Analysis of Possible Noise Reduction Arrangements inside Olive Oil Mills: A Case Study

Abstract

:1. Introduction

2. Materials and Methods

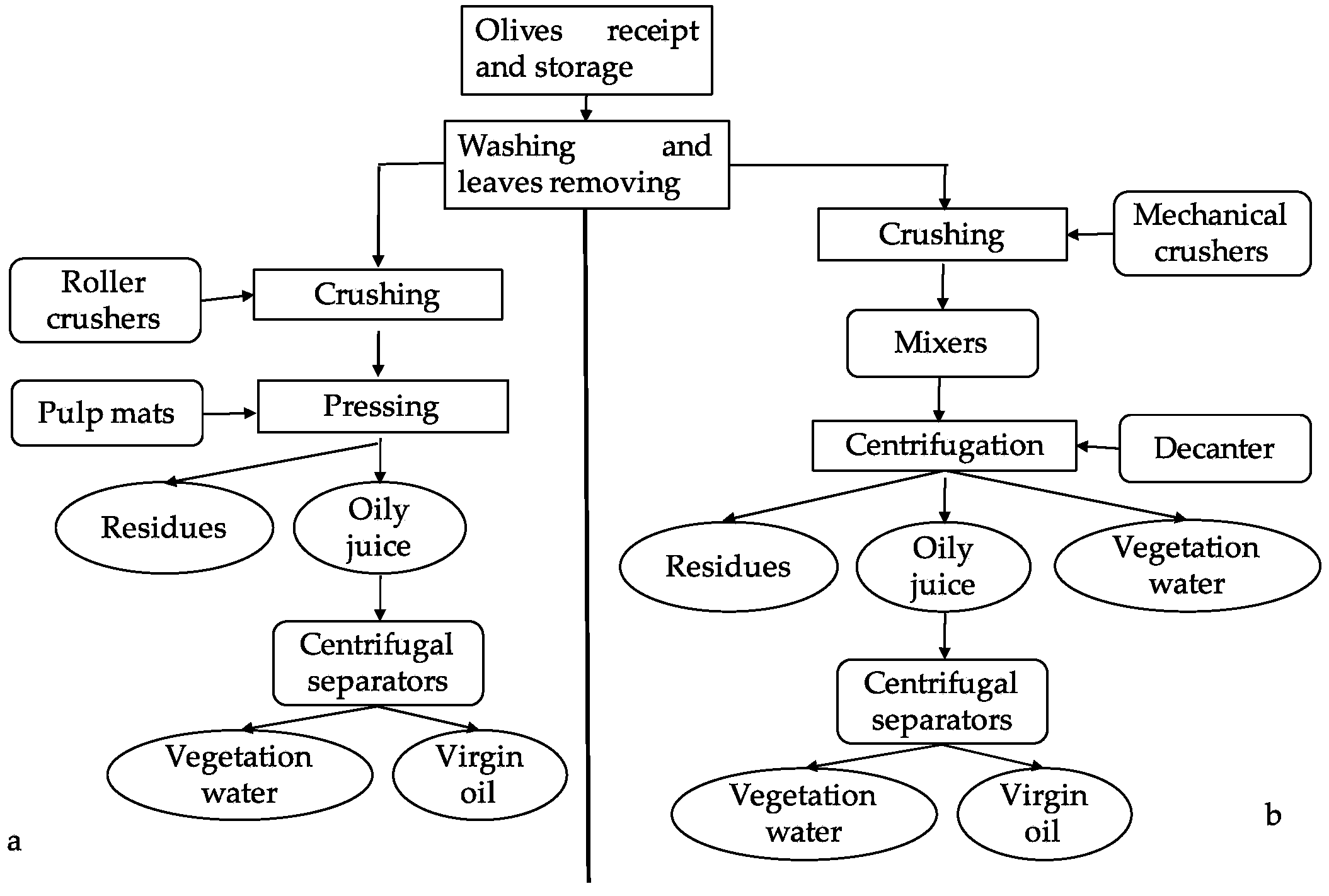

2.1. Tested Olive Oil Mill

2.2. Noise Measurements

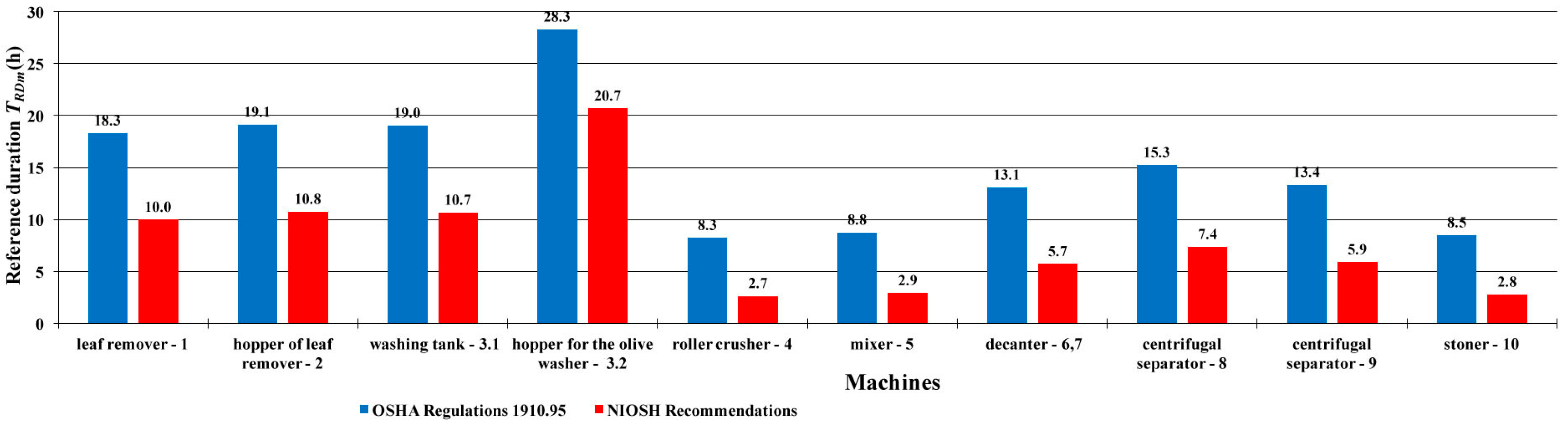

3. Results and Discussion

4. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| TWA | Time Weighted Average (Noise Levels) |

| PEL | Permissible Exposure Limit |

| Lp,A,eqT | A-weighted equivalent continuous sound pressure level |

| Lp,A,eqT,m | A-weighted equivalent continuous sound pressure level during a task |

| Lp,Cpeak | Peak sound pressure level |

| LEX,8h | Daily A-weighted noise exposure level |

| LEX,8h,m | Daily A-weighted noise exposure level during a task |

| D | Total daily noise dose |

| TRDm(OSHA) | Reference duration time according OSHA |

| TWA(OSHA) | Time Weighted Average (Noise Levels) according OSHA |

| TRDm(NIOSH) | Reference duration time according NIOSH |

| TWA(NIOSH) | Time Weighted Average (Noise Levels) according NIOSH |

References

- Pascuzzi, S. A multibody approach applied to the study of driver injuries due to a narrow-track wheeled tractor rollover. J. Agric. Eng. 2015, 46, 105–114. [Google Scholar] [CrossRef]

- Pascuzzi, S. The effects of the forward speed and air volume of an air-assisted sprayer on spray deposition in “tendone” trained vineyards. J. Agric. Eng. 2013, 3, 125–132. [Google Scholar] [CrossRef]

- Baldoin, C.; Balsari, P.; Cerruto, E.; Pascuzzi, S.; Raffaelli, M. Improvement in pesticide application on greenhouse crops: Results of a survey about greenhouse structures in Italy. Acta Hortic. 2008, 801, 609–614. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F. Evaluation of farmers’ OSH hazards in operation nearby mobile telephone radio base stations. In Proceedings of the 16th International Scientific Conference on Engineering for rural development, Jelgava, Latvia, 24–26 May 2017; Latvia University of Agriculture-Faculty of Engineering: Jelgava, Latvia, 2017; pp. 748–755. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Santoro, F. Exposure of farm workers to electromagnetic radiation from cellular network radio base stations situated on rural agricultural land. Int. J. Occup. Saf. Ergon. 2015, 21, 351–358. [Google Scholar] [CrossRef] [PubMed]

