Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions

Abstract

:1. Introduction

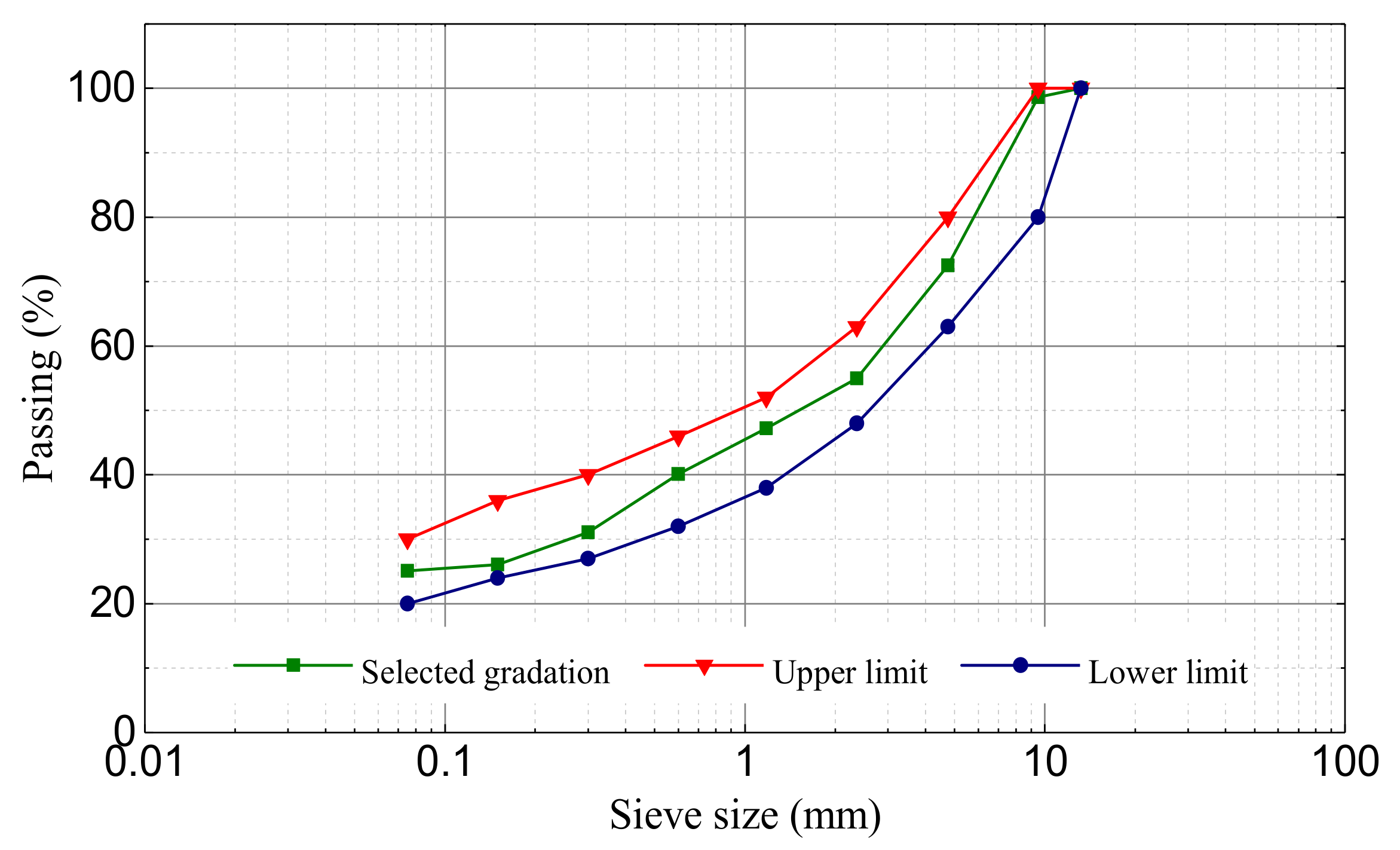

2. Material Design and Evaluation

2.1. Materials

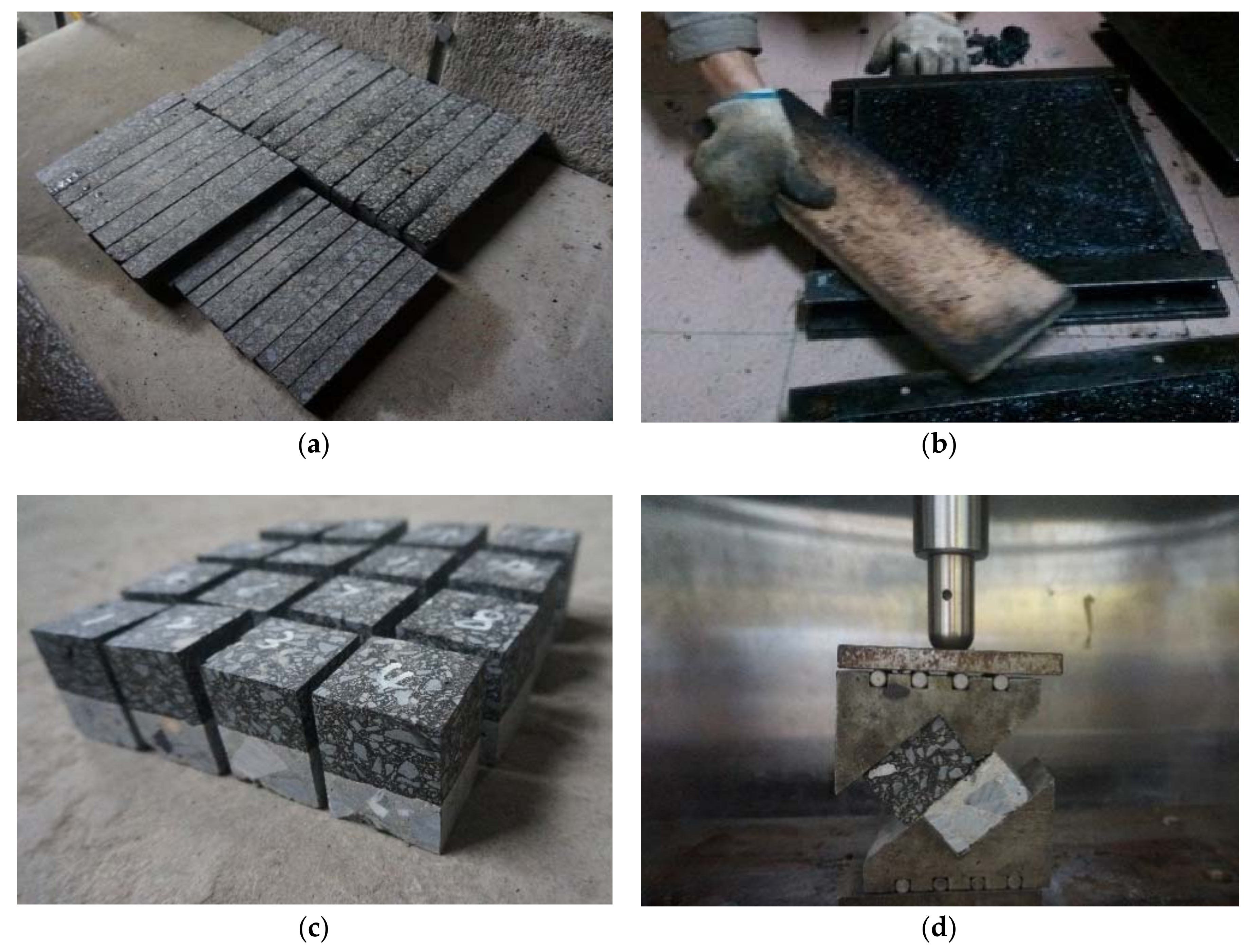

2.2. Laboratory Tests

2.2.1. Specimen Preparation

2.2.2. Lueer Fluidity

2.2.3. Permeation Test

2.2.4. Low Temperature Bending Test

2.2.5. Rutting Test

2.2.6. Interface Bond Strength Test

2.3. Test Results and Discussion

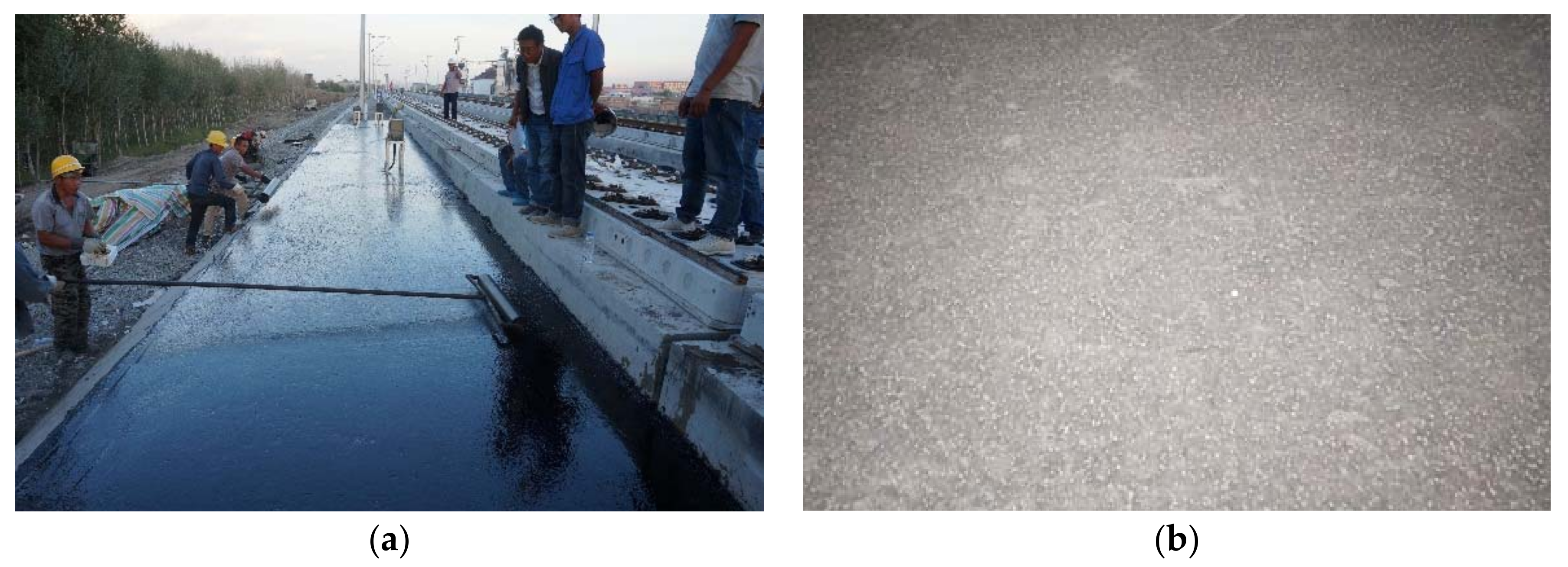

3. Construction of Test Section

3.1. Material Preparation and Paving

