Rapid Prototyping of Multi-Functional Battery Energy Storage System Applications

Abstract

:1. Introduction

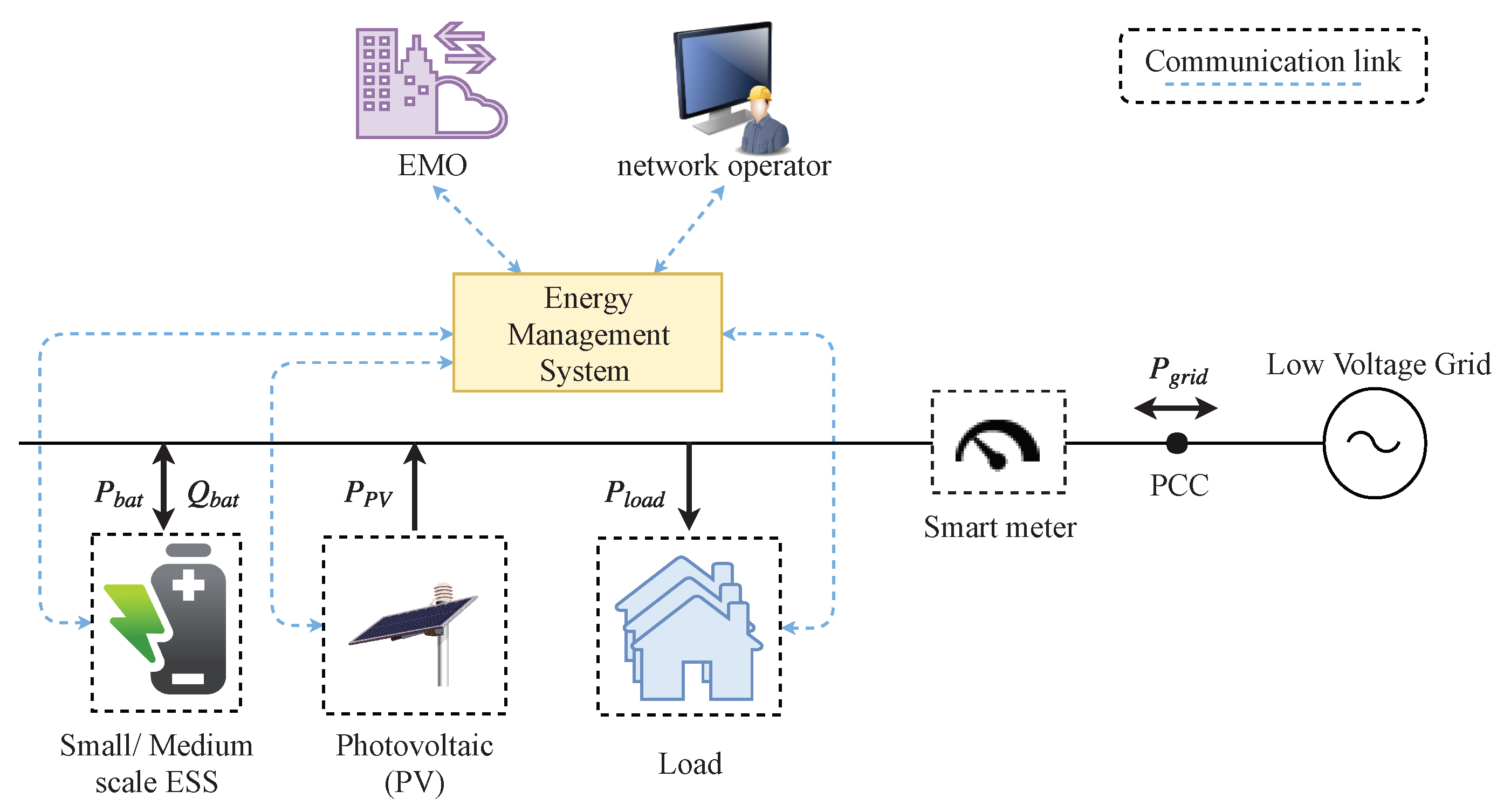

2. Multi-Functional Energy Storage System Application Development

2.1. Use Cases and Applications

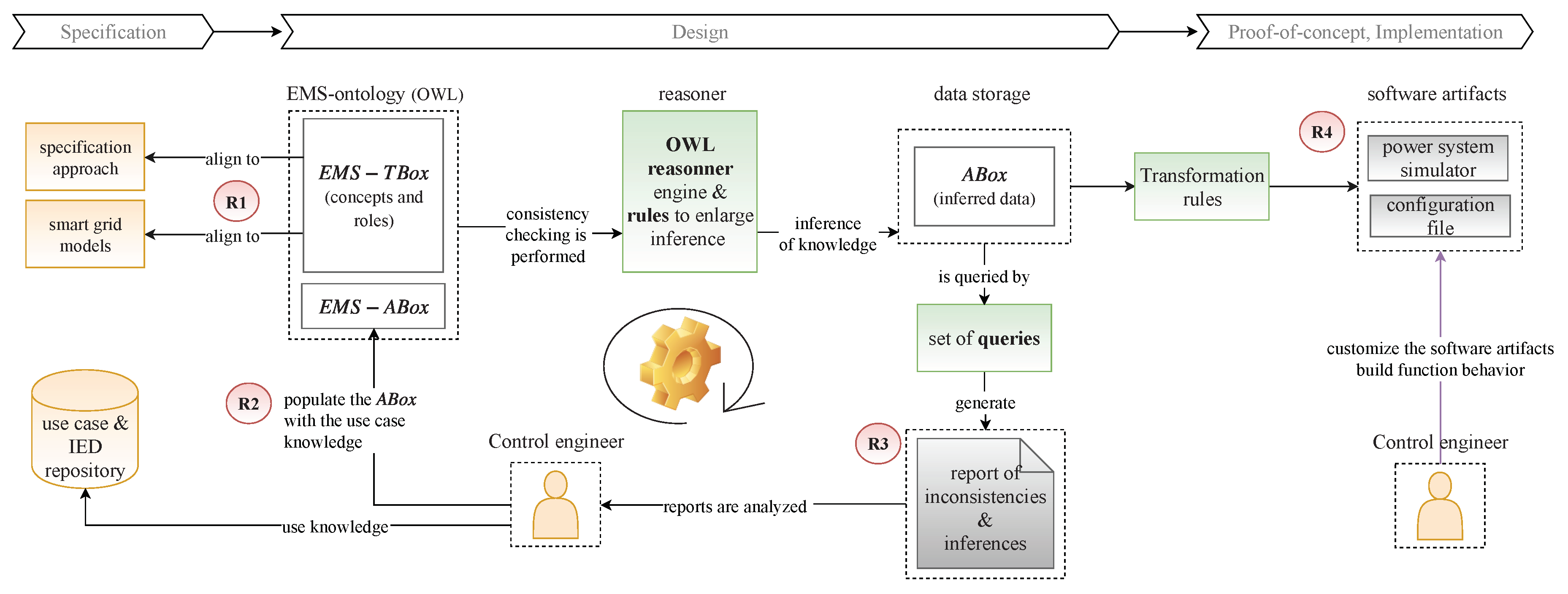

2.2. Specification and Development Process

2.3. Open Issues

- Flexibility: The integration of new and different actors into the power distribution grid such as Electrical Vehicles (EV) and EMO motivates evolving services focused on BESS participation. Thus, EMS should be flexible enough to implement those services and future ICT requirements.

- Complexity: The complex-nature of EMS is based on the manifold of services provided by BESS and the deployment of them in the ICT and power system infrastructure. The implementation of such services may be centralized or decentralized. In case of a decentralized configuration, where services are deployed in different hardware controllers, more than one control engineer may be required for the EMS design. Thereby, the lack of a common vocabulary and design language may lead to errors during EMS design and later on operation in the field.

- Overlapping: An EMS focused on multi-services for BESS is vulnerable to conflicts between UCs. This overlapping across them could cause a non-expected function behavior. For instance, an EMS that operates UC2 and UC3 would need to setup mechanisms to align both use cases in the event of a simultaneous operation. Otherwise, those UCs would not be attained.

- Interoperability: The realization and validation of smart grid and BESS-based applications entails the use of a wide range of power system, automation and communication tools. This goes from power system emulators/design, network simulators to co-simulation frameworks. However, a method to interoperate those tools during the whole chain of the engineering process is missing.

