Effect of Metallic Waste Addition on the Physical and Mechanical Properties of Cement-Based Mortars

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

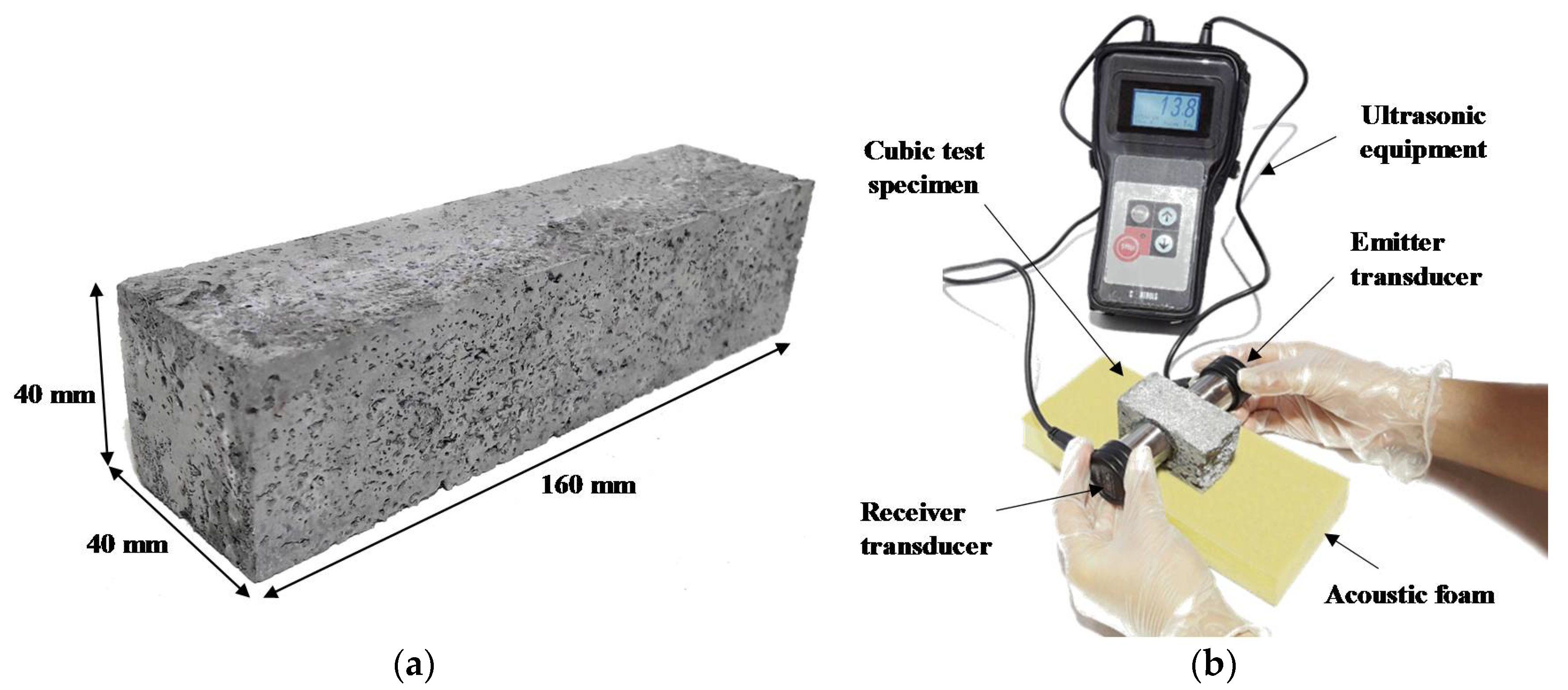

2.2. Manufacturing of the Test Specimens

- First, cement and sand were mixed under dry conditions for 60 s at low speed. At the same time, water and additive were manually mixed in a separate bowl. Then, water with additive was added to the laboratory mixer slowly for 60 s, and then quickly for 60 s.

- After that, the mix was left for 120 s, and then the process was finished with 60 s of fast mixing. In cases where metallic wastes was added to the mortar, they were gradually incorporated while mixing at low speed in order to avoid clusters. Then, the reinforced mortar mixture was mixed at low speed for 120 s.

- After the mixing process, the cement-mortar mixtures with and without metallic waste were poured into the prismatic metallic moulds (40 × 40 × 160 mm) from one end of the specimen to the other end using a wide scoop. The specimens were slightly vibrated for 5 s to minimise the presence of air bubbles inside them.

- Following the casting and compaction procedures, the prismatic moulds were covered with acetate sheets and placed in the laboratory at ambient conditions for 24 h to set prior to demoulding.

- After demoulding, the specimens were cured in a water tank with a standard controlled atmosphere at a temperature of 22 ± 5 °C and 97 ± 2% humidity for 7 and 28 days.

