1. Introduction

With rapid economic development, global urbanization has reached an unprecedented level. High urbanization generates excessive resource consumption and increased carbon emissions, which results in great changes in the global climate [

1]. Cities are increasingly feeling the effects of extreme weather and many urban problems are caused by climate change, such as flooding and urban heat island phenomena [

2]. It is extremely urgent to seek solutions for the mitigation of climate change impact and urban water management [

3]. Pervious concrete, also called porous concrete, has been used since the 1970s in the United States and Japan. It is a kind of porous lightweight concrete made of aggregate, cement, and water. It has a honeycomb structure with uniformly distributed pores formed by coarse aggregate and a thin layer of cement paste [

4,

5]. With little or no fine aggregate, pervious concrete (PC) has the characteristics of high permeability, high noise absorption, and high heat dissipation [

6,

7,

8]. Compared to traditional impervious concrete pavement, PC pavement is a functionally and environmentally friendly material [

9]. It allows rainwater to permeate into the ground and replenish groundwater, which effectively alleviates the rapid decline of groundwater. In addition, PC pavement can solve other urban environmental problems [

10,

11,

12]. With the development of Chinese sponge city construction, PC will be widely applied in road structure [

13]. Therefore, PC is of great significance for mitigating climate change, solving urban problems, and promoting the development of human society [

14,

15,

16].

