Numerical Simulation of Temperature Fields in a Three-Dimensional SiC Crystal Growth Furnace with Axisymmetric and Spiral Coils

Abstract

:1. Introduction

2. Modeling of Induction Heating and Heat Transfer

3. Three-Dimensional Silicon Carbide Crystal Growth Furnace

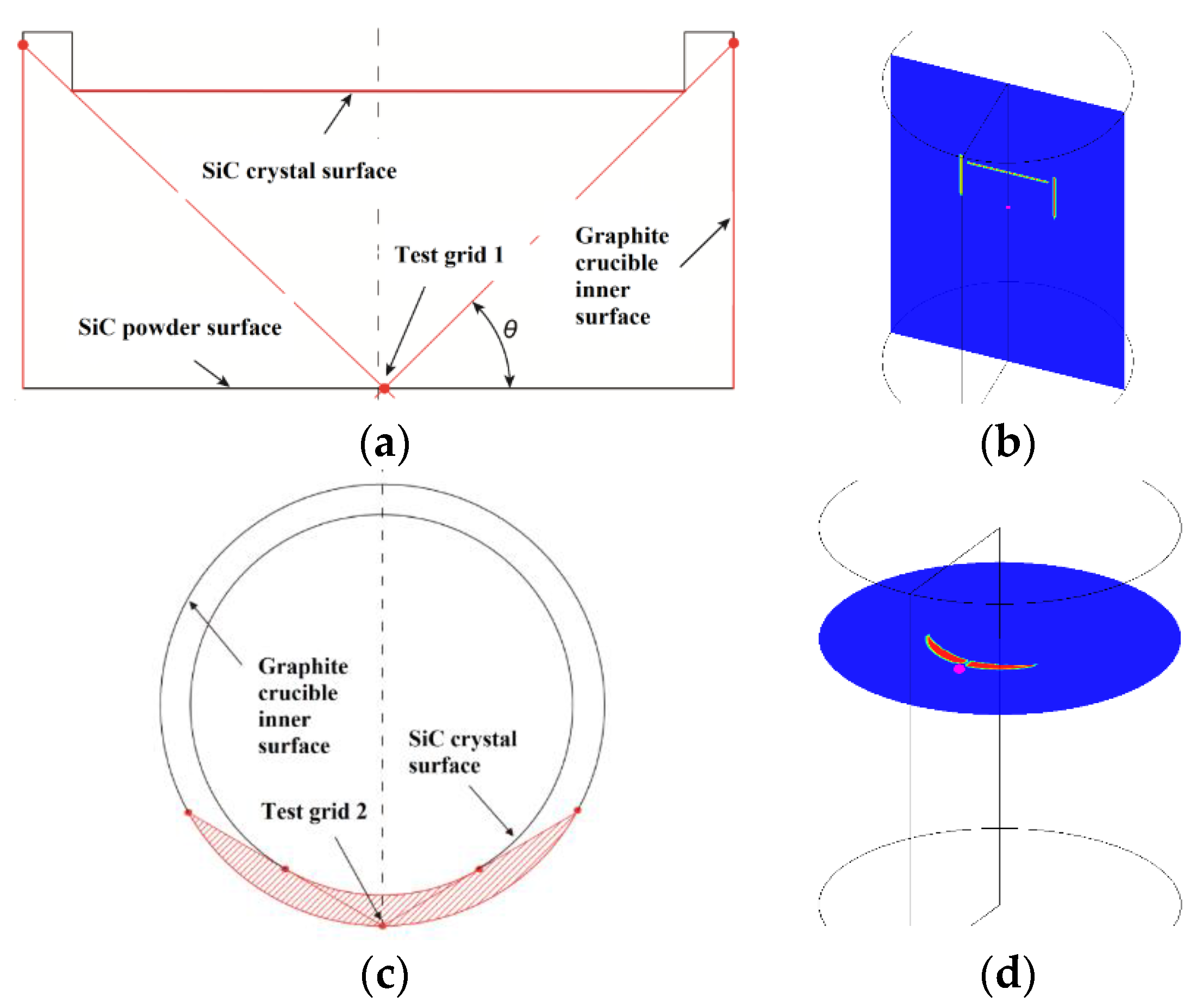

4. Radiation Heat Transfer in Crystal Growth Chamber