3.2. Joints Treatment

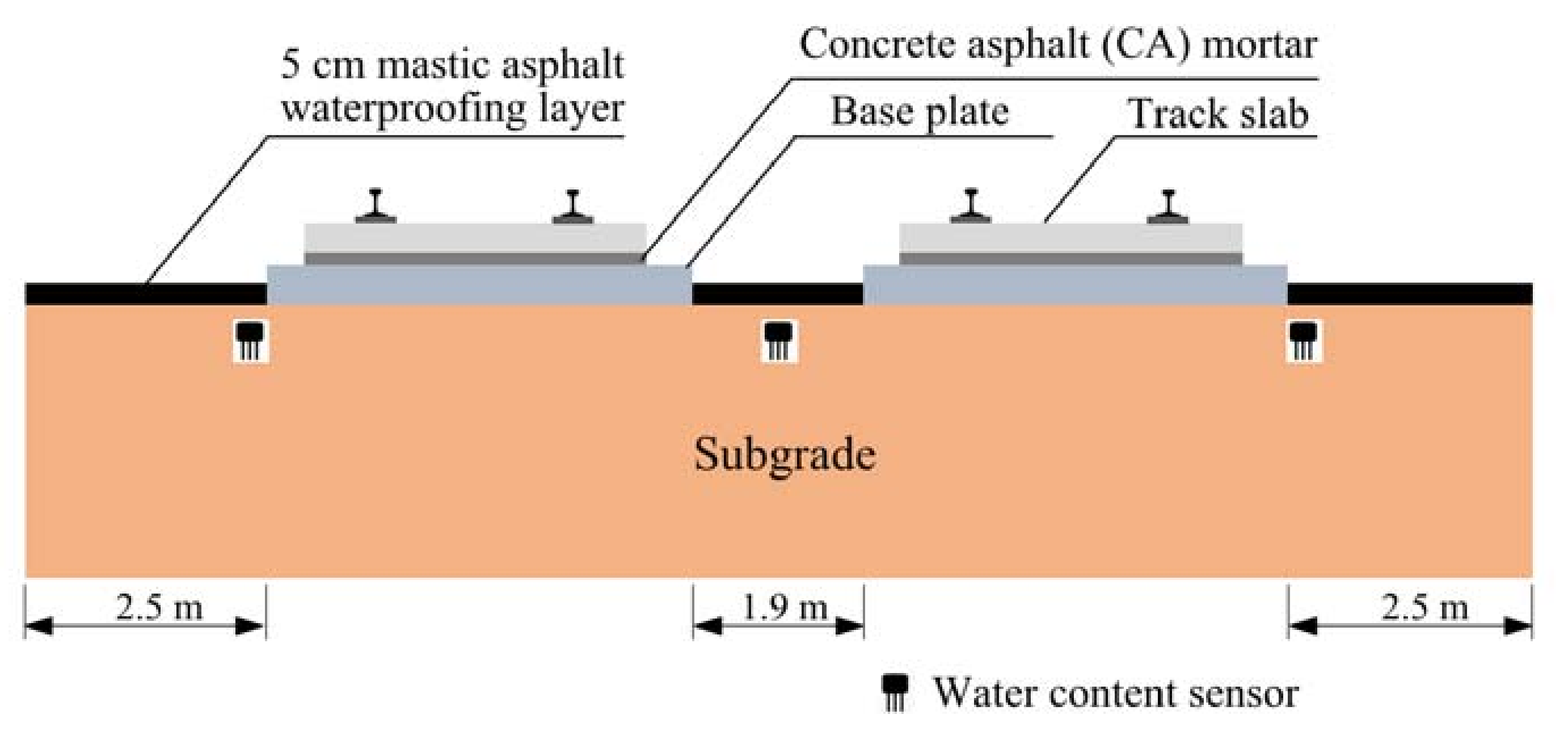

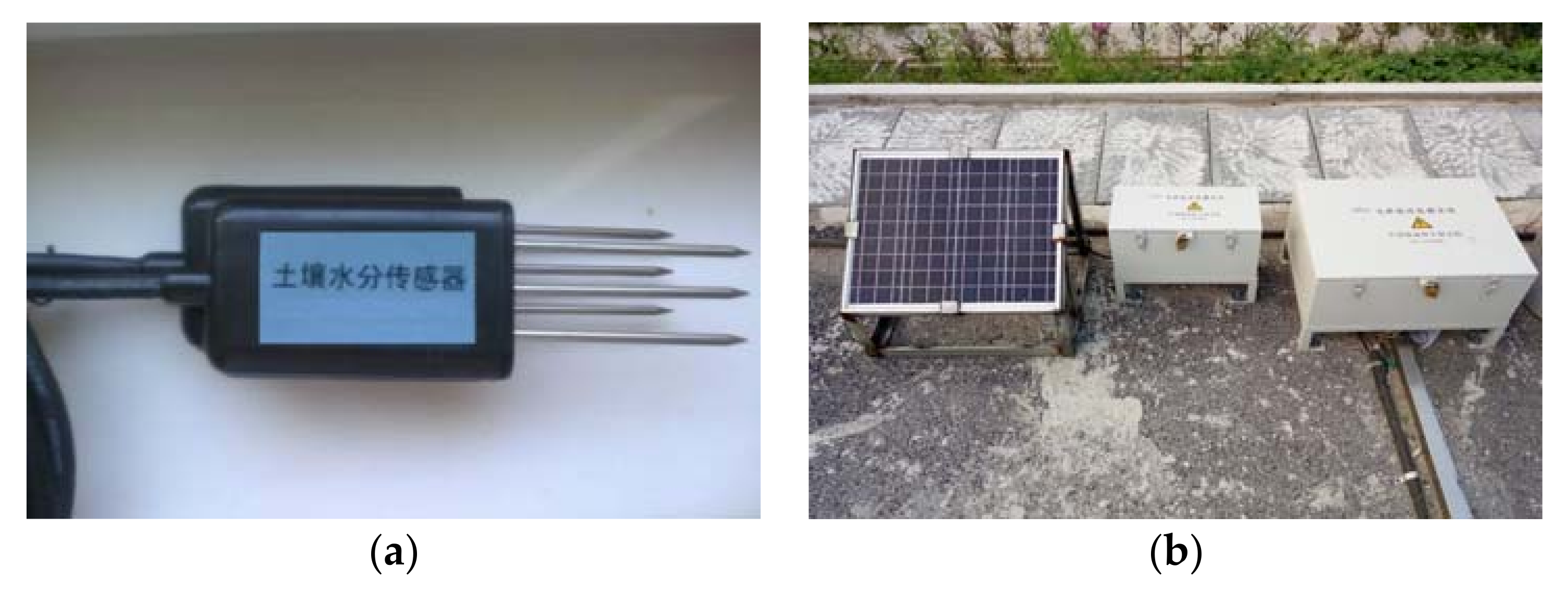

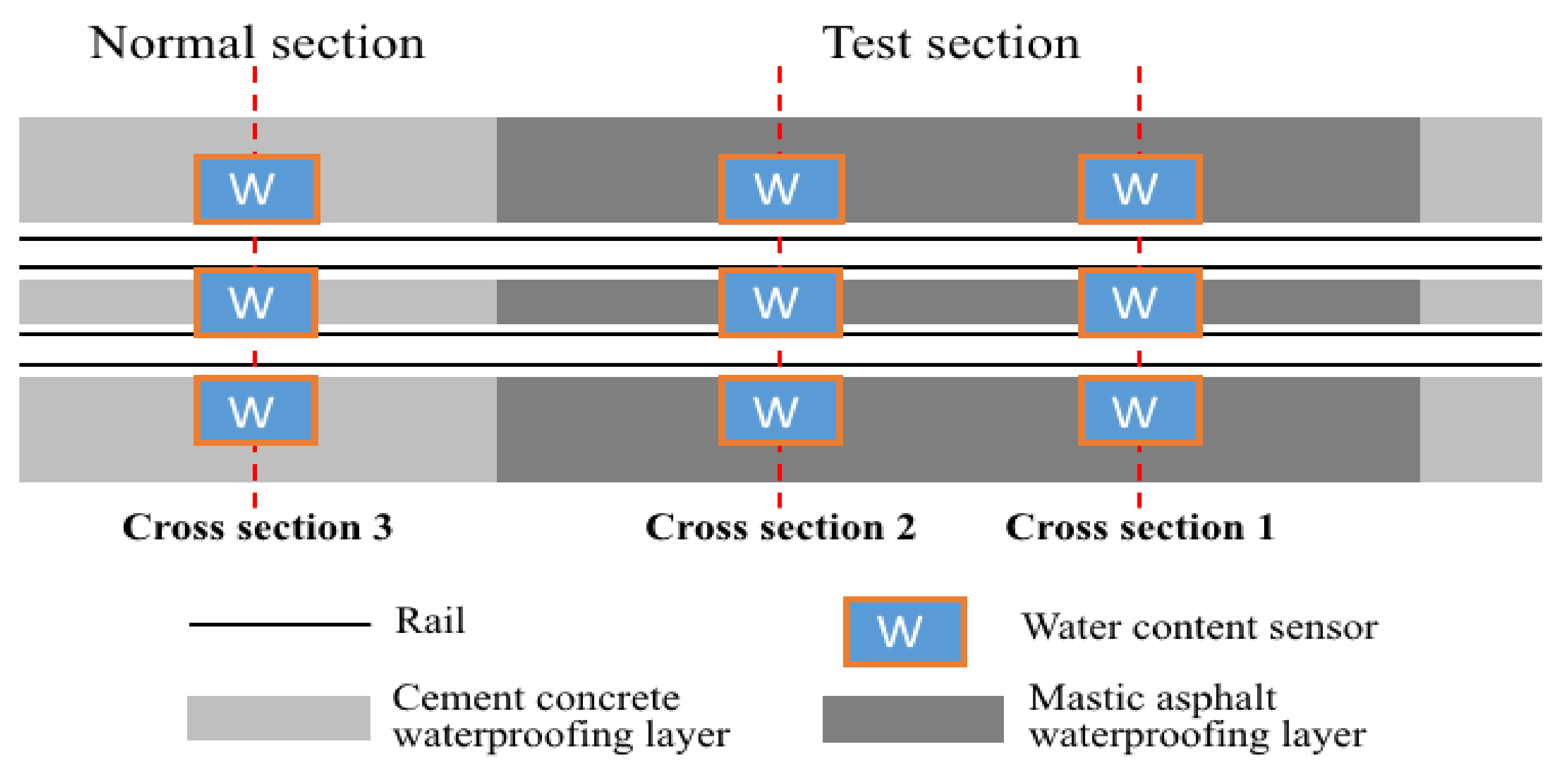

3.3. Water Content Monitoring System

4. Field Validation

4.1. Investigation of Surface Condition

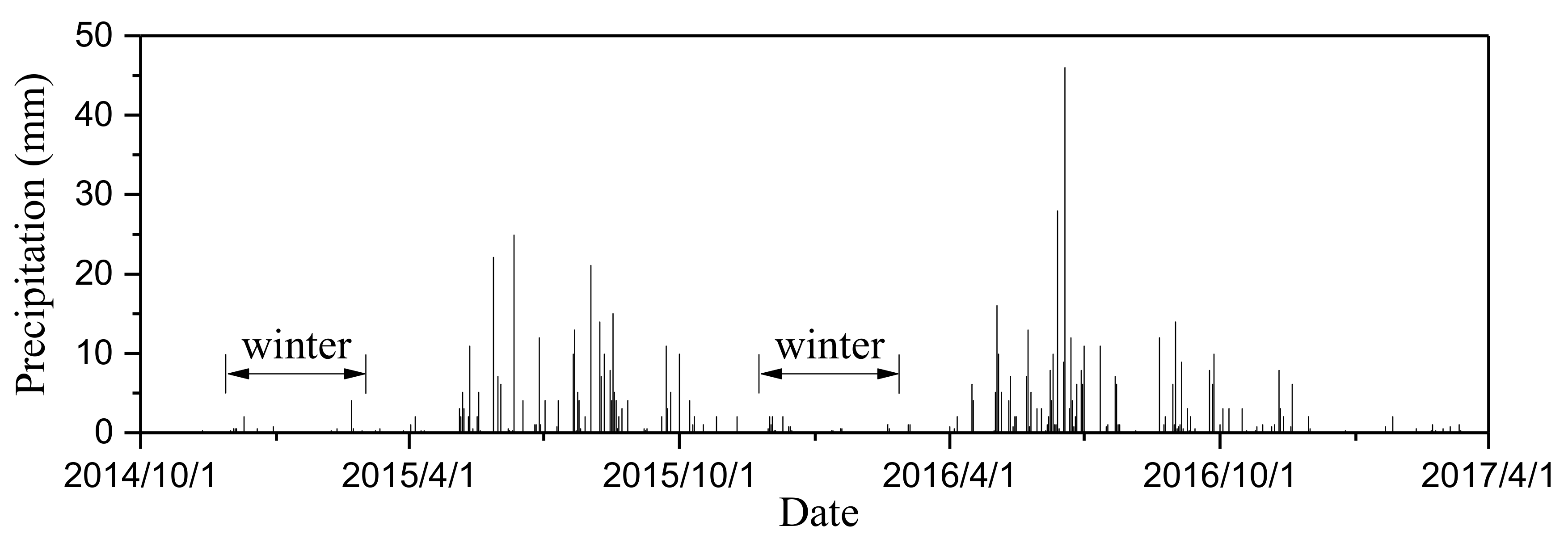

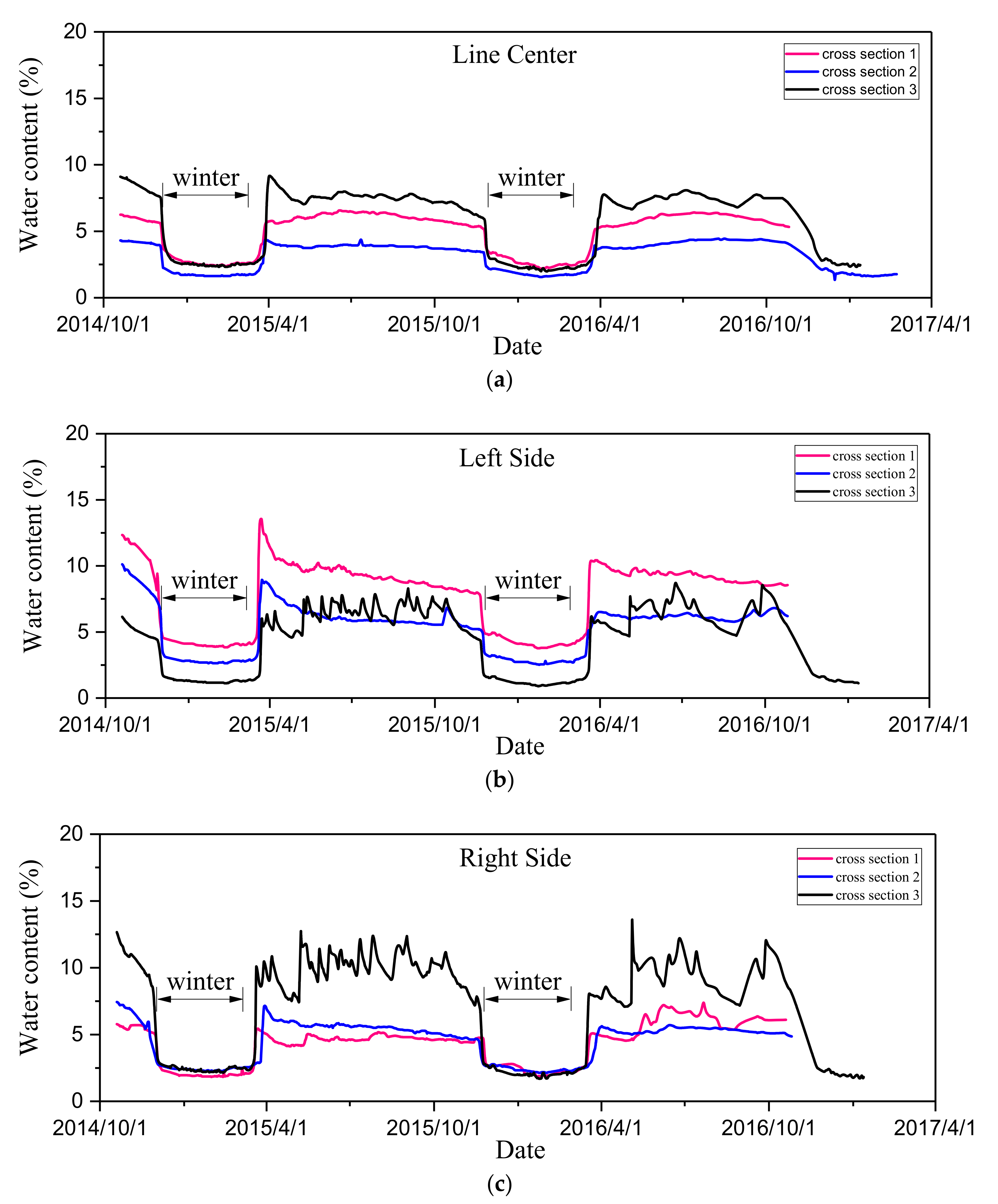

4.2. Subgrade Water Content Monitoring Results

5. Conclusions

- Application of mastic asphalt significantly improves the waterproof performance of waterproofing layer beside the slab track system, and therefore helps to reduce freeze-thaw damage;

