Efficiently Combining Water Reuse and Desalination through Forward Osmosis—Reverse Osmosis (FO-RO) Hybrids: A Critical Review

Abstract

:1. Introduction

1.1. Need for Alternative Water Resources and Management

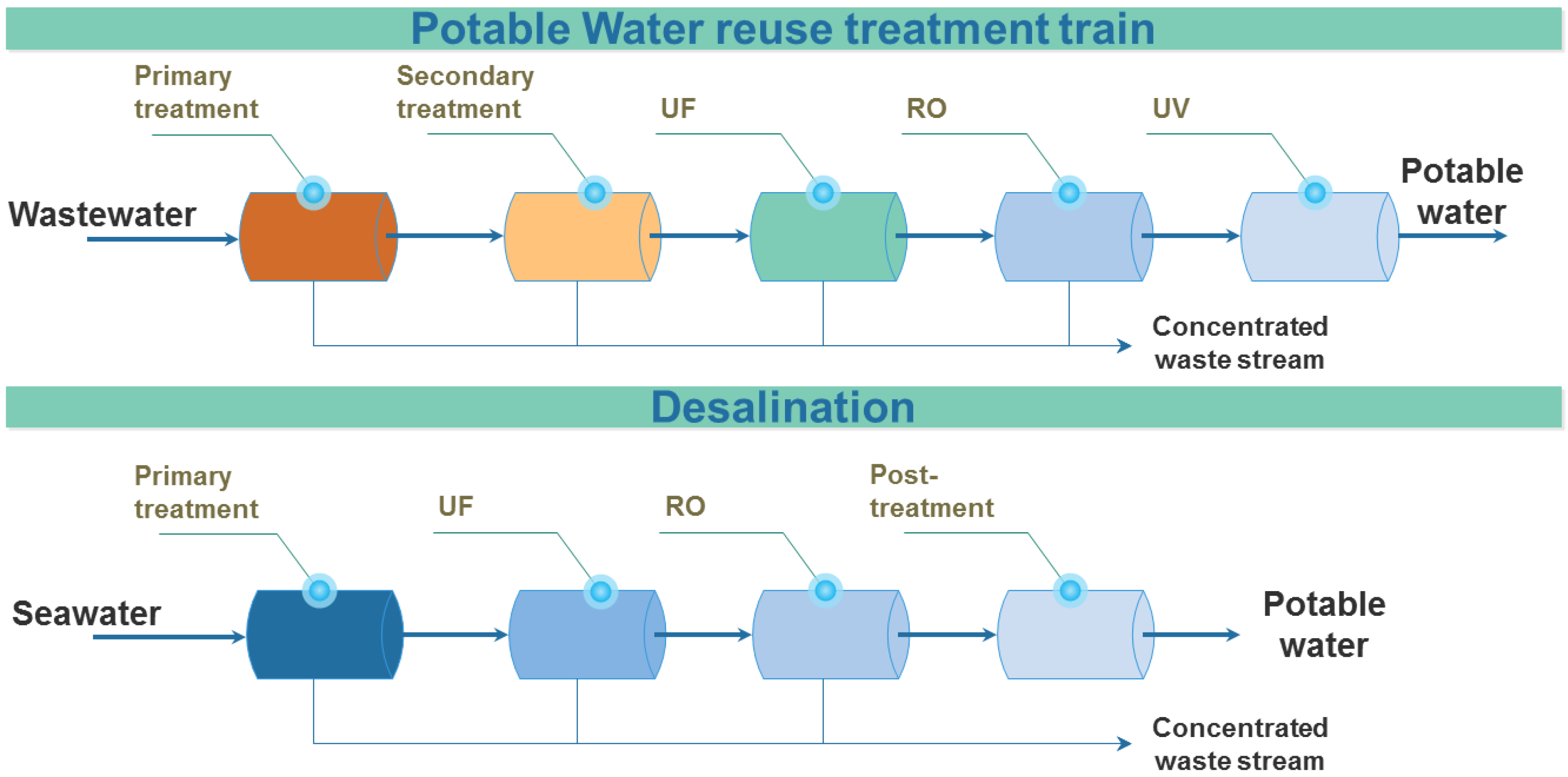

1.2. State of the Art of Desalination and Water Reuse Schemes

1.3. Opportunities and Challenges of Combining Desalination and Water Reuse Schemes

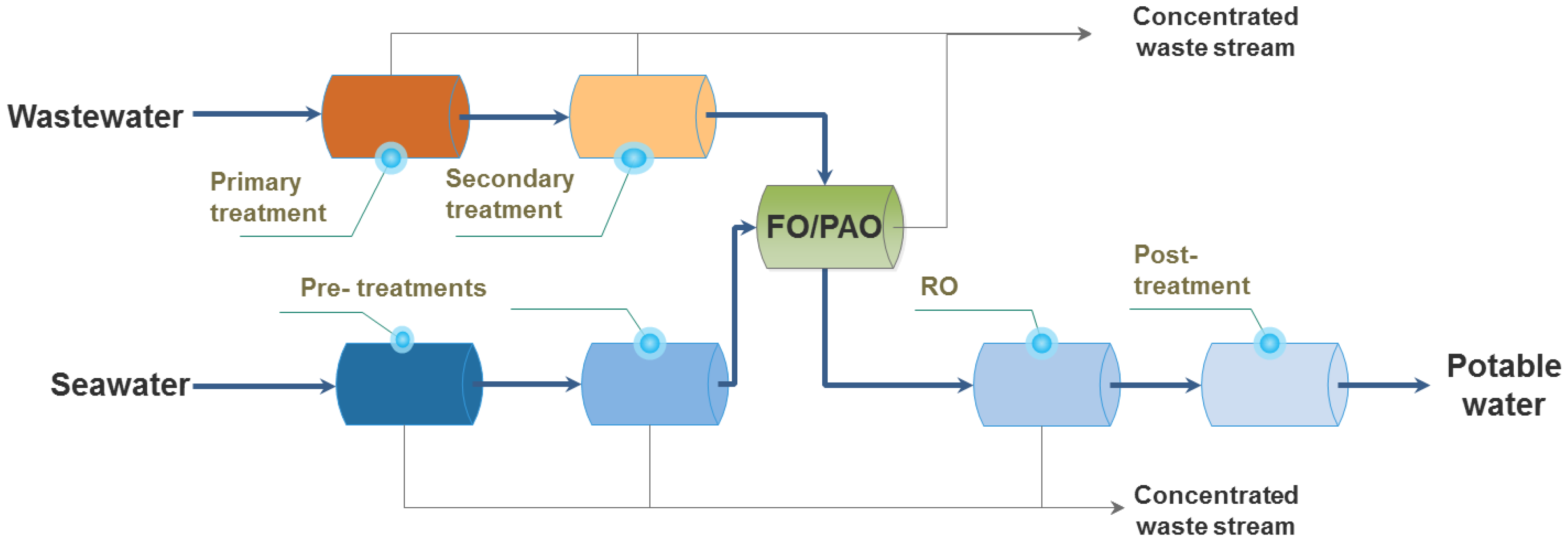

2. Combining Desalination and Water Reuse through FO-RO Hybrids

2.1. The Emergence of FO

2.2. The FO-RO Hybrid Process

- lower energy use (due to lower operating pressure) for SWRO desalination thanks to the osmotic dilution,

- beneficial reuse of wastewater, i.e., water recycling,

- Multi-barrier protection (two successive dense membrane processes, i.e., FO and RO) to increase consumer confidence in water recycling,

- Reduction in RO membrane fouling due to dilution of the pollutant load and lower operating pressure.

