Optimization of and Experiment on Simulation Parameters for Rotary Hole Filling Corn Precision Metering Device

Abstract

:1. Introduction

2. Materials and Methods

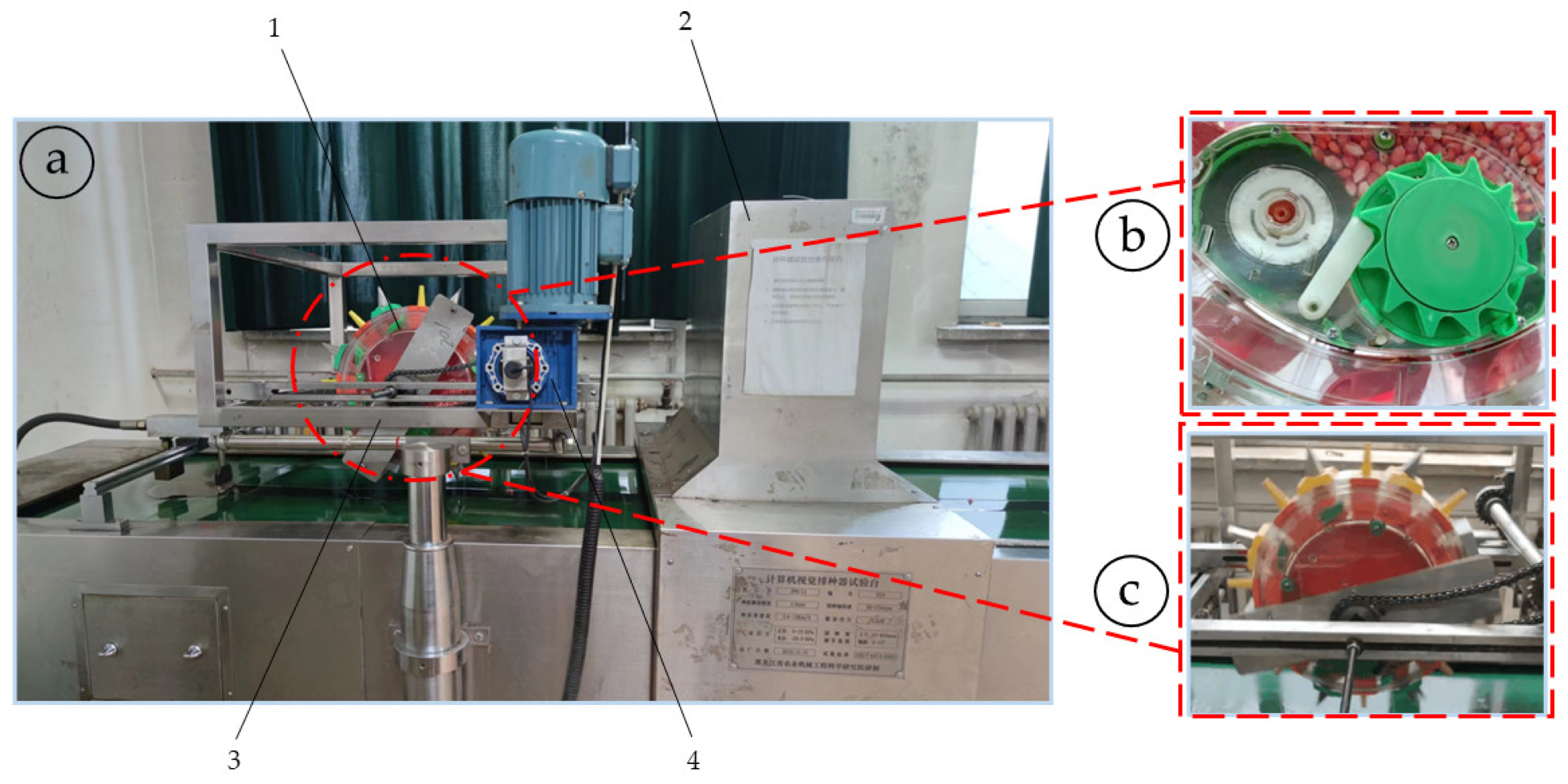

2.1. Structure and Working Principle

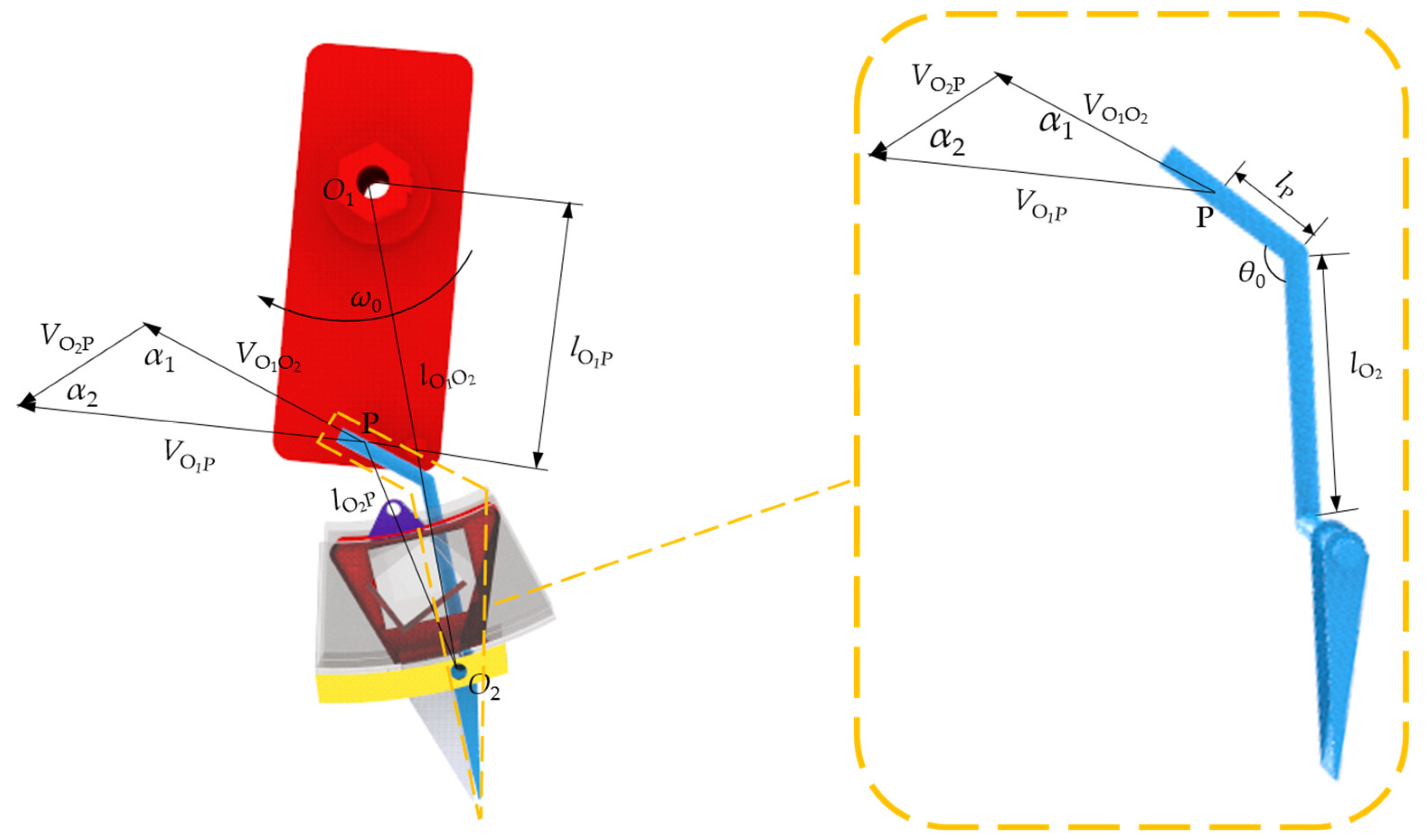

2.2. Characterization of the Movement of Duckbill Tied Cavities into the Soil

2.3. Simulation Modeling

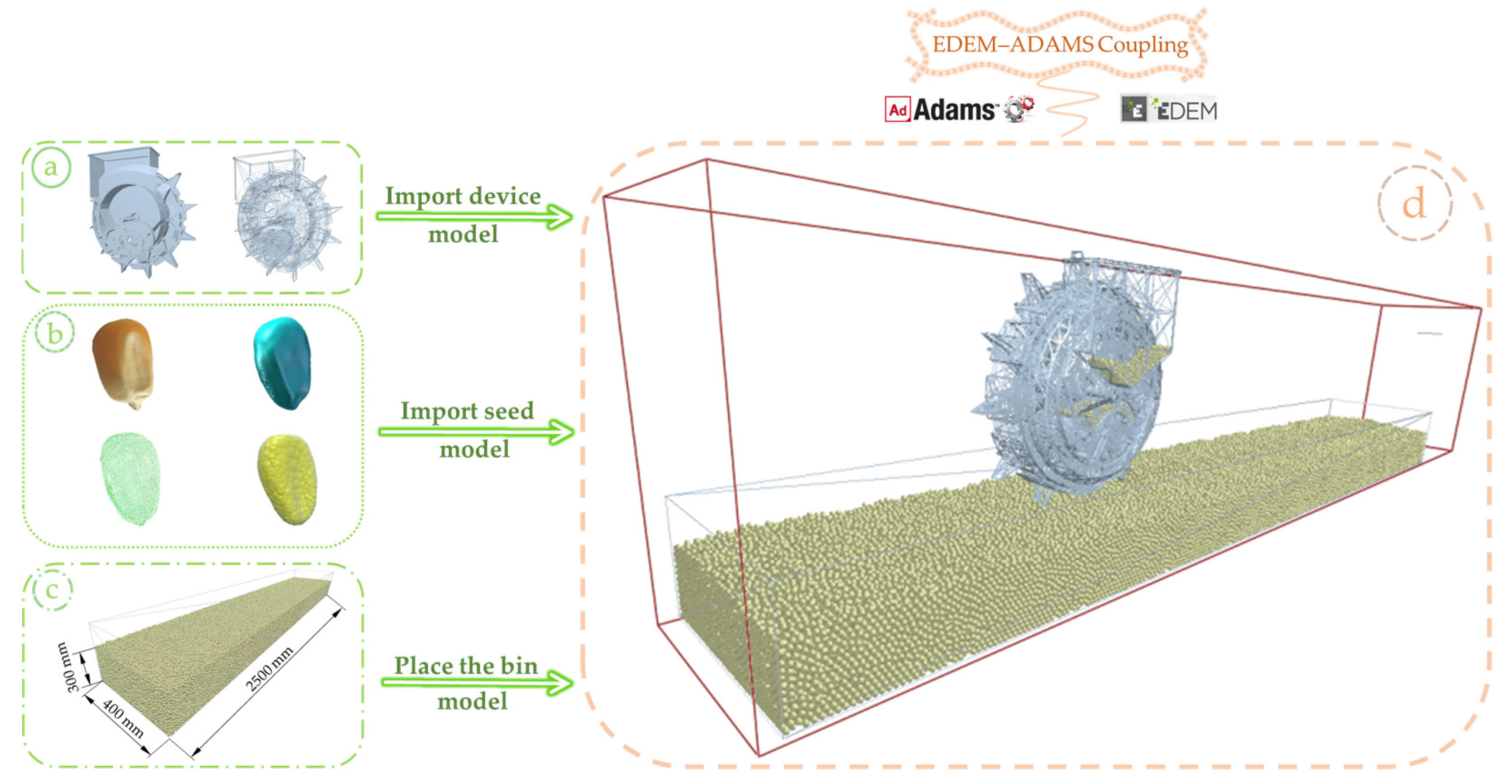

2.3.1. DEM Modeling

2.3.2. MBD–DEM Coupling Model

2.4. Bench Experiment

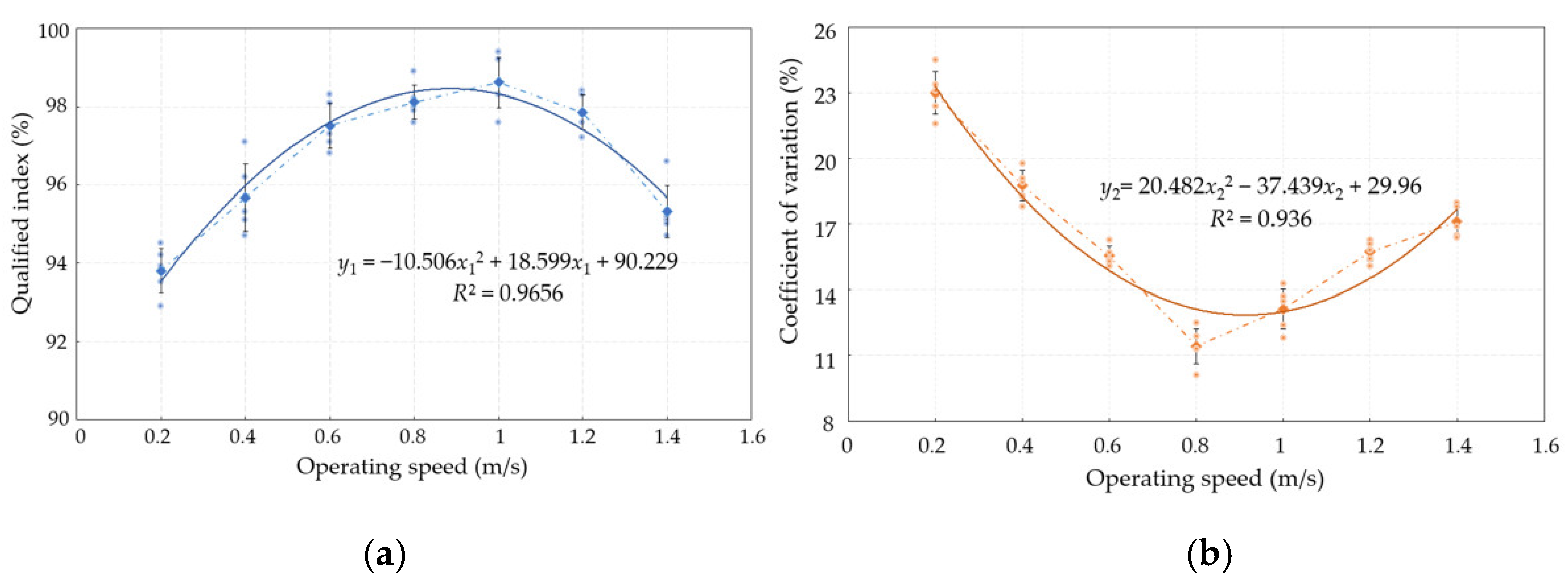

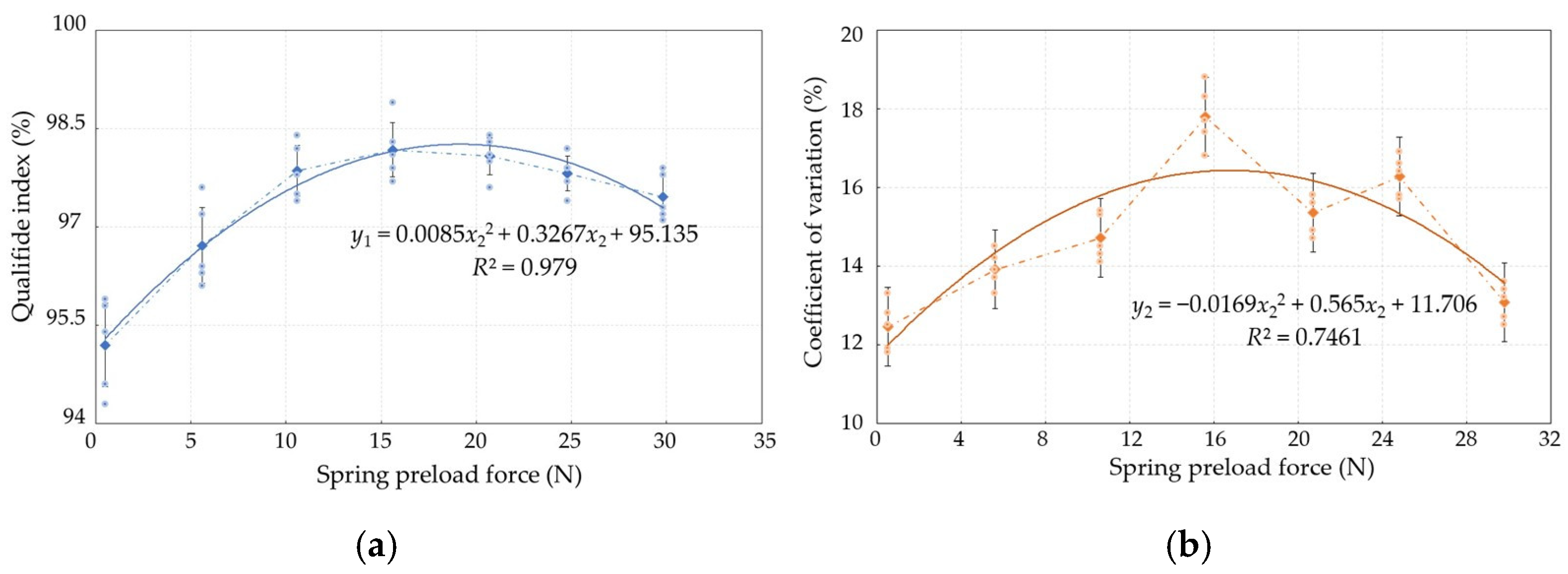

2.4.1. Single-Factor Experiment

2.4.2. Multi-Factor Experiment

3. Results and Discussion

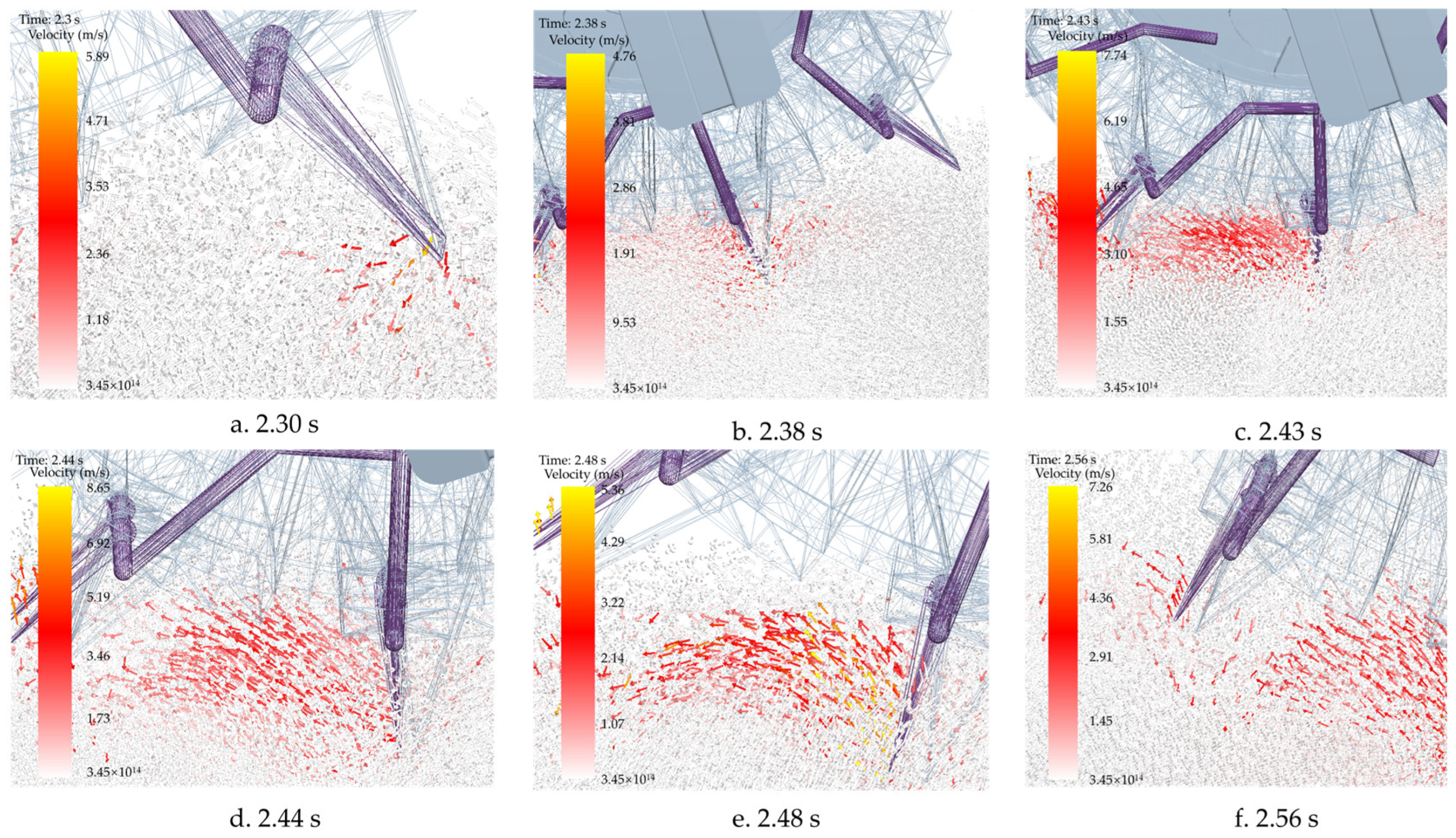

