40 W All-Fiber Er/Yb MOPA System Using Self-Fabricated High-Power Passive Fiber Components

Abstract

:1. Introduction

2. Experimental Setup

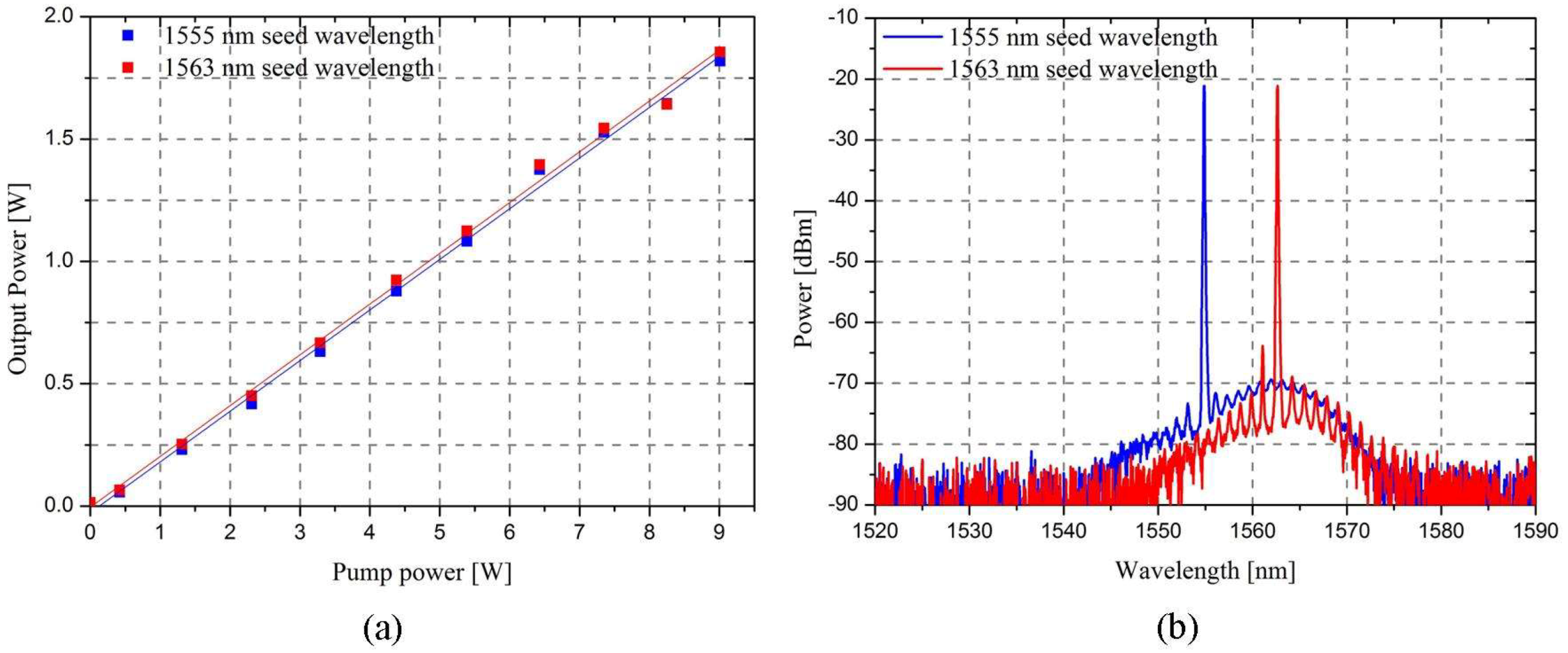

2.1. First and Second MOPA Stage: Pre-Amplifier EDFA and Medium-Power Amplifier EYDFA