2.3. Chemical Characterisation of Raw Materials

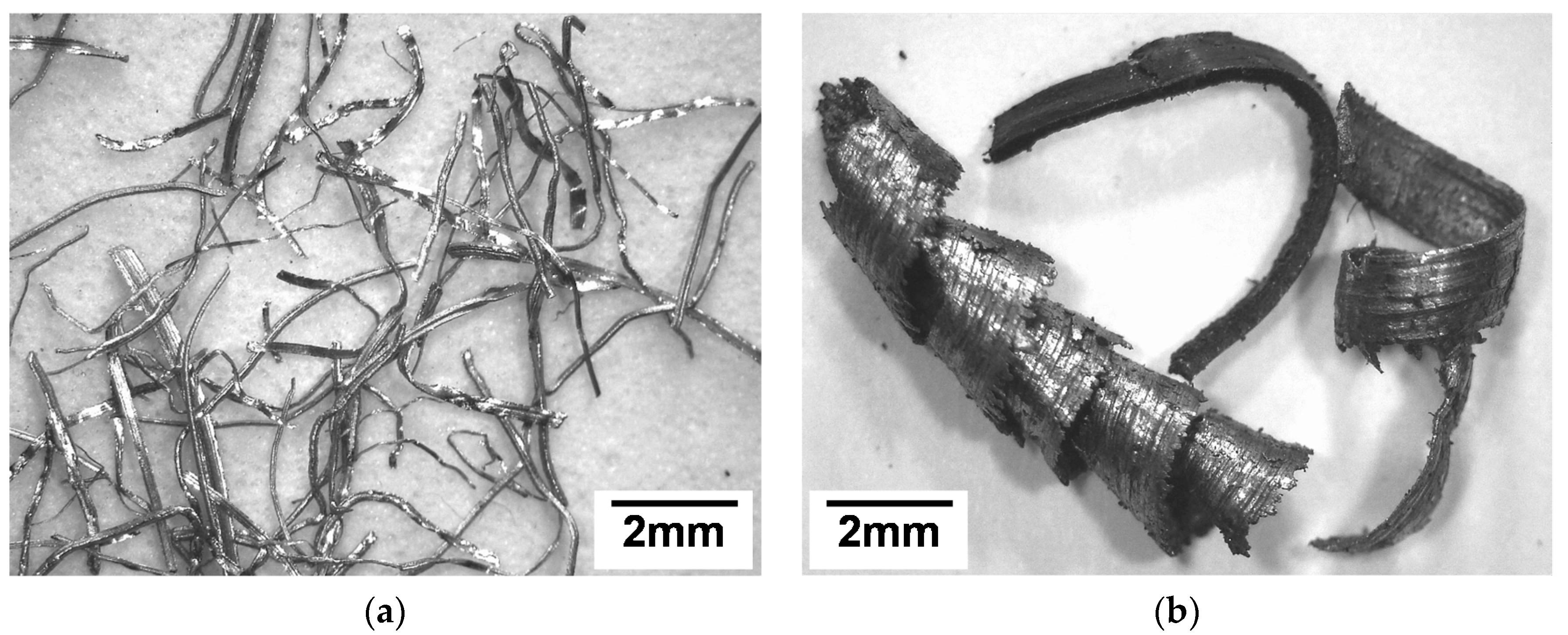

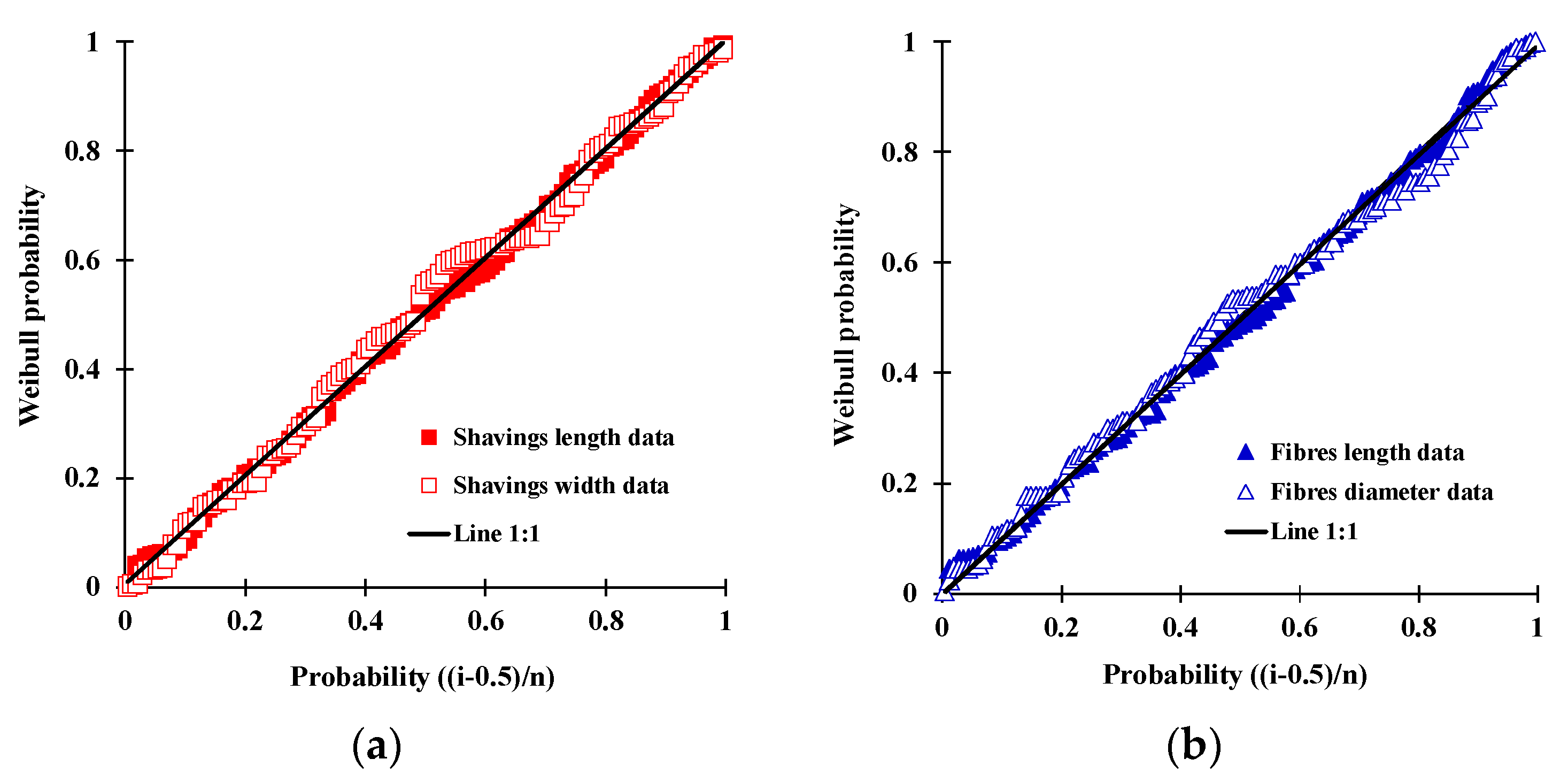

2.4. Morphological Characterisation of Metallic Waste

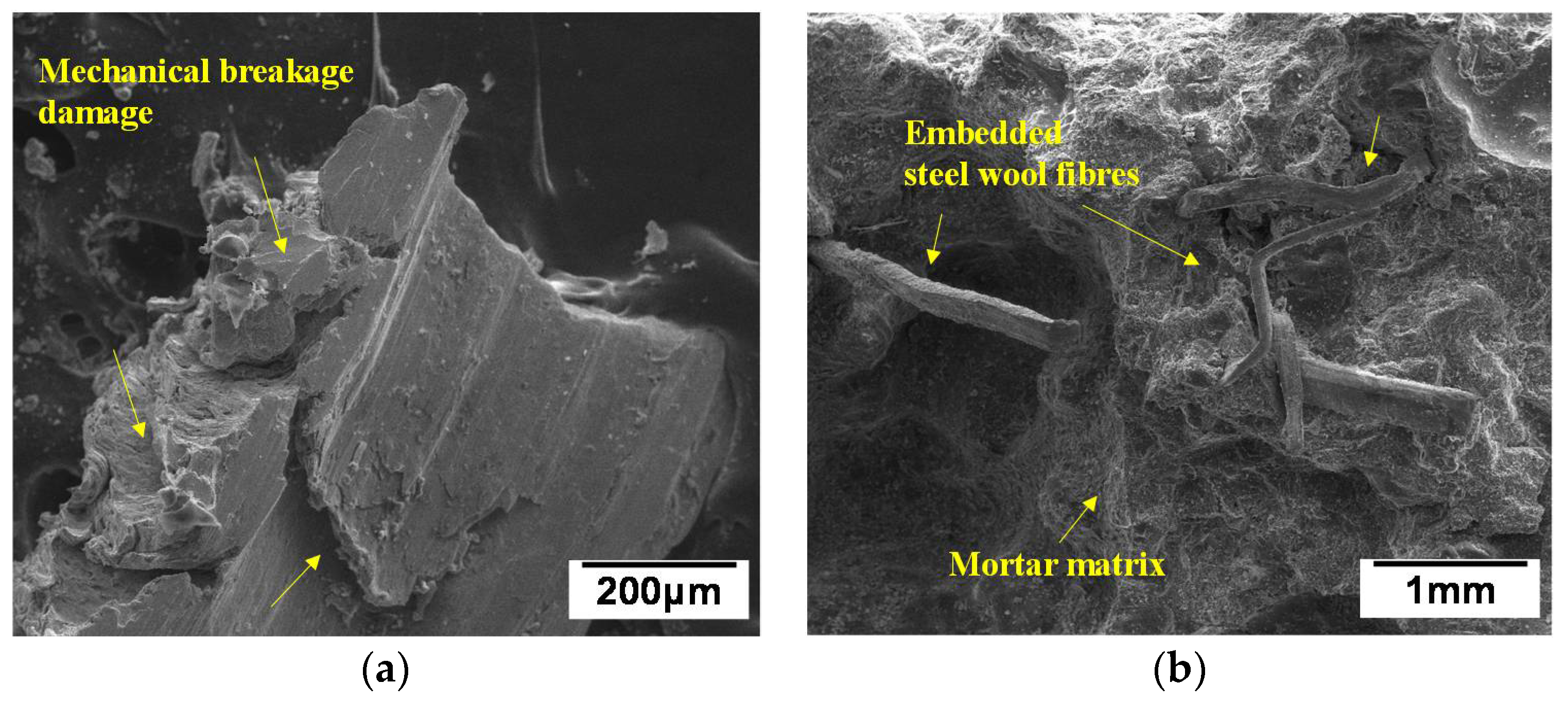

2.5. Fractographic Analysis of Cement Mortar Failure Surfaces by SEM

2.6. Measurement of the Density of Metallic Waste

2.7. Physical Characterisation of the Test Specimens

2.8. Flexural and Compressive Properties of the Test Specimens

2.9. Dynamic Elastic Modulus Measurement by Ultrasonic Test

3. Results and Discussion

