Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete

Abstract

:1. Introduction

2. Materials and Mix Proportions

2.1. Raw Materials

2.2. RPC Mixtures and Curing Conditions

- (I)

- The cement, silica fume, quartz sand, and quartz powder are mixed in a dry state for approximately 2 min at a low speed of approximately 140 rpm. During this dry mixing process, steel fibre was added to the mixtures.

- (II)

- 50% of the water and 50% of the superplasticizer were gradually added to the mixtures, and the mixtures were stirred for 3 min at a high speed of approximately 280 rpm.

- (III)

- The remaining 50% of the water and the superplasticizer were added to the mixtures, which were then stirred again for 3 min at a high speed of approximately 280 rpm.

- (IV)

- After mixing, the RPC was poured into moulds and vibrated until fully consolidated.

3. Experiments

3.1. Compressive Strength and Elastic Modulus Tests

3.2. Shrinkage Tests of RPC

3.3. Creep Tests of RPC

4. Results and Discussion

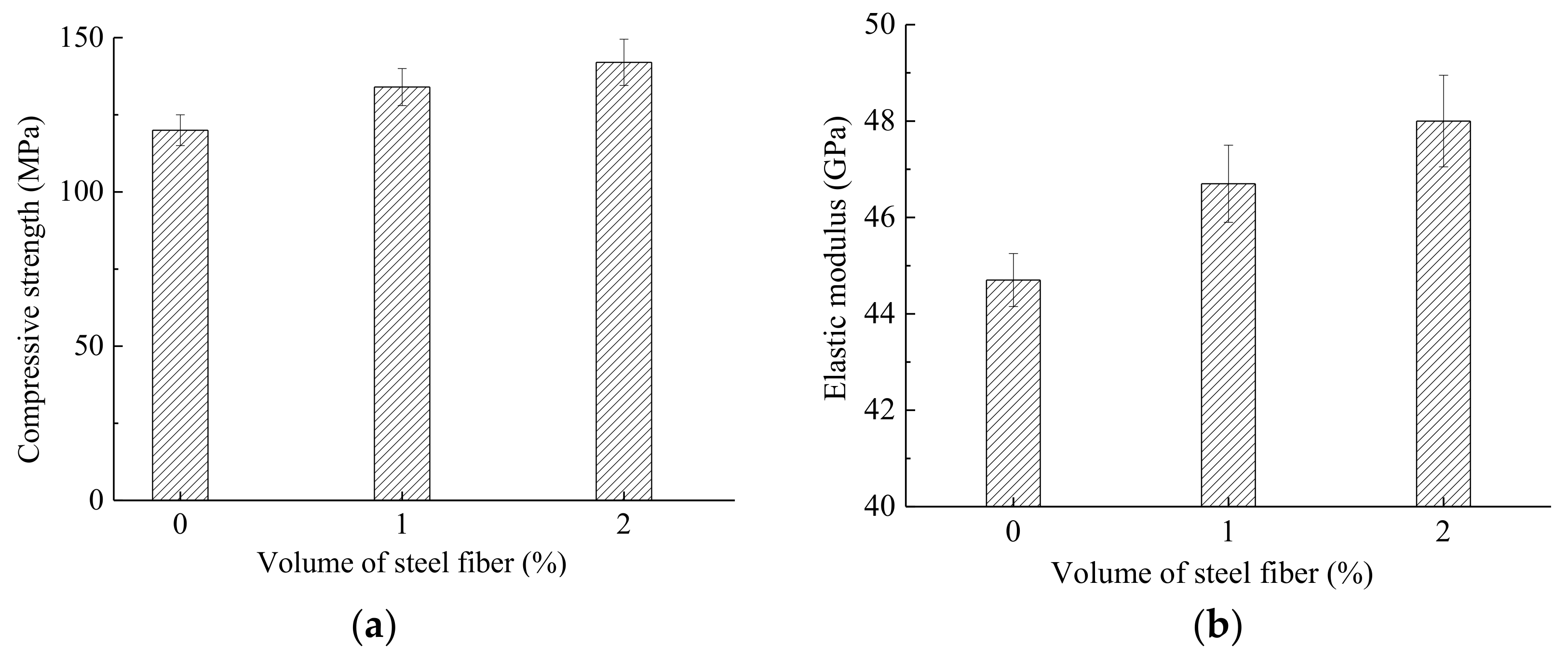

4.1. Compressive Strength and Elastic Modulus of RPC

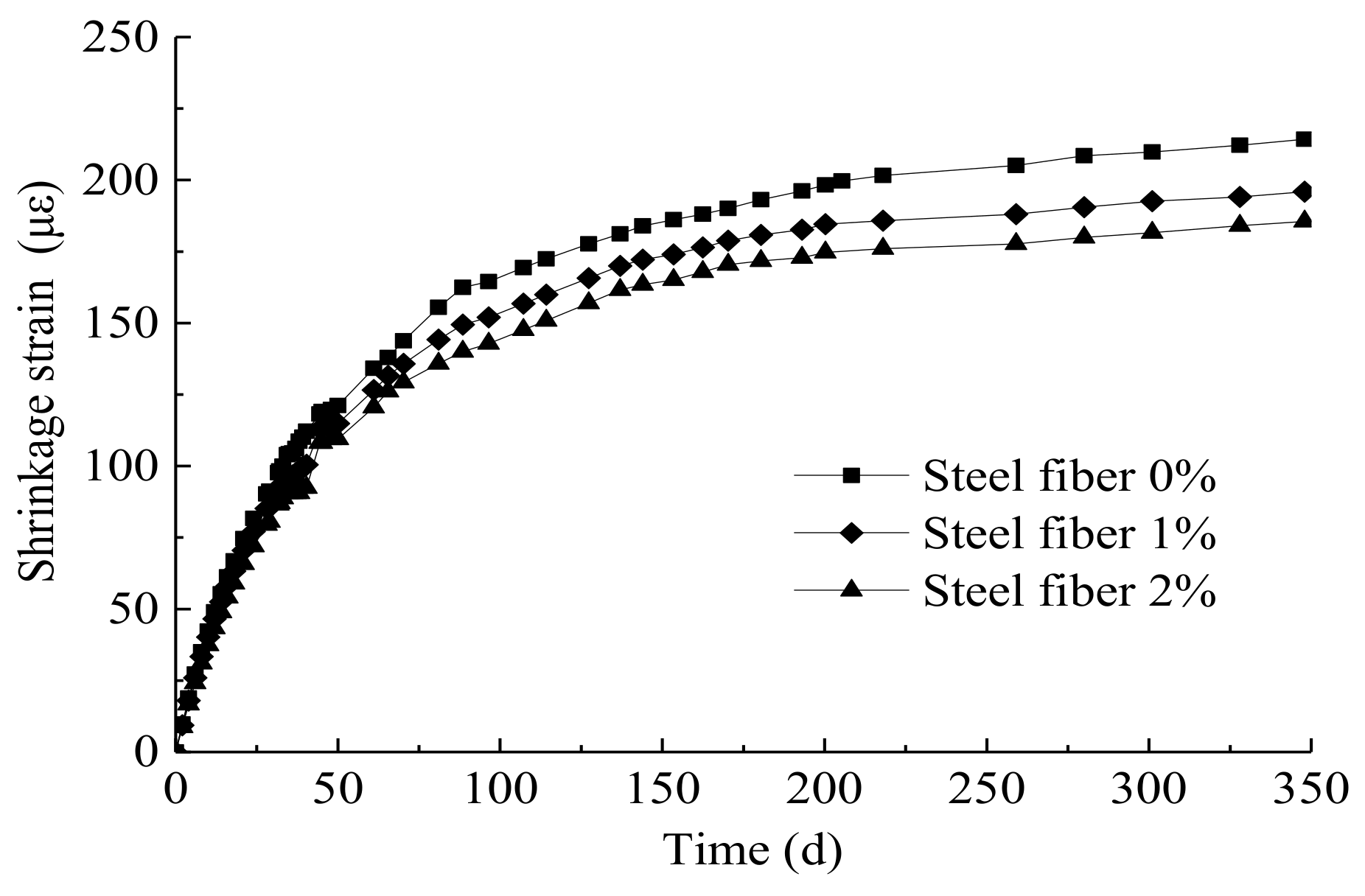

4.2. Shrinkage of RPC

- (I)

- During the process of mixing the steel fibre into the RPC matrix, some micron-scale water films are formed on the steel fibre surface. As a result, calcium hydroxide crystals form directly on the surface of the fibre and grow with no constraints, which forms a loose reticular structure at the interface of the steel fibre and RPC matrix, thereby reducing shrinkage [43].