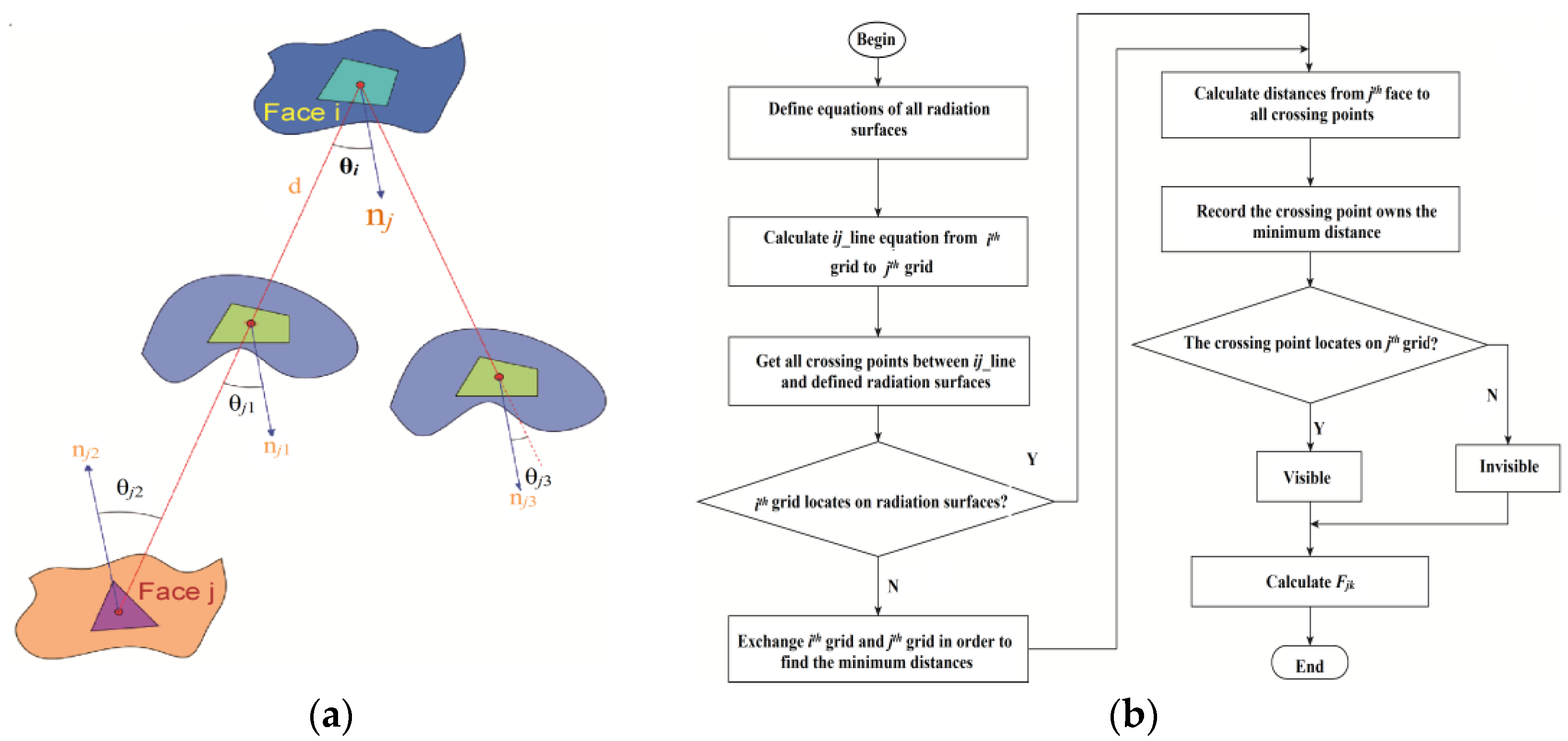

4.1. Surface Visibility Checking Algorithm for S2S Radiation Model

4.2. Acceleration to Solve S2S Radiation Heat