3. Related Work and Background

3.1. Smart Grid Domain Standards

- IEC 61970/IEC 61968 Common Information Model (CIM): Its main concern is to ensure interoperability across power networks, [18]. Thereby, it offers a common semantic for EMS, Supervisory and Control Data Acquisition (SCADA) and power system topology. This is formally represented by a Unified Modeling Language (UML) model, including over 1300 classes.

- IEC 61850: It is mainly conceived to improve interoperability between IEDs in a power system substation; nowadays, it has been extended to DERs and power utility components among other areas [8]. Functional aspects of an IED are mapped into a Logical Node (LN). They are referenced in the standard IEC 61850-7-4 and extended by IEC 61850-7-420 [19], where functionalities of DERs such as inverters and batteries are modeled.

- IEC 62325: It provides a set of standards related to market communication using CIM, covering data models for market participants and market operators.

- IEC 62056: It applies mainly to smart home and data exchange for meter reading.

- Open Platform Communications Unified Architecture (OPC UA): Since the EMS should support the exchange with other IEDs distributed along the power utility grid, the consideration of information models from the automation domain such as OPC UA is relevant. It is a standard of OPC foundation that focuses on exchanging real-time data within the process automation. It is platform-independent, thereby not tied to one operating system. It is standardized under IEC 62541, part 5 of that standard defines the information model (IEC 62541-5) [20].

3.2. Smart Grid Control Application Development Approaches

- Unified Modeling Language: UML is a general-purpose language for an object-oriented software development [21]. It has been standardized by the Object Management Group (OMG) and approved as an ISO standard. UML specifies behavior and structural diagrams to model software applications. Thereby, it has been used in the power system domain to model use cases [22].

- System Modeling Language (SysML): SysML is conceived as an extension of a subset of UML. It is mainly designed to support the system engineering process (i.e., specification, design). Thereby, elements in UML not required by systems engineering were excluded to conceive SysML [21].

- IntelliGrid (IEC 62559): Intelligrid introduces a methodology to document and detail smart grid UCs. From this, a UC template [23] that covers best practices to describe requirements engineering is originated. In those templates, a UC may be described by a visual representation (e.g., UML diagram). IEC 62559 is largely accepted by the power system community as an example the adoption of it by the ELECTRA project [22].

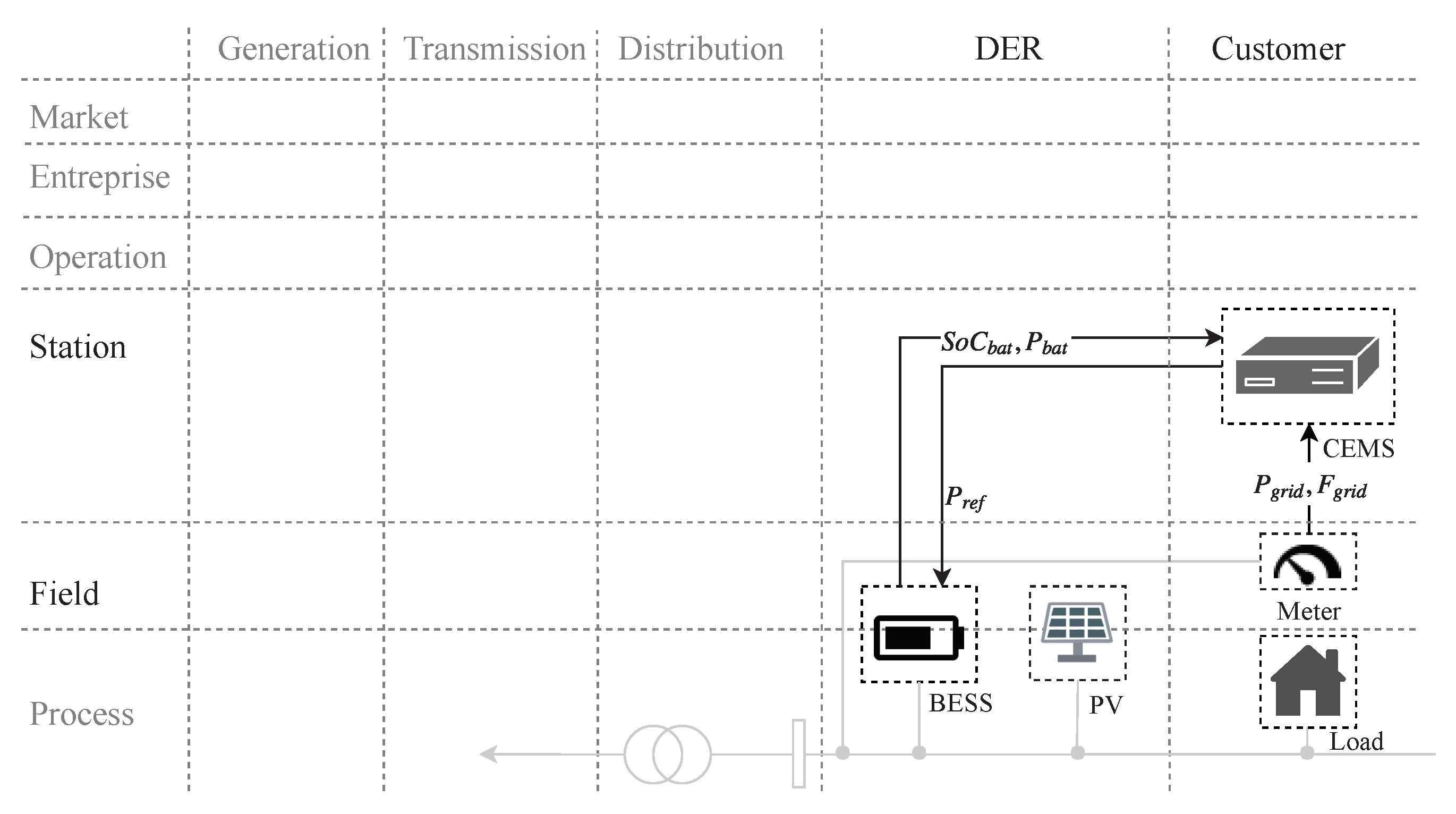

- Smart Grid Architecture Model: SGAM is introduced by the SG-CG/RA (Smart Grid Coordination Group/Reference Architecture) [24]. SGAM is conceived to model smart grid uses cases architecture in a technology-neutral manner. It consists of five interoperability layers, those layers are matched to a smart grid plane composed of domains and zones. The domains cover the electricity conversion chain (i.e., transmission, distribution, etc.). The zones cover the automation pyramid (i.e., process, field, etc.). An implementation of SGAM is conceived in [25] as a plugin of the Sparx Systems Enterprise Architecture tool, it is called SGAM-Toolbox (SGAM-TB).

- Power System Automation Language: PSAL is a DSL to model SGAM compatible use case specifications. It supports control engineers during the whole development process, from use case design to implementation and deployment. In addition to this, PSAL offers executable code and communication configuration file generation [7].

- MATLAB/Simulink: This tool provides libraries to model and simulate electrical power systems. C-code generation is also contemplated for a rapid prototyping of MATLAB/Simulink models. Since this tool is largely accepted and employed in the power system domain, it is considered as a worthy approach to be analyzed along the control application development process.

- IEC 61499: This approach provides a reference model for Distributed Control Systems (DCS) in the domain of industrial processes. A main objective is to reach portability, configurability and interoperability across DCSs [9].

- IEC 61131-3: IEC 61131 is an IEC standard supported by Programmable Logic Controller (PLC). One of the main goals of IEC 61131 is to standardize the programming approaches. Thus, the part IEC 61131-3 offers graphical and textual programming languages such as function block diagram and structured text among others [10].

3.3. Ontologies for Smart Grid Applications

3.4. Model-Driven Engineering in Power Systems

3.5. Research Needs and Requirements

- Alignment with Domain Standards (R1): An appropriate solution to model a multi-functional BESS should benefit from the extensive data models provided by the mentioned standards in Section 3.1.

