Optically Transparent Nano-Patterned Antennas: A Review and Future Directions

Abstract

:1. Introduction

2. Transparent Antennas: A Review

2.1. Nano Carbon

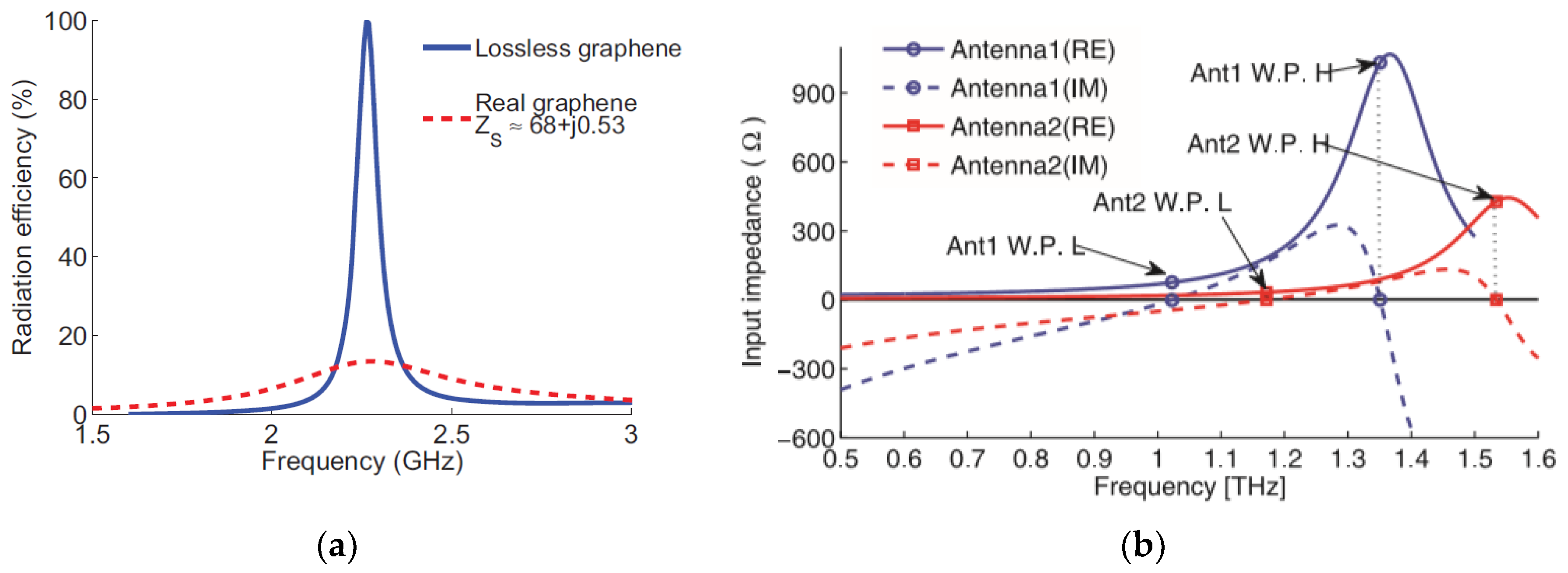

2.1.1. Graphene

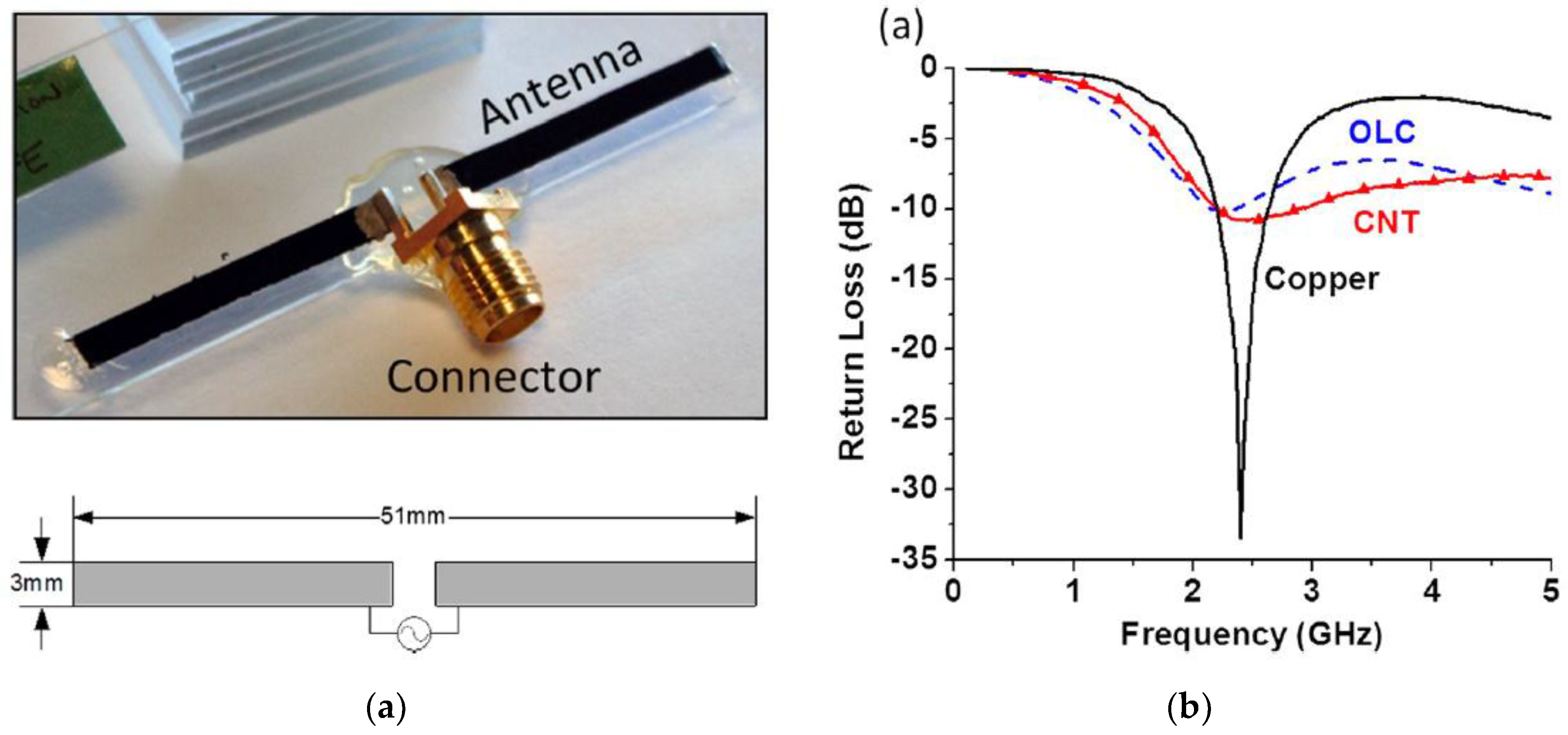

2.1.2. Carbon Nanotubes

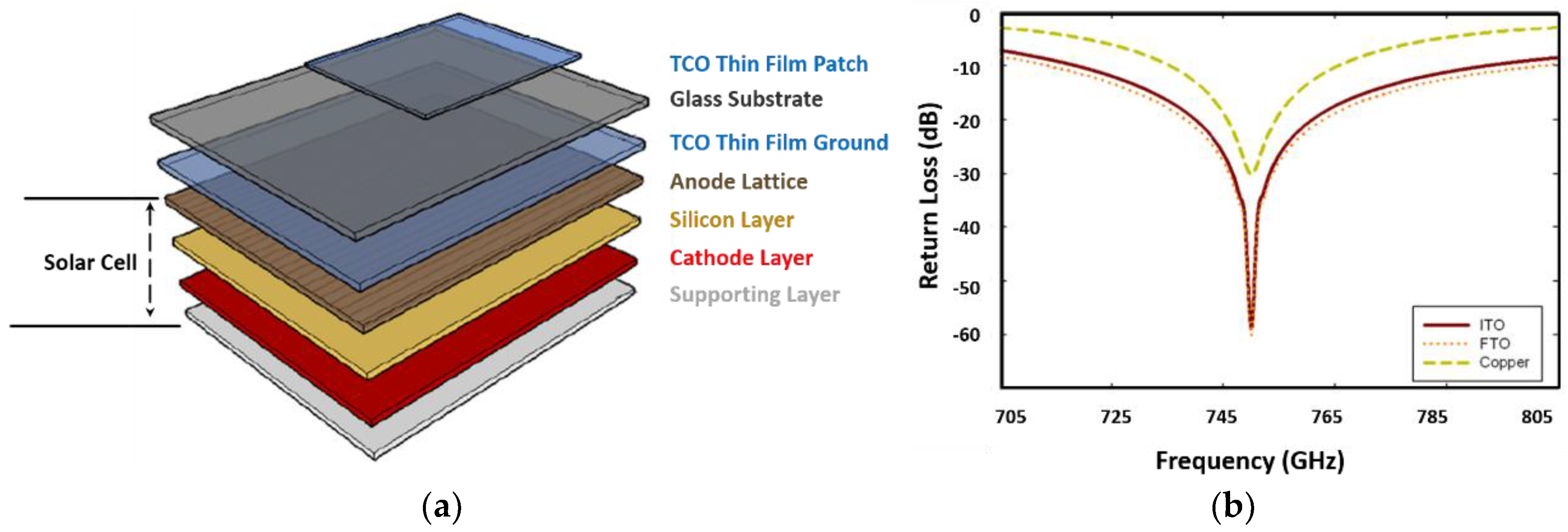