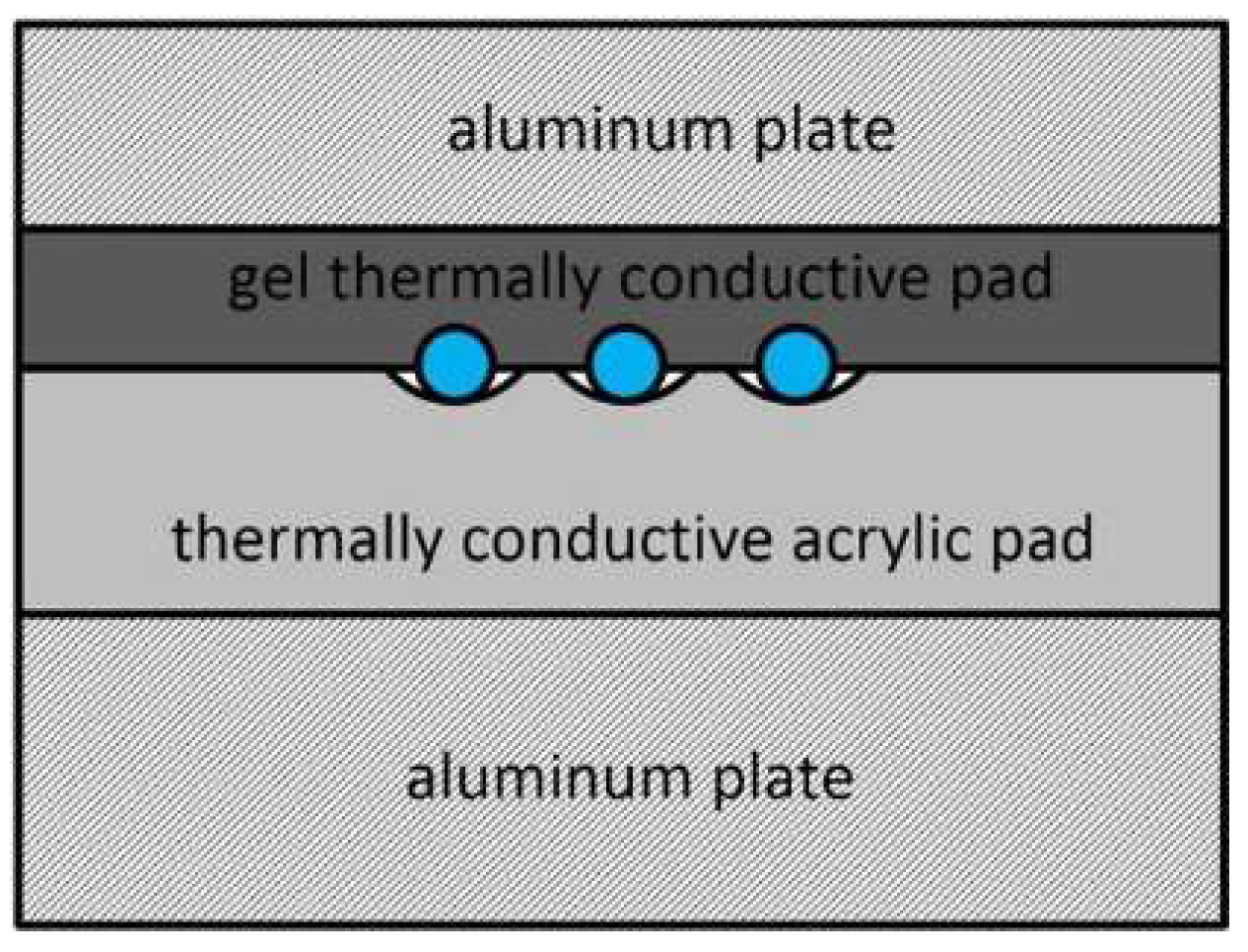

2.2. Setup of Third-Stage Amplifier: High-Power EYDFA

- 1st additional splice as a combiner with MFA,

- 2nd additional splice inside the MFA combined with an active fiber.