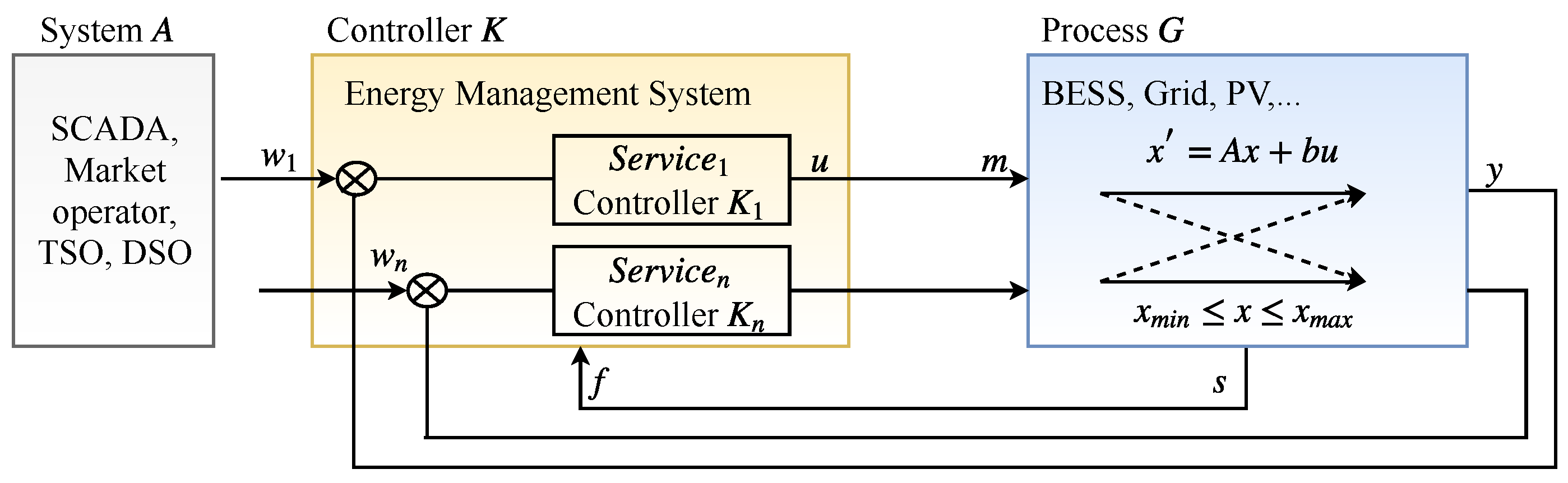

- Common Ontology for Multi-Functional BESS (R2): A comparison of smart grid control development approaches was carried out in Section 3.2. This demonstrates a lack of one approach that fully covers the function and information domains during the design phase. What is not covered is a method to handle a high amount of data and also a vocabulary for a common understanding of EMS applications. The characterization of EMS behavior is dismissed since it is completely covered by other approaches (e.g., MATLAB, IEC 61499). Attempts to propose a pattern for control strategies were done in SGAM. However, it needs to be enlarged in order to cover features mainly important to BESS use cases. An ontology is a good candidate to integrate the knowledge from EMS as highlighted in Section 3.3. Thereby, R2 searches for an ontology focused on multi-functional BESS and also for mechanisms to achieve a population of it. The resulting ontology that represents and describes EMS should guide control engineers during the design stage. A derived benefit from this is to enable the access of EMS capabilities to external systems (e.g., EMO).

- Identification of Conflicts and Inconsistencies (R3): An early diagnosis of potential conflicts within EMS corresponds to the overlapping issue in Section 2.3. That topic was tackled in [37], as a result a classification of conflicts (Conflict ) and its modeling by ontologies is achieved. In addition to this, the study formally defines DL queries to identify the classified conflicts and a handling solution per conflict type is exposed and recommended. The outcomes from [37] should be implemented in a whole solution that supports the design of EMS.

- Generation of Software Artifacts (R4): One of the issues highlighted in Section 2.3 requires implementing EMS applications into different power system tools (i.e., design, emulator). Thereby, the generation of software artifacts at the proof-of-concept and implementation phase should be assured. MDE invokes two types of transformations: Model-to-model (M2M) and Model-to-text (M2T) transformations by the setting up of transformation rules. Both transformations should be carried out at the design stage, and this would improve the rapidity and interoperability of the EMS engineering process. The generation of code and models from an EMS platform-independent model is part of the requirement R4.