3.1. Analysis of the Morphology and Composition of Metallic Waste

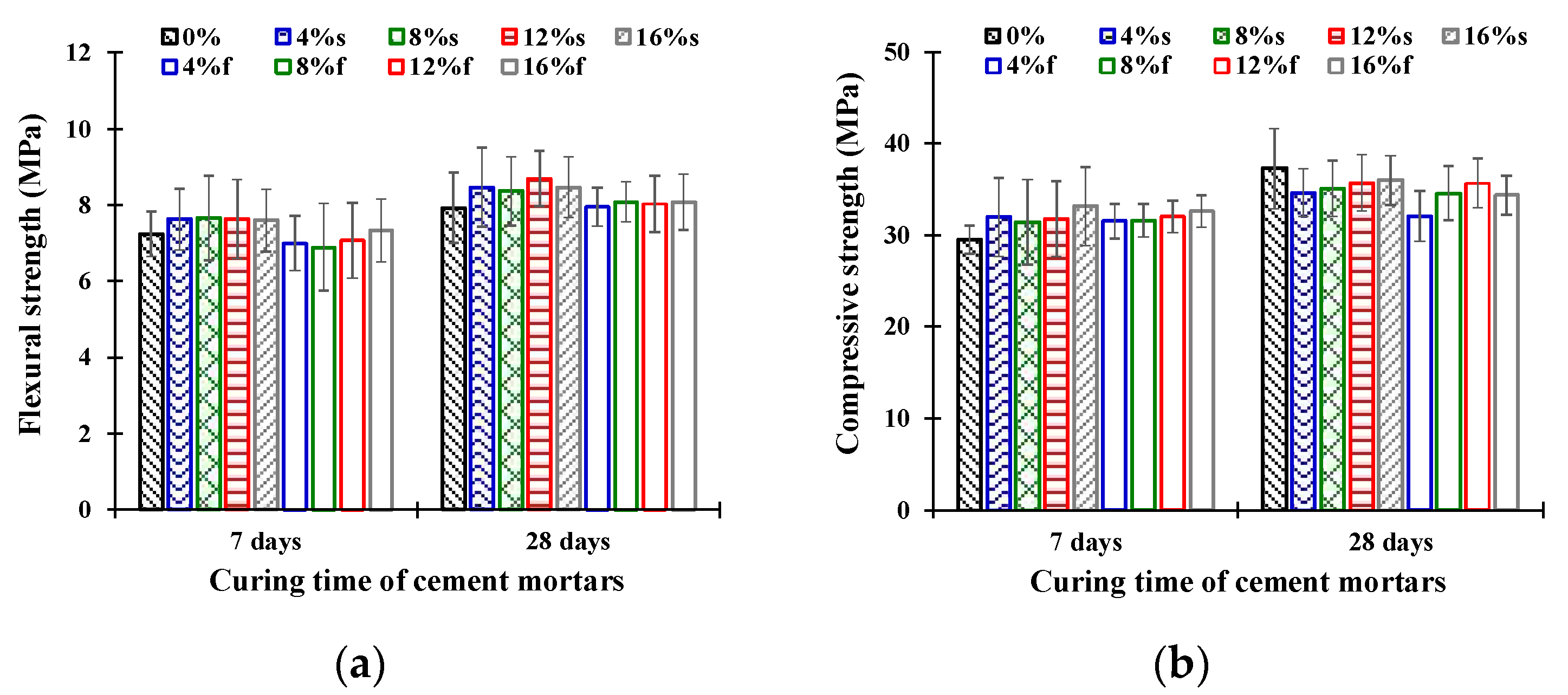

3.2. Effect of Metallic Waste on the Mechanical Strength of the Test Specimens

3.3. Influence of Metallic Waste on the Elastic Modulus of the Test Specimens

4. Conclusions

- Regarding the mechanical performance of mortar specimens, it was concluded that the addition of metallic waste produced slight variations on their flexural and compressive strength. In addition, mechanical resistance of mortar specimens with metallic waste proportionally increased with the increase of the waste content.