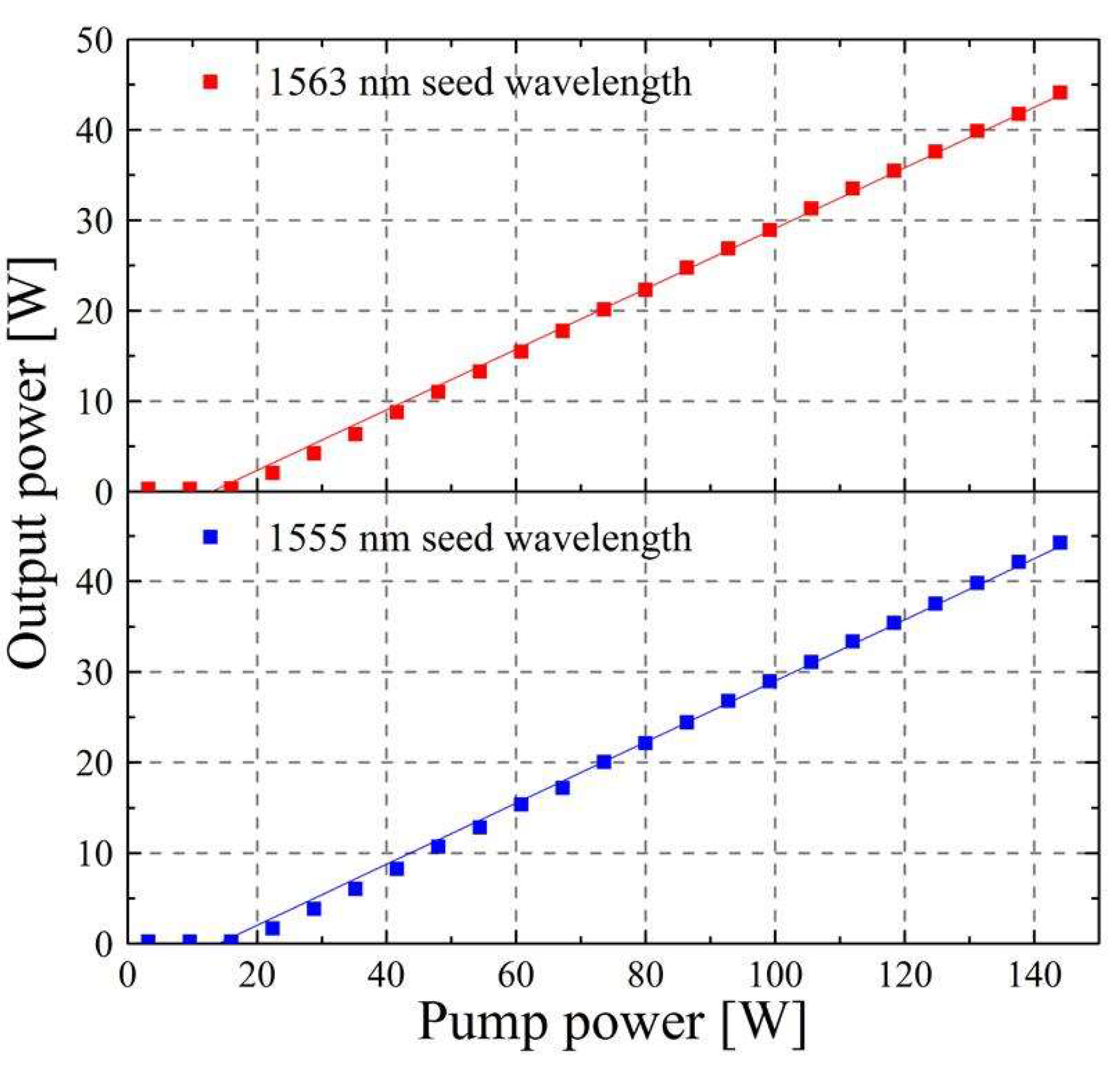

3. Experimental Results

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Philippov, V.; Codemard, C.; Jeong, Y.; Alegria, C.; Sahu, J.K.; Nilsson, J.; Pearson, G.N. High-energy in-fiber pulse amplification for coherent lidar applications. Opt. Lett. 2004, 29, 2590–2592. [Google Scholar] [CrossRef] [PubMed]

- Codemard, C.; Farrell, C.; Dupriez, P.; Philippov, V.; Sahu, J.K.; Nilsson, J. Millijoule, high-peak power, narrow-linewidth, subhundred nanosecond pulsed fibre Master-Oscillator Power- Amplifier ar 1.55 μm. C. R. Phys. 2006, 7, 170–176. [Google Scholar] [CrossRef]

- Dolfi-Bouteyre, A.; Canat, G.; Valla, M.; Augere, B.; Besson, C.; Goular, D.; Lombard, L.; Cariou, J.P.; Durecu, A.; Fleury, D.; et al. Pulsed 1.5-μm LIDAR for axial aircraft wake vortex detection based on highbrightness large-core fiber amplifier. IEEE J. Sel. Top. Quantum Electron. 2009, 15, 441–450. [Google Scholar] [CrossRef]

- Wagener, J.L.; DiGiovanni, D.J.; Wysocki, P.F.; Digonnet, M.J.F.; Shaw, H.J. Effects of concentration and clusters in erbium-doped fiber lasers. Opt. Lett. 1993, 18, 2014–2016. [Google Scholar] [CrossRef] [PubMed]