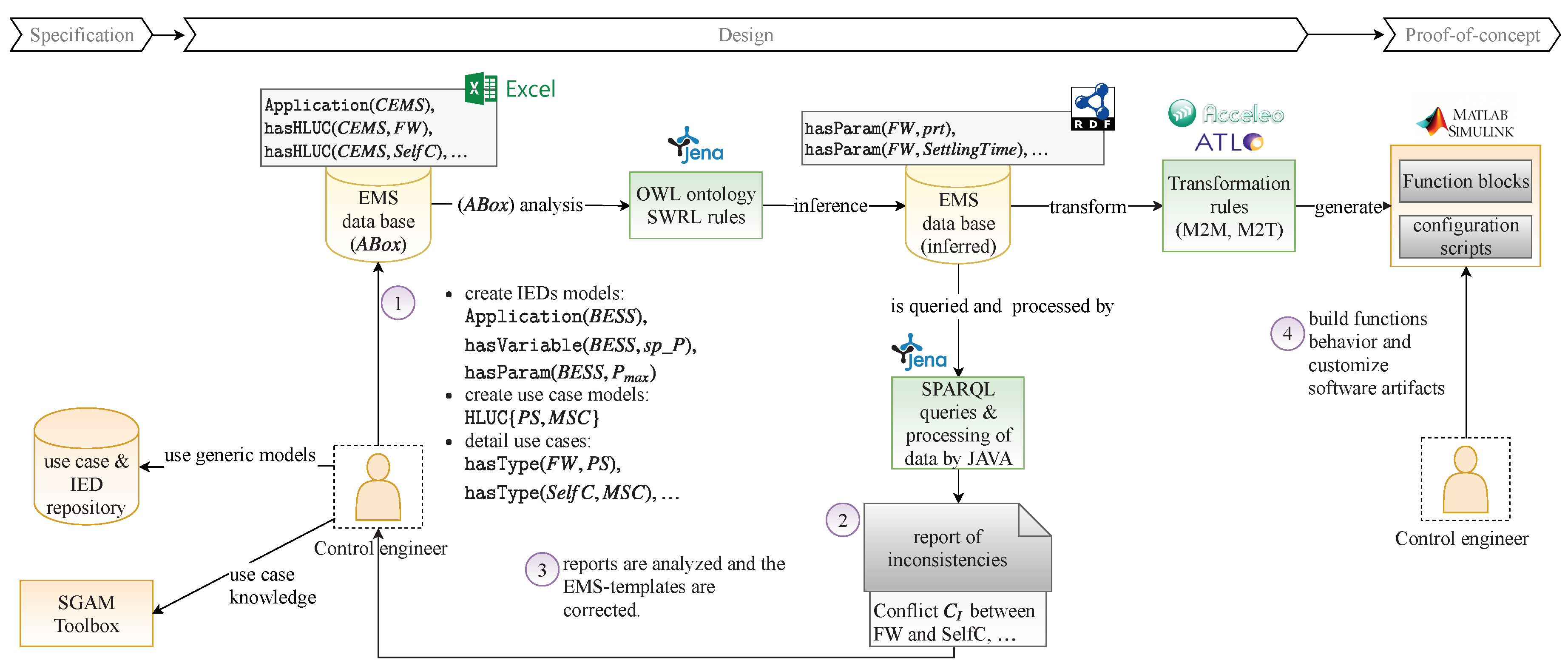

4. Application Development with the EMSOnto Approach

4.1. General Overview of the Approach

4.2. Core EMS-Ontology Use Cases

4.3. Alignment with Smart Grid Domain Models

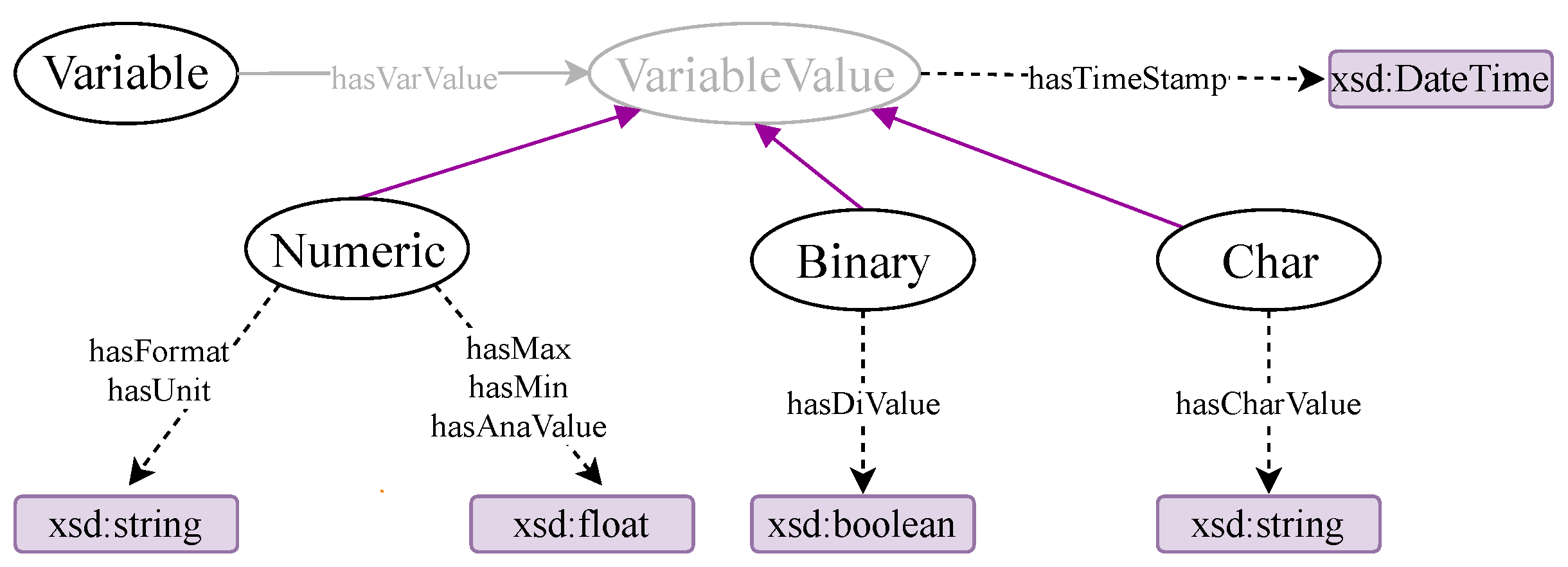

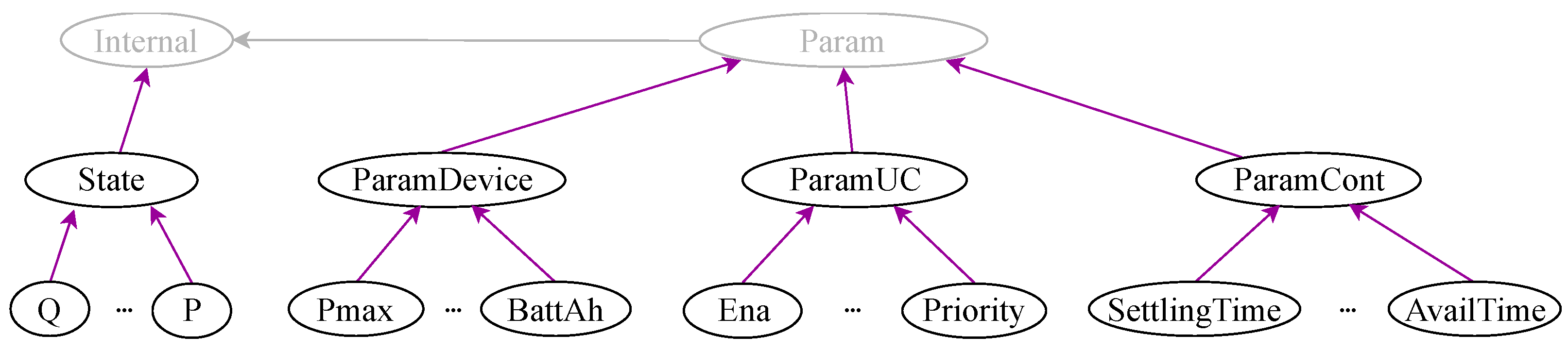

4.4. EMS-Ontology for Modelling BESS Applications

4.5. Templates for Application Design

- Knowledge is consistent with the : EMS-templates set restrictions to the data gathered within the spreadsheets. Control engineers manually fill those spreadsheets, where data entered is pre-checked to be aligned to the already specified . For instance, the knowledge: a control signal is assigned only to variables of type setpoint, is represented by the axiom within the . Due to EMS-templates being built under the basis, only setpoints can be associated with control variables in the scope of EMS-templates.

- Gathering unlimited amount of data: None of the approaches already presented in Table 2 support control engineers with an easy collection and treatment of data. EMS-templates ease the gathering of data because of the tabular format. Moreover, filtering, comparison, ordering, exporting, data formatting, etc. are also possible in a large set of tools to process tabular format (e.g., Microsoft Excel, OpenOffice, LibreOffice Calc, etc.).

- Setting-up of models: EMS-templates facilitate the creation of pre-defined models to be stored within the IED and use case repository for further use (e.g., , ). Those models are afterward assigned to individuals of type EMS, BESS, HLUC, etc. by the role hasType. Moreover, EMS-templates enable the inspection of available models within the repository.