2.2. Transparents Conductive Oxides

2.2.1. Mono-Layer

2.2.2. Multilayer

2.3. Conductive Polymer

2.4. Metallic Nanostructure

2.4.1. Nanowire

Silver Nanowires

Copper Nanowires

2.4.2. Ultra-Thin Metal Films

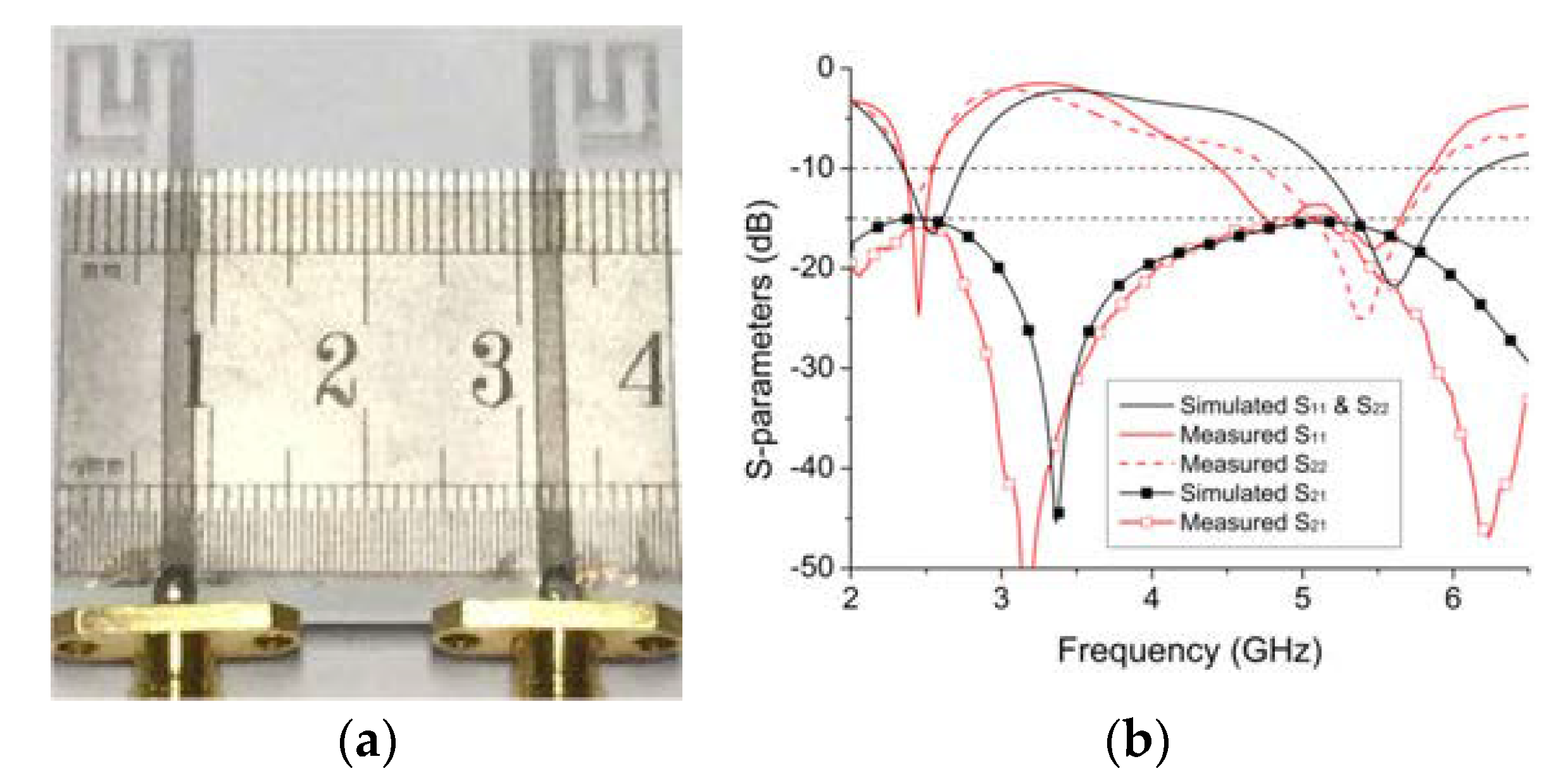

2.4.3. Patterned Metal Grid

Au and Ag Grids

Metal Grid

3. Summary of Various Transparent Antennas

4. Conclusions

Funding

Conflicts of Interest

References

- Simons, R.N.; Lee, R.Q. Feasibility study of optically transparent microstrip patch antenna. In Proceedings of the IEEE Antennas and Propagation Society International Symposium, Montreal, QC, Canada, 13–18 July 1997. [Google Scholar]

