New Facility for Membrane Fouling Investigations under Customizable Hydrodynamics: Validation and Preliminary Experiments with Pulsating Cross-Flow

Abstract

:1. Introduction

2. Experimental Methods

2.1. Overall Description of the Facility

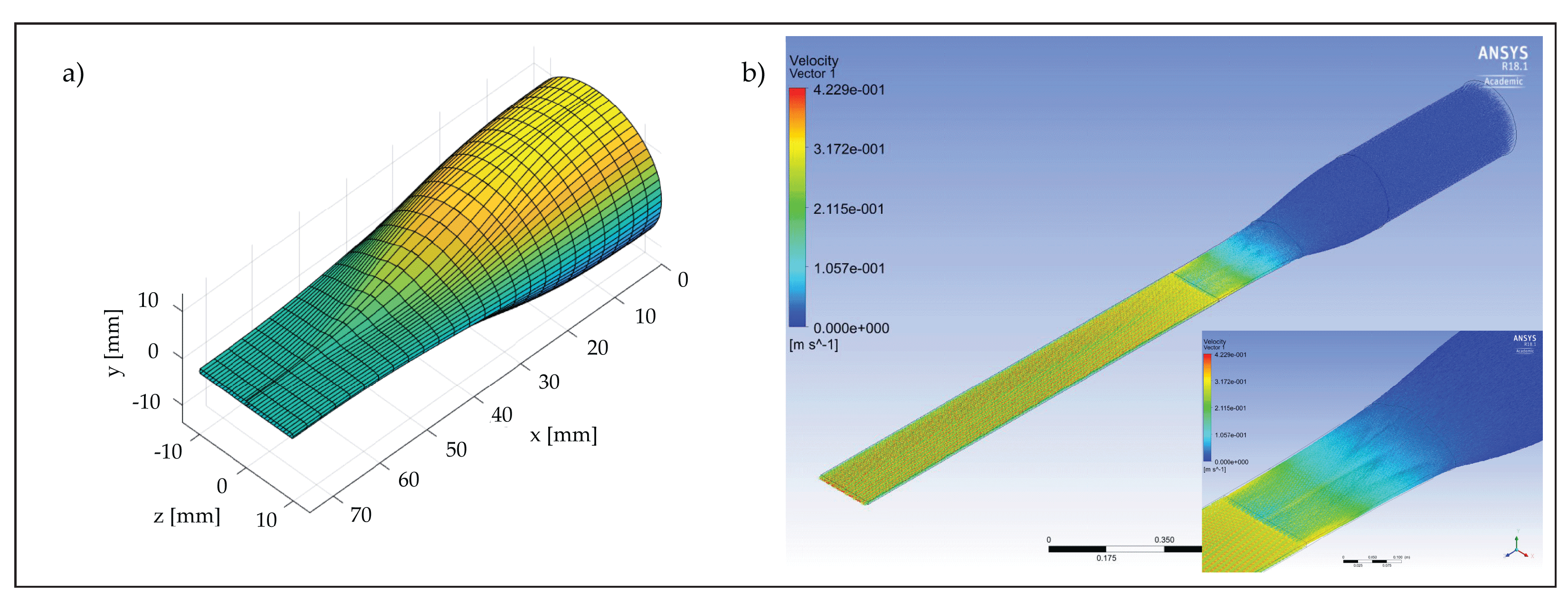

2.2. Description of the Test Section

- (i)

- The development of a so-called “canonical” channel flow (i.e., a rectangular channel flow as largely investigated within the remit of the literature pertaining to fluid dynamics) allowing for full control and extensive validation of flow properties. Following the recommendations from the literature, the channel was designed with a large aspect ratio (i.e., ratio between width and depth) of 20, which allows flow properties in the mid cross section to be independent of lateral walls and hence comparable to theoretical predictions as well as measured or numerically modeled data [15];

- (ii)

- The length, L, of the channel had to be minimized to avoid working with very large volumes of water while allowing for fully developed and self-similar flows (i.e., flows whose velocity statistics, once appropriately scaled, are independent of the longitudinal coordinate) to form. This put constraints on the height H of the channel, because the higher the H the longer is the required L to obtain fully developed flows [16].

2.3. Description of the Flow-Conditioning Unit and Pulsating Flow System

- (i)

- (ii)

- The convergent had to be gradual to avoid boundary layer separation and the potential shedding of undesired eddies resulting from boundary layer separation;

- (iii)

- The convergent shape was very unconventional (i.e., never investigated before) as it had to gradually join the bulk circular cross section of the settling chamber to the wide and thin rectangular slit of the test section.

