An Improved Objective Function for Modal-Based Damage Identification Using Substructural Virtual Distortion Method

Abstract

:1. Introduction

2. A Traditional Objective Function in Damage Identification

3. An Improved Objective Function Based on SVDM

3.1. The Improved Objective Function

- (1)

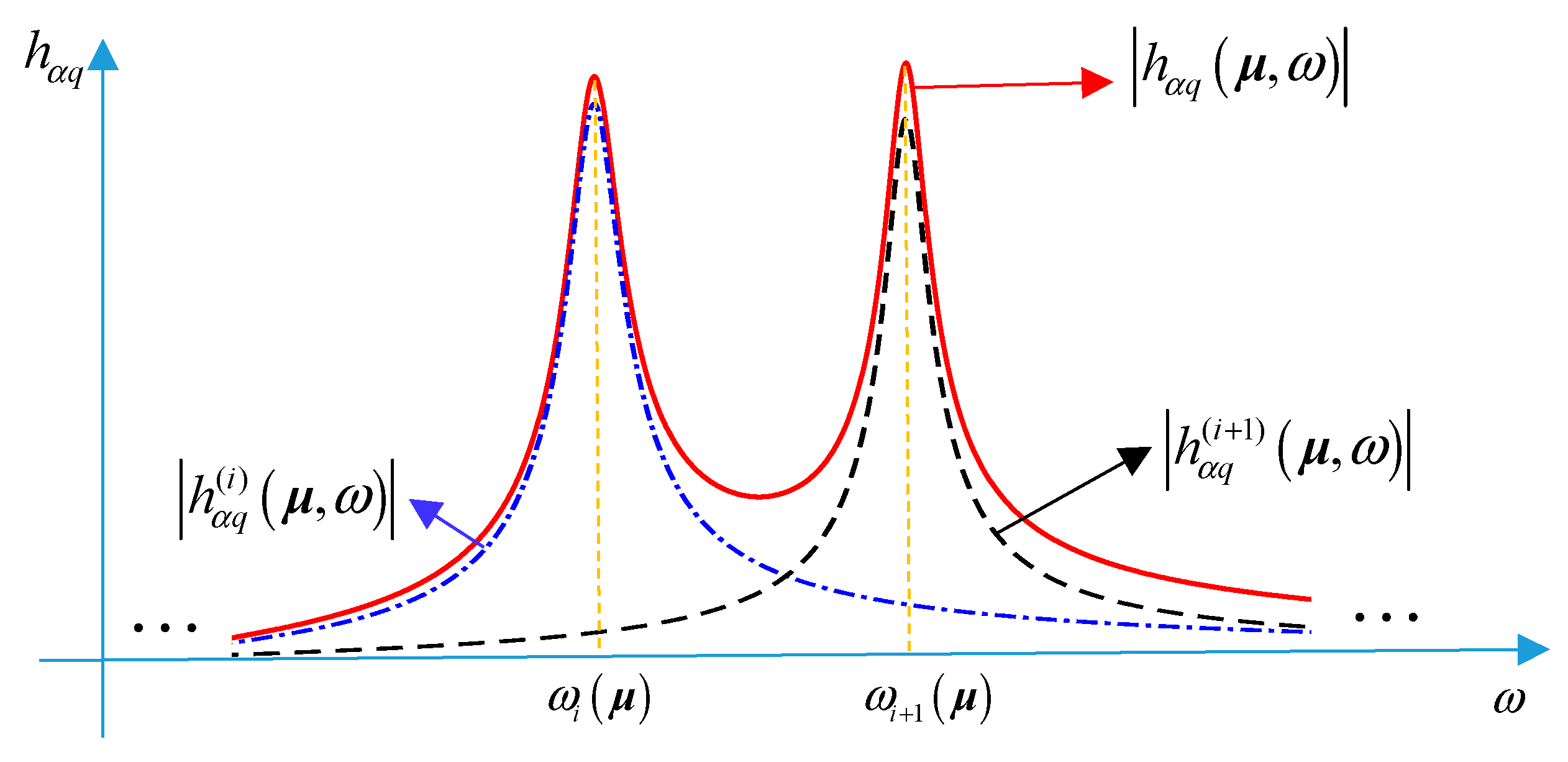

- Involving the mode shape :Consider the special case and note that , that is, at the i-th natural frequency the frequency response is dominated by the contribution of the i-th mode. Thus, Equation (3) can be approximated and expressed as Equation (4). It can be seen from Equation (4) that the structural i-th mode shape is approximately proportional to , where , i.e., . When , then , and . So if , then , and in Equation (1) can be substituted by the frequency response .