- Zhang, Q.; Wan, X.; Xing, F.; Huang, L.; Long, G.; Yi, N.; Ni, W.; Liu, Z.; Tian, J.; Chen, Y. Solution-processable graphene mesh transparent electrodes for organic solar cells. Nano Res. 2013, 6, 478–484. [Google Scholar] [CrossRef]

- Hu, L.; Wu, H.; Cui, Y. Metal nanogrids, nanowires, and nanofibers for transparent electrodes. MRS Bull. 2011, 36, 760–765. [Google Scholar] [CrossRef]

- Avouris, P. Graphene: Electronic and photonic properties and devices. Nano Lett. 2010, 10, 4285–4294. [Google Scholar] [CrossRef] [PubMed]

- Perruisseau-Carrier, J.; Tamagnone, M.; Gomez-Diaz, J.S.; Carrasco, E. Graphene antennas: Can integration and reconfigurability compensate for the loss? In Proceedings of the 2013 IEEE European Microwave Conference (EuMC), Nuremberg, Germany, 6–10 October 2013; pp. 369–372. [Google Scholar]

- Gomez-Diaz, J.S.; Perruisseau-Carrier, J. Microwave to THz properties of graphene and potential antenna applications. In Proceedings of the 2012 IEEE International Symposium on Antennas and Propagation (ISAP), Nagoya, Japan, 29 October–2 November 2012; pp. 239–242. [Google Scholar]

- Tamagnone, M.; Gomez-Diaz, J.S.; Mosig, J.R.; Perruisseau-Carrier, J. Analysis and design of terahertz antennas based on plasmonic resonant graphene sheets. J. Appl. Phys. 2013, 112, 114915. [Google Scholar] [CrossRef]

- Carrasco, E.; Tamagnone, M.; Perruisseau-Carrier, J. Tunable graphene reflective cells for THz reflectarrays and generalized law of reflection. Appl. Phys. Lett. 2013, 102, 104103. [Google Scholar] [CrossRef]

- Fallahi, A.; Perruisseau-Carrier, J. Design of tunable biperiodic graphene metasurfaces. Phys. Rev. B 2012, 86, 195408. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56. [Google Scholar] [CrossRef]

- Vacirca, N.A.; McDonough, J.K.; Jost, K.; Gogotsi, Y.; Kurzweg, T.P. Onion-like carbon and carbon nanotube film antennas. Appl. Phys. Lett. 2013, 103, 073301. [Google Scholar] [CrossRef]

- Elwi, T.A.; Al-Rizzo, H.M.; Rucker, D.G.; Dervishi, E.; Li, Z.; Biris, A.S. Multi-walled carbon nanotube-based RF antennas. Nanotechnology 2009, 21, 045301. [Google Scholar] [CrossRef] [PubMed]

- Tung, V.C.; Chen, L.M.; Allen, M.J.; Wassei, J.K.; Nelson, K.; Kaner, R.B.; Yang, Y. Low-temperature solution processing of grapheme–carbon nanotube hybrid materials for high-performance transparent conductors. Nano Lett. 2009, 9, 1949–1955. [Google Scholar] [CrossRef] [PubMed]

- Shimoni, A.; Azoubel, S.; Magdassi, S. Inkjet printing of flexible high-performance carbon nanotube transparent conductive films by “coffee ring effect”. Nanoscale 2014, 6, 11084–11089. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-K.; Min, D.-H. Durable large-area thin films of graphene/carbon nanotube double layers as a transparent electrode. Langmuir 2009, 25, 11302–11306. [Google Scholar] [CrossRef] [PubMed]

- Ali, N.M.; Misran, N.; Mansor, M.F.; Jamlos, M.F. Transparent solar antenna of 28 GHz using transparent conductive oxides (TCO) thin film. J. Phys. Conf. Ser. 2017, 852, 012036. [Google Scholar]

- Thampy, A.S.; Dhamodharan, S.K. Performance analysis and comparison of ITO-and FTO-based optically transparent terahertz U-shaped patch antennas. Phys. E 2015, 66, 52–58. [Google Scholar] [CrossRef]

