Wood Surface Modification with Hybrid Materials Based on Multi-Walled Carbon Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Nanomaterial Dispersion in PHBHV Solution

2.2. Wood Preparation

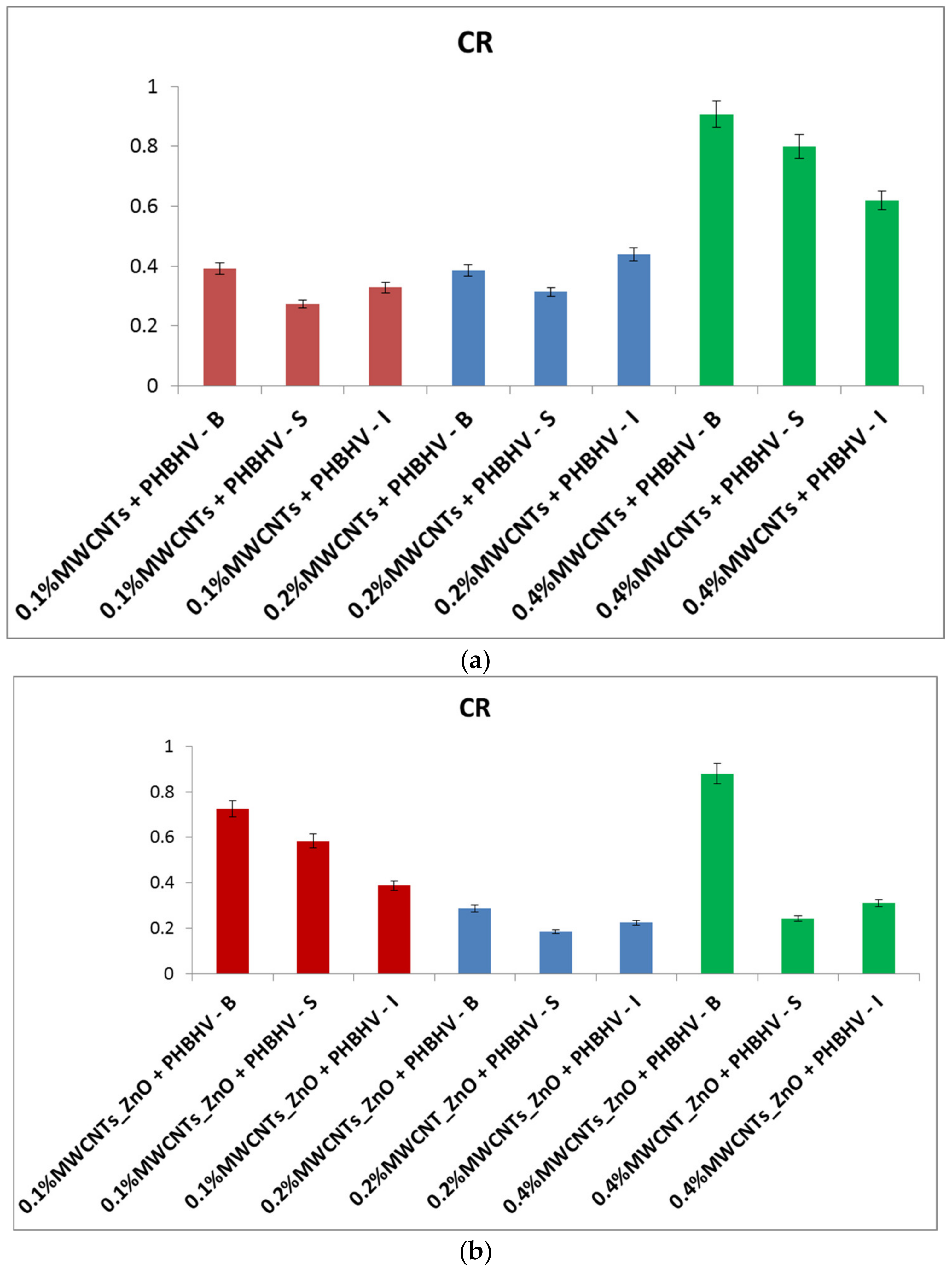

2.3. Consolidant Retention (CR)

2.4. Optical Microscopy (OM)

2.5. Fourier Transform Infrared Spectroscopy (FTIR)

2.6. Wavelength-Dispersive X-ray Fluorescence (WDXRF)

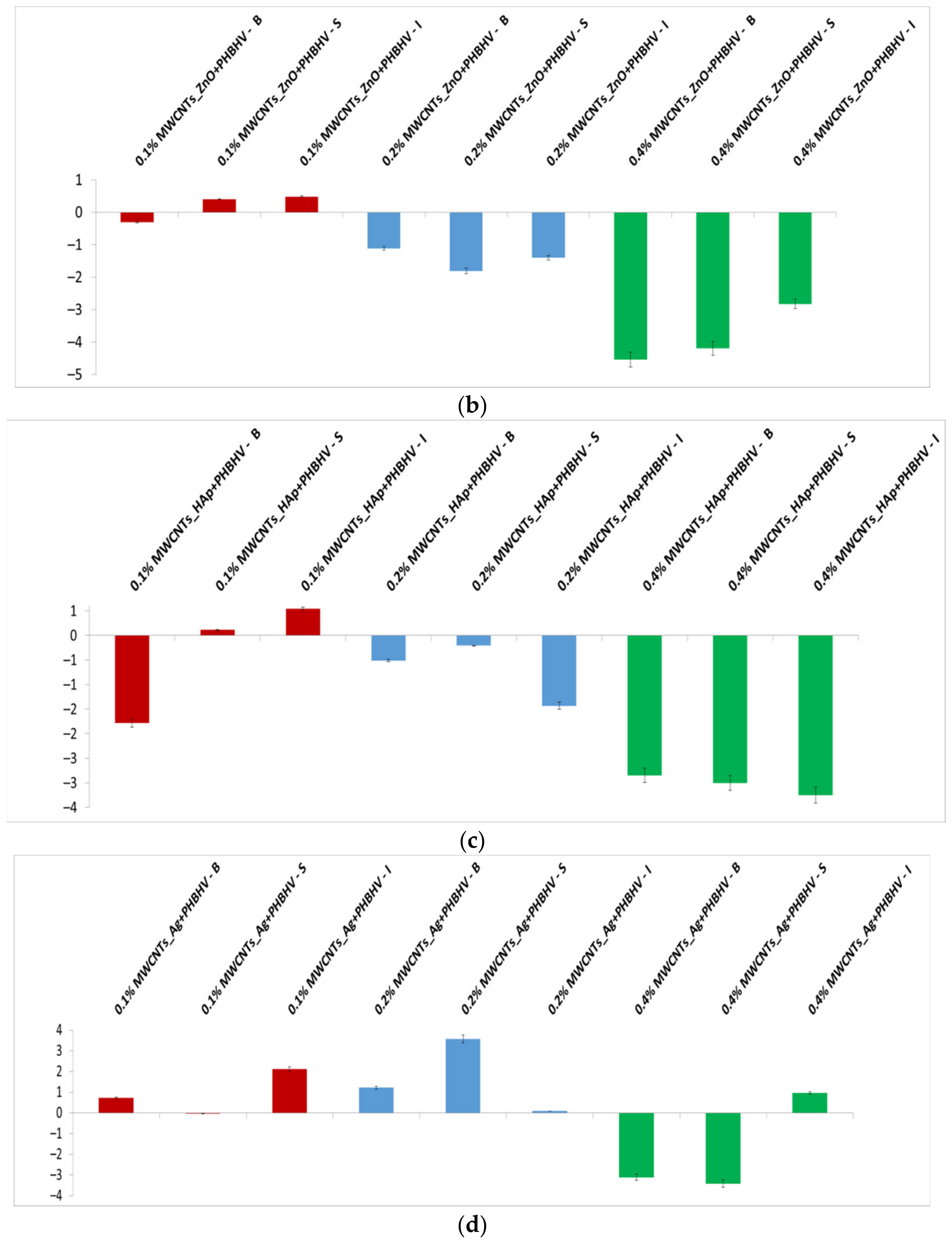

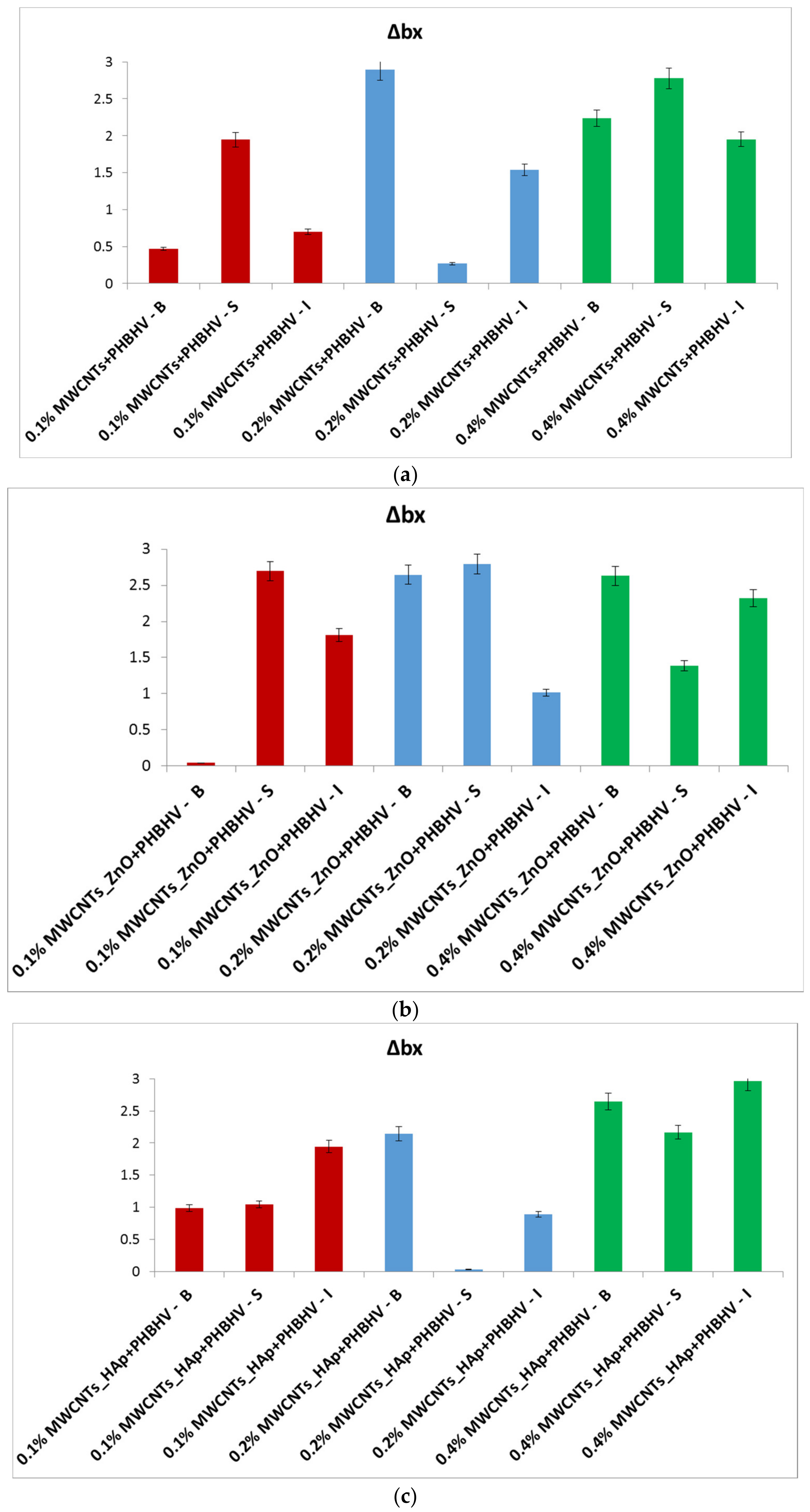

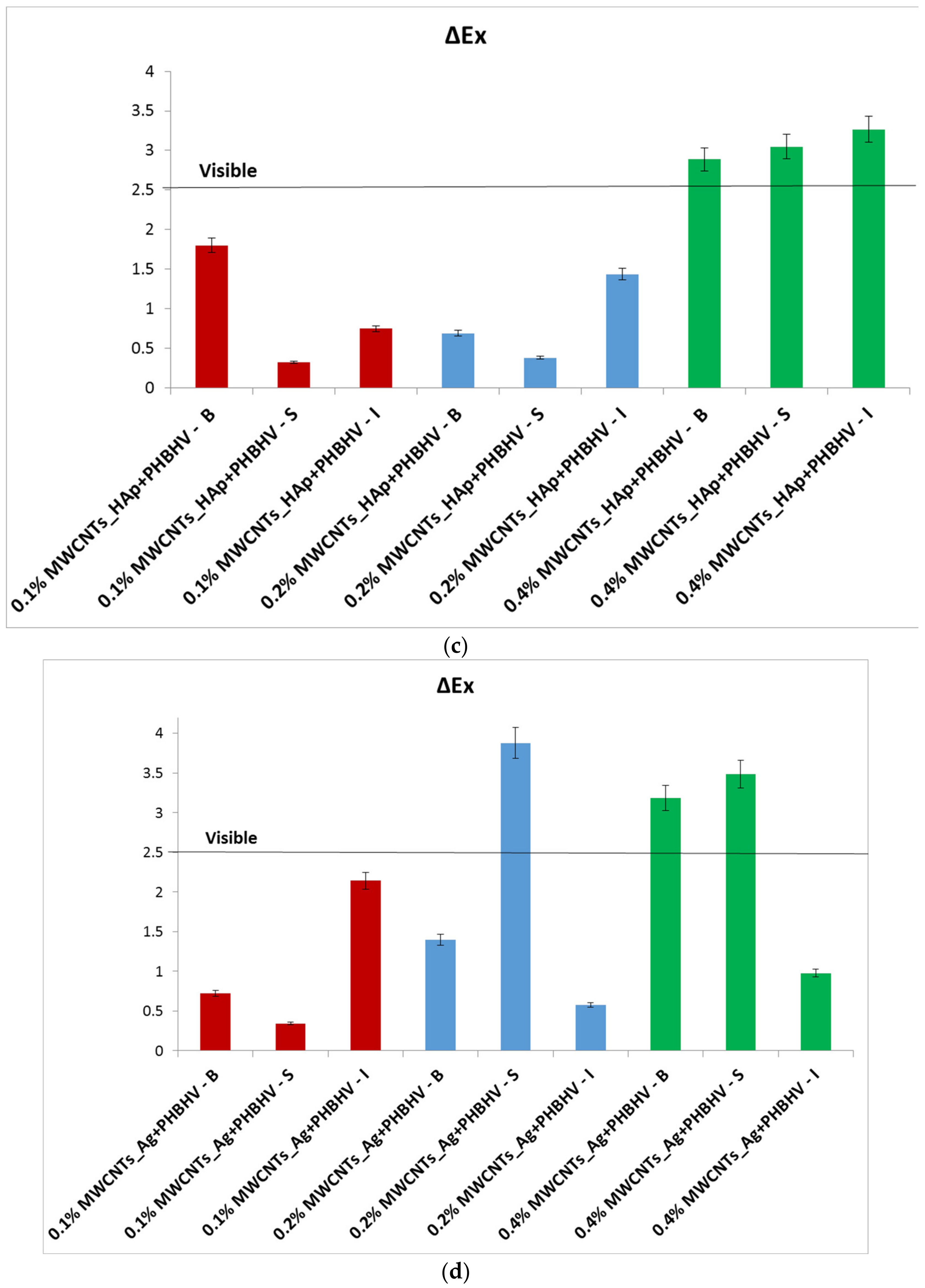

2.7. Colorimetric Tests

2.8. Water Absorption Test (WA)

2.9. Humidity Test (U)

2.10. Contact Angle

2.11. Mechanical Tests

2.12. Accelerated Aging Behavior

2.12.1. Artificial Aging Test by UV Radiation Exposure

2.12.2. Artificial Aging Test by Exposure to Temperature Variations

2.13. Antifungal Activity

2.14. Statistical Analysis

3. Results

3.1. Consolidant Retention

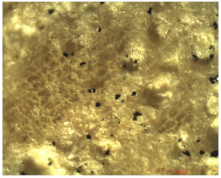

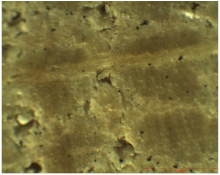

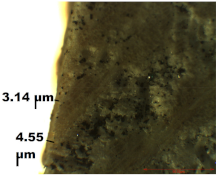

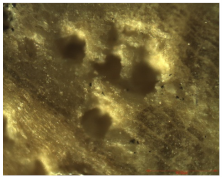

3.2. Optical Microscopy

3.3. FTIR Analysis

3.4. WDXRF Analysis