2.3. Other FO-RO Hybrid Configurations

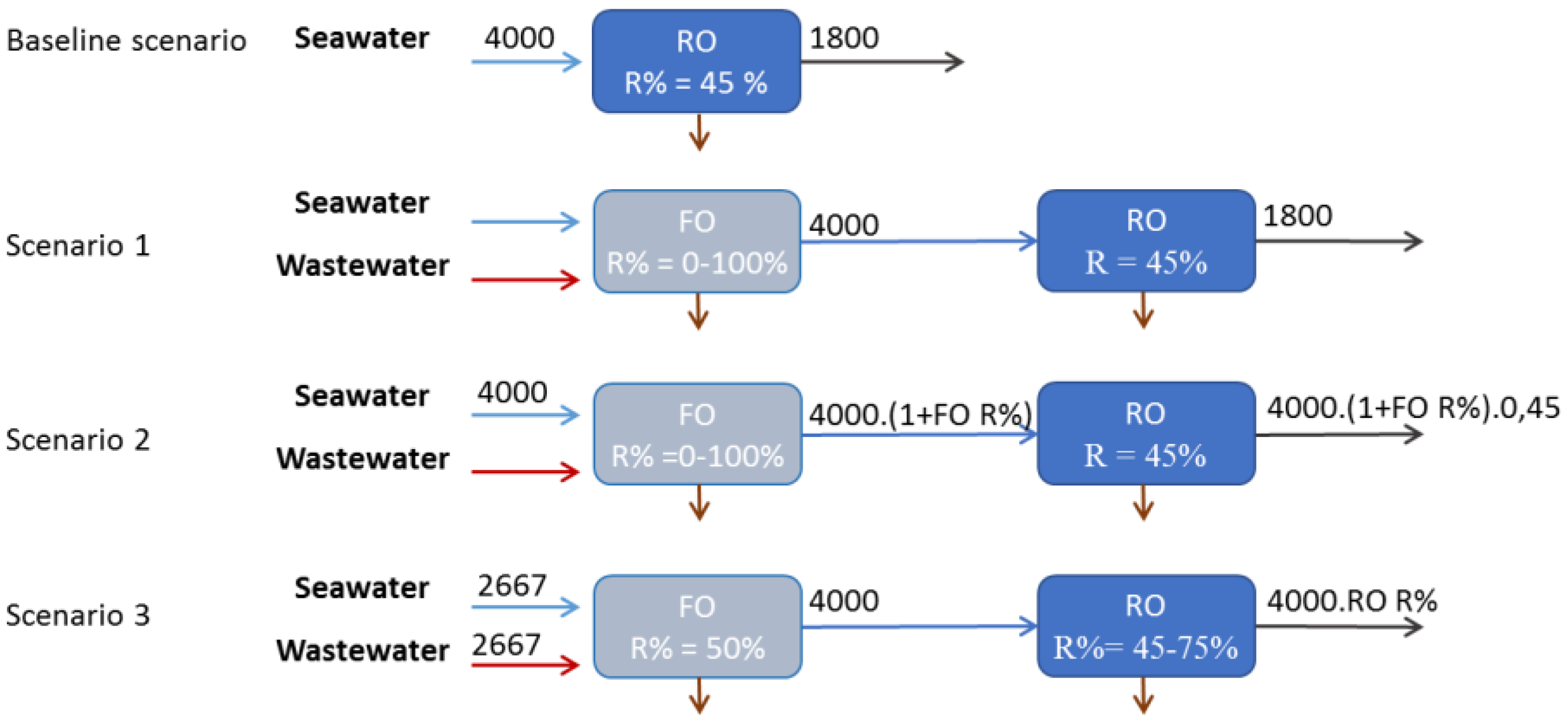

2.4. FO Integration in Existing RO Desalination Schemes

2.5. FO Economics: Need for Higher Permeation Flux

- Implementation of FO will require investment costs

- Energy consumption in RO is getting close to the thermodynamic limit and additional energy savings may become marginal [70].

- The FO-RO hybrid also has to demonstrate advantages in comparison with two independent and established water treatment streams (i.e., water reuse and/or desalination) or simple mixing of these streams before treatment [71].

3. Recent Development to Improve Flux in FO

3.1. Membrane Development

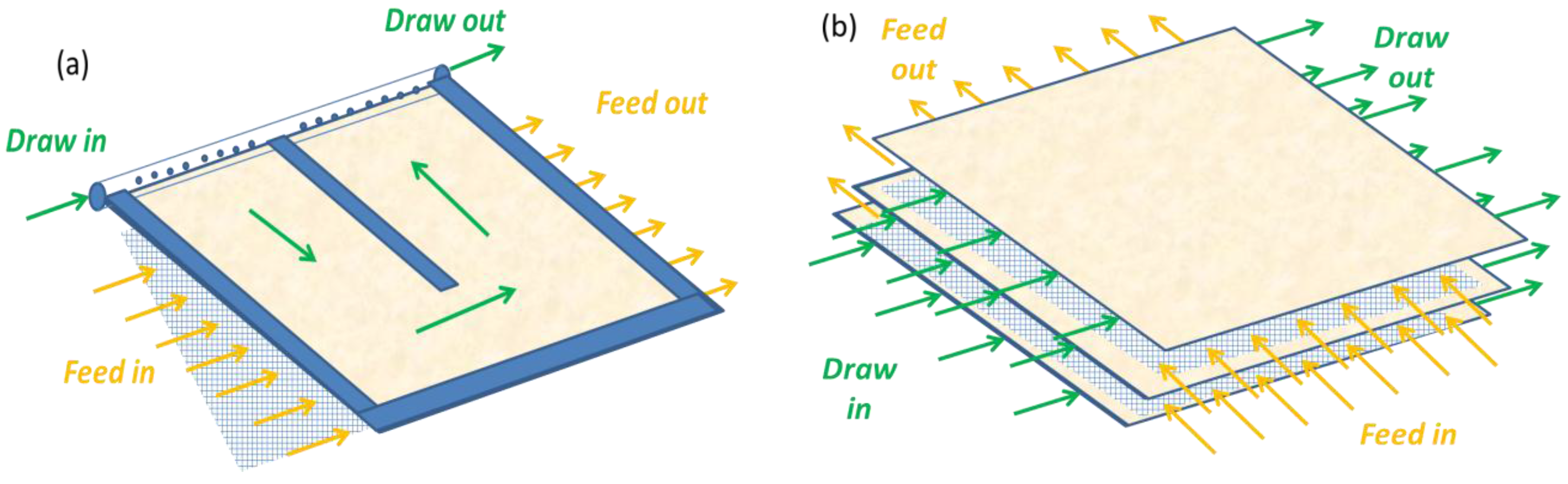

3.2. Module Development

- Plate and frame modules are developed by Porifera under the commercial name of PFO elements. Porifera PFO elements are claimed to offer relative high packing density (similar to RO modules), low pressure drop and filtration surface from 1 up to 7 m2 per module [102]. Up onto now, however, the performance of these modules has not been systematically reported in literature.

- Hollow fiber modules were developed by Toyobo, as adapted from their 8 inch SWRO modules. These modules featuring high packing density have been tested for PRO [104], and the authors provided proof for resistance to operation at high hydraulic pressure (25 bar). However, the authors did mention the need for optimised design through adapted flow patterns for both feed and draw sides.

- Spiral wound modules were developed by HTI using the CTA FO membrane. The modules were developed in a range of module sizes, varying from 2.5 to 8 inches, and for a variety of feed spacers (fine (FS), medium (MS) and corrugated (CS) spacer) to allow for operation with different types of feed waters. Most FO studies on pilot scale were performed using the HTI CTA modules (see Table 2).

