Milk–Ta2O5 Hybrid Memristors with Crossbar Array Structure for Bio-Organic Neuromorphic Chip Applications

Abstract

:1. Introduction

2. Experimental Method

2.1. Materials

2.2. Fabrication of Milk–Ta2O5 Hybrid Crossbar Array Memristors

2.3. Characterization of Milk–Ta2O5 Hybrid Crossbar Array Memristors

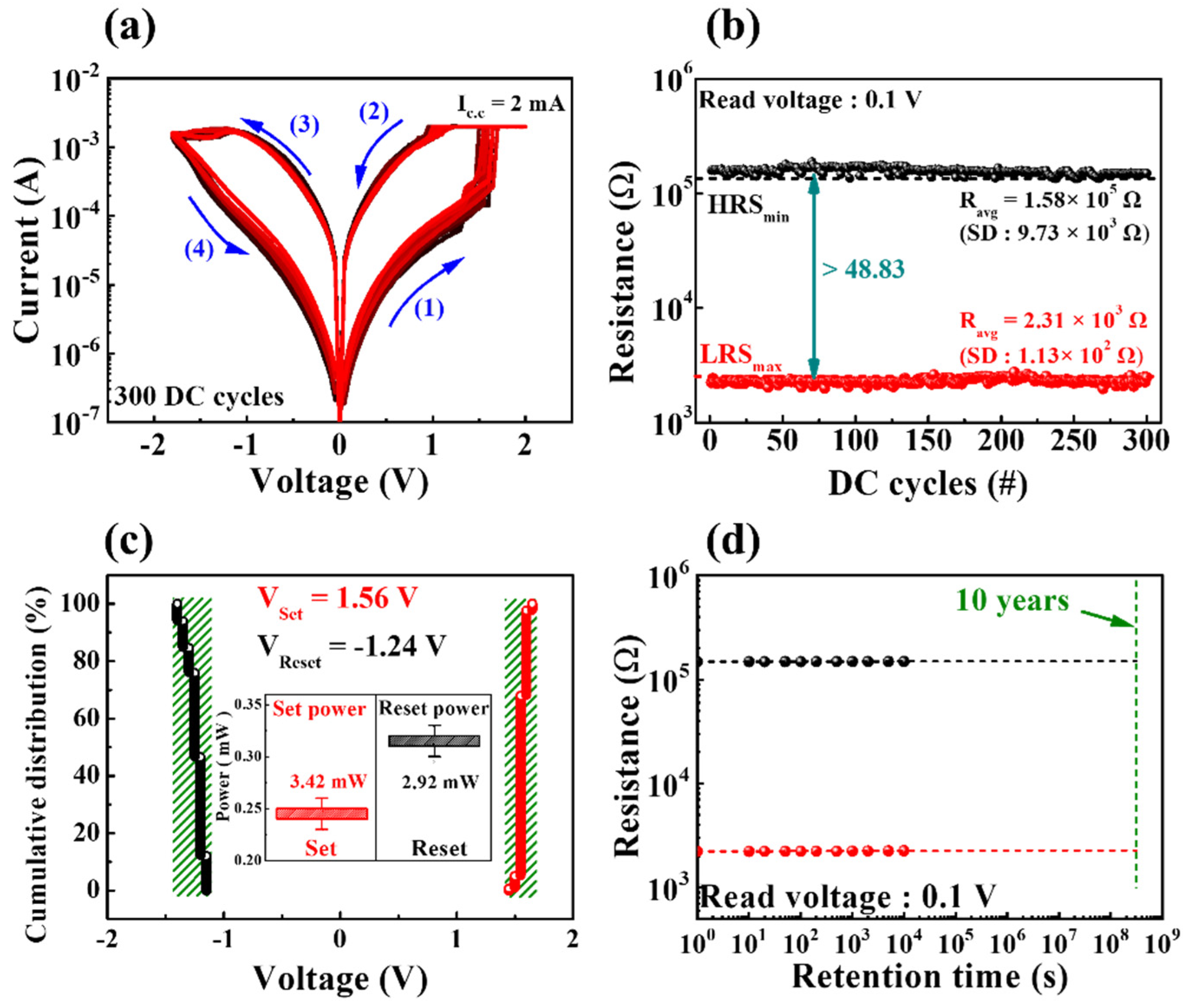

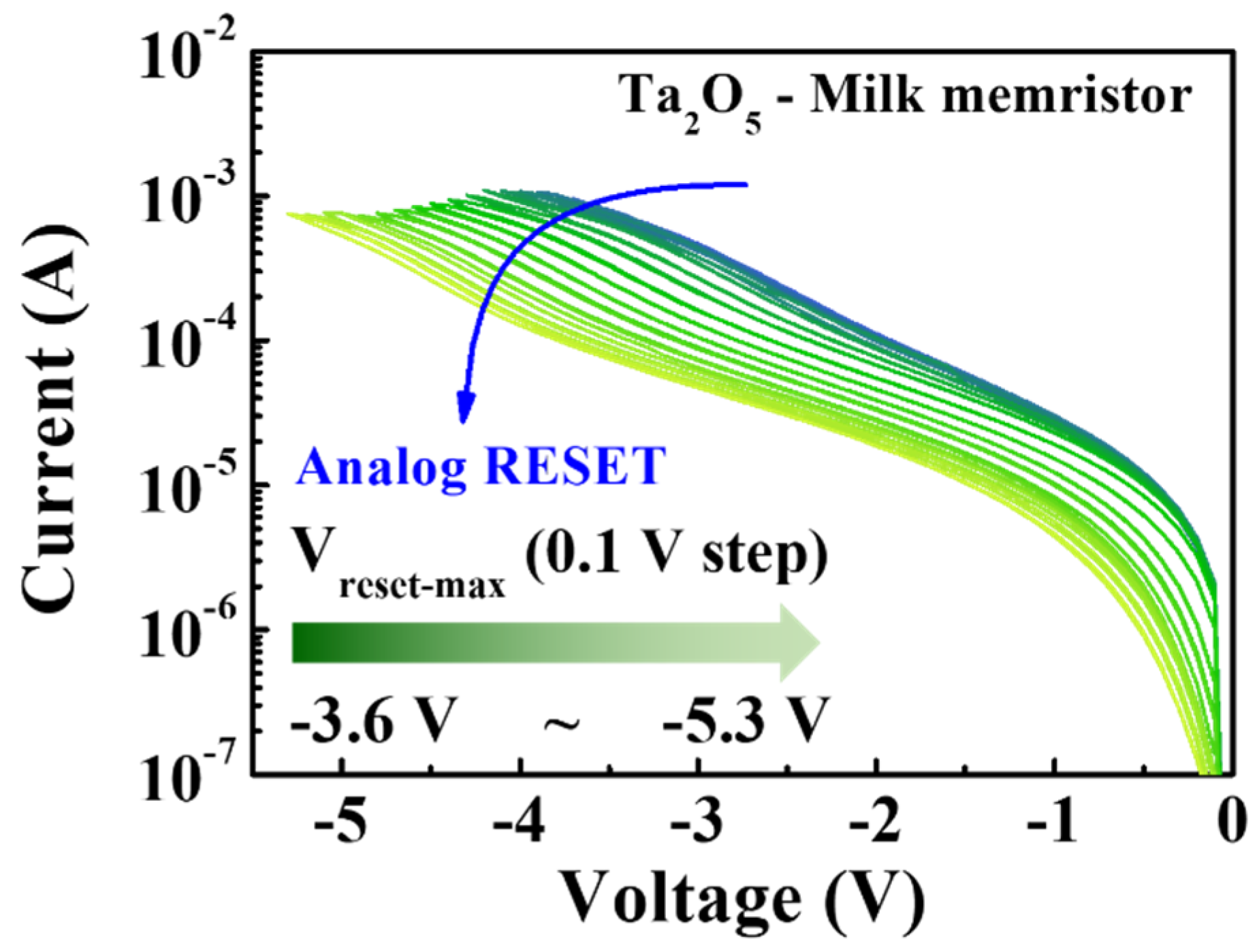

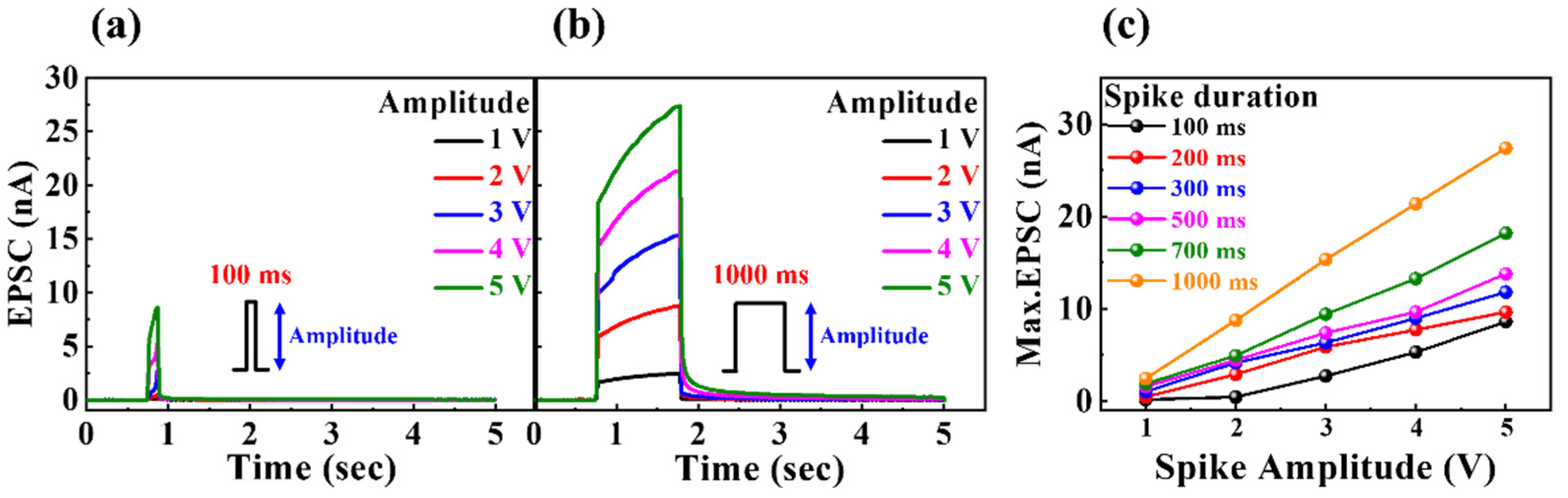

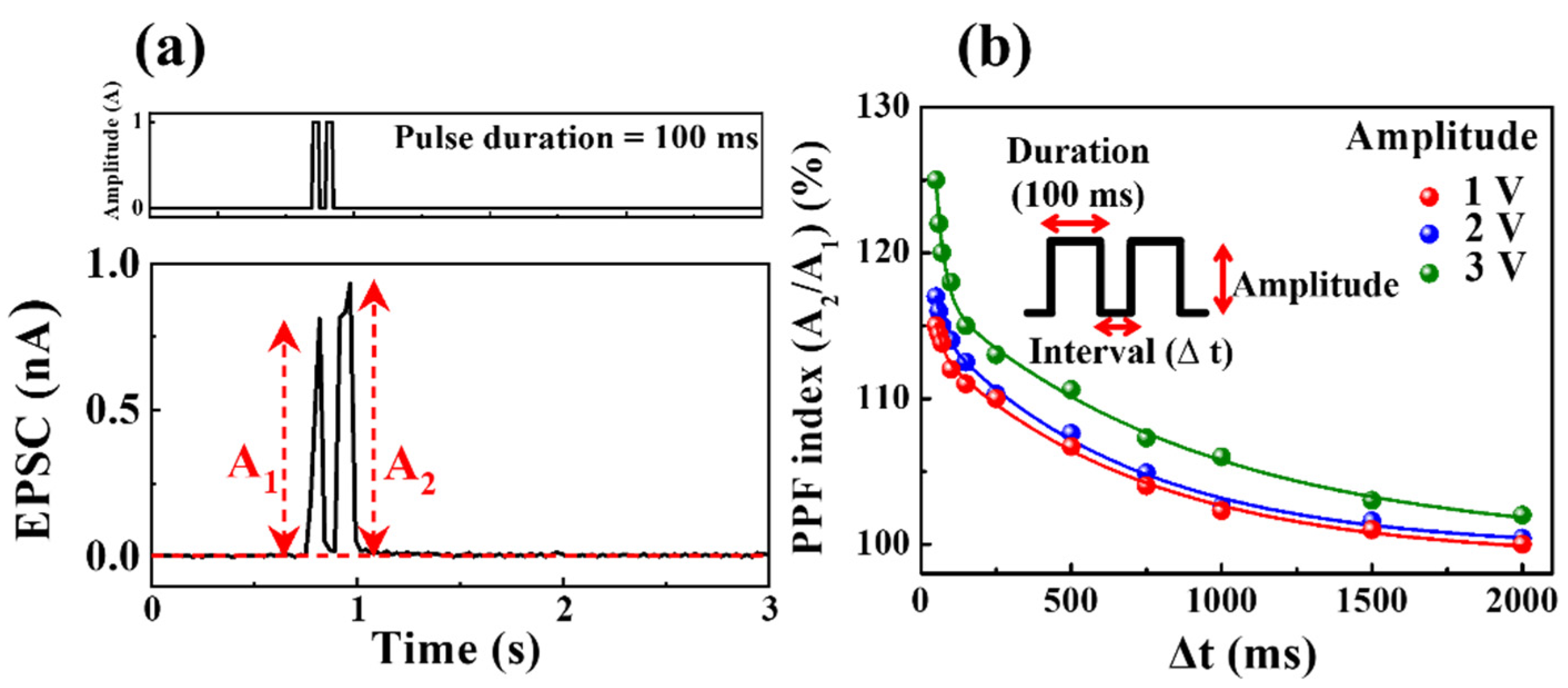

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wan, Q.; Sharbati, M.T.; Erickson, J.R.; Du, Y.; Xiong, F. Emerging artificial synaptic devices for neuromorphic computing. Adv. Mater. Technol. 2019, 4, 1900037. [Google Scholar] [CrossRef]