- MAWL outperforms conventional concrete waterproofing layer due to better cracking resistance, the observed cracks in MAWL are mostly short cracks caused by the expansion of construction joints in the concrete side slope;

- MAWL showed relatively high stability during the two years of investigation period, no obvious deterioration was observed in the test section;

- Construction joint failure is the key problem of existing discontinuous MAWL in slab track system, and further study is still needed to improve existing practices.

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Li, Q.; Ling, X.; Zhang, F.; Wang, J. The effect of subgrade inhomogeneity induced by freeze-thaw on the dynamic response of track-subgrade system. Sci. Cold Arid Reg. 2013, 5, 554–561. [Google Scholar]

- Yu, X.B.; Liu, Y.; Gonzalez, J.; Yu, B. A new TDR sensor for accurate freeze-thaw measurement. Int. J. Pavement Eng. 2012, 13, 523–534. [Google Scholar] [CrossRef]

- Wang, H.Y.; Silvast, M.; Markine, V.; Wiljanen, B. Analysis of the dynamic wheel loads in railway transition zones considering the moisture condition of the ballast and subballast. Appl. Sci. 2017, 7, 1208. [Google Scholar] [CrossRef]

- Niu, F.; Li, A.; Luo, J.; Lin, Z.; Yin, G.; Liu, M.; Zheng, H.; Liu, H. Soil moisture, ground temperatures, and deformation of a high-speed railway embankment in northeast China. Cold Reg. Sci. Technol. 2017, 133, 7–14. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, J.; Chen, X. Mastic asphalt concrete waterproof layer on high-speed railway subgrade in cold regions. In Proceedings of the Transportation Research Board 94th Annual Meeting, Washington, DC, USA, 11–15 January 2015; Transportation Research Board: Washington, DC, USA, 2015. [Google Scholar]

- Liu, S.; Yang, J.; Chen, X.; Wang, M.; Zhou, W. Design of asphalt waterproofing layer for high-speed railway subgrade: A case study in Heilongjiang province, China. In Proceedings of the Transportation Research Board 96th Annual Meeting, Washington, DC, USA, 8–12 January 2017; Transportation Research Board: Washington, DC, USA, 2017. [Google Scholar]