4.6. Controller Inconsistencies Identification

4.7. Generation of Software Artifacts

5. Proof-of-Concept Evaluation

5.1. Framework Prototype and Validation Example

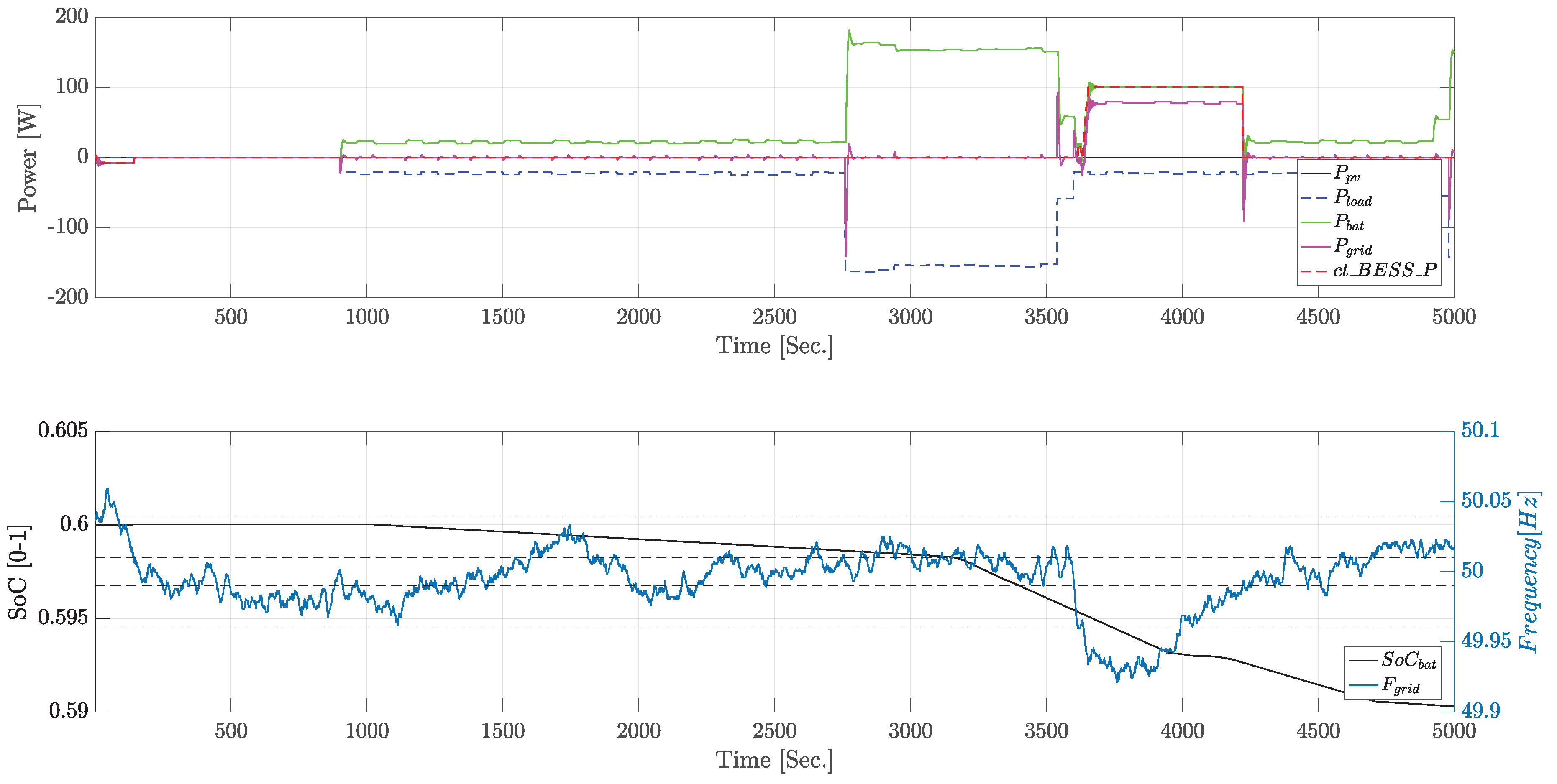

5.1.1. BESS Model

5.1.2. PV, Load, Grid Profiles

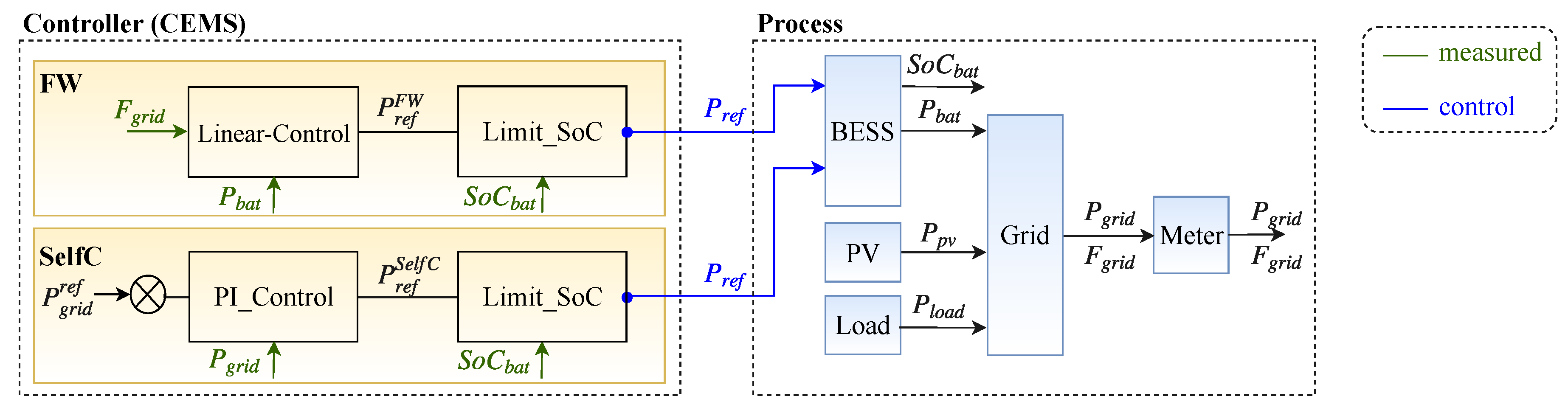

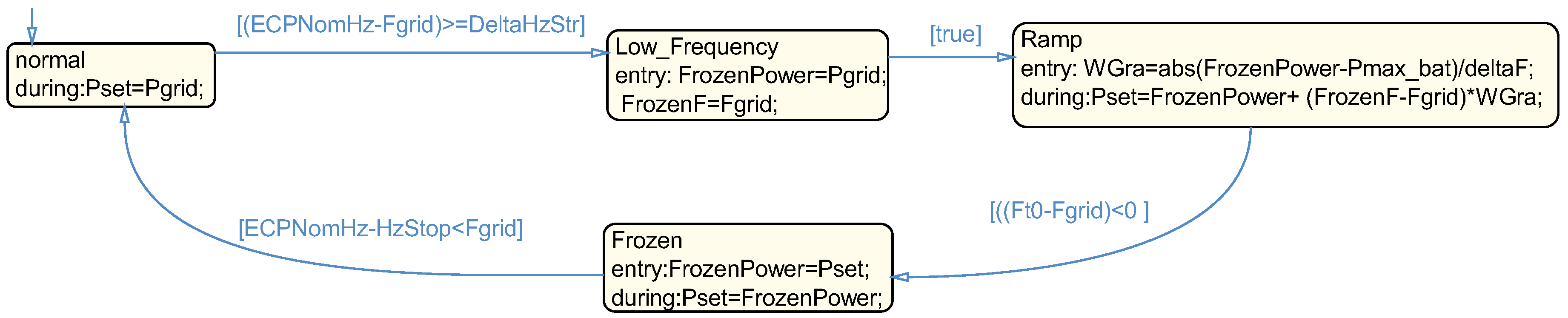

5.1.3. Control Mechanism

5.2. Realized Development Example

5.2.1. Step 1: CEMS Description via EMS-Templates

5.2.2. Step 2: Assertions Derived from EMS-ABox

5.2.3. Step 3: Design of the EMS based on Analysis of Reports

5.2.4. Step 4: Customization of the Software Artifacts

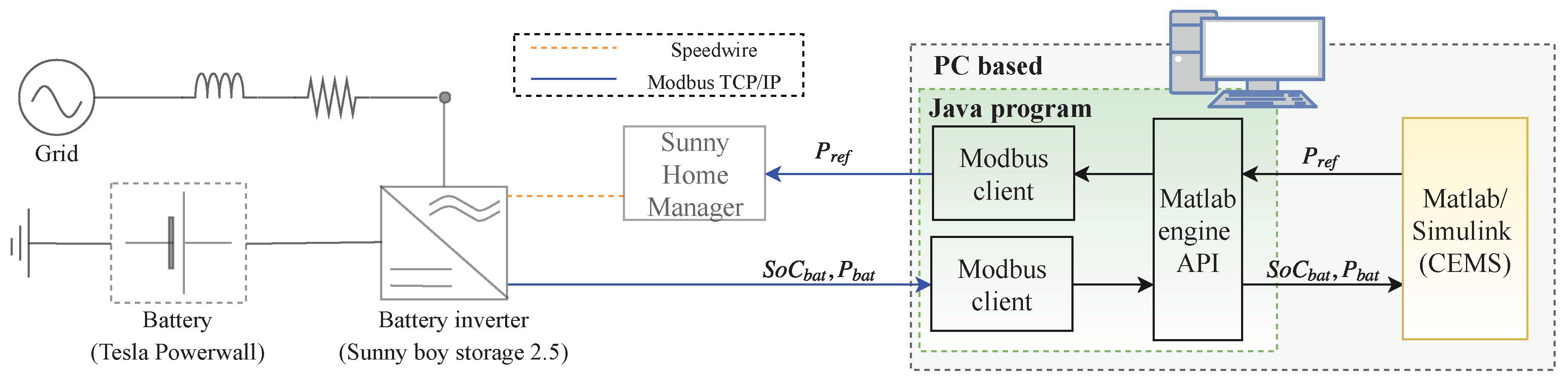

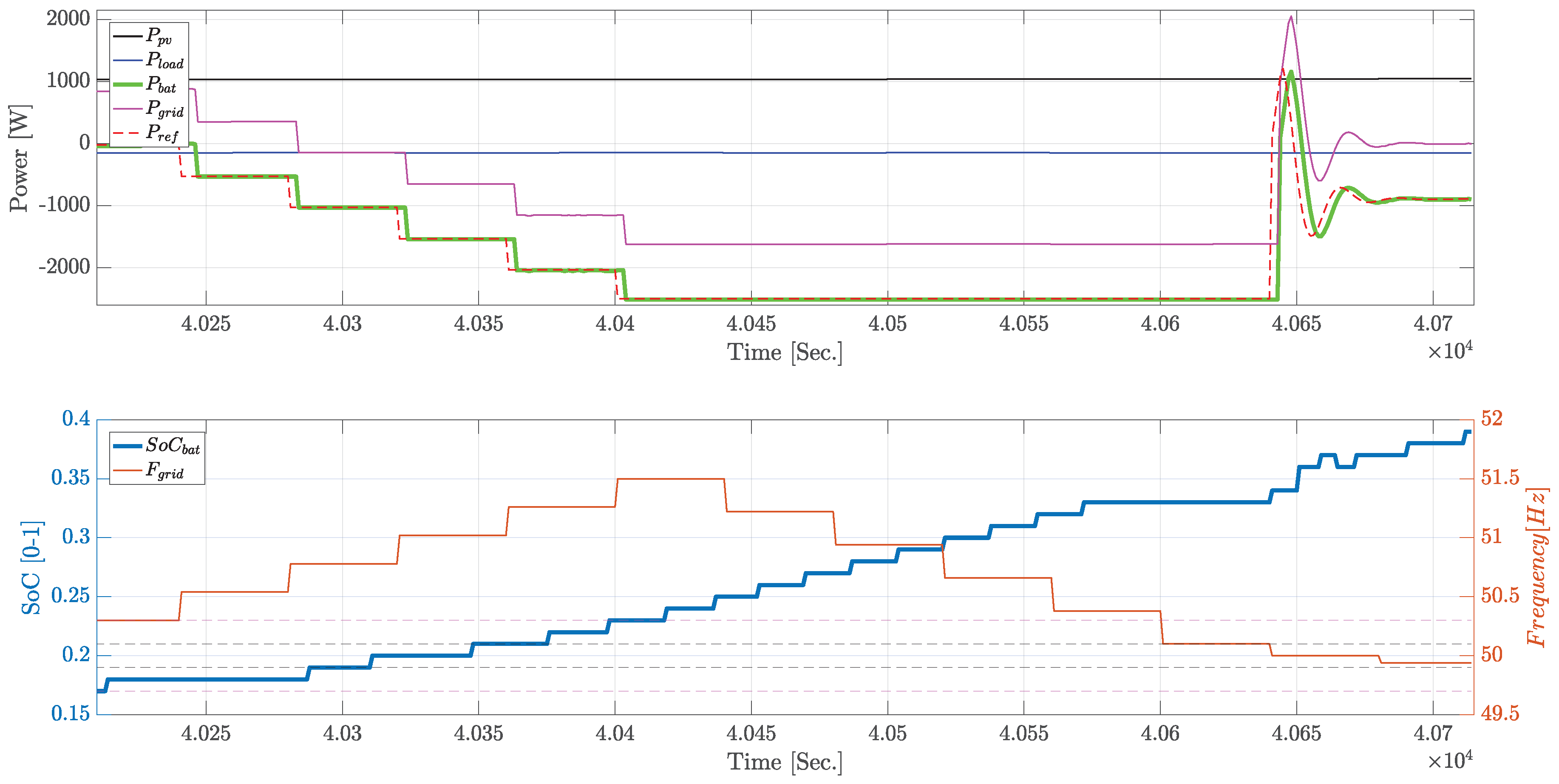

5.3. Laboratory Implementation and Results

5.4. Evaluation of Requirements and Open Issues

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A. TBox of the EMS Ontology

References

- Tayyebi, A.; Bletterie, B.; Kupzog, F. Primary Control Reserve and Self-Sufficiency Provision with Central Battery Energy Storage Systems. In Proceedings of the 2017 Conference on Sustainable Energy Supply and Energy Storage Systems (NEIS), Hamburg, Germany, 21–22 September 2017; pp. 21–22. [Google Scholar]

- Braam, F.; Diazgranados, L.M.; Hollinger, R.; Engel, B.; Bopp, G.; Erge, T. Distributed Solar Battery Systems Providing Primary Control Reserve. IET Renew. Power Gener. 2016, 10, 63–70. [Google Scholar]

- Kathan, J. Increasing the Hosting Capacity of Photovoltaics with Electric Storage-Simulation and Hardware-in-the-Loop Concept. Master’s Thesis, Vienna University of Technology, Wien, Austria, 2011. [Google Scholar]

- EERA Joint Programme on Smart Grids-Sub-Programme 4-Electrical Energy Technologies; Technical Report D4.3 Integration of Storage Resources to Smart Grids: Possible Services, D4.4 Control Algorithms for Storage Applications in Smart Grid; EERA: Brussels, Belgium, 2014.

- Riffonneau, Y.; Bacha, S.; Barruel, F.; Ploix, S. Optimal Power Flow Management for Grid Connected PV Systems With Batteries. IEEE Trans. Sustain. Energy 2011, 2, 309–320. [Google Scholar] [CrossRef]

- Zanabria, C.; Pröstl Andrén, F.; Strasser, T.I. Comparing Specification and Design Approaches for Power Systems Applications. In Proceedings of the 2018 IEEE PES Transmission and Distribution Conference and Exhibition–Latin America, Lima, Peru, 18–21 September 2018; p. 5, in press. [Google Scholar]

- Andrén, F.; Strasser, T.; Kastner, W. Engineering Smart Grids: Applying Model-Driven Development from Use Case Design to Deployment. Energies 2017, 10, 374. [Google Scholar] [CrossRef]

- International Electrotechnical Commission. IEC 61850: Communication Networks and Systems for Power Utility Automation; International Electrotechnical Commission: Geneva, Switzerland, 2010. [Google Scholar]

- Zoitl, A.; Lewis, R. Modelling Control Systems Using IEC 61499; The Institution of Engineering and Technology: Stevenage, UK, 2014. [Google Scholar]

- International Electrotechnical Commission. IEC 61131-3: Programmable Controllers—Part 3: Programming Languages; International Electrotechnical Commission: Geneva, Switzerland, 2012. [Google Scholar]