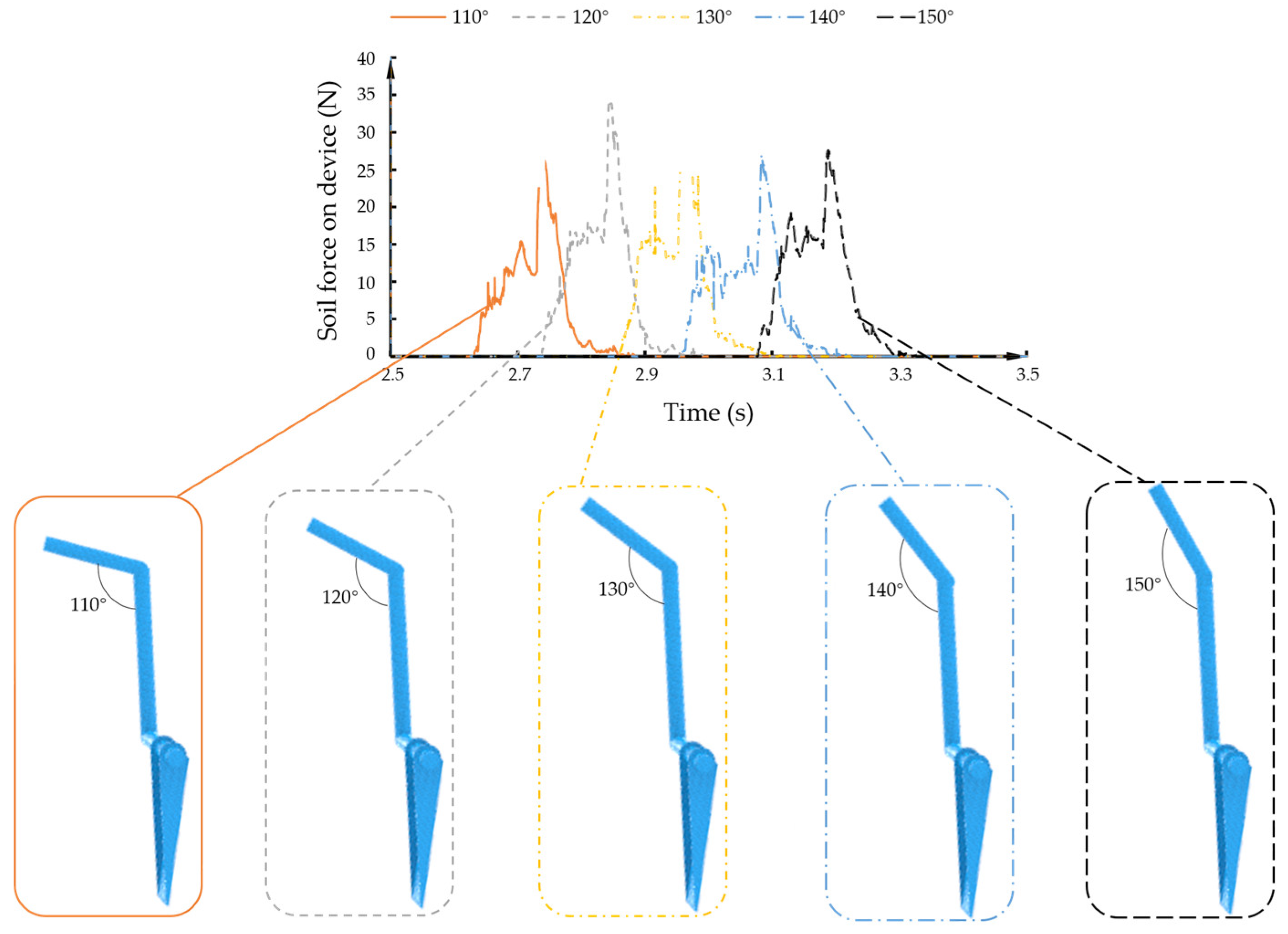

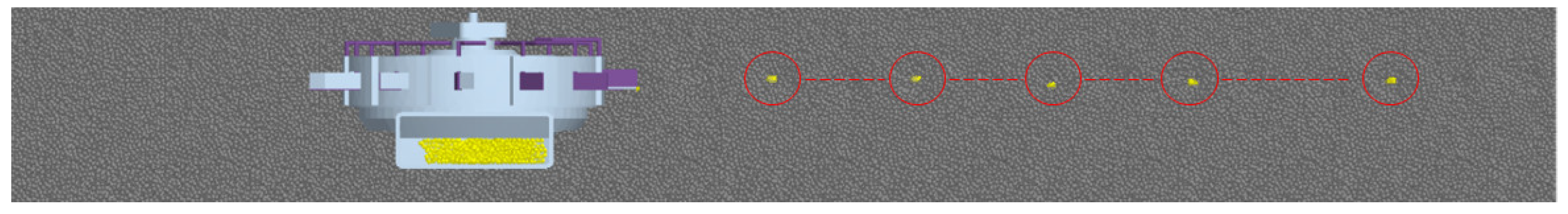

3.1. Coupling Simulation Analysis

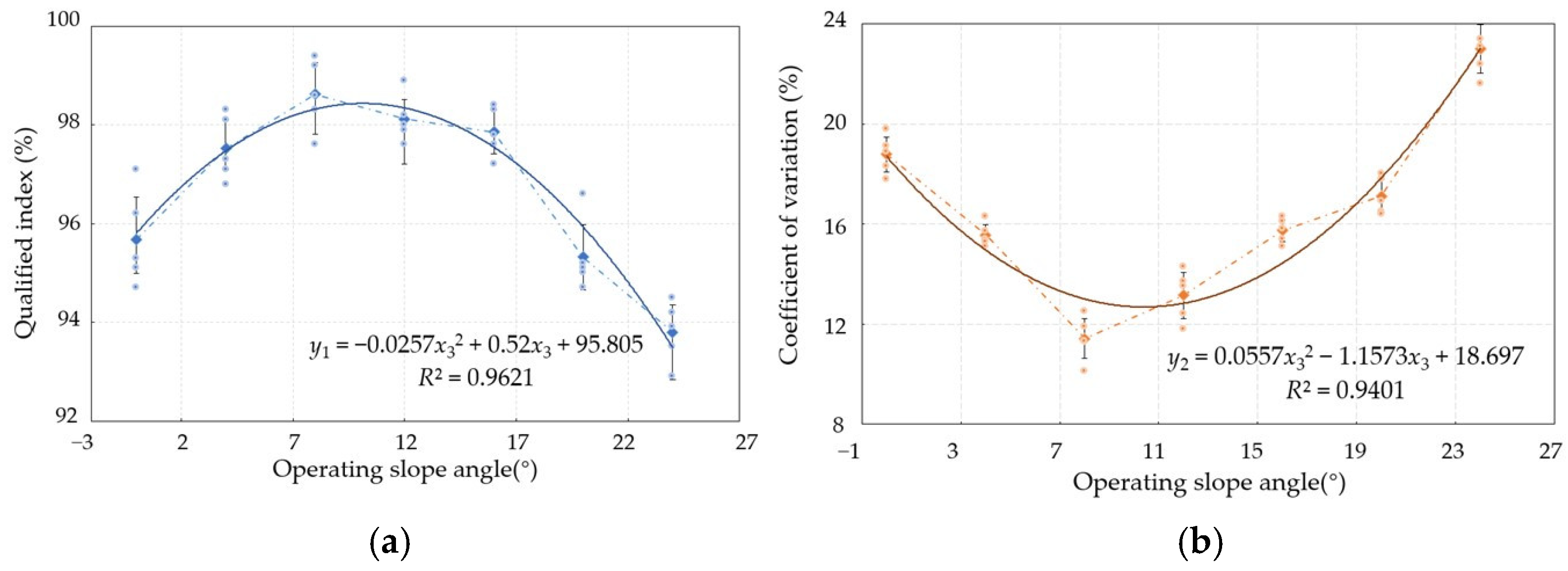

3.2. Analysis of Single-Factor Experiment Results

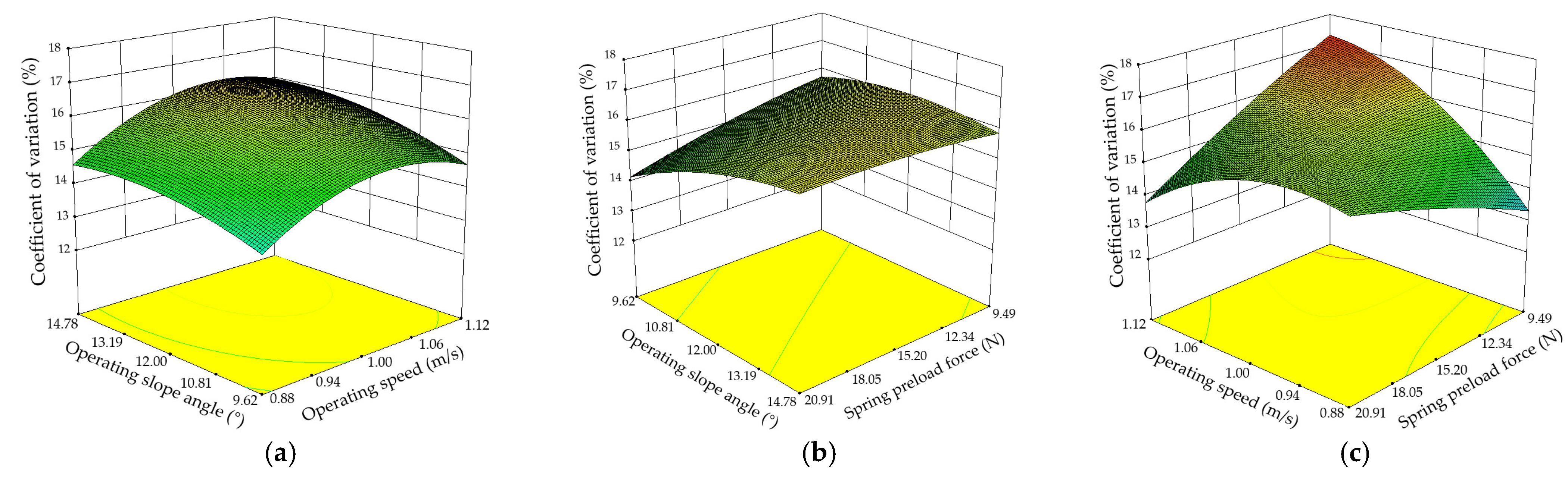

3.3. Analysis of Multi-Factor Test Results

3.4. Multi-Factor Experimental Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, J.; Tang, H.; Zhou, W. Improved Design and Experiment on Pickup Finger Precision Seed Metering Device. Trans. Chin. Soc. Agric. Mach. 2015, 46, 68–76. [Google Scholar] [CrossRef]

- Luo, X.; Liao, J.; Hu, L.; Zang, Y.; Zhou, Z. Improving Agricultural Mechanization Level to Promote Agricultural Sustainable Development. Trans. Chin. Soc. Agric. Eng. 2016, 32, 1–11. [Google Scholar] [CrossRef]