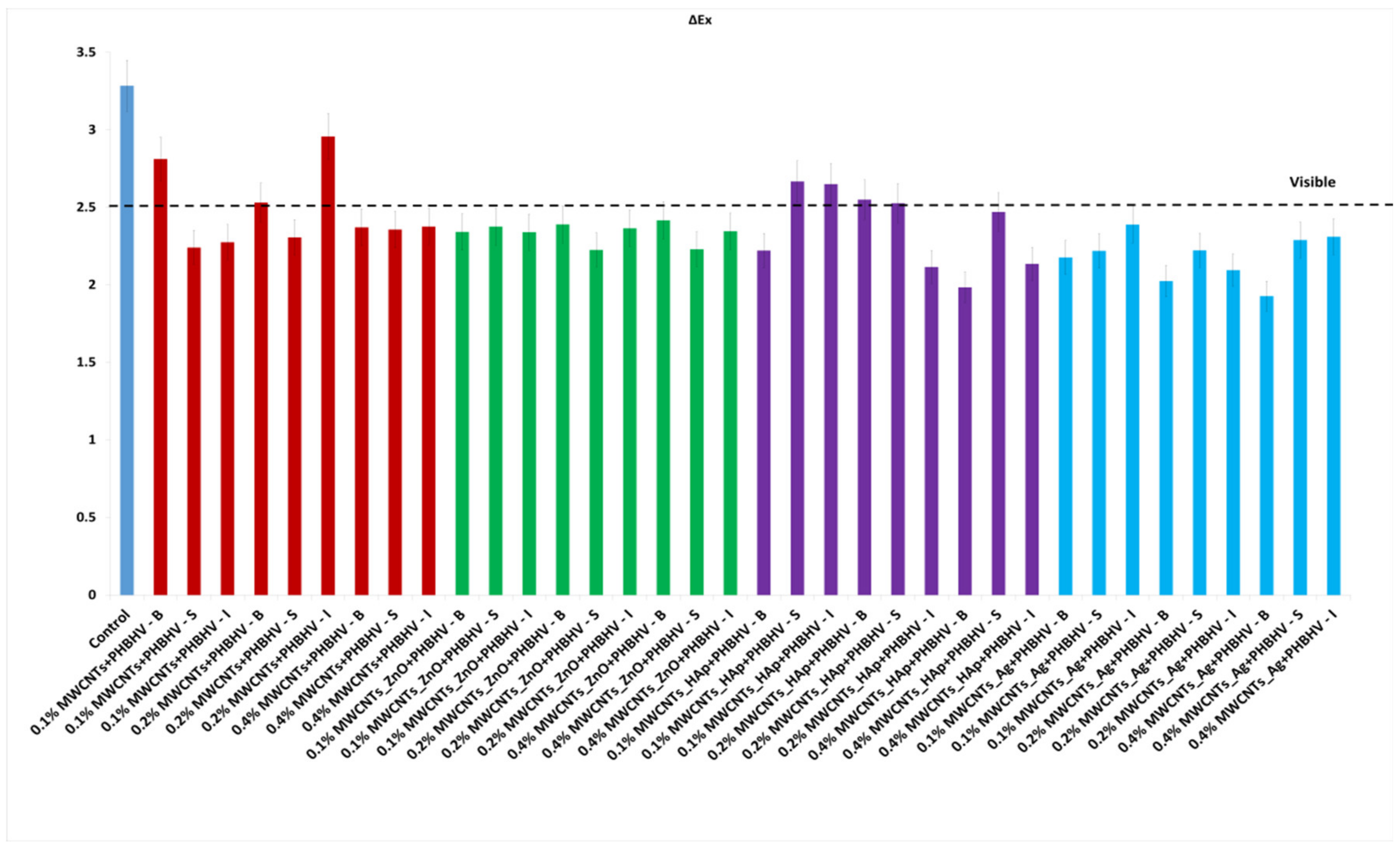

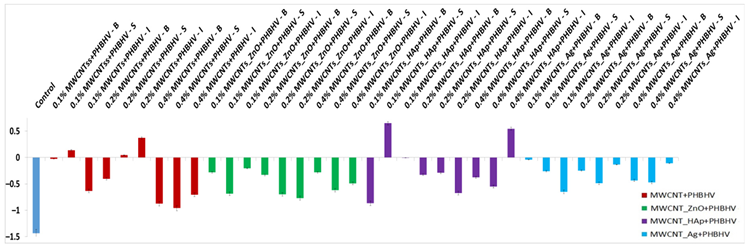

3.5. Colorimetric Tests

Data Analysis

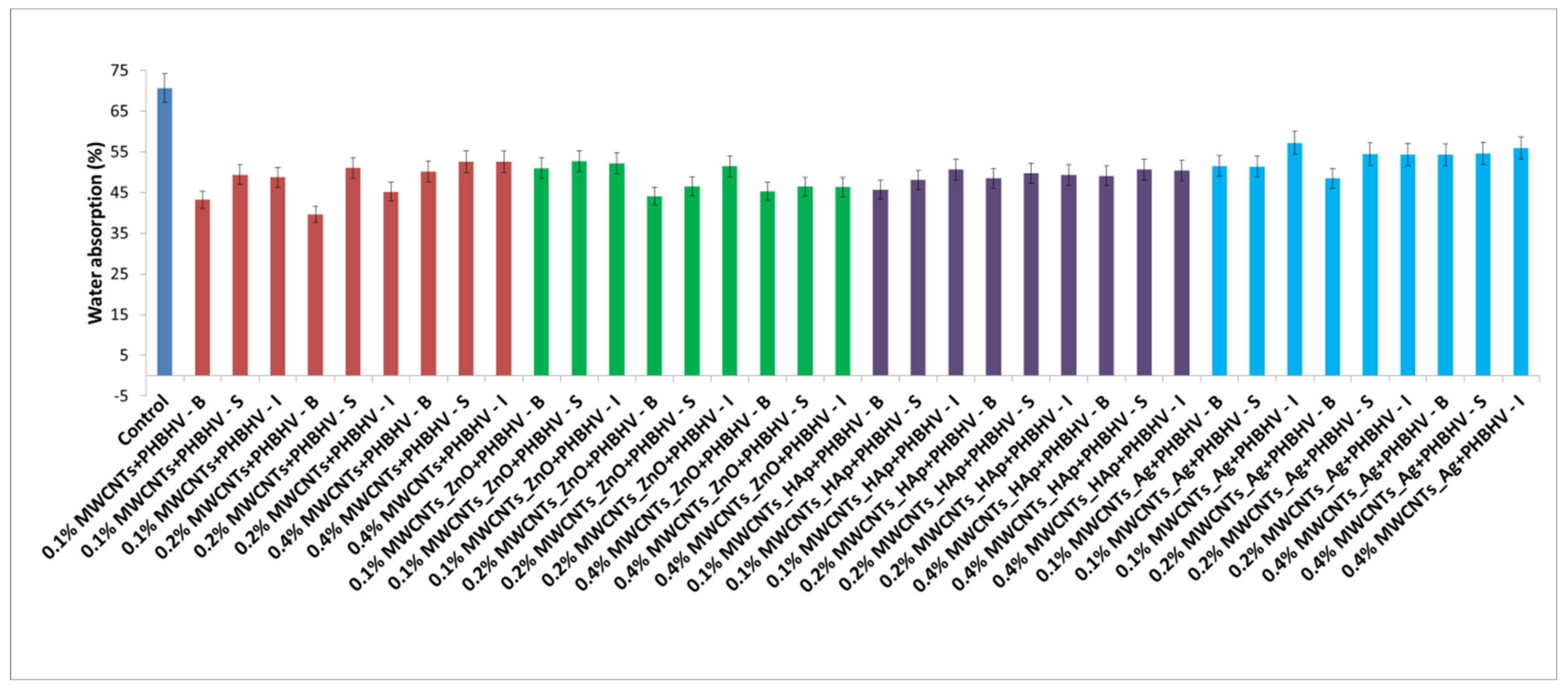

3.6. Water Absorption Test

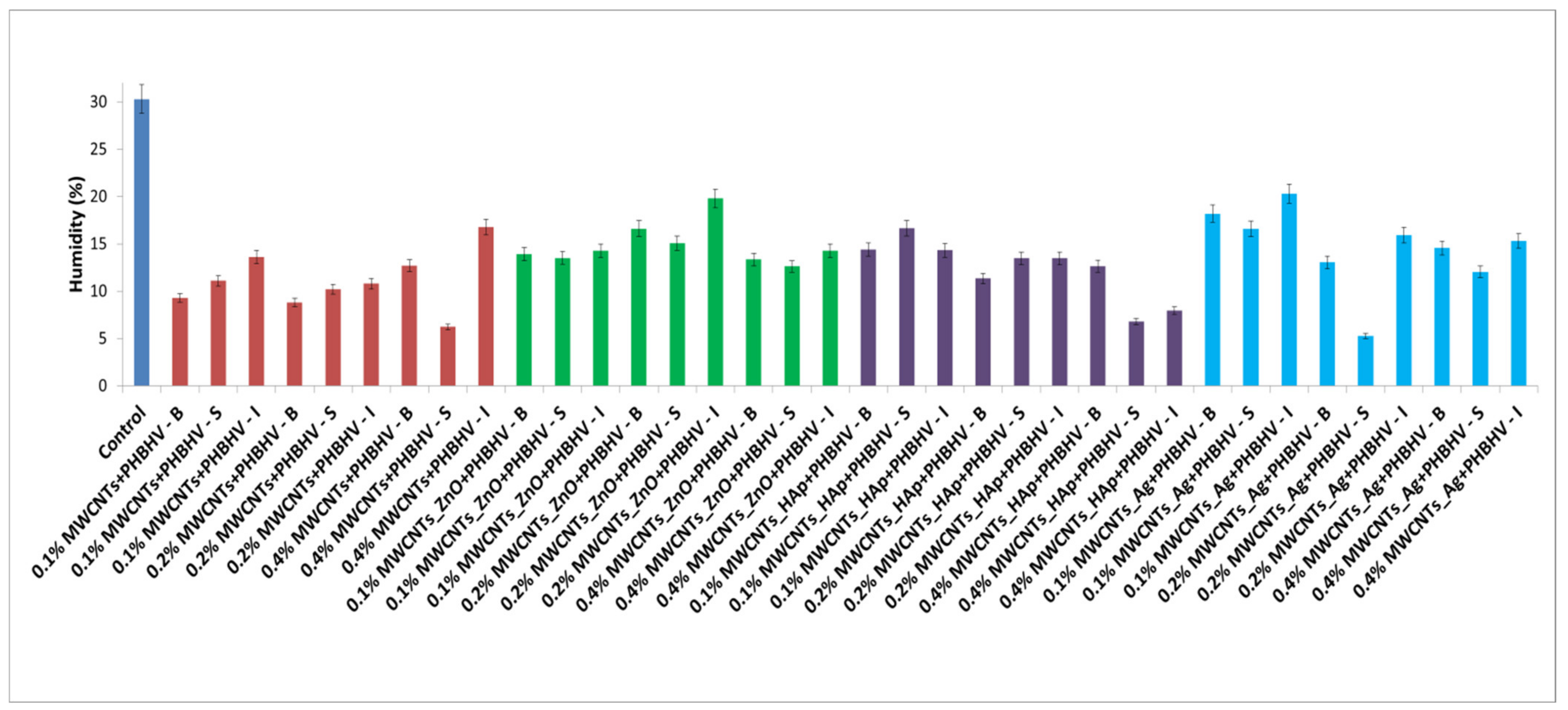

3.7. Humidity Test

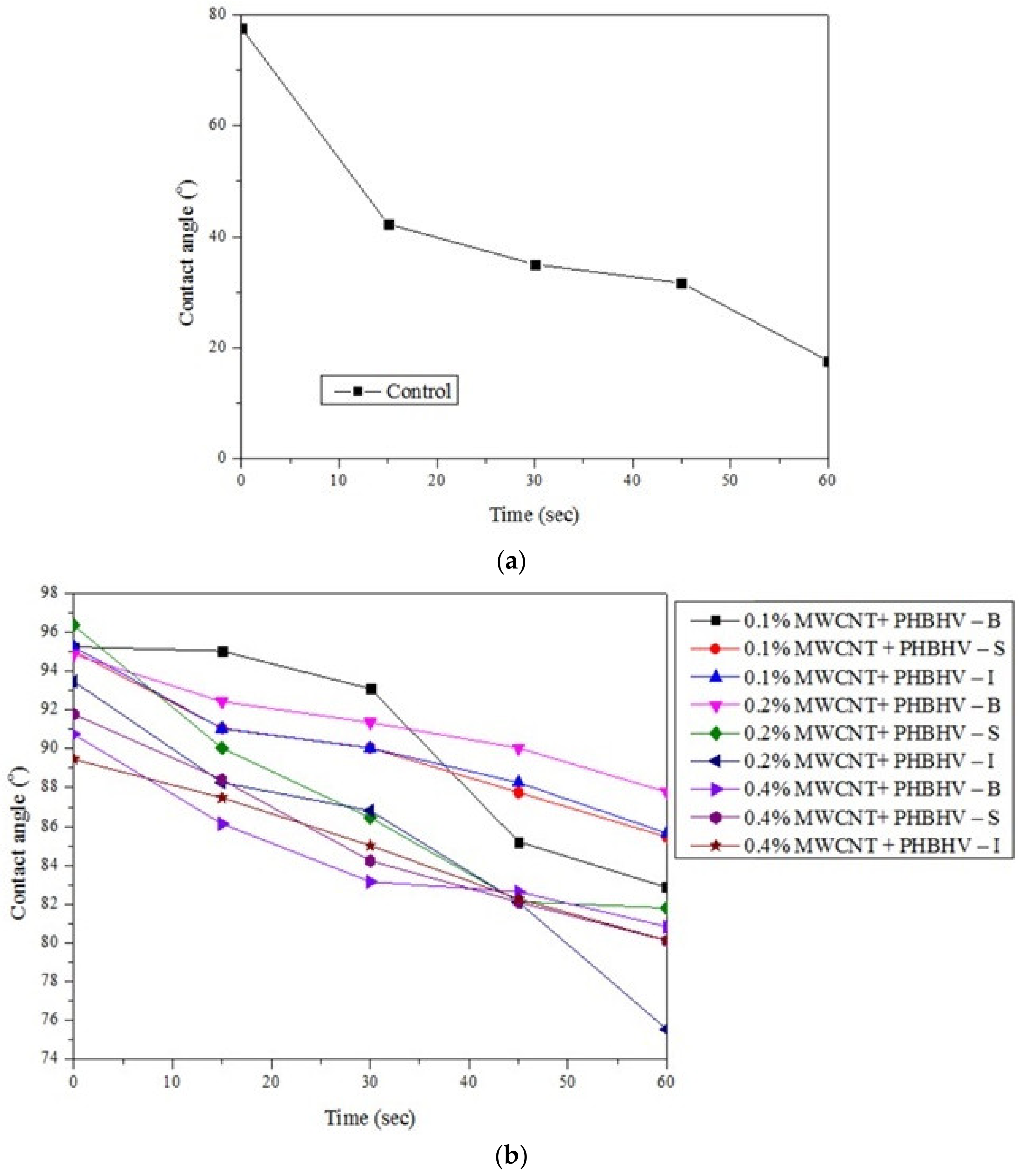

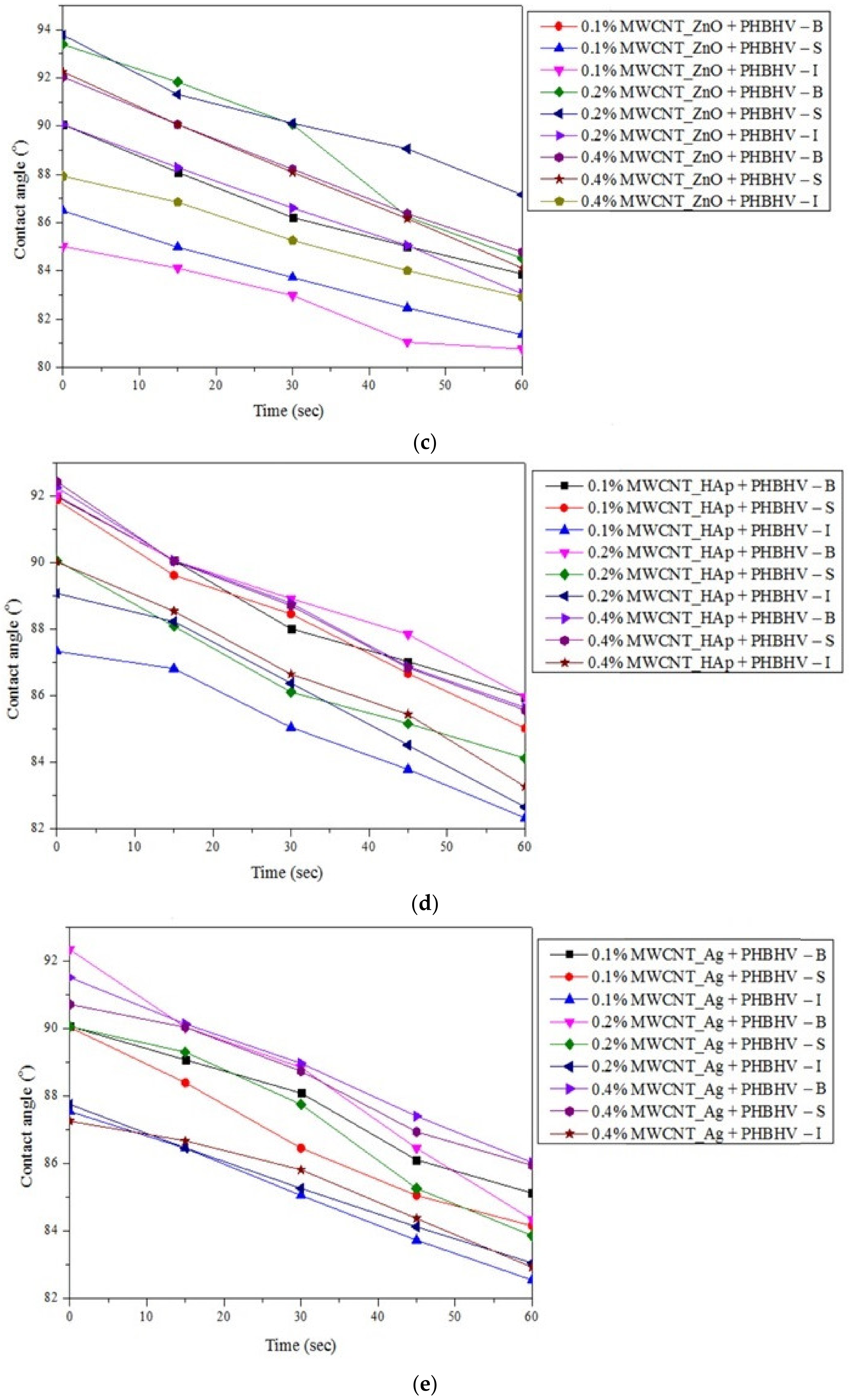

3.8. Contact Angle

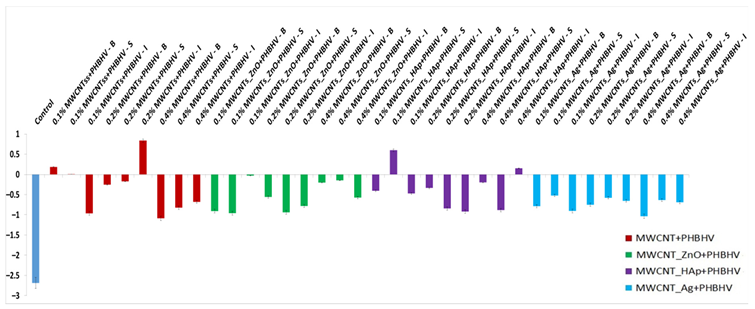

3.9. Mechanical Tests

Data Analysis

3.10. Accelerated Aging Behavior

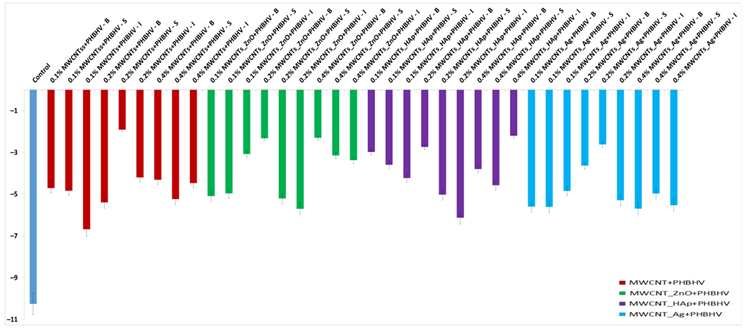

3.10.1. Artificial Aging Test by UV Radiation Exposure

3.10.2. Artificial Aging Test by Temperature Variation Exposure

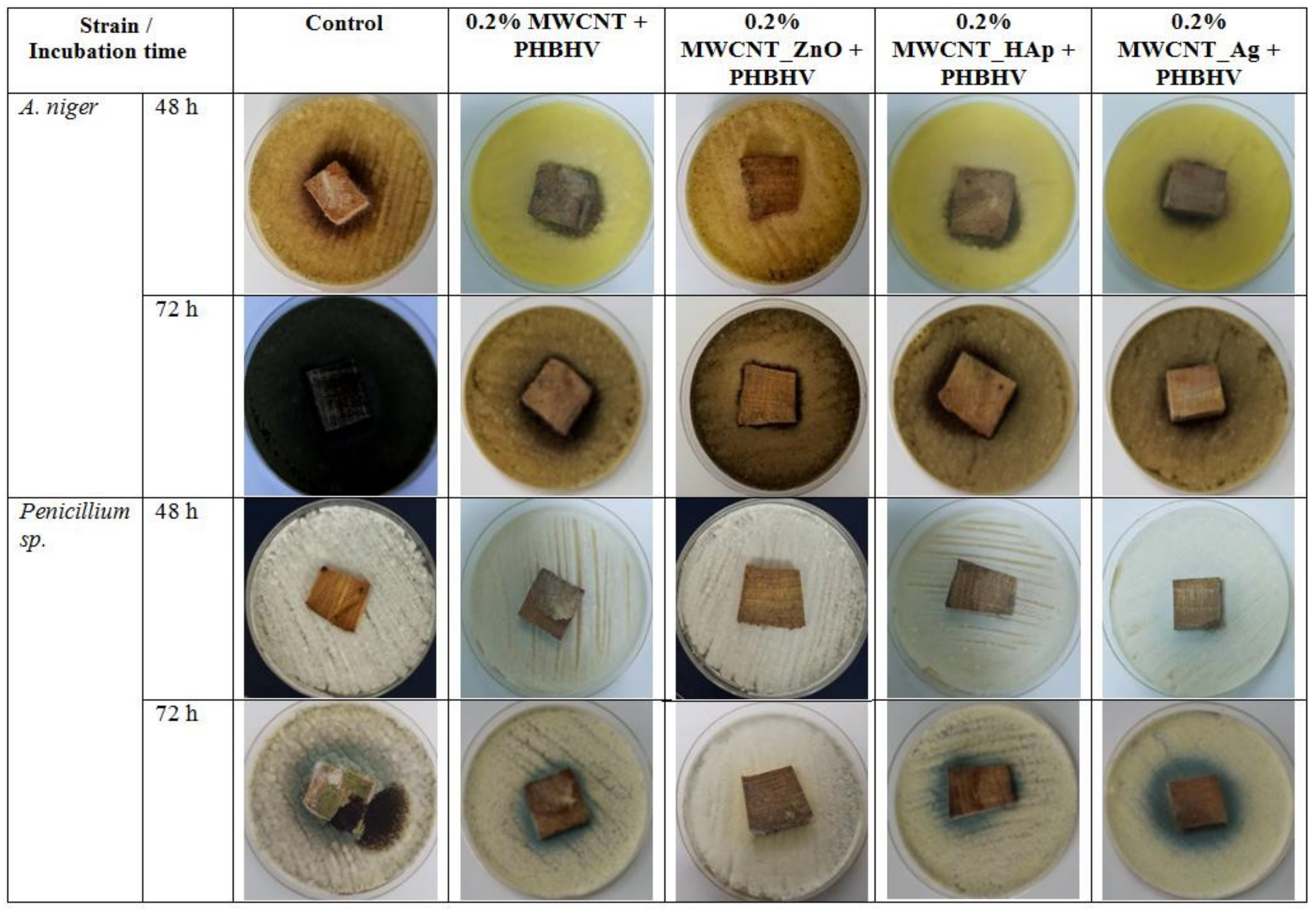

3.11. Antifungal Activity

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- David, M.E.; Ion, R.-M.; Andrei, E.R.; Grigorescu, R.M.; Iancu, L.; Filipescu, M.I. Superhydrophobic Coatings Based On Cellulose Acetate For Pinewood Preservation. J. Sci. Arts 2020, 1, 171–182. [Google Scholar]

- David, M.E.; Ion, R.-M.; Grigorescu, R.M.; Iancu, L.; Andrei, E.R. Nanomaterials Used in Conservation and Restoration of Cultural Heritage: An Up-to-Date Overview. Materials 2020, 13, 2064. [Google Scholar] [CrossRef] [PubMed]