- Zanabria, C.; Pröstl Andrén, F.; Kathan, J.; Strasser, T. Towards an Integrated Development of Control Applications for Multi-Functional Energy Storages. In Proceedings of the IEEE 21st International Conference on Emerging Technologies and Factory Automation (ETFA), Berlin, Germany, 6–9 September 2016; pp. 1–4. [Google Scholar]

- International Electrotechnical Commission. IEC/TR 61850-90-7—Communication Networks and Systems for Power Utility Automation—Part 90-7: Object Models for Power Converters in Distributed Energy Resources (DER) Systems; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- Von Appen, J.; Stetz, T.; Braun, M.; Schmiegel, A. Local Voltage Control Strategies for PV Storage Systems in Distribution Grids. IEEE Trans. Smart Grid 2014, 5, 1002–1009. [Google Scholar] [CrossRef]

- Faschang, M. Rapid Control Prototyping for Networked Smart Grid Systems Based on an Agile Development Process. Ph.D. Thesis, Vienna University of Technology, Wien, Austria, 2015. [Google Scholar]

- Faschang, M.; Schwalbe, R.; Einfalt, A.; Mosshammer, R. Controller Hardware in the Loop Approaches Supporting Rapid Prototyping of Smart Low Voltage Grid Control. In Proceedings of the IEEE PES Innovative Smart Grid Technologies, Istanbul, Turkey, 12–15 October 2014; pp. 1–5. [Google Scholar]

- Andrén, F.; Lehfuss, F.; Strasser, T. A Development and Validation Environment for Real-Time Controller-Hardware-in-the-Loop Experiments in Smart Grids. Int. J. Distrib. Energy Resour. Smart Grids 2013, 9, 27–50. [Google Scholar]

- International Electrotechnical Commission. IEC Smart Grid Standardization Roadmap; International Electrotechnical Commission: Geneva, Switzerland, 2013. [Google Scholar]

- Uslar, M.; Specht, M.; Rohjans, S.; Trefke, J.; González, J.M. The Common Information Model CIM: IEC 61968/61970 and 62325-A Practical Introduction to the CIM; Springer Science & Business Media: Berlin, Germany, 2012; Volume 66. [Google Scholar]

- International Electrotechnical Commission (IEC). Communication Networks and Systems in Substations–Part 7-420: Communications Systems for Distributed Energy Resources (DER)–Logical Nodes; International Electrotechnical Commission: Geneva, Switzerland, 2006. [Google Scholar]

- Mahnke, W.; Leitner, S.H.; Damm, M. OPC Unified Architecture; Springer: Berlin, Germany, 2009. [Google Scholar]

- Weilkiens, T. Systems Engineering with SysML/UML: Modeling, Analysis, Design; Elsevier: New York, NY, USA, 2011. [Google Scholar]

- Tornelli, C.; Radaelli, L.; Rikos, E.; Uslar, M. WP 4 Fully Interoperable Systems. Deliverable R4.1: Description of the Methodology for the Detailed Functional Specification of the ELECTRA Solutions; Technical Report; European Educational Research Association: Berlin, Germany, 2015. [Google Scholar]

- International Electrotechnical Commission (IEC). IEC 62559-2 Use Case Methodology-Part2: Definition of the Templates for Use Cases, Actor List and Requirement List; IEC: Geneva, Switzerland, 2015. [Google Scholar]

- CEN-CENELEC-ETSI Smart Grid Coordination Group. Reference Architecture for the Smart Grid; Technical Report; CEN-CENELEC-ETSI Smart Grid Coordination Group: Brussels, Belgium, 2012. [Google Scholar]

