Experimental Study and Optimization of the Organic Rankine Cycle with Pure NovecTM649 and Zeotropic Mixture NovecTM649/HFE7000 as Working Fluid

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

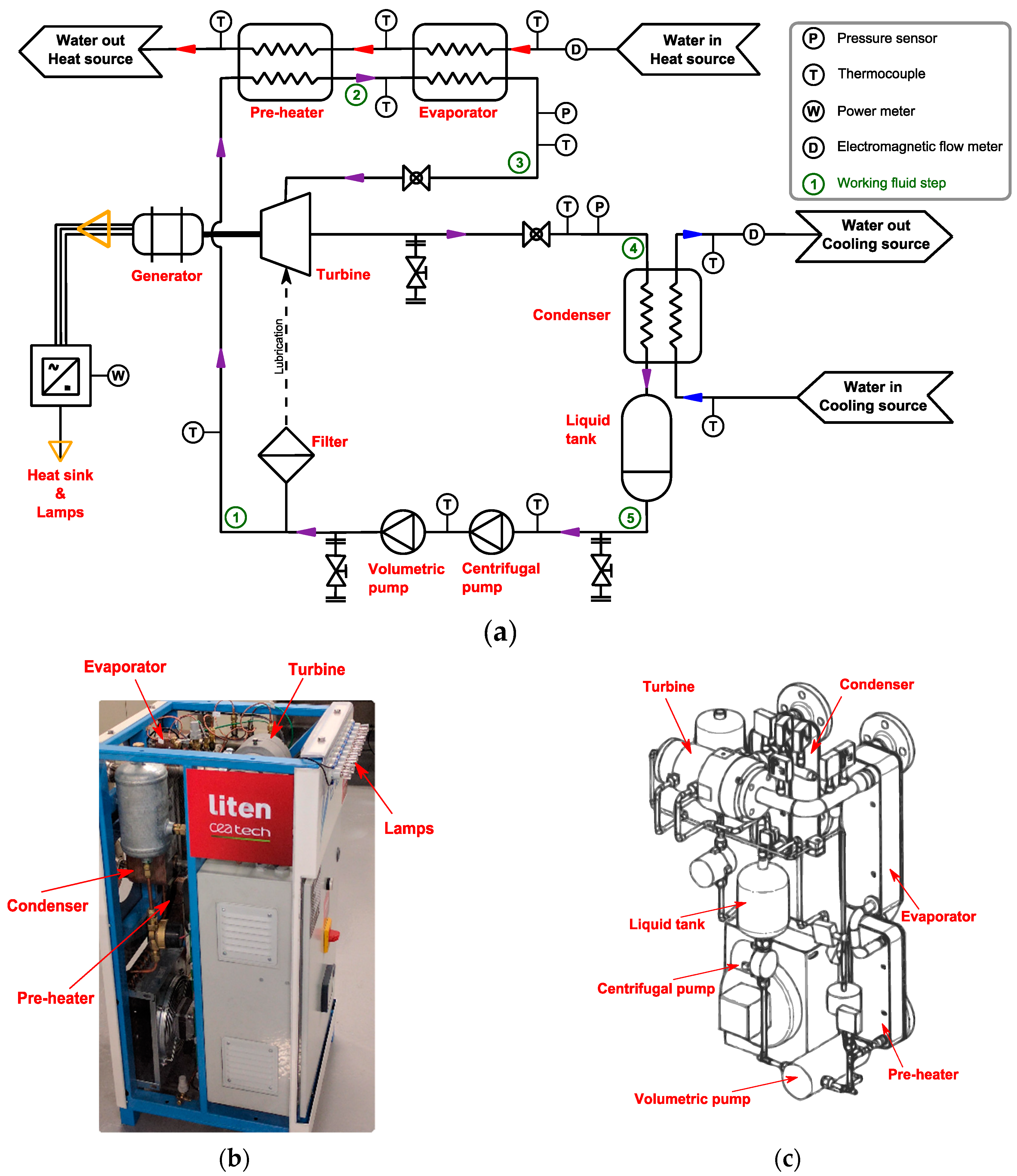

2.1. The ORC System

2.2. Heating and Cooling Loops

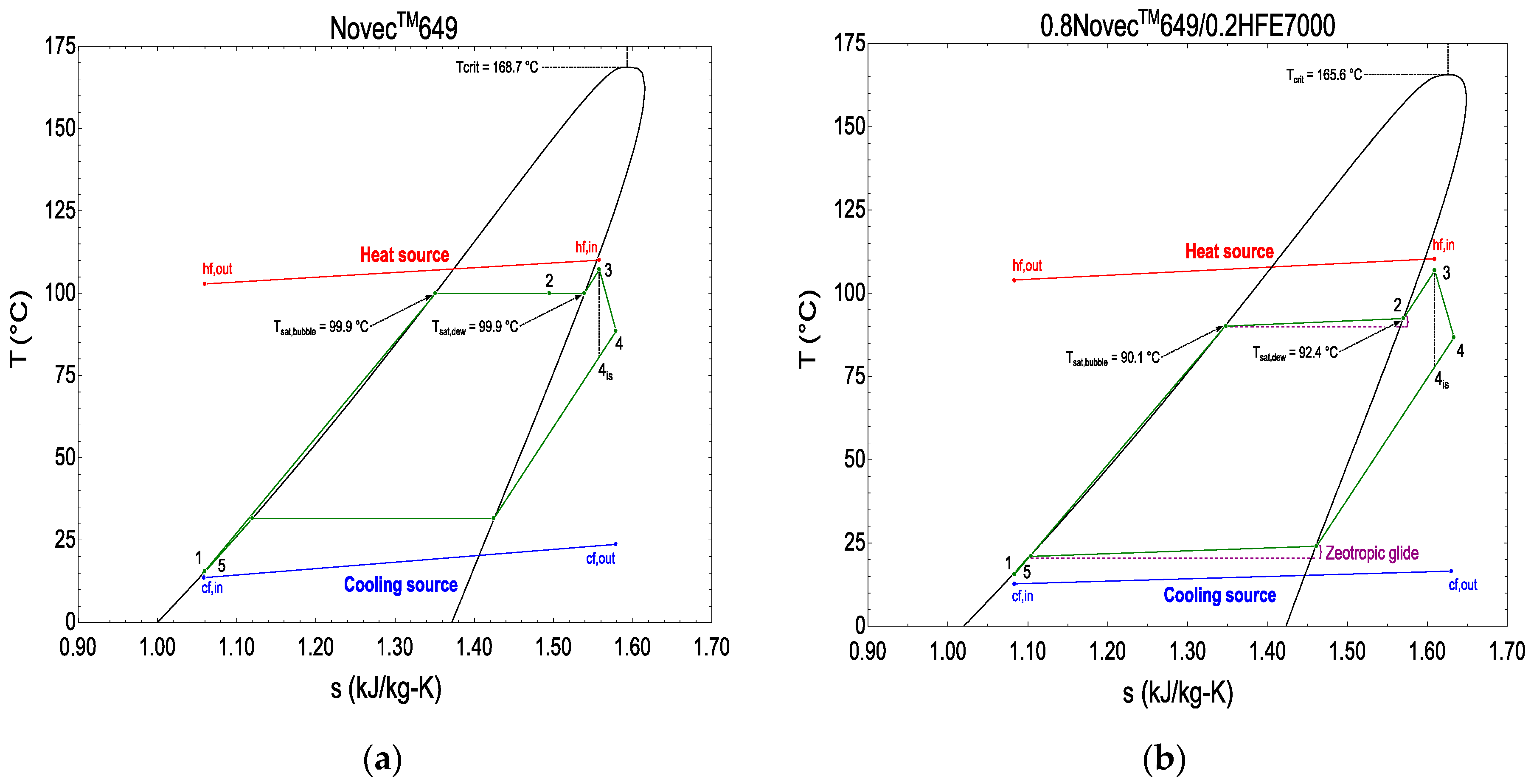

2.3. Working Fluid Selection

2.4. Instrumentation

3. Data Processing

3.1. Experimental Investigation

3.2. Thermodynamic Investigation

3.2.1. Performances Analysis and Calculation

3.2.2. Mass Flow Rate Reconciliation

4. Results and Discussion

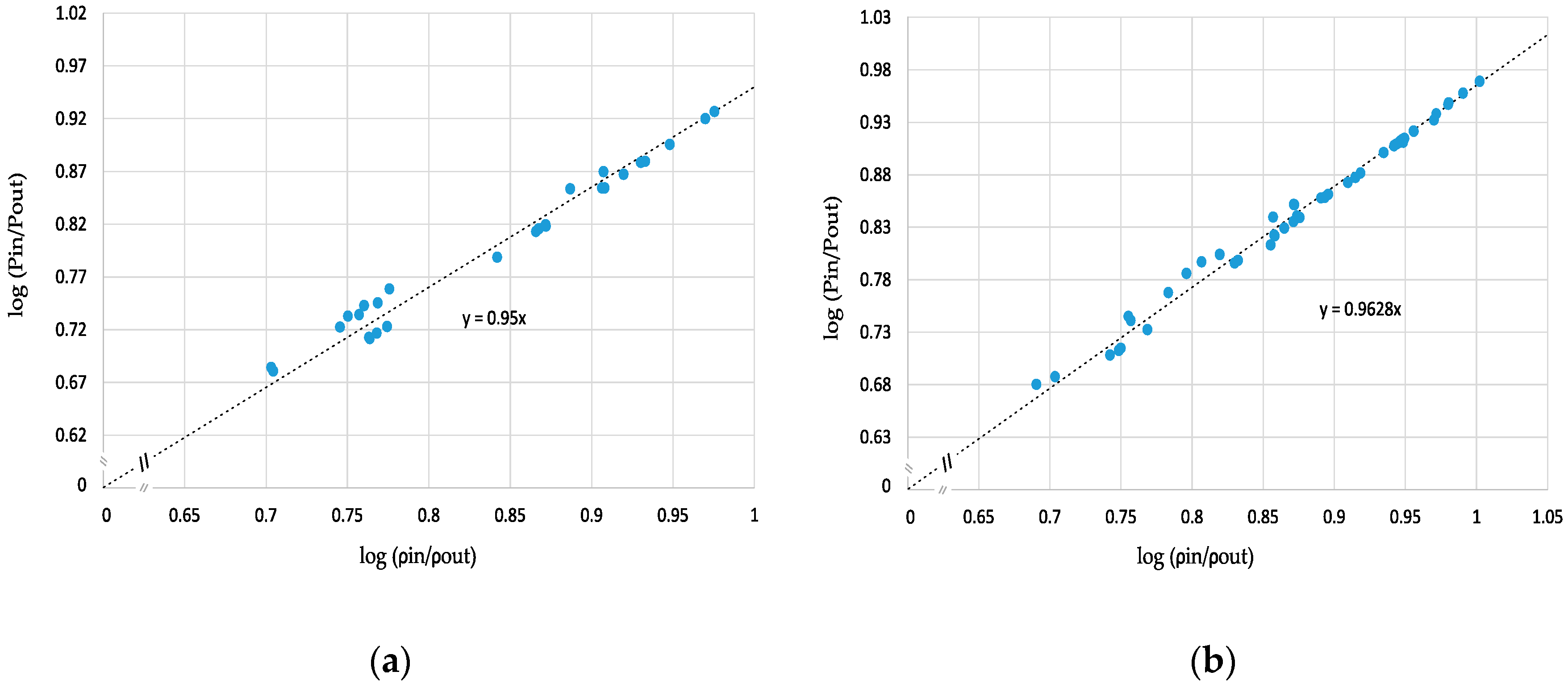

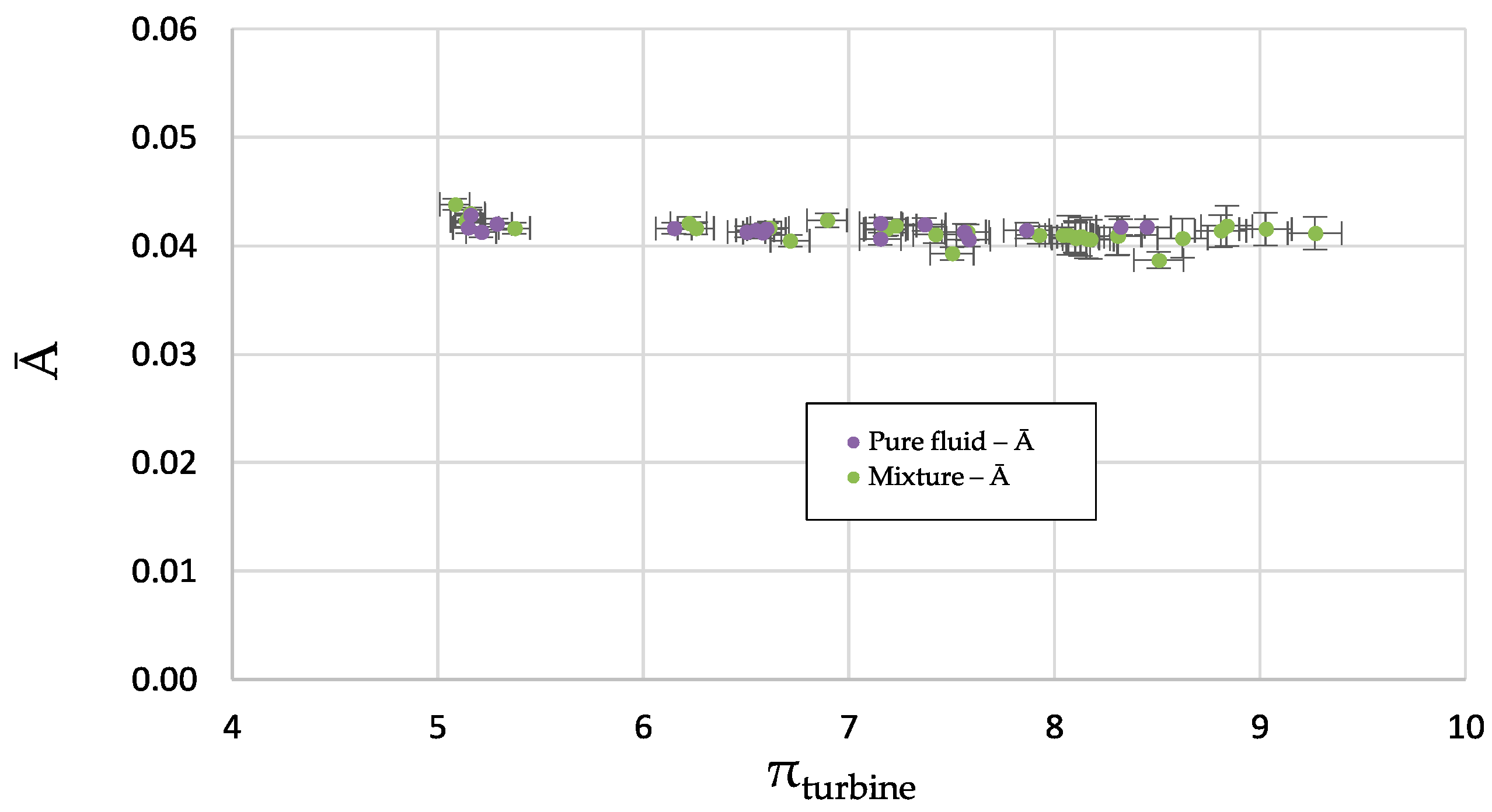

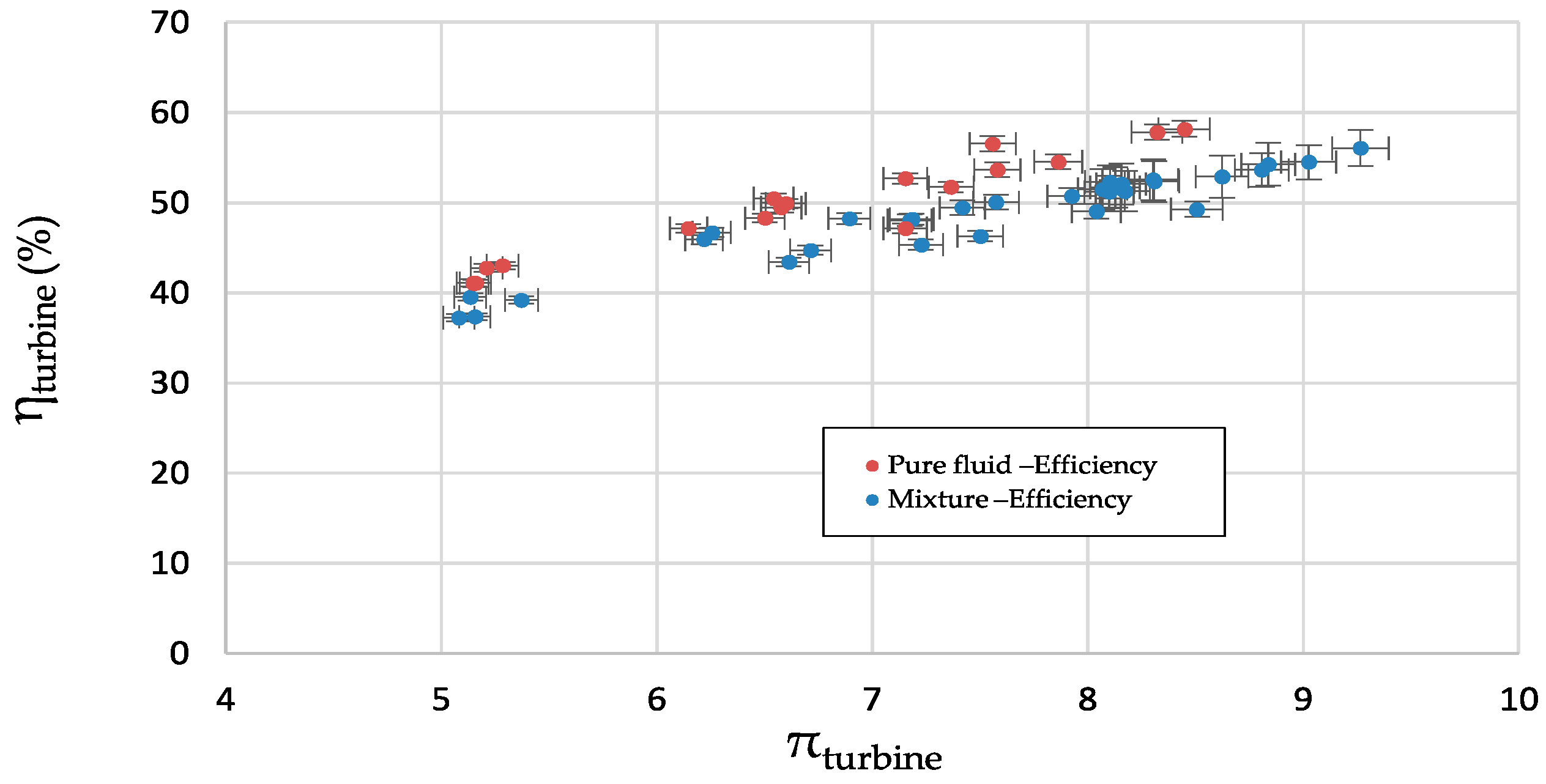

4.1. Turbine Performances

4.2. ORC Performances

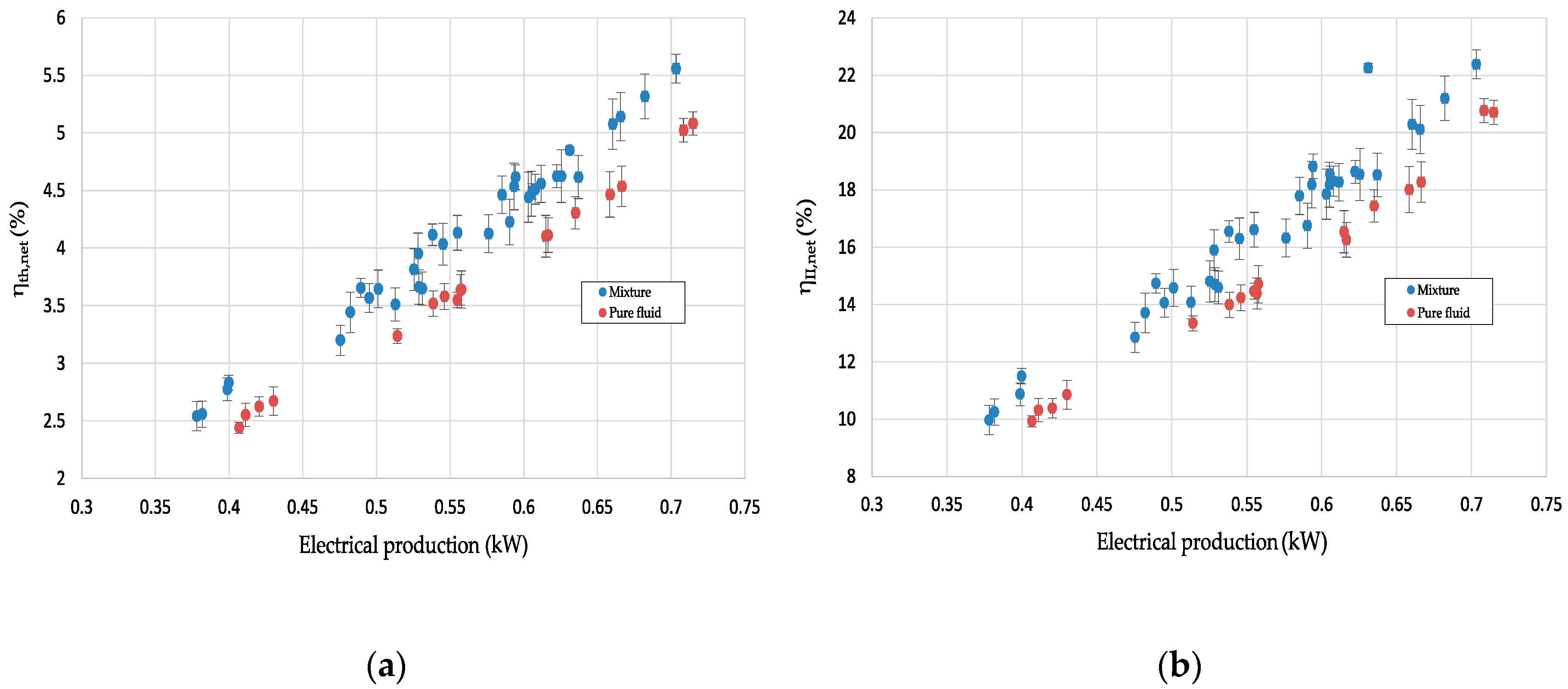

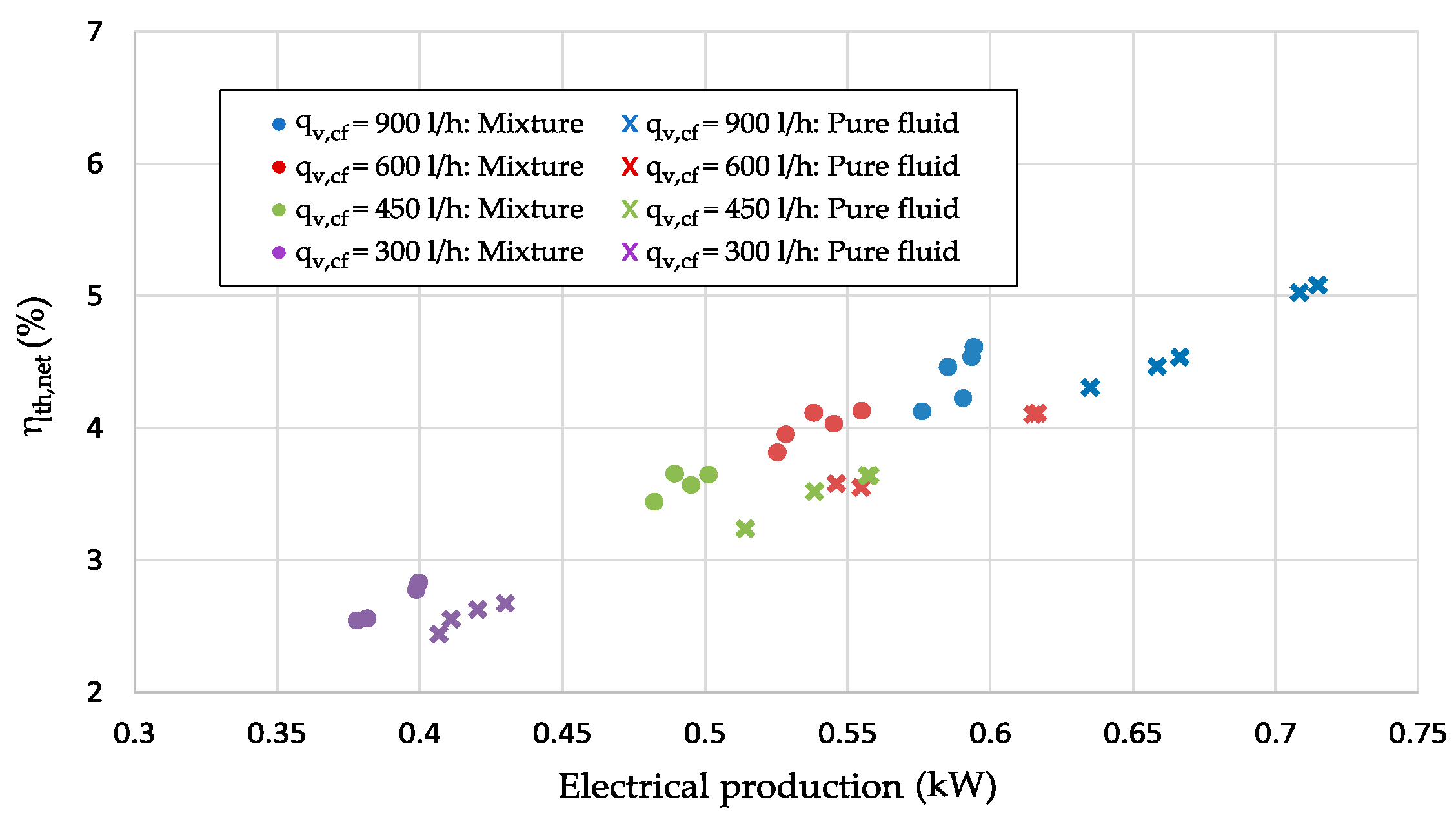

4.2.1. Pure Fluid and Mixture Comparison

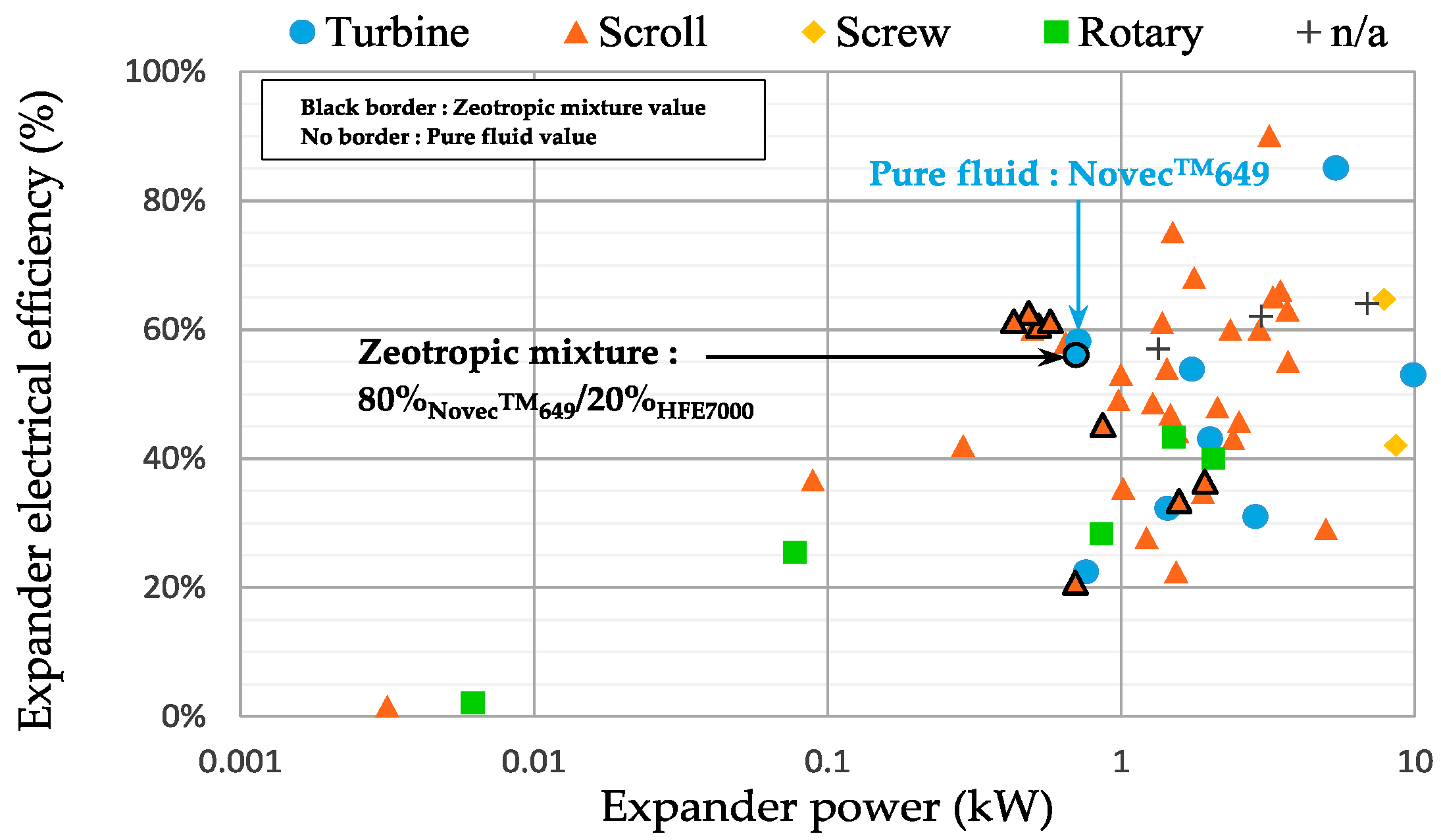

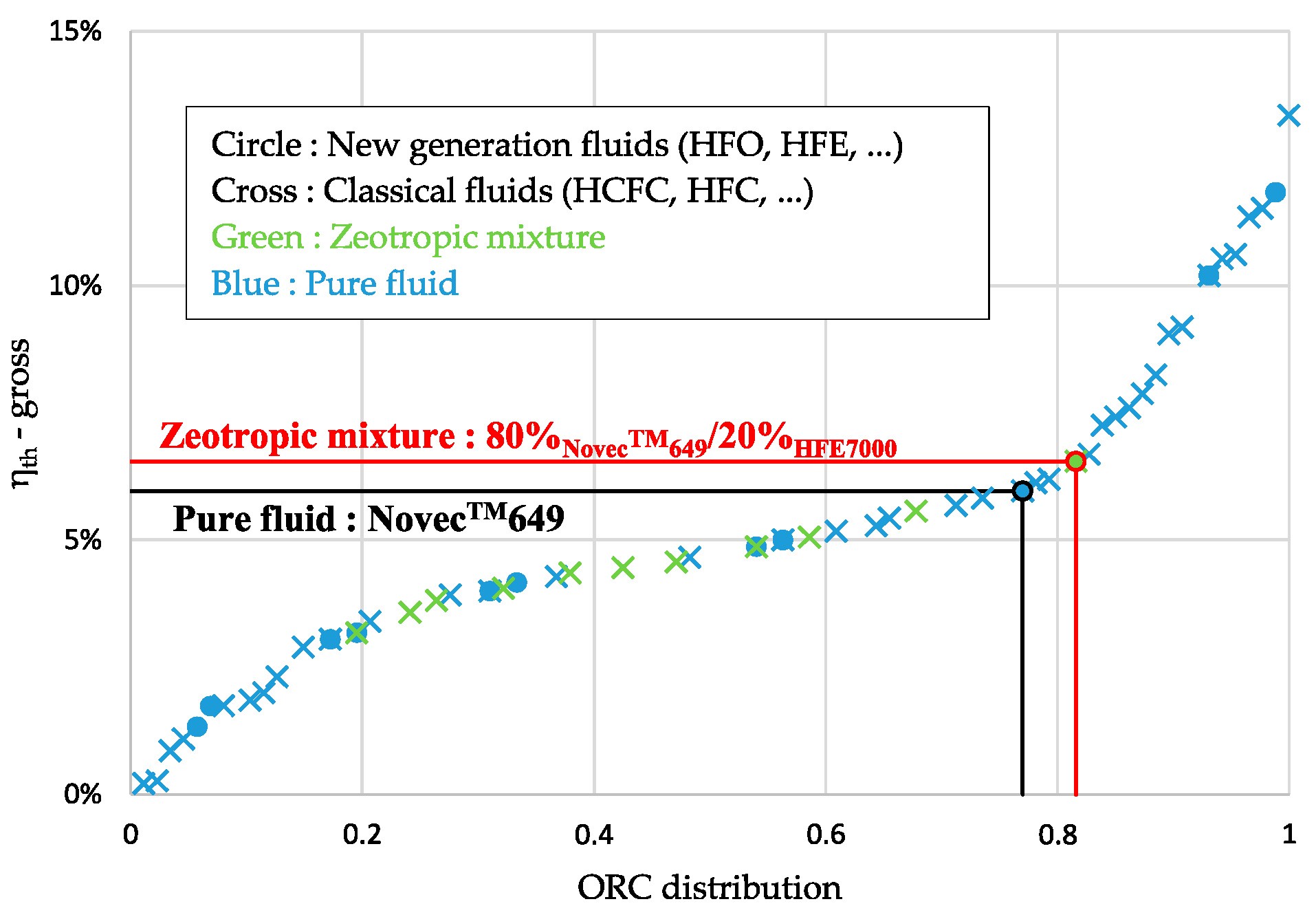

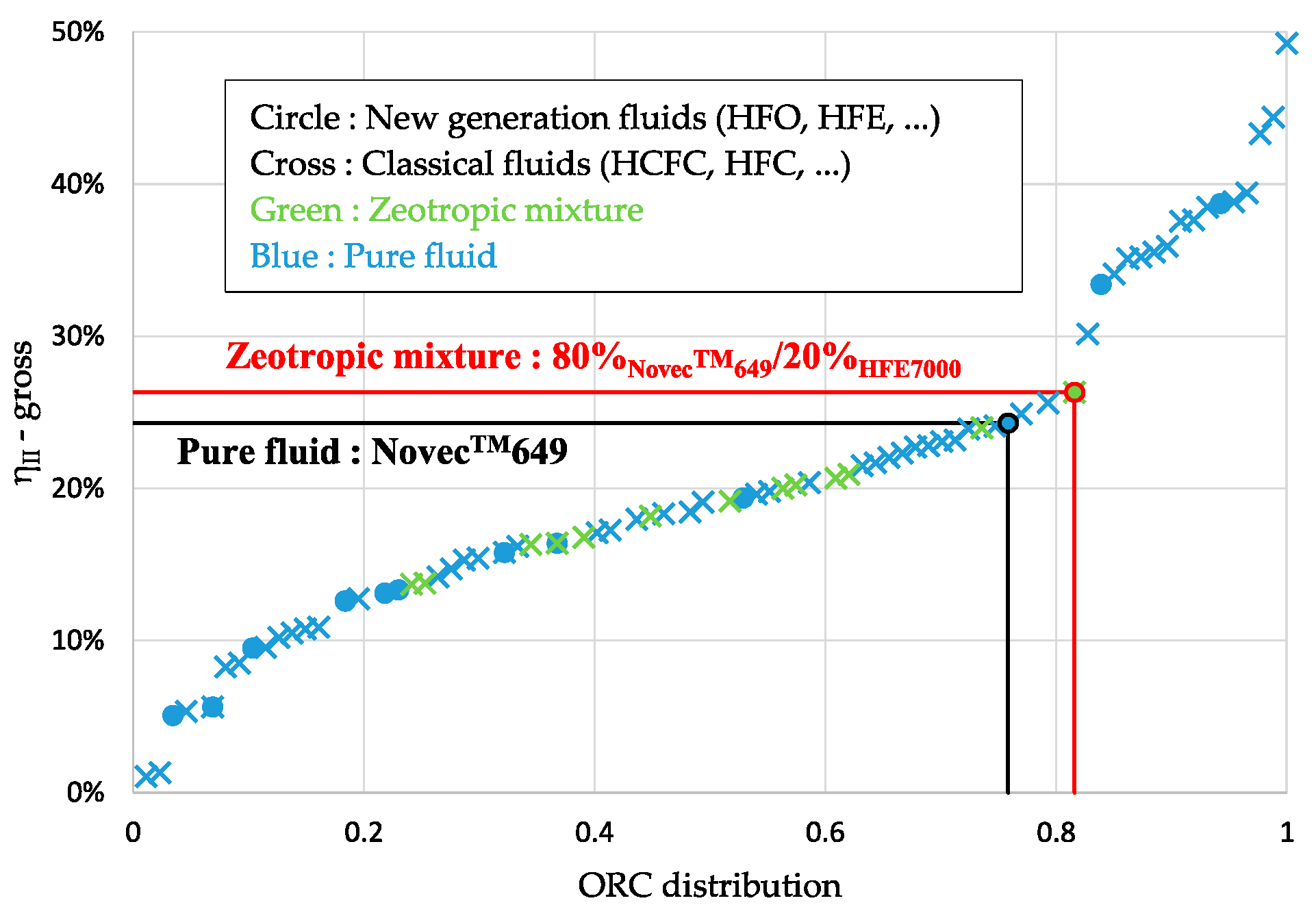

4.2.2. ORC Literature Comparison

4.2.3. Cycle High Pressure

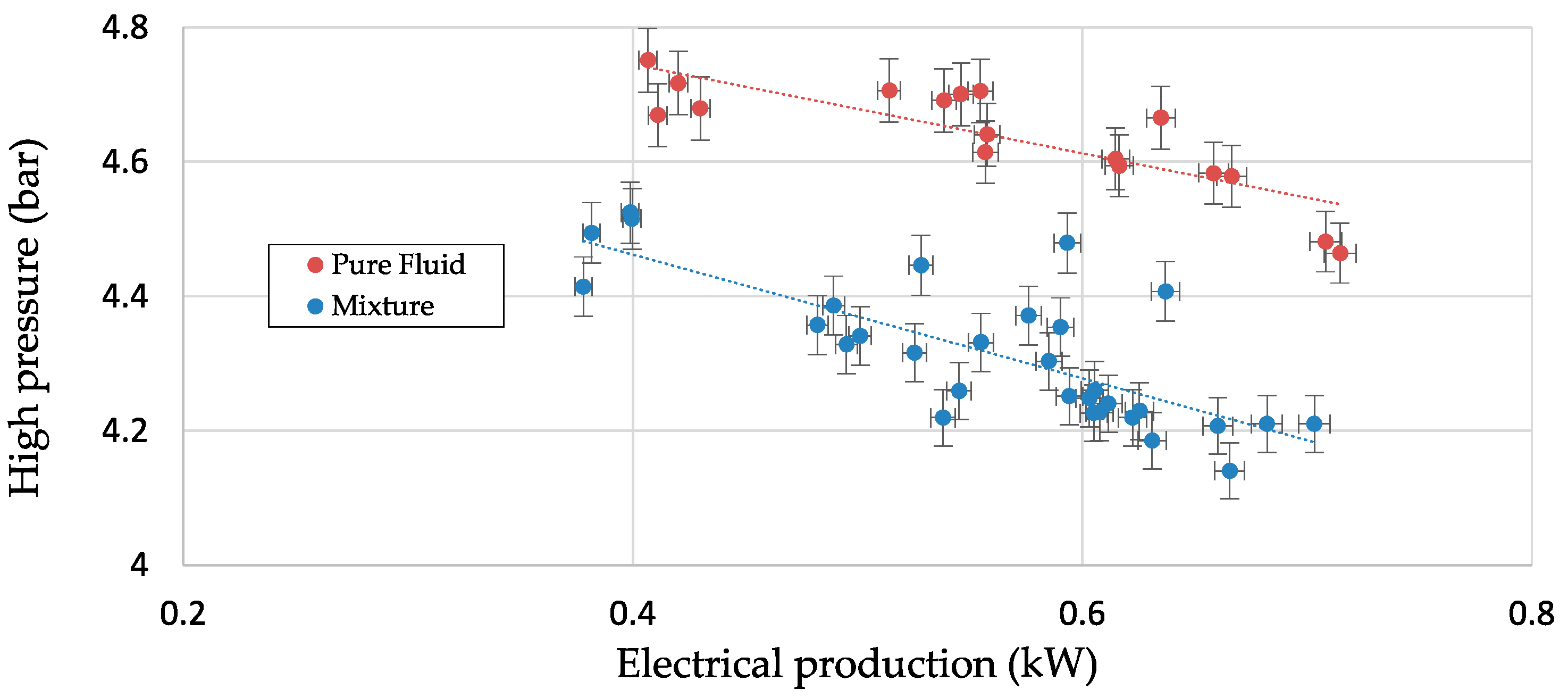

4.3. Mass Flow Rate Validation and Reconciliation

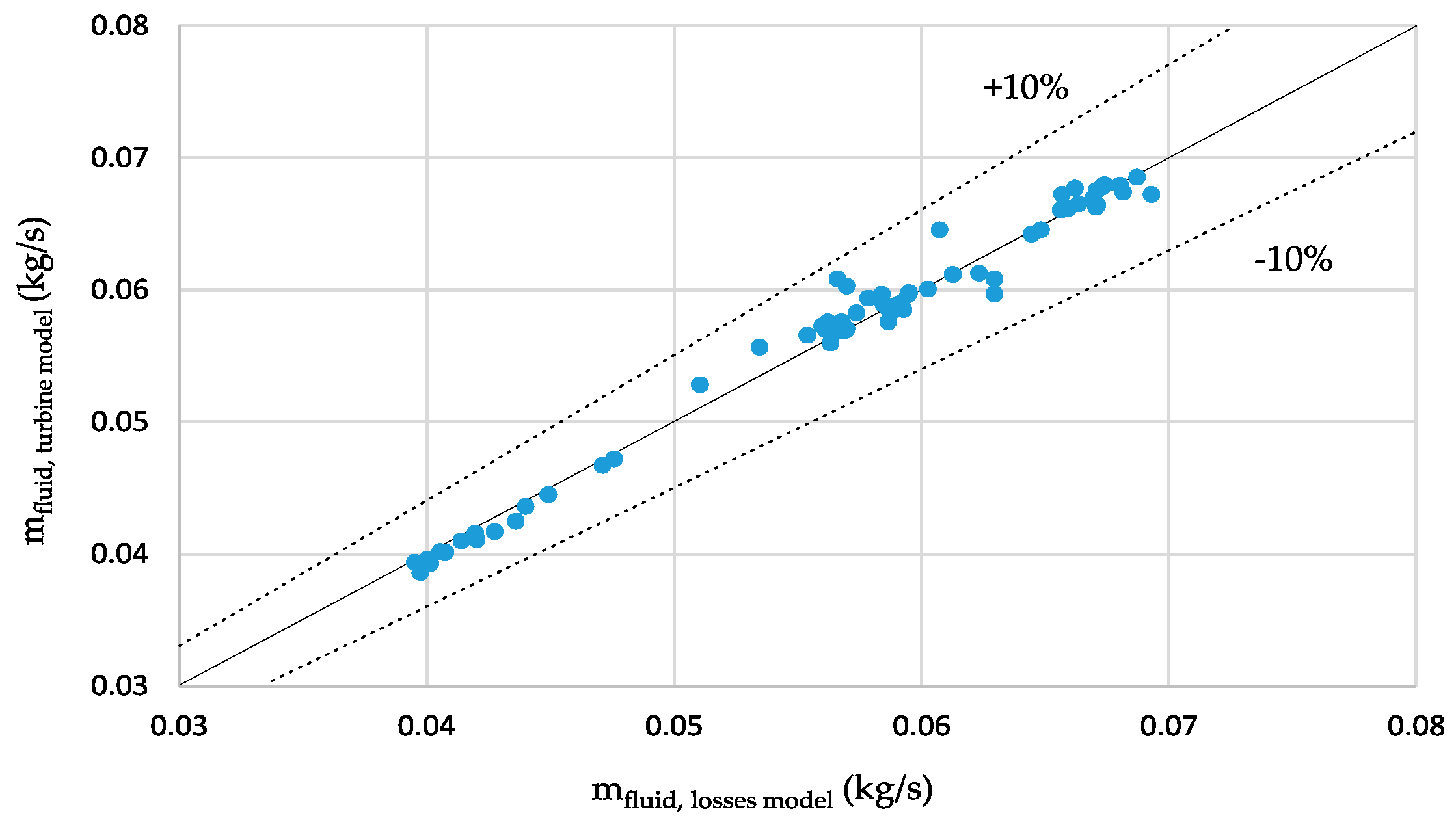

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbols | ||

| Ᾱ | dimensionless turbine parameter | [–] |

| A* | blade critical section | [m2] |

| A0 | turbine reference section | [m2] |