3. Experimental Procedure and Measuring Equipment

3.1. Fluid Dynamic Tests

3.2. Filtration Tests

4. Results

4.1. Fluid Dynamic Tests

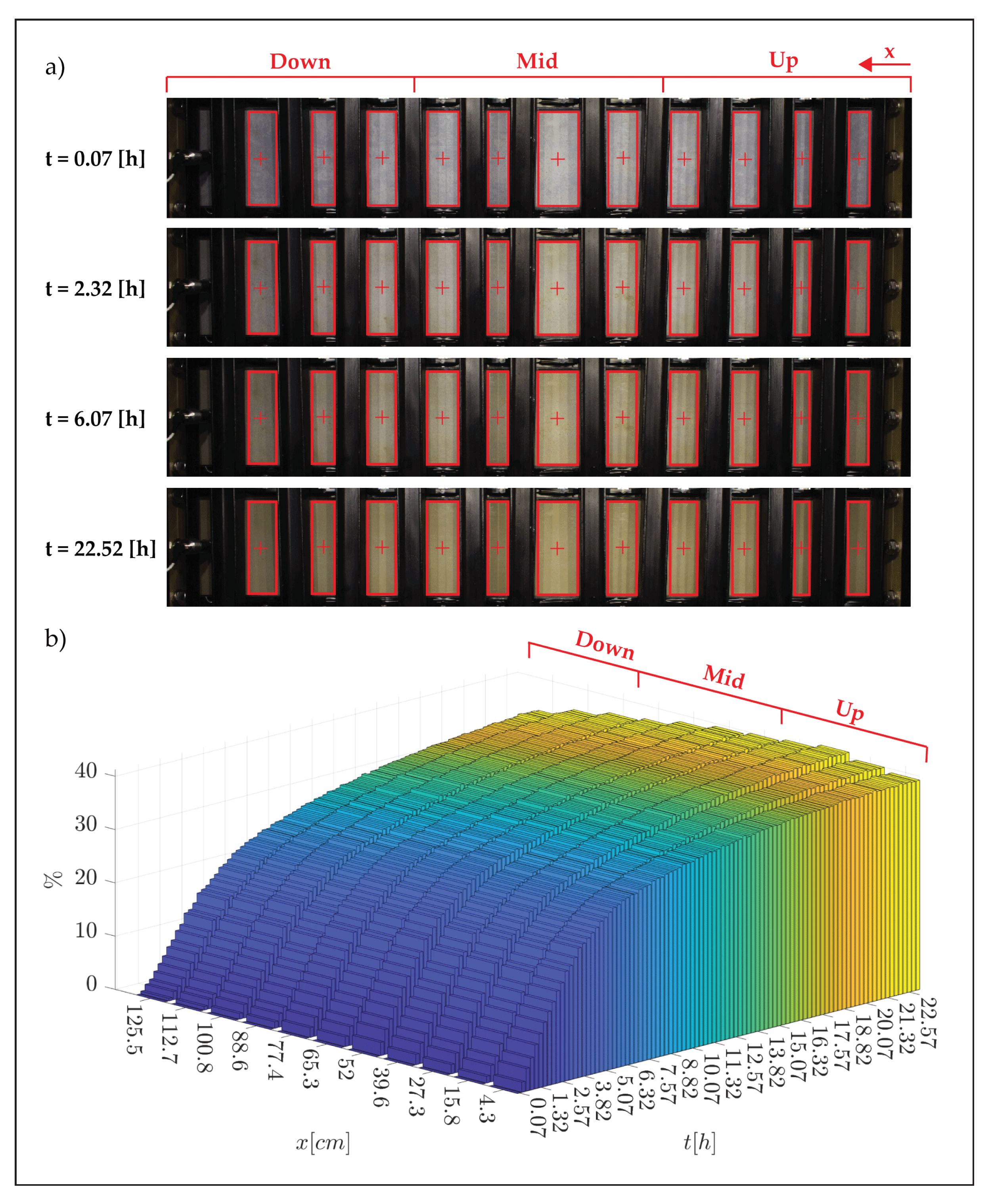

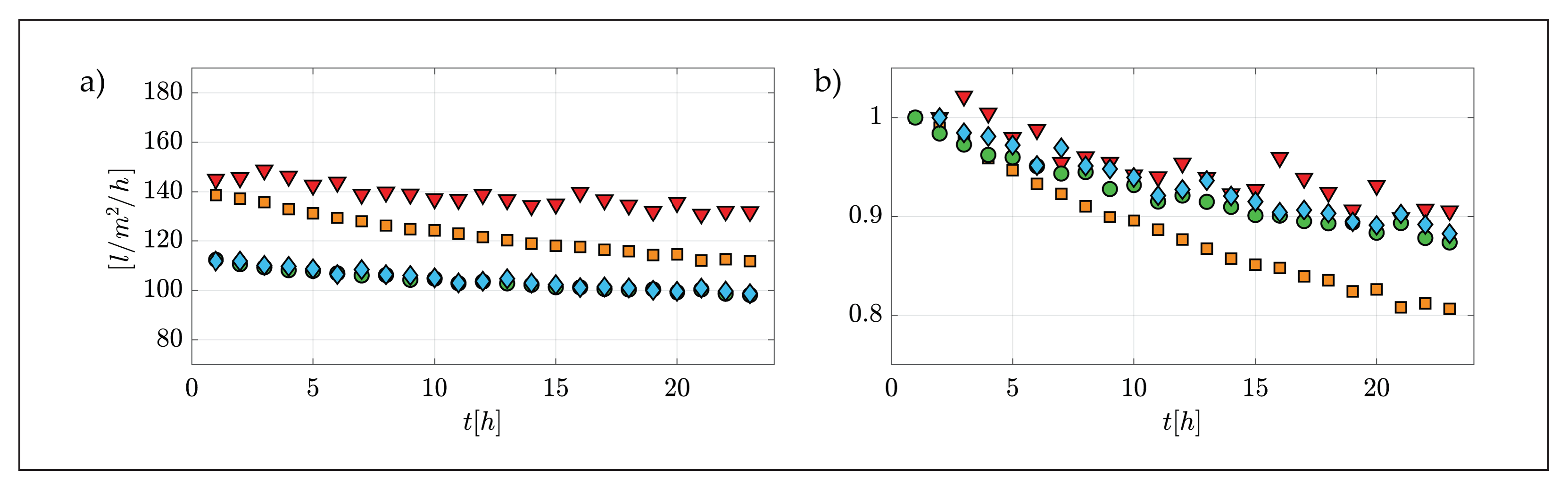

4.2. Filtration Tests

- (i)

- Filtration tests carried out in the channel facility are controllable and repeatable because tests carried out at essentially identical experimental conditions display overlapping curves of filtrate vs. time (blue and green symbols).

- (ii)

- The pulsed flow case (red triangles, see Table 2) provided much improved filtrate flux behavior over time when compared to its steady flow counterpart (orange squares), as hypothesized in Section 3.2. Note that flux differences are much greater than those associated with experimental uncertainty, as supported by the previous point about experimental repeatability. Specifically, flux values were maintained always larger than 130 in the pulsed flow case and a final normalized flux of 0.9 was achieved, thus halving the fouling-related flux reduction compared to the stead flow case. This observation suggests the potential of hydrodynamic methods to reduce colloidal fouling in ultrafiltration membrane systems.

5. Concluding Remarks

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Water, U. The United Nations World Water Development Report 2021: Valuing Water; UNESCO: Paris, France, 2021. [Google Scholar]

- Zotalis, K.; Dialynas, E.G.; Mamassis, N.; Angelakis, A.N. Desalination technologies: Hellenic experience. Water 2014, 6, 1134–1150. [Google Scholar] [CrossRef] [Green Version]

- Caldera, U.; Bogdanov, D.; Breyer, C. Local cost of seawater RO desalination based on solar PV and wind energy: A global estimate. Desalination 2016, 385, 207–216. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Cornelis, G.; Vandecasteele, C.; Devreese, I. Fouling of nanofiltration and ultrafiltration membranes applied for wastewater regeneration in the textile industry. Desalination 2005, 175, 111–119. [Google Scholar] [CrossRef]

- Allen, S.; Holena, D.; McCunn, M.; Kohl, B.; Sarani, B. A review of the fundamental principles and evidence base in the use of extracorporeal membrane oxygenation (ECMO) in critically ill adult patients. J. Intensive Care Med. 2011, 26, 13–26. [Google Scholar] [CrossRef] [PubMed]