- Li, F.; Sun, J. Current Situation, Problems and Countermeasures of Rational Development and Utilization System Construction of Sloping Arable Land. China Soil Water Conserv. 2021, 72, 18–20. [Google Scholar] [CrossRef]

- Yang, L.; Yan, B.; Zhang, D.; Zhang, T.; Wang, Y.; Cui, T. Research Progress on Precision Planting Technology of Corn. Trans. Chin. Soc. Agric. Mach. 2016, 47, 38–48. [Google Scholar] [CrossRef]

- Geng, D.; Sun, Y.; Li, H. Design and Experiment of Crawler Corn Harvester for Sloping Fields. Trans. Chin. Soc. Agric. Eng. 2021, 37, 11–19. [Google Scholar]

- Dhok, A.S.; Biwal, V.D.; Ghadge, S.B. Performance Evaluation of Bullock Drawn Planter with Low Cost Metering Device. Int. J. Agric. Eng. 2015, 8, 136–139. [Google Scholar] [CrossRef]

- Taghinezhad, J.; Alimardani, R.; Alimardani, R. Development and Evaluation of Three Metering Device Models for Sugarcane Setts. J. Agric. Sci. 2014, 20, 164–174. [Google Scholar] [CrossRef]

- Sandip, M.; Prasanna, K.G.V.; Hetal, T. Design and Evaluation of a Pneumatic Metering Mechanism for Power Tiller Operated Precision Planter. Curr. Sci. 2018, 115, 1106–1114. [Google Scholar] [CrossRef]

- Anantachar, M.; Kumar, P.; Guruswamy, T. Neural Network Prediction of Performance Parameters of an Inclined Plate Seed Metering Device and its Reverse Mapping for the Determination of Optimum Design and Operational Parameters. Comput. Electron. Agric. 2010, 72, 87–98. [Google Scholar] [CrossRef]