- Guzman-Chavez, D.; Barmenkov, Y.O.; Kir’yanov, A.V. Spectral dependence of the excited-state absorption of erbium in silica fiber within the 1.48–1.59 m range. Appl. Phys. Lett. 2008, 92, 191111. [Google Scholar] [CrossRef]

- Delevaque, E.; Georges, T.; Monerie, M.; Lamouler, P.; Bayon, J.-F. Modeling of pair-induced quenching in erbium-doped silicate fibers. IEEE Photon. Technol. Lett. 1993, 5, 73–75. [Google Scholar] [CrossRef]

- Kuhn, V.; Kracht, D.; Neumann, J.; Weßels, P. 67 W of output power from an Yb-free Er-doped fiber amplifier cladding pumped at 976 nm. IEEE Photon. Technol. Lett. 2011, 23, 432–434. [Google Scholar] [CrossRef]

- Zhang, J.; Fromzel, V.; Dubinskii, M. Resonantly cladding-pumped Yb-free Er-doped LMA fiber laser with record high power and efficiency. Opt. Express 2011, 19, 5574–5578. [Google Scholar] [CrossRef] [PubMed]

- Dubinskii, M.; Zhang, J.; Ter-Mikirtychev, V. Highly scalable, resonantly cladding-pumped, Er-doped fiber laser with record efficiency. Opt. Lett. 2009, 34, 1507–1509. [Google Scholar] [CrossRef] [PubMed]

- Lim, E.L.; Alam, S.U.; Richardson, D.J. High-energy, in-band pumped erbium doped fiber amplifiers. Opt. Express 2012, 20, 18803–18818. [Google Scholar] [CrossRef] [PubMed]

- Yahel, E.; Hardy, A. Efficiency optimization of high-power, Er3+-Yb3+-codoped fiber amplifiers for wavelength-division-multiplexing applications. J. Opt. Soc. Am. B 2003, 20, 1189–1197. [Google Scholar] [CrossRef]

- Jeong, Y.; Yoo, S.; Codemard, C.A.; Nilsson, J.; Sahu, J.K.; Payne, D.N.; Horley, R.; Turner, P.W.; Hickey, L.; Harker, A.; et al. Erbium:ytterbium codoped large-core fiber laser with 297-W continuous-wave output power. IEEE J. Sel. Top. Quantum 2007, 13, 573–579. [Google Scholar] [CrossRef]

- Jeong, Y.; Sahu, J.K.; Soh, D.B.S.; Codemard, C.A.; Nilsson, J. High-power tunable single-frequency single-mode erbium:ytterbium codoped large-core fiber master-oscillator power amplifier source. Opt. Lett. 2005, 30, 2997–2999. [Google Scholar] [CrossRef] [PubMed]

- De Varona, O.; Fittkau, W.; Booker, P.; Theeg, T.; Steinke, M.; Kracht, D.; Neumann, J.; Wessels, P. Single-frequency fiber amplifier at 1.5 µm with 100 W in the linearly-polarized TEM00 mode for next-generation gravitational wave detectors. Opt. Express 2017, 25, 24880–24892. [Google Scholar] [CrossRef] [PubMed]

- Gonthier, F.; Martineau, L.; Azami, N.; Faucher, M.; Seguin, F.; Stryckman, D.; Villeneuve, A. High-power all-fibre components: The missing link for high-power fibre lasers. Proc. SPIE 2004, 5335. [Google Scholar] [CrossRef]

- Richardson, D.J.; Nilsson, J.; Clarkson, W.A. High power fiber lasers: Current status and future perspectives [Invited]. J. Opt. Soc. Am. B 2010, 27, B63–B92. [Google Scholar] [CrossRef]

- Shi, W.; Fang, Q.; Zhu, X.; Norwood, R.A.; Peyghambarian, N. Fibre lasers and their applications [Invited]. Appl. Opt. 2014, 53, 6554–6568. [Google Scholar] [CrossRef] [PubMed]

- Gapontsev, V.P.; Samartsev, L.E. High-power fiber laser. OSA Proc. Adv. Solid State Lasers 1990, 6. [Google Scholar] [CrossRef]

- Gapontsev, V.P.; Samartsev, I. Coupling Arrangement between a Multi-Mode Light Source and an Optical Fiber through an Intermediate Optical Fiber Length. U.S. Patent 5,999,673, 7 December 1999. Available online: https://patentimages.storage.googleapis.com/b3/5d/29/390f769901abd7/US5999673.pdf (accessed on 25 May 2018).