| c0 | stagnation turbine soundspeed | [m/s] |

| exergy | [kW] | |

| h | specific enthalpy | [kJ/kg] |

| mass flow | [kg/s] | |

| P | pressure | [bar] |

| thermal power | [kW] | |

| qv | volumetric flow | [L/h] |

| s | specific entropy | [kJ/kg-K] |

| S | section de passage | [m2] |

| T | temperature | [°C or K] |

| power | [kW] | |

| Greek symbols | ||

| η | efficiency | [%] |

| π | pressure ratio | [–] |

| γ | polytropic coefficient | [–] |

| ρ0 | stagnation turbine density | [kg/m3] |

| Subscripts | ||

| cond | condenser | |

| cf | cooling fluid | |

| cooling | cooling source | |

| el | electric | |

| evap | evaporator | |

| gross | gross | |

| heat | heating source | |

| hf | heating fluid | |

| II | second law | |

| in | inlet | |

| is | isentropic | |

| losses | losses | |

| net | net | |

| out | outlet | |

| pre | pre-heater | |

| ps | pumps | |

| ref | reference | |

| th | thermal | |

| tur | turbine | |

| wf | working fluid | |

| Acronyms | ||

| APS | Absolute Pressure Sensor | |

| EFM | Electromagnetic Flow Meter | |

| GWP | Global Warming Potential | |

| HCFC | Hydrochlorofluorocarbon | |

| HCFO | Hydrochlorofluoroolefin | |

| HFC | Hydrofluorocarbon | |

| HFE | Hydrofluoroether | |

| HFO | Hydrofluoroolefin | |

| ODP | Ozone Depletion Potential | |

| ORC | Organic Rankine Cycle | |

| PFD | Process Flow Diagram | |