- Greaves, H. The bacterial factor in wood decay. Wood Sci. Technol. 1971, 5, 6–16. [Google Scholar] [CrossRef]

- Hernández, R.E.; Passarini, L.; Koubaa, A. Effects of temperature and moisture content on wood mechanical properties associated to the chipping process. In Proceedings of the 21st International Wood Machining Seminar (IWMS-21), Tsukuba, Japan, 4–7 August 2014; pp. 1–8. [Google Scholar]

- Karim, M.; Daryaei, M.G.; Torkaman, J.; Oladi, R.; Ghanbary, M.A.T.; Bari, E. In vivo investigation of chemical alteration in oak wood decayed by Pleurotus ostreatus. Int. Biodeterior. Biodegrad. 2016, 108, 127–132. [Google Scholar] [CrossRef]

- Teng, T.-J.; Arip, M.N.M.; Sudesh, K.; Nemoikina, A.; Jalaludin, Z.; Ng, E.-P.; Lee, H.-L. Conventional technology and nanotechnology in wood preservation: A review. BioResources 2018, 13, 9220–9252. [Google Scholar] [CrossRef] [Green Version]

- Monaco, A.L.; Balletti, F.; Pelosi, C. Wood in cultural heritage. Properties and conservation of historical wooden artefacts. Eur. J. Sci. Theol. 2018, 14, 161–171. [Google Scholar]