- Pareek, C.M.; Tewari, V.K.; Rajendra, M. Optimizing the Seed-cell filling Performance of an Inclined Plate Seed Metering Device Using Integrated ANN-PSO Approach. Artif. Intell. Agric. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Yazgi, A.; Degirmencioglu, A. Measurement of Seed Spacing Uniformity Performance of a Precision Metering Unit as Function of the Number of Holes on Vacuum Plate. Measurement 2014, 56, 128–135. [Google Scholar] [CrossRef]

- Kostic, M.; Rakic, D.; Radomirovic, D. Corn Seeding Process Fault Cause Analysis Based on a Theoretical and Experimental Approach. Comput. Electron. Agric. 2018, 151, 207–218. [Google Scholar] [CrossRef]

- Abdolahzare, Z.; Mehdizadeh, S.A. Real Time Laboratory and Field Monitoring of the Effect of the Operational Parameters on Seed Falling Speed and Trajectory of Pneumatic Planter. Comput. Electron. Agric. 2018, 145, 187–198. [Google Scholar] [CrossRef]

- Amirkhani, M.; Mayton, H.S.; Netravali, A.N.; Taylor, A.G. A Seed Coating Delivery System for Bio-Based Biostimulants to Enhance Plant Growth. Sustainability 2019, 11, 5304. [Google Scholar] [CrossRef]

- Inderpal, S.; Anand, G.; Kumar, D. Development and Evaluation of Inclined Plate Metering Mechanism for the Sowing of Corn (Zea mays L) Seed. Curr. J. Appl. Sci. Technol. 2020, 39, 118–128. [Google Scholar]

- Dylan, S.J.; Hesterman, D.C.; Guzzomi, A.L. Precision Metering of Santalum spicatum (Australian Sandalwood) Seeds. Biosyst. Eng. 2013, 115, 171–183. [Google Scholar] [CrossRef]

