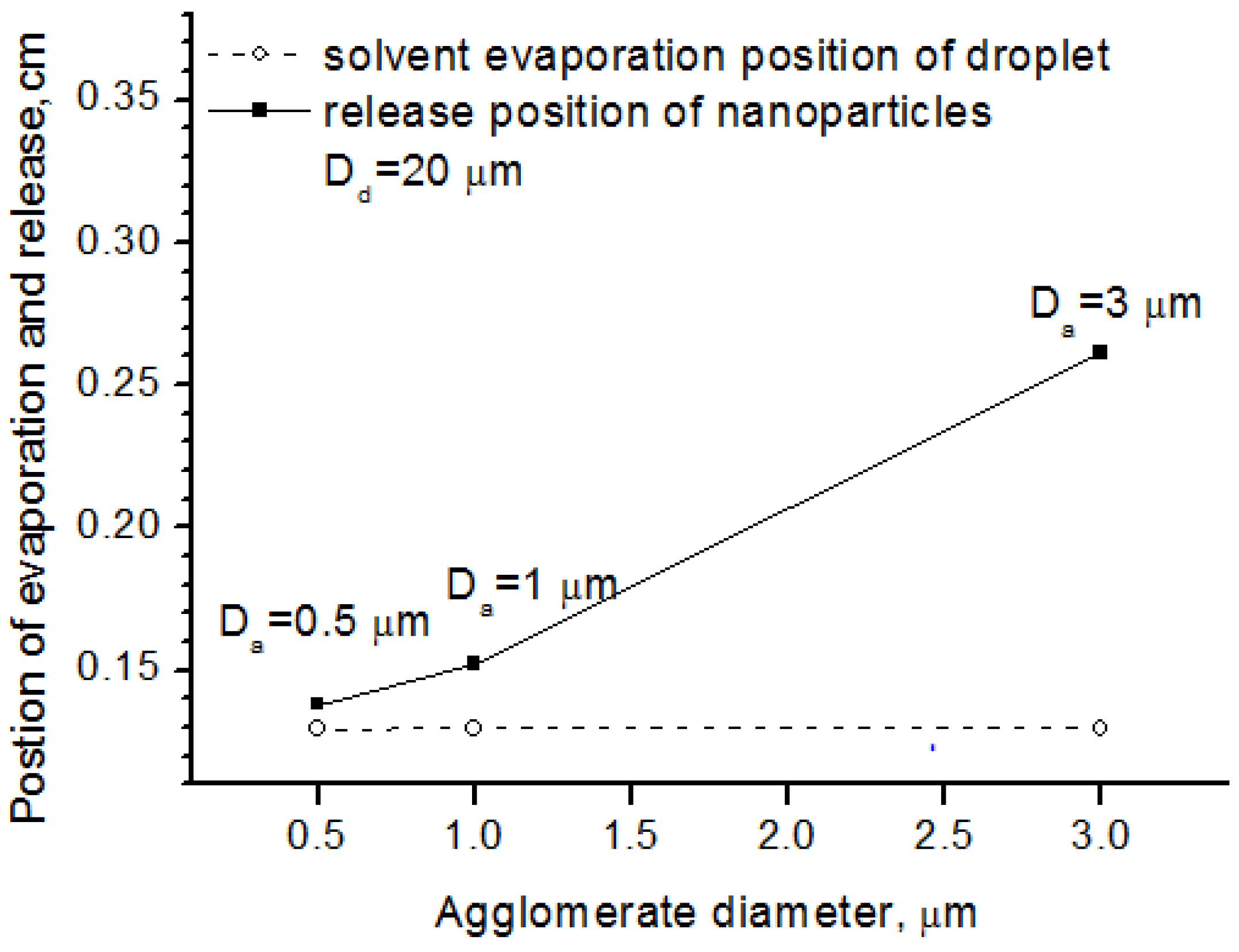

5.3. Effects of Atomization Injection Parameters on Nanoparticle Release

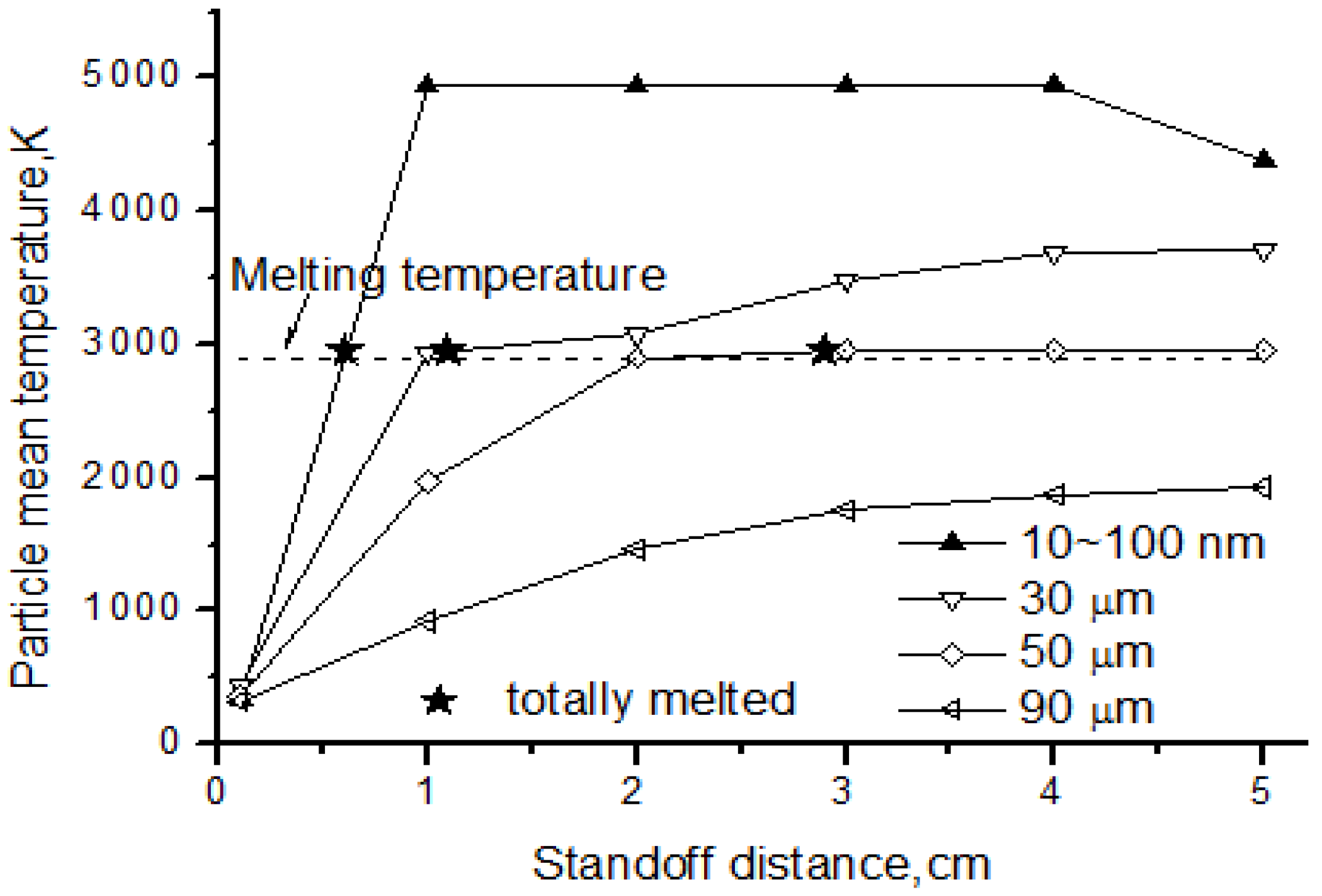

5.4. Velocity, Temperature and Melting of Nanoparticles and Agglomerates

5.5. Critical Agglomerate and Droplet Size

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomemclature

| CD | drag coefficient |

| Cp | specific heat, J·kg−1·K−1 |

| Dd | droplet diameter, μm |

| Da | agglomerate diameter, μm |

| dij | deformation tensor |

| dp | particle diameter, m |

| fKn | factor ofKnudsen effect |

| fprop | factor to account property variation |

| fv | factor formass transfer |

| G0 | zero-mean, unit-variance independent Gauss random number |

| h | heat transfer coefficient, W·m−2·K−1 or the half-thickness of sheath |

| k | thermal conductivity, W·m−1·K−1 or wave number |

| K c | constant coefficient in Saffman lift force |

| Kn | Knudsen number |

| Lm | latent heat of fusion, J·kg−1 |

| Lv | latent heat of vaporization, J·kg−1 |

| mp | particle mass, kg |

| vaporization rate, kg·s−1 | |

| Nu | Nusselt number |

| p | pressure, Pa |

| Pr | Prandtl number, Pr = μCpk−1 |

| Q | heat flux, W·m−2 or the gas/liquid density ratio |

| R | gas constant, J·mol−1·K−1 |

| r | radial coordinate for the particle, m |

| inner radius of melting interface, m | |

| outer radius of melting interface, m | |

| rm | position of particle melting interface, m |

| rp | particle radius, m |

| S0 | spectral intensity |

| SMD | Sauter mean diameter, μm |

| T | temperature, K |

| t | time, s |

| T∞ | temperature outside boundary layer, K |

| Td,0 | droplet initial temperature, K |

| Tm,d | droplet melting point, K |

| Ts | particle surface temperature, K |

| Tw | gas temperature near particle surface, K |

| vg | gas velocity, m·s−1 |