| PID | Proportional Integral Derivative |

References

- World Overview of the Organic Rankine Cycle Technology. ORC World Map. Available online: http://orc-world-map.org/ (accessed on 18 April 2019).

- Quoilin, S.; Broek, M.V.D.; Declaye, S.; Dewallef, P.; Lemort, V. Techno-economic survey of Organic Rankine Cycle (ORC) systems. Renew. Sustain. Energy Rev. 2013, 22, 168–186. [Google Scholar] [CrossRef] [Green Version]

- Tauveron, N.; Colasson, S.; Gruss, J.-A. Available systems for the conversion of waste heat to electricity. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Colonna, P.; Casati, E.; Trapp, C.; Mathijssen, T.; Larjola, J.; Turunen-Saaresti, T.; Uusitalo, A. Organic Rankine Cycle Power Systems: From the Concept to Current Technology, Applications, and an Outlook to the Future. J. Eng. Gas Turbines Power 2015, 137, 100801. [Google Scholar] [CrossRef] [Green Version]

- Pereira, J.S.; Ribeiro, J.B.; Mendes, R.; Vaz, G.C.; André, J.C. ORC based micro-cogeneration systems for residential application—A state of the art review and current challenges. Renew. Sustain. Energy Rev. 2018, 92, 728–743. [Google Scholar] [CrossRef]

- Lion, S.; Michos, C.N.; Vlaskos, I.; Rouaud, C.; Taccani, R. A review of waste heat recovery and Organic Rankine Cycles (ORC) in on-off highway vehicle Heavy Duty Diesel Engine applications. Renew. Sustain. Energy Rev. 2017, 79, 691–708. [Google Scholar] [CrossRef]

