Nominal vs. Effective Wake Fields and Their Influence on Propeller Cavitation Performance

Abstract

:1. Introduction

1.1. Motivation

1.2. Background

2. Methods

2.1. Boundary Element Method for Propeller Analysis

Mathematical Formulation

2.2. RANS-BEM Coupling

3. Case Study

4. Results and Discussion

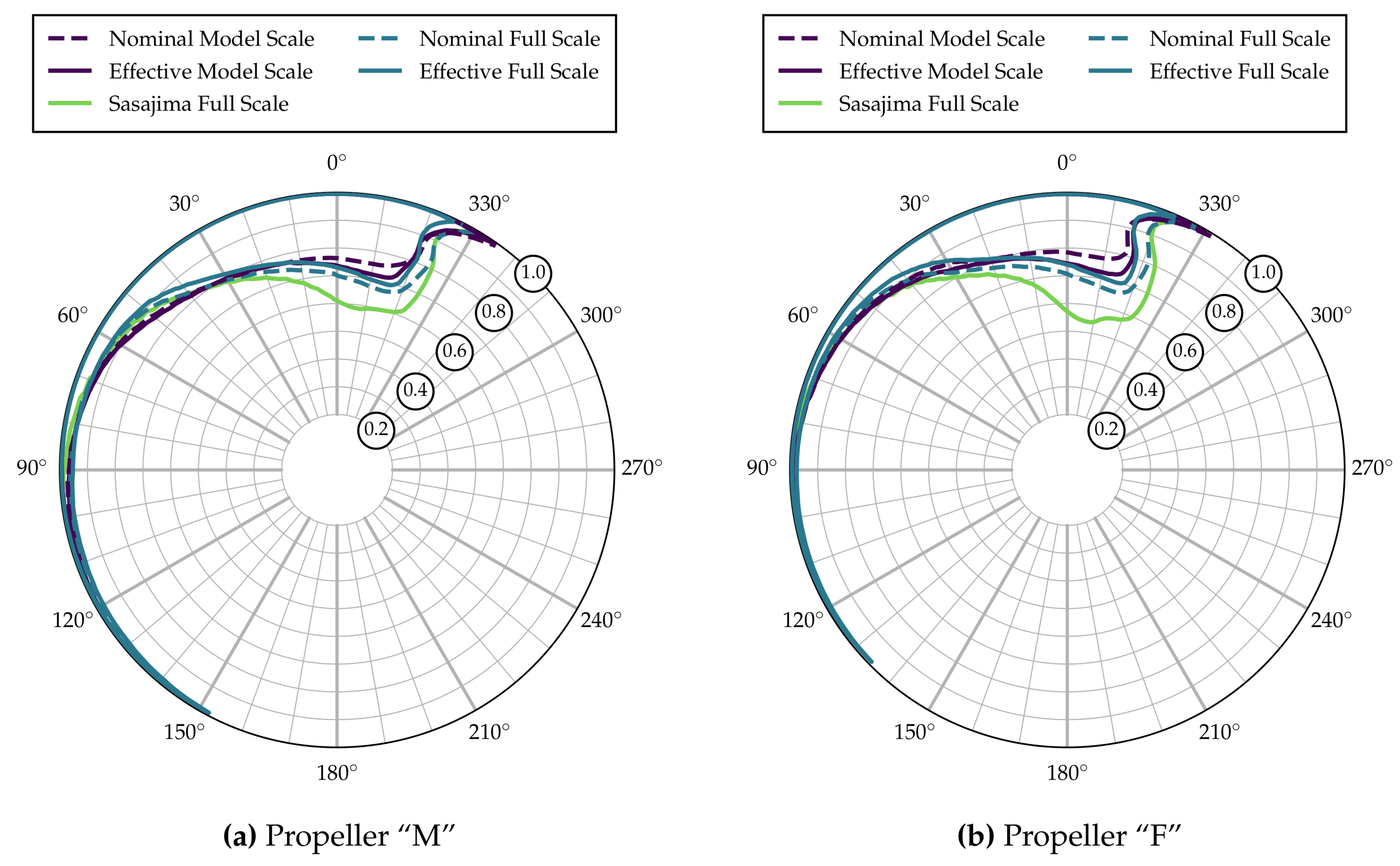

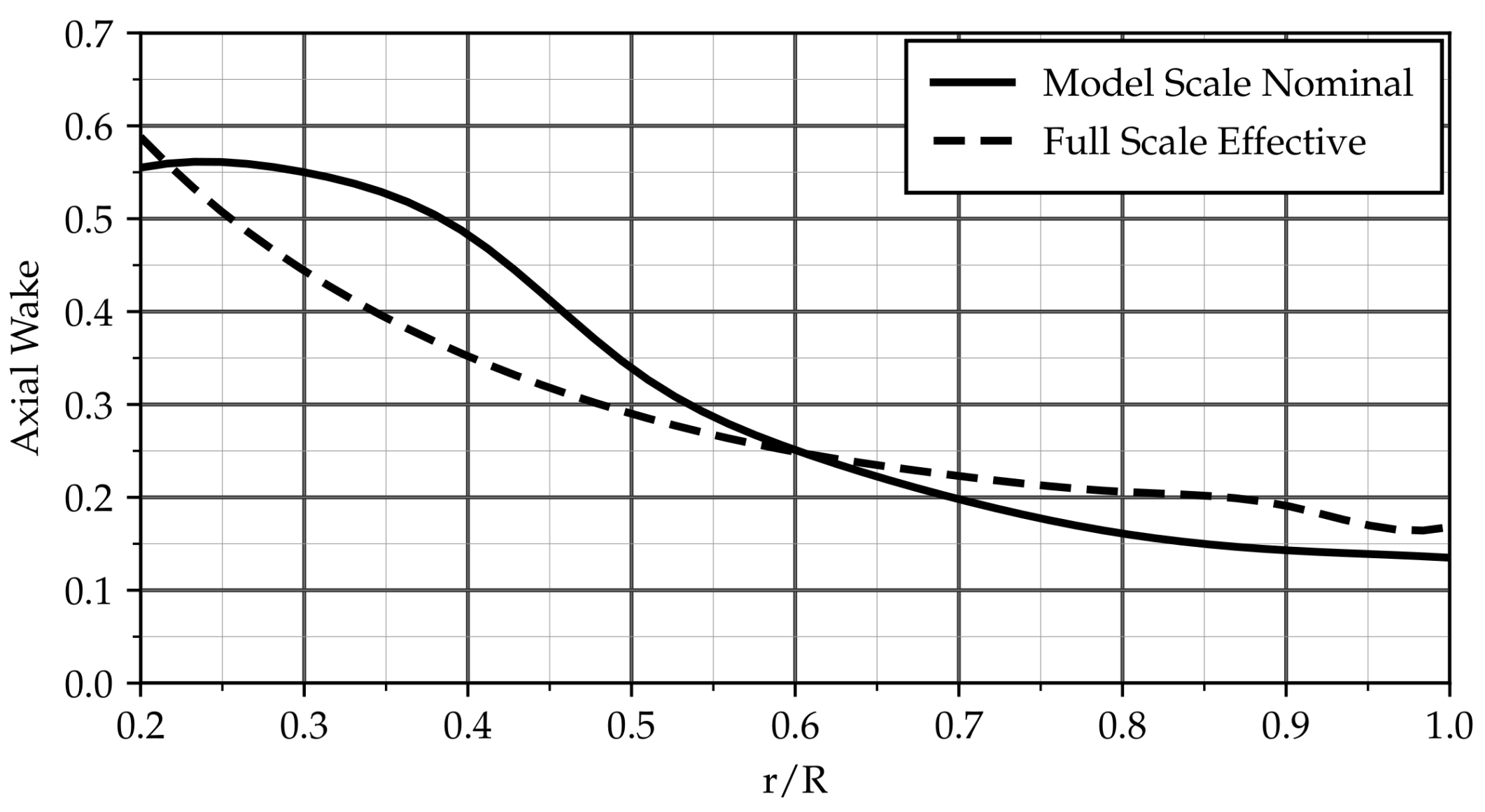

4.1. Wake Fields

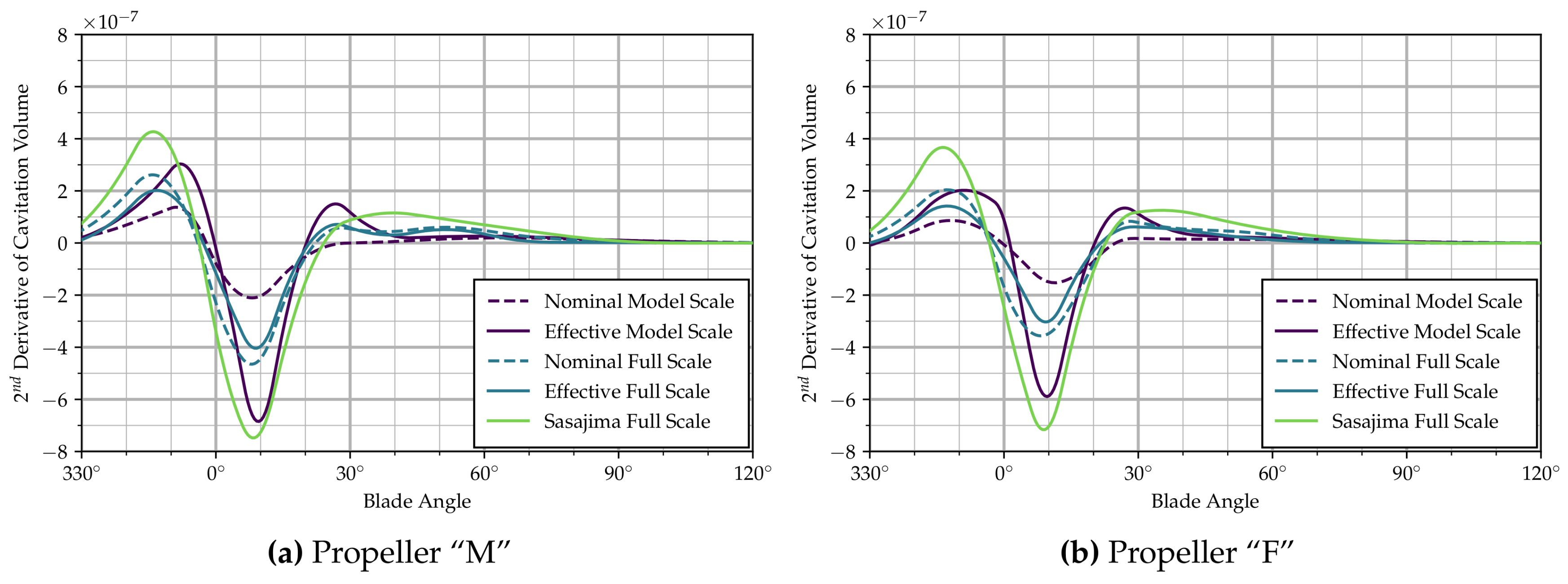

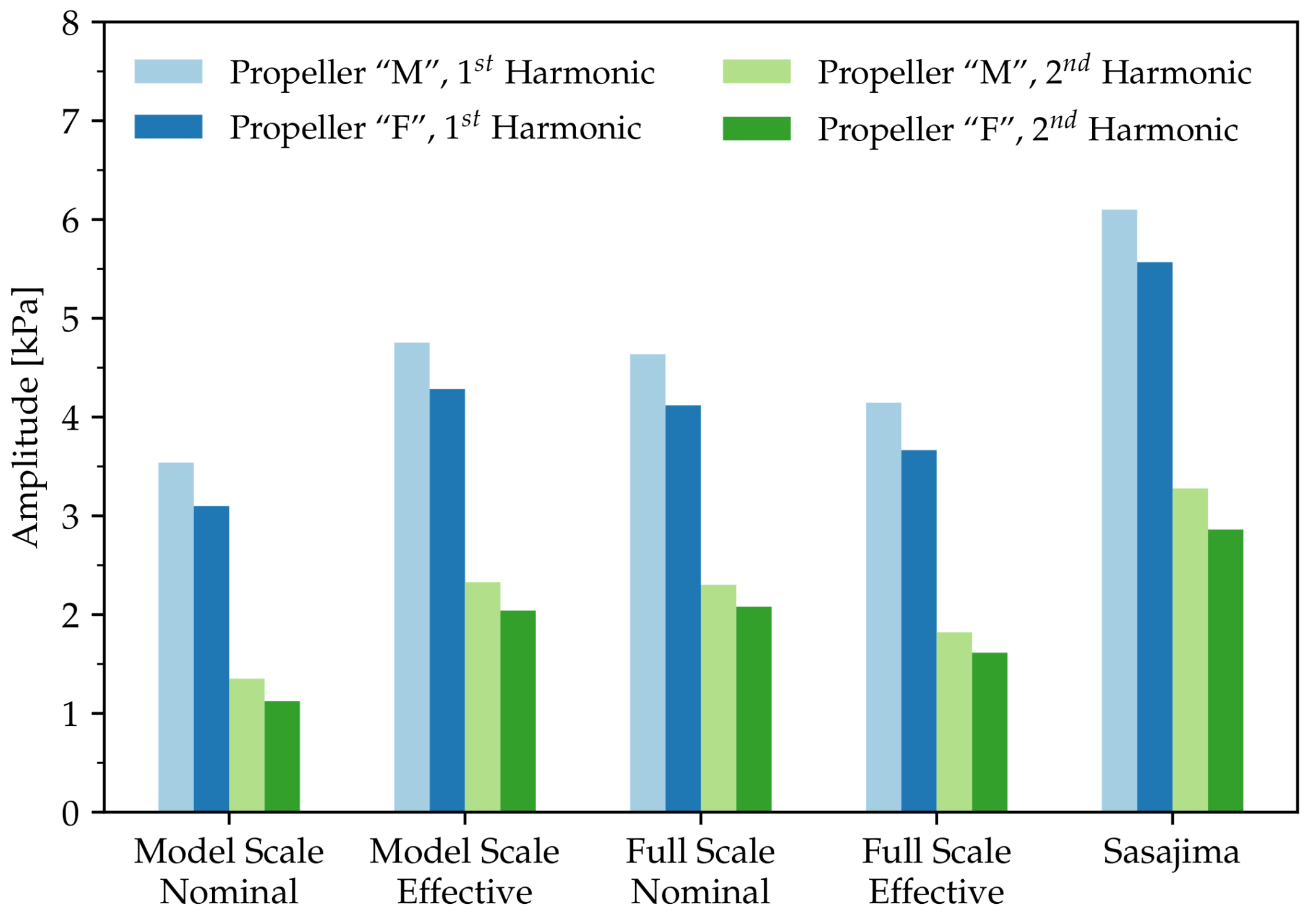

4.2. Sheet Cavitation

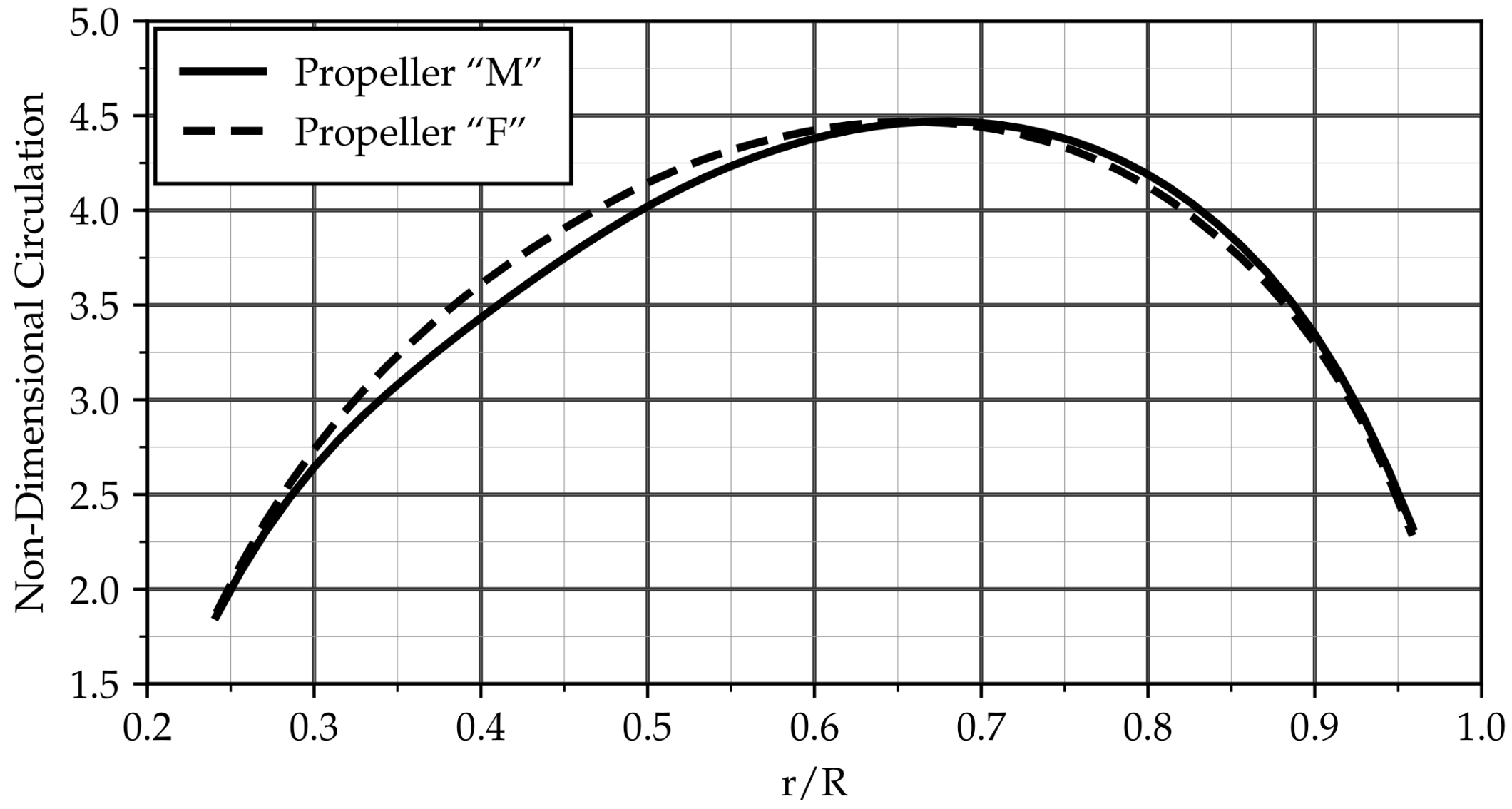

5. Results for Alternative Propeller Design

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Jessup, S.; Mewis, F.; Bose, N.; Dugue, C.; Esposito, P.G.; Holtrop, J.; Lee, J.T.; Poustoshny, A.; Salvatore, F.; Shirose, Y. Final Report of the Propulsion Committee. In Proceedings of the 23rd International Towing Tank Conference, Venice, Italy, 8–14 September 2002; Volume I, pp. 89–151. [Google Scholar]

- Fu, T.C.; Takinaci, A.C.; Bobo, M.J.; Gorski, W.; Johannsen, C.; Heinke, H.J.; Kawakita, C.; Wang, J.B. Final Report of The Specialist Committee on Scaling of Wake Field. In Proceedings of the 26th International Towing Tank Conference, Rio de Janeiro, Brazil, 28 August–3 September 2011; Volume II, pp. 379–417. [Google Scholar]

- Sasajima, H.; Tanaka, I. Report of the Performance Committee, Appendix X: On the Estimation of Wake of Ships. In Proceedings of the 11th International Towing Tank Conference, Tokyo, Japan, 11–20 October 1966; pp. 140–144. [Google Scholar]

