Prediction of the Tensile Load of Drilled CFRP by Artificial Neural Network

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimens and Drill Bit

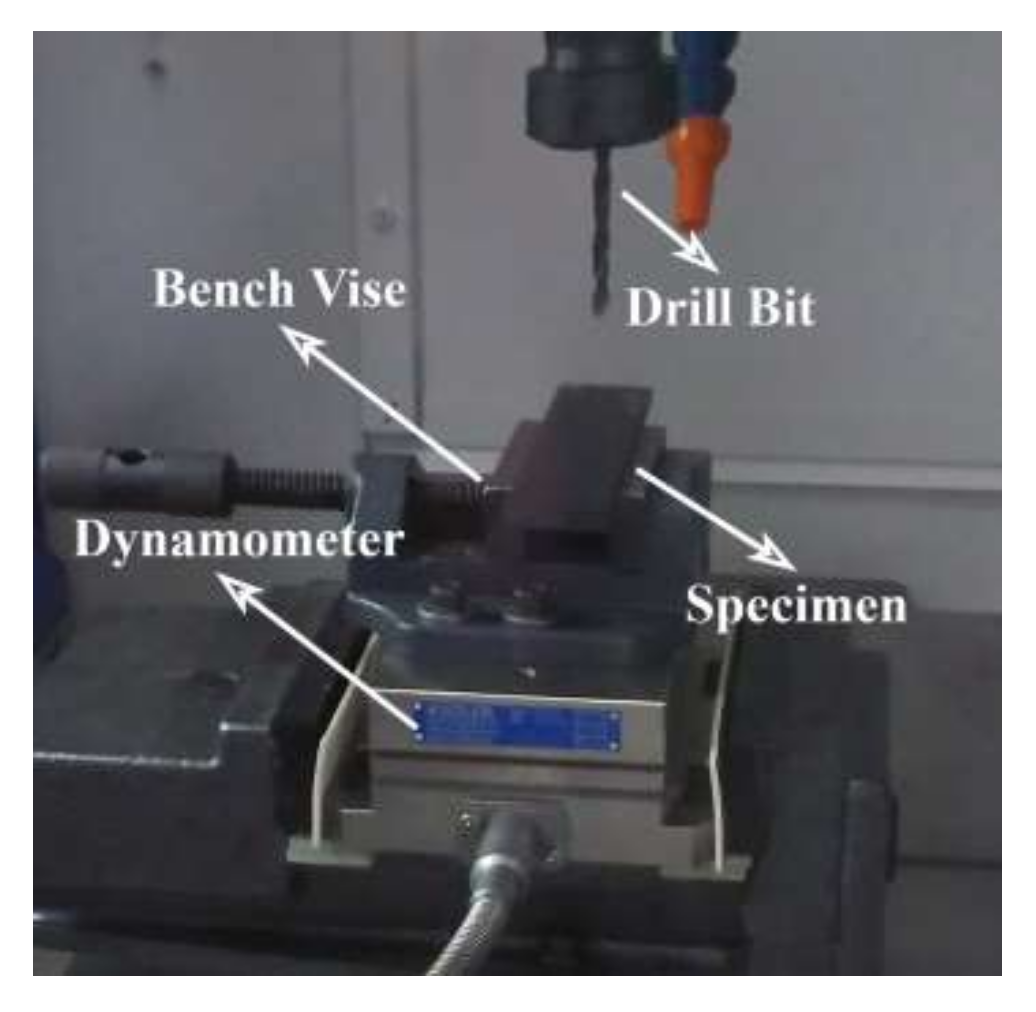