- Mahmoudi, A.; Fazli, M.; Morad, M.R. A recent review of waste heat recovery by Organic Rankine Cycle. Appl. Therm. Eng. 2018, 143, 660–675. [Google Scholar] [CrossRef]

- Braimakis, K.; Preißinger, M.; Brüggemann, D.; Karellas, S.; Panopoulos, K. Low grade waste heat recovery with subcritical and supercritical Organic Rankine Cycle based on natural refrigerants and their binary mixtures. Energy 2015, 88, 80–92. [Google Scholar] [CrossRef]

- Papapetrou, M.; Kosmadakis, G.; Cipollina, A.; La Commare, U.; Micale, G. Industrial waste heat: Estimation of the technically available resource in the EU per industrial sector, temperature level and country. Appl. Therm. Eng. 2018, 138, 207–216. [Google Scholar] [CrossRef]

- Imran, M.; Haglind, F.; Asim, M.; Zeb Alvi, J. Recent research trends in organic Rankine cycle technology: A bibliometric approach. Renew. Sustain. Energy Rev. 2018, 81, 552–562. [Google Scholar] [CrossRef]

- Mansoury, M.; Jafarmadar, S.; Khalilarya, S. Energetic and exergetic assessment of a two-stage Organic Rankine Cycle with reactivity controlled compression ignition engine as a low temperature heat source. Energy Convers. Manag. 2018, 166, 215–232. [Google Scholar] [CrossRef]

- Dong, S.; Zhang, Y.; He, Z.; Yu, X.; Zhang, Y.; Kong, X. Optimum design method of Organic Rankine Cycle system based on semi-empirical model and experimental validation. Energy Convers. Manag. 2016, 108, 85–95. [Google Scholar] [CrossRef]