- Rajaiah, P.; Mani, I.; Kumar, A.; Lande, S.D.; Singh, A.K.; Vergese, C. Development and Evaluation of Electronically Controlled Precision Seed-Metering Device for Direct-Seeded Paddy Planter. Indian J. Agric. Sci. 2016, 86, 598–604. [Google Scholar]

- Devesh, K.; Ashok, T.; Kamal, K. Design and Laboratory Test of a Seed Metering Device of Sowing Soyabean Seeds. Asian J. Multidimens. Res. 2017, 6, 57–66. [Google Scholar]

- Li, M. Dynamics Analysis and Simulation of Pneumatic Corn Precision Seed rower. Village Technol. 2021, 12, 119–120. [Google Scholar]

- Du, X.; Liu, C.; Jiang, M. Design and Experiment of Self-Disturbance Inner-Filling Cell Wheel Corn Precision Seed-Metering Device. Trans. Chin. Soc. Agric. Eng. 2019, 35, 23–34. [Google Scholar]

- Song, Y.; Zhang, H.; Wang, N. High Quality Sowing Technology for Corn in the Three Rivers Plain Area of Heilongjiang Province. Mod. Agric. Technol. 2022, 821, 55–58. [Google Scholar]

- Wang, J.; Tang, H.; Wang, J. Numerical Analysis and Performance Optimization Experiment on Hanging Unilateral Ridger for Paddy Field. Trans. Chin. Soc. Agric. Mach. 2017, 48, 72–80. [Google Scholar] [CrossRef]

- Lu, Y.; Chen, X.; Yang, H. Experiment of Air-Suction Cotton Precision Metering Mechanism. Guangdong Agric. Sci. 2013, 40, 182–184. [Google Scholar] [CrossRef]

- Chen, X.; Zhong, L. Design and Test on Belt-Type Seed Delivery of Air-Suction Metering Device. Trans. Chin. Soc. Agric. Eng. 2012, 28, 8–15. [Google Scholar] [CrossRef]

- Zhang, C.; Fan, X.; Li, M. Simulation Analysis and Experiment of Soil Disturbance by Chisel Plow Based on EDEM. J. Agric. Mach. 2022, 53, 52–59. [Google Scholar]

- Mohamed, A.; Xavier, P.; Craig, P. DROD: A Hybrid Biomimetic Undulatory and Reciprocatory Drill: Quantitative Analysis and Numerical Study. ACTA Astronaut. 2021, 182, 131–143. [Google Scholar] [CrossRef]

- Lü, J.; Yi, S.; Tao, G. Design and Experiment of Precision Air-Suction Type Planter for Potato. Trans. Chin. Soc. Agric. Eng. 2018, 34, 16–24. [Google Scholar]

| Key Components | Material | Poisson’s Ratio | Shear Modulus (Pa) | Density (kg·m−3) |

|---|---|---|---|---|

| Duckbill device | 65 Mn | 0.35 | 7.27 × 1010 | 7830 |

| The shell of seed rower | ABS plastic | 0.50 | 1.80 × 108 | 1176 |

| Outer ring of seed rower | ||||

| Fork | ||||

| Nesting rollers | ||||

| Seed cleaning rollers | Pig bristle | 0.40 | 1.0 × 108 | 1150 |

| Parameters | Value |

|---|---|

| Poisson’s ratio | 0.400 |

| Shear modulus/(Pa) | 1.37 × 108 |

| Corn seed density/(kg·m−3) | 1197 |

| Coefficient of static friction between corn seeds | 0.275 |

| Coefficient of dynamic friction between corn seeds | 0.067 |

| Recovery coefficient among corn seeds | 0.382 |

| Coefficient of static friction between corn seeds and soil particles | 0.400 |

| Coefficient of kinetic friction between corn seeds and soil particles | 0.100 |

| Recovery coefficient of corn seeds and soil particles | 0.700 |

| Coefficient of static friction between corn seeds and duckbill device | 0.300 |

| Coefficient of dynamic friction between corn seeds and duckbill device | 0.025 |

| Recovery coefficient of corn seeds with duckbill device | 0.380 |

| Coefficient of static friction between corn seeds and seed cleaning roller | 0.530 |

| Coefficient of dynamic friction between corn seed and seed cleaning roller | 0.120 |

| Recovery coefficients of corn seeds with seed cleaning rolls | 0.030 |

| Coefficient of static friction between corn seeds and other components | 0.530 |

| Coefficient of dynamic friction between corn seeds and other components | 0.120 |

| Recovery factor of corn seeds with other components | 0.092 |

| Parameters | Value |

|---|---|

| Recovery coefficient between particles and duckbill device | 0.30 |

| Soil water content/(%) | 16 |

| Soil particle density/(kg·m−3) | 2060 |

| Soil Poisson’s ratio | 0.38 |

| Soil shear modulus/(Pa) | 1.05 × 1010 |

| Inter-particle normal contact stiffness coefficient | 1.20 × 108 |

| Critical normal stress between particles/(MPa) | 180 |

| Critical inter-particle tangential stress/(Mpa) | 74 |

| Static friction coefficient between soil particles | 0.40 |

| Coefficient of dynamic friction between soil particles | 0.22 |

| Recovery coefficient between soil particles | 0.20 |

| Level Code | Experimental Factors | ||

|---|---|---|---|

| Operating Speed x1/(m/s) | Spring Preload Force x2/(N) | Operating Slope Angle x3/(°) | |

| 1 | 0.2 | 0.5 | 0 |

| 2 | 0.4 | 5.6 | 4 |

| 3 | 0.6 | 10.6 | 8 |

| 4 | 0.8 | 15.2 | 12 |

| 5 | 1.0 | 20.7 | 16 |

| 6 | 1.2 | 24.8 | 20 |

| 7 | 1.4 | 29.8 | 24 |

| Level Code | Experiment Factors | ||

|---|---|---|---|

| Operating Speed X1/(m/s) | Spring Preload force X2/(N) | Operating Slope Angle X3/(°) | |