- Pascuzzi, S.; Blanco, I.; Anifantis, A.S.; Scarascia Mugnozza, G. Hazard assessment and technical actions due to the production of pressured hydrogen within a pilot photovoltaic-electrolyzer-fuel cell power system for agricultural equipment. J. Agric. Eng. 2016, 47, 89–93. [Google Scholar] [CrossRef]

- Marucci, A.; Pagniello, B.; Monarca, D.; Colantoni, A.; Biondi, P. Heat stress suffered by workers employed in vegetable grafting in greenhouses. J. Food Agric. Environ. 2012, 10, 1117–1121. [Google Scholar]

- Boubaker, K.; Colantoni, A.; Allegrini, E.; Longo, L.; Di Giacinto, S.; Monarca, D.; Cecchini, M. A model for musculoskeletal disorder-related fatigue in upper limb manipulation during industrial vegetables sorting. Int. J. Ind. Ergon. 2014, 44, 601–605. [Google Scholar] [CrossRef]

- Colantoni, A.; Marucci, A.; Monarca, D.; Pagniello, B.; Cecchini, M.; Bedini, R. The risk of musculoskeletal disorders due to repetitive movements of upper limbs for workers employed to vegetable grafting. J. Food Agric. Environ. 2012, 103, 14–18. [Google Scholar]

- Di Giacinto, S.; Colantoni, A.; Cecchini, M.; Monarca, D.; Moscetti, R.; Massantini, R. Dairy production in restricted environment and safety for the workers. Ind. Aliment. 2012, 530, 5–12. [Google Scholar]

- Manetto, G.; Cerruto, E.; Pascuzzi, S.; Santoro, F. Improvements in citrus packing lines to reduce the mechanical damage to fruit. Chem. Eng. Trans. 2017, 58, 391–396. [Google Scholar] [CrossRef]

- Bianchi, B.; Tamborrino, A.; Santoro, F. Assessment of the energy and separation efficiency of the decanter centrifuge with regulation capability of oil water ring in the industrial process line using a continuous method. J. Agric. Eng. 2013, 44, 278–282. [Google Scholar] [CrossRef]

- Cecchini, M.; Contini, M.; Massantini, R.; Monarca, D.; Moscetti, R. Effects of controlled atmospheres and low temperature on storability of chestnuts manually and mechanically harvested. Postharvest Biol. Technol. 2011, 61, 131–136. [Google Scholar] [CrossRef]

- Italian National Institute of Statistics (ISTAT). Area (Hectares) and Production (Quintals) of Olives 2016. Available online: http://agri.istat.it/sag_is_pdwout/jsp/NewDownload.jsp?id=15A|21A|32A&anid=2016 (accessed on 5 July 2017).

- Leone, A.; Romaniello, R.; Tamborrino, A.; Xu, X.Q.; Juliano, P. Microwave and megasonics combined technology for a continuous olive oil process with enhanced extractability. Innov. Food Sci. Emerg. Technol. 2017, 42, 56–63. [Google Scholar] [CrossRef]

- Vivaldi, G.A.; Strippoli, G.; Pascuzzi, S.; Stellacci, A.M.; Camposeo, S. Olive genotypes cultivated in an adult high-density orchard respond differently to canopy restraining by mechanical and manual pruning. Sci. Hortic. 2015, 192, 391–399. [Google Scholar] [CrossRef]

- Clodoveo, M.L.; Camposeo, S.; de Gennaro, B.; Pascuzzi, S.; Roselli, L. In the ancient world virgin olive oil has been called “liquid gold” by Homer and the “great healer” by Hippocrates. Why is this mythic image forgotten? Food Res. Int. 2014, 62, 1062–1068. [Google Scholar] [CrossRef]

- Manetto, G.; Cerruto, E. Vibration risk evaluation in hand-held harvesters for olives. J. Agric. Eng. 2013, 44, 705–709. [Google Scholar] [CrossRef]

- Cirillo, E. Applied Acoustics; McGraw-Hill: Trento, Italy, 1997; 216p. (In Italian) [Google Scholar]

- International Organization for Standardization. Acoustics—Estimation of Noise-Induced Hearing Loss; ISO 1999:2013; International Organization for Standardization: Geneva, Switzerland, 2013. [Google Scholar]

- U.S. Occupational Safety and Health Administration. OSHA 1910.95. Available online: https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=standards&p_id=9735 (accessed on 22 September 2017).