- Usman, M.; Imran, M.; Lee, D.H.; Park, B.-S. Experimental investigation of off-grid organic Rankine cycle control system adapting sliding pressure strategy under proportional integral with feed-forward and compensator. Appl. Therm. Eng. 2017, 110, 1153–1163. [Google Scholar] [CrossRef]

- Yun, E.; Kim, D.; Yoon, S.E.; Kim, K.C. Experimental study on parallel expander organic rankine cycle with two different capacity expanders. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2015, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Wang, J.; Yan, Z.; Wang, M.; Li, M.; Dai, Y. Multi-objective optimization of an organic Rankine cycle (ORC) for low grade waste heat recovery using evolutionary algorithm. Energy Convers. Manag. 2013, 71, 146–158. [Google Scholar] [CrossRef]

- Leontaritis, A.-D.; Pallis, P.; Karellas, S.; Papastergiou, A.; Antoniou, N.; Vourliotis, P.; Kakalis, N.M.; Dimopoulos, G. Experimental Study on a Low Temperature ORC Unit for Onboard Waste Heat Recovery from Marine Diesel Engines. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2015, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Ziviani, D.; James, N.A.; Accorsi, F.A.; Braun, J.E.; Groll, E.A. Experimental and numerical analyses of a 5 kWe oil-free open-drive scroll expander for small-scale organic Rankine cycle (ORC) applications. Appl. Energy 2018, 230, 1140–1156. [Google Scholar] [CrossRef]