- (2)

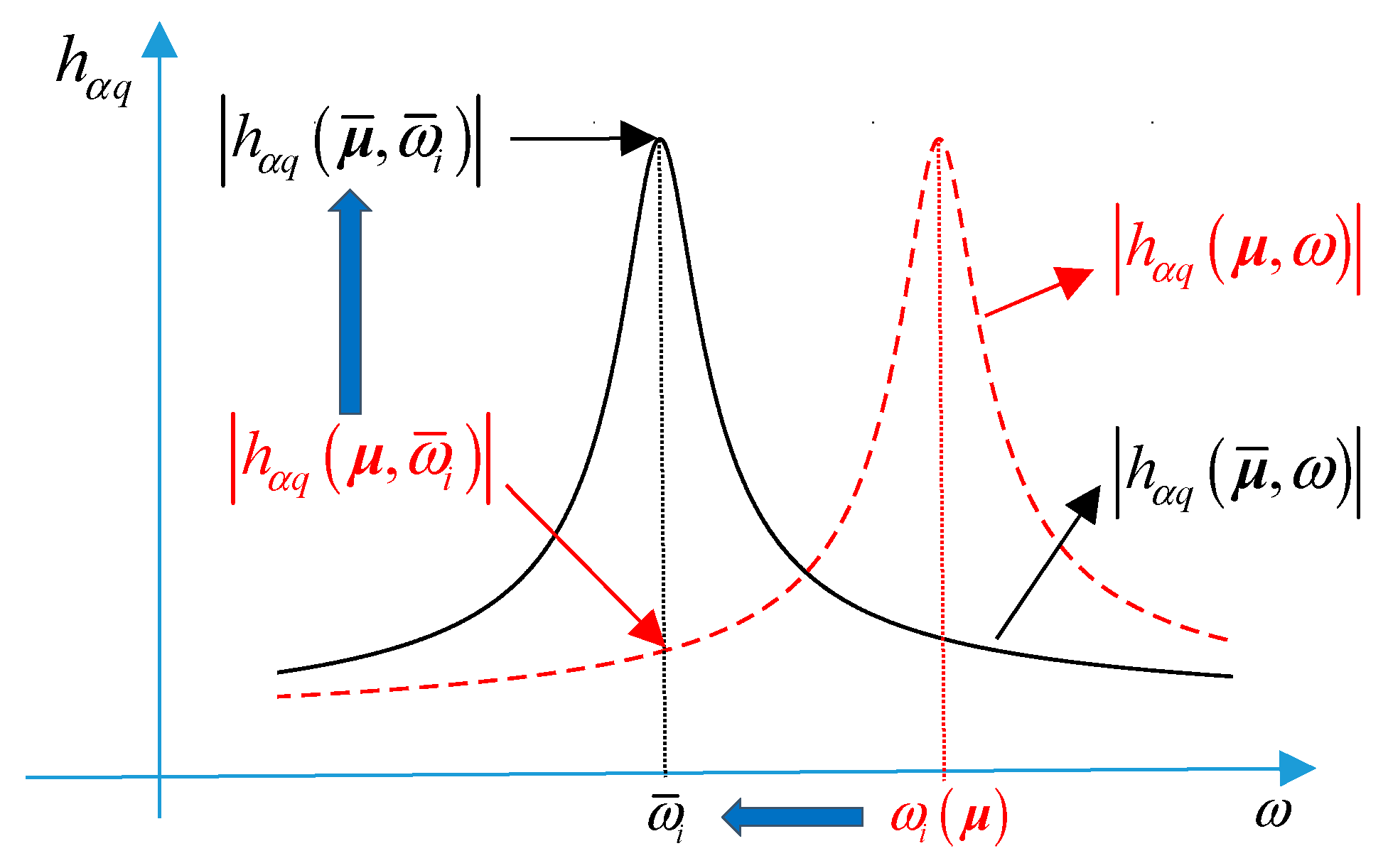

- Involving the natural frequency:It can be seen from Figure 2 that reaches its local maximum value at , and so attains the local minimum value at . Therefore, when the modeled damage factors converge to the actual damage factors, , then the modeled natural frequency converges to the measured natural frequency, , and . In the traditional objective function, the frequency error term also reaches its minimum value when . Therefore, the objective function can be modified by replacing with .