- Borges, C.C.; Tonoli, G.H.D.; Cruz, T.M.; Duarte, P.J.; Junqueira, T.A. Nanoparticles-based wood preservatives: The next generation of wood protection? Cerne 2018, 24, 397–407. [Google Scholar] [CrossRef]

- Pánek, M.; Oberhofnerová, E.; Zeidler, A.; Šedivka, P. Efficacy of hydrophobic coatings in protecting oak wood surfaces during accelerated weathering. Coatings 2017, 7, 172. [Google Scholar] [CrossRef] [Green Version]

- Favarim, H.R.; Leite, L.O. Performance of ZnO nanoparticles for fire retardant and UV protection of pine wood. BioResources 2018, 13, 6963–6969. [Google Scholar] [CrossRef]

- Clausen, C.A.; Kartal, S.N.; Arango, R.A.; Green, F. The role of particle size of particulate nano-zinc oxide wood preservatives on termite mortality and leach resistance. Nanoscale Res. Lett. 2011, 6, 427. [Google Scholar] [CrossRef] [Green Version]

- Soltani, M.; Najafi, A.; Yousefian, S.; Naji, H.R.; Bakar, E.S. Water repellent effect and dimension stability of beech wood impregnated with nano-zinc oxide. BioResources 2013, 8, 6280–6287. [Google Scholar] [CrossRef] [Green Version]