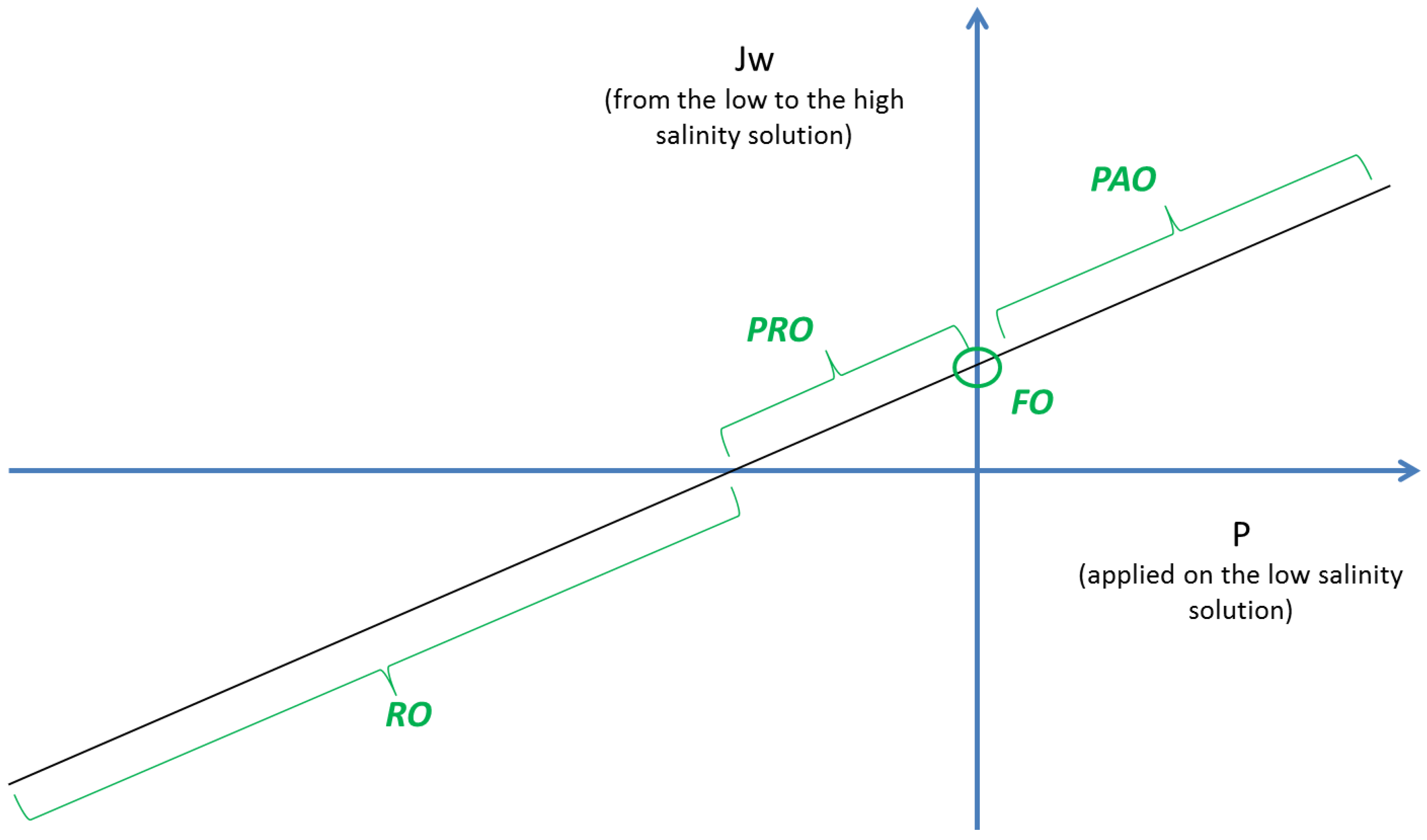

3.3. The Concept of Pressure Assisted Osmosis (PAO)

4. Challenges Associated with FO Flux Improvement

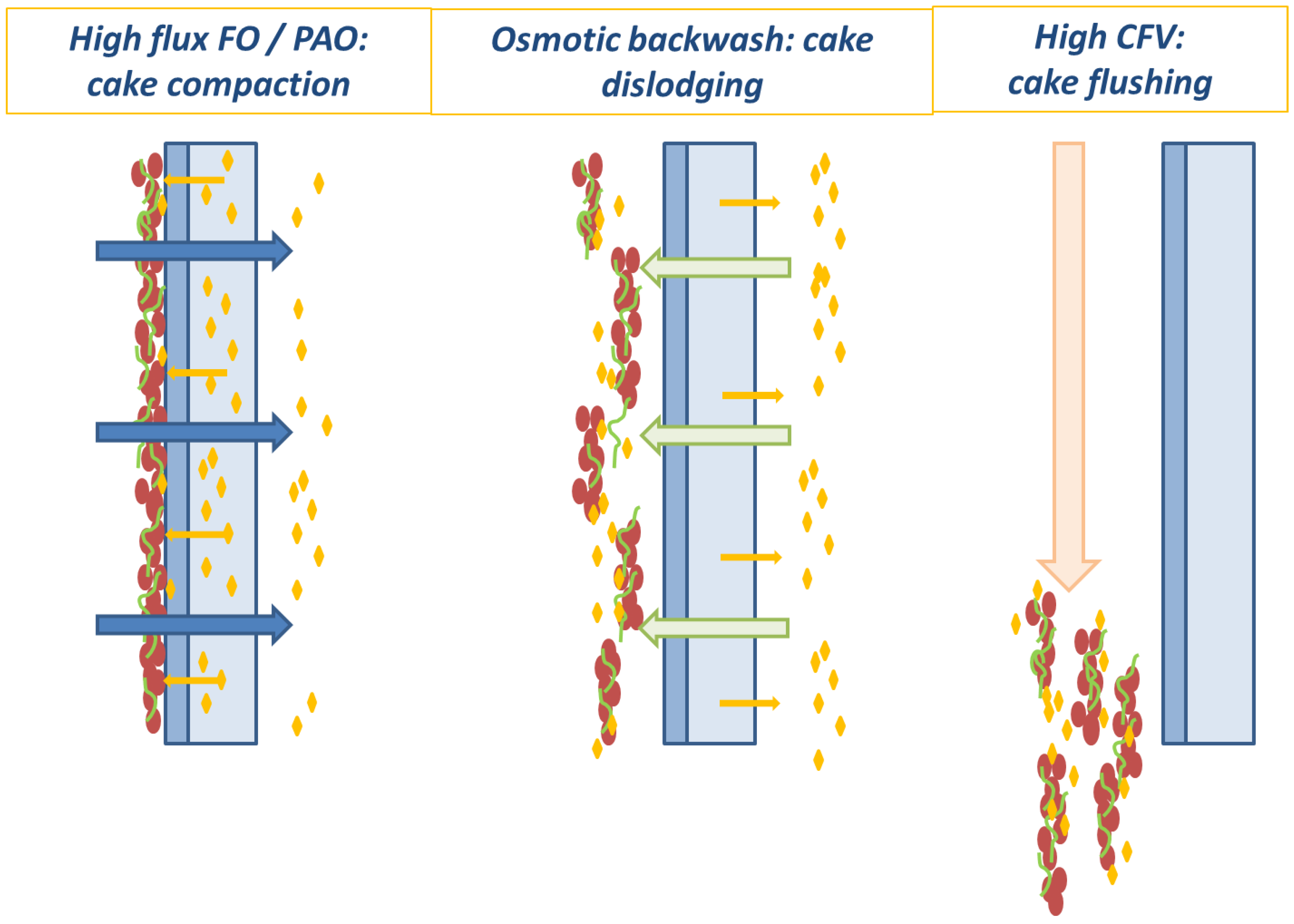

4.1. Fouling and Cleaning

4.2. Rejection of Trace Organic Contaminants

5. Concluding Remarks

- Up-scaling: most of the studies in literature have been conducted using small flat-sheet coupons. More pilot scale and full scale tests are needed to assess up-scaling challenges in term of mass transfer limitations on module scale, the effects of spacer design on pressure drop, effects of fouling and the feasibility of cleaning strategies.

- Improved economic assessment: The economic models used for FO should be updated by incorporation of fouling models that are better able to simulate practical implementation of FO/PAO-RO hybrids. In addition, a better integration of cost savings from the water recycling scheme may be considered as any treatment step avoided in the water recycling scheme as a result of combination with desalination will help to support FO/PAO-RO hybrids economic credentials.

Acknowledgments

Conflicts of Interest

References

- UNICEF-WHO. Progress on Sanitation and Drinking Water: 2015 Update and MDG Assessment; World Health Organization: Geneva, Switzerland, 2015. [Google Scholar]

- Hochstrat, R.; Wintgens, T.; Kazner, C.; Melin, T.; Gebel, J. Options for water scarcity and drought management—The role of desalination. Desalination Water Treat. 2010, 18, 96–102. [Google Scholar] [CrossRef]

- Global_Water_Intelligence. Available online: http://www.desaldata.com (accessed on 6 October 2015).

- Elimelech, M.; Phillip, W.A. The future of seawater desalination: Energy, technology, and the environment. Science 2011, 333, 712–717. [Google Scholar] [CrossRef] [PubMed]

- Hurlimann, A.; Dolnicar, S. Acceptance of water alternatives in australia—2009. Water Sci. Technol. 2010, 61, 2137–2142. [Google Scholar] [CrossRef] [PubMed]

- Dolnicar, S.; Hurlimann, A.; Grün, B. What affects public acceptance of recycled and desalinated water? Water Res. 2011, 45, 933–943. [Google Scholar] [CrossRef] [PubMed]

- Fielding, K.S.; Roiko, A.H. Providing information promotes greater public support for potable recycled water. Water Res. 2014, 61, 86–96. [Google Scholar] [CrossRef] [PubMed]

- Miller, G.W. Integrated concepts in water reuse: Managing global water needs. Desalination 2006, 187, 65–75. [Google Scholar] [CrossRef]

- Semiat, R.; Hasson, D. Water desalination. Rev. Chem. Eng. 2012, 28, 43–60. [Google Scholar] [CrossRef]

- Shannon, M.A.; Bohn, P.W.; Elimelech, M.; Georgiadis, J.G.; Marinas, B.J.; Mayes, A.M. Science and technology for water purification in the coming decades. Nature 2008, 452, 301–310. [Google Scholar] [CrossRef] [PubMed]

- Zhu, A.; Christofides, P.D.; Cohen, Y. On RO membrane and energy costs and associated incentives for future enhancements of membrane permeability. J. Membr. Sci. 2009, 344, 1–5. [Google Scholar] [CrossRef]

- Zhu, A.; Christofides, P.D.; Cohen, Y. Effect of thermodynamic restriction on energy cost optimization of RO membrane water desalination. Ind. Eng. Chem. Res. 2008, 48, 6010–6021. [Google Scholar] [CrossRef]

- Bartman, A.R.; Zhu, A.; Christofides, P.D.; Cohen, Y. Minimizing energy consumption in reverse osmosis membrane desalination using optimization-based control. J. Process Control 2010, 20, 1261–1269. [Google Scholar] [CrossRef]

- Angelakis, A.N.; Durham, B. Water recycling and reuse in EUREAU countries: Trends and challenges. Desalination 2008, 218, 3–12. [Google Scholar] [CrossRef]