| V | velocity, m·s−1 |

| vw | mean molecular speed, m·s−1 |

| W | molecular weight of thegas mixture, kg·mol−1 |

| Weber | Weber number, dimensionless |

| wt | solid weight content in suspension, dimensionless |

| y | deformation parameter, dimensionless |

| σs | Stefan-Boltzmann constant |

Greek symbols

| ρ | density, kg·m−3 |

| μ | viscosity, kg·s−1·m−1 |

| γw | specific heat ratio of gas, dimensionless |

| α | weight fraction or void fraction |

| ε | surface emissivity coefficient |

| δ | the thickness of annular liquid sheath |

| σ | surface tension |

| ω | the growth rate of surface disturbances |

Subscript

| d | suspension droplet embedded with nanoparticles |

| f | film around the particle |

| g | plasma gas |

| p | solid nanoparticles or agglomerates |

| sl | solvent |

References

- Fauchais, P.; Montavon, G.; Lima, R.S.; Marple, B.R. Engineering a new class of thermal spray nano-based microstructures from agglomerated nanostructured particles, suspensions and solutions: An invited review. J. Phys. D 2011, 44. [Google Scholar] [CrossRef] [Green Version]

- Ye, F.; Ohmori, A.; Li, C. New approach to enhance the photocatalytic activity of plasma sprayed TiO2 coatings using p-n junctions. Surf. Coat. Technol. 2004, 184, 233–238. [Google Scholar] [CrossRef]

- Meillot, E.; Vincent, S.; Caruyer, C.; Damiani, D.; Caltagirone, J.P. Modelling the interactions between a thermal plasma flow and a continuous liquid jet in a suspension spraying process. J. Phys. D 2013, 46. [Google Scholar] [CrossRef]

- Marchand, C.; Chazelas, C.; Mariaux, G.; Vardelle, A. Liquid precursor plasma spraying: Modeling the interactions between the transient plasma jet and the droplets. J. Ther. Spray Technol. 2007, 16, 705–712. [Google Scholar] [CrossRef]