- Habibzade, S.; Taghiyari, H.R.; Omidvar, A.; Roudi, H.R. Effects of impregnation with styrene and nano-zinc oxide on fire-retarding, physical, and mechanical properties of poplar wood. Cerne 2016, 22, 465–474. [Google Scholar] [CrossRef] [Green Version]

- Papadopoulos, A.N.; Taghiyari, H.R. Innovative wood surface treatments based on nanotechnology. Coatings 2019, 9, 866. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Wu, X.; Wang, Y.; Tian, Y.; Mu, H.; Li, J. Hydrophobic and UV-resistant properties of environmentally friendly nano-ZnO-coated wood. Holzforschung 2021, 75, 138–147. [Google Scholar] [CrossRef]

- Liao, S.; Zhang, Y.; Pan, X.; Zhu, F.; Jiang, C.; Liu, Q.; Cheng, Z.; Dai, G.; Wu, G.; Wang, L.; et al. Antibacterial activity and mechanism of silver nanoparticles against multidrug-resistant Pseudomonas aeruginosa. Int. J. Nanomed. 2019, 14, 1469–1487. [Google Scholar] [CrossRef] [Green Version]

- Künniger, T.; Gerecke, A.C.; Ulrich, A.; Huch, A.; Vonbank, R.; Heeb, M.; Wichser, A.; Haag, R.; Kunz, P.; Faller, M. Release and environmental impact of silver nanoparticles and conventional organic biocides from coated wooden façades. Environ. Pollut. 2014, 184, 464–471. [Google Scholar] [CrossRef]