- Cipollone, R.; Bianchi, G.; Di Battista, D.; Contaldi, G.; Murgia, S. Mechanical Energy Recovery from Low Grade Thermal Energy Sources. Energy Procedia 2014, 45, 121–130. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Goswami, D.Y.; Stefanakos, E.K. A review of thermodynamic cycles and working fluids for the conversion of low-grade heat. Renew. Sustain. Energy Rev. 2010, 14, 3059–3067. [Google Scholar] [CrossRef]

- Cataldo, F.; Mastrullo, R.; Mauro, A.W.; Vanoli, G.P. Fluid selection of Organic Rankine Cycle for low-temperature waste heat recovery based on thermal optimization. Energy 2014, 72, 159–167. [Google Scholar] [CrossRef]

- Hærvig, J.; Sørensen, K.; Condra, T.J. Guidelines for optimal selection of working fluid for an organic Rankine cycle in relation to waste heat recovery. Energy 2016, 96, 592–602. [Google Scholar] [CrossRef]

- Dickes, R.; Dumont, O.; Guillaume, L.; Quoilin, S.; Lemort, V. Charge-sensitive modelling of organic Rankine cycle power systems for off-design performance simulation. Appl. Energy 2018, 212, 1262–1281. [Google Scholar] [CrossRef]

- Landelle, A. Experimental Organic Rankine Cycle Database—v2016.12. Available online: https://github.com/alandelle/Experimental-ORC-database/tree/2016.12.1 (accessed on 18 April 2019).