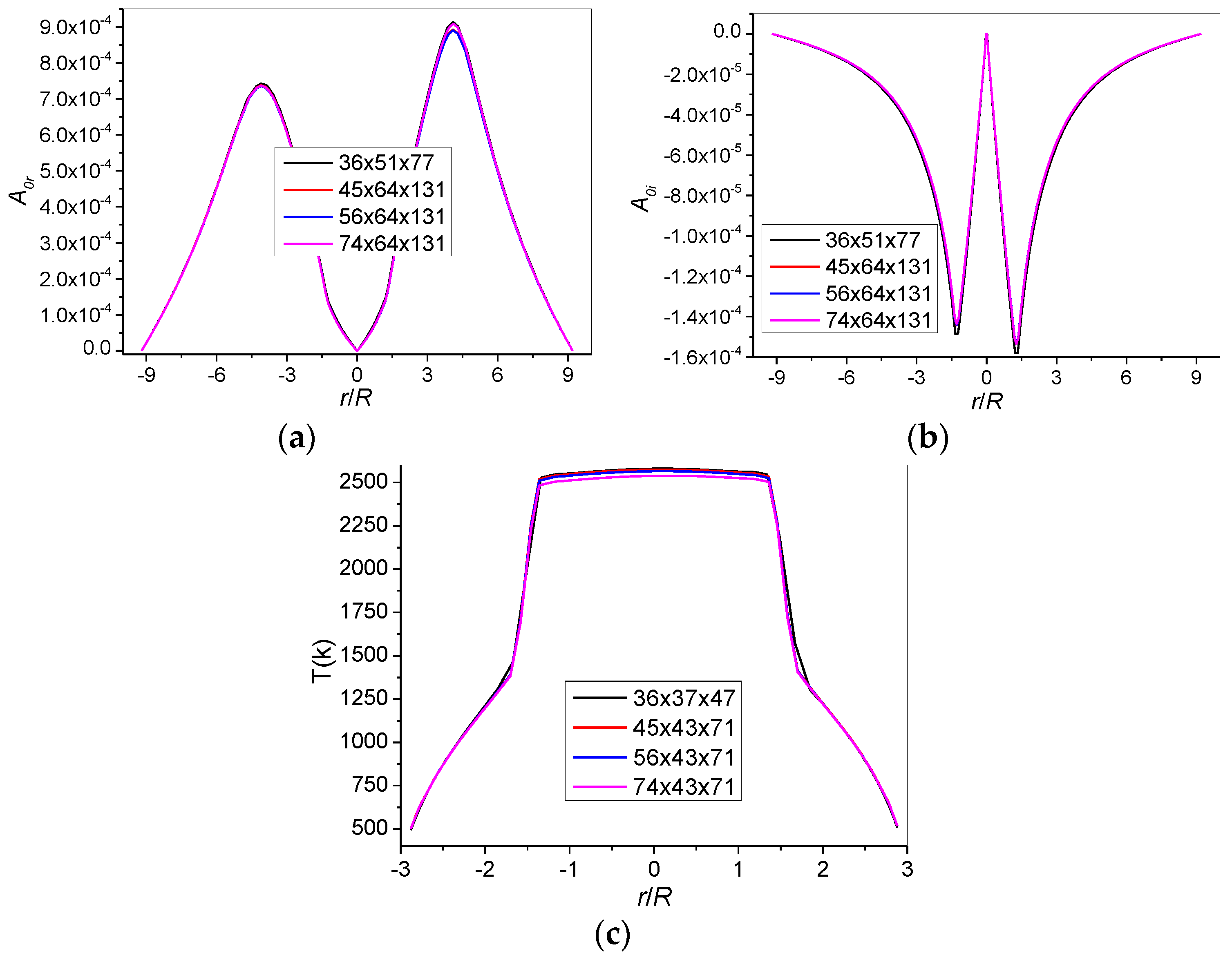

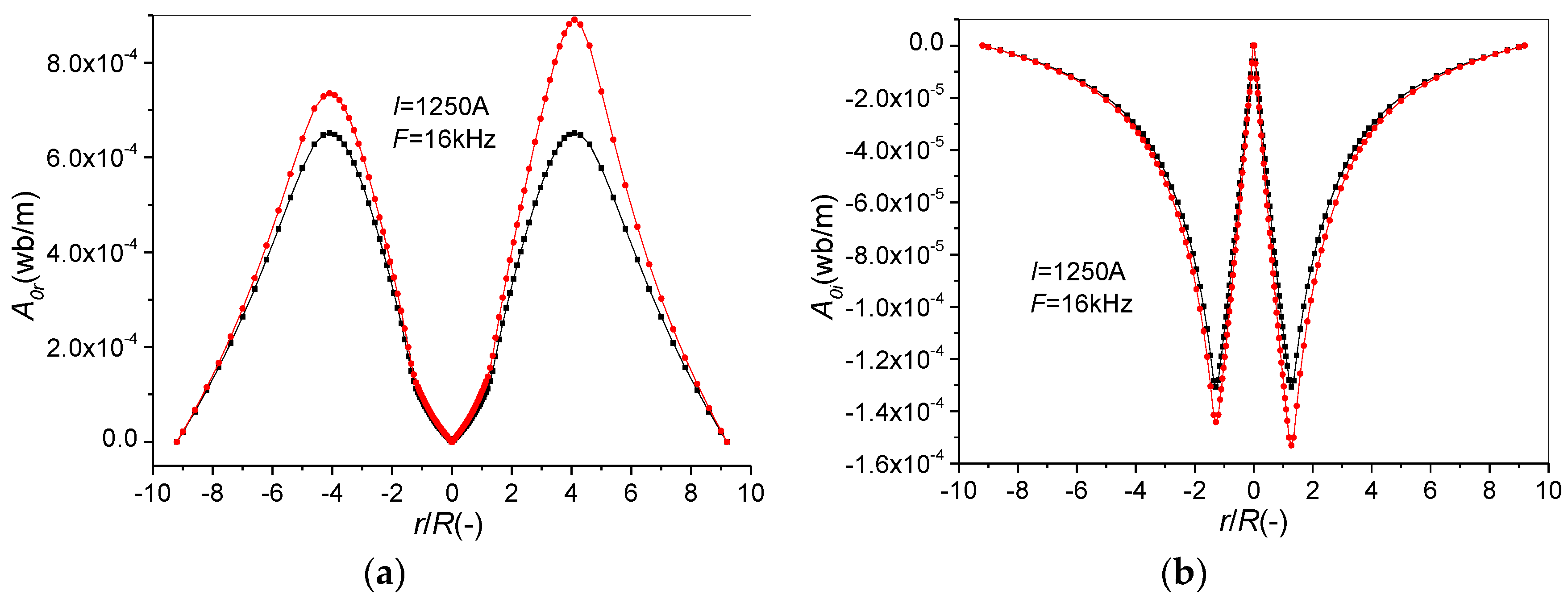

5. Test of Mesh Independence

6. Results and Discussion

7. Conclusions

- (1)