- Daufin, G.; Escudier, J.P.; Carrère, H.; Bérot, S.; Fillaudeau, L.; Decloux, M. Recent and emerging applications of membrane processes in the food and dairy industry. Food Bioprod. Process. 2001, 79, 89–102. [Google Scholar] [CrossRef]

- Al Aani, S.; Mustafa, T.N.; Hilal, N. Ultrafiltration membranes for wastewater and water process engineering: A comprehensive statistical review over the past decade. J. Water Process Eng. 2020, 35, 101241. [Google Scholar] [CrossRef]

- Wang, F.; He, M.; Gao, K.; Su, Y.; Zhang, R.; Liu, Y.; Shen, J.; Jiang, Z.; Kasher, R. Constructing membrane surface with synergistic passive antifouling and active antibacterial strategies through organic-inorganic composite modifier. J. Membr. Sci. 2019, 576, 150–160. [Google Scholar] [CrossRef]

- Lu, X.; Arias Chavez, L.H.; Romero-Vargas Castrillon, S.; Ma, J.; Elimelech, M. Influence of active layer and support layer surface structures on organic fouling propensity of thin-film composite forward osmosis membranes. Environ. Sci. Technol. 2015, 49, 1436–1444. [Google Scholar] [CrossRef] [PubMed]

- Jaffrin, M.Y. Hydrodynamic techniques to enhance membrane filtration. Annu. Rev. Fluid Mech. 2012, 44, 77–96. [Google Scholar] [CrossRef]

- Gupta, B.; Blanpain, P.; Jaffrin, M. Permeate flux enhancement by pressure and flow pulsations in microfiltration with mineral membranes. J. Membr. Sci. 1992, 70, 257–266. [Google Scholar] [CrossRef]

- Howell, J.; Field, R.; Wu, D. Yeast cell microfiltration: Flux enhancement in baffled and pulsatile flow systems. J. Membr. Sci. 1993, 80, 59–71. [Google Scholar] [CrossRef]

- Al-haj Ali, M.; Ajbar, A.; Ali, E.; Alhumaizi, K. Optimization-based periodic forcing of RO desalination process for improved performance. Desalin. Water Treat. 2013, 51, 6961–6969. [Google Scholar] [CrossRef]

- Saremirad, P.; Gomaa, H.; Zhu, J. Effect of flow oscillations on mass transfer in electrodialysis with bipolar membrane. J. Membr. Sci. 2012, 405, 158–166. [Google Scholar] [CrossRef]

- Vinuesa, R.; Noorani, A.; Lozano-Durán, A.; Khoury, G.K.E.; Schlatter, P.; Fischer, P.F.; Nagib, H.M. Aspect ratio effects in turbulent duct flows studied through direct numerical simulation. J. Turbul. 2014, 15, 677–706. [Google Scholar] [CrossRef]

- Çengel, Y.; Cimbala, J. Fluid Mechanics: Fundamentals and Applications; McGraw-Hill Education: New York, NY, USA, 2018. [Google Scholar]

- Ferro, M. Experimental Study on Turbulent Boundary-Layer Flows with Wall Transpiration. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2017. [Google Scholar]

- Piomelli, U.; Balaras, E.; Pascarelli, A. Turbulent structures in accelerating boundary layers. J. Turbul. 2000, 1, 001. [Google Scholar] [CrossRef]

- Finnicum, D.S.; Hanratty, T.J. Effect of favorable pressure gradients on turbulent boundary layers. AIChE J. 1988, 34, 529–540. [Google Scholar] [CrossRef]

- Eckert, W.T.; Mort, K.W.; Jope, J. Aerodynamic Design Guidelines and Computer Program for Estimation of Subsonic Wind Tunnel Performance; National Aeronautics and Space Administration: Washington, DC, USA, 1976. [Google Scholar]

- Nedyalkov, I. Design of Contraction, Test Section, and Diffuser for a High-Speed Water Tunnel. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2012. [Google Scholar]

- Ramaprian, B.; Tu, S.W. An experimental study of oscillatory pipe flow at transitional Reynolds numbers. J. Fluid Mech. 1980, 100, 513–544. [Google Scholar] [CrossRef]

- Ahn, K.H.; Cha, H.Y.; Yeom, I.T.; Song, K.G. Application of nanofiltration for recycling of paper regeneration wastewater and characterization of filtration resistance. Desalination 1998, 119, 169–176. [Google Scholar] [CrossRef]