- Slavakis, K.; Giannakis, G.B.; Mateos, G. Modeling and optimization for big data analytics: (Statistical) learning tools for our era of data deluge. IEEE Signal Process. Mag. 2014, 31, 18–31. [Google Scholar] [CrossRef]

- Pershin, Y.V.; Di Ventra, M. Neuromorphic, digital, and quantum computation with memory circuit elements. Proc. IEEE. 2011, 100, 2071–2080. [Google Scholar] [CrossRef]

- Indiveri, G.; Liu, S.C. Memory and information processing in neuromorphic systems. Proc. IEEE. 2015, 103, 1379–1397. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, D.W.; Zhou, P. Two-dimensional materials for synaptic electronics and neuromorphic systems. Sci. Bull. 2019, 64, 1056–1066. [Google Scholar] [CrossRef]

- Zanotti, T.; Puglisi, F.M.; Pavan, P. Smart logic-in-memory architecture for low-power non-von neumann computing. IEEE J. Electron Devices Soc. 2020, 8, 757–764. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Z.; Shi, T.; Bi, C.; Rao, F.; Cai, Y.; Zhou, P. Memory materials and devices: From concept to application. InfoMat 2020, 2, 261–290. [Google Scholar] [CrossRef]

- Premsankar, G.; Di Francesco, M.; Taleb, T. Edge computing for the Internet of Things: A case study. IEEE Int. Things J. 2018, 5, 1275–1284. [Google Scholar] [CrossRef]

- Yanagida, T.; Nagashima, K.; Oka, K.; Kanai, M.; Klamchuen, A.; Park, B.H.; Kawai, T. Scaling effect on unipolar and bipolar resistive switching of metal oxides. Sci. Rep. 2013, 3, 1657. [Google Scholar] [CrossRef]

- Waser, R.; Aono, M. Nanoscience and Technology: A Collection of Reviews from Nature Journals; World Scientific: Singapore, 2009. [Google Scholar]

- Khalid, M. Review on various memristor models, characteristics, potential applications, and future works. Trans. Electr. Electron. Mater. 2019, 20, 289–298. [Google Scholar] [CrossRef]

- Jo, S.H.; Chang, T.; Ebong, I.; Bhadviya, B.B.; Mazumder, P.; Lu, W. Nanoscale memristor device as synapse in neuromorphic systems. Nano Lett. 2010, 10, 1297–1301. [Google Scholar] [CrossRef]

- Ohno, T.; Hasegawa, T.; Tsuruoka, T.; Terabe, K.; Gimzewski, J.K.; Aono, M. Short-term plasticity and long-term potentiation mimicked in single inorganic synapses. Nat. Mater. 2016, 10, 591–595. [Google Scholar] [CrossRef]

- Wang, Z.; Joshi, S.; Savel’ev, S.E.; Jiang, H.; Midya, R.; Lin, P.; Hu, M.; Ge, N.; Strachan, J.P.; Li, Z.; et al. Memristors with diffusive dynamics as synaptic emulators for neuromorphic computing. Nat. Mater. 2017, 16, 101–108. [Google Scholar] [CrossRef]

- Bakan, G.; Gerislioglu, B.; Dirisaglik, F.; Jurado, Z.; Sullivan, L.; Dana, A.; Lam, C.; Gokirmak, A.; Silva, H. Extracting the temperature distribution on a phase-change memory cell during crystallization. J. Appl. Phys. 2016, 120, 164504. [Google Scholar] [CrossRef]

- Raeis-Hosseini, N.; Lee, J.S. Resistive switching memory using biomaterials. J. Electroceramics 2017, 39, 223–238. [Google Scholar] [CrossRef]

- Li, Y.; Qian, Q.; Zhu, X.; Li, Y.; Zhang, M.; Li, J.; Zhang, Q. Recent advances in organic-based materials for resistive memory applications. InfoMat 2020, 2, 995–1033. [Google Scholar] [CrossRef]

- Xia, Y.; He, Y.; Zhang, F.; Liu, Y.; Leng, J. A review of shape memory polymers and composites: Mechanisms, materials, and applications. Adv. Mater. 2021, 33, 2000713. [Google Scholar] [CrossRef]

