Abstract

Cutting regime parameters play an important role in determining the efficiency of the grinding process and the quality of the ground parts. In this study, the influences of the cutting parameters, including the cutting depth (ae), the feed rate (Fe) and the wheel speed (RPM) on the grinding time when grinding tablet shape punches by a cubic boron nitride (CBN) wheel on a CNC (Computerized Numerical Control) milling machine are investigated. The Taguchi technique based on orthogonal array and analysis of variance (ANOVA) was then applied to design the number of experiments and evaluate the influence of cutting depth, feed rate and wheel speed on the grinding time. The results show that among the three cutting parameters, the most influential parameter on the grinding time is the cutting depth. The second influential parameter on the grinding time is the feed rate. The least influential parameter on grinding time is the wheel speed. In addition, the optimal condition of cutting parameters obtained for grinding tablet shape punches by cubic boron nitride wheels on a CNC milling machine are a cutting depth of 0.03 mm, wheel speed of 5000 rpm and feed rate of 3500 mm/min. This optimum cutting parameters ensure the least grinding time.

1. Introduction

Grinding is an important finishing process for many engineering components to give the best surface quality and the highest accuracy to various hard-to-machine metallic alloys [1]. In a certain grinding process, cutting mode parameters are flexibly controlled. Meanwhile, the cutting mode parameters directly influence the technical and economic efficiency of the grinding process [1,2,3]. Thus, a problem that continues to confront the manufacturing industry is the establishment of optimal grinding mode parameters.

At present, numerous investigations have been carried out to determine optimal cutting parameters for grinding operations, which contribute significantly to enhancing the economic and technical efficiency of the grinding process. Previous studies have established and solved optimal problems with different objective functions and sets of variables in specific applications. In 2001, R. Gupta introduced a procedure called “enumeration method” to select optimal process parameters in grinding operations [2]. In this procedure, the user tests different values of process variables and assesses the corresponding values of the desired target function while meeting the process constraints [2]. In 2002, a multi-parameter optimization problem in the cylindrical grinding process was developed by Li G. F. [3]. The optimal grinding control parameters were obtained through computer simulation. In addition, the actual grinding process was controlled by these optimal parameters [3]. In 2015, a methodology for the design of optimal multivariable stepwise cycles internal grinding processing was introduced by P.P. Pereverzev [4]. This method provides multi-parameter optimization of the control program for CNC machines on internal grinding operations [4]. In 2018, the influence of grinding parameters on surface temperature and burn behaviors of grinding rail were investigated by B. Lin et al. [5]. In 2018, Saikat Chatterjee [1] analyzed the influences of cutting mode parameters on surface roughness of cylindrical traverse cut grinding of aluminum bronze material. In addition, the optimal cutting mode parameters were determined by the Taguchi method. The wear of the grinding wheel and the conditioning during creep feed grinding of aeronautical alloys were analyzed in [6]. A method of modeling and calculating the material removal of abrasive belt grinding process using ANFIS (An adaptive neuro-fuzzy inference system or adaptive network-based fuzzy inference system) is reported in [7]. Recently, a study on optimization of dressing parameters for grinding tablet shape punches 90CrSi by CBN wheel on CNC milling machine was carried out [8]. However, none of the previous researches had studied the problem of optimizing cutting parameters for grinding tablet shape punches by cubic boron nitride wheels (CBN wheels) on CNC milling machine.

For grinding tablet shape punches by cubic boron nitride wheels on CNC milling machine, setting up optimal cutting conditions increases machining productivity and ensures quality of the grinding part as well. Thus, the economic and technical targets of the machining process are directly affected by setting up optimal cutting conditions. The optimization of cutting regime to determine and set up suitable cutting mode parameters is the most basic and effective method to control product quality and enhance machining productivity.

In this study, the input process parameters, including the cutting depth (aed), the wheel speed (Rpm) and the feed rate (Fe), were investigated for evaluating their influence on the grinding time as well as for finding the minimum grinding time when grinding tablet punches with CBN wheel on CNC milling machine by using the Taguchi method. Based on that, the optimum set of cutting parameters for grinding tablet shape punches by cubic boron nitride wheels on a CNC milling machine has been determined.

2. Methodology

2.1. Experimental Setup

To optimize the grinding time when grinding tablet punches by CBN wheel on a CNC milling machine, an experiment was designed by using the Taguchi method. The grinding conditions for the experiment are presented in Table 1. The work material was 90CrSi tool steel, hardened and tempered to 56–58 HRC (Rockwell hardness). The dimensions of the specimens were 13 mm × 13 mm × 30 mm.

Table 1.

Grinding conditions for the experiment.