- Colombel, F.; Castel, X.; Himdi, M.; Legeay, G.; Vigneron, S.; Cruz, E.M. Ultrathin metal layer, ITO film and ITO/Cu/ITO multilayer towards transparent antenna. IET Sci. Meas. Technol. 2009, 3, 229–234. [Google Scholar] [CrossRef]

- Choi, K.H.; Nam, H.J.; Jeong, J.A.; Cho, S.W.; Kim, H.K.; Kang, J.W.; Kim, D.G.; Cho, W.J. Highly flexible and transparent InZnSnOx/Ag/InZnSnOx multilayer electrode for flexible organic light emitting diodes. Appl. Phys. Lett. 2008, 92, 3302–3305. [Google Scholar] [CrossRef]

- Hong, S.; Kim, Y.; Jung, C.W. Transparent microstrip patch antennas with multilayer and metal-mesh films. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 772–775. [Google Scholar] [CrossRef]

- Chiang, C.K.; Fincher, C.R., Jr.; Park, Y.W.; Heeger, A.J.; Shirakawa, H.; Louis, E.J.; Gau, S.C.; MacDiarmid, A.G. Electrical conductivity in doped polyacetylene. Phys. Rev. Lett. 1977, 39, 1098. [Google Scholar] [CrossRef]

- Kirsch, N.J.; Vacirca, N.A.; Plowman, E.E.; Kurzweg, T.P.; Fontecchio, A.K.; Dandekar, K.R. Optically transparent conductive polymer RFID meandering dipole antenna. In Proceedings of the 2013 IEEE International Conference on RFID, Orlando, FL, USA, 30 April–2 May 2013; pp. 278–282. [Google Scholar]

- Rmili, H.; Miane, J.L.; Zangar, H.; Olinga, T. Design of microstrip-fed proximity-coupled conducting-polymer patch antenna. Microw. Opt. Technol. Lett. 2006, 48, 655–660. [Google Scholar] [CrossRef]

- Lee, J.; Lee, P.; Lee, H.B.; Hong, S.; Lee, I.; Yeo, J.; Lee, S.S.; Kim, T.S.; Lee, D.; Ko, S.H. Room-temperature nanosoldering of a very long metal nanowire network by conducting-polymer-assisted joining for a flexible touch-panel application. Adv. Funct. Mater. 2013, 23, 4171–4176. [Google Scholar] [CrossRef]

- Hecht, D.S.; Hu, L.; Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene, and metallic nanostructures. Adv. Mater. 2011, 23, 1482–1513. [Google Scholar] [CrossRef] [PubMed]

- Hu, L.; Kim, H.S.; Lee, J.Y.; Peumans, P.; Cui, Y. Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 2010, 4, 2955–2963. [Google Scholar] [CrossRef] [PubMed]

- Dao, Q.H.; Tchuigoua, R.; Geck, B.; Manteuffel, D.; von Witzendorff, P.; Overmeyer, L. Optically transparent patch antennas based on silver nanowires for mm-wave applications. In Proceedings of the 2017 IEEE International Symposium on Antennas and Propagation & USNC/URSI National Radio Science Meeting, San Diego, CA, USA, 9–14 July 2017; pp. 2189–2190. [Google Scholar]

- Rai, T.; Dantes, P.; Bahreyni, B.; Kim, W.S. A stretchable RF antenna with silver nanowires. IEEE Electron Device Lett. 2013, 34, 544–546. [Google Scholar] [CrossRef]

- Song, L.; Myers, A.C.; Adams, J.J.; Zhu, Y. Stretchable and reversibly deformable radio frequency antennas based on silver nanowires. ACS Appl. Mater. Interfaces 2014, 6, 4248–4253. [Google Scholar] [CrossRef] [PubMed]

- Li, Q.L.; Cheung, S.W.; Wu, D.; Yuk, T.I. Optically transparent dual-band MIMO antenna using micro-metal mesh conductive film for WLAN system. IEEE Antennas Wirel. Propag. Lett. 2017, 16, 920–923. [Google Scholar] [CrossRef]