3.2. Substructural Virtual Distortion Method (SVDM) in Frequency Domain

3.3. Selection of Key Parameters in Improved Objective Function

3.3.1. Selection of the Damping Ratio

3.3.2. Selection of Excitation

3.3.3. Selection of the Weights of the Frequency and Mode Shape Terms

3.3.4. The Gradient of the Improved Objective Function

3.3.5. Optimization Efficiency

4. Numerical Simulation

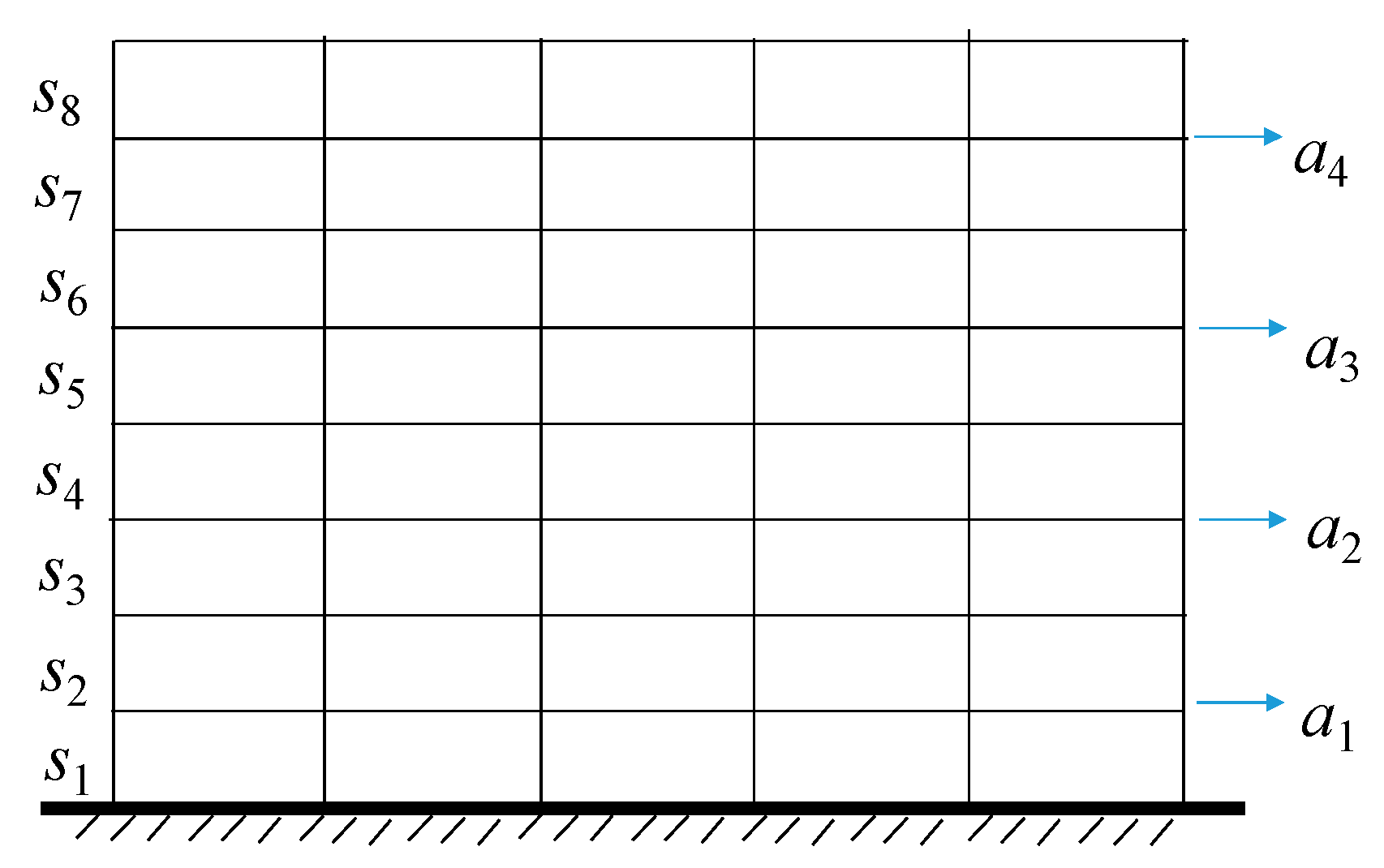

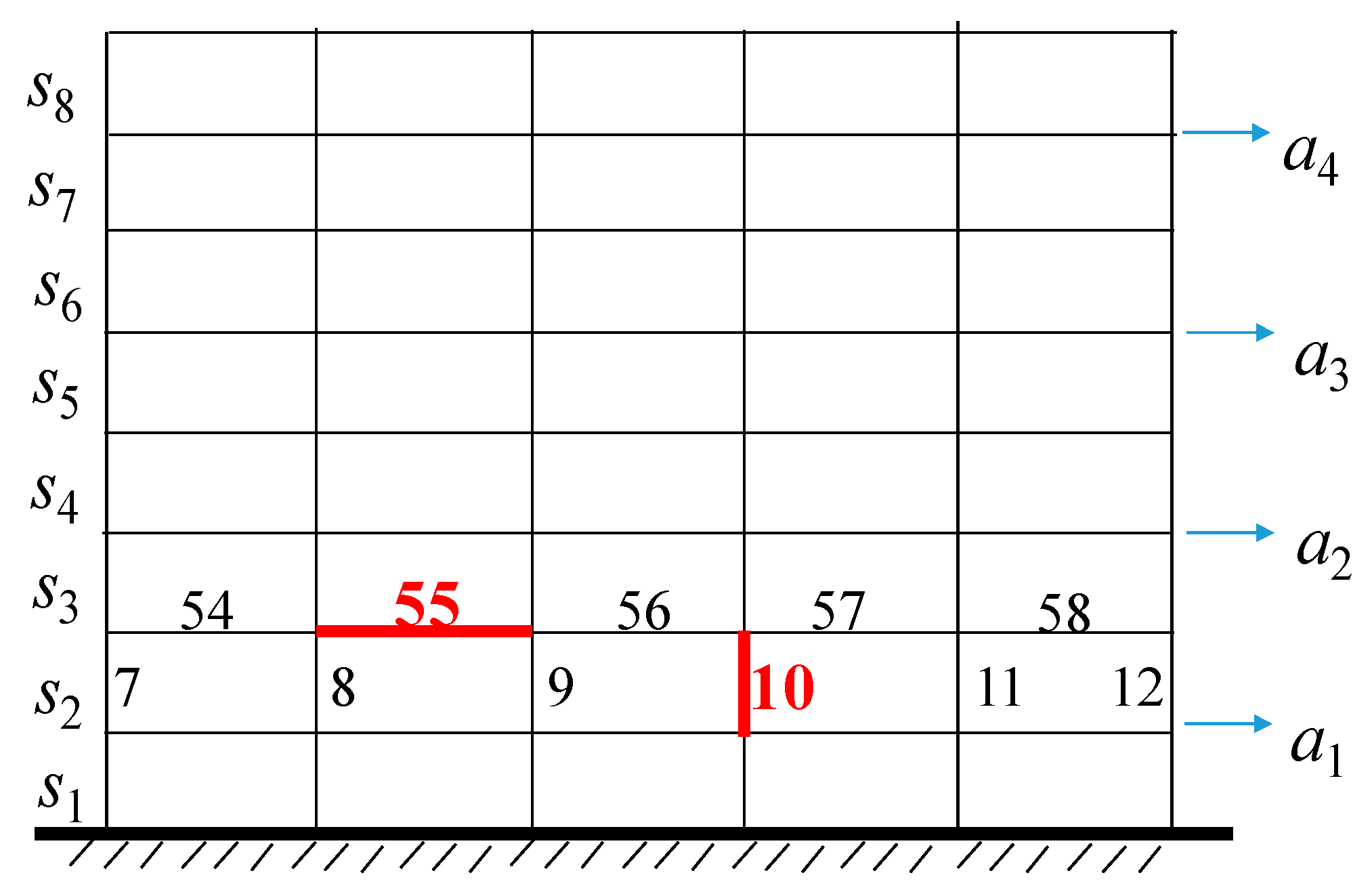

4.1. The Structural FE Model

4.2. Substructure Response