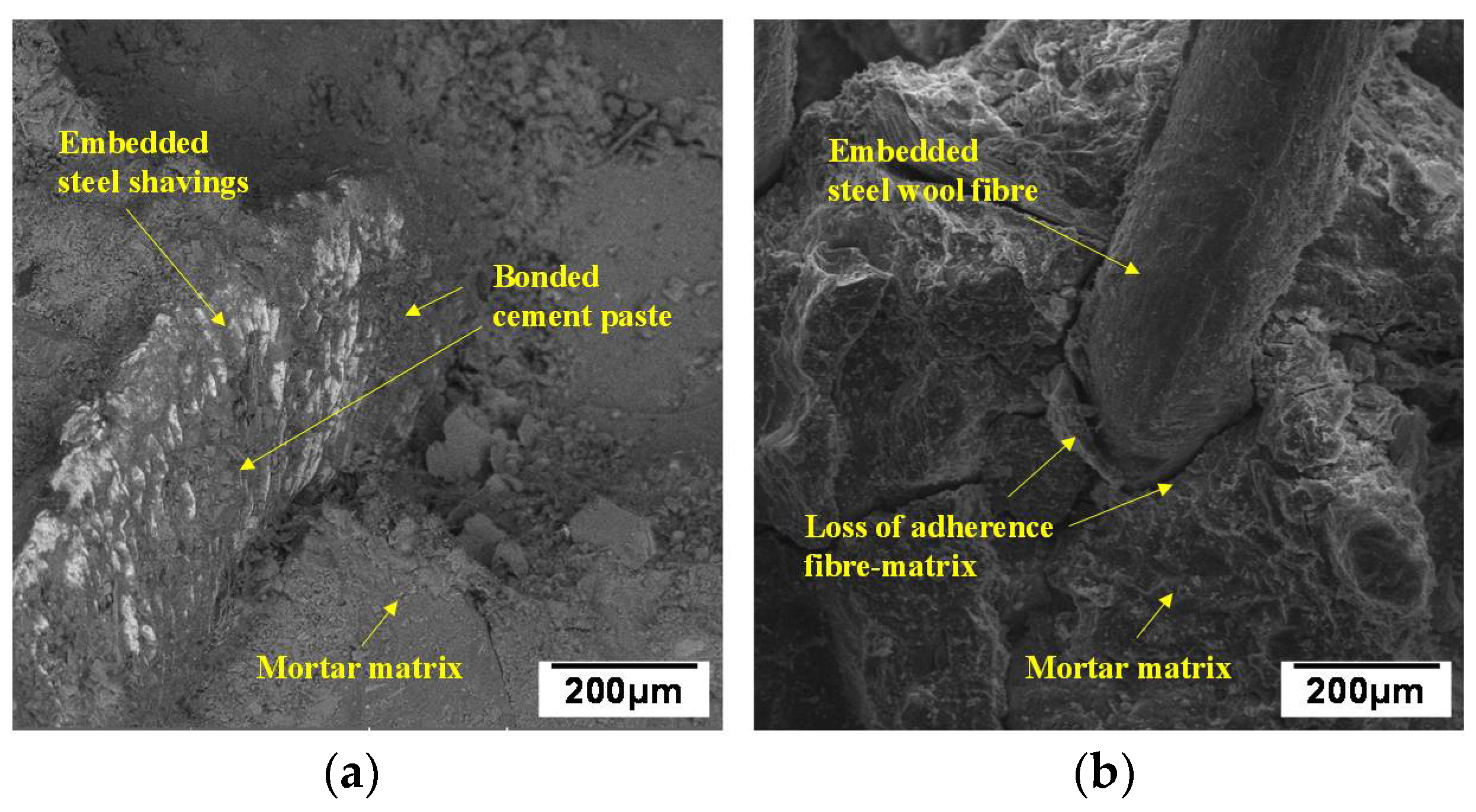

- Additionally, it was found that specimens with shavings presented, on average, higher values of their mechanical properties than did specimens with fibres. This was attributed to the surface aspect of metallic waste, since shavings have a rough surface that facilitated the adherence between them and the mortar matrix, thus avoiding slipping on the shavings’ edges, while fibres presented a smooth surface, which was more susceptible to failure by pull-out slipping.