- Nikolova, J.; Islam, M. Contribution of adsorbed layer resistance to the flux-decline in an ultrafiltration process. J. Membr. Sci. 1998, 146, 105–111. [Google Scholar] [CrossRef]

- Davide, V.; Pardos, M.; Diserens, J.; Ugazio, G.; Thomas, R.; Dominik, J. Characterisation of bed sediments and suspension of the river Po (Italy) during normal and high flow conditions. Water Res. 2003, 37, 2847–2864. [Google Scholar] [CrossRef]

- Arpa Piemonte. Water Quality in Torino (2009–2017). 2020. Available online: http://webgis.arpa.piemonte.it/monitoraggio_qualita_acque/indexp.php?numcodice=001095 (accessed on 22 November 2021).

- He, S.; Jackson, J. An experimental study of pulsating turbulent flow in a pipe. Eur. J. Mech. B/Fluids 2009, 28, 309–320. [Google Scholar] [CrossRef]

- Peruzzi, C.; Poggi, D.; Ridolfi, L.; Manes, C. On the scaling of large-scale structures in smooth-bed turbulent open-channel flows. J. Fluid Mech. 2020, 889. [Google Scholar] [CrossRef]

- Tsukahara, T.; Seki, Y.; Kawamura, H.; Tochio, D. DNS of turbulent channel flow at very low Reynolds numbers. In Proceedings of the Fourth International Symposium on Turbulence and Shear Flow Phenomen, Williamsburg, VA, USA, 27–29 June 2005; Begel House Inc.: Danbury, CT, USA, 2005. [Google Scholar]

- Pope, S.B. Turbulent Flows; Cambridge University Press: Cambridge, UK, 2011. [Google Scholar]

- Tang, C.Y.; Chong, T.; Fane, A.G. Colloidal interactions and fouling of NF and RO membranes: A review. Adv. Colloid Interface Sci. 2011, 164, 126–143. [Google Scholar] [CrossRef] [PubMed]

- Kastl, A.; Bar-Zeev, E.; Spinnler, M.; Sattelmayer, T. Impact of pulsating flows on particle deposition in forward osmosis with spacers. J. Membr. Sci. 2021, 635, 119444. [Google Scholar] [CrossRef]

- Bogler, A.; Kastl, A.; Spinnler, M.; Sattelmayer, T.; Be’er, A.; Bar-Zeev, E. Where, when and why? Quantifying the relation of particle deposition to crossflow velocity and permeate water flux in forward osmosis. J. Membr. Sci. 2020, 604, 118055. [Google Scholar] [CrossRef]

| Test Name | Symbol | Coordinates [cm] | [-] | [-] | [m/s] | [m/s] |

|---|---|---|---|---|---|---|

| F-1 |  | x = 82.5, z = 5 | 3981 | 70 | 0.267 | 0.0148 |

| F-2 |  | x = 34.5, z = 5 | 3981 | 70 | 0.267 | 0.0144 |

| F-3 |  | x = 130.5, z = 5 | 4038 | 68 | 0.265 | 0.0145 |

| Test Name | Symbol | [-] | P [bar] | [] | [-] |

|---|---|---|---|---|---|

| S-4_1 |  | 4005 | 1.00 | 1.37 | - |

| S-4_1r |  | 4013 | 1.00 | 1.38 | - |

| S-4_1.5 |  | 3983 | 1.52 | 1.63 | - |

| P-4_1.5_2.5 |  | 3974 | 1.51 | 1.84 | 0.0025 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bert, R.; Manes, C.; Tiraferri, A. New Facility for Membrane Fouling Investigations under Customizable Hydrodynamics: Validation and Preliminary Experiments with Pulsating Cross-Flow. Membranes 2022, 12, 334. https://doi.org/10.3390/membranes12030334

Bert R, Manes C, Tiraferri A. New Facility for Membrane Fouling Investigations under Customizable Hydrodynamics: Validation and Preliminary Experiments with Pulsating Cross-Flow. Membranes. 2022; 12(3):334. https://doi.org/10.3390/membranes12030334

Chicago/Turabian StyleBert, Roberto, Costantino Manes, and Alberto Tiraferri. 2022. "New Facility for Membrane Fouling Investigations under Customizable Hydrodynamics: Validation and Preliminary Experiments with Pulsating Cross-Flow" Membranes 12, no. 3: 334. https://doi.org/10.3390/membranes12030334