- Tchobanoglous, G.; Leverenz, H.; Nellor, M.H.; Crook, J. Direct Potable Reuse: A Path Forward; WateReuse Research Foundation: Alexandria, VA, USA, 2011. [Google Scholar]

- Cirja, M.; Ivashechkin, P.; Schäffer, A.; Corvini, P.X. Factors affecting the removal of organic micropollutants from wastewater in conventional treatment plants (CTP) and membrane bioreactors (MBR). Rev. Environ. Sci. Biotechnol. 2008, 7, 61–78. [Google Scholar] [CrossRef]

- Jelic, A.; Gros, M.; Ginebreda, A.; Cespedes-Sánchez, R.; Ventura, F.; Petrovic, M.; Barcelo, D. Occurrence, partition and removal of pharmaceuticals in sewage water and sludge during wastewater treatment. Water Res. 2011, 45, 1165–1176. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Englehardt, J.; Wu, T. Review of cost versus scale: Water and wastewater treatment and reuse processes. Water Sci. Technol. 2014, 69, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Khan, S. Drinking Water through Recycling: The Benefits and Costs of Supplying Direct to the Distribution System; Australian Academy of Technological Sciences and Engineering: Melbourne, Australia, 2013. [Google Scholar] [CrossRef]

- Barr, P. Treatment optimization—providing more effective multiple-barrier protection. J. Am. Water Works Assoc. 2007, 99, 40–43. [Google Scholar]

- Plummer, R.; Velaniškis, J.; de Grosbois, D.; Kreutzwiser, R.D.; de Loë, R. The development of new environmental policies and processes in response to a crisis: The case of the multiple barrier approach for safe drinking water. Environ. Sci. Policy 2010, 13, 535–548. [Google Scholar] [CrossRef]

- Lim, S.J.; Fox, P. Prediction of the potential fates of future pharmaceutical compounds in indirect potable reuse systems. Sci. Total Environ. 2013, 444, 417–422. [Google Scholar] [CrossRef] [PubMed]

- Yangali-Quintanilla, V.; Maeng, S.K.; Fujioka, T.; Kennedy, M.; Amy, G. Proposing nanofiltration as acceptable barrier for organic contaminants in water reuse. J. Membr. Sci. 2010, 362, 334–345. [Google Scholar] [CrossRef]

- Lekkerkerker-Teunissen, K.; Chekol, E.T.; Maeng, S.K.; Ghebremichael, K.; Houtman, C.J.; Verliefde, A.R.D.; Verberk, J.Q.J.C.; Amy, G.L.; Van Dijk, J.C. Pharmaceutical removal during managed aquifer recharge with pretreatment by advanced oxidation. Water Sci. Technol. Water Supply 2012, 12, 755–767. [Google Scholar] [CrossRef]

- Reungoat, J.; Macova, M.; Carswell, S.; Escher, B.I.; Mueller, J.F.; Gernjak, W.; Keller, J. Effective removal of pathogens and micropollutants by ozone and GAC. Water 2010, 37, 69–72. [Google Scholar]

- Iglesias, R.; Ortega, E.; Batanero, G.; Quintas, L. Water reuse in spain: Data overview and costs estimation of suitable treatment trains. Desalination 2010, 263, 1–10. [Google Scholar] [CrossRef]

- Lee, H.; Tan, T.P. Singapore’s experience with reclaimed water: Newater. Int. J. Water Resour. Dev. 2016, 32, 611–621. [Google Scholar] [CrossRef]

- Pankratz, T. Desalination technology trends. Bienn. Rep. Seawater Desalin. 2004, 2. Available online: http://texaswater.tamu.edu/readings/desal/desaltechtrends.pdf (accessed on 28 June 2016). [Google Scholar]

- Hamed, O.A. Overview of hybrid desalination systems—Current status and future prospects. Desalination 2005, 186, 207–214. [Google Scholar] [CrossRef]

- El-Zanati, E.; El-Khatib, K.M. Integrated membrane-based desalination system. Desalination 2007, 205, 15–25. [Google Scholar] [CrossRef]

- Cath, T.Y.; Gormly, S.; Beaudry, E.G.; Flynn, M.T.; Adams, V.D.; Childress, A.E. Membrane contactor processes for wastewater reclamation in space: Part I. Direct osmotic concentration as pretreatment for reverse osmosis. J. Membr. Sci. 2005, 257, 85–98. [Google Scholar] [CrossRef]

- Beaudry, E.G.; Herron, J.R.; Peterson, S. Direct Osmosis Concentration of Waste Water: Final Report; Osmotek Inc.: Corvallis, OR, USA, 1999. [Google Scholar]

- McCutcheon, J.R.; McGinnis, R.L.; Elimelech, M. A novel ammonia–carbon dioxide forward (direct) osmosis desalination process. Desalination 2005, 174, 1–11. [Google Scholar] [CrossRef]

- Cath, T.Y.; Childress, A.E.; Elimelech, M. Forward osmosis: Principles, applications, and recent developments. J. Membr. Sci. 2006, 281, 70–87. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Verliefde, A.R.D.; Roest, K.; Rietveld, L.C.; Cornelissen, E.R. Forward osmosis for application in wastewater treatment: A review. Water Res. 2014, 58, 179–197. [Google Scholar] [CrossRef] [PubMed]

- Klaysom, C.; Cath, T.Y.; Depuydt, T.; Vankelecom, I.F.J. Forward and pressure retarded osmosis: Potential solutions for global challenges in energy and water supply. Chem. Soc. Rev. 2013, 42, 6959–6989. [Google Scholar] [CrossRef] [PubMed]

- Field, R.W.; Wu, J.J. Mass transfer limitations in forward osmosis: Are some potential applications overhyped? Desalination 2013, 318, 118–124. [Google Scholar] [CrossRef]

- Zhao, S.F.; Zou, L.; Tang, C.Y.Y.; Mulcahy, D. Recent developments in forward osmosis: Opportunities and challenges. J. Membr. Sci. 2012, 396, 1–21. [Google Scholar] [CrossRef]

- She, Q.; Wang, R.; Fane, A.G.; Tang, C.Y. Membrane fouling in osmotically driven membrane processes: A review. J. Membr. Sci. 2016, 499, 201–233. [Google Scholar] [CrossRef]

- Coday, B.D.; Yaffe, B.G.M.; Xu, P.; Cath, T.Y. Rejection of trace organic compounds by forward osmosis membranes: A literature review. Environ. Sci. Technol. 2014, 48, 3612–3624. [Google Scholar] [CrossRef] [PubMed]

- Chekli, L.; Phuntsho, S.; Shon, H.K.; Vigneswaran, S.; Kandasamy, J.; Chanan, A. A review of draw solutes in forward osmosis process and their use in modern applications. Desalination Water Treat. 2012, 43, 167–184. [Google Scholar] [CrossRef]

- Qin, J.J.; Lay, W.C.L.; Kekre, K.A. Recent developments and future challenges of forward osmosis for desalination: A review. Desalination Water Treat. 2012, 39, 123–136. [Google Scholar] [CrossRef]

- Chung, T.-S.; Zhang, S.; Wang, K.Y.; Su, J.; Ling, M.M. Forward osmosis processes: Yesterday, today and tomorrow. Desalination 2012, 287, 78–81. [Google Scholar] [CrossRef]

- Shaffer, D.L.; Werber, J.R.; Jaramillo, H.; Lin, S.; Elimelech, M. Forward osmosis: Where are we now? Desalination 2015, 356, 271–284. [Google Scholar] [CrossRef]

- Chekli, L.; Phuntsho, S.; Kim, J.E.; Kim, J.; Choi, J.Y.; Choi, J.-S.; Kim, S.; Kim, J.H.; Hong, S.; Sohn, J.; et al. A comprehensive review of hybrid forward osmosis systems: Performance, applications and future prospects. J. Membr. Sci. 2016, 497, 430–449. [Google Scholar] [CrossRef]

- Shaffer, D.L.; Yip, N.Y.; Gilron, J.; Elimelech, M. Seawater desalination for agriculture by integrated forward and reverse osmosis: Improved product water quality for potentially less energy. J. Membr. Sci. 2012, 415–416, 1–8. [Google Scholar] [CrossRef]

- Xie, M.; Nghiem, L.D.; Price, W.E.; Elimelech, M. Toward resource recovery from wastewater: Extraction of phosphorus from digested sludge using a hybrid forward osmosis–membrane distillation process. Environ. Sci. Technol. Lett. 2014, 1, 191–195. [Google Scholar] [CrossRef]

- D’Haese, A.; Le-Clech, P.; Van Nevel, S.; Verbeken, K.; Cornelissen, E.R.; Khan, S.J.; Verliefde, A.R. Trace organic solutes in closed-loop forward osmosis applications: Influence of membrane fouling and modeling of solute build-up. Water Res. 2013, 47, 5232–5244. [Google Scholar] [CrossRef] [PubMed]