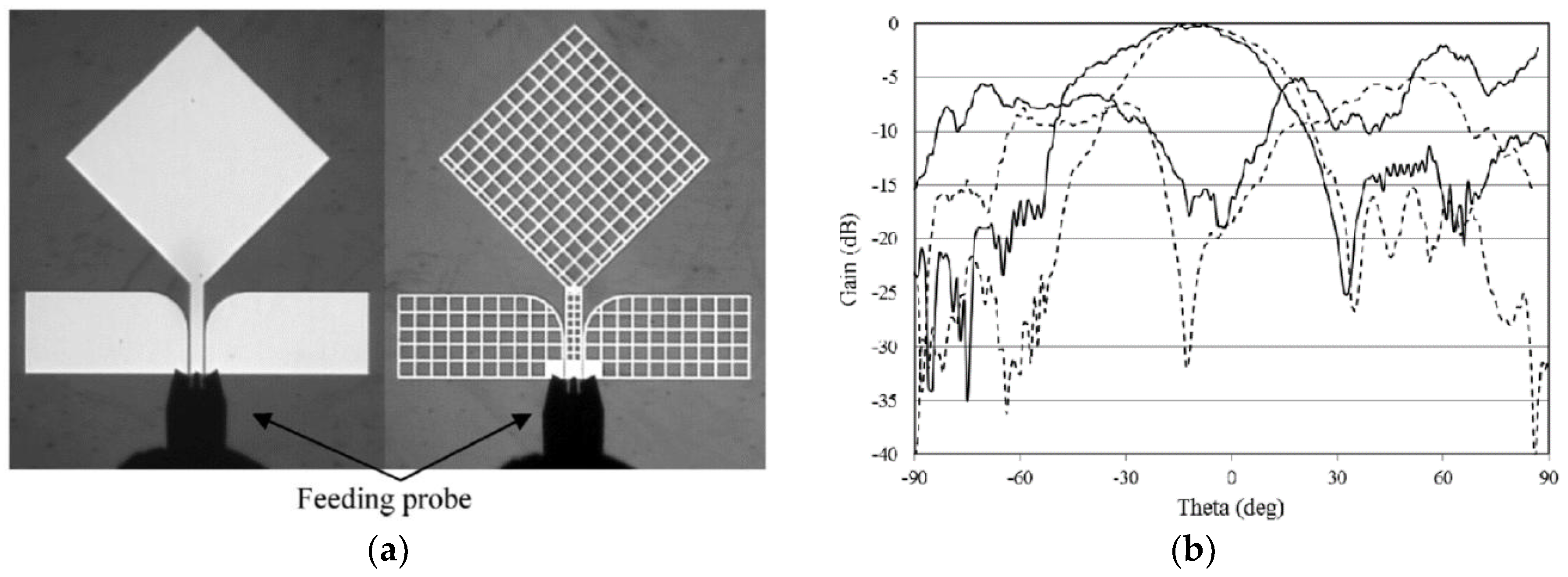

- Sa’ad, B.M.; Rahim, S.K.A.; Peter, T.; Rani, M.S.B.A.; Ausordin, S.F.; Zaidel, D.N.A.; Krishnan, C. Transparent branch-line coupler using micro-metal mesh conductive film. IEEE Microw. Wirel. Compon. Lett. 2014, 2, 857–859. [Google Scholar] [CrossRef]

- Yun, J. Ultrathin metal films for transparent electrodes of flexible optoelectronic devices. Adv. Funct. Mater. 2017, 27, 1606641. [Google Scholar] [CrossRef]

- Optical Filters for Electronic Displays. Available online: http://www.instrumentplastics.co.uk/products/ito-film-and-ito-coatings (accessed on 30 April 2018).