- Huang, P.C.; Heberlein, J.; Pfender, E. Particle behavior in a two-fluid turbulent plasma jet. Surf. Coat. Technol. 1995, 73, 142–151. [Google Scholar] [CrossRef]

- Fazilleau, J.; Delbos, C.; Rat, V.; Coudert, J.F.; Fauchais, P.; Pateyron, B. Phenomena involved in suspension plasma spraying part 1: Suspension injection and behavior. Plasma Chem. Plasma Process. 2006, 26, 371–391. [Google Scholar] [CrossRef]

- Ozturk, A.; Cetegen, B.M. Modeling of axially and transversely injected precursor droplets into a plasma environment. Int. J. Heat Mass Transf. 2005, 48, 4367–4383. [Google Scholar] [CrossRef]

- Jabbari, F.; Jadidi, M.; Wuthrich, R.; Dolatabadi, A. A Numerical Study of Suspension Injection in Plasma-Spraying Process. J. Ther. Spray Technol. 2014, 23, 3–13. [Google Scholar] [CrossRef]

- Lund, M.T.; Sojka, P.E.; Lefebvre, A.H.; Gosselin, P.G. Effervescent atomization at low mass flow rates. Part I: The influence of surface tension. Atom. Sprays 1993, 3, 77–89. [Google Scholar] [CrossRef]

- Ishii, M. One-Dimensional Drift-Flux Model and Constitutive Equations for Relative Motion between Phases in Various Two-Phase Flow Regimes; Argonne National Laboratory: Argonne, IL, USA, 1977; pp. 47–77.

- Weber, C. Disintegration of liquid jets. Z. Angew. Math. Mech. 1931, 11, 136–159. [Google Scholar] [CrossRef]

- Senecal, P.K.; Schmidt, D.P.; Nouar, I.; Rutland, C.J.; Reitz, R.D.; Corradini, M.L. Modeling high-speed viscous liquid sheet atomization. Int. J. Mult. Flow 1999, 25, 1073–1097. [Google Scholar] [CrossRef]

- Xiong, H.B.; Zheng, L.L.; Sampath, S.; Williamson, R.L.; Fincke, J.R. Three-dimensional simulation of plasma spray: Effects of carrier gas flow and particle injection on plasma jet and entrained particle behavior. Int. J. Heat Mass Transf. 2004, 47, 5189–5200. [Google Scholar] [CrossRef]