- Bamaga, O.A.; Yokochi, A.; Zabara, B.; Babaqi, A.S. Hybrid FO/RO desalination system: Preliminary assessment of osmotic energy recovery and designs of new FO membrane module configurations. Desalination 2011, 268, 163–169. [Google Scholar] [CrossRef]

- Cath, T.Y.; Drewes, J.E.; Lundin, C.D. A Novel Hybrid forward Osmosis Process for Drinking Water Augmentation Using Impaired Water and Saline Water Sources; Water Research Foundation: Las Cruces, NM, USA, 2009. [Google Scholar]

- Yangali-Quintanilla, V.; Olesen, L.; Lorenzen, J.; Rasmussen, C.; Laursen, H.; Vestergaard, E.; Keiding, K. Lowering desalination costs by alternative desalination and water reuse scenarios. Desalination Water Treat. 2015, 55, 2437–2445. [Google Scholar] [CrossRef]

- Tan, C.H.; Ng, H.Y. A novel hybrid forward osmosis–nanofiltration (FO–NF) process for seawater desalination: Draw solution selection and system configuration. Desalination Water Treat. 2010, 13, 356–361. [Google Scholar] [CrossRef]

- Park, S.M.; Koo, J.W.; Choi, Y.K.; Lee, S.; Sohn, J.; Hwang, T.M. Optimization of hybrid system consisting of forward osmosis and reverse osmosis: A Monte Carlo simulation approach. Desalination Water Treat. 2012, 43, 274–280. [Google Scholar] [CrossRef]

- McCutcheon, J.R.; McGinnis, R.L.; Elimelech, M. Desalination by ammonia–carbon dioxide forward osmosis: Influence of draw and feed solution concentrations on process performance. J. Membr. Sci. 2006, 278, 114–123. [Google Scholar] [CrossRef]

- Cath, T.Y.; Hancock, N.T.; Lundin, C.D.; Hoppe-Jones, C.; Drewes, J.E. A multi-barrier osmotic dilution process for simultaneous desalination and purification of impaired water. J. Membr. Sci. 2010, 362, 417–426. [Google Scholar] [CrossRef]

- Holloway, R.W.; Childress, A.E.; Dennett, K.E.; Cath, T.Y. Forward osmosis for concentration of anaerobic digester centrate. Water Res. 2007, 41, 4005–4014. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, N.C.; Chen, S.-S.; Yang, H.-Y.; Hau, N.T. Application of forward osmosis on dewatering of high nutrient sludge. Bioresour. Technol. 2013, 132, 224–229. [Google Scholar] [CrossRef] [PubMed]

- Cornelissen, E.R.; Harmsen, D.; Beerendonk, E.F.; Qin, J.J.; Oo, H.; De Korte, K.F.; Kappelhof, J.W.M.N. The innovative osmotic membrane bioreactor (OMBR) for reuse of wastewater. Water Sci. Technol. 2011, 63, 1557–1565. [Google Scholar] [CrossRef] [PubMed]

- Holloway, R.W.; Achilli, A.; Cath, T.Y. The osmotic membrane bioreactor: A critical review. Environ. Sci. Water Res. Technol. 2015, 1, 581–605. [Google Scholar] [CrossRef]

- Boo, C.; Lee, S.; Elimelech, M.; Meng, Z.; Hong, S. Colloidal fouling in forward osmosis: Role of reverse salt diffusion. J. Membr. Sci. 2012, 390–391, 277–284. [Google Scholar] [CrossRef]

- Luo, W.; Hai, F.I.; Kang, J.; Price, W.E.; Nghiem, L.D.; Elimelech, M. The role of forward osmosis and microfiltration in an integrated osmotic–microfiltration membrane bioreactor system. Chemosphere 2015, 136, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Holloway, R.W.; Wait, A.S.; Fernandes da Silva, A.; Herron, J.; Schutter, M.D.; Lampi, K.; Cath, T.Y. Long-term pilot scale investigation of novel hybrid ultrafiltration–osmotic membrane bioreactors. Desalination 2015, 363, 64–74. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Cornelissen, E.R.; Harmsen, D.J.H.; Post, J.W.; Lampi, K.; Ramaekers, H.; Rietveld, L.C.; Roest, K. Water recovery from sewage using forward osmosis. Water Sci. Technol. 2011, 64, 1443–1449. [Google Scholar] [CrossRef] [PubMed]

- Butler, R.; MacCormick, T. Opportunities for decentralized treatment, sewer mining and effluent re-use. Desalination 1996, 106, 273–283. [Google Scholar] [CrossRef]

- Xie, M.; Nghiem, L.D.; Price, W.E.; Elimelech, M. A forward osmosis–membrane distillation hybrid process for direct sewer mining: System performance and limitations. Environ. Sci. Technol. 2013, 47, 13486–13493. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.; Valladares Linares, R.; Abu-Ghdaib, M.; Zhan, T.; Yangali-Quintanilla, V.; Amy, G. Osmotically driven membrane process for the management of urban runoff in coastal regions. Water Res. 2014, 48, 200–209. [Google Scholar] [CrossRef] [PubMed]

- Blandin, G.; Verliefde, A.R.D.; Tang, C.Y.; Le-Clech, P. Opportunities to reach economic sustainability in forward osmosis–reverse osmosis hybrids for seawater desalination. Desalination 2015, 363, 26–36. [Google Scholar] [CrossRef]

- Teusner, A.; Blandin, G.; Le-Clech, P. Augmenting water supply by combined desalination/water recycling methods: An economic assessment. Environ. Technol. 2016, 1–32. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.; Boo, C.; Elimelech, M.; Hong, S. Comparison of fouling behavior in forward osmosis (FO) and reverse osmosis (RO). J. Membr. Sci. 2010, 365, 34–39. [Google Scholar] [CrossRef]

- Semiat, R.; Sapoznik, J.; Hasson, D. Energy aspects in osmotic processes. Desalination Water Treat. 2010, 15, 228–235. [Google Scholar] [CrossRef]

- Takabatake, H.; Noto, K.; Uemura, T.; Ueda, S. More than 30% energy saving seawater desalination system by combining with sewage reclamation. Desalination Water Treat. 2012, 51, 733–741. [Google Scholar] [CrossRef]

- Yangali-Quintanilla, V.; Li, Z.; Valladares, R.; Li, Q.; Amy, G. Indirect desalination of red sea water with forward osmosis and low pressure reverse osmosis for water reuse. Desalination 2011, 280, 160–166. [Google Scholar] [CrossRef]

- Wang, K.Y.; Chung, T.S.; Amy, G. Developing thin-film-composite forward osmosis membranes on the PES/SPSf substrate through interfacial polymerization. AIChE J. 2012, 58, 770–781. [Google Scholar] [CrossRef]

- Chung, T.S.; Li, X.; Ong, R.C.; Ge, Q.; Wang, H.; Han, G. Emerging forward osmosis (FO) technologies and challenges ahead for clean water and clean energy applications. Curr. Opin. Chem. Eng. 2012, 1, 246–257. [Google Scholar] [CrossRef]

- Song, X.; Liu, Z.; Sun, D.D. Nano gives the answer: Breaking the bottleneck of internal concentration polarization with a nanofiber composite forward osmosis membrane for a high water production rate. Adv. Mater. 2011, 23, 3256–3260. [Google Scholar] [CrossRef] [PubMed]

- Qi, S.R.; Li, W.Y.; Zhao, Y.; Ma, N.; Wei, J.; Chin, T.W.; Tang, C.Y.Y. Influence of the properties of layer-by-layer active layers on forward osmosis performance. J. Membr. Sci. 2012, 423, 536–542. [Google Scholar] [CrossRef]

- Qi, S.; Qiu, C.Q.; Zhao, Y.; Tang, C.Y. Double-skinned forward osmosis membranes based on layer-by-layer assembly—FO performance and fouling behavior. J. Membr. Sci. 2012, 405–406, 20–29. [Google Scholar] [CrossRef]

- Qiu, C.; Qi, S.; Tang, C.Y. Synthesis of high flux forward osmosis membranes by chemically crosslinked layer-by-layer polyelectrolytes. J. Membr. Sci. 2011, 381, 74–80. [Google Scholar] [CrossRef]

- Saren, Q.; Qiu, C.Q.; Tang, C.Y. Synthesis and characterization of novel forward osmosis membranes based on layer-by-layer assembly. Environm. Sci. Technol. 2011, 45, 5201–5208. [Google Scholar] [CrossRef] [PubMed]

- Tang, C.Y.; Zhao, Y.; Wang, R.; Hélix-Nielsen, C.; Fane, A.G. Desalination by biomimetic aquaporin membranes: Review of status and prospects. Desalination 2013, 308, 34–40. [Google Scholar] [CrossRef]

- Wang, Y.N.; Wei, J.; She, Q.; Pacheco, F.; Tang, C.Y. Microscopic characterization of FO/PRO membranes—A comparative study of CLSM, TEM and SEM. Environ. Sci. Technol. 2012, 46, 9995–10003. [Google Scholar] [CrossRef] [PubMed]