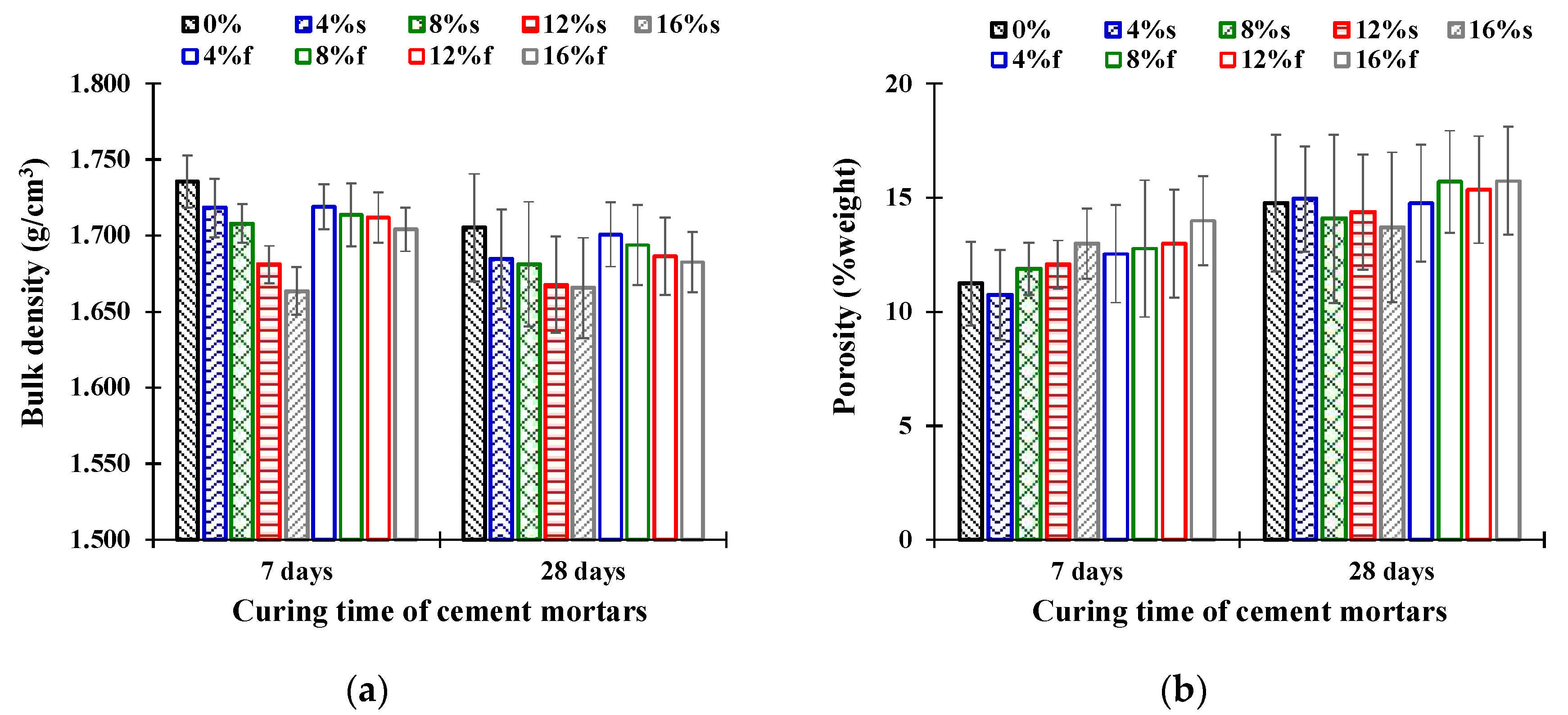

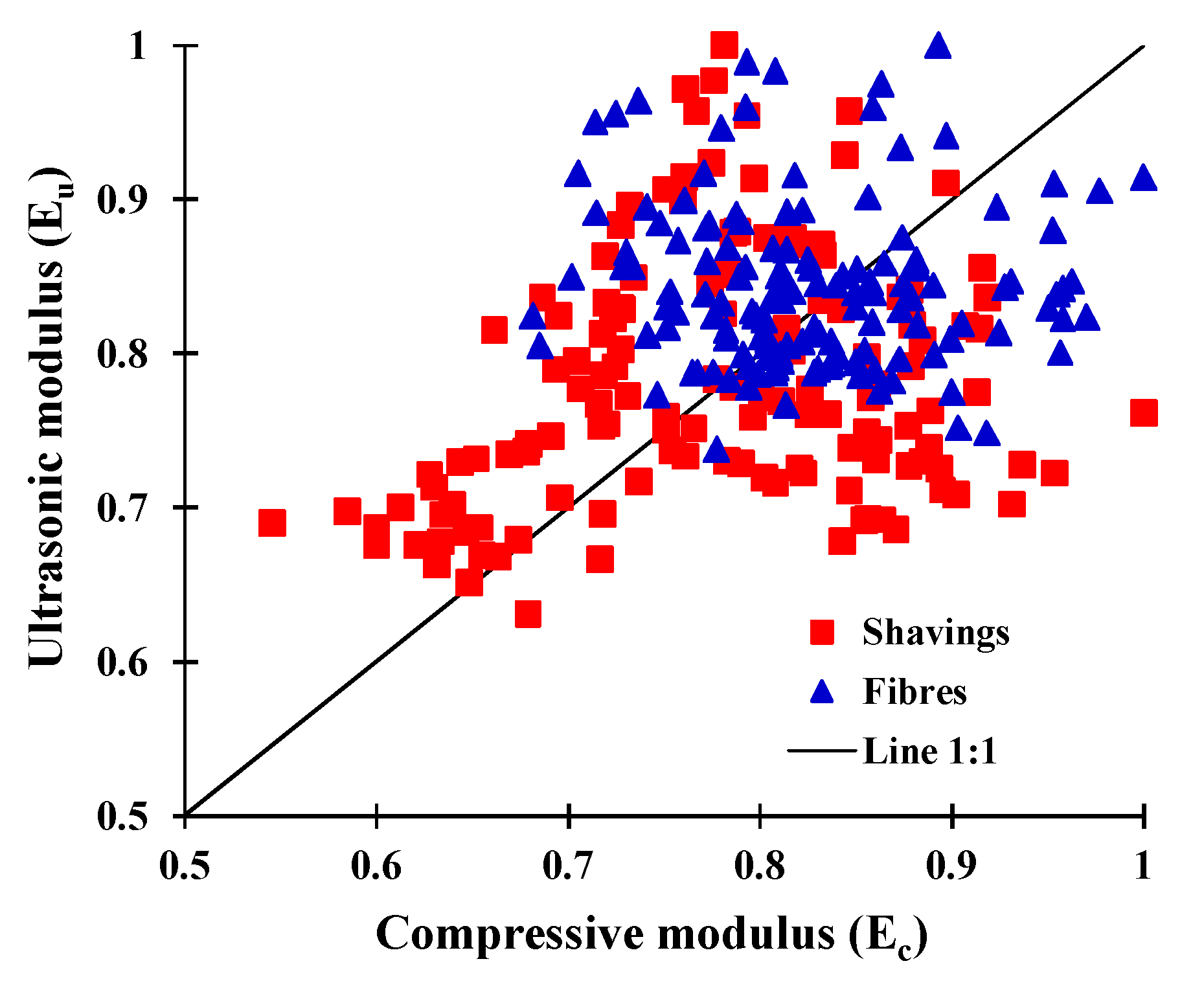

- Furthermore, the results showed that the compressive elastic modulus increased with the amount of metallic waste added to the mortar, while in contrast, the dynamic elastic modulus obtained from ultrasonic tests decreased with the increase of metallic waste. This was associated with the increase on the mortar porosity due to the addition of metallic waste, which resulted in specimens with higher contents of metallic particles presenting higher ultrasonic pulse times and consequently lower values of dynamic moduli.

- Moreover, it was found that the elastic modulus measured by ultrasonic tests was on average higher than that measured by compressive tests. Besides, due to the random distribution of