- Seymour, R.B. Nitrate (Celluloid) in 1868. Fillers were also used in casein plastic (Galalith, milk stone) in Germany in 1897 (4). Leo Baekeland used wood flour as a filler in his molded phenolic. In History of Polymeric Composites; VNU Science Press: Utrecht, The Netherlands, 1987; pp. 51–56. [Google Scholar]

- Brother, G.H. Casein plastics. Ind. Eng. Chem. 1940, 32, 31–33. [Google Scholar] [CrossRef]

- Jefferson, M.T.; Rutter, C.; Fraine, K.; Borges, G.V.; de Souza Santos, G.M.; Schoene, F.A.; Hurst, G.A. Valorization of sour milk to form bioplastics: Friend or foe? J. Chem. Educ. 2020, 97, 1073–1076. [Google Scholar] [CrossRef]

- Andrade, J.; Pereira, C.G.; Almeida Junior, J.C.; Viana, C.C.R.; de Oliveira Neves, L.N.; da Silva, P.H.F.; Bell, M.J.V.; Anjos, V.C. FTIR-ATR Determination of Protein Content to Evaluate Whey Protein Concentrate Adulteration. LWT 2019, 99, 166–172. [Google Scholar] [CrossRef]

- Lefier, D.; Grappin, R.; Pochet, S. Determination of Fat, Protein, and Lactose in Raw Milk by Fourier Transform Infrared Spectroscopy and by Analysis with a Conventional Filter-Based Milk Analyzer. J. AOAC Int. 1996, 79, 711–717. [Google Scholar] [CrossRef]

- Durazzo, A.; Gabrielli, P.; Manzi, P. Qualitative Study of Functional Groups and Antioxidant Properties of Soy-Based Beverages Compared to Cow Milk. Antioxidants 2015, 4, 523–532. [Google Scholar] [CrossRef]

- Heuer, C.; Luinge, H.J.; Lutz, E.T.G.; Schukken, Y.H.; Van Der Maas, J.H.; Wilmink, H.; Noordhuizen, J.P.T.M. Determination of Acetone in Cow Milk by Fourier Transform Infrared Spectroscopy for the Detection of Subclinical Ketosis. J. Dairy Sci. 2001, 84, 575–582. [Google Scholar] [CrossRef]

- Conceição, D.G.; Gonçalves, B.H.R.; da Hora, F.F.D.; Faleiro, A.S.; Santos, L.S.; Ferrão, S.P. Use of FTIR-ATR SpectroscopyCombined with Multivariate Analysis as a Screening Tool to Identify Adulterants in Raw Milk. J. Braz. Chem. Soc. 2019, 30, 780–785. [Google Scholar]

- Movasaghi, Z.; Rehman, S.; ur Rehman, D.I. Fourier transform infrared (FTIR) spectroscopy of biological tissues. Appl. Spectrosc. Rev. 2008, 43, 134–179. [Google Scholar] [CrossRef]

- Bresser, D.; Buchholz, D.; Moretti, A.; Varzi, A.; Passerini, S. Alternative Binders for Sustainable Electrochemical Energy Storage–the Transition to Aqueous Electrode Processing and Bio-Derived Polymers. Energy Environ. Sci. 2018, 11, 3096–3127. [Google Scholar] [CrossRef]

- Cordeschi, M.; Di Paola, L.; Marrelli, L.; Maschietti, M. Net Proton Charge of -and -Casein in Concentrated Aqueous Electrolyte Solutions. Biophys. Chem. 2003, 103, 77–88. [Google Scholar] [CrossRef]

- West, I.C.; Mitchell, P. Stoicheiometry of Lactose–Proton Symport Across the Plasma Membrane of Escherichia coli. Biochem. J. 1973, 132, 587–592. [Google Scholar] [CrossRef]

- Abramson, J.; Smirnova, I.; Kasho, V.; Verner, G.; Kaback, H.R.; Iwata, S. Structure and Mechanism of the Lactose Permease of Escherichia coli. Science 2003, 301, 610–615. [Google Scholar] [CrossRef]

- Wong, H.S.P.; Lee, H.Y.; Yu, S.; Chen, Y.S.; Wu, Y.; Chen, P.S.; Lee, B.; Chen, F.T.; Tsai, M.J. Metal–oxide RRAM. Proc. IEEE 2012, 100, 1951–1970. [Google Scholar] [CrossRef]

- Chen, M.-C.; Chang, T.-C.; Tsai, C.-T.; Huang, S.-Y.; Chen, S.-C.; Hu, C.-W.; Sze, S.M.; Tsai, M.-J. Influence of electrode material on the resistive memory switching property of indium gallium zinc oxide thin films. Appl. Phys. Lett. 2010, 96, 262110. [Google Scholar] [CrossRef] [Green Version]