- Muhammad, U.; Imran, M.; Lee, D.H.; Park, B.S. Design and experimental investigation of a 1kW organic Rankine cycle system using R245fa as working fluid for low-grade waste heat recovery from steam. Energy Convers. Manag. 2015, 103, 1089–1100. [Google Scholar] [CrossRef]

- Desideri, A.; Gusev, S.; van den Broek, M.; Lemort, V.; Quoilin, S. Experimental comparison of organic fluids for low temperature ORC (organic Rankine cycle) systems for waste heat recovery applications. Energy 2016, 97, 460–469. [Google Scholar] [CrossRef]

- Quoilin, S.; Lemort, V.; Lebrun, J. Experimental study and modeling of an Organic Rankine Cycle using scroll expander. Appl. Energy 2010, 87, 1260–1268. [Google Scholar] [CrossRef]

- Feng, Y.-Q.; Hung, T.-C.; Wu, S.-L.; Lin, C.-H.; Li, B.-X.; Huang, K.C.; Qin, J. Operation characteristic of a R123-based organic Rankine cycle depending on working fluid mass flow rates and heat source temperatures. Energy Convers. Manag. 2017, 131, 55–68. [Google Scholar] [CrossRef]

- Galloni, E.; Fontana, G.; Staccone, S. Design and experimental analysis of a mini ORC (organic Rankine cycle) power plant based on R245fa working fluid. Energy 2015, 90, 768–775. [Google Scholar] [CrossRef]

- Chang, J.-C.; Hung, T.-C.; He, Y.-L.; Zhang, W. Experimental study on low-temperature organic Rankine cycle utilizing scroll type expander. Appl. Energy 2015, 155, 150–159. [Google Scholar] [CrossRef]

- Miao, Z.; Xu, J.; Yang, X.; Zou, J. Operation and performance of a low temperature organic Rankine cycle. Appl. Therm. Eng. 2015, 75, 1065–1075. [Google Scholar] [CrossRef]

- Lei, B.; Wang, W.; Wu, Y.-T.; Ma, C.-F.; Wang, J.-F.; Zhang, L.; Li, C.; Zhao, Y.-K.; Zhi, R.P. Development and experimental study on a single screw expander integrated into an Organic Rankine Cycle. Energy 2016, 116, 43–52. [Google Scholar] [CrossRef]

- Saiai, P.; Chaitep, S.; Bundhurat, D.; Watanawanyoo, P. An Experimental Investigation of Vapor Generator Characteristics in a Low-pressure Turbine Engine. Indian J. Sci. Technol. 2014, 7, 1130–1136. [Google Scholar] [CrossRef]

- Serrano, D.; Smague, P.; Tona, P.; Leduc, P.; Mintsa, A.C.; Leroux, A.; Chevalier, P. Improving Train Energy Efficiency by Organic Rankine Cycle (ORC) for Recovering Waste Heat from Exhaust Gas. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2015, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Mu, Y.; Zhang, Y.; Deng, N.; Nie, J. Experimental Study of a Low-Temperature Power Generation System in an Organic Rankine Cycle. J. Energy Eng. 2015, 141, 04014017. [Google Scholar] [CrossRef] [Green Version]

- Gusev, S.; Ziviani, D.; van den Broek, M. Experimental characterization of single screw expander performance under different testing conditions and working fluids. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2015, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Darawun, W.; Songprakorp, R.; Monyakul, V.; Thepa, S. Testing of Low-grade Heat Source Organic Rankine Cycle with Small Hot Vapor Reciprocating Engine. Energy Procedia 2015, 79, 335–340. [Google Scholar] [CrossRef] [Green Version]

- Oudkerk, J.F.; Dickes, R.; Dumont, O.; Lemort, V. Experimental performance of a piston expander in a small- scale organic Rankine cycle. IOP Conf. Ser. Mater. Sci. Eng. 2015, 90, 012066. [Google Scholar] [CrossRef] [Green Version]

- Kolasiński, P. The Influence of the Heat Source Temperature on the Multivane Expander Output Power in an Organic Rankine Cycle (ORC) System. Energies 2015, 8, 3351–3369. [Google Scholar] [CrossRef] [Green Version]

- Tahir, M.; Yamada, N.; Hoshino, T. Efficiency of compact organic rankine cycle system with Rotary-Vane-Type expander for low-temperature waste heat recovery. Int. J. Environ. Sci. Eng. 2010, 2, 11–16. [Google Scholar]

- Wu, Y.-T.; Zhao, Y.-K.; Zhang, C.; Lei, B.; Guo, H.; Ma, C.F. Simulation Study of Cooling System on ORC Performance. Kung Cheng Je Wu Li Hsueh Pao/J. Eng. Thermophys. 2018, 39, 1412–1416. [Google Scholar]

- Kosmadakis, G.; Manolakos, D.; Papadakis, G. Experimental investigation of a low-temperature organic Rankine cycle (ORC) engine under variable heat input operating at both subcritical and supercritical conditions. Appl. Therm. Eng. 2016, 92, 1–7. [Google Scholar] [CrossRef]

- Montreal Protocol on Substances that Deplete the Ozone Layer. Available online: https://treaties.un.org/doc/publication/unts/volume%201522/volume-1522-i-26369-english.pdf (accessed on 18 April 2019).

- Text of the Kyoto Protocol. Available online: https://unfccc.int/process/the-kyoto-protocol/history-of-the-kyoto-protocol/text-of-the-kyoto-protocol (accessed on 18 April 2019).

- Bobbo, S.; Nicola, G.D.; Zilio, C.; Brown, J.S.; Fedele, L. Low GWP halocarbon refrigerants: A review of thermophysical properties. Int. J. Refrig. 2018, 90, 181–201. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Wang, L.; Bu, X. Thermodynamic Analysis of Organic Rankine Cycle with Hydrofluoroethers as Working Fluids. Energy Procedia 2017, 105, 1889–1894. [Google Scholar] [CrossRef]

- Sarkar, J. Property-based selection criteria of low GWP working fluids for organic Rankine cycle. J. Braz. Soc. Mech. Sci. Eng. 2016, 39, 1419–1428. [Google Scholar] [CrossRef]

- Invernizzi, C.M.; Iora, P.; Preißinger, M.; Manzolini, G. HFOs as substitute for R-134a as working fluids in ORC power plants: A thermodynamic assessment and thermal stability analysis. Appl. Therm. Eng. 2016, 103, 790–797. [Google Scholar] [CrossRef] [Green Version]

- Upadhyaya, S.; Gumtapure, V. Thermodynamic analysis of organic Rankine cycle with Hydrofluoroethers as working fluids. IOP Conf. Ser. Mater. Sci. Eng. 2018, 376, 012026. [Google Scholar] [CrossRef]

- Navarro-Esbrí, J.; Molés, F.; Peris, B.; Mota-Babiloni, A.; Kontomaris, K. Experimental study of an Organic Rankine Cycle with HFO-1336mzz-Z as a low global warming potential working fluid for micro-scale low temperature applications. Energy 2017, 133, 79–89. [Google Scholar] [CrossRef]

- Yang, J.; Ye, Z.; Yu, B.; Ouyang, H.; Chen, J. Simultaneous experimental comparison of low-GWP refrigerants as drop-in replacements to R245fa for Organic Rankine cycle application: R1234ze(Z), R1233zd(E), and R1336mzz(E). Energy 2019, 173, 721–731. [Google Scholar] [CrossRef]

- Cambi, M.; Tascioni, R.; Cioccolanti, L.; Bocci, E. Converting a commercial scroll compressor into an expander: Experimental and analytical performance evaluation. Energy Procedia 2017, 129, 363–370. [Google Scholar] [CrossRef]

- Qiu, G.; Shao, Y.; Li, J.; Liu, H.; Riffat, S.B. Experimental investigation of a biomass-fired ORC-based micro-CHP for domestic applications. Fuel 2012, 96, 374–382. [Google Scholar] [CrossRef] [Green Version]

- Jradi, M.; Li, J.; Liu, H.; Riffat, S. Micro-scale ORC-based combined heat and power system using a novel scroll expander. Int. J. Low-Carbon Technol. 2014, 9, 91–99. [Google Scholar] [CrossRef]

- Kaczmarczyk, T.Z.; Zywica, G.; Ihnatowicz, E. Experimental investigation of a radial microturbine in organic rankine cycle system with hfe7100 as working fluid. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition 2015, Houston, TX, USA, 13–19 November 2015. [Google Scholar]

- Pu, W.; Yue, C.; Han, D.; He, W.; Liu, X.; Zhang, Q.; Chen, Y. Experimental study on Organic Rankine cycle for low grade thermal energy recovery. Appl. Therm. Eng. 2016, 94, 221–227. [Google Scholar] [CrossRef]

- Scaccabarozzi, R.; Tavano, M.; Invernizzi, C.M.; Martelli, E. Comparison of working fluids and cycle optimization for heat recovery ORCs from large internal combustion engines. Energy 2018, 158, 396–416. [Google Scholar] [CrossRef]

- Lu, H.; Wang, Z.; Wang, L.; Xu, S.; Hu, B. Experimental study on a small-scale pumpless organic Rankine cycle with R1233zd(E) as working fluid at low temperature heat source. Int. J. Energy Res. 2019, 43, 1203–1216. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, R. Experimental and simulation analysis of low temperature heat sources driven adsorption air conditioning, refrigeration, integrating ammonia, and organic expanding power generation. Int. J. Energy Res. 2018, 42, 4157–4169. [Google Scholar] [CrossRef]

- Ghaebi, H.; Yari, M.; Gargari, S.G.; Rostamzadeh, H. Thermodynamic modeling and optimization of a combined biogas steam reforming system and organic Rankine cycle for coproduction of power and hydrogen. Renew. Energy 2019, 130, 87–102. [Google Scholar] [CrossRef]