- Lee, S.H.; Lee, J.W.; Park, D.W.; Vo, H.V. Evaluation of asphalt concrete mixtures for railway track. Constr. Build. Mater. 2014, 73, 13–18. [Google Scholar] [CrossRef]

- Rose, J.G.; Teixeira, P.F.; Ridgway, N.E. Utilization of Asphalt/Bituminous Layers and Coatings in Railway Trackbeds—A Compendium of International Applications; Amer Soc Mechanical Engineers: New York, NY, USA, 2010; pp. 239–255. [Google Scholar]

- Sol-Sanchez, M.; Pirozzolo, L.; Moreno-Navarro, F.; Rubio-Gamez, M.C. A study into the mechanical performance of different configurations for the railway track section: A laboratory approach. Eng. Struct. 2016, 119, 13–23. [Google Scholar] [CrossRef]

- Sol-Sánchez, M.; D’Angelo, G. Review of the design and maintenance technologies used to decelerate the deterioration of ballasted railway tracks. Constr. Build. Mater. 2017, 157, 402–415. [Google Scholar] [CrossRef]

- Teixeira, P.F.; Pita, A.L.; Ferreira, P.A. New possibilities to reduce track costs on high-speed lines using a bituminous sub-ballast layer. Int. J. Pavement Eng. 2010, 11, 301–307. [Google Scholar] [CrossRef]

- Ferreira, T.M.; Teixeira, P.F.; Cardoso, R. Impact of bituminous subballast on railroad track deformation considering atmospheric actions. J. Geotech. Geoenviron. Eng. 2011, 137, 288–292. [Google Scholar] [CrossRef]

- Rose, J.G.; Souleyrette, R. Hot-Mix Asphalt (Bituminous) Railway Trackbeds: In-Track Tests, Evaluations, and Performances-a Global Perspective: Part Ii-United States Asphalt Trackbed Applications and Practices; Crc Press-Taylor & Francis Group: Boca Raton, FL, USA, 2014; pp. 683–690. [Google Scholar]

- Rose, J.G.; Souleyrette, R. Hot-Mix Asphalt (Bituminous) Railway Trackbeds: In-Track Tests, Evaluations, and Performances-a Global Perspective: Part Iii-Us Asphalt Trackbed Materials Evaluations and Tests; CRC Press-Taylor & Francis Group: Boca Raton, FL, USA, 2014; pp. 691–700. [Google Scholar]

- Chupin, O.; Martin, A.; Piau, J.M.; Hicher, P.Y. Calculation of the dynamic response of a viscoelastic railway structure based on a quasi-stationary approach. Int. J. Solids Struct. 2014, 51, 2297–2307. [Google Scholar] [CrossRef]

- Cardona, D.R.; Di Benedetto, H.; Sauzeat, C.; Calon, N.; Saussine, G. Use of a bituminous mixture layer in high-speed line trackbeds. Constr. Build. Mater. 2016, 125, 398–407. [Google Scholar] [CrossRef]

- Ferreira, P.A.; López-Pita, A. Numerical modelling of high speed train/track system for the reduction of vibration levels and maintenance needs of railway tracks. Constr. Build. Mater. 2015, 79, 14–21. [Google Scholar] [CrossRef]

- Ferreira, T.M.; Teixeira, P.F. Rail track performance with different subballast solutions: Traffic and environmental effects on subgrade service life. J. Transp. Eng. 2012, 138, 1541–1550. [Google Scholar] [CrossRef]

- Momoya, Y.; Sekine, E. Performance-based design method for railway asphalt roadbed. Doboku Gakkai Ronbunshuu E 2007, 63, 608–619. [Google Scholar] [CrossRef]

- Lee, S.H.; Choi, Y.T.; Lee, H.M.; Park, D.W. Performance evaluation of directly fastened asphalt track using a full-scale test. Constr. Build. Mater. 2016, 113, 404–414. [Google Scholar] [CrossRef]

- Lechner, B. Developments in road pavement construction and railway track technology for a sustainable surface transportation infrastructure. In Proceedings of the 8th International Conference of Chinese Logistics and Transportation Professionals, Chengdu, China, 8–10 October 2008; American Society of Civil Engineers: Reston, VA, USA, 2008; pp. 2656–2665. [Google Scholar]

- Lee, S.H.; Vo, H.V.; Park, D.W.; Na, I.H. Comparisons of structural behavior between level and cant area of asphalt concrete track. Constr. Build. Mater. 2017, 153, 578–587. [Google Scholar] [CrossRef]

- Li, Q.S.; Ding, H.B.; Rahman, A.; He, D.P. Evaluation of basic oxygen furnace (BOF) material into slag-based asphalt concrete to be used in railway substructure. Constr. Build. Mater. 2016, 115, 593–601. [Google Scholar] [CrossRef]

- Yang, E.; Wang, K.C.P.; Qiu, Y.; Luo, Q. Asphalt concrete for high-speed railway infrastructure and performance comparisons. J. Mater. Civ. Eng. 2016, 28, 04015202. [Google Scholar] [CrossRef]