- (II)

4.3. Creep of RPC

4.3.1. Effect of the Axial Stress Ratio on the Creep of RPC

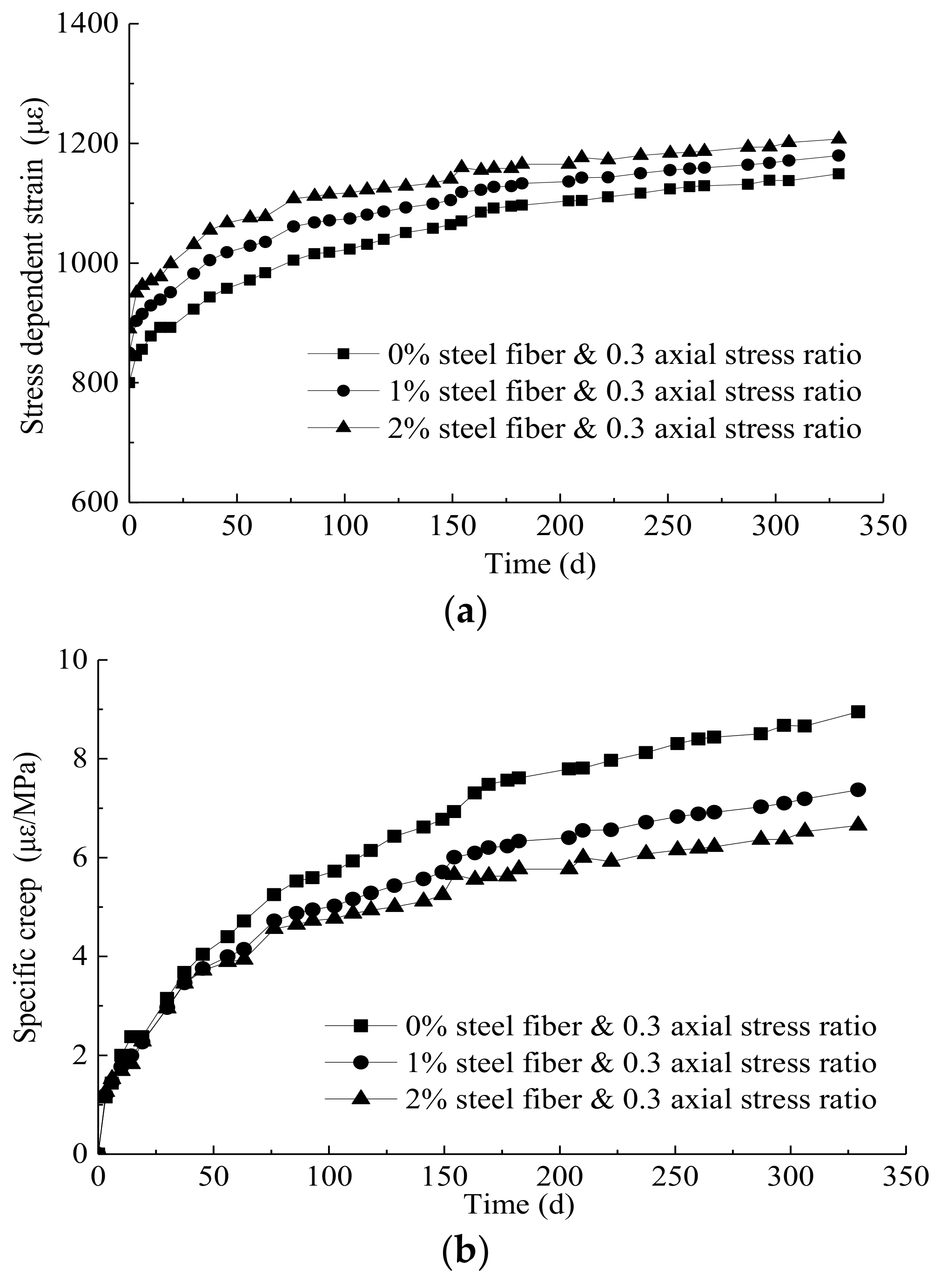

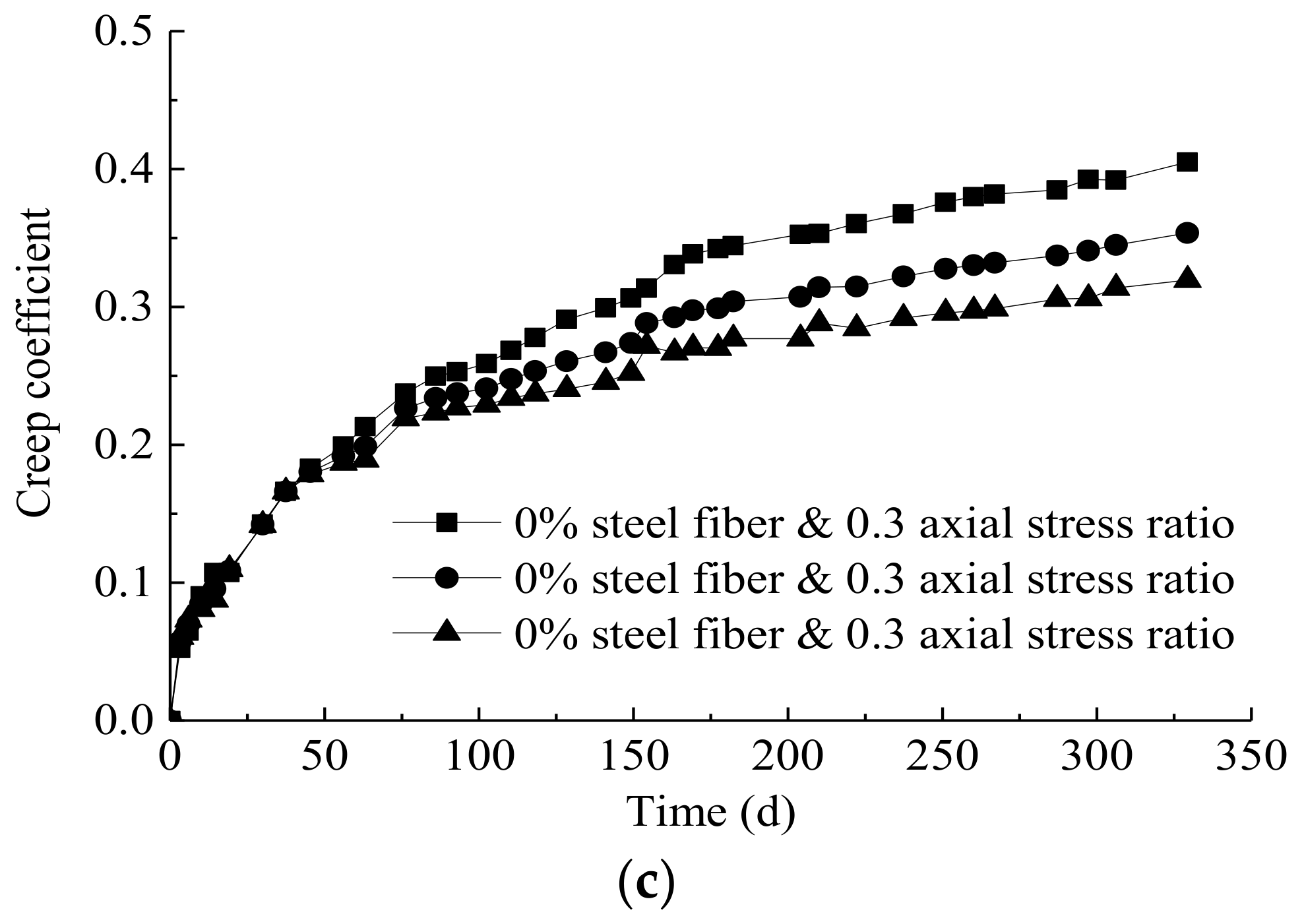

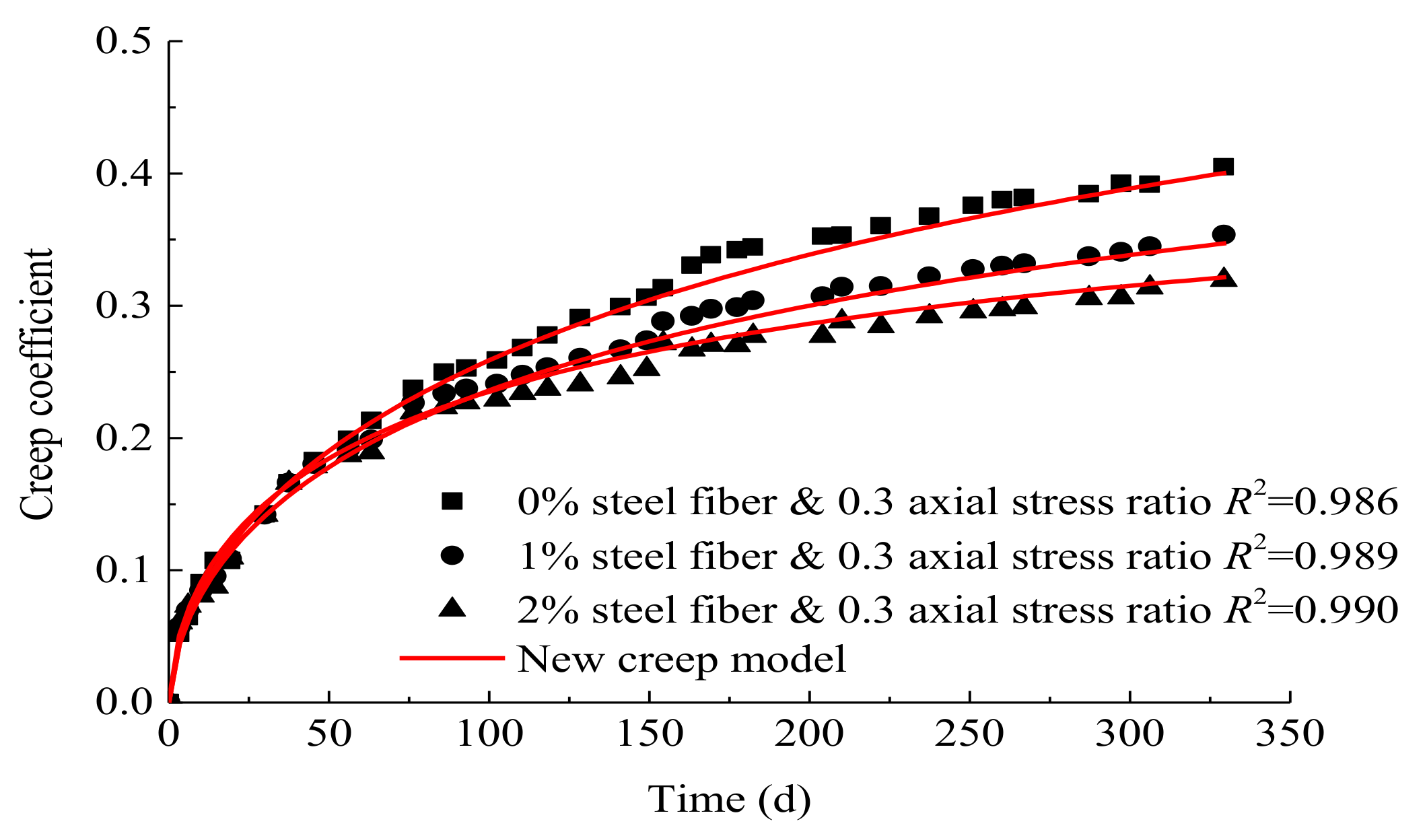

4.3.2. Effect of Steel Fibre on Creep of RPC

- (I)

- Even within the linear creep range, when the RPC carries a compressive load, microcracks can form and develop gradually inside the RPC due to the inhomogeneity of the RPC matrix. As the microcracks emerge during the later stage, the steel fibres passing through the microcracks can prevent the microcracks from developing further. Hence, the creep strain is reduced.

- (II)

- During the early period after loading, the steel fibre and RPC matrix produce a section slip. As a result, the inhibition effect of the steel fibre on creep is not significant. On the other hand, during the later period after loading, the slip between the steel fibre and RPC matrix tends to be stable. Hence, the ability of steel fibre to inhibit creep gradually appears.