- U.S. Department of Health and Human Services. Department of Health and Human Services. Revised Criteria 1998. Available online: https://www.cdc.gov/niosh/docs/98-126/pdfs/98-126.pdf (accessed on 23 August 2017).

- EU. Directive 2003/10/EC on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (Noise); European Parliament and the Council: Brussels, Belgium, 2003. [Google Scholar]

- Official Gazette of the Italian Republic. Safety and Health in Workplaces Act of 2008; Italian Law Decree No. 81 (9 April 2008); Official Gazette of the Italian Republic: Rome, Italy, 2008. (In Italian) [Google Scholar]

- International Organization for Standardization (ISO). Acoustics—Determination of Occupational Noise Exposure—Engineering Method; ISO 9612:2009; International Organization for Standardization: Geneva, Switzerland, 2009. [Google Scholar]

- UNI. Acoustics—Determination of Occupational Noise Exposure; UNI 9432:2011; Italian Organization for Standardization: Milan, Italy, 2011. (In Italian) [Google Scholar]

- International Electrotechnical Commission (IEC). Electroacoustic—Sound Level Meters—Part 1: Specification; IEC 61672-1:2013; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- International Electrotechnical Commission (IEC). Electroacoustic—Octave-Band and Fractional-Octave-Band Filters—Part 1: Specification; IEC 61260-1:2014; International Electrotechnical Commission: Geneva, Switzerland, 2014. [Google Scholar]

- International Electrotechnical Commission (IEC). Electroacoustic—Sound Calibration; IEC 60942:2003; International Electrotechnical Commission: Geneva, Switzerland, 2003. [Google Scholar]

- Lercher, P.; Hortnagl, J.; Kofler, W. Work Noise Annoyance and Blood Pressure: Combined Effects with Stressful Working Conditions. Int. Arch. Occup. Environ. Health 1993, 65, 23–28. [Google Scholar] [CrossRef] [PubMed]

- Loewen, L.; Suedfeld, P. Cognitive and arousal effects of masking office noise. Environ. Behav. 1992, 24, 381–395. [Google Scholar] [CrossRef]

- Evans, G.W. Environmental stress and health. In Handbook of Health Psychology; Baum, A., Revenson, T., Singer, J., Eds.; Wiley: New York, NY, USA, 2001; Volume 1, pp. 571–610. [Google Scholar]

- Melamed, S.; Fried, Y.; Froom, P. The interactive effect of chronic exposure to noise and job. J. Occup. Health Psychol. 2001, 6, 182–195. [Google Scholar] [CrossRef] [PubMed]

- Van Kempen, E.E.; Kruize, H.; Boshuizen, H.C.; Ameling, C.B.; Staatsen, B.A.M.; de Hollander, A.E.M. The association between noise exposure and blood pressure and ischemic heart disease: A meta-analysis. Environ. Health Perspect. 2002, 110, 307–317. [Google Scholar] [CrossRef] [PubMed]

- Willich, S.N.; Wegscheider, K.; Stallmann, M.; Keil, T. Noise burden and the risk of myocardial infarction. Eur. Heart J. 2006, 27, 276–282. [Google Scholar] [CrossRef] [PubMed]

| Daily Noise Dose D% | 8 h Work Shift Noise Exposure Level LEX,8h—TWA dB(A) | ||

|---|---|---|---|

| Computed | Limit | ||

| OSHA 1910.95 | 76.4 | 88.1 | 90 |

| NIOSH criteria | 188.9 | 87.8 | 85 |

| Italian Regulations | / | 86.9 | 87 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pascuzzi, S.; Santoro, F. Analysis of Possible Noise Reduction Arrangements inside Olive Oil Mills: A Case Study. Agriculture 2017, 7, 88. https://doi.org/10.3390/agriculture7100088

Pascuzzi S, Santoro F. Analysis of Possible Noise Reduction Arrangements inside Olive Oil Mills: A Case Study. Agriculture. 2017; 7(10):88. https://doi.org/10.3390/agriculture7100088

Chicago/Turabian StylePascuzzi, Simone, and Francesco Santoro. 2017. "Analysis of Possible Noise Reduction Arrangements inside Olive Oil Mills: A Case Study" Agriculture 7, no. 10: 88. https://doi.org/10.3390/agriculture7100088