- Dumée, L.; Lee, J.; Sears, K.; Tardy, B.; Duke, M.; Gray, S. Fabrication of thin film composite poly(amide)-carbon-nanotube supported membranes for enhanced performance in osmotically driven desalination systems. J. Membr. Sci. 2013, 427, 422–430. [Google Scholar] [CrossRef] [Green Version]

- Goh, P.S.; Ismail, A.F.; Ng, B.C. Carbon nanotubes for desalination: Performance evaluation and current hurdles. Desalination 2013, 308, 2–14. [Google Scholar] [CrossRef]

- Gai, J.G.; Gong, X.L. Zero internal concentration polarization fo membrane: Functionalized graphene. J. Mater. Chem. A 2014, 2, 425–429. [Google Scholar] [CrossRef]

- Lee, K.P.; Arnot, T.C.; Mattia, D. A review of reverse osmosis membrane materials for desalination—Development to date and future potential. J. Membr. Sci. 2011, 370, 1–22. [Google Scholar] [CrossRef] [Green Version]

- McCutcheon, J.R.; Elimelech, M. Influence of concentrative and dilutive internal concentration polarization on flux behavior in forward osmosis. J. Membr. Sci. 2006, 284, 237–247. [Google Scholar] [CrossRef]

- McCutcheon, J.R.; Elimelech, M. Influence of membrane support layer hydrophobicity on water flux in osmotically driven membrane processes. J. Membr. Sci. 2008, 318, 458–466. [Google Scholar] [CrossRef]

- Arena, J.T.; McCloskey, B.; Freeman, B.D.; McCutcheon, J.R. Surface modification of thin film composite membrane support layers with polydopamine: Enabling use of reverse osmosis membranes in pressure retarded osmosis. J. Membr. Sci. 2011, 375, 55–62. [Google Scholar] [CrossRef]

- Wang, K.Y.; Chung, T.S.; Qin, J.J. Polybenzimidazole (PBI) nanofiltration hollow fiber membranes applied in forward osmosis process. J. Membr. Sci. 2007, 300, 6–12. [Google Scholar] [CrossRef]

- Wang, K.Y.; Yang, Q.; Chung, T.S.; Rajagopalan, R. Enhanced forward osmosis from chemically modified polybenzimidazole (PBI) nanofiltration hollow fiber membranes with a thin wall. Chem. Eng. Sci. 2009, 64, 1577–1584. [Google Scholar] [CrossRef]

- Yang, Q.; Wang, K.Y.; Chung, T.S. Dual-layer hollow fibers with enhanced flux as novel forward osmosis membranes for water production. Environ. Sci. Technol. 2009, 43, 2800–2805. [Google Scholar] [CrossRef] [PubMed]

- Setiawan, L.; Wang, R.; Li, K.; Fane, A.G. Fabrication of novel poly(amide-imide) forward osmosis hollow fiber membranes with a positively charged nanofiltration-like selective layer. J. Membr. Sci. 2011, 369, 196–205. [Google Scholar] [CrossRef]

- Qiu, C.; Setiawan, L.; Wang, R.; Tang, C.Y.; Fane, A.G. High performance flat sheet forward osmosis membrane with an NF-like selective layer on a woven fabric embedded substrate. Desalination 2012, 287, 266–270. [Google Scholar] [CrossRef]

- Pankratz, T. FO Company’s Woes Continue. Water Desalination Report. Available online: https://www.desalination.com/publications/desalination-report-wdr (accessed on 30 May 2015).

- Nicoll, P.G. Forward Osmosis—Abrief Introduction. In Proceedings of the The International Desalination Association World Congress on Desalination and Water Reuse, Tianjin, China, 2013.

- Wei, J.; Qiu, C.; Tang, C.Y.; Wang, R.; Fane, A.G. Synthesis and characterization of flat-sheet thin film composite forward osmosis membranes. J. Membr. Sci. 2011, 372, 292–302. [Google Scholar] [CrossRef]

- Coday, B.D.; Heil, D.M.; Xu, P.; Cath, T.Y. Effects of transmembrane hydraulic pressure on performance of forward osmosis membranes. Environ. Sci. Technol. 2013, 47, 2386–2393. [Google Scholar] [CrossRef] [PubMed]

- Fam, W.; Phuntsho, S.; Lee, J.H.; Shon, H.K. Performance comparison of thin-film composite forward osmosis membranes. Desalination Water Treat. 2013, 51, 6274–6280. [Google Scholar] [CrossRef]

- Phuntsho, S.; Sahebi, S.; Majeed, T.; Lotfi, F.; Kim, J.E.; Shon, H.K. Assessing the major factors affecting the performances of forward osmosis and its implications on the desalination process. Chem. Eng. J. 2013, 231, 484–496. [Google Scholar] [CrossRef]

- Madsen, H.T.; Bajraktari, N.; Hélix-Nielsen, C.; Van der Bruggen, B.; Søgaard, E.G. Use of biomimetic forward osmosis membrane for trace organics removal. J. Membr. Sci. 2015, 476, 469–474. [Google Scholar] [CrossRef]

- Technical specifications CSM module FO8040; CSM Toray: Seoul, South Korea, 2015.

- Poriferanano. Element packing density comparison. Available online: http://porifera.com/pfo-advantages/ (accessed 1 May 2016).

- Majeed, T.; Lotfi, F.; Phuntsho, S.; Yoon, J.K.; Kim, K.; Shon, H.K. Performances of PA hollow fiber membrane with the CTA flat sheet membrane for forward osmosis process. Desalination Water Treat. 2013, 53, 1744–1754. [Google Scholar] [CrossRef]

- Saito, K.; Irie, M.; Zaitsu, S.; Sakai, H.; Hayashi, H.; Tanioka, A. Power generation with salinity gradient by pressure retarded osmosis using concentrated brine from SWRO system and treated sewage as pure water. Desalination Water Treat. 2012, 41, 114–121. [Google Scholar] [CrossRef]

- Mehta, G.D. Further results on the performance of present-day osmotic membranes in various osmotic regions. J. Membr. Sci. 1982, 10, 3–19. [Google Scholar] [CrossRef]

- Coday, B.D.; Xu, P.; Beaudry, E.G.; Herron, J.; Lampi, K.; Hancock, N.T.; Cath, T.Y. The sweet spot of forward osmosis: Treatment of produced water, drilling wastewater, and other complex and difficult liquid streams. Desalination 2014, 333, 23–35. [Google Scholar] [CrossRef]

- Xu, Y.; Peng, X.; Tang, C.Y.; Fu, Q.S.; Nie, S. Effect of draw solution concentration and operating conditions on forward osmosis and pressure retarded osmosis performance in a spiral wound module. J. Membr. Sci. 2010, 348, 298–309. [Google Scholar] [CrossRef]

- Hancock, N.T.; Xu, P.; Heil, D.M.; Bellona, C.; Cath, T.Y. Comprehensive bench- and pilot-scale investigation of trace organic compounds rejection by forward osmosis. Environ. Sci. Technol. 2011, 45, 8483–8490. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.C.; Park, S.J. Experimental study of a 4040 spiral-wound forward-osmosis membrane module. Environ. Sci. Technol. 2011, 45, 7737–7745. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.E.; Phuntsho, S.; Lotfi, F.; Shon, H.K. Investigation of pilot-scale 8040 FO membrane module under different operating conditions for brackish water desalination. Desalination Water Treat. 2015, 53, 2782–2791. [Google Scholar] [CrossRef]

- Cornelissen, E.; Harmsen, D.; Beerendonk, E.; Qin, J.; Kappelhof, J. Effect of draw solution type and operational mode of forward osmosis with laboratory-scale membranes and a spiral wound membrane module. J. Water Reuse Desalination 2011, 1, 133–140. [Google Scholar] [CrossRef]

- Mulder, M. Basic Principles of Membrane Technology; Kluwer Academic: Dordrecht, The Netherlands, 1996. [Google Scholar]

- Schwinge, J.; Neal, P.R.; Wiley, D.E.; Fletcher, D.F.; Fane, A.G. Spiral wound modules and spacers: Review and analysis. J. Membr. Sci. 2004, 242, 129–153. [Google Scholar] [CrossRef]

- She, Q.; Hou, D.; Liu, J.; Tan, K.H.; Tang, C.Y. Effect of feed spacer induced membrane deformation on the performance of pressure retarded osmosis (PRO): Implications for PRO process operation. J. Membr. Sci. 2013, 445, 170–182. [Google Scholar] [CrossRef]

- Gruber, M.F.; Johnson, C.J.; Tang, C.Y.; Jensen, M.H.; Yde, L.; Hélix-Nielsen, C. Computational fluid dynamics simulations of flow and concentration polarization in forward osmosis membrane systems. J. Membr. Sci. 2011, 379, 488–495. [Google Scholar] [CrossRef]

- Gruber, M.F.; Johnson, C.J.; Tang, C.; Jensen, M.H.; Yde, L.; Helix-Nielsen, C. Validation and analysis of forward osmosis CFD model in complex 3D geometries. Membranes 2012, 2, 764–782. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sagiv, A.; Christofides, P.D.; Cohen, Y.; Semiat, R. On the analysis of FO mass transfer resistances via CFD analysis and film theory. J. Membr. Sci. 2015, 495, 198–205. [Google Scholar] [CrossRef]

- Park, M.; Kim, J.H. Numerical analysis of spacer impacts on forward osmosis membrane process using concentration polarization index. J. Membr. Sci. 2013, 427, 10–20. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Harmsen, D.; Wols, B.; Verliefde, A.; Post, J.W.; Cornelissen, E.R. Pressure assisted osmosis (PAO) to enhance forward osmosis (FO) performance. In Proceedings of the thrid osmosis membrane summit, Barcelona, Spain, 26–27 April 2012.