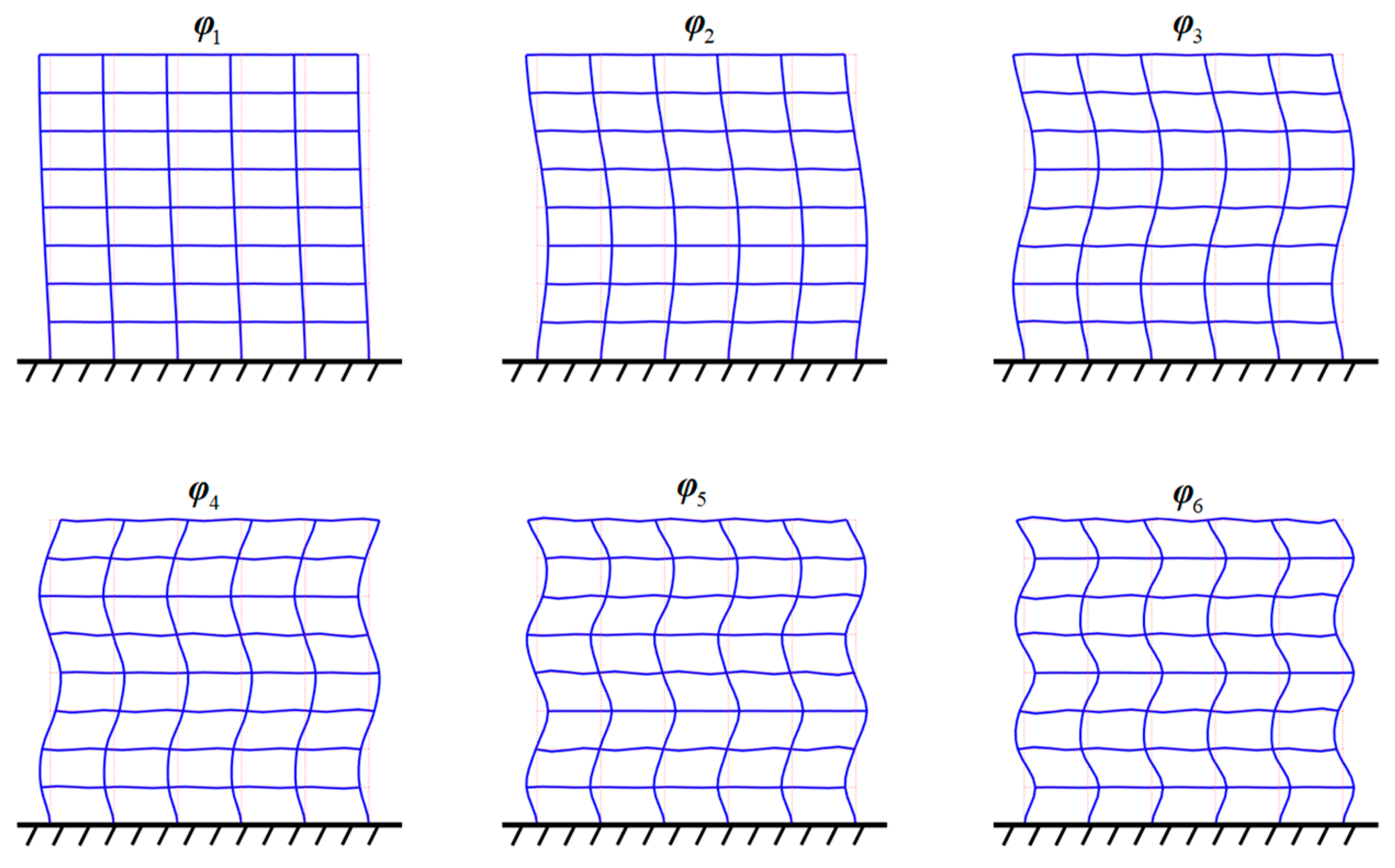

4.3. Structural Mode Shapes and Frequencies

4.4. Selection of the Main Virtual Distortions

4.5. Fast Calculation of Structural Frequency Response

4.6. Damage Identification Based on the Proposed Method

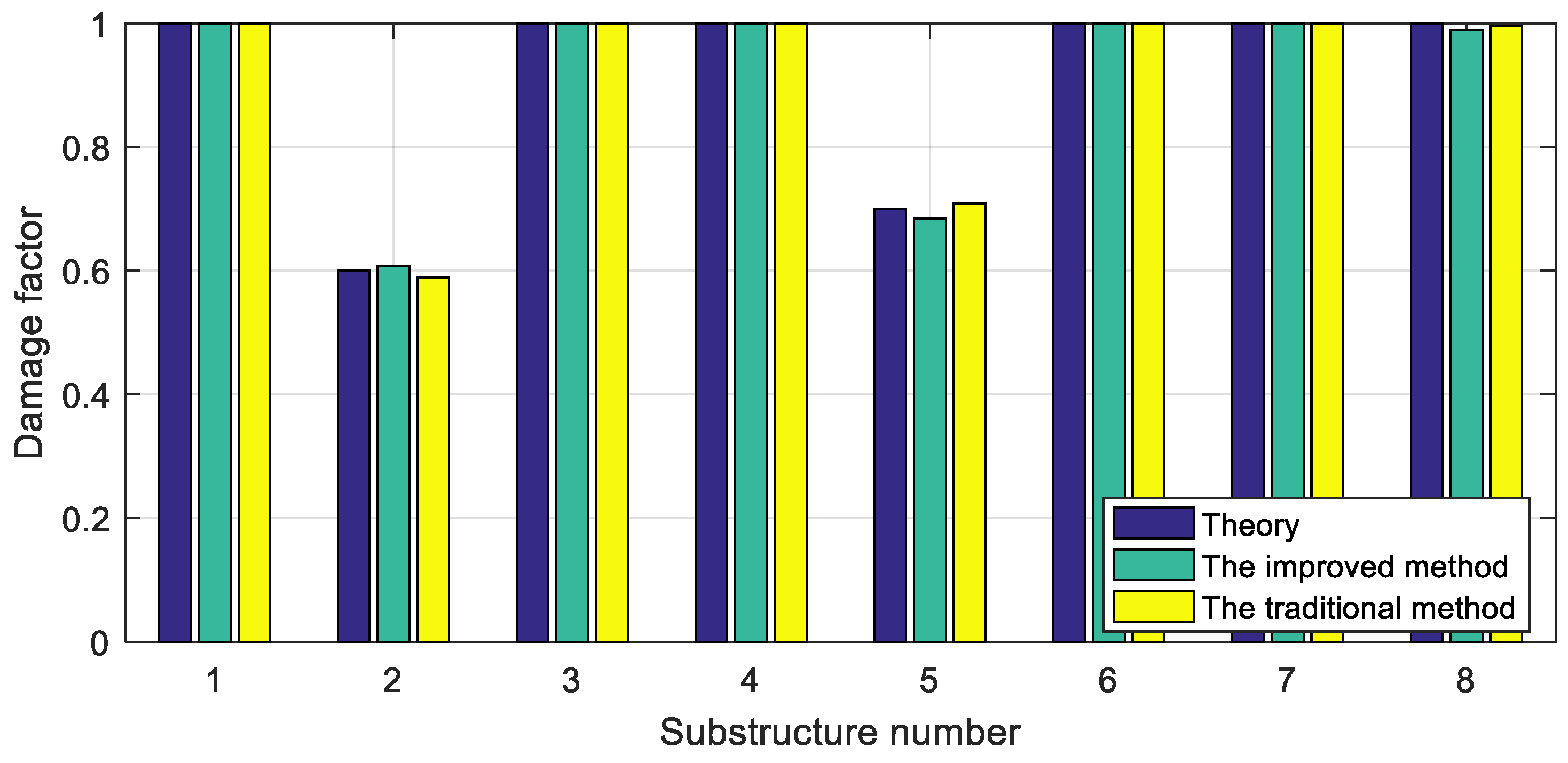

4.6.1. Damage Case 1

4.6.2. Damage Case 2

4.6.3. Damage Case 3

4.6.4. Damage Case 4

4.7. The Discussion about the Number of Modes Used

5. Conclusions

- Considering the characteristic that the amplitude of the frequency response attains a local maximum at the position of structural natural frequencies, an improved objective function is developed which avoids the repeated calculation of structural modes in the optimization procedure and improves the computational efficiency.

- Utilizing the fast structural re-analysis approach of the SVDM, frequency response in the improved objective function can be computed quickly, and the gradient expression of the objective function can be derived which further improves the optimization efficiency.