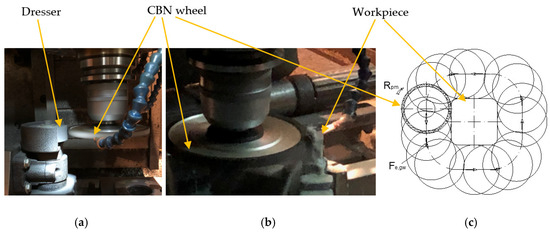

In addition, the experimental setup is shown in Figure 1. The grinding process of the tablet punches was carried out on an M-V50C CNC milling machine of Mitsubishi. The abrasive of the grinding wheel, which was used for the material removal, was a cubic boron nitride (JIS code: S2556-CBN 325-N75B53-3.0). The experiment was conducted in the following sequence: First, the CBN grinding wheel was dressed by the dresser equipment of a diamond form roller (Figure 1a) according to the optimum dressing parameters including the cutting depth of 0.02 mm, the wheel speed of 1000 rpm and the feed rate of 400 mm/min [8]. After that, the work-pieces were ground (Figure 1b) according to the schema in Figure 1c. In the grinding process, the grinding wheel rotated around its center and moved in orbit that had been programmed in the machining program.

Figure 1.

Experimental setup. (a) Dressing setup; (b) grinding setup; (c) grinding schema.

In practice, the key parameters that affect the grinding operation of the tablet punches include the cutting depth (aed), the feed rate (Fe) and the grinding wheel speed (Rpm). Thus, they were selected as input process parameters in this study. The grinding time was taken as the response parameter. Those input values of grinding mode parameters were chosen based on the manufacturing technology manual of the M-V50C CNC milling machine. The assigned values of input machining parameters at different levels and their designation are tabulated in Table 2.

Table 2.

Input process parameters and design levels.

2.2. Design of Experiment

To evaluate the impact of the input factors on grinding time and to determine the optimum factors in grinding operation for tablet punches, the Taguchi method was used. Then, the results were converted into signal-to-noise (S/N) ratio. This ratio was also employed to represent the quality characteristics. The impact of each parameter was determined by using S/N ratio, which helped to find the strength of experiments for the optimization of cutting parameters [9]. There exist three quality characteristics of the Taguchi technique known as the higher-the-better (HB), the lower-the-better (LB) and the nominal-the-best (NB) [6,7,8,9,10,11,12,13,14]. In this study, LB criterion was selected to be corresponding to the objective to achieve the least grinding time [6,7,8,9,10,11,12,13,14]. Thus, the grinding time value of each sample in this study was analyzed by S/N ratio using the Taguchi method with the lower-the-better condition in order to determine the optimal cutting mode parameters. Then, the confirmation experiment was conducted to evaluate the appropriateness of the optimum parameters obtained from the Taguchi experimental design. This method allowed the analysis of the influence of cutting mode parameters on a selected response of the grinding process without a prohibitively high amount of experimentation and helped to determine optimal cutting parameters with a minimal number of experiments [6,7,8,9,10,11,12,13,14].

Regarding the above mentioned key factors, it is noticed that each factor changes three levels. Thus, the Taguchi design of the experiment was used to optimize the input parameters using an L9 (33) orthogonal array, presented in Table 3 [6,7,8,9,10,11,12,13,14]. Each experimental run was performed three times. In this study, Minitab software was applied to analyze data according to the Taguchi experimental design. Based on that, the S/N ratio and the impacts of cutting parameters on the grinding time were determined.

Table 3.

Standard L9 (33) orthogonal matrix.

3. Results and Discussion

After processing, the grinding time of the ground parts was measured (grinding time is displayed on the control panel of CNC milling machine). The different levels of the input parameters and the results of the output response (the grinding time of the ground parts) are presented in Table 4.

Table 4.

Experimental results of L9 (33) for grinding time and their corresponding S/N ratios.

After collecting results, the data were analyzed using ANOVA in Minitab 18 software. With the target function of the least grinding time, the criterion LB was selected for the S/N ratio, and it is described by the following equation [6,7,8,9,10,11,12,13,14]:

where n is the number of experiments under the same design parameter conditions, and yi is the value of measured surface roughness for the ith experiment (i = 1, 2, 3). The experimental results and corresponding S/N ratios are given in Table 4.

3.1. Determining the Influence of Cutting Parameters

Table 5 summarizes the information for analysis of variance and case statistics for further interpretation. Table 5 clearly indicates that the feed rate (Fe) and the cutting depth (aed) had more influence on grinding time, while the wheel speed had the least influence on grinding time.

Table 5.

The ANOVA values of part’s medium grinding time ().

Table 6 shows that the feed, depth, and speed of cutting are ranked first, second, and third, respectively. It was found that the feed rate had the largest effect on the grinding time, while the influence of the wheel speed on the grinding time was the smallest.