4.4. Comparison of Shrinkage and Creep of RPC with Existing Models

4.5. Shrinkage and Creep Model of RPC

5. Conclusions

- (1)

- The compressive strength of RPC is obviously higher than normal strength concrete due to its dense microstructure. The compressive strength and the modulus elastic increase with increasing steel fibre content, as the streel fibre restricts the development of microcracks and transverse deformation.

- (2)

- The shrinkage of RPC is much smaller than normal strength concrete with the improved uniformity and the narrowed pore size. The shrinkage decreases with increasing steel fibre content due to the micro-scale water films formed on the steel fibre surface and skeleton formed by the cross and overlap of steel fibre.

- (3)

- The creep of RPC decreases with increasing steel fibre content which is obvious during the later period after loading, as steel fibre can prevent the development of microcracks (emerging mainly during the later stage). Besides, the slip between the steel fibre and RPC matrix tends to be stable in the later period, the ability of steel fibre to inhibit creep gradually appears.

- (4)

- For axial stress ratios of less than 0.4, the creep strain of RPC varies linearly with the axial stress (RPC is in the linear creep stage).

- (5)

- The shrinkage strains of RPC predicted by the ACI 209-82 model, B3 model, and GL 2000 model are significantly greater than the corresponding experimental results. However, the shrinkage strains of RPC predicted by the CEB-FIP 90 model are significantly smaller than the experimental results. Moreover, all four models overestimate the creep strain of RPC. Thus, these models cannot be used for predicting the shrinkage and creep of RPC.