- The optimization efficiency using the traditional objective function is related to the number of DOFs of the entire structure, while the optimization efficiency based on the improved objective function is related to the number of damage factors to be identified and the number of selected virtual distortions.

Author Contributions

Funding

Conflicts of Interest

References

- Annamdas, V.G.M.; Bhalla, S.; Soh, C.K. Applications of structural health monitoring technology in Asia. Struct. Health Monit. 2017, 16, 324–346. [Google Scholar] [CrossRef]

- Zhou, L.R.; Yan, G.R.; Wang, L.; Ou, J.P. Review of benchmark studies and guidelines for structural health monitoring. Adv. Struct. Eng. 2013, 16, 1187–1206. [Google Scholar] [CrossRef]

- Xie, L.Y.; Zhou, Z.W.; Zhao, L.; Wan, C.F.; Tang, H.S.; Xue, S.T. Parameter identification for structural health monitoring with extended Kalman filter considering integration and noise effect. Appl. Sci. 2018, 8, 2480. [Google Scholar] [CrossRef]

- Hu, W.H.; Tang, D.H.; Teng, J.; Said, S.; Rohrmann, R.G. Structural health monitoring of a prestressed concrete bridge based on statistical pattern recognition of continuous dynamic measurements over 14 years. Sensors 2018, 18, 4117. [Google Scholar] [CrossRef] [PubMed]

- Jiang, T.Y.; Zhang, Y.W.; Wang, L.; Zhang, L.; Song, G.B. Monitoring fatigue damage of modular bridge expansion joints using piezoceramic transducers. Sensors 2018, 18, 3973. [Google Scholar] [CrossRef] [PubMed]

- Shen, S.; Jiang, S.F. Distributed deformation monitoring for a single-cell box girder based on distributed long-gage fiber bragg grating sensors. Sensors 2018, 18, 2597. [Google Scholar] [CrossRef] [PubMed]

- Na, W.S.; Seo, D.W.; Kim, B.C.; Park, K.T. Effects of applying different resonance amplitude on the performance of the impedance-based health monitoring technique subjected to damage. Sensors 2018, 18, 2267. [Google Scholar] [CrossRef] [PubMed]

- Fan, W.; Qiao, P.Z. Vibration-based damage identification methods: A review and comparative study. Struct. Health Monit. 2011, 10, 83–111. [Google Scholar] [CrossRef]

- Xu, K.; Deng, Q.S.; Cai, L.J.; Ho, S.C.; Song, G.B. Damage detection of a concrete column subject to blast loads using embedded piezoceramic transducers. Sensors 2018, 18, 1377. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Noori, M.; Altabey, W.A.; Ghiasi, R.; Wu, Z.S. Deep learning-based damage, load and support identification for a composite pipeline by extracting modal macro strains from dynamic excitations. Appl. Sci. 2018, 8, 2564. [Google Scholar] [CrossRef]

- Moreno-Gomez, A.; Amezquita-Sanchez, J.P.; Valtierra-Rodriguez, M.; Perez-Ramirez, C.A.; Dominguez-Gonzalez, A.; Chavez-Alegria, O. Emd-Shannon entropy-based methodology to detect incipient damages in a truss structure. Appl. Sci. 2018, 8, 2068. [Google Scholar] [CrossRef]

- Kordestani, H.; Xiang, Y.Q.; Ye, X.W.; Jia, Y.K. Application of the random decrement technique in damage detection under moving load. Appl. Sci. 2018, 8, 753. [Google Scholar] [CrossRef]

- Peng, J.; Hu, S.; Zhang, J.; Cai, C.S.; Li, L.Y. Influence of cracks on chloride diffusivity in concrete: A five-phase mesoscale model approach. Constr. Build. Mater. 2019, 197, 587–596. [Google Scholar] [CrossRef]

- Hearn, G.; Testa, R.B. Modal analysis for damage detection in structures. J. Struct. Eng. 1991, 117, 3042–3063. [Google Scholar] [CrossRef]

- Dilena, M.; Morassi, A. The use of antiresonances for crack detection in beams. J. Sound Vib. 2004, 276, 195–214. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Law, S.S.; Zhang, L.M. Damage localization by directly using incomplete mode shapes. J. Eng. Mech. 2000, 126, 656–660. [Google Scholar] [CrossRef]

- Pandey, A.K.; Biswas, M.; Samman, M.M. Damage detection from changes in curvature mode shapes. J. Sound Vib. 1991, 145, 321–332. [Google Scholar] [CrossRef]

- Shi, Z.Y.; Law, S.S.; Zhang, L.M. Structural damage localization from modal strain energy change. J. Sound Vib. 1998, 218, 825–844. [Google Scholar] [CrossRef]

- Kim, J.T.; Ryu, Y.S.; Cho, H.M.; Stubbs, N. Damage identification in beam-type structures: Frequency-based method vs mode-shape-based method. Eng. Struct. 2003, 25, 57–67. [Google Scholar] [CrossRef]

- Huynh, T.C.; Lee, S.Y.; Dang, N.L.; Kim, J.T. Vibration-based structural identification of caisson-foundation system via in situ measurement and simplified model. Struct. Control Health Monit. 2019, 26, e2315. [Google Scholar] [CrossRef]