2.2. Experimental Measurement

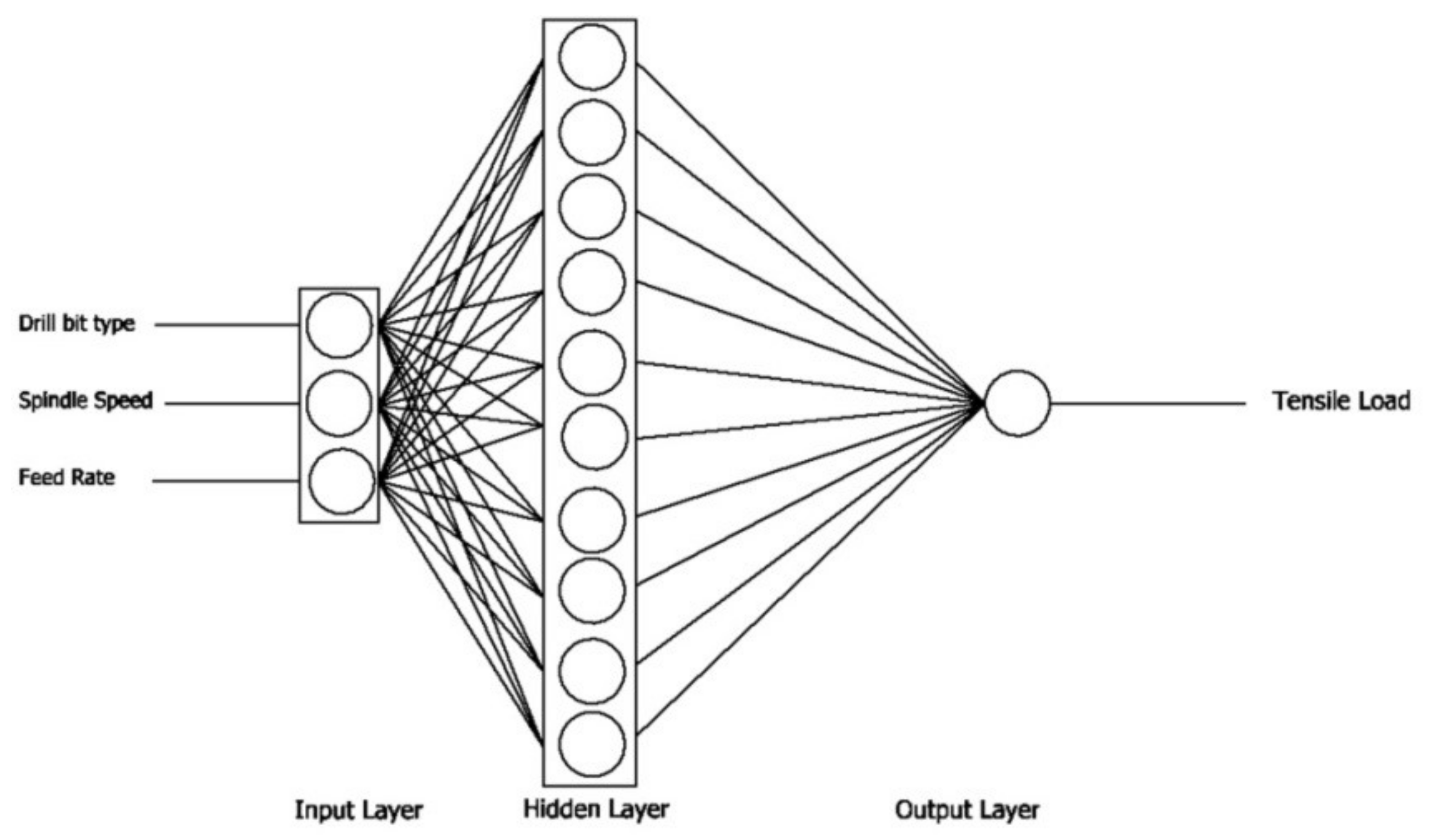