- Cornelissen, E.R.; Harmsen, D.; Qin, J.; Kappelhof, J.W.M.N. Additional feed pressure (Pulsation) to increase forward osmosis membrane performance. In Proceedings of the International congress on membranes, Amsterdam, The Netherlands, 2011.

- Yun, T.G.; Kim, Y.J.; Lee, S.; Hong, S.K. Pressure assisted forward osmosis: Effect of membrane materials and operating conditions. Procedia Eng. 2012, 44, 1906. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.D.; Tang, C.Y.Y.; Childress, A.E.; Le-Clech, P. Validation of assisted forward osmosis (AFO) process: Impact of hydraulic pressure. J. Membr. Sci. 2013, 447, 1–11. [Google Scholar] [CrossRef]

- Lutchmiah, K.; Harmsen, D.J.H.; Wols, B.A.; Rietveld, L.C.; Qin, J.; Cornelissen, E.R. Continuous and discontinuous pressure assisted osmosis (PAO). J. Membr. Sci. 2015, 476, 182–193. [Google Scholar] [CrossRef]

- Oh, Y.; Lee, S.; Elimelech, M.; Lee, S.; Hong, S. Effect of hydraulic pressure and membrane orientation on water flux and reverse solute flux in pressure assisted osmosis. J. Membr. Sci. 2014, 465, 159–166. [Google Scholar] [CrossRef]

- Yun, T.; Kim, Y.J.; Lee, S.; Hong, S.; Kim, G.I. Flux behavior and membrane fouling in pressure-assisted forward osmosis. Desalination Water Treat. 2014, 52, 564–569. [Google Scholar] [CrossRef]

- Blandin, G.; Vervoort, H.; Verliefde, A.; Le-Clech, P. Critical evaluation of pressure assisted osmosis (PAO): Impact of hydraulic pressure on water flux, fouling and economics. In Proceedings of the IFOA World Summit, Lisbon, Portugal, 18–19 September 2014.

- Cornelissen, E.R.; Harmsen, D.; de Korte, K.F.; Ruiken, C.J.; Qin, J.-J.; Oo, H.; Wessels, L.P. Membrane fouling and process performance of forward osmosis membranes on activated sludge. J. Membr. Sci. 2008, 319, 158–168. [Google Scholar] [CrossRef]

- Boo, C.; Elimelech, M.; Hong, S. Fouling control in a forward osmosis process integrating seawater desalination and wastewater reclamation. J. Membr. Sci. 2013, 444, 148–156. [Google Scholar] [CrossRef]

- Li, Z.-Y.; Yangali-Quintanilla, V.; Valladares-Linares, R.; Li, Q.; Zhan, T.; Amy, G. Flux patterns and membrane fouling propensity during desalination of seawater by forward osmosis. Water Res. 2012, 46, 195–204. [Google Scholar] [CrossRef] [PubMed]

- Mi, B.; Elimelech, M. Chemical and physical aspects of organic fouling of forward osmosis membranes. J. Membr. Sci. 2008, 320, 292–302. [Google Scholar] [CrossRef]

- Mi, B.; Elimelech, M. Organic fouling of forward osmosis membranes: Fouling reversibility and cleaning without chemical reagents. J. Membr. Sci. 2010, 348, 337–345. [Google Scholar] [CrossRef]

- Parida, V.; Ng, H.Y. Forward osmosis organic fouling: Effects of organic loading, calcium and membrane orientation. Desalination 2013, 312, 88–98. [Google Scholar] [CrossRef]

- She, Q.; Jin, X.; Li, Q.; Tang, C.Y. Relating reverse and forward solute diffusion to membrane fouling in osmotically driven membrane processes. Water Res. 2012, 46, 2478–2486. [Google Scholar] [CrossRef] [PubMed]

- Valladares Linares, R.; Yangali-Quintanilla, V.; Li, Z.; Amy, G. Nom and tep fouling of a forward osmosis (FO) membrane: Foulant identification and cleaning. J. Membr. Sci. 2012, 421–422, 217–224. [Google Scholar] [CrossRef]

- Zhao, S.; Zou, L.; Mulcahy, D. Effects of membrane orientation on process performance in forward osmosis applications. J. Membr. Sci. 2011, 382, 308–315. [Google Scholar] [CrossRef]

- Liu, Y.; Mi, B. Combined fouling of forward osmosis membranes: Synergistic foulant interaction and direct observation of fouling layer formation. J. Membr. Sci. 2012, 407–408, 136–144. [Google Scholar] [CrossRef]

- Motsa, M.M.; Mamba, B.B.; D’Haese, A.; Hoek, E.M.V.; Verliefde, A.R.D. Organic fouling in forward osmosis membranes: The role of feed solution chemistry and membrane structural properties. J. Membr. Sci. 2014, 460, 99–109. [Google Scholar] [CrossRef]

- Mi, B.; Elimelech, M. Silica scaling and scaling reversibility in forward osmosis. Desalination 2012, 312, 75–81. [Google Scholar] [CrossRef]

- Gray, G.T.; McCutcheon, J.R.; Elimelech, M. Internal concentration polarization in forward osmosis: Role of membrane orientation. Desalination 2006, 197, 1–8. [Google Scholar] [CrossRef]

- Zou, S.; Gu, Y.; Xiao, D.; Tang, C.Y. The role of physical and chemical parameters on forward osmosis membrane fouling during algae separation. J. Membr. Sci. 2011, 366, 356–362. [Google Scholar] [CrossRef]

- Goosen, M.F.A.; Sablani, S.S.; Al-Hinai, H.; Al-Obeidani, S.; Al-Belushi, R.; Jackson, D. Fouling of reverse osmosis and ultrafiltration membranes: A critical review. Sep. Sci. Technol. 2004, 39, 2261–2297. [Google Scholar] [CrossRef]

- Field, R.W.; Wu, D.; Howell, J.A.; Gupta, B.B. Critical flux concept for microfiltration fouling. J. Membr. Sci. 1995, 100, 259–272. [Google Scholar] [CrossRef]

- Le Clech, P.; Jefferson, B.; Chang, I.S.; Judd, S.J. Critical flux determination by the flux-step method in a submerged membrane bioreactor. J. Membr. Sci. 2003, 227, 81–93. [Google Scholar] [CrossRef]

- Monclus, H.; Zacharias, S.; Santos, A.; Pidou, M.; Judd, S. Criticality of flux and aeration for a hollow fiber membrane bioreactor. Sep. Sci. Technol. 2010, 45, 956–961. [Google Scholar] [CrossRef]

- Stoller, M. Effective fouling inhibition by critical flux based optimization methods on a NF membrane module for olive mill wastewater treatment. Chem. Eng. J. 2011, 168, 1140–1148. [Google Scholar] [CrossRef]

- Chong, T.H.; Fane, A.G. Implications of critical flux and cake enhanced osmotic pressure (CEOP) on colloidal fouling in reverse osmosis: Modeling approach. Desalination Water Treat. 2009, 8, 68–90. [Google Scholar] [CrossRef]

- Tang, C.Y.; She, Q.; Lay, W.C.L.; Wang, R.; Fane, A.G. Coupled effects of internal concentration polarization and fouling on flux behavior of forward osmosis membranes during humic acid filtration. J. Membr. Sci. 2010, 354, 123–133. [Google Scholar] [CrossRef]

- Blandin, G.; Vervoort, H.; Le-Clech, P.; Verliefde, A.R.D. Fouling and cleaning of high permeability forward osmosis membranes. J. Water Process Eng. 2016, 9, 161–169. [Google Scholar] [CrossRef]

- Kim, Y.; Elimelech, M.; Shon, H.K.; Hong, S. Combined organic and colloidal fouling in forward osmosis: Fouling reversibility and the role of applied pressure. J. Membr. Sci. 2014, 460, 206–212. [Google Scholar] [CrossRef]