- Van Terwisga, T.; van Wijngaarden, E.; Bosschers, J.; Kuiper, G. Achievements and Challenges in Cavitation Research on Ship Propellers. Int. Shipbuild. Prog. 2007, 54, 165–187. [Google Scholar]

- Bosschers, J.; Vaz, G.; Starke, B.; van Wijngaarden, E. Computational analysis of propeller sheet cavitation and propeller-ship interaction. In Proceedings of the RINA Conference “MARINE CFD2008”, Southampton, UK, 26–27 March 2008. [Google Scholar]

- Gaggero, S.; Villa, D.; Viviani, M.; Rizzuto, E. Ship wake scaling and effect on propeller performances. In Developments in Maritime Transportation and Exploitation of Sea Resources; CRC Press: London, UK, 2014; pp. 13–21. [Google Scholar]

- Kinnas, S.A.; Fine, N.E. A Numerical Nonlinear Analysis of the Flow Around Two- and Three-dimensional Partially Cavitating Hydrofoils. J. Fluid Mech. 1993, 254, 151–181. [Google Scholar] [CrossRef]

- Fine, N.E. Nonlinear Analysis of Cavitating Propellers in Nonuniform Flow. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 1992. [Google Scholar]

- Vaz, G.; Bosschers, J. Modelling Three Dimensional Sheet Cavitation on Marine Propellers Using a Boundary Element Method. In Proceedings of the 6th International Symposium on Cavitation (CAV2006), Wageningen, The Netherlands, 11–15 September 2006. [Google Scholar]

- Vaz, G.; Hally, D.; Huuva, T.; Bulten, N.; Muller, P.; Becchi, P.; Herrer, J.L.R.; Whitworth, S.; Mace, R.; Korsström, A. Cavitating Flow Calculations for the E779A Propeller in Open Water and Behind Conditions: Code Comparison and Solution Validation. In Proceedings of the 4th International Symposium on Marine Propulsors (smp’15), Austin, TX, USA, 31 May–4 June 2015; pp. 330–345. [Google Scholar]

- Hally, D. Propeller Analysis Using RANS/BEM Coupling Accounting for Blade Blockage. In Proceedings of the 4th International Symposium on Marine Propulsors (smp’15), Austin, TX, USA, 31 May–4 June 2015; pp. 297–304. [Google Scholar]

- Rijpkema, D.; Starke, B.; Bosschers, J. Numerical simulation of propeller–hull interaction and determination of the effective wake field using a hybrid RANS-BEM approach. In Proceedings of the 3rd International Symposium on Marine Propulsors (smp’13), Tasmania, Australia, 5–7 May 2013; pp. 421–429. [Google Scholar]

- Regener, P.B.; Mirsadraee, Y.; Andersen, P. Nominal vs. Effective Wake Fields and their Influence on Propeller Cavitation Performance. In Proceedings of the 5th International Symposium on Marine Propulsors (smp’17), Helsinki, Finland, 12–15 June 2017; pp. 331–337. [Google Scholar]

| Wake Field | Axial Wake Fraction |

|---|---|

| Nominal Model Scale | 0.360 |

| Effective Model Scale | 0.300 |

| Nominal Full Scale | 0.240 |

| Effective Full Scale | 0.237 |

| Sasajima Scaling | 0.236 |

| Target Value | 0.250 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Regener, P.B.; Mirsadraee, Y.; Andersen, P. Nominal vs. Effective Wake Fields and Their Influence on Propeller Cavitation Performance. J. Mar. Sci. Eng. 2018, 6, 34. https://doi.org/10.3390/jmse6020034

Regener PB, Mirsadraee Y, Andersen P. Nominal vs. Effective Wake Fields and Their Influence on Propeller Cavitation Performance. Journal of Marine Science and Engineering. 2018; 6(2):34. https://doi.org/10.3390/jmse6020034

Chicago/Turabian StyleRegener, Pelle Bo, Yasaman Mirsadraee, and Poul Andersen. 2018. "Nominal vs. Effective Wake Fields and Their Influence on Propeller Cavitation Performance" Journal of Marine Science and Engineering 6, no. 2: 34. https://doi.org/10.3390/jmse6020034