- Akhtari, M.; Ganjipour, M. Effect of nano-silver and nano-copper and nano zinc oxide on Paulownia wood exposed to white rot fungus. Agric. Sci. Dev. 2013, 2, 116–119. [Google Scholar]

- Moya, R.; Rodriguez-Zuñiga, A.; Berrocal, A.; Vega-Baudrit, J. Effect of silver nanoparticles synthesized with NPsAg-ethylene glycol (C2H6O2) on brown decay and white decay fungi of nine tropical woods. J. Nanosci. Nanotechnol. 2017, 17, 5233–5240. [Google Scholar] [CrossRef]

- Can, A.; Palanti, S.; Sivrikaya, H.; Hazer, B.; Stefanı, F. Physical, biological and chemical characterisation of wood treated with silver nanoparticles. Cellulose 2019, 26, 5075–5084. [Google Scholar] [CrossRef]

- Ion, R.-M.; Nyokong, T.; Nwahara, N.; Suica-Bunghez, R.; Iancu, L.; Teodorescu, S.; Dulama, I.D.; Stirbescu, R.M.; Gheboianu, A.; Grigorescu, R.M. Wood preservation with gold hydroxyapatite system. Herit. Sci. 2018, 6, 37. [Google Scholar] [CrossRef] [Green Version]

- Clausen, C.A. Nanotechnology: Implications for the Wood Preservation Industry; IRG/WP 07-30415; IRG Secretariat: Stockholm, Sweden, 2007; 10p.