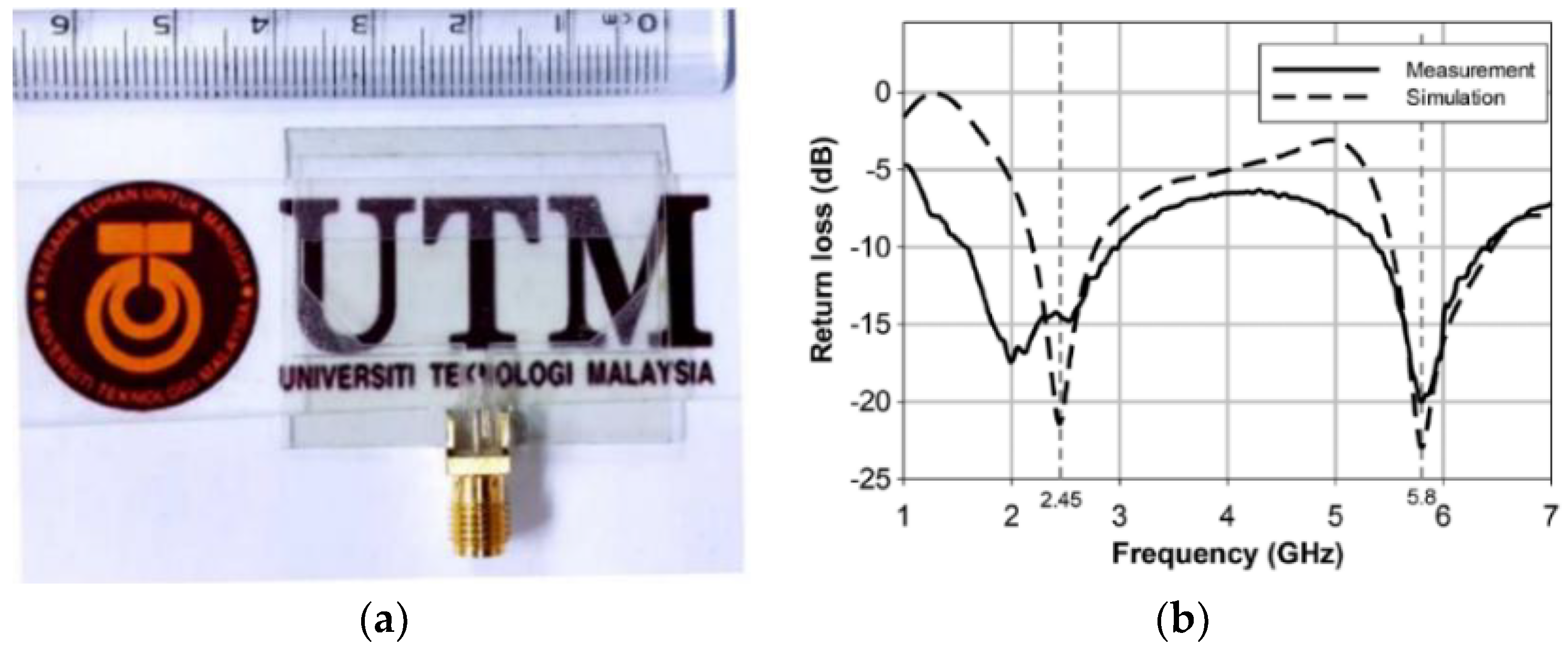

- Malek, M.A.; Hakimi, S.; Rahim, S.A.; Evizal, A.K. Dual-band CPW-fed transparent antenna for active RFID tags. IEEE Antennas Wirel. Propag. Lett. 2015, 14, 919–922. [Google Scholar] [CrossRef]

- Jizat, N.M.; Rahim, S.K.A.; Lo, Y.C.; Mansor, M.M. Compact size of CPW dual-band meander-line transparent antenna for WLAN applications. In Proceedings of the 2014 IEEE Asia-Pacific Conference on Applied Electromagnetics (APACE), Johor Bahru, Malaysia, 8–10 December 2014; pp. 20–22. [Google Scholar]

- Hautcoeur, J.; Talbi, L.; Hettak, K. Feasibility study of optically transparent CPW-fed monopole antenna at 60-GHz ISM bands. IEEE Trans. Antennas Propag. 2013, 61, 1651–1657. [Google Scholar] [CrossRef]