- Yang, E.H.; Wang, K.C.P.; Luo, Q.; Qiu, Y.J. Asphalt concrete layer to support track slab of high-speed railway. Transp. Res. Record 2015, 2505, 6–14. [Google Scholar] [CrossRef]

- Research Institute of Highway Ministry of Transport. Technical Specifications for Construction of Highway Asphalt Pavements; China Communications Press: Beijing, China, 2004; JTG F40-2004. [Google Scholar]

- Research Institute of Highway Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering; China Communications Press: Beijing, China, 2011; JTG E20-2011. [Google Scholar]

- Qian, J.S.; Wang, Q.Z.; Wu, W.J.; Zhang, H. Fatigue performance of gussasphalt concrete made from modified ahAH-70# asphalt. Mater. Des. 2013, 52, 686–692. [Google Scholar]

- Rahman, A.; Ai, C.F.; Xin, C.F.; Gao, X.W.; Lu, Y. State-of-the-art review of interface bond testing devices for pavement layers: Toward the standardization procedure. J. Adhes. Sci. Technol. 2017, 31, 109–126. [Google Scholar] [CrossRef]

- Kim, T.W.; Baek, J.; Lee, H.J.; Choi, J.Y. Fatigue performance evaluation of SBS modified mastic asphalt mixtures. Constr. Build. Mater. 2013, 48, 908–916. [Google Scholar] [CrossRef]

- Wang, H.; Li, G. Study of factors influencing gussasphalt mixture performance. Constr. Build. Mater. 2015, 101, 193–200. [Google Scholar] [CrossRef]

- Lee, S.H.; Park, D.W.; Vo, H.V.; Dessouky, S. Asphalt mixture for the first asphalt concrete directly fastened track in Korea. Adv. Mater. Sci. Eng. 2015, 2015, 701940. [Google Scholar] [CrossRef]

- Zhu, S.Y.; Cai, C.B. Interface damage and its effect on vibrations of slab track under temperature and vehicle dynamic loads. Int. J. Non-Linear Mech. 2014, 58, 222–232. [Google Scholar] [CrossRef]

- Zhao, H.D.; Cao, J.F.; Zheng, Y. Investigation of the interface bonding between concrete slab and asphalt overlay. Road Mater. Pavement Design 2017, 18, 109–118. [Google Scholar] [CrossRef]

- Song, W.; Shu, X.; Huang, B.; Woods, M. Influence of interface characteristics on the shear performance between open-graded friction course and underlying layer. J. Mater. Civ. Eng. 2017, 29, 04017077. [Google Scholar] [CrossRef]

- Sol-Sanchez, M.; Moreno-Navarro, F.; Garcia-Trave, G.; Rubio-Gamez, M.C. Laboratory study of the long-term climatic deterioration of asphalt mixtures. Constr. Build. Mater. 2015, 88, 32–40. [Google Scholar] [CrossRef]

- Sol-Sanchez, M.; Pirozzolo, L.; Moreno-Navarro, F.; Rubio-Gamez, M.C. Advanced characterisation of bituminous sub-ballast for its application in railway tracks: The influence of temperature. Constr. Build. Mater. 2015, 101, 338–346. [Google Scholar] [CrossRef]

| Indexes | Test Results | Requirements |

|---|---|---|

| Penetration (25 °C, 5 s, 100 g), 0.1 mm | 104 | >80 |

| Penetration index (PI) | 0.60 | ≥−0.8 |

| Ductility at 5 °C, cm | 72.8 | ≥40 |

| Softening point (R & B), °C | 83 | ≥50 |

| Dynamic viscosity at 135 °C, Pa·s | 1.771 | ≤3 |

| Test Methods | Index (Unit) | Tested Value | Requirements |

|---|---|---|---|

| Lueer test | Fluidity (s) | 10.5 | 5–40 |

| Air voids | Air void (%) | 1.8 | - |

| Permeation test | Permeability coefficient (ml/min) | 3 | - |

| Three-point bending beam test | Failure strain (−10 °C, με) | 5641 | >3000 |

| Rutting test | Dynamic stability (times/mm) | 2548 | >2000 |

| Slant shear test | Shear strength (25 °C, MPa) | 2.01 | - |

| Test Methods | Index (Unit) | Tested Value | Requirements | |

|---|---|---|---|---|

| Field | Laboratory | |||

| Lueer test | Fluidity (s) | <20 | 10.5 | 5–40 |

| Air voids of cores | Air void (%) | <1.13 | 1.8 | - |

| Field permeation test | Permeability coefficient (mL/min) | <1 | 3 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Yang, J.; Chen, X.; Yang, G.; Cai, D. Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions. Appl. Sci. 2018, 8, 667. https://doi.org/10.3390/app8050667

Liu S, Yang J, Chen X, Yang G, Cai D. Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions. Applied Sciences. 2018; 8(5):667. https://doi.org/10.3390/app8050667

Chicago/Turabian StyleLiu, Song, Jun Yang, Xianhua Chen, Guotao Yang, and Degou Cai. 2018. "Application of Mastic Asphalt Waterproofing Layer in High-Speed Railway Track in Cold Regions" Applied Sciences 8, no. 5: 667. https://doi.org/10.3390/app8050667