- Cestari, C.; Marzi, T.; Invernizzi, S. Use of nanotechnologies for conservation, reinforcement and maintenance: Timber construction in cultural heritage of the mediterranean basin. In Proceedings of the 4th International Congress on “Science and Technology for the Safeguard of Cultural Heritage in the Mediterranean Basin”, Cairo, Egypt, 6–8 December 2009. [Google Scholar]

- Kaymakci, A.; Ayrilmis, N.; Gulec, T.; Tufan, M. Preparation and characterization of high-performance wood polymer nanocomposites using multi-walled carbon nanotubes. J. Compos. Mater. 2017, 51, 1187–1195. [Google Scholar] [CrossRef]

- Zhang, Y.; Fang, J.; Li, J.; Guo, Y.; Wang, Q. The effect of carbon nanotubes on the mechanical properties of wood plastic composites by selective laser sintering. Polymers 2017, 9, 728. [Google Scholar] [CrossRef] [Green Version]

- David, M.; Ion, R.-M.; Grigorescu, R.; Iancu, L.; Holban, A.; Nicoara, A.; Alexandrescu, E.; Somoghi, R.; Ganciarov, M.; Vasilievici, G.; et al. Hybrid materials based on multi-walled carbon nanotubes and nanoparticles with antimicrobial properties. Nanomaterials 2021, 11, 1415. [Google Scholar] [CrossRef] [PubMed]

- David, M.E.; Grigorescu, R.M.; Iancu, L.; Andrei, E.R.; Somoghi, R.; Frone, A.N.; Atkinson, I.; Predoana, L.; Nicoara, A.-I.; Ion, R.-M. Synthesis and characterization of multi-walled carbon nanotubes decorated with hydroxyapatite. Full-Nanotub. Carbon Nanostruct. 2021, 29, 423–430. [Google Scholar] [CrossRef]

- Grigore, M.E.; Grigorescu, R.M.; Iancu, L.; Ion, R.-M.; Zaharia, C.; Andrei, E.R. Methods of synthesis, properties and biomedical applications of polyhydroxyalkanoates: A review. J. Biomater. Sci. Polym. Ed. 2019, 30, 695–712. [Google Scholar] [CrossRef] [PubMed]

- Vandi, L.-J.; Chan, C.M.; Werker, A.; Richardson, D.; Laycock, B.; Pratt, S. Wood-PHA composites: Mapping opportunities. Polymers 2018, 10, 751. [Google Scholar] [CrossRef] [Green Version]

- David, M.E.; Grigorescu, R.M.; Iancu, L.; Andrei, E.R.; Ion, R.-M. Poly (3-HydroxyButyrate-co-3-HydroxyValerate) based Inorganic Consolidate for Firwood Preservation. Ann. “Dunarea De Jos” Univ. Galati. Fascicle IX Metall. Mater. Sci. 2021, 44, 34–39. [Google Scholar] [CrossRef]

- Tuduce-Trǎistaru, A.A.; Sandu, C.A.; Timar, M.; Dumitrescu, G.; Sandu, I. SEM-EDX, water absorption, and wetting capability studies on evaluation of the influence of nano-zinc oxide as additive to paraloid B72 solutions used for wooden artifacts consolidation. Microsc. Res. Tech. 2013, 76, 209–218. [Google Scholar] [CrossRef]

- ASTM D2244; Standard Practice for Calculation of Color Tolerances and Color Differences from Instrumentally Measured Color Coordinates. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003.

- Mcnatt, J.D. Test methods for basic properties of woodbased panels: Past experience and today’s needs. In Proceedings of the 18th International Particleboard/Composite Materials Symposium, Pullman, WA, USA, 28–29 March 1984. [Google Scholar]

- Janssen, J. Bamboo-Determination of physical and mechanical properties—Part 1: Requirements. In Grading the Bamboo; Janssen, J., Ed.; International Network for Bamboo and Rattan (INBAR): Beijing, China, 2004. [Google Scholar]

- Aurélien, S.; Daniel, S. Drop Shape Analysis. Available online: http://bigwww.epfl.ch/demo/dropanalysis/ (accessed on 23 February 2022).

- ASTM C 805; Standard Test Method for Rebound Number of Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2008.

- Kajaks, J.; Kalnins, K.; Matvejs, J. Accelerated aging of WPCs based on polypropylene and plywood production residues. Open Eng. 2019, 9, 115–128. [Google Scholar] [CrossRef]

- EN 927-6; Paints and Varnishes—Coating Materials and Coating Systems for Exterior Wood—Part 6: Exposure of Wood Coatings to Artificial Weathering Using Fluorescent UV Lamps and Water. CEN: Brussels, Belgium, 2006.

- Budakçi, M.; Korkut, D.S. The color changes on varnish layers after accelerated aging through the hot and cold-check test. Afr. J. Biotechnol. 2010, 9, 3595–3602. [Google Scholar]

- Hare, J. Sabouraud Agar for Fungal Growth Protocols. MicrobeLibrary Website. 2008. Available online: http://www.microbelibrary.org/library/laboratorytest/3156-sabouraud-agar-for-fungal-growth-protocols (accessed on 10 March 2022).

- Kubovský, I.; Kačíková, D.; Kačík, F. Structural changes of oak wood main components caused by thermal modification. Polymers 2020, 12, 485. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lucejko, J.J.; Tamburini, D.; Zborowska, M.; Babiński, L.; Modugno, F.; Colombini, M.P. Oak wood degradation processes induced by the burial environment in the archaeological site of Biskupin (Poland). Herit. Sci. 2020, 8, 44. [Google Scholar] [CrossRef]

- Mumtaz, T.; Abd-Aziz, S.; Yee, P.L.; Yunus, W.M.Z.W.; Shirai, Y.; Hassan, M.A. Synthesis, characterization, and structural properties of intracellular copolyester poly (3-hydroxybutyrate-co-3-hydroxyvalerate) produced by Comamonas sp. EB 172 from renewable resource. Int. J. Polym. Anal. Caract. 2010, 15, 329–340. [Google Scholar] [CrossRef]

- Ion, R.; Iancu, L.; Grigorescu, R.; Carutiu-Turcanu, D.; Tincu, S.; Ion, N.; Bucurica, I.; Teodorescu, S.; Dulama, I.; Stirbescu, R.M.; et al. Arhaeometric concepts and methods of intervention on historical monument buildings. The case of the Corvins’ Castle. IOP Conf. Ser. Mater. Sci. Eng. 2018, 374, 012073. [Google Scholar] [CrossRef]

- Ab Ghani, M.H.; Ahmad, S. The comparison of water absorption analysis between counterrotating and corotating twin-screw extruders with different antioxidants content in wood plastic composites. Adv. Mater. Sci. Eng. 2011, 2011, 406284. [Google Scholar] [CrossRef] [Green Version]

- Khan, M.A.; Hussain, Z.; Liaqat, U.; Liaqat, M.A.; Zahoor, M. Preparation of PBS/PLLA/HAP composites by the solution casting method: Mechanical properties and biocompatibility. Nanomaterials 2020, 10, 1778. [Google Scholar] [CrossRef]

- Mohan, S.; Oluwafemi, O.S.; Songca, S.P.; Rouxel, D.; Miska, P.; Lewu, F.; Kalarikkal, N.; Thomas, S. Completely green synthesis of silver nanoparticle decorated MWCNT and its antibacterial and catalytic properties. Pure Appl. Chem. 2016, 88, 71–81. [Google Scholar] [CrossRef]

- Rozilah, A.; Jaafar, C.N.A.; Sapuan, S.M.; Zainol, I.; Ilyas, R.A. The Effects of Silver Nanoparticles Compositions on the Mechanical, Physiochemical, Antibacterial, and Morphology Properties of Sugar Palm Starch Biocomposites for Antibacterial Coating. Polymers 2020, 12, 2605. [Google Scholar] [CrossRef]

- Moncmanová, A. Environmental Deterioration of Materials; WIT Press: London, UK, 2007; Volume 21. [Google Scholar]

- Johnston, S.R.; Boddy, L.; Weightman, A. Bacteria in decomposing wood and their interactions with wood-decay fungi. FEMS Microbiol. Ecol. 2016, 92, fiw179. [Google Scholar] [CrossRef] [Green Version]

- Andreotti, S.; Franzoni, E.; Degli Esposti, M.; Fabbri, P. Poly(hydroxyalkanoate)s-based hydrophobic coatings for the protection of stone in cultural heritage. Materials 2018, 11, 165. [Google Scholar] [CrossRef] [Green Version]

- Chan, C.M.; Pratt, S.; Halley, P.; Richardson, D.; Werker, A.; Laycock, B.; Vandi, L.J. Mechanical and physical stability of polyhydroxyalkanoate (PHA)-based wood plastic composites (WPCs) under natural weathering. Polym. Test. 2019, 73, 214–221. [Google Scholar] [CrossRef]