- Hsu, C.H.; Fan, Y.S.; Liu, P.T. Multilevel resistive switching memory with amorphous InGaZnO-based thin film. Appl. Phys. Lett. 2013, 102, 062905. [Google Scholar] [CrossRef]

- Wu, M.C.; Jang, W.Y.; Lin, C.H.; Tseng, T.Y. A study on low–power, nanosecond operation and multilevel bipolar resistance switching in Ti/ZrO2/Pt nonvolatile memory with 1T1R architecture. Semicond. Sci. Technol. 2012, 27, 065010. [Google Scholar] [CrossRef]

- Liu, R.; He, Y.; Jiang, S.; Wang, L.; Wan, Q. Synaptic plasticity modulation and coincidence detection emulated in multi-terminal neuromorphic transistors. Org. Electron. 2021, 92, 106–125. [Google Scholar] [CrossRef]

- Kim, K.; Chen, C.L.; Truong, Q.; Shen, A.M.; Chen, Y. A carbon nanotube synapse with dynamic logic and learning. Adv. Mater. 2013, 25, 1693–1698. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, Y.; Shi, Y.; Wan, Q. Solution-processed chitosan-gated IZO-based transistors for mimicking synaptic plasticity. IEEE Electron Device Lett. 2014, 35, 280–282. [Google Scholar] [CrossRef]

- Yu, F.; Zhu, L.Q.; Xiao, H.; Gao, W.T.; Guo, Y.B. Restickable oxide neuromorphic transistors with spike-timing-dependent plasticity and pavlovian associative learning activities. Adv. Funct. Mater. 2018, 28, 1804025. [Google Scholar] [CrossRef]

- Majumdar, S.; Tan, H.; Qin, Q.H.; van Dijken, S. Energy-efficient organic ferroelectric tunnel junction memristors for neuromorphic computing. Adv. Electron. Mater. 2019, 5, 1800795. [Google Scholar] [CrossRef]

- Bliss, T.V.; Lømo, T. Long-lasting potentiation of synaptic transmission in the dentate area of the anaesthetized rabbit following stimulation of the perforant path. J. Physiol. 1973, 232, 331–356. [Google Scholar] [CrossRef]

- Bliss, T.V.; Collingridge, G.L. A synaptic model of memory: Long-term potentiation in the hippocampus. Nature 1993, 361, 31–39. [Google Scholar] [CrossRef]