- (6)

- Simple shrinkage and creep models for RPC which consider the influence of steel fibre have been developed.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Richard, P.; Cheyrezy, M. Composition of reactive powder concretes. Cem. Concr. Res. 1995, 25, 1501–1511. [Google Scholar] [CrossRef]

- Richard, P.; Cheyrezy, M. Reactive powder concretes with high ductility and 200–800 MPa compressive strength. ACI 1994, 114, 507–518. [Google Scholar]

- Cheyrezy, M.; Maret, V.; Frouin, L. Microstructural analysis of RPC (Reactive Powder Concrete). Cem. Concr. Res. 1995, 25, 1491–1500. [Google Scholar] [CrossRef]

- Wang, R.; Gao, X.J. Relationship between Flowability, Entrapped Air Content and Strength of UHPC Mixtures Containing Different Dosage of Steel Fiber. Appl. Sci. 2016, 6, 216. [Google Scholar] [CrossRef]

- Blais, P.Y.; Couture, M. Precast, Prestressed Pedestrian Bridge—World’s First Reactive Powder Concrete Structure. PCI. J. 1999, 44, 60–71. [Google Scholar] [CrossRef]

- Tam, C.M.; Tam, V.W.Y.; Ng, K.M. Assessing drying shrinkage and water permeability of reactive powder concrete produced in Hong Kong. Constr. Build. Mater. 2013, 26, 79–89. [Google Scholar] [CrossRef]

- Zheng, W.Z.; Lu, X.Y. Literature review of reactive powder concrete. J. Build. Struct. 2015, 36, 44–58. (In Chinese) [Google Scholar]

- Yazıcı, H.; Yardımcı, M.Y.; Aydın, S.; Karabulut, A.S. Mechanical properties of reactive powder concrete containing mineral admixtures under different curing regimes. Const. Build. Mater. 2009, 23, 1223–1231. [Google Scholar] [CrossRef]

- Su, A.; Qin, L.; Zhang, S.; Zhang, J.; Li, Z. Effects of Shrinkage Reducing Agent and Expansive Admixture on the Volume Deformation of Ultrahigh Performance Concrete. Adv. Mater. Sci. Eng. 2017, 5, 1–7. [Google Scholar]

- Morin, V.; Tenoudji, F.C.; Feylessoufi, A.; Richard, P. Superplasticizer effects on setting and structuration mechanisms of ultrahigh-performance concrete. Cem. Concr. Res. 2001, 31, 63–71. [Google Scholar] [CrossRef]

- Feylessoufi, A.; Tenoudji, F.C.; Morin, V.; Richard, P. Early ages shrinkage mechanisms of ultra-high-performance cement-based materials. Cem. Concr. Res. 2001, 31, 1573–1579. [Google Scholar] [CrossRef]

- Soliman, A. Effect of partially hydrated cementitious materials on early-age shrinkage of ultra-high-performance concrete. Mag. Con. Res. 2013, 65, 1147–1154. [Google Scholar] [CrossRef]

- Maruyama, I.; Teramoto, A. Temperature dependence of autogenous shrinkage of silica fume cement pastes with a very low water–binder ratio. Cem. Concr. Res. 2013, 50, 41–50. [Google Scholar] [CrossRef]

- Jensen, O.M.; Hansen, P.E. Autogenous Relative Humidity Change in Silica Fume Modified Cement Paste. Aci. Mater. J. 1996, 7, 539–543. [Google Scholar] [CrossRef]

- Yang, Y.; Sato, R.; Kawai, K. Autogenous shrinkage of high-strength concrete containing silica fume under drying at early ages. Cem. Concr. Res. 2005, 35, 449–456. [Google Scholar] [CrossRef]

- Ghafari, E.; Ghahari, S.A.; Costa, H.; Júlio, E.; Portugal, A.; Durães, L. Effect of supplementary cementitious materials on autogenous shrinkage of ultra-high performance concrete. Const. Build. Mater. 2016, 127, 43–49. [Google Scholar] [CrossRef]

- Yazdizadeh, Z.; Marzouk, H.; Hadianfard, M.A. Monitoring of concrete shrinkage and creep using Fiber Bragg Grating sensors. Const. Build. Mater. 2017, 137, 505–512. [Google Scholar] [CrossRef]

- Baant, Z.P.; Prasannan, S. Solidification theory for aging creep. Cem. Concr. Res. 1988, 18, 923–932. [Google Scholar] [CrossRef]

- Bazant, Z.P. Prediction of concrete creep and shrinkage: past, present and future. Nucl. Eng. Des. 2001, 203, 27–38. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Baweja, S. Creep and shrinkage prediction model for analysis and design of concrete structures—model B 3. Mater. Struct. 1995, 28, 357–365. [Google Scholar]