Table 6.

The impact level of cutting parameters on part’s medium grinding time ().

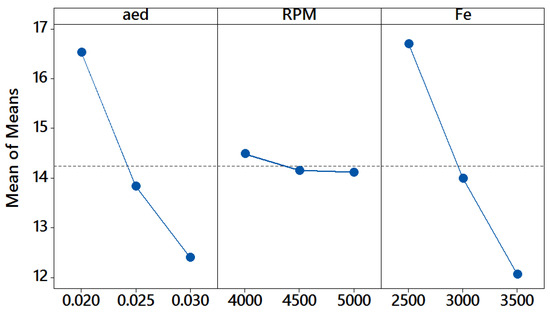

The linear model analysis in the Taguchi method of S/N ratio for grinding time was carried out with the criterion LB. The S/N ratio, which was calculated for three factors including aed, RPM and Fe in different levels, is listed in Table 4. The plot about the main effects of cutting parameters for means of grinding time is illustrated in Figure 2. From this figure, it can be seen that when the cutting depth (aed) increased, the grinding time (t) decreased and received the smallest value at the third level (equivalent to the cutting depth value of 0.03 mm). As the grinding wheel speed (Rpm) grew, the grinding time (t) declined. It reached the smallest value at a wheel speed of 5000 rpm (equivalent to the wheel speed value at the third level). When the feed rate (Fe) rose, the grinding time (t) fell to the lowest value at the third level (equivalent to the feed rate value of 3500 mm/min).

Figure 2.

Main effect plots of cutting parameters for means of grinding time ().

3.2. Determining the Optimum Cutting Parameters

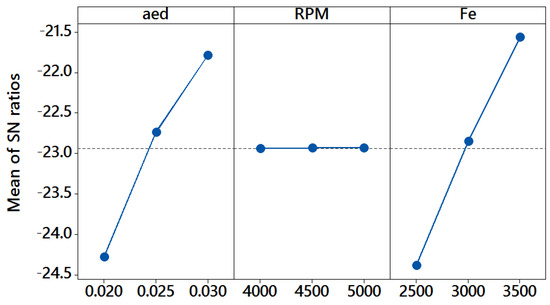

To determine the optimum cutting parameters, the ANOVA values for S/N ratios were calculated as shown in Table 7. Based on that, the main effect plots of cutting parameters for S/N ratios were determined as illustrated in Figure 3.

Table 7.

The ANOVA values for S/N ratios.

Figure 3.

Main effect plots of cutting parameters for S/N ratios.

Figure 3 indicates the main effect plots for the grinding time which clearly shows that the 3rd level of cutting depth (0.03 mm), 3rd level of wheel speed (5000 rpm) and 3rd level of feed rate (3500 mm/min) were the optimum values of cutting parameters for the grinding time. These values would help to get the least grinding time.

3.3. Determining the Optimum Surface Roughness Value

From the above results of the experiment, the predicted optimum value of the grinding time was determined by the levels of the cutting parameters that strongly affect the S/N ratio as follows:

where, , are the mean grinding time values corresponding to the cutting depth value, the wheel speed value, and the feed rate value, respectively, at the third level; is the mean grinding time value of the total experiment. The values of these parameters can be determined from Table 4 as follows:

Therefore:

3.4. Determining Confidence Interval

The confidence interval (CI) is calculated by:

where, fe is the freedom degrees of error (fe = 2), Ve is the average error (Ve = 0.1206), is the Fisher coefficient corresponding to the confidence level (α) of 90% (, R is the number of iterations of an experiment, and Ne is the number of effective iterations which can be computed as follows:

where, Ssum is the total number of experiments and Af is the total freedom of all averaged parameters. Substituting , Ve, R and Ne into (3) we have:

Accordingly, at a confidence level (α) of 90%, the grinding time is predicted with the optimum level of the input parameters as follows:

Or:

In addition, a confirmation experiment was conducted to evaluate the appropriateness of the optimum parameters. The experimental results and predicted values are given in Table 8. Since the error between experimental and predicted value was appropriately 6.6% of the range, the experimental work is said to be satisfactory.

Table 8.

Comparison results between calculation value and experimental value.

4. Conclusions

In this paper, the process parameters influencing the machining time in grinding operation for tablet punches were optimized and analyzed using the Taguchi method. The research method used in this paper is credible and verified by confirmation experiments, which can provide meaningful guidance in selecting input parameters of the grinding process of tablet punches by CBN wheel on CNC milling machine. Based on the analytical and experimental results obtained in this study, the following conclusions are drawn:

The input parameters like the feed rate and the cutting depth have a significant effect on the grinding time, whereas the grinding wheel speed has the least effect on the grinding time.