- DiGiovanni, D.J.; Stentz, A.J. Tapered Fiber Bundles for Coupling Light Into and Out of Cladding-Pumped Fiber Devices. U.S. Patent 5,864,644, 26 January 1999. Available online: https://patentimages.storage.googleapis.com/a9/94/bb/7cd3fbe58cd27c/US5864644.pdf (accessed on 25 May 2018).

- Jauregui, C.; Bohme, S.; Wenetiadis, G.; Limpert, J.; Tünnermann, A. Side-pump combiner for all-fiber monolithic fiber lasers and amplifiers. J. Opt. Soc. Am. B 2010, 27, 1011–1015. [Google Scholar] [CrossRef]

- Braglia, A.; Califano, A.; Liu, Y.; Perrone, G. Architectures and components for high power CW fiber lasers. Int. J. Mod. Phys. B 2014, 28, 1442001. [Google Scholar] [CrossRef]

- Yusim, A.; Barsalou, J.; Gapontsev, D.; Platonov, N.S.; Shkurikhin, O.; Gapontsev, V.P.; Barannikov, Y.A.; Shcherbina, F.V. 100 watt single-mode CW linearly polarized all-fiber format 1.56 μm laser with suppression of parasitic lasing effects. Proc. SPIE 2005, 5709. [Google Scholar] [CrossRef]

- Bai, X.; Sheng, Q.; Zhang, H.; Fu, S.; Shi, W.; Yao, J. High-Power All-Fiber Single-Frequency Erbium–Ytterbium Co-Doped Fiber Master Oscillator Power Amplifier. IEEE Photon. J. 2015, 7, 1–6. [Google Scholar] [CrossRef]

- Kotov, L.V.; Likhachev, M.E.; Bubnov, M.M.; Medvedkov, O.I.; Yashkov, M.V.; Guryanov, A.N.; Février, S.; Lhermite, J.; Cormier, E. Yb-free Er-doped all-fiber amplifier cladding-pumped at 976 nm with output power in excess of 100 W. Proc. SPIE 2014, 8961. [Google Scholar] [CrossRef]

- Noordegraaf, D.; Maack, M.D.; Skovgaard, P.M.W.; Johansen, J.; Becker, F.; Belke, S.; Blomqvist, M.; Laegsgaard, J. All-fiber 7x1 signal combiner for incoherent laser beam combining. Proc. SPIE Int. Soc. Opt. Eng. 2011, 7914. [Google Scholar] [CrossRef] [Green Version]

- Kosterin, A.; Temyanko, V.; Fallahi, M.; Mansuripur, M. Tapered fiber bundles for high power applications. In Proceedings of the Technical Digest, Optical Fiber Communication Conference, Anaheim, CA, USA, 6–11 March 2005. [Google Scholar]

- Braglia, A.; Olivero, M.; Neri, A.; Perrone, G. Fabrication of pump combiners for high power fibre lasers. Proc. SPIE 2011, 7914. [Google Scholar] [CrossRef]

- Zhao, K.; Chang, X.; Chen, Z.; Wang, Z.; Jiang, H. Fabrication of high-efficiency pump and signal combiner based on a thermally expanded core technique. Opt. Laser Technol. 2015, 75, 1–5. [Google Scholar] [CrossRef]

- Koška, P.; Baravets, Y.; Peterka, P.; Bohata, J.; Pisarik, M. Mode_field adapter for tapered_fibre_bundle signal and pump combiners. Appl. Opt. 2015, 54, 751–756. [Google Scholar] [CrossRef] [PubMed]

- Sliwinska, D.; Kaczmarek, P.; Abramski, K.M. Tapered fiber bundle couplers for high-power fiber amplifiers. Proc. SPIE 2014, 9441. [Google Scholar] [CrossRef]

- Stachowiak, D.; Kaczmarek, P.; Abramski, K.M. High-power pump combiners for Tm-doped fibre lasers. Opto-Electron. Rev. 2015, 23, 259–264. [Google Scholar] [CrossRef]

- Sévigny, B.; Poirier, P.; Faucher, M. Pump combiner loss as a function of input numerical aperture power distribution. Proc. SPIE 2009, 7195. [Google Scholar] [CrossRef]

- Wiley, R.; Clark, B. High-power, fused assemblies enabled by advances in fiber processing technologies. Proc. SPIE 2011, 7914. [Google Scholar] [CrossRef]

- Wang, B.; Mies, E. Review of fabrication techniques for fused fibre components for fibre lasers. Proc. SPIE 2009, 7195. [Google Scholar] [CrossRef]