- Shen, P.; Lu, L.; He, Y.; Rao, M.; Fu, Z.; Wang, F.; Hu, S. Experimental investigation on the autogenous shrinkage of steam cured ultra-high performance concrete. Const. Build. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Ahmad, S.; Zubair, A.; Maslehuddin, M. Effect of the key mixture mixture parameters on shrinkage of reactive powder concrete. Sci. World. J. 2014, 6. [Google Scholar] [CrossRef] [PubMed]

- Tuan, N.V.; Ye, G.; Breugel, K.V. Effect of rice husk ash on autogenous shrinkage of ultra high performance concrete. In Proceedings of the International Rilem Conference on Use of Superabsorbent Polymers and Other New Additives in Concrete, Lyngby, Denmark, 15–18 August 2010. [Google Scholar]

- Bentz, D.P.; Peltz, M.A. Reducing Thermal and Autogenous Shrinkage Contributions to Early-Age Cracking. Aci. Mater. J. 2008, 105, 414–420. [Google Scholar]

- Nmai, C.K.; Tomita, R.; Hondo, F.; Buffenbarger, J. Shrinkage-reducing admixtures. Int. J. Concr. Struct. 1998, 20, 31–37. [Google Scholar]

- Soliman, A.M.; Nehdi, M.L. Effects of shrinkage reducing admixture and wollastonite microfiber on early-age behavior of ultra-high performance concrete. Cem. Concr. Comp. 2014, 46, 81–89. [Google Scholar] [CrossRef]

- Soliman, A.M.; Nehdi, M.L. Effect of drying conditions on autogenous shrinkage in ultra-high performance concrete at early-age. Mater. Struct. 2011, 44, 879–899. [Google Scholar] [CrossRef]

- Mo, J.; Ou, Z.; Zhao, X.; Wang, Y. Influence of superabsorbent polymer on shrinkage properties of reactive powder concrete blended with granulated blast furnace slag. Const. Build. Mater. 2017, 146, 283–296. [Google Scholar] [CrossRef]

- Cwirzen, A.; Penttala, V.; Vornanen, C. Reactive powder based concretes: mechanical properties, durability and hybrid use with OPC. Cem. Concr. Res. 2008, 38, 1217–1226. [Google Scholar] [CrossRef]

- Graybeal, A. Characterization of the Behavior of Ultrahigh Performance Concrete. Ph.D. Thesis, University of Maryland, College Park, MD, USA, 2005. [Google Scholar]

- Yoo, D.Y.; Kim, S.; Kim, M.J. Comparative shrinkage behavior of ultra-high-performance fiber-reinforced concrete under ambient and heat curing conditions. Const. Build. Mater. 2018, 162, 406–419. [Google Scholar] [CrossRef]

- Pan, Z.; Li, B.; Lu, Z. Re-evaluation of CEB-FIP 90 prediction models for creep and shrinkage with experimental database. Constr. Build. Mater. 2013, 38, 1022–1030. [Google Scholar] [CrossRef]

- Jiang, L.Z.; Yan, B.L.; Xiao, Z.M.; Wang, W.Y.; Zhang, D.T. General purposed portland cement. Cement 2008, 4, 1–2. (In Chinese) [Google Scholar]

- Madandoust, R.; Ranjbar, M.M.; Ghavidel, R.; Shahabi, S.F. Assessment of factors influencing mechanical properties of steel fiber reinforced self-compacting concrete. Mater. Des. 2015, 83, 284–294. [Google Scholar] [CrossRef]

- Zheng, W.Z.; Luo, B.F.; Wang, Y. Compressive and tensile properties of reactive powder concrete with steel fibres at elevated temperatures. Constr. Build. Mater. 2013, 41, 844–851. [Google Scholar] [CrossRef]

- GB 50010-2002. Ministry of Construction of the People’s Republic of China, Code for Design of Concrete Structures; Chinese Architecture and Building Press: Beijing, China, 2002. (In Chinese) [Google Scholar]

- GB/T 50081-2009. Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; China Architecture and Building Press: Beijing, China, 2009. (In Chinese) [Google Scholar]

- Wang, C.; Liu, F.; Wan, C.; Pu, X. Preparation of Ultra-High Performance Concrete with common technology and materials. Cem. Concr. Comp. 2012, 34, 538–544. [Google Scholar] [CrossRef]

- Gao, D.Y.; Cheng, H.Q.; Zhu, H.T. Splitting Tensile Bonding Strength of Steel Fiber Reinforced Concrete to Old Concrete. J. Build. Mater. 2007, 10, 505–509. (In Chinese) [Google Scholar]

- Ren, G.M.; Wu, H. Effects of steel fiber content and type on static mechanical properties of UHPCC. Constr. Build. Mater. 2017, 163, 826–839. [Google Scholar] [CrossRef]