- Wang, J.Y.; Ko, J.M.; Ni, Y.Q. Modal sensitivity analysis of Tsing Ma Bridge for structural damage detection. Proc. SPIE Int. Soc. Opt. Eng. 2000, 3995, 300–311. [Google Scholar]

- Guo, H.Y.; Li, Z.L. Structural multi-damage identification based on modal strain energy equivalence index method. Int. J. Struct. Stab. Dyn. 2014, 14, 1450028. [Google Scholar] [CrossRef]

- Kaveh, A.; Maniat, M. Damage detection based on MCSS and PSO using modal data. Smart Struct. Syst. 2015, 15, 1253–1270. [Google Scholar] [CrossRef]

- Cui, H.Y.; Xu, X.; Peng, W.Q.; Zhou, Z.H.; Hong, M. A damage detection method based on strain modes for structures under ambient excitation. Measurement 2018, 125, 438–446. [Google Scholar] [CrossRef]

- Liang, Y.B.; Li, D.S.; Song, G.B.; Feng, Q. Frequency Co-integration-based damage detection for bridges under the influence of environmental temperature variation. Measurement 2018, 125, 163–175. [Google Scholar] [CrossRef]

- Qin, S.Q.; Zhang, Y.Z.; Zhou, Y.L.; Kang, J.T. Dynamic model updating for bridge structures using the Kriging model and PSO algorithm ensemble with higher vibration modes. Sensors 2018, 18, 1879. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.Y.; Guo, X.L.; Hu, X.F. Crack identification based on Kriging surrogate model. Struct. Eng. Mech. 2012, 41, 25–41. [Google Scholar] [CrossRef]

- Guo, J.L.; Ma, L.Y.; Li, Y.J. A new structural damage identification method based on Kriging surrogate model. China Mech. Eng. 2016, 27, 1203–1207. [Google Scholar]

- Hou, J.L.; An, Y.H.; Wang, S.J.; Wang, Z.Z.; Jankowski, Ł.; Ou, J.P. Structural damage localization and quantification based on additional virtual masses and Bayesian theory. J. Eng. Mech. 2018, 144, 04018097. [Google Scholar] [CrossRef]

- Kołakowski, P.; Wikło, M.; Holnicki-Szulc, J. The virtual distortion method-a versatile reanalysis tool for structures and systems. Struct. Multidiscip. Optim. 2008, 36, 217–234. [Google Scholar] [CrossRef]

- Świercz, A.; Kołakowski, P.; Holnicki-Szulc, J. Damage identification in skeletal structures using the virtual distortion method in frequency domain. Mech. Syst. Signal Process. 2008, 22, 1826–1839. [Google Scholar] [CrossRef] [Green Version]

- Zhang, Q.X.; Jankowski, Ł.; Duan, Z.D. Simultaneous identification of moving masses and structural damage. Struct. Multidiscip. Optim. 2010, 42, 907–922. [Google Scholar] [CrossRef] [Green Version]

- Xing, Z.H.; Mita, A. A substructure approach to local damage detection of shear structure. Struct. Control Health Monit. 2012, 19, 309–318. [Google Scholar] [CrossRef]

- Li, J.; Law, S.S.; Ding, Y. Substructure damage identification based on response reconstruction in frequency domain and model updating. Eng. Struct. 2012, 41, 270–284. [Google Scholar] [CrossRef]

- Hou, J.L.; Jankowski, Ł.; Ou, J.P. Experimental study of the substructure isolation method for local health monitoring. Struct. Control Health Monit. 2012, 19, 491–510. [Google Scholar] [CrossRef]

- Zhu, H.P.; Mao, L.; Weng, S. Calculation of dynamic response sensitivity to substructural damage identification under moving load. Adv. Struct. Eng. 2013, 16, 1621–1632. [Google Scholar] [CrossRef]

- Li, J.; Hao, H. Substructure damage identification based on wavelet-domain response reconstruction. Struct. Health Monit. 2014, 13, 389–405. [Google Scholar] [CrossRef]

- Hou, J.L.; Jankowski, Ł.; Ou, J.P. Frequency-domain substructure isolation for local damage identification. Adv. Struct. Eng. 2015, 18, 137–153. [Google Scholar] [CrossRef]

- Zhang, Q.X.; Jankowski, Ł. Damage identification using structural modes based on substructure virtual distortion method. Adv. Struct. Eng. 2017, 20, 257–271. [Google Scholar] [CrossRef]