metallic waste inside the test specimens, there was no relationship between the static and dynamic elastic moduli, in contrast with conclusions obtained in previous works.

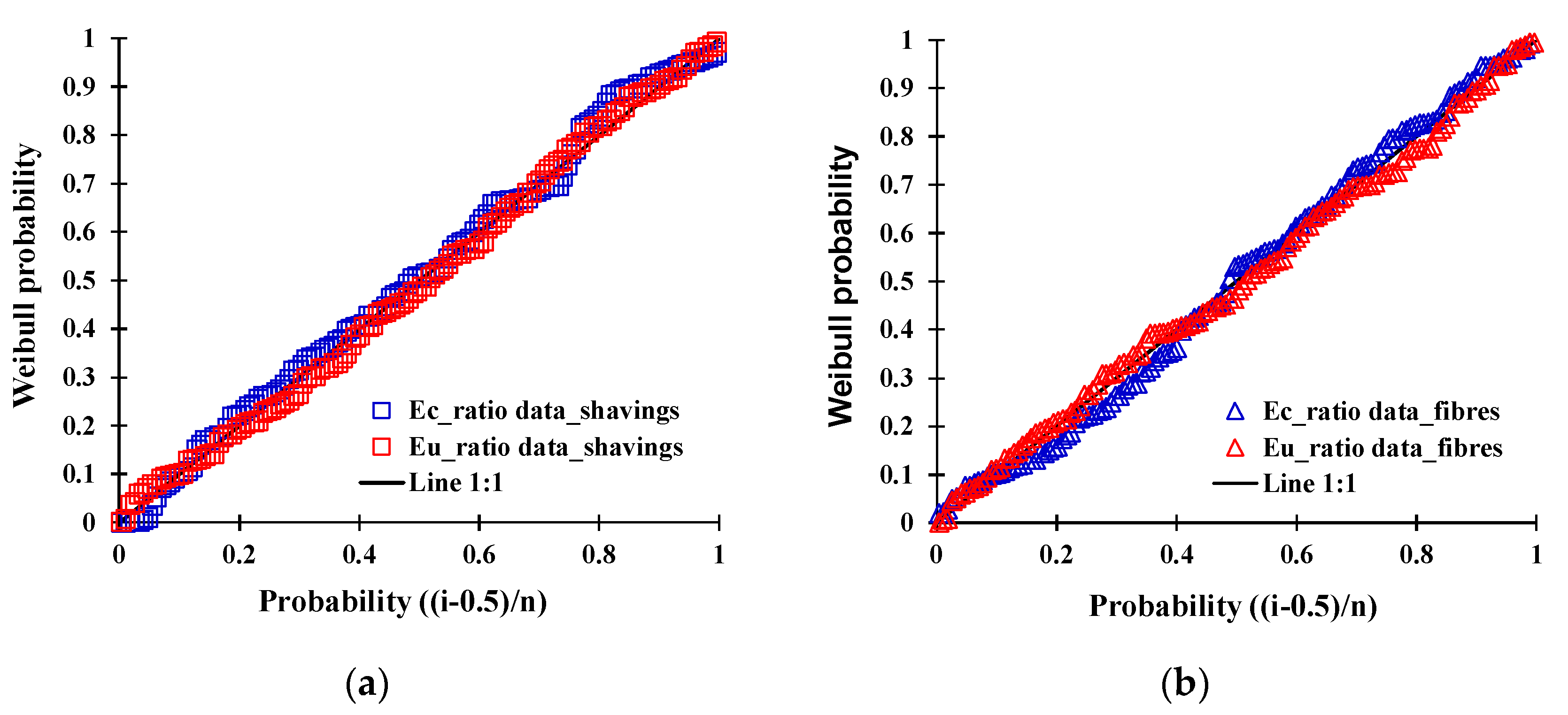

- Finally, based on a probability analysis of the obtained results, it was concluded that neither the type and amount of metallic waste, nor the curing time applied to the mortar specimens produced a significant variation on either the mechanical strength (flexural and compressive) or the elastic modulus of mortars measured by destructive and non-destructive methods.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Liu, Z.; Hansen, W. Pore damage in cementitious binders caused by deicer salt frost exposure. Constr. Build. Mater. 2015, 98, 204–216. [Google Scholar] [CrossRef]