2.3. ANN Model for Prediction Tensile Load

3. Results

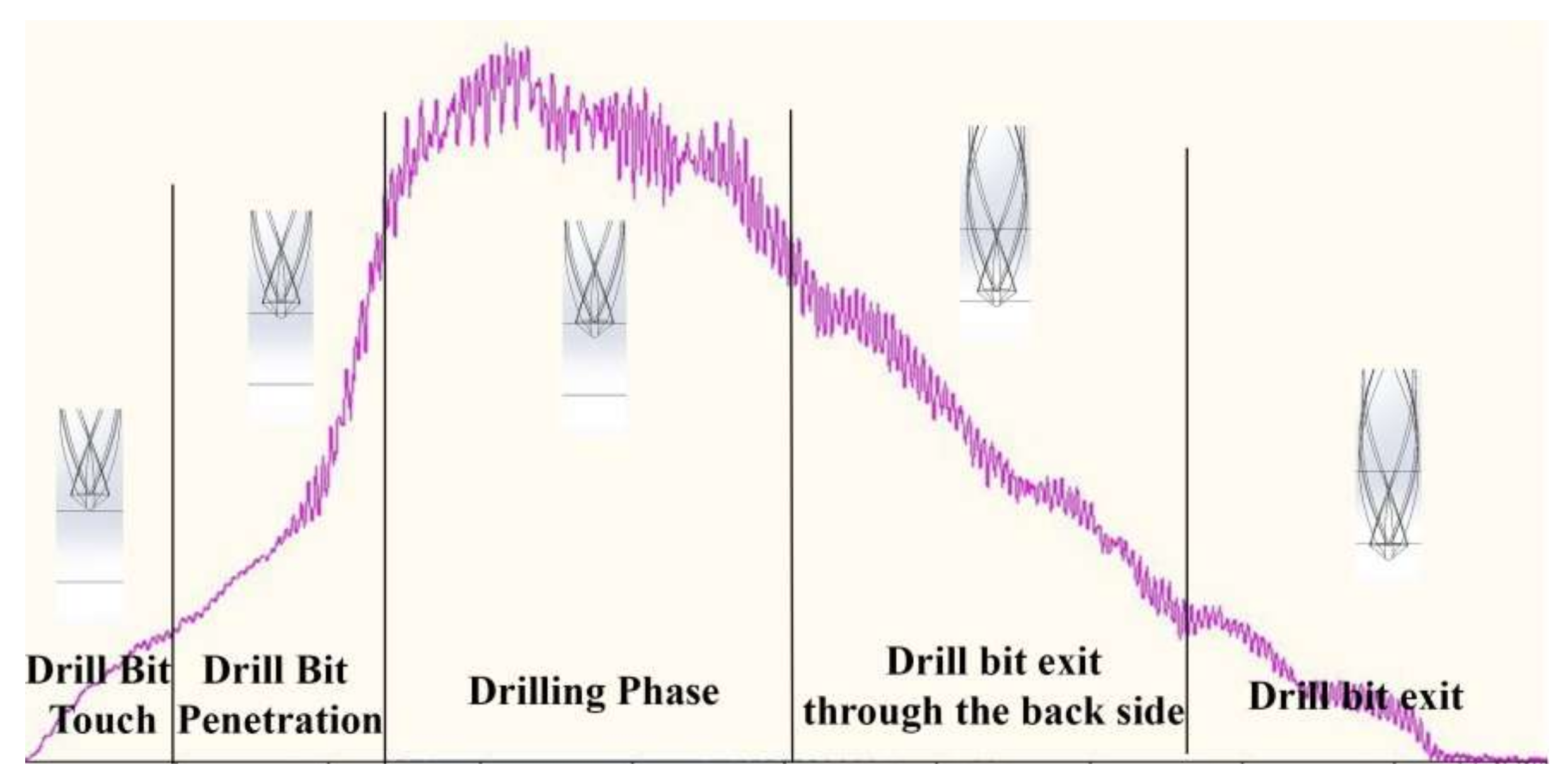