- Dänekas, C.; Neureiter, C.; Rohjans, S.; Uslar, M.; Engel, D. Towards a Model-Driven-Architecture Process for Smart Grid Projects. In Digital Enterprise Design & Management; Springer: Cham, Switzerland, 2014; Volume 261, pp. 47–58. [Google Scholar]

- Hitzler, P.; Krotzsch, M.; Rudolph, S. Foundations Of Semantic Web Technologies; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Baader, F. The Description Logic Handbook: Theory, Implementation and Applications; Cambridge University Press: Cambridge, UK, 2003. [Google Scholar]

- Santodomingo, R.; Rohjans, S.; Uslar, M.; Rodríguez-Mondéjar, J.; Sanz-Bobi, M. Ontology Matching System for Future Energy Smart Grids. Eng. Appl. Artif. Intell. 2014, 32, 242–257. [Google Scholar] [CrossRef]

- Dubinin, V.; Vyatkin, V.; Yang, C.W.; Pang, C. Automatic Generation of Automation Applications Based on Ontology Transformations. In Proceedings of the 2014 IEEE International Conference on Emerging Technology and Factory Automation (ETFA), Barcelona, Spain, 16–19 September 2014; pp. 1–4. [Google Scholar]

- Schachinger, D.; Kastner, W.; Gaida, S. Ontology-Based Abstraction Layer for Smart Grid Interaction in Building Energy Management Systems. In Proceedings of the 2016 IEEE International Energy Conference (ENERGYCON), Leuven, Belgium, 4–8 April 2016; pp. 1–6. [Google Scholar]

- Zhou, Q.; Natarajan, S.; Simmhan, Y.; Prasanna, V. Semantic Information Modeling for Emerging Applications in Smart Grid. In Proceedings of the 2012 Ninth International Conference on Information Technology—New Generations, Las Vegas, NV, USA, 16–18 April 2012; pp. 775–782. [Google Scholar]

- Samirmi, F.D.; Tang, W.; Wu, Q. Fuzzy Ontology Reasoning for Power Transformer Fault Diagnosis. Adv. Electr. Comput. Eng. 2015, 15, 107–114. [Google Scholar] [CrossRef]

- Feldmann, S.; Herzig, S.J.; Kernschmidt, K.; Wolfenstetter, T.; Kammerl, D.; Qamar, A.; Lindemann, U.; Krcmar, H.; Paredis, C.J.J.; Vogel-Heuser, B. Towards Effective Management of Inconsistencies in Model-Based Engineering of Automated Production Systems. IFAC-PapersOnLine 2015, 48, 916–923. [Google Scholar] [CrossRef]

- Brambilla, M.; Cabot, J.; Wimmer, M. Model-Driven Software Engineering in Practice. Synth. Lect. Softw. Eng. 2012, 1, 1–182. [Google Scholar] [CrossRef]

- Strasser, T.; Rooker, M.; Ebenhofer, G.; Hegny, I.; Wenger, M.; Sünder, C.; Martel, A.; Valentini, A. Multi-Domain Model-Driven Design of Industrial Automation and Control Systems. In Proceedings of the 2008 IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Hamburg, Germany, 15–18 September 2008; pp. 1067–1071. [Google Scholar]

- Andrén, F.; Strasser, T.; Kastner, W. Model-Driven Engineering Applied to Smart Grid Automation Using IEC 61850 and IEC 61499. In Proceedings of the Power Systems Computation Conference (PSCC), Wroclaw, Poland, 18–22 August 2014; pp. 1–7. [Google Scholar]

- Zanabria, C.; Pröstl Andrén, F.; Kathan, J.; Strasser, T. Approach for Handling Controller Conflicts within Multi-Functional Energy Storage Systems. CIRED-Open Access Proc. J. 2017, 2017, 1575–1578. [Google Scholar] [CrossRef]

- Zanabria, C.; Tayyebi, A.; Pröstl Andrén, F.; Kathan, J.; Strasser, T. Engineering Support for Handling Controller Conflicts in Energy Storage Systems Applications. Energies 2017, 10, 1595. [Google Scholar] [CrossRef]

- Sirin, E.; Parsia, B.; Grau, B.C.; Kalyanpur, A.; Katz, Y. Pellet: A Practical OWL-DL Reasoner. Web Semant. Sci. Serv. Agents World Wide Web 2007, 5, 51–53. [Google Scholar] [CrossRef]

- Working Group Sustainable Processes (SG-CG/SP). CEN-CENELEC-ETSI Smart Grid Coordination Group—Sustainable Processes; Technical Report, CEN-CENELEC-ETSI; Working Group Sustainable Processes (SG-CG/SP): Brussels, Belgium, 2012. [Google Scholar]

- International Electrotechnical Commission. Communication Networks and Systems for Power Utility Automation. Part 7-3: Basic Communication Structure-Common Data Classes; International Electrotechnical Commission: Geneva, Switzerland, 2011. [Google Scholar]

- Lutz, C.; Areces, C.; Horrocks, I.; Sattler, U. Keys, Nominals, and Concrete Domains. J. Artif. Intell. Res. 2005, 23, 667–726. [Google Scholar]

- Tremblay, O.; Dessaint, L.A.; Dekkiche, A.I. A Generic Battery Model for the Dynamic Simulation of Hybrid Electric Vehicles. In Proceedings of the 2007 IEEE Vehicle Power and Propulsion Conference, Arlington, TX, USA, 9–12 September 2007; pp. 284–289. [Google Scholar]

- Skoplaki, E.; Palyvos, J. On the Temperature Dependence of Photovoltaic Module Electrical Performance: A Review of Efficiency/Power Correlations. Sol. Energy 2009, 83, 614–624. [Google Scholar] [CrossRef]

- HELIOCLIM-3. 2005. Available online: http://www.soda-pro.com/web-services/radiation/helioclim-3-archives-for-free (accessed on 1 January 2015).

- Autonomous Decentralised Renewable Energy Systems-ADRES. 2009. Available online: https://www.ea.tuwien.ac.at/projects/adres_concept/EN/ (accessed on 1 January 2015).

- ENTSO-E Netzfrequenz. 2018. Available online: http://www.50hertz.com/de/Maerkte/Regelenergie/Regelenergie-Downloadbereich (accessed on 15 June 2018).

- Norma Italiana, CEI. Reference Technical Rules for the Connection of Active and Passive Users to the LV Electrical Utilities (in Italian); Norma Italiana, CEI: Milano, Italy, 2012. [Google Scholar]

- Martinez-Gil, J.; Aldana-Montes, J.F. Reverse Ontology Matching. ACM SIGMOD Rec. 2011, 39, 5. [Google Scholar] [CrossRef]

- Rohjans, S.; Uslar, M.; Juergen Appelrath, H. OPC UA and CIM: Semantics for the Smart Grid. In Proceedings of the Transmission and Distribution Conference and Exposition, 2010 IEEE PES, New Orleans, LA, USA, 19–22 April 2010; pp. 1–8. [Google Scholar]

- Baader, F.; Lippmann, M. Runtime Verification Using the Temporal Description Logic ALC-LTL Revisited. J. Appl. Log. 2014, 12, 584–613. [Google Scholar] [CrossRef]

| Use Case, Controller Type | Description |

|---|---|

| Volt-VAr mode (UC1) | Reactive power from the battery () is injected to stabilize the voltage at the Point of Common Coupling (PCC), see Volt-Var mode VV1 in [12]. |

| Frequency-watt (FW) (UC2) | Active power from the battery () supports the balancing of frequency of the grid (), see FW mode FW21 in [12]. |

| Self-consumption (UC3) | helps to minimize the energy consumed from the grid (), see PVBat1 control strategy in [13]. |

| Min. of costs with peak shaving (UC4) | Electricity costs are reduced and peak-shaving is pursued, see [5]. |

| Multi-functional BESS medium scale (UC5) | Self-consumption is provided to a group of households by injecting active power (), Primary Control Reserve (PCR) participation follows the logic in UC2. Voltage is controlled by reactive power provision ; to accomplish this, a Proportional Integral (PI) controller is designed as exposed in [1]. |

| Phase | Design | Proof | Implementation | ||||

|---|---|---|---|---|---|---|---|

| Approach | function | inform. | comm. | comp. | function | function | rapid prot. |

| UML |  | ✕ | ✕ | ✕ | ✕ |  | ✕ |

| SysML |  |  | ✕ | ✕ | ✕ |  | ✕ |

| IntelliGrid |  | ✕ | ✕ | ✕ | ✕ | ✕ | ✕ |

| SGAM-TB |  | ✕ |  |  | ✕ |  |  |

| PSAL |  |  | ✔ | ✔ | ✕ | ✔ | ✔ |

| MATLAB |  |  | ✕ |  | ✔ | ✔ | ✔ |

| IEC61499 |  |  | ✔ | ✔ | ✔ | ✔ | ✕ |

| IEC61131-3 |  |  | ✔ |  | ✔ | ✔ | ✕ |

), supported but not totally (

), supported but not totally (  ), and well supported (✔).