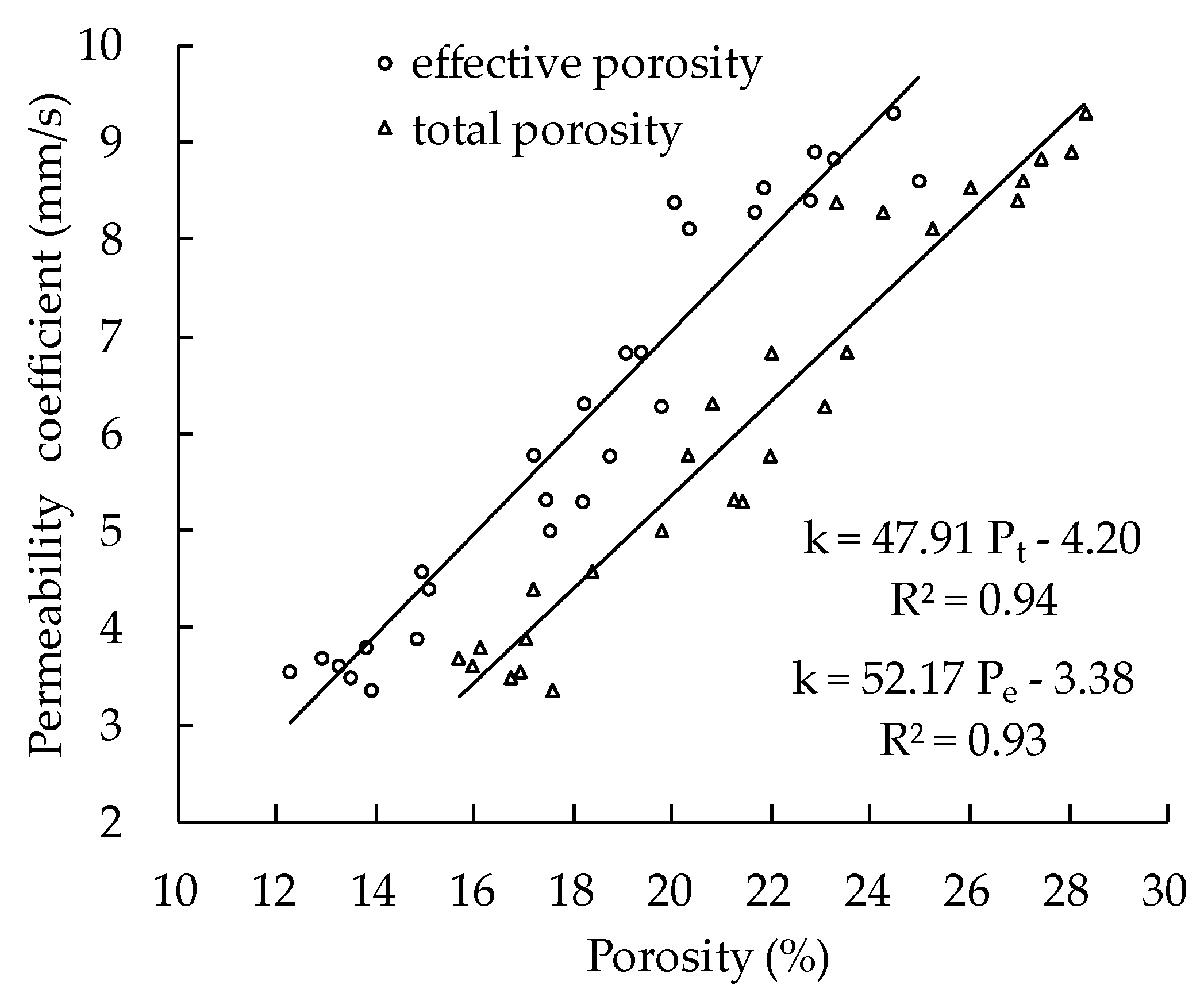

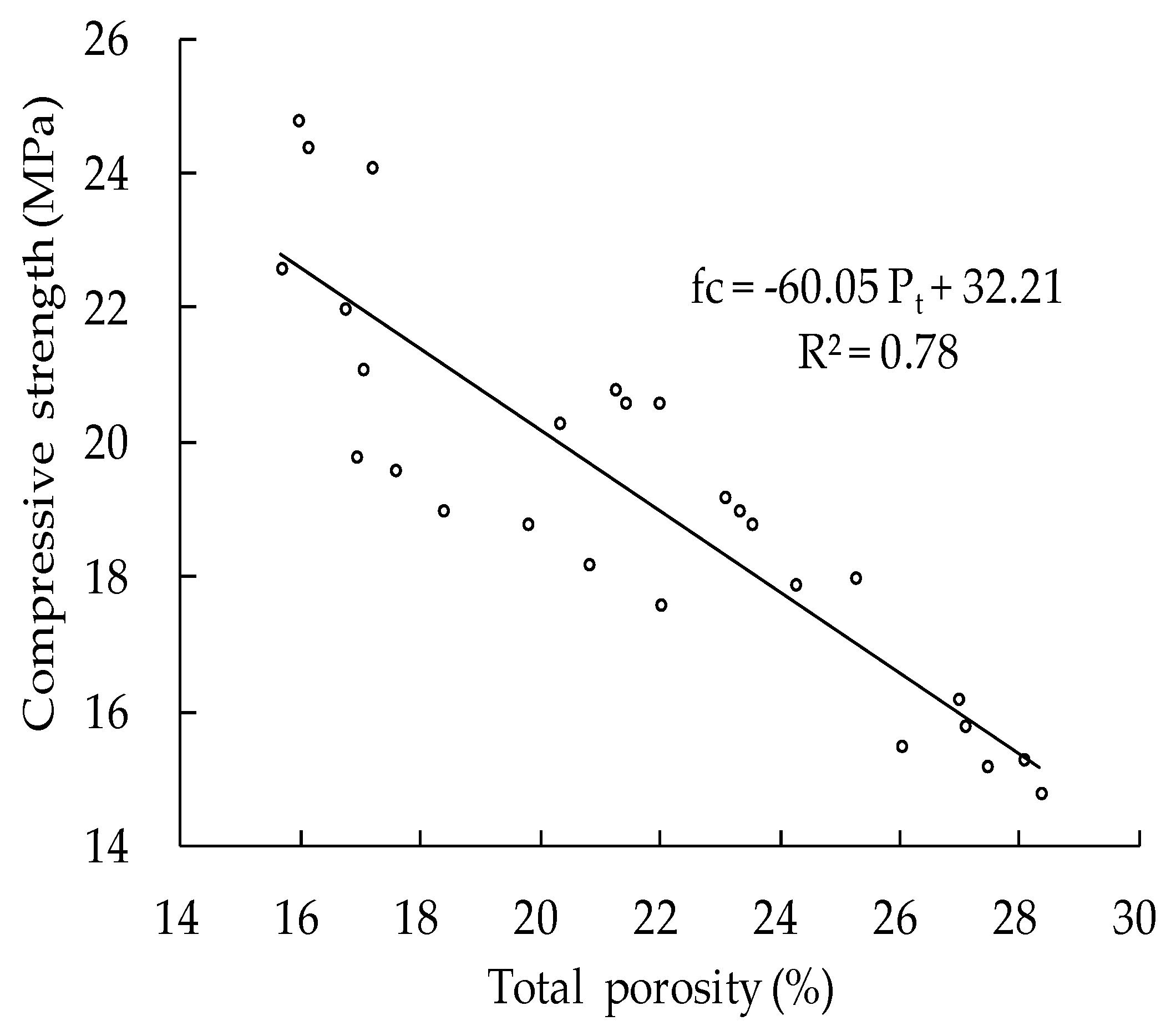

The main properties of PC are strength, permeability, and durability. A porous structure is the key feature of PC, and porosity is the most important factor influencing mechanical strength, permeability, and durability. In general, the porosity of PC mixtures is 15–30% and the corresponding permeability coefficient lies in the range of 1–15 mm/s [

17,

18]. Higher porosity produces higher permeability, but is disadvantageous to mechanical strength and durability. Due to the absence of fine aggregate and the existence of high porosity, the strength of PC is lower than that of traditional impervious concrete. The compressive strength of PC is 5–30 MPa and tensile strength is 1.5–4.0 MPa [

19,

20]. In addition, the freeze-thaw durability of PC is a very important property, especially for PC used in seasonally frozen regions. However, the freeze-thaw durability of PC is significantly lower than that of conventional concrete. Based on the characteristics of PC, it is widely used in low-volume areas such as parks, sidewalks, squares, airports, and residential roads.