The optimized parameters for minimum grinding time are a cutting depth of 0.03 mm, wheel speed of 5000 rpm and feed rate of 3500 mm/min. The optimized minimum grinding time is 9.4 min.

A model in determining the grinding time is therefore recommended. The error between the values of the grinding time calculated by the proposed model and measured from the experimental result is appropriately 6.6% of the range. This is also proven to be an effective way to grind tablet shape punches with the least duration of time.

Author Contributions

All authors discussed the original idea. A.-T.L., V.-T.N., N.-P.V. and X.-H.L. designed and performed the experiments; A.-T.N. wrote this manuscript with support from Q.-T.N., T.-H.T., H.-K.L., and N.-P.V.; N.-P.V and V.-T.N. conducted the figure of experiment setup; all authors provided critical feedback and helped shape the research, analysis, and manuscript; N.-P.V. supervised this work and revised the article.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Chatterjee, S.; Rudrapati, R.; pal, P.K.; Nand, G. Experiments, analysis and parametric optimization of cylindrical traverse cut grinding of aluminum bronze. Mater. Today Proc. 2018, 5, 5272–5280. [Google Scholar] [CrossRef]

- Gupta, R.; Shishodia, K.S.; Sekhon, G.S. Optimization of grinding process parameters using enumeration method. J. Mater. Process. Technol. 2001, 112, 63–67. [Google Scholar] [CrossRef]

- Li, G.F.; Wang, L.S.; Yang, L.B. Multi-parameter optimization and control of the cylindrical grinding process. J. Mater. Process. Technol. 2002, 129, 232–236. [Google Scholar] [CrossRef]

- Pereverzev, P.P.; Akintseva, A.V. Automatic Cycles Multiparametric Optimization of Internal Grinding. Procedia Eng. 2015, 129, 121–126. [Google Scholar] [CrossRef]

- Lin, B.; Zhou, K.; Guo, J.; Liu, Q.Y.; Wang, W.J. Influence of grinding parameters on surface temperature and burn behaviors of grinding rail. Tribol. Int. 2018, 122, 151–162. [Google Scholar] [CrossRef]

- Vidal, G.; Ortega, N.; Bravo, H.; Dubar, M.; González, H. An Analysis of Electroplated cBN Grinding Wheel Wear and Conditioning during Creep Feed Grinding of Aeronautical Alloys. Metals 2018, 8, 350. [Google Scholar] [CrossRef]

- Pandiyan, V.; Caesarendra, W.; Tjahjowidodo, T.; Praveen, G. Predictive Modelling and Analysis of Process Parameters on Material Removal Characteristics in Abrasive Belt Grinding Process. Appl. Sci. 2017, 7, 363. [Google Scholar] [CrossRef]

- Ky, L.H.; Hong, T.T.; Dung, H.T.; Tuan, N.A.; van Tung, N.; Tung, L.A.; Pi, V.N. Optimization of dressing parameters for grinding table shape punches by CBN wheel on CNC milling machine. Int. J. Mech. Eng. Technol. 2019, 10, 960–967. [Google Scholar]

- Du, S.; Chen, M.; Xie, L.; Zhu, Z.; Wan, X. Optimization of process parameters in the high-speed milling of titanium alloy TB17 for surface integrity by the Taguchi-Grey relational analysis method. Adv. Mech. Eng. 2016, 8, 1–12. [Google Scholar] [CrossRef]

- Thi-Bich, M.; Van-Chien, D.; Tien-Long, B.; Duc-Toan, N. Cutting Force Model for Thermal-Assisted Machining of Tool Steel Based on the Taguchi Method. Metals 2018, 8, 992. [Google Scholar] [CrossRef]

- Nguyen, H.; Hsu, Q. Surface Roughness Analysis in the Hard Milling of JIS SKD61 Alloy Steel. Appl. Sci. 2016, 6, 172. [Google Scholar] [CrossRef]

- Do, T.; Hsu, Q. Optimization of Minimum Quantity Lubricant Conditions and Cutting Parameters in Hard Milling of AISI H13 Steel. Appl. Sci. 2017, 6, 83. [Google Scholar] [CrossRef]

- Niu, W.; Mo, R.; Chang, Z.; Wan, N. Investigating the Effect of Cutting Parameters of Ti–6Al–4V on Surface Roughness Based on a SPH Cutting Model. Appl. Sci. 2019, 9, 654. [Google Scholar] [CrossRef]

- Kim, N.; Bhalerao, I.; Han, D.; Yang, C.; Lee, H. Improving Surface Roughness of Additively Manufactured Parts Using a Photopolymerization Model and Multi-Objective Particle Swarm Optimization. Appl. Sci. 2019, 9, 151. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).