Comparison of Polytetrafluoroethylene Flat-Sheet Membranes with Different Pore Sizes in Application to Submerged Membrane Bioreactor

Abstract

:1. Introduction

2. Experimental Section

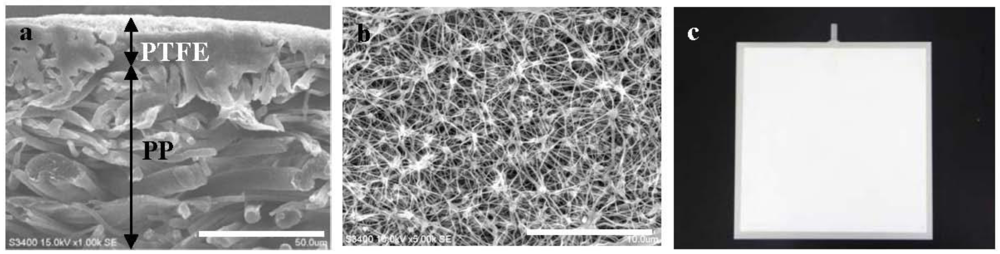

2.1. Membrane Characteristics and Experimental MBR Set-Up

| Nominal pore size [μm] | Pore size range [μm] a | Contact angle [°] | Membrane thickness [μm] | Pore morphology | Surface porosity [%] |

|---|---|---|---|---|---|

| 0.3 | 0.2–0.4 | 135 | 25 ± 10 | symmetric | 85 |

| 0.5 | 0.4–0.7 | 135 | 15 ± 10 | symmetric | 88 |

| 1.0 | 0.7–1.3 | 135 | 10 ± 10 | symmetric | 90 |

2.2. Synthetic Wastewater and Operational Conditions

2.3. Membrane Cleaning and Membrane Resistance Measurement

2.4. Scanning Electron Microscope (SEM) Analysis

2.5. Analytical Methods

3. Results and Discussion

3.1. Filtration Performance of Each Membrane Module

3.2. Membrane Resistance of Each Module

3.3. Correlation between Membrane Resistances and Transmembrane Pressure

3.4. SEM Examination of Membrane Surfaces

4. Conclusions

Acknowledgments

References

- Xue, Y.; Yang, F.; Liu, S.; Fu, Z. The influence of controlling factors on the start-up and operation for partial nitrification in membrane bioreactor. Bioresour. Technol. 2009, 100, 1055–1060. [Google Scholar] [CrossRef]

- Meng, F.G.; Yang, F.L.; Shi, B.Q.; Zhang, H.M. A comprehensive study on membrane fouling in submerged membrane bioreactors operated under different aeration intensities. Sep. Purif. Technol. 2008, 59, 91–100. [Google Scholar] [CrossRef]

- Le-Clech, P.; Chen, V.; Fane, T.A.G. Fouling in membranebioreactors used in wastewater treatment. J. Membr. Sci. 2006, 284, 17–53. [Google Scholar] [CrossRef]

- Yang, W.; Cicek, N.; Ilg, J. State-of-the-art of membrane bioreactors: Worldwide research and commercial applications in North America. J. Membr. Sci. 2006, 270, 201–211. [Google Scholar] [CrossRef]

- Yamato, N.; Kimura, K.; Miyoshi, T.; Watanabe, Y. Difference in membrane fouling in membrane bioreactors (MBRs) caused by membrane polymer materials. J. Membr. Sci. 2006, 280, 911–919. [Google Scholar] [CrossRef]

- Choi, J.-H.; Ng, H.Y. Effect of membrane type and material on performance of a submerged membrane bioreactor. Chemosphere 2008, 71, 853–859. [Google Scholar] [CrossRef]

- Liao, B.Q.; Bagley, D.M.; Kraemer, H.E.; Leppard, G.G.; Liss, S.N. A review of biofouling and its control in membrane separation bioreactors. Water Environ. Res. 2004, 76, 425–436. [Google Scholar] [CrossRef]

- Choi, J.-H.; Park, S.-K.; Ng, H.-Y. Membrane fouling in a submerged membrane bioreactor using track-etched and phase-inversed porous membranes. Sep. Purif. Technol. 2009, 65, 184–192. [Google Scholar] [CrossRef]

- Ou, S.-H.; You, S.-J.; Lee, Y.-C. Extracellular polymeric substance characteristics and fouling formation mechanisms in submerged membrane bioreactors. Desalin. Water Treat. 2010, 18, 175–181. [Google Scholar]

- Astm F316-86, Standard Test Methods for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test; ASTM Committee on Standards: West Conshohocken, PA, USA, 1986.

- Nagashima, A. Viscosity of water substance-new international formulation and its background. J.Phys. Chem. Ref. Data 1977, 6, 1133–1166. [Google Scholar] [CrossRef]

- American Public Health Association (APHA), Standard Methods for the Examination of Water and Wastewater, 20th ed; American Public Health Association/American Water Works Association/Water Environment Federation: Washington, DC, USA, 1998.

- van der Marel, P.; Zwijnenburg, A.; Kemperman, A.; Wessling, M.; Temmink, H.; van der Meer, W. Influence of membrane properties on fouling in submerged membrane bioreactors. J. Membr. Sci. 2010, 348, 66–74. [Google Scholar] [CrossRef]

- Fan, B.; Huang, X. Characteristics of a self-forming dynamic membrane coupled with a bioreactor for municipal wastewater treatment. Environ. Sci. Technol. 2002, 36, 5245–5251. [Google Scholar] [CrossRef]

© 2012 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/3.0/).

Share and Cite

Nittami, T.; Hitomi, T.; Matsumoto, K.; Nakamura, K.; Ikeda, T.; Setoguchi, Y.; Motoori, M. Comparison of Polytetrafluoroethylene Flat-Sheet Membranes with Different Pore Sizes in Application to Submerged Membrane Bioreactor. Membranes 2012, 2, 228-236. https://doi.org/10.3390/membranes2020228

Nittami T, Hitomi T, Matsumoto K, Nakamura K, Ikeda T, Setoguchi Y, Motoori M. Comparison of Polytetrafluoroethylene Flat-Sheet Membranes with Different Pore Sizes in Application to Submerged Membrane Bioreactor. Membranes. 2012; 2(2):228-236. https://doi.org/10.3390/membranes2020228

Chicago/Turabian StyleNittami, Tadashi, Tetsuo Hitomi, Kanji Matsumoto, Kazuho Nakamura, Takaharu Ikeda, Yoshihiro Setoguchi, and Manabu Motoori. 2012. "Comparison of Polytetrafluoroethylene Flat-Sheet Membranes with Different Pore Sizes in Application to Submerged Membrane Bioreactor" Membranes 2, no. 2: 228-236. https://doi.org/10.3390/membranes2020228