| 1.68 | 1.2 | 24.8 | 16 |

| 1 | 1.1 | 20.7 | 14 |

| 0 | 1.0 | 15.2 | 12 |

| −1 | 0.9 | 10.6 | 10 |

| −1.68 | 0.8 | 5.6 | 8 |

| Performance Indicators | Source | Square Sum | Degree of Freedom | Mean Square | F Value | Significance |

|---|---|---|---|---|---|---|

| Qualified index | Regression model | 92.10 | 2 | 46.05 | 89.48 | <0.0001 |

| Factor x1 | 17.93 | 1 | 17.93 | 34.84 | <0.0001 | |

| Factor x12 | 74.17 | 1 | 74.17 | 144.12 | <0.0001 | |

| Error | 16.47 | 32 | 0.51 | |||

| Sum | 108.57 | 34 | ||||

| Coefficient of variation | Regression model | 403.93 | 2 | 201.97 | 140.36 | <0.0001 |

| Factor x1 | 122.02 | 1 | 122.02 | 84.80 | <0.0001 | |

| Factor x12 | 281.92 | 1 | 281.92 | 195.92 | <0.0001 | |

| Error | 46.04 | 32 | 1.44 | |||

| Sum | 449.98 | 34 |

| Performance Indicators | Source | Square Sum | Degree of Freedom | Mean Square | F Value | Significance |

|---|---|---|---|---|---|---|

| Qualified index | Regression model | 32.58 | 2 | 16.29 | 67.94 | <0.0001 |

| Factor x1 | 14.37 | 1 | 14.37 | 59.92 | <0.0001 | |

| Factor x12 | 17.85 | 1 | 17.85 | 74.44 | <0.0001 | |

| Error | 7.67 | 32 | 0.24 | |||

| Sum | 40.26 | 34 | ||||

| Coefficient of variation | Regression model | 68.00 | 2 | 34.00 | 34.26 | <0.0001 |

| Factor x1 | 45.65 | 1 | 45.65 | 46.00 | <0.0001 | |

| Factor x12 | 21.63 | 1 | 21.63 | 21.80 | <0.0001 | |

| Error | 31.76 | 32 | 0.99 | |||

| Sum | 99.76 | 34 |

| Performance Indicators | Source | Square Sum | Degree of Freedom | Mean Square | F Value | Significance |

|---|---|---|---|---|---|---|

| Qualified index | Regression model | 26.72 | 2 | 13.36 | 65.77 | <0.0001 |

| Factor x3 | 4.32 | 1 | 4.32 | 21.27 | <0.0001 | |

| Factor x32 | 22.40 | 1 | 22.40 | 110.26 | <0.0001 | |

| Error | 6.50 | 32 | 0.20 | |||

| Sum | 33.23 | 34 | ||||

| Coefficient of variation | Regression model | 330.25 | 2 | 165.12 | 227.80 | <0.0001 |

| Factor x3 | 273.56 | 1 | 273.56 | 377.40 | <0.0001 | |

| Factor x32 | 56.69 | 1 | 56.69 | 78.20 | <0.0001 | |

| Error | 23.20 | 32 | 0.72 | |||

| Sum | 353.44 | 34 |

| No. | Test Factors | Performance Indicators | |||

|---|---|---|---|---|---|

| Operating Speed X1/(m/s) | Spring Preload Force X2/(N) | Operating Slope Angle X3/(°) | Qualified Index Y1/(%) | Coefficient of Variation Y2/(%) | |

| 1 | −1 | −1 | −1 | 96.24 | 12.13 |

| 2 | 1 | −1 | −1 | 87.90 | 12.86 |

| 3 | −1 | 1 | −1 | 88.98 | 14.23 |

| 4 | 1 | 1 | −1 | 85.79 | 14.35 |

| 5 | −1 | 1 | 1 | 91.03 | 15.28 |

| 6 | 1 | −1 | 1 | 91.69 | 13.94 |

| 7 | −1 | 1 | 1 | 89.90 | 13.58 |

| 8 | 1 | 1 | 1 | 95.89 | 15.79 |

| 9 | −1.68 | 0 | 0 | 93.28 | 15.38 |

| 10 | 1.68 | 0 | 0 | 85.76 | 13.17 |

| 11 | 0 | −1.68 | 0 | 92.56 | 12.81 |

| 12 | 0 | 1.68 | 0 | 86.42 | 13.21 |

| 13 | 0 | 0 | −1.68 | 91.56 | 15.81 |

| 14 | 0 | 0 | 1.68 | 93.02 | 16.31 |

| 15 | 0 | 0 | 0 | 90.76 | 15.97 |

| 16 | 0 | 0 | 0 | 91.62 | 16.32 |

| 17 | 0 | 0 | 0 | 88.14 | 15.57 |

| 18 | 0 | 0 | 0 | 90.52 | 16.07 |

| 19 | 0 | 0 | 0 | 89.97 | 16.61 |

| 20 | 0 | 0 | 0 | 91.25 | 15.55 |

| 21 | 0 | 0 | 0 | 90.95 | 14.98 |

| 22 | 0 | 0 | 0 | 91.55 | 16.05 |

| 23 | 0 | 0 | 0 | 90.24 | 15.89 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, W.; Wang, C.; Zhu, G.; Gu, Z.; Tang, H.; Wang, J.; Wang, J. Optimization of and Experiment on Simulation Parameters for Rotary Hole Filling Corn Precision Metering Device. Agriculture 2023, 13, 1093. https://doi.org/10.3390/agriculture13051093

Weng W, Wang C, Zhu G, Gu Z, Tang H, Wang J, Wang J. Optimization of and Experiment on Simulation Parameters for Rotary Hole Filling Corn Precision Metering Device. Agriculture. 2023; 13(5):1093. https://doi.org/10.3390/agriculture13051093

Chicago/Turabian StyleWeng, Wuxiong, Changyu Wang, Guixuan Zhu, Zejun Gu, Han Tang, Jinfeng Wang, and Jinwu Wang. 2023. "Optimization of and Experiment on Simulation Parameters for Rotary Hole Filling Corn Precision Metering Device" Agriculture 13, no. 5: 1093. https://doi.org/10.3390/agriculture13051093