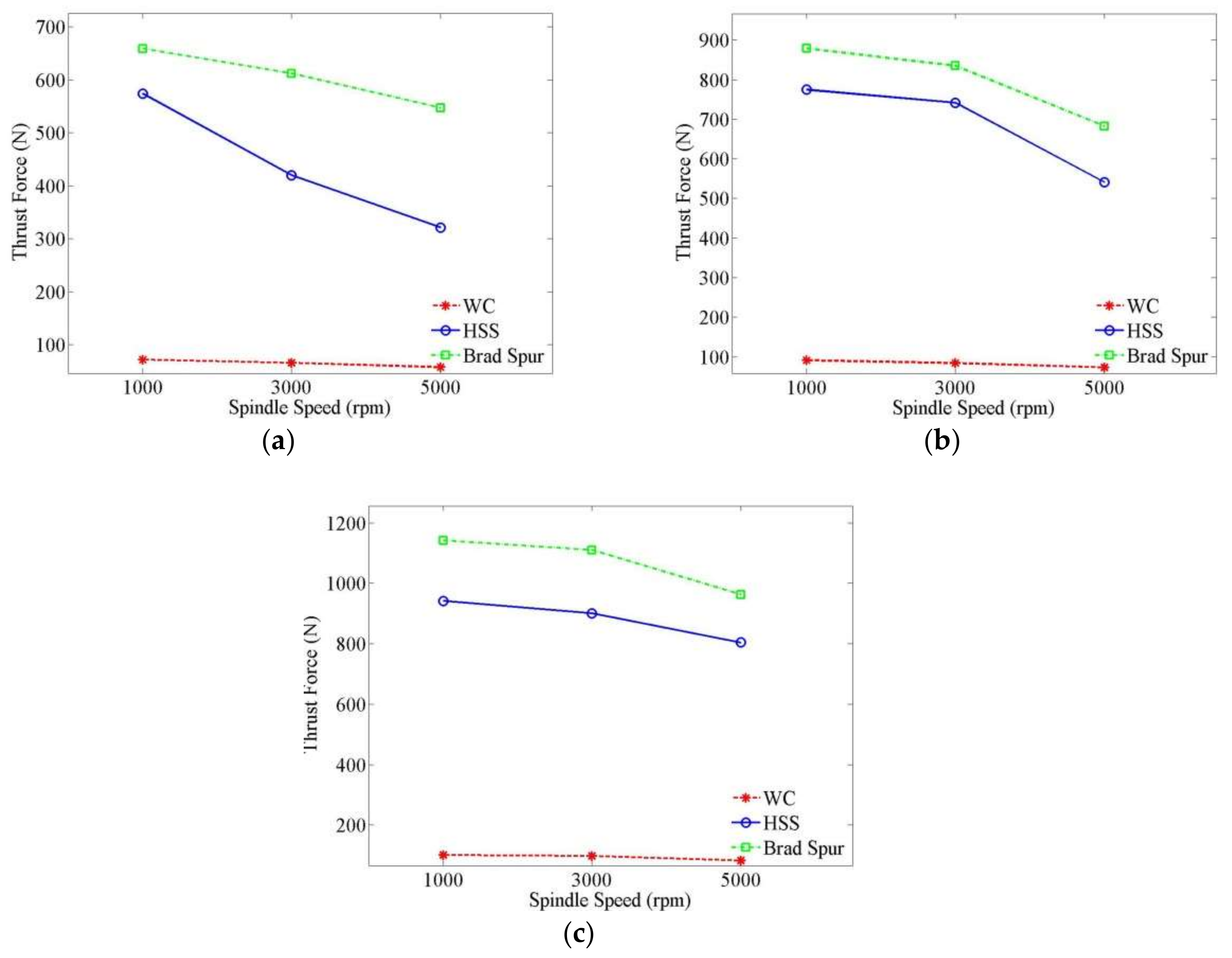

3.1. Thrust Force Analyses

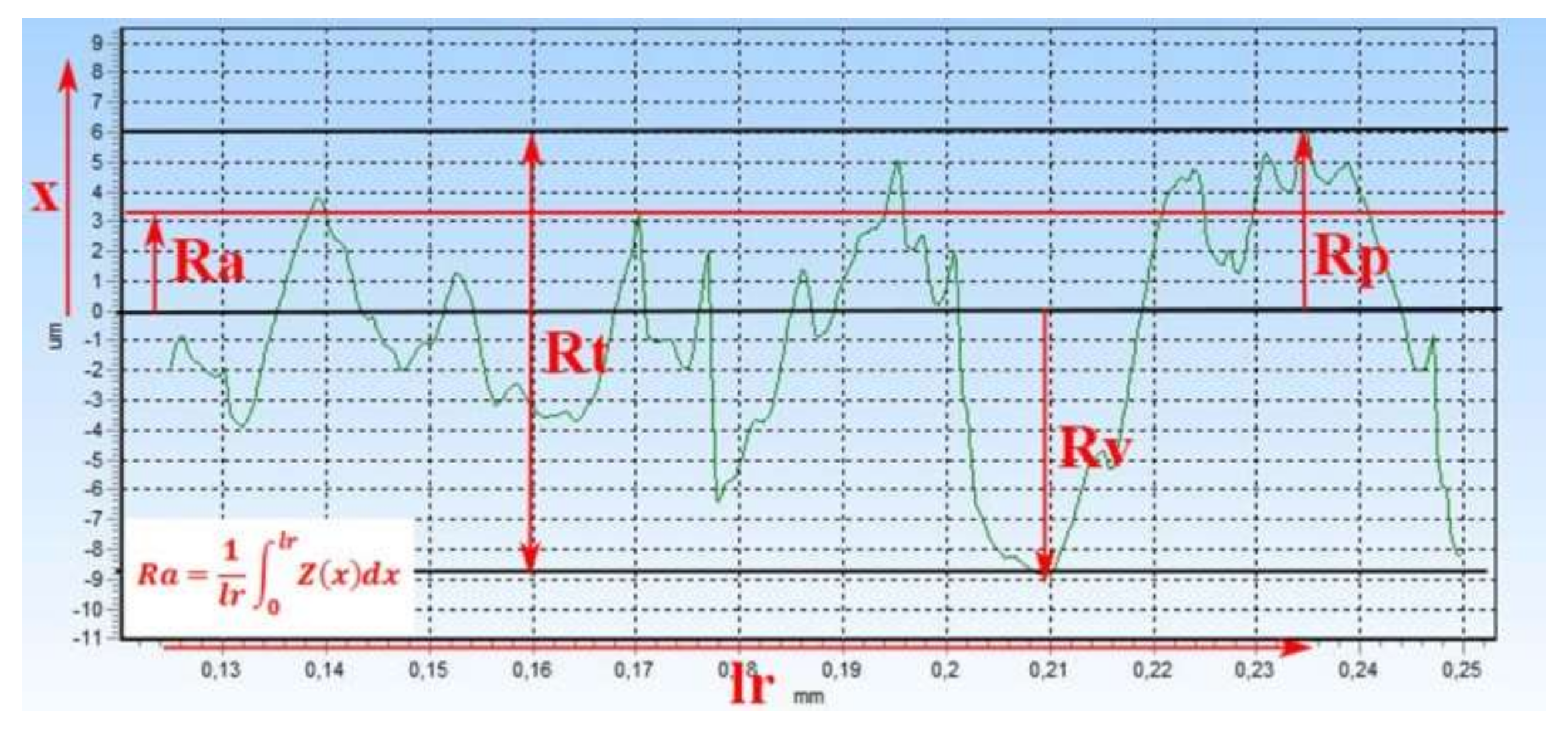