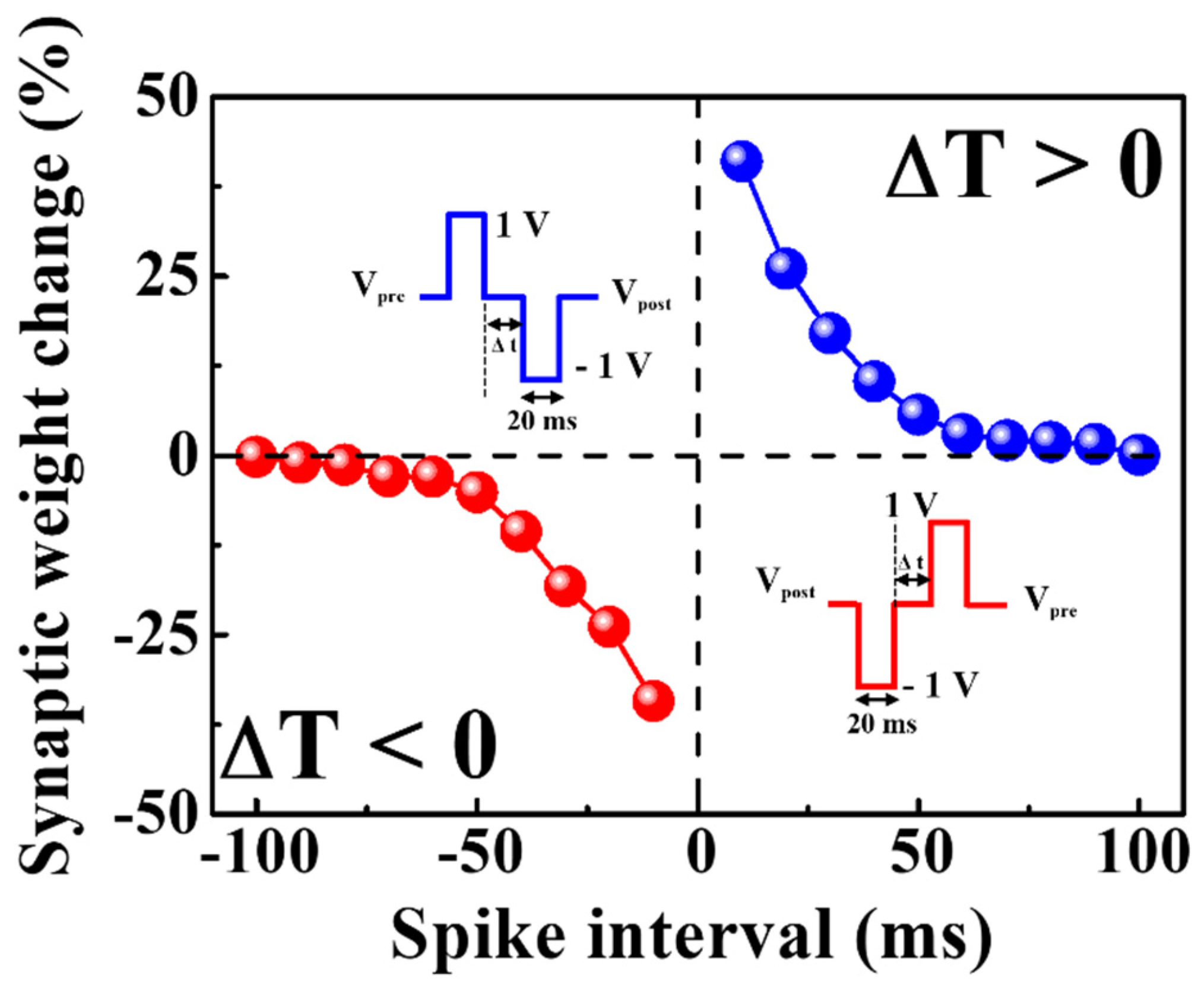

- Bi, G.Q.; Poo, M.M. Synaptic modifications in cultured hippocampal neurons: Dependence on spike timing, synaptic strength, and postsynaptic cell type. J. Neurosci. 1998, 18, 10464–10472. [Google Scholar] [CrossRef] [PubMed]

- Song, S.; Miller, K.D.; Abbott, L.F. Competitive Hebbian learning through spike-timing-dependent synaptic plasticity. Nat. Neurosci. 2000, 3, 919–926. [Google Scholar] [CrossRef] [PubMed]

- Feldman, D.E. The spike-timing dependence of plasticity. Neuron 2012, 75, 556–571. [Google Scholar] [CrossRef] [PubMed]

- Sjostrom, P.J.; Rancz, E.A.; Roth, A.; Hausser, M. Dendritic excitability and synaptic plasticity. Physiol. Rev. 2008, 88, 769–840. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.; Du, C.; Sheridan, P.; Ma, W.; Choi, S.; Lu, W.D. Experimental demonstration of a second-order memristor and its ability to biorealistically implement synaptic plasticity. Nano Lett. 2015, 15, 2203–2211. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.I.; Tao, H.W.; Holt, C.E.; Harris, W.A.; Poo, M. A critical window for cooperation and competition among developing retinotectal synapses. Nature 1998, 395, 37–44. [Google Scholar] [CrossRef]

- Markram, H.; Lübke, J.; Frotscher, M.; Sakmann, B. Regulation of synaptic efficacy by coincidence of postsynaptic APs and EPSPs. Science 1997, 275, 213–215. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Li, Y.; Wang, Y.; Xu, X.; Fu, M.; Liu, Y.; Lin, Z.; Ling, H.; Gkoupidenis, P.; Yi, M.; et al. Thin-film transistors for emerging neuromorphic electronics: Fundamentals, materials, and pattern recognition. J. Mater. Chem. C 2021, 9, 11464–11483. [Google Scholar] [CrossRef]