- Zhutovsky, S.; Hooton, R.D. Experimental study on physical sulfate salt attack. Mater. Struct. 2017, 50, 54. [Google Scholar] [CrossRef]

- Koenig, A.; Dehn, F. Main considerations for the determination and evaluation of the acid resistance of cementitious materials. Mater. Struct. 2016, 49, 1693–1703. [Google Scholar] [CrossRef]

- Çavdar, A. Investigation of freeze-thaw effects on mechanical properties of fiber reinforced cement mortars. Compos. Part B Eng. 2014, 58, 463–472. [Google Scholar] [CrossRef]

- Bentur, A.; Mindess, S. Fiber Reinforced Cementitious Composites, 2nd ed.; Taylor & Francis: Abingdon, UK; Oxon, UK, 2007. [Google Scholar]

- Banthia, N.; Dubeau, S. Carbon and steel microfiber-reinforced cement-based composites for thin repairs. J. Mater. Civ. Eng. 1994, 6, 88–99. [Google Scholar] [CrossRef]

- Brandt, A.M. Fibre reinforced cement-based (FRC) composites after over 40 years of development in building and civil engineering. Compos. Struct. 2008, 86, 3–9. [Google Scholar] [CrossRef]

- Quadir, U.M.T.; Islam, K.; Billah, A.M.; Alam, M.S. Mechanical and durability properties of concrete using recycled granulated steel. Constr. Build. Mater. 2016, 123, 174–183. [Google Scholar] [CrossRef]

- Pacheco-Torgal, F.; Jalali, S. Cementitious building materials reinforced with vegetable fibres: A review. Constr. Build. Mater. 2011, 25, 575–581. [Google Scholar] [CrossRef] [Green Version]

- Norambuena-Contreras, J.; Thomas, C.; Borinaga-Treviño, R.; Lombillo, I. Influence of recycled carbon powder waste addition on the physical and mechanical properties of cement pastes. Mater. Struct. 2016, 49, 5147–5159. [Google Scholar] [CrossRef]

- Nishiwaki, T.; Koda, M.; Yamada, M.; Mihashi, H.; Kikuta, T. Experimental study on self-healing capability of FRCC using different types of synthetic fibers. J. Adv. Concr. Technol. 2012, 10, 195–206. [Google Scholar] [CrossRef]

- Martinelli, E.; Caggiano, A.; Xargay, H. An experimental study on the post-cracking behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298. [Google Scholar] [CrossRef]

- Sengul, O. Mechanical behavior of concretes containing waste steel fibers recovered from scrap tires. Constr. Build. Mater. 2016, 122, 649–658. [Google Scholar] [CrossRef]

- Graeff, A.G.; Pilakoutas, K.; Neocleous, K.; Peres, M.V.N.N. Fatigue resistance and cracking mechanism of concrete pavements reinforced with recycled steel fibres recovered from post-consumer tyres. Eng. Struct. 2012, 45, 385–395. [Google Scholar] [CrossRef]

- Holschemacher, K.; Mueller, T.; Ribakov, Y. Effect of steel fibres on mechanical properties of high-strength concrete. Mater. Des. 2010, 31, 2604–2615. [Google Scholar] [CrossRef]

- Wang, H.T.; Wang, L.C. Experimental study on static and dynamic mechanical properties of steel fiber reinforced lightweight aggregate concrete. Constr. Build. Mater. 2013, 38, 1146–1151. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W.; Wu, L. Effects of steel fiber content and shape on mechanical properties of ultra high performance concrete. Constr. Build. Mater. 2016, 103, 8–14. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Quilodran, J.; Gonzalez-Torre, I.; Chávez, M.; Borinaga-Treviño, R. Electrical and thermal characterisation of cement-based mortars containing recycled metallic waste. J. Clean. Prod. 2018, 190, 737–751. [Google Scholar] [CrossRef]

- Lee, S.F.; Jacobsen, S. Study of interfacial microstructure, fracture energy, compressive energy and debonding load of steel fiber-reinforced mortar. Mater. Struct. 2011, 44, 1451–1465. [Google Scholar] [CrossRef] [Green Version]

- Kim, D.J.; Kang, S.H.; Ahn, T.H. Mechanical Characterization of high-performance steel-fiber reinforced cement composites with self-healing effect. Materials 2014, 7, 508–526. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.L.; Song, J.; Manathamsombat, C.; Kim, D.J. Comparative electromechanical damage-sensing behaviors of six strain-hardening steel fiber-reinforced cementitious composites under direct tension. Compos. Part B Eng. 2015, 69, 159–168. [Google Scholar] [CrossRef]

- Erdem, S.; Hanbay, S.; Blankson, M.A. Self-sensing damage assessment and image-based surface crack quantification of carbon nanofibre reinforced concrete. Constr. Build. Mater. 2017, 134, 520–529. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Wang, R. The influence of rheological parameters of cement paste on the dispersion of carbon nanofibers and self-sensing performance. Constr. Build. Mater. 2017, 134, 673–683. [Google Scholar] [CrossRef]

- Al-Dahawi, A.; Yıldırım, G.; Öztürk, O.; Şahmaran, M. Assessment of self-sensing capability of Engineered Cementitious Composites within the elastic and plastic ranges of cyclic flexural loading. Constr. Build. Mater. 2017, 145, 1–10. [Google Scholar] [CrossRef]

- Lataste, J.F.; Behloul, M.; Breysse, D. Characterisation of fibres distribution in a steel fibre reinforced concrete with electrical resistivity measurements. NDT E Int. 2008, 41, 638–647. [Google Scholar] [CrossRef]