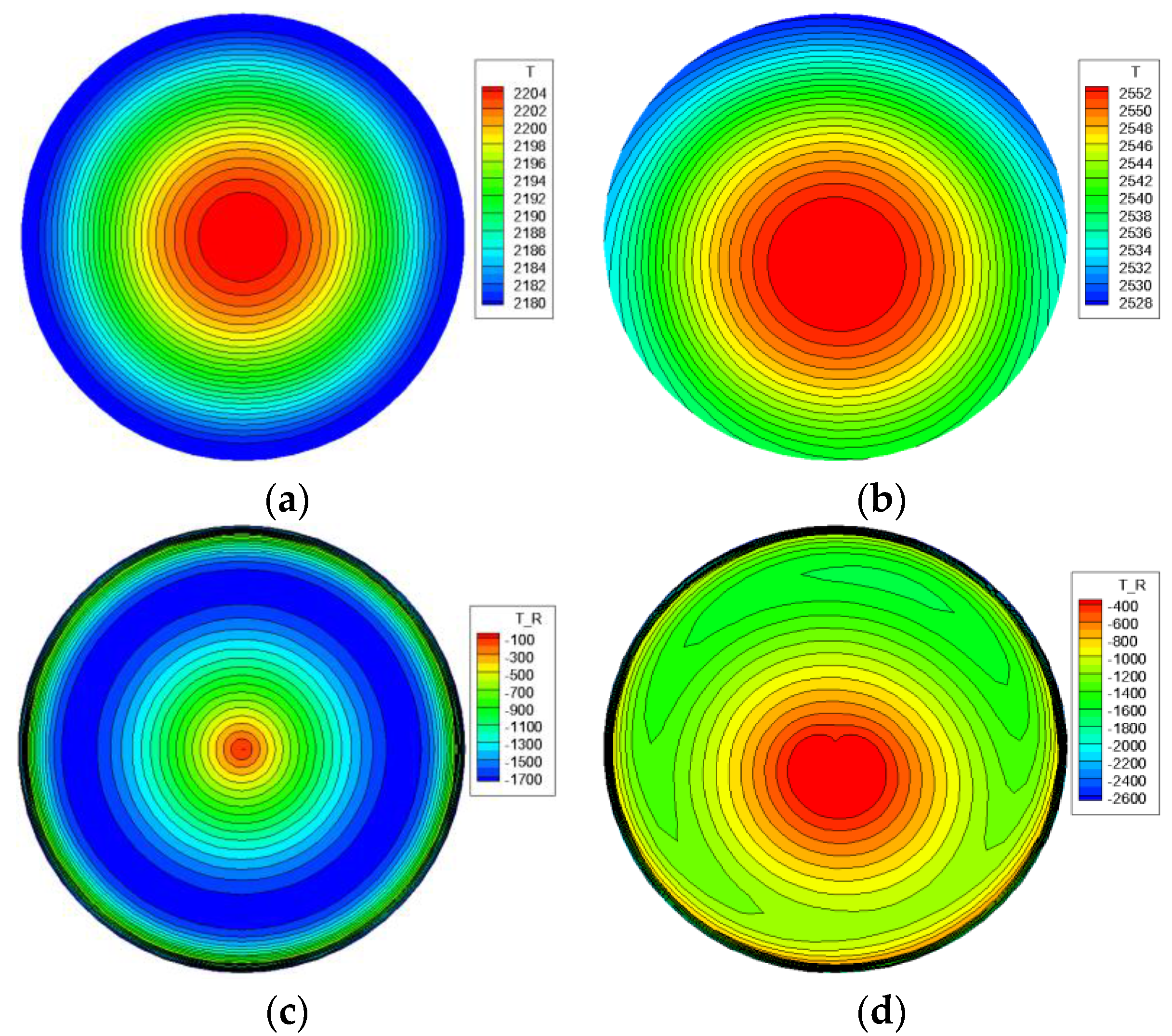

- The coil structure has a great effect on temperature field of SiC crystal growth furnace, spiral coil will cause non-axisymmetric temperature field;

- (2)