- Scaccabarozzi, R.; Tavano, M.; Invernizzi, C.M.; Martelli, E. Thermodynamic Optimization of heat recovery ORCs for heavy duty Internal Combustion Engine: Pure fluids vs. zeotropic mixtures. Energy Procedia 2017, 129, 168–175. [Google Scholar] [CrossRef]

- Bonk, C.D.; Laux, C.; Rödder, M.; Neef, M. Design of a 1 KW Organic Rankine Cycle for Teaching and Research Issues. Energy Procedia 2017, 129, 931–938. [Google Scholar] [CrossRef]

- Bamorovat Abadi, G.; Kim, K.C. Investigation of organic Rankine cycles with zeotropic mixtures as a working fluid: Advantages and issues. Renew. Sustain. Energy Rev. 2017, 73, 1000–1013. [Google Scholar] [CrossRef]

- Modi, A.; Haglind, F. A review of recent research on the use of zeotropic mixtures in power generation systems. Energy Convers. Manag. 2017, 138, 603–626. [Google Scholar] [CrossRef]

- Su, W.; Zhao, L.; Deng, S.; Xu, W.; Yu, Z. A limiting efficiency of subcritical Organic Rankine cycle under the constraint of working fluids. Energy 2018, 143, 458–466. [Google Scholar] [CrossRef]

- Zhao, L. Zeotropic Mixture and Organic Ranking Cycle. SpringerLink 2017, 133–168. [Google Scholar] [CrossRef]

- Xiao, L.; Wu, S.-Y.; Yi, T.-T.; Liu, C.; Li, Y.-R. Multi-objective optimization of evaporation and condensation temperatures for subcritical organic Rankine cycle. Energy 2015, 83, 723–733. [Google Scholar] [CrossRef]

- Zhai, H.; An, Q.; Shi, L. Zeotropic mixture active design method for organic Rankine cycle. Appl. Therm. Eng. 2018, 129, 1171–1180. [Google Scholar] [CrossRef]

- Zhao, L.; Bao, J. Thermodynamic analysis of organic Rankine cycle using zeotropic mixtures. Appl. Energy 2014, 130, 748–756. [Google Scholar] [CrossRef]

- Deethayat, T.; Asanakham, A.; Kiatsiriroat, T. Performance analysis of low temperature organic Rankine cycle with zeotropic refrigerant by Figure of Merit (FOM). Energy 2016, 96, 96–102. [Google Scholar] [CrossRef]

- Kuo, C.-R.; Hsu, S.-W.; Chang, K.-H.; Wang, C.-C. Analysis of a 50kW organic Rankine cycle system. Energy 2011, 36, 5877–5885. [Google Scholar] [CrossRef]

- Zhou, Y.; Zhang, F.; Yu, L. The discussion of composition shift in organic Rankine cycle using zeotropic mixtures. Energy Convers. Manag. 2017, 140, 324–333. [Google Scholar] [CrossRef]

- Tian, H.; Li, L.; Shu, G.; Yan, N.; Li, X.; Yu, Z. Composition shift in zeotropic mixture–based organic Rankine cycle system for harvesting engine waste heat. Int. J. Energy Res. 2018, 42, 4345–4359. [Google Scholar] [CrossRef]

- Chys, M.; van den Broek, M.; Vanslambrouck, B.; De Paepe, M. Potential of zeotropic mixtures as working fluids in organic Rankine cycles. Energy 2012, 44, 623–632. [Google Scholar] [CrossRef]

- Landelle, A.; Tauveron, N.; Revellin, R.; Haberschill, P.; Colasson, S.; Roussel, V. Performance investigation of reciprocating pump running with organic fluid for organic Rankine cycle. Appl. Therm. Eng. 2017, 113, 962–969. [Google Scholar] [CrossRef]

- 3MTMNovecTM649 Engineered Fluid. Available online: https://multimedia.3m.com/mws/media/569865O/3mtm-novectm-649-engineered-fluid.pdf (accessed on 18 April 2019).

- 3MTM NovecTM 7000 Engineered Fluid. Available online: https://multimedia.3m.com/mws/media/121372O/3m-novec-7000-engineered-fluid-tds.pdf (accessed on 18 April 2019).

- EES: Engineering Equation Solver|F-Chart Software: Engineering Software. Available online: http://www.fchart.com/ees/ (accessed on 18 April 2019).

- REFPROP. NIST. 18 April 2013. Available online: https://www.nist.gov/srd/refprop (accessed on 18 April 2019).

- McLinden, M.O.; Perkins, R.A.; Lemmon, E.W.; Fortin, T.J. Thermodynamic Properties of 1,1,1,2,2,4,5,5,5-Nonafluoro-4-(trifluoromethyl)-3-pentanone: Vapor Pressure, (p, ρ, T) Behavior, and Speed of Sound Measurements, and an Equation of State. J. Chem. Eng. Data 2015, 60, 3646–3659. [Google Scholar] [CrossRef]

- Outcalt, S.L.; Lemmon, E.W. Bubble-point measurements of eight binary mixtures for organic Rankine cycle applications. J. Chem. Eng. Data 2013, 58, 1853–1860. [Google Scholar] [CrossRef]

- Nederstigt, P. Real Gas Thermodynamics: And the Isentropic Behavior of Substances; Delft University of Technology: Delft, The Netherlands, 2017; pp. 1–112. Available online: http://resolver.tudelft.nl/uuid:ee16f7e5-4251-4629-9192-8f4a2e3d599b (accessed on 17 April 2019).

- Landelle, A.; Tauveron, N.; Haberschill, P.; Revellin, R.; Colasson, S. Organic Rankine cycle design and performance comparison based on experimental database. Appl. Energy 2017, 204, 1172–1187. [Google Scholar] [CrossRef]

| Property | NovecTM649 | 0.8NovecTM649/0.2HFE7000 | HFE7000 |

|---|---|---|---|

| Type | Dry | Dry | Dry |

| Molar mass (g/mol) | 316 | 283.2 | 200.1 |

| Normal boiling point (°C) | 49.1 | 41.2 | 34.2 |

| Normal latent heat (kJ/kg) | 88.1 | 99.6 | 133.9 |

| Critical temperature (°C) | 168.7 | 165.6 | 164.6 |

| Critical pressure (bar) | 18.7 | 20.3 | 24.8 |

| Ozone Depletion Potential | 0 | 0 | 0 |

| Global Warming Potential | 1 | 107 | 530 |

| Inflammability | Nonflammable | Nonflammable | Nonflammable |

| Variable | Device | Range | Uncertainty |

|---|---|---|---|

| Electrical power | Wattmeter | 0–3250 W | ±0.3% |

| Volumetric flow rate (heat source) | EFM | 0–3500 L/h | ±0.23% |

| Volumetric flow rate (cooling source) | EFM | 0–2500 L/h | ±0.33% |

| Temperature | Type-K thermocouples | 0–1100 °C | ±0.1 °C |

| Pressure | APS | 0–7 bar | ±1% |

| Tin,hf,evap | Tin,cf,cond | qv,hf | qv,cf | ṁwf |

|---|---|---|---|---|

| (°C) | (°C) | (L/h) | (L/h) | (kg/s) |

| 110 | 13.5 | 300–3500 | 250–2500 | 0.055–0.069 |

| Data | NovecTM649 | 0.8NovecTM649/0.2HFE7000 | |

|---|---|---|---|

| (kg/s) | 0.4 | 0.4 | |

| (kg/s) | 0.236 | 0.56 | |

| (kg/s) | 0.065 | 0.057 | |

| (°C) | 110 | 110.2 | |

| (°C) | 13.5 | 12.6 | |

| (°C) | 13.5 | 12.6 | |

| (bar) | 4.5 | 4.2 | |

| (bar) | 0.53 | 0.45 | |

| (kW) | 12 | 10.8 | |

| (kW) | 10 | 9.3 | |

| (kW) | 0.715 | 0.703 | |

| (kW) | 0.104 | 0.104 | |

| (%) | 58.2 | 56 | |

| (%) | 61.4 | 61.5 | |

| (%) | 5 | 5.6 | |

| (%) | 20.8 | 22.4 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blondel, Q.; Tauveron, N.; Caney, N.; Voeltzel, N. Experimental Study and Optimization of the Organic Rankine Cycle with Pure NovecTM649 and Zeotropic Mixture NovecTM649/HFE7000 as Working Fluid. Appl. Sci. 2019, 9, 1865. https://doi.org/10.3390/app9091865

Blondel Q, Tauveron N, Caney N, Voeltzel N. Experimental Study and Optimization of the Organic Rankine Cycle with Pure NovecTM649 and Zeotropic Mixture NovecTM649/HFE7000 as Working Fluid. Applied Sciences. 2019; 9(9):1865. https://doi.org/10.3390/app9091865

Chicago/Turabian StyleBlondel, Quentin, Nicolas Tauveron, Nadia Caney, and Nicolas Voeltzel. 2019. "Experimental Study and Optimization of the Organic Rankine Cycle with Pure NovecTM649 and Zeotropic Mixture NovecTM649/HFE7000 as Working Fluid" Applied Sciences 9, no. 9: 1865. https://doi.org/10.3390/app9091865