- ASTM C595/C595M-16. Standard Specification for Blended Hydraulic Cements; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- EN 196-3:2005+A1:2009. Methods of Testing Cement-Part 3: Determination of Setting Times and Soundness; CEN European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- ASTM C642-13. Standard Test Method for Density, Absorption, and Voids in Hardened Concrete; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- ASTM C348-14. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C349-14. Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM C597-16. Standard Test Method for Pulse Velocity through Concrete; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Valentini, L.; Parisatto, M.; Russo, V.; Ferrari, G.; Bullard, J.W.; Angel, R.J.; Dalconi, M.C.; Artioli, G. Simulation of the hydration kinetics and elastic moduli of cement mortars by microstructural modelling. Cem. Concr. Compos. 2014, 52, 54–63. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Gutierrez Aguilar, V.; González-Torre, I. Physical and mechanical behaviour of a fibre-reinforced membrane with self-healing purposes via microwave heating. Constr. Build. Mater. 2015, 94, 45–56. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Serpell, R.; Valdés, G.; Gonzalez, A.; Schlangen, E. Effect of fibres addition on the physical and mechanical properties of asphalt mixtures with crack-healing purposes by microwave radiation. Constr. Build. Mater. 2016, 127, 369–382. [Google Scholar] [CrossRef]

- García, A.; Norambuena-Contreras, J.; Partl, M.N.; Schuetz, P. Uniformity and mechanical properties of dense asphalt concrete with steel wool fibers. Constr. Build. Mater. 2013, 43, 107–117. [Google Scholar] [CrossRef]

- Norambuena-Contreras, J.; Castro-Fresno, D.; Vega-Zamanillo, A.; Celaya, M.; Lombillo-Vozmediano, I. Dynamic modulus of asphalt mixture by ultrasonic direct test. NDT E Int. 2010, 43, 629–634. [Google Scholar] [CrossRef]

- Sevkat, E.; Li, J.; Liaw, B.; Delale, F. A statistical model of electrical resistance of carbon fiber reinforced composites under tensile loading. Compos. Sci. Technol. 2008, 68, 2214–2219. [Google Scholar] [CrossRef]

| Cement Weight (g) | Sand Weight (g) | Water Weight (g) | Additive Volume (cm3) | Fibres and Shavings Amount (% by Weight/Cement) | Weight of Fibres and Shavings (g) |

|---|---|---|---|---|---|

| 450 | 1350 | 225 | 4.2 | 4 | 18 |

| 8 | 36 | ||||

| 12 | 54 | ||||

| 16 | 72 |

| Oxide Type/Amount (wt %) | SiO2 | Al2O3 | Fe2O3 | MgO | CaO | Na2O | K2O | SO3 | TiO2 | Sum |

|---|---|---|---|---|---|---|---|---|---|---|

| Portland-Pozzolana Cement | 25.95 | 14.41 | 5.39 | 2.76 | 40.56 | 2.45 | 1.34 | 2.31 | 0.53 | 95.69 |

| Fine Sand | 44.93 | 20.81 | 7.83 | 6.13 | 9.09 | 4.94 | 0.68 | - | 1.87 | 96.29 |

| Statistical Parameters | Shavings | Fibres | ||

|---|---|---|---|---|

| Length | Width | Length | Diameter | |

| Average (mm) | 7.181 | 1.310 | 5.833 | 0.133 |

| Variance (mm2) | 11.344 | 0.769 | 3.948 | 0.003 |

| Std. Dev (mm) | 3.368 | 0.877 | 1.987 | 0.056 |

| CV (-) | 0.469 | 0.669 | 0.341 | 0.422 |

| Range (mm) | 3–21 | 0.5–4 | 2–14 | 0.1–0.5 |

| N° samples (unit) | 120 | 120 | 120 | 120 |

| Metallic Waste | Element Type and Amount (wt %) | |||||

|---|---|---|---|---|---|---|

| Fe | Mn | Si | Cr | C | Sum | |

| Shavings | 97.49 | 1.44 | 0.51 | 0.21 | 0.30 | 99.95 |

| Fibres | 98.38 | 1.30 | 0.18 | - | 0.12 | 99.98 |

| Metallic Waste Content | Compressive Modulus Ec | Ultrasonic Modulus Eu | ||||||

|---|---|---|---|---|---|---|---|---|

| 7 Days | 28 Days | 7 Days | 28 Days | |||||

| Shavings | Fibres | Shavings | Fibres | Shavings | Fibres | Shavings | Fibres | |

| 4% | 1.083 | 1.068 | 0.930 | 0.861 | 0.953 | 1.010 | 0.971 | 0.920 |

| 8% | 1.064 | 1.071 | 0.941 | 0.928 | 0.928 | 0.975 | 0.981 | 0.894 |

| 12% | 1.077 | 1.085 | 0.958 | 0.957 | 0.923 | 0.948 | 0.930 | 0.869 |

| 16% | 1.122 | 1.105 | 0.965 | 0.922 | 0.889 | 0.937 | 0.926 | 0.865 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Norambuena-Contreras, J.; Cartes, A.; Gonzalez-Torre, I.; Chavez, M.; Kanellopoulos, A. Effect of Metallic Waste Addition on the Physical and Mechanical Properties of Cement-Based Mortars. Appl. Sci. 2018, 8, 929. https://doi.org/10.3390/app8060929

Norambuena-Contreras J, Cartes A, Gonzalez-Torre I, Chavez M, Kanellopoulos A. Effect of Metallic Waste Addition on the Physical and Mechanical Properties of Cement-Based Mortars. Applied Sciences. 2018; 8(6):929. https://doi.org/10.3390/app8060929

Chicago/Turabian StyleNorambuena-Contreras, Jose, Ariel Cartes, Irene Gonzalez-Torre, Manuel Chavez, and Antonios Kanellopoulos. 2018. "Effect of Metallic Waste Addition on the Physical and Mechanical Properties of Cement-Based Mortars" Applied Sciences 8, no. 6: 929. https://doi.org/10.3390/app8060929