- Huang, K.; Deng, M.; Mo, L.; Wang, Y. Early age stability of concrete pavement by using hybrid fiber together with MgO expansion agent in high altitude locality. Constr. Build. Mate. 2013, 48, 685–690. [Google Scholar] [CrossRef]

- Miao, B.Q. Influences of fibre content on properties of self-compacting steel fibre reinforced concrete. J. Chin. Inst. Eng. 2003, 26, 523–530. (In Chinese) [Google Scholar] [CrossRef]

- Yu, J.C.; Zhao, Q.X. Effect of steel fibre on creep behaviour of concrete. J. Chin. Ceram. Soc. 2013, 8, 1087–1093. (In Chinese) [Google Scholar]

- Noushini, A.; Vessalas, K.; Arabian, G.; Samali, B. Drying Shrinkage Behaviour of Fibre Reinforced Concrete Incorporating Polyvinyl Alcohol Fibres and Fly Ash. Adv. Civil. Eng. 2014, 356–365. [Google Scholar] [CrossRef]

- Mo, J.; Ou, Z.; Wang, Y. Influence of MgO and Hybrid Fiber on the Bonding Strength between Reactive Powder Concrete and Old Concrete. Adv. Mater. Sci. Eng. 2016, 5, 1–13. [Google Scholar]

- ACI Committee209. Prediction of Creep, Shrinkage, and Temperature Effects in Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 1992. [Google Scholar]

- Clark, L.A. CEB-FIP Model Code 1990. Progr. Usenix Unix Suppl. Doc. 2008, 40, 233–235. [Google Scholar]

- Gardner, N.J.; Lockman, M.J. Design Provisions for Drying Shrinkage and Creep of Normal-Strength Concrete. Aci. Mater. J. 2001, 98, 159–167. [Google Scholar]

| Constituent | Cement (%) | Silica Fume (%) |

|---|---|---|

| CaO | 63.37 | 0.39 |

| SiO2 | 22.08 | 95.11 |

| Al2O3 | 5.72 | 0.43 |

| Fe2O3 | 3.05 | 0.42 |

| K2O | 0.43 | 0.48 |

| MgO | 2.02 | 0.17 |

| Na2O | 0.19 | 0.19 |

| Equivalent alkalis (Na2O + 0.658K2O) | 0.33 | 0.64 |

| SO3 | 2.10 | 0.28 |

| Loss on ignition | 0.71 | 1.89 |

| W/B | Cement | SF | Quartz Sand | Quartz Powder | SP | ST 1 (%) |

|---|---|---|---|---|---|---|

| 0.20 | 1.00 | 0.30 | 0.70 | 0.35 | 0.024 | 0 |

| 0.20 | 1.00 | 0.30 | 0.70 | 0.35 | 0.024 | 1 |

| 0.20 | 1.00 | 0.30 | 0.70 | 0.35 | 0.024 | 2 |

| Group | t0 (day) | Δt (day) | fc (MPa) | η | ST% |

|---|---|---|---|---|---|

| I | 28 | 330 | 120 | 0.2 | 0 |

| II | 329 | 120 | 0.3 | 0 | |

| III | 329 | 120 | 0.4 | 0 | |

| IV | 329 | 134 | 0.3 | 1 | |

| V | 329 | 142 | 0.3 | 2 |

| Parameters | ACI 209-82 | CEB-FIP 90 | B3 | GL 2000 |

|---|---|---|---|---|

| fc28 (MPa) | - | 20–90 | 17.2–69 | 16–82 |

| Cement content (kg/m3) | - | - | 160–719 | - |

| W/B | - | - | 0.35–0.85 | 0.40–0.60 |

| Relative humidity (%) | 40–100 | 40–100 | 40–100 | 20–100 |

| tc (Moist cured) | ≥7 days | ≤14 days | - | ≥1 day |

| tc (Steam cured) | ≥1 day | ≤14 days | - | ≥1 day |

| η | ≤0.4 | ≤0.4 | ≤0.45 | ≤0.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, P.; Zheng, W.; Wang, Y.; Chang, W. Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete. Appl. Sci. 2018, 8, 732. https://doi.org/10.3390/app8050732

Chen P, Zheng W, Wang Y, Chang W. Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete. Applied Sciences. 2018; 8(5):732. https://doi.org/10.3390/app8050732

Chicago/Turabian StyleChen, Pang, Wenzhong Zheng, Ying Wang, and Wei Chang. 2018. "Analysis and Modelling of Shrinkage and Creep of Reactive Powder Concrete" Applied Sciences 8, no. 5: 732. https://doi.org/10.3390/app8050732