- Tanner, F.X. Development and validation of a cascade atomization and drop breakup model for high-velocity dense sprays. Atom. Sprays 2004, 14, 211–242. [Google Scholar] [CrossRef]

- O’Rourke, P.J.; Amsden, A.A. The TAB Method for Numerical Calculation of Spray Droplet Breakup; No. 872089, SAE Technical Paper; SAE International: Warrendale, PA, USA, 1987. [Google Scholar]

- Reitz, R.D. Modeling atomization processes in high-pressure vaporizing sprays. Atom. Spray Technol. 1987, 3, 309–337. [Google Scholar]

- Delbos, C.; Fazilleau, J.; Rat, V.; Coudert, J.F.; Fauchais, P.; Pateyron, B. Phenomena involved in suspension plasma spraying Part 2: Zirconia particle treatment and coating formation. Plasma Chem. Plasma Process. 2006, 26, 393–414. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G. Latest developments in suspension and liquid precursor thermal spraying. J. Ther. Spray Technol. 2010, 19, 226–239. [Google Scholar] [CrossRef]

- Chen, X.; Pfender, E. Behavior of small particles in a thermal plasma flow. Plasma Chem. Plasma Process. 1983, 3, 351–366. [Google Scholar] [CrossRef]

- Lee, Y.C.; Hsu, K.C.; Pfender, E. Modeling of particles injected into a DC plasma jet. In Proceedings of the 5th International Symposium on Plasma Chemistry, Edinburgh, UK, 10–14 August 1981; Volume 2, p. 795.

- Chen, X.; Pfender, E. Effect of the Knudsen number on heat transfer to a particle immersed into a thermal plasma. Plasma Chem. Plasma Process. 1983, 3, 97–113. [Google Scholar] [CrossRef]

- Xiong, H.B.; Lin, J.Z. Nanoparticles modeling in axially injection suspension plasma spray of zirconia and alumina ceramics. J. Ther. Spray Technol. 2009, 18, 887–895. [Google Scholar] [CrossRef]

- Saffman, P.G.T. The lift on a small sphere in a slow shear flow. J. Fluid Mech. 1965, 22, 385–400. [Google Scholar] [CrossRef]

- Wan, Y.P.; Prasad, V.; Wang, G.; Sampath, S.; Fincke, J.R. Model and powder particle heating, melting, resolidification, and evaporation in plasma spraying processes. J. Heat Transf. 1999, 121, 691–699. [Google Scholar] [CrossRef]

- Chen, X.; Pfender, E. Heat transfer to a single particle exposed to a thermal plasma. Plasma Chem. Plasma Process. 1982, 2, 185–212. [Google Scholar] [CrossRef]

- Ramshaw, J.D.; Chang, C.H. Computational fluid dynamics modeling of multicomponent thermal plasmas. Plasma Chem. Plasma Process. 1992, 12, 299–325. [Google Scholar] [CrossRef]

- Brossa, M.; Pfender, E. Probe measurements in thermal plasma jets. Plasma Chem. Plasma Process. 1988, 8, 75–90. [Google Scholar] [CrossRef]

- Fauchais, P.; Etchart-Salas, R.; Rat, V.; Coudert, J.F.; Caron, N.; Wittmann-Ténèze, K. Parameters controlling liquid plasma spraying: Solutions, sols, or suspensions. J. Ther. Spray Technol. 2008, 17, 31–59. [Google Scholar] [CrossRef]

| Particle Diameter | Maximum of Melting Percentage | Mostly Melted Position |

|---|---|---|

| 10–100 nm | 100% | 6 mm |

| 30 μm | 100% | 11 mm |

| 40 μm | 100% | 15 mm |

| 50 μm | 100% | 29 mm |

| 60 μm | 93.26% | 38 mm |

| 70 μm | 76.40% | 62 mm |

| 80 μm | 2.25% | 74 mm |

| 90 μm | 0 | None |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, H.-b.; Zhang, C.-y.; Zhang, K.; Shao, X.-m. Effects of Atomization Injection on Nanoparticle Processing in Suspension Plasma Spray. Nanomaterials 2016, 6, 94. https://doi.org/10.3390/nano6050094

Xiong H-b, Zhang C-y, Zhang K, Shao X-m. Effects of Atomization Injection on Nanoparticle Processing in Suspension Plasma Spray. Nanomaterials. 2016; 6(5):94. https://doi.org/10.3390/nano6050094

Chicago/Turabian StyleXiong, Hong-bing, Cheng-yu Zhang, Kai Zhang, and Xue-ming Shao. 2016. "Effects of Atomization Injection on Nanoparticle Processing in Suspension Plasma Spray" Nanomaterials 6, no. 5: 94. https://doi.org/10.3390/nano6050094