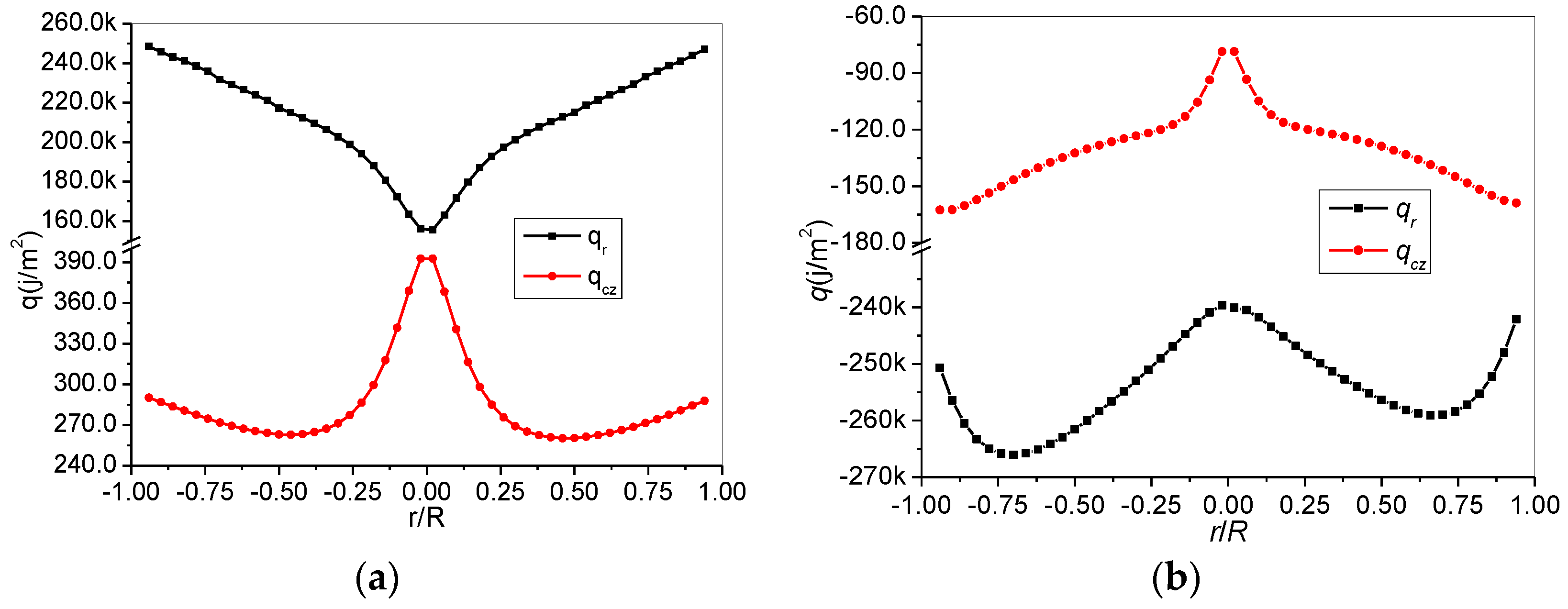

- Radiation heat flux is about 2~3 orders of magnitude bigger than conduction heat flux in the growth chamber, and radiation is helpful to make more uniform temperature field and decrease temperature gradient between powder surface and crystal surface;

- (3)

- The non-axisymmetric temperature and its gradient in the crystal caused by the spiral coil are adverse to grow crystal with fewer defects.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Shiramomo, T.; Gao, B.; Mercier, F.; Nishizawa, S.; Nakano, S.; Kangawa, Y.; Kakimoto, K. Thermodynamical analysis of polytype stability during PVT growth of SiC using 2D nucleation theory. J. Cryst. Growth 2012, 352, 177–180. [Google Scholar] [CrossRef]

- Su, J.; Chen, X.; Li, Y. Numerical design of induction heating in the PVT growth of SiC crystal. J. Cryst. Growth 2014, 401, 128–132. [Google Scholar] [CrossRef]

- Hofmann, D.; Heinze, M.; Winnacker, A.; Durst, F.; Kadinski, L.; Kaufmann, P.; Makarov, Y.; Schäfer, M. On the sublimation growth of SiC bulk crystals: Development of a numerical process model. J. Cryst. Growth 1995, 146, 214–219. [Google Scholar] [CrossRef]

- Hofmann, D.; Bickermann, M.; Eckstein, R.; Kölbl, M.; Müller, S.G.; Schmitt, E.; Weber, A.; Winnacker, A. Sublimation growth of silicon carbide bulk crystals: Experimental and theoretical studies on defect formation and growth rate augmentation. J. Cryst. Growth 1999, 198–199 Pt 2, 1005–1010. [Google Scholar] [CrossRef]

- Liu, X.; Chen, B.; Song, L.; Shi, E.; Chen, Z. The behavior of powder sublimation in the long-term PVT growth of SiC crystals. J. Cryst. Growth 2010, 312, 1486–1490. [Google Scholar] [CrossRef]

- Selder, M.; Kadinski, L.; Durst, F.; Straubinger, T.; Hofmann, D. Numerical simulation of global heat transfer in reactors for SiC bulk crystal growth by physical vapor transport. Mater. Sci. Eng. B 1999, 61–62, 93–97. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, H.; Ma, R.; Prasad, V.; Balkas, C.M.; Yushin, N.K. Modeling of transport processes and kinetics of silicon carbide bulk growth. J. Cryst. Growth 2001, 225, 299–306. [Google Scholar] [CrossRef]

- Klein, O.; Philip, P. Transient temperature phenomena during sublimation growth of silicon carbide single crystals. J. Cryst. Growth 2003, 249, 514–522. [Google Scholar] [CrossRef]

- Klein, O.; Philip, P. Transient numerical investigation of induction heating during sublimation growth of silicon carbide single crystals. J. Cryst. Growth 2003, 247, 219–235. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, Z.; Chen, Q. Numerical simulation of the flow field and concentration distribution in the bulk growth of silicon carbide crystals. J. Cryst. Growth 2006, 292, 519–522. [Google Scholar] [CrossRef]

- Chen, Q.; Yan, J.; Prasad, V. Application of flow-kinetics model to the PVT growth of SiC crystals. J. Cryst. Growth 2007, 303, 357–361. [Google Scholar] [CrossRef]