A large number of laboratory studies have been conducted focusing on properties of PC. Li et al. [

21] used the orthogonal test method to study the influences of aggregate type, cementitious material dosage, and molding pressure on the permeability coefficient of PC. The experimental results showed that the aggregate type had no effect on the permeability coefficient, and the permeability coefficient decreased with an increased amount of cementitious material and forming pressure. Nguyen et al. [

22] proposed an improved design method for PC based on the aggregate surface area and cement mortar layer thickness. The PC designed with this method had a compressive strength of 28.6 MPa and a permeability coefficient of 1 mm/s. The compressive strength was higher than what was reported in other studies.

Kayhanian et al. [

23] studied the permeability of PC pavement in parking lots. It was concluded that age was the most important factor affecting permeability. Chandrappa and Biligiri [

24] produced 18 groups of PC specimens with different aggregate sizes and the permeability coefficients were measured with a falling head permeability test. Based on scanning electron microscopy (SEM), the effects of pore size, connectivity, and distribution on permeability were analyzed and the relationship between hydraulic gradient, flow velocity, and pore distribution was established. Zhong et al. [

25] studied the effect of pore tortuosity on the permeability of PC and proposed relative pore size and pore tortuosity indices. Relative pore size and pore tortuosity were introduced into the Kozeny–Carman model to assess permeability. At the same time, the effect of mortar workability, aggregate size, and aggregate-binder ratio on permeability was tested. The experimental results showed that the workability of cement affected the porosity tortuosity and aggregate size affected the connectivity of pores. The aggregate-binder ratio was directly related to effective porosity.

Gaedicke et al. [

26] studied the relationship between the split tensile strength and compressive strength of PC. The strength experiment was conducted with specimens molded in the lab and core samples obtained from actual pavement. The results showed that the type of aggregate had a great influence on the strength of PC. Based on the experimental data, a relationship between split tensile strength and compressive strength was proposed. Zhong and Wille [

27,

28] analyzed the influencing factors of compressive strength with different aggregate sizes and aggregate-binder ratios. The results indicated that strength decreased with increased aggregate size. The aggregate-binder ratio affected strength by affecting porosity. A semi-empirical prediction equation for PC compressive strength was established. The effects of cementitious material strength, total porosity, aggregate size, and average pore size on compressive strength were also studied. Li et al. [

29] produced a high-strength PC that was formed by making a certain number of vertical cylindrical holes 4 mm in diameter on high-strength concrete specimens. In the test, porosity was 1.3–2.8%, measured compressive strength was over 70 MPa, tensile strength was 10 MPa, and the water permeability coefficient reached 13–22 mm/s.

Akand et al. [

30] studied the relationship between microscopic pore structure and macroscopic properties of PC through scanning technology and the finite element method. 20% porosity concrete specimens were made in the lab. The pore size, distribution, and shape were obtained. Based on scanning images, the finite element model of PC was established. Strength and elastic modulus calculated by finite element model were compared with the measured values. The results showed that the accuracy of the established model was satisfied. Pieralisi et al. [

31] established PC discrete element constitutive law based on cementation between aggregate and cement paste. The effectiveness of the method was verified by the experiments with different aggregate types, grading curves, and aggregate-to-binder ratios. Based on the mathematical approach and the finite element method, Samuel et al. [

32] established the prediction model of permeability with the microstructure parameters (pore size, pore distribution) of PC. The predicted values of the model were consistent with the measured values.

The existing studies are mainly focused on the design of mixed ratios, mechanical properties, and permeability. The test parameters (such as aggregate size, water-binder ratio, and porosity) adopted are different, which results in a great difference among studies. For example, most researchers use mono-sized coarse aggregate, but some researchers adopt continuous-graded coarse aggregate. However, there are few studies concentrating on the influence of coarse aggregate size, water-binder ratio, and porosity on mechanical strength, permeability, and freeze-thaw durability of PC. It is necessary to carry out systematic and comprehensive research. Based on the current literature, this article studies the influence of aggregate size, porosity, and water-binder ratio on compressive strength, tensile strength, permeability coefficient, and freeze-thaw durability based on an orthogonal experiment.