- Harandi, D.; González-Benito, J.; Olmos, D. Consolidation of Fir Wood by Poly(vinyl butyral-co-vinyl alcohol-co-vinyl acetate) Treatment: Study of Surface and Mechanical Characteristics. Polymers 2020, 12, 1039. [Google Scholar] [CrossRef]

- Hossain, M.M.; Shima, H.; Islam, A.; Hasan, M.; Lee, M. Simple synthesis process for ZnO sphere-decorated CNT fiber and its electrical, optical, thermal, and mechanical properties. RSC Adv. 2015, 6, 4683–4694. [Google Scholar] [CrossRef]

- Salla, J.; Pandey, K.K.; Srinivas, K. Improvement of UV resistance of wood surfaces by using ZnO nanoparticles. Polym. Degrad. Stab. 2012, 97, 592–596. [Google Scholar] [CrossRef]

- Ghamsari, M.S.; Alamdari, S.; Han, W.; Park, H.-H. Impact of nanostructured thin ZnO film in ultraviolet protection. Int. J. Nanomed. 2017, 12, 207–216. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bi, W.; Li, H.; Hui, D.; Gaff, M.; Lorenzo, R.; Corbi, I.; Corbi, O.; Ashraf, M. Effects of chemical modification and nanotechnology on wood properties. Nanotechnol. Rev. 2021, 10, 978–1008. [Google Scholar] [CrossRef]

- Hincapié, I.; Künniger, T.; Hischier, R.; Cervellati, D.; Nowack, B.; Som, C. Nanoparticles in facade coatings: A survey of industrial experts on functional and environmental benefits and challenges. J. Nanopart. Res. 2015, 17, 287. [Google Scholar] [CrossRef]

- Wu, Y.; Wu, X.; Yang, F.; Ye, J. Preparation and characterization of waterborne UV lacquer product modified by zinc oxide with flower shape. Polymers 2020, 12, 668. [Google Scholar] [CrossRef] [Green Version]

| Sample | Central Zone (10×) | End Zone (4×) |

|---|---|---|

| Control |  |  |

| 0.1% MWCNT+ PHBHV—brushing |  |  |

| 0.1% MWCNT+ PHBHV—immersion |  |  |

| 0.1% MWCNT+ PHBHV—spraying |  |  |

| Compound | Wood (%) | Wood + MWCNTs + PHBHV (%) | Wood+ MWCNTs_ZnO + PHBHV (%) | Wood+ MWCNTs_HAp + PHBHV (%) | Wood + MWCNT_Ag + PHBHV (%) |

|---|---|---|---|---|---|

| SiO2 | 5.1821 | 25.7321 | 7.4745 | 18.4805 | 7.7196 |

| SO3 | 5.8244 | 4.0752 | 3.0447 | 3.4126 | 4.1864 |

| Cl | 1.2235 | 7.6076 | 1.4374 | 1.7123 | 3.5031 |

| K2O | 14.6479 | 18.3917 | 5.6448 | 11.7196 | 23.5348 |

| CaO | 59.4586 | 28.5891 | 68.4308 | 39.4028 | 49.5594 |

| Fe2O3 | 6.9201 | 1.4846 | - | 2.287 | 3.7029 |

| P2O5 | 4.7242 | 3.3406 | 1.1225 | 22.5611 | 3.0425 |

| Al2O3 | 1.0652 | 7.3128 | 7.1676 | - | - |

| MnO | 0.5368 | 1.6982 | - | - | 2.5784 |

| MgO | 0.4172 | 1.7681 | 3.7201 | 0.4241 | 1.8244 |

| ZnO | - | - | 1.9576 | - | - |

| Ag2O | - | - | - | - | 0.3485 |

| Dependent Variable: ΔEx (After Consolidation) | |||||||

|---|---|---|---|---|---|---|---|

| Variables | Source of Variation | Sum of Squares | Df | Mean Square | F | p-Value | |

| Type of treatment | MWCNT+ PHBHV | Concentration | 1.9256 | 2 | 0.9628 | 0.3514 | 0.7172 |

| Method | 9.5254 | 3 | 3.1751 | 1.1590 | 0.3996 | ||

| MWCNT_ZnO+ PHBHV | Concentration | 11.0994 | 2 | 5.5497 | 8.3345 | 0.0185 | |

| Method | 9.4055 | 3 | 3.1351 | 4.7084 | 0.0410 | ||

| MWCNT_HAp+ PHBHV | Concentration | 7.6432 | 2 | 3.8216 | 7.4622 | 0.0235 | |

| Method | 4.9421 | 3 | 1.6473 | 4.7166 | 0.0439 | ||

| MWCNT_Ag+ PHBHV | Concentration | 2.8366 | 2 | 1.4182 | 0.9158 | 0.4496 | |

| Method | 8.6371 | 3 | 2.8790 | 1.8592 | 0.2372 | ||

| Type of treatment application | Brushing | Brushing method vs. concentration | 14.7134 | 1 | 14.7134 | 19.8295 | 0.0001 |

| Spraying | Spraying method vs. concentration | 25.2806 | 1 | 25.2806 | 16.8983 | 0.0005 | |

| Immersion | Immersion method vs. concentration | 25.0684 | 1 | 25.0684 | 16.5376 | 0.0005 | |

| Nanocomposite concentration | 0.1% | Concentration type vs. methods | 10.0715 | 1 | 10.0715 | 12.1486 | 0.0020 |

| 0.2% | Concentration type vs. methods | 8.8493 | 1 | 8.8493 | 20.7264 | 0.0001 | |

| 0.4% | Concentration type vs. methods | 19.5577 | 1 | 19.5577 | 15.7231 | 0.0047 | |

| Dependent Variable: Compressive Strength (After Consolidation) | ||||||

|---|---|---|---|---|---|---|

| Type of Treatment | Source of Variation | Sum of Squares | Df | Mean Square | F | p-Value |

| MWCNT+ PHBHV | Concentration | 4.3569 | 2 | 2.1784 | 1.8139 | 0.2420 |

| Method | 556.0621 | 3 | 185.3540 | 154.3387 | 4.557 × 10−6 | |

| Error | 7.2057 | 6 | 1.2009 | |||

| MWCNT_ZnO+ PHBHV | Concentration | 6.2816 | 2 | 3.1408 | 5.1534 | 0.0498 |

| Method | 459.2200 | 3 | 153.0733 | 251.1636 | 1.075 × 10−6 | |

| Error | 3.6567 | 6 | 0.6094 | |||

| MWCNT_HAp+ PHBHV | Concentration | 0.8043 | 2 | 0.4021 | 0.8123 | 0.4872 |

| Method | 569.7249 | 3 | 189.9083 | 383.6067 | 3.046 × 10−7 | |

| Error | 2.9703 | 6 | 0.4950 | |||

| MWCNT_Ag+ PHBHV | Concentration | 3.9594 | 2 | 1.9797 | 1.3635 | 0.3249 |

| Method | 517.4135 | 3 | 172.4711 | 118.7925 | 9.867 × 10−6 | |

| Error | 8.7112 | 6 | 1.4518 | |||

| Exposure Time (h) | ΔEx |

|---|---|

| 100 | |

| |

| 200 | |

| |

| 300 | |

| |

| 400 | |

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

David, M.E.; Ion, R.-M.; Grigorescu, R.M.; Iancu, L.; Constantin, M.; Stirbescu, R.M.; Gheboianu, A.I. Wood Surface Modification with Hybrid Materials Based on Multi-Walled Carbon Nanotubes. Nanomaterials 2022, 12, 1990. https://doi.org/10.3390/nano12121990

David ME, Ion R-M, Grigorescu RM, Iancu L, Constantin M, Stirbescu RM, Gheboianu AI. Wood Surface Modification with Hybrid Materials Based on Multi-Walled Carbon Nanotubes. Nanomaterials. 2022; 12(12):1990. https://doi.org/10.3390/nano12121990

Chicago/Turabian StyleDavid, Madalina Elena, Rodica-Mariana Ion, Ramona Marina Grigorescu, Lorena Iancu, Mariana Constantin, Raluca Maria Stirbescu, and Anca Irina Gheboianu. 2022. "Wood Surface Modification with Hybrid Materials Based on Multi-Walled Carbon Nanotubes" Nanomaterials 12, no. 12: 1990. https://doi.org/10.3390/nano12121990

.jpg)