- Inui, F.; Gao, B.; Nakano, S.; Kakimoto, K. Numerical analysis of the velocity of SiC growth by the top seeding method. J. Cryst. Growth 2012, 348, 71–74. [Google Scholar] [CrossRef]

- Böttcher, K.; Cliffe, K.A. Three-dimensional thermal stresses in on-axis grown SiC crystals. J. Cryst. Growth 2005, 284, 425–433. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, H.; Prasad, V.; Balkas, C.M.; Yushin, N.K.; Wang, S. Kinetics and modeling of sublimation growth of silicon carbide bulk crystal. J. Cryst. Growth 2001, 224, 101–110. [Google Scholar] [CrossRef]

- Bogdanov, M.V.; Galyukov, A.O.; Karpov, S.Y.; Kulik, A.V.; Kochuguev, S.K.; Ofengeim, D.K.; Tsiryulnikov, A.V.; Ramm, M.S.; Zhmakin, A.I.; Makarov, Y.N. Virtual reactor as a new tool for modeling and optimization of SiC bulk crystal growth. J. Cryst. Growth 2001, 225, 307–311. [Google Scholar] [CrossRef]

- Geiser, J.; Klein, O.; Philip, P. Transient numerical study of temperature gradients during sublimation growth of SiC: Dependence on apparatus design. J. Cryst. Growth 2006, 297, 20–32. [Google Scholar] [CrossRef]

- Xue, S.; Proulx, P.; Boulos, M.I. Extended-field electromagnetic model for inductively coupled plasma. J. Phys. D Appl. Phys. 2001, 34, 1897–1906. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, H.; Prasad, V. Heat transfer and kinetics of bulk growth of silicon carbide. J. Cryst. Growth 2001, 230, 239–246. [Google Scholar] [CrossRef]

- Chen, X.; Nishizawa, S.; Kakimoto, K. Numerical simulation of a new SiC growth system by the dual-directional sublimation method. J. Cryst. Growth 2010, 312, 1697–1702. [Google Scholar] [CrossRef]

| Material Name | Density (ρ) kg/m3 | Heat Capacity (cp) J/(kg·K) | Conductivity (λ) W/(m·K) |

|---|---|---|---|

| SiC crystal | 3140.0 | ||

| Graphite crucible | 1750.0 | ||

| Felt | 170.0 | 2100.0 |

| Case | Mesh Number | Number of Radiation Surface | CPU Time (s) | GPU Time (s) | ΔT (K/cm) |

|---|---|---|---|---|---|

| 1 | 36 × 51 × 77 | 2304 | 255 | 71 | 37.36 |

| 2 | 45 × 43 × 71 | 4320 | 1971 | 97 | 34.88 |

| 3 | 56 × 43 × 71 | 5184 | 3355 | 203 | 34.76 |

| 4 | 74 × 43 × 71 | 6912 | 14,421 | 247 | 35.15 |

| No. | Electromagnetic Field | Temperature Field |

|---|---|---|

| 1 | 36 × 51 × 77 | 36 × 51 × 77 |

| 2 | 45 × 64 × 131 | 45 × 43 × 71 |

| 3 | 56 × 64 × 131 | 56 × 43 × 71 |

| 4 | 74 × 64 × 131 | 74 × 43 × 71 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, C.; Liu, G.; Chen, C.; Hou, Y.; Xu, M.; Zhang, Y. Numerical Simulation of Temperature Fields in a Three-Dimensional SiC Crystal Growth Furnace with Axisymmetric and Spiral Coils. Appl. Sci. 2018, 8, 705. https://doi.org/10.3390/app8050705

Yang C, Liu G, Chen C, Hou Y, Xu M, Zhang Y. Numerical Simulation of Temperature Fields in a Three-Dimensional SiC Crystal Growth Furnace with Axisymmetric and Spiral Coils. Applied Sciences. 2018; 8(5):705. https://doi.org/10.3390/app8050705

Chicago/Turabian StyleYang, Chunzhen, Guangxia Liu, Chengmin Chen, Yanjin Hou, Min Xu, and Yongxian Zhang. 2018. "Numerical Simulation of Temperature Fields in a Three-Dimensional SiC Crystal Growth Furnace with Axisymmetric and Spiral Coils" Applied Sciences 8, no. 5: 705. https://doi.org/10.3390/app8050705