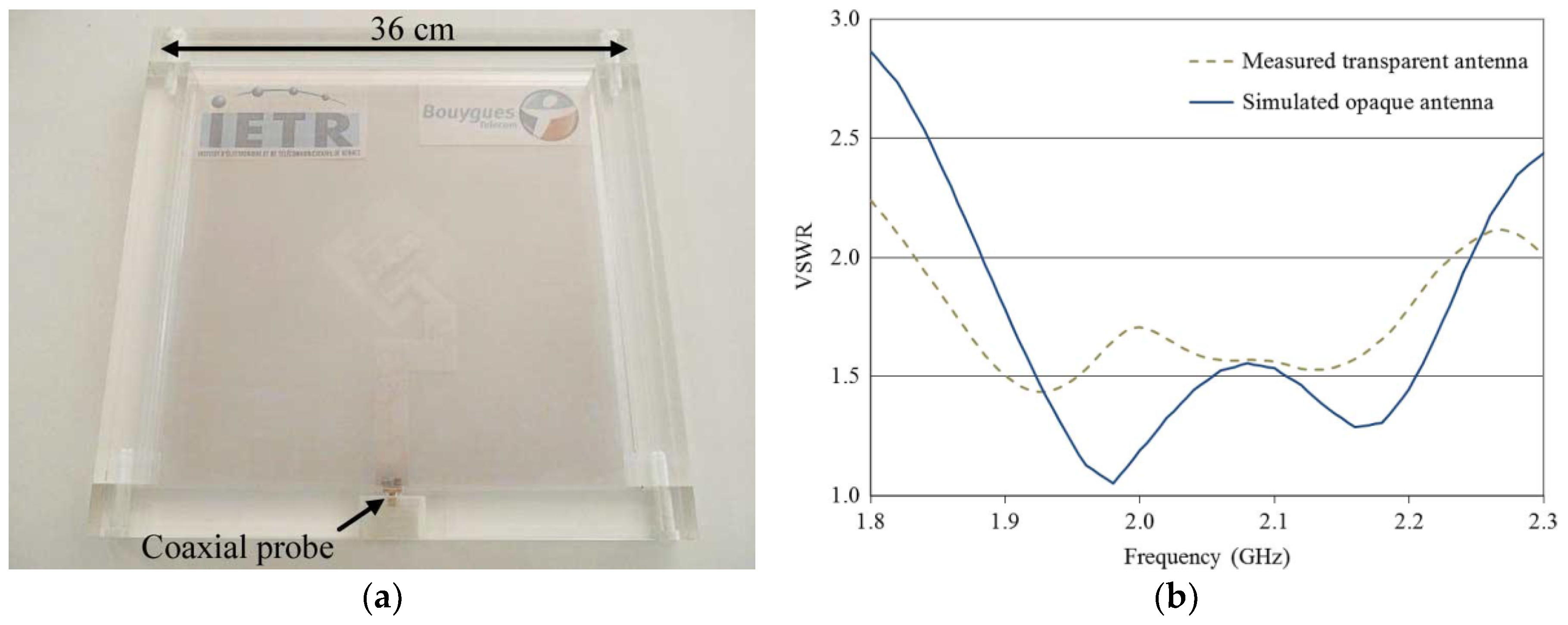

- Hautcoeur, J.; Colombel, F.; Himdi, M.; Castel, X.; Cruz, E.M. Large and optically transparent multilayer for broadband H-shaped slot antenna. IEEE Antennas Wirel. Propag. Lett. 2013, 12, 933–936. [Google Scholar] [CrossRef]

- Lee, S.Y.; Choi, D.; Youn, Y.; Hong, W. Electrical characterization of highly efficient, optically transparent nanometers-thick unit cells for antenna-on-display applications. In Proceedings of the 2018 IEEE MTT-S International Microwave Symposium (IMS), Philadelphia, PA, USA, 10–15 June 2018. [Google Scholar]

| Materials | Ref. | Details | Rs (Ω/sq) | T (%) | FoM |

|---|---|---|---|---|---|

| Nano Carbons | [5] | Graphene | N.A. | N.A. | - |

| [6] | Graphene | N.A. | N.A. | - | |

| [4] | Graphene | 30 | 90 | 116.2 | |

| [11] | OLC and MWCNT | N.A. | N.A. | - | |

| [12] | MWCNT | N.A. | N.A. | - | |

| [13] | CNT | 280 | 90 | 12.4 | |

| Transparent Conductive Oxides (TCOs) | [16] | ITO | 10 | N.A. | - |

| [17] | FTO | 24 | N.A. | - | |

| [18] | ITO/CU/ITO | 4.7 | 61 | 143.0 | |

| [20] | IZTO/Ag/IZTO | 2.52 | 80 | 663.7 | |

| Conductive Polymers | [22] | PEDOT-PSS | N.A. | N.A. | - |

| [23] | - | N.A. | N.A. | - | |

| [24] | AgNW/PEDOT:PSS | 25 | 90 | 139.4 | |

| Metallic Nanostructures | [27] | AgNW | 0.36 | 51 | 1308.1 |

| [28] | AgNW | 5 | N.A. | - | |

| [30] | CuNW | 0.05 | 75 | 24,369.6 | |

| [31] | CuNW | 0.7 | 75 | 1740.7 | |

| [34] | AgHT-8 | 8 | 80 | 199.6 | |

| [34] | AgHT-4 | 4 | N.A. | - | |

| [36] | AuGL | 0.44 | 83 | 4387.5 | |

| [37] | AgGL | 0.054 | 81.3 | 32,007.8 | |

| [38] | Metal grid | 3.22 | 88 | 887.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, S.Y.; Choo, M.; Jung, S.; Hong, W. Optically Transparent Nano-Patterned Antennas: A Review and Future Directions. Appl. Sci. 2018, 8, 901. https://doi.org/10.3390/app8060901

Lee SY, Choo M, Jung S, Hong W. Optically Transparent Nano-Patterned Antennas: A Review and Future Directions. Applied Sciences. 2018; 8(6):901. https://doi.org/10.3390/app8060901

Chicago/Turabian StyleLee, Seung Yoon, Moogoong Choo, Sohyeon Jung, and Wonbin Hong. 2018. "Optically Transparent Nano-Patterned Antennas: A Review and Future Directions" Applied Sciences 8, no. 6: 901. https://doi.org/10.3390/app8060901