- Stachowiak, D.; Kaczmarek, P.; Abramski, K.M. (5 + 1) × 1 pump and signal power combiner with 9/80 µm feed-through signal fiber. Opt. Laser Technol. 2017, 93, 33–40. [Google Scholar] [CrossRef]

- Bansal, L.; Rosalesgarcia, A.; Supradeepa, V.R.; Taunay, T.; Headley, C. Efficient pump combiner’s for fiber lasers and amplifiers. Proc. SPIE 2016, 9728. [Google Scholar] [CrossRef]

- Liao, L.; Liu, P.; Wang, X.Y.B.; Dai, N.L.; Li, J.Y.; He, B.; Zhou, J. The crucial fiber components and gain fiber for high power ytterbium-doped fiber laser. Proc. SPIE 2015, 9621. [Google Scholar] [CrossRef]

- Zheng, J.; Zhao, W.; Zhao, B.; Li, Z.; Chang, C.; Li, G.; Gao, Q.; Ju, P.; Gao, W.; She, S.; et al. High pumping-power fiber combiner for double-cladding fiber lasers and amplifiers. Opt. Eng. 2018, 57, 036105. [Google Scholar] [CrossRef]

- Zou, S.; Chen, H.; Yu, H.; Sun, J.; Zhao, P.; Lin, X. High-efficiency (6 + 1) × 1 pump–signal combiner based on low-deformation and high-precision alignment fabrication. Appl. Phys. B 2017, 123. [Google Scholar] [CrossRef]

- Gooch & Housego, 6 + 1 × 1 MM Power Combiner with Signal Feedthrough. Available online: https://goochandhousego.com/wp-content/uploads/2018/02/GH-DS-FO-TFB-61x1-Power-Combiner.pdf (accessed on 19 April 2018).

- Lightcomm Technology. Available online: http://www.lightcomm.com/product/view/typeid/130/id/72.html (accessed on 19 April 2018).

- Sobon, G.; Kaczmarek, P.R.; Sliwinska, D.; Sotor, J.; Abramski, K.M. High-Power Fiber-Based Femtosecond CPA System at 1560 nm. IEEE J. Sel. Top. Quantum Electron. 2014, 20, 492–496. [Google Scholar] [CrossRef]

| Ref. | Gain Medium | Output Power | Pump Power | Slope Efficiency | System Type |

|---|---|---|---|---|---|

| Construction with bulk optics | |||||

| [7] | LMA Er3+ | 67 W @ 1570 nm | 225 W @ 976 nm | 30% | MOPA |

| [12] | DC LMA Er3+/Yb3+ | 297 W @ 1567 nm | 1.2 kW @ 975 nm | 40% → 19% | Laser |

| [13] | DC LMA Er3+/Yb3+ | 151 W @ 1563 nm | 470 W @ 975 nm | 35% → 29% | MOPA |

| All-fiber amplifier construction + free-space seed signal coupling | |||||

| [14] | DC LMA Er3+/Yb3+ | 110 W @ 1556 nm | 250 W @ 940 nm | 46% | MOPA |

| All-fiber construction | |||||

| [23] | PM DC LMA Er3+/Yb3+ | 100 W @ 1566.5 nm | 360 W @ 965 nm | 29% | MOPA |

| [24] | PM DC LMA Er3+/Yb3+ | 56.4 W @ 1550 nm | 150 W @ 976 nm | 37% | MOPA |

| [25] | DC LMA Er3+ | 103 W @ 1585 nm | 275 W @ 976 nm | 37% | MOPA |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kaczmarek, P.; Stachowiak, D.; Abramski, K.M. 40 W All-Fiber Er/Yb MOPA System Using Self-Fabricated High-Power Passive Fiber Components. Appl. Sci. 2018, 8, 869. https://doi.org/10.3390/app8060869

Kaczmarek P, Stachowiak D, Abramski KM. 40 W All-Fiber Er/Yb MOPA System Using Self-Fabricated High-Power Passive Fiber Components. Applied Sciences. 2018; 8(6):869. https://doi.org/10.3390/app8060869

Chicago/Turabian StyleKaczmarek, Pawel, Dorota Stachowiak, and Krzysztof M. Abramski. 2018. "40 W All-Fiber Er/Yb MOPA System Using Self-Fabricated High-Power Passive Fiber Components" Applied Sciences 8, no. 6: 869. https://doi.org/10.3390/app8060869