), and well supported (✔).| Regulat.-y | Setpoint- | Controller- | Control-u | |

|---|---|---|---|---|

| Volt-VAr mode (UC1) | : voltage at PCC : nominal voltage | open loop , : constants | ||

| Frequency-watt (UC2) | : nominal frequency | open loop , : constants | ||

| Self-consumption (UC3) | PI control | |||

| Minimization of costs with peak shaving (UC4) | : cash flow : feed-in tarif : electricity grid price | - | dynamic programming, | |

| Multi-functional BESS (UC5) | : setpoint from house-holds : setpoint from PCR service | PI control |

| SWRL Rule & DL Axiom | Description |

|---|---|

| , | The role hasControl is included within hasVariable. The range of hasControl is Control. |

| An individual x hasVariable y, if the variable y is of type Control. Then, it is deduced that, the individual x hasControl y. | |

| , | The role IsVarLinkVar has as range and domain the concept Variable. The assertion IsVarLinkVar(x,y) states that a manipulation of Variable(x) would affect the value of Variable(y). |

| , , | The role hasFctVar relates a ControlGoal with a Variable. The role IsFcLinkFc has as range and domain the concept ControlGoal. The constructor ∘ is of type composition [27]. It allows for stating a complex role inclusion axiom. The referred axioms investigate a ControlGoal that is manipulated by a PUC. |

| System | Application | Application Description | Type | HLUC | HLUC description | Type | PUC |

| Sys | Battery | battery connected to the grid | BESS | - | - | - | - |

| Sys | Meter | model of a meter located at PCC | Meter | - | - | - | - |

| Sys | HouseHold | pool of households that demands active power | Load | - | - | - | - |

| Sys | EMS | control application that deploys multi-services | - | VoltageCtr | battery supports the control of voltage at PCC point | PQ | PIControl |

| Sys | EMS | control application that deploys multi-services | - | FW | battery supports the regulation of grid frequency | PS | K1 |

| Sys | EMS | control application that deploys multi-services | - | SelfC | self-consumption is provided to a pool of houses | MSC | K2 |

| HLUC | Variable | Type | Variable Description | Value | Format | Unit | Min | Max |

| VoltageCtr | prt | Priority | priority of the use case | 2 | Float | - | - | - |

| VoltageCtr | SoC | UCSoC | SoC of the use case | 40 | Float | % | 20 | 80 |

| PUC | Variable | Type | variable description | Value | Format | Unit | Min | Max |

| PIControl | Feedback | voltage read from meter | 230 | double | volt | - | - | |

| PIControl | Control | signal to control react. power of a battery | 8 | double | kVar | −10 | +10 | |

| PUC | ControlGoal | control goal description | Var. | Type | IsVarLinkVar | |||

| PIControl | is regulated | Manipulated | - | |||||

| PIControl | is regulated | Param | - | |||||

| PUC | ControlGoal | Control Goal Description | manipulated | Variable | Type | IsVarLinkVar |

| puc1 | puc1 | x | Control | y | ||

| puc2 | , y: manipulated value, : setpoint | puc2, puc1 | y | Manipulated | - |

| Query | Description | DL Query |

|---|---|---|

| What is the Enable parameter of a specific HLUC named ? | ||

| What is the Priority parameter of a specific HLUC named ? | ||

| What are the main functionalities to be provided by an application of type EMS? | ||

| What are the sub-functionalities provided by a HLUC? | ||

| What are the parameters of a specific controller named ? |

| System | Application | Description | Type | HLUC | Description | Type |

| Sys | CEMS | cmcustomer energy management system | - | FW | active power is injected to support frequency regulation | PS |

| SelfC | power from the grid is avoided | MSC | ||||

| BESS | battery energy storage system | BESS | - | - | - | |

| PV | photovoltaic system | PV | - | - | - | |

| Meter | meter located at the pcc point | Meter | - | - | - | |

| Load | consumption of energy by the household | Load | - | - | - | |

| Grid | grid simulation to model the frequency and power behavior | Grid | - | - | - |

| HLUC | PUC | Description | Type | Variable | Description | Type |

| FW | Linear-Control | The active power is decreased or augmented linearly according to frequency variations | FWHZ | feedback of the frequency at the PCC point | Feedback | |

| FW | Limit_SoC | SoC of the battery is monitored before setting | - | signal to control the active power of the battery | Control | |

| SelfC | PI_Control | PI control is executed to keep equal to zero | - | signal to control the active power of the battery | Control |

| HLUC | Variable | Description | Type | Value | Format | Unit |

| FW | Prt | priority of the use case | ParamUC | 1 | Float | - |

| FW | SettlingTime | time within the reference value is reached | ParamCont | 30 | Float | sec |

| Application | Variable | Description | Type | Value | Format | Unit |

| BESS | sp_P | reference active power to control charge/discharge | Setpoint | - | double | kW |

| Pmax | maximum active power | Param | 4 | double | kW |

| PUC | Variable | Description | Type | Value | Format | Unit |

| Linear-Control | Wgra | active power gradient in percent of frozen active power value per Hz | Param | 40% | Float | W/Hz |

| Linear-Control | HzStr | delta frequency between start frequency and nominal frequency | Param | 0.04 | Float | Hz |

| Linear-Control | HzStop | delta frequency between stop frequency and nominal frequency | Param | 0.01 | Float | Hz |

| PUC | ControlGoal | Control Goal Description | Variable | Type | IsVarLinkVar |

| Linear-Control | Manipulated | PI_Control. | |||

| PI_Control | Manipulated | - |

| Inconsistency | Detected | Conclusion Derived from Queries | Control Engineer Analysis |

|---|---|---|---|

| Multi-objective optimization/ | ✔ | Linear-Control and PI_Control affect the same variable . PI_Control requires to be zero and Linear-Control requires equal to , which indirectly affects | This conflict is considered as severe, the recommendation from EMSOnto (PUC(CI)) is implemented |

| Setpoint set by at least two use cases/ | ✔ | The setpoint of the PUC(BESS) is set by two PUC{Limit_SoC, PI_Control} | The commanding of the same setpoint by two different PUC are not considered as a harmful conflict. However due to the presence of , only one control signal should be sent |

| HLUC | PUC | Description | Type | Variable | Description | Type |

| CEMS | Handling | A function that resolves the conflicts between FW and SelfC | SelfC_BESS_P | signal sent by the HLUC SelfC to control the active power of the battery | Feedback | |

| FW_BESS_P | signal sent by the HLUC FW to control the active power of the battery | Feedback |

| HLUC | Variable | Description | Type | Value | Format | Unit |

| FW | Prt | priority of the use case | ParamUC | 2 | Float | - |

| SelfC | Prt | priority of the use case | ParamUC | 1 | Float | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zanabria, C.; Andrén, F.P.; Kathan, J.; Strasser, T.I. Rapid Prototyping of Multi-Functional Battery Energy Storage System Applications. Appl. Sci. 2018, 8, 1326. https://doi.org/10.3390/app8081326

Zanabria C, Andrén FP, Kathan J, Strasser TI. Rapid Prototyping of Multi-Functional Battery Energy Storage System Applications. Applied Sciences. 2018; 8(8):1326. https://doi.org/10.3390/app8081326

Chicago/Turabian StyleZanabria, Claudia, Filip Pröstl Andrén, Johannes Kathan, and Thomas I. Strasser. 2018. "Rapid Prototyping of Multi-Functional Battery Energy Storage System Applications" Applied Sciences 8, no. 8: 1326. https://doi.org/10.3390/app8081326

APA StyleZanabria, C., Andrén, F. P., Kathan, J., & Strasser, T. I. (2018). Rapid Prototyping of Multi-Functional Battery Energy Storage System Applications. Applied Sciences, 8(8), 1326. https://doi.org/10.3390/app8081326