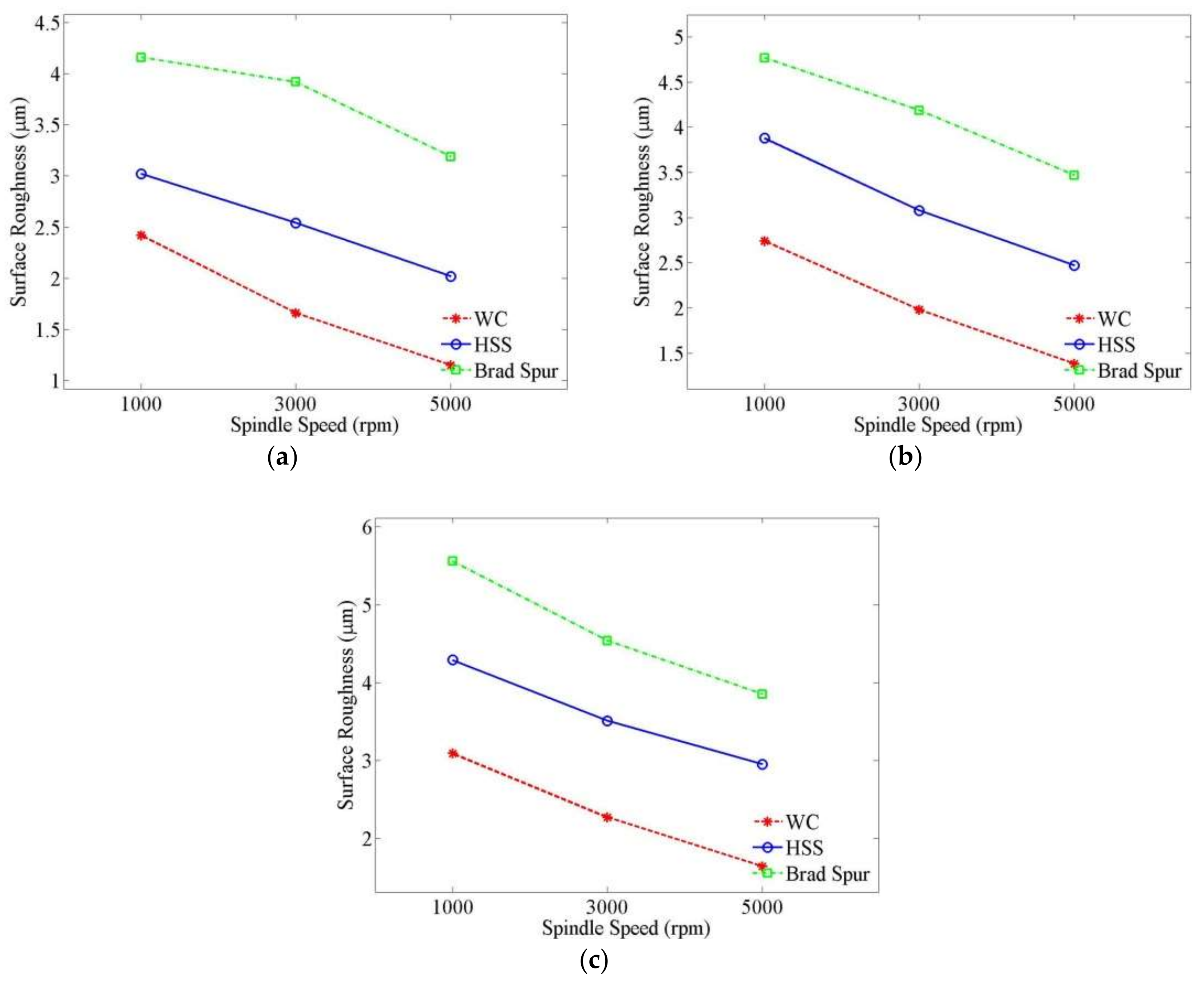

3.2. Surface Roughness Analyses