- Blandin, G.; Verliefde, A.R.D.; Le-Clech, P. Pressure enhanced fouling and adapted anti-fouling strategy in pressure assisted osmosis (PAO). J. Membr. Sci. 2015, 493, 557–567. [Google Scholar] [CrossRef]

- Xie, M.; Lee, J.; Nghiem, L.D.; Elimelech, M. Role of pressure in organic fouling in forward osmosis and reverse osmosis. J. Membr. Sci. 2015, 493, 748–754. [Google Scholar] [CrossRef]

- Yun, T.; Koo, J.W.; Sohn, J.; Lee, S. Pressure assisted forward osmosis for shale gas wastewater treatment. Desalination Water Treat. 2015, 54, 829–837. [Google Scholar] [CrossRef]

- Hilal, N.; Ogunbiyi, O.O.; Miles, N.J.; Nigmatullin, R. Methods employed for control of fouling in MF and UF membranes: A comprehensive review. Sep. Sci. Technol. 2005, 40, 1957–2005. [Google Scholar] [CrossRef]

- Duong, P.H.H.; Chung, T.-S. Application of thin film composite membranes with forward osmosis technology for the separation of emulsified oil–water. J. Membr. Sci. 2014, 452, 117–126. [Google Scholar] [CrossRef]

- Gu, Y.; Wang, Y.N.; Wei, J.; Tang, C.Y. Organic fouling of thin-film composite polyamide and cellulose triacetate forward osmosis membranes by oppositely charged macromolecules. Water Res. 2013, 47, 1867–1874. [Google Scholar] [CrossRef] [PubMed]

- Artuǧ, G.; Hapke, J. Characterization of nanofiltration membranes by their morphology, charge and filtration performance parameters. Desalination 2006, 200, 178–180. [Google Scholar] [CrossRef]

- Tang, C.Y.; Kwon, Y.N.; Leckie, J.O. Effect of membrane chemistry and coating layer on physiochemical properties of thin film composite polyamide RO and NF membranes. II. Membrane physiochemical properties and their dependence on polyamide and coating layers. Desalination 2009, 242, 168–182. [Google Scholar] [CrossRef]

- Duong, P.H.H.; Chung, T.S.; Wei, S.; Irish, L. Highly permeable double-skinned forward osmosis membranes for anti-fouling in the emulsified oil–water separation process. Environ. Sci. Technol. 2014, 48, 4537–4545. [Google Scholar] [CrossRef] [PubMed]

- Romero-Vargas Castrillón, S.; Lu, X.; Shaffer, D.L.; Elimelech, M. Amine enrichment and poly(ethylene glycol) (PEG) surface modification of thin-film composite forward osmosis membranes for organic fouling control. J. Membr. Sci. 2014, 450, 331–339. [Google Scholar] [CrossRef]

- Nguyen, A.; Zou, L.; Priest, C. Evaluating the antifouling effects of silver nanoparticles regenerated by TiO2 on forward osmosis membrane. J. Membr. Sci. 2014, 454, 264–271. [Google Scholar] [CrossRef]

- Valladares Linares, R.; Li, Z.; Yangali-Quintanilla, V.; Li, Q.; Amy, G. Cleaning protocol for a FO membrane fouled in wastewater reuse. Desalination Water Treat. 2013, 51, 4821–4824. [Google Scholar] [CrossRef]

- Achilli, A.; Cath, T.Y.; Marchand, E.A.; Childress, A.E. The forward osmosis membrane bioreactor: A low fouling alternative to MBR processes. Desalination 2009, 239, 10–21. [Google Scholar] [CrossRef]

- Lay, W.C.L.; Zhang, J.; Tang, C.; Wang, R.; Liu, Y.; Fane, A.G. Factors affecting flux performance of forward osmosis systems. J. Membr. Sci. 2012, 394–395, 151–168. [Google Scholar] [CrossRef]

- Valladares Linares, R.; Li, Z.; Abu-Ghdaib, M.; Wei, C.H.; Amy, G.; Vrouwenvelder, J.S. Water harvesting from municipal wastewater via osmotic gradient: An evaluation of process performance. J. Membr. Sci. 2013, 447, 50–56. [Google Scholar] [CrossRef]

- Ramon, G.Z.; Nguyen, T.V.; Hoek, E.M.V. Osmosis-assisted cleaning of organic-fouled seawater RO membranes. Chem. Eng. J. 2013, 218, 173–182. [Google Scholar] [CrossRef]

- Schwarzenbach, R.P.; Escher, B.I.; Fenner, K.; Hofstetter, T.B.; Johnson, C.A.; Von Gunten, U.; Wehrli, B. The challenge of micropollutants in aquatic systems. Science 2006, 313, 1072–1077. [Google Scholar] [CrossRef] [PubMed]

- Siegrist, H.; Joss, A. Review on the fate of organic micropollutants in wastewater treatment and water reuse with membranes. Water Sci. Technol. 2012, 66, 1369–1376. [Google Scholar] [CrossRef] [PubMed]

- Xie, M.; Nghiem, L.D.; Price, W.E.; Elimelech, M. Relating rejection of trace organic contaminants to membrane properties in forward osmosis: Measurements, modelling and implications. Water Res. 2014, 49, 265–274. [Google Scholar] [CrossRef] [PubMed]

| Company | Type | Commercial Name | Status | FO Performance | Ref. | ||

|---|---|---|---|---|---|---|---|

| Draw | Jw | Js/Jw | |||||

| L·m−2·h−1 | g·L−1 | ||||||

| HTI | flat-sheet | CTA-NW | commercial | 2M NaCl | 8.5 | 0.1 | [96] |

| HTI | flat-sheet | CTA-ES | commercial | 1M NaCl | 10.1 | 0.5 | [97] |

| HTI | flat-sheet | TFC | commercial | 1M NaCl | 10 | 0.8 | [97] |

| Oasys | flat-sheet | TFC | pre-commercial | 1M NaCl | 30 | 0.7 | [97] |

| Woongjin Chemicals | flat-sheet | TFC-1 | development | 1M KCl | 16 | 1.3 | [98] |

| Woongjin Chemicals | flat-sheet | TFC-2 | development | 1M KCl | 27.9 | 0.4 | [99] |

| Aquaporin | flat-sheet | AqP | pre-commercial | 1M NaCl | 9.5 | [100] | |

| CSM-Toray | flat-sheet | FO membrane | commercial | 1M NaCl | 35.0 | <0.5 | [101] |

| Porifera | flat-sheet | PFO elements | commercial | 1M NaCl | 33.0 | 0.2–0.6 | [102] |

| Samsung | hollow fiber | HFFO lumens | development | 1M KCl | 9.3 | 0.6 | [103] |

| Toyobo | hollow fiber | – | commercial | – | – | – | [95] |

| Module | Feed Spacer | Draw Spacer | Filtration Surface (m2) | CFV Feed (cm·s−1) | P Feed (bar) | CFV Draw (cm·s−1) | P Draw (bar) | Ref. |

|---|---|---|---|---|---|---|---|---|

| Prototype | RO feed spacer | RO feed spacer | 0.94 | 0.1 | n.r. a | 0.1 | 2 | [107] |

| 4040 | 2.5mm RO feed spacer | n.r.a | 1.58 | 5 | n.r. a | 1.5 | n.r. a | [108] |

| 4040-MS | 1.14mm RO feed spacer | Permeate carrier | 3.2 | 16 | 1.22 | 4.3 | 1 | [109] |

| 8040-MS | 1.14mm RO feed spacer | Permeate carrier | 11.2 | 62 | n.r. a | 0.4 | 2 | [110] |

| 8040-CS | 2.5mm RO feed spacer | Permeate carrier | 9 | 30 | <1 | 0.4 | <0.7 | [110] |

| 4040-MS | 1.14mm RO feed spacer | n.r. a | 3.3 | 15 | 0.7–1.1 | 10.0 | 0.5 | [111] |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blandin, G.; Verliefde, A.R.D.; Comas, J.; Rodriguez-Roda, I.; Le-Clech, P. Efficiently Combining Water Reuse and Desalination through Forward Osmosis—Reverse Osmosis (FO-RO) Hybrids: A Critical Review. Membranes 2016, 6, 37. https://doi.org/10.3390/membranes6030037

Blandin G, Verliefde ARD, Comas J, Rodriguez-Roda I, Le-Clech P. Efficiently Combining Water Reuse and Desalination through Forward Osmosis—Reverse Osmosis (FO-RO) Hybrids: A Critical Review. Membranes. 2016; 6(3):37. https://doi.org/10.3390/membranes6030037

Chicago/Turabian StyleBlandin, Gaetan, Arne R.D. Verliefde, Joaquim Comas, Ignasi Rodriguez-Roda, and Pierre Le-Clech. 2016. "Efficiently Combining Water Reuse and Desalination through Forward Osmosis—Reverse Osmosis (FO-RO) Hybrids: A Critical Review" Membranes 6, no. 3: 37. https://doi.org/10.3390/membranes6030037