| Order | Identified | Damaged Model | Undamaged Model |

|---|---|---|---|

| 1 | 1.972 | 1.961 | 2.133 |

| 2 | 6.141 | 6.142 | 6.568 |

| 3 | 11.254 | 11.257 | 11.472 |

| 4 | 16.091 | 16.095 | 16.963 |

| 5 | 22.007 | 22.006 | 23.052 |

| 6 | 27.330 | 27.339 | 29.484 |

| Number | All | ω1 | ω2 | ω3 | ω4 | ω5 | ω6 |

|---|---|---|---|---|---|---|---|

| 1 | 18 | 2 | 1 | 0 | 2 | 3 | 3 |

| 2 | 35 | 8 | 8 | 7 | 3 | 6 | 7 |

| 3 | 34 | 7 | 10 | 5 | 8 | 7 | 3 |

| 4 | 35 | 6 | 7 | 7 | 7 | 6 | 7 |

| 5 | 34 | 6 | 7 | 8 | 6 | 8 | 7 |

| 6 | 35 | 5 | 6 | 5 | 7 | 7 | 3 |

| 7 | 34 | 8 | 9 | 4 | 9 | 10 | 17 |

| 8 | 36 | 6 | 5 | 6 | 7 | 7 | 7 |

| Total | 261 | 48 | 53 | 42 | 49 | 54 | 54 |

| No | Theory | The Improved Method | The Traditional Method |

|---|---|---|---|

| 1 | 1.0000 | 0.9999 | 0.9996 |

| 2 | 0.6000 | 0.6084 | 0.5897 |

| 3 | 1.0000 | 0.9999 | 1.0000 |

| 4 | 1.0000 | 0.9998 | 0.9997 |

| 5 | 0.7000 | 0.6846 | 0.7087 |

| 6 | 1.0000 | 0.9998 | 1.0000 |

| 7 | 1.0000 | 0.9997 | 1.0000 |

| 8 | 1.0000 | 0.9896 | 0.9963 |

| No | Theory | The Improved Method | The Traditional Method |

|---|---|---|---|

| 1 | 1.0000 | 0.9999 | 1.0000 |

| 2 | 0.9000 | 0.8836 | 0.8926 |

| 3 | 1.0000 | 0.9767 | 0.9933 |

| 4 | 0.9000 | 0.9042 | 0.8897 |

| 5 | 0.9400 | 0.9376 | 0.9339 |

| 6 | 1.0000 | 0.9999 | 0.9952 |

| 7 | 0.9600 | 0.9754 | 0.9752 |

| 8 | 1.0000 | 1.0000 | 0.9998 |

| No | Theory | The Improved Method | The Traditional Method |

|---|---|---|---|

| 1 | 1.0000 | 1.0000 | 1.0000 |

| 2 | 1.0000 | 0.9999 | 1.0000 |

| 3 | 1.0000 | 1.0000 | 1.0000 |

| 4 | 1.0000 | 1.0000 | 1.0000 |

| 5 | 1.0000 | 0.9998 | 1.0000 |

| 6 | 1.0000 | 1.0000 | 1.0000 |

| 7 | 0.9600 | 0.9633 | 0.9653 |

| 8 | 1.0000 | 0.9911 | 0.9900 |

| Damage Case | 10th Column with Damage Factor 0.5 | 10th Column with Damage Factor 0.8 | 55th Beam with Damage Factor 0.5 | 55th Beam with Damage Factor 0.8 |

|---|---|---|---|---|

| The improved method | 0.9205 | 0.9802 | 0.9642 | 0.9908 |

| The traditional method | 0.9246 | 0.9824 | 0.9538 | 0.9875 |

| No | Theory | The Improved Method | The Traditional Method | |

|---|---|---|---|---|

| Column | 7 | 1.0000 | 0.7586 | 0.9992 |

| 8 | 1.0000 | 0.7669 | 0.9988 | |

| 9 | 1.0000 | 0.8834 | 0.9980 | |

| 10 | 0.5000 | 0.9319 | 0.9964 | |

| 11 | 1.0000 | 0.9388 | 0.8254 | |

| 12 | 1.0000 | 0.9564 | 0.5761 | |

| Beam | 54 | 1.0000 | 0.9909 | 0.9982 |

| 55 | 1.0000 | 0.9931 | 0.9999 | |

| 56 | 1.0000 | 0.9960 | 0.9998 | |

| 57 | 1.0000 | 0.9967 | 0.9998 | |

| 58 | 1.0000 | 0.9970 | 0.9999 |

| The First Three Mode Shapes Used | The First Two Mode Shapes Used | The First Mode Shape Used | |

|---|---|---|---|

| The First Six Frequencies Used | 0.0154 | 0.0184 | 0.0365 |

| The First Three Frequencies Used | 0.0320 | 0.0383 | 0.2147 |

| The First Three Mode Shapes Used | The First Two Mode Shapes Used | The First Mode Shape Used | |

|---|---|---|---|

| The First Six Frequencies Used | 0.0103 | 0.0162 | 0.0421 |

| The First Three Frequencies Used | 0.0172 | 0.0206 | 0.1755 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, J.; Wang, S.; Zhang, Q.; Jankowski, Ł. An Improved Objective Function for Modal-Based Damage Identification Using Substructural Virtual Distortion Method. Appl. Sci. 2019, 9, 971. https://doi.org/10.3390/app9050971

Hou J, Wang S, Zhang Q, Jankowski Ł. An Improved Objective Function for Modal-Based Damage Identification Using Substructural Virtual Distortion Method. Applied Sciences. 2019; 9(5):971. https://doi.org/10.3390/app9050971

Chicago/Turabian StyleHou, Jilin, Sijie Wang, Qingxia Zhang, and Łukasz Jankowski. 2019. "An Improved Objective Function for Modal-Based Damage Identification Using Substructural Virtual Distortion Method" Applied Sciences 9, no. 5: 971. https://doi.org/10.3390/app9050971