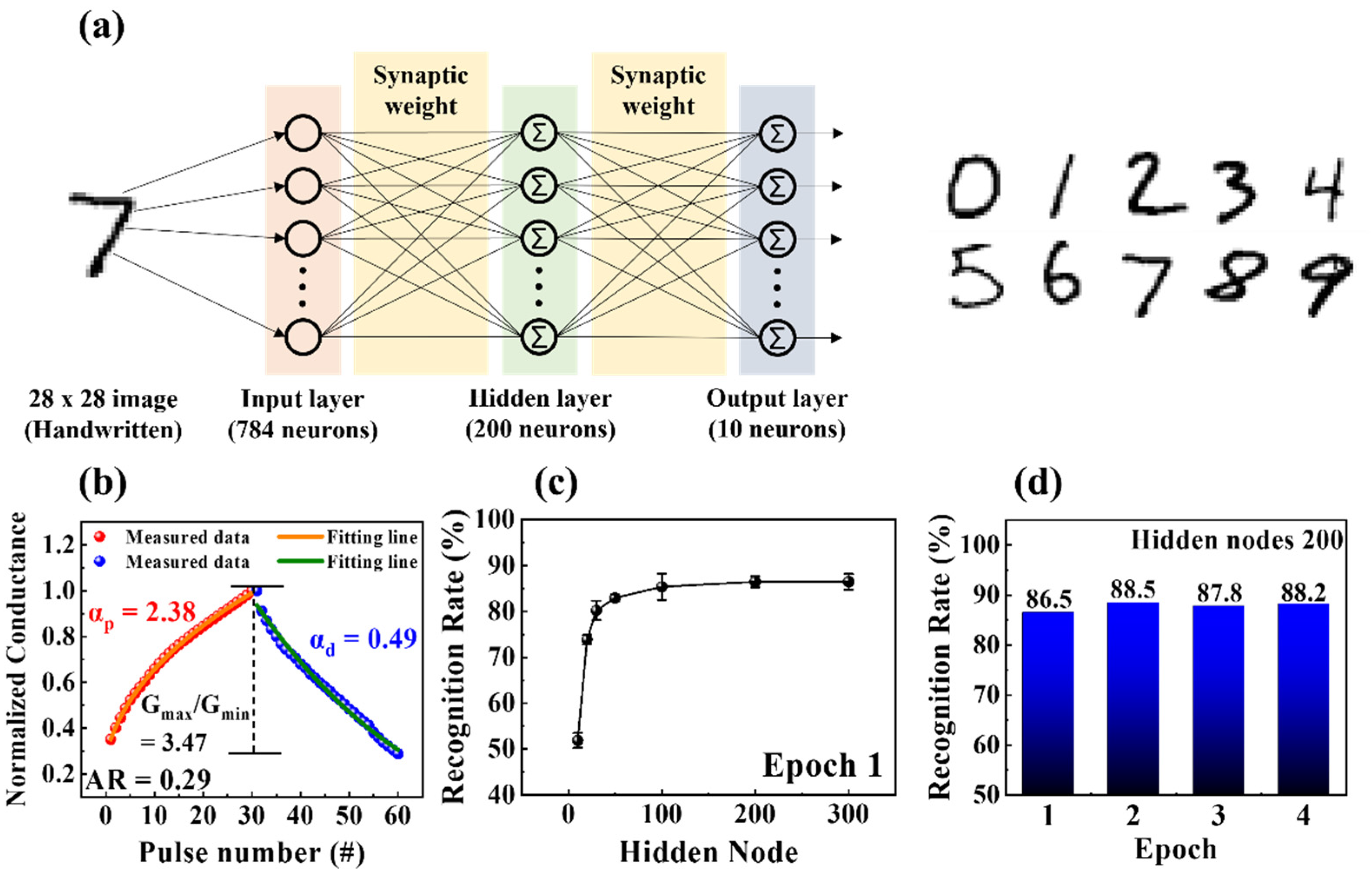

- Yang, C.S.; Shang, D.S.; Liu, N.; Fuller, E.J.; Agrawal, S.; Talin, A.A.; Li, Y.Q.; Shen, B.G.; Sun, Y. All-solid-state synaptic transistor with ultralow conductance for neuromorphic computing. Adv. Funct. Mater. 2018, 28, 1804170. [Google Scholar] [CrossRef]

- Jang, J.; Park, S.; Burr, G.W.; Hwang, H.; Jeong, Y.H. Optimization of conductance change in Pr1−x CaxMnO3-based synaptic devices for neuromorphic systems. IEEE Electron Device Lett. 2015, 36, 457–459. [Google Scholar] [CrossRef]

- Jang, J.; Park, S.; Jeong, Y.; Hwang, H. ReRAM-based synaptic device for neuromorphic computing. In 2014 IEEE International Symposium on Circuits and Systems (ISCAS); IEEE: Piscataway Township, NJ, USA, 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Min, J.-G.; Park, H.; Cho, W.-J. Milk–Ta2O5 Hybrid Memristors with Crossbar Array Structure for Bio-Organic Neuromorphic Chip Applications. Nanomaterials 2022, 12, 2978. https://doi.org/10.3390/nano12172978

Min J-G, Park H, Cho W-J. Milk–Ta2O5 Hybrid Memristors with Crossbar Array Structure for Bio-Organic Neuromorphic Chip Applications. Nanomaterials. 2022; 12(17):2978. https://doi.org/10.3390/nano12172978

Chicago/Turabian StyleMin, Jin-Gi, Hamin Park, and Won-Ju Cho. 2022. "Milk–Ta2O5 Hybrid Memristors with Crossbar Array Structure for Bio-Organic Neuromorphic Chip Applications" Nanomaterials 12, no. 17: 2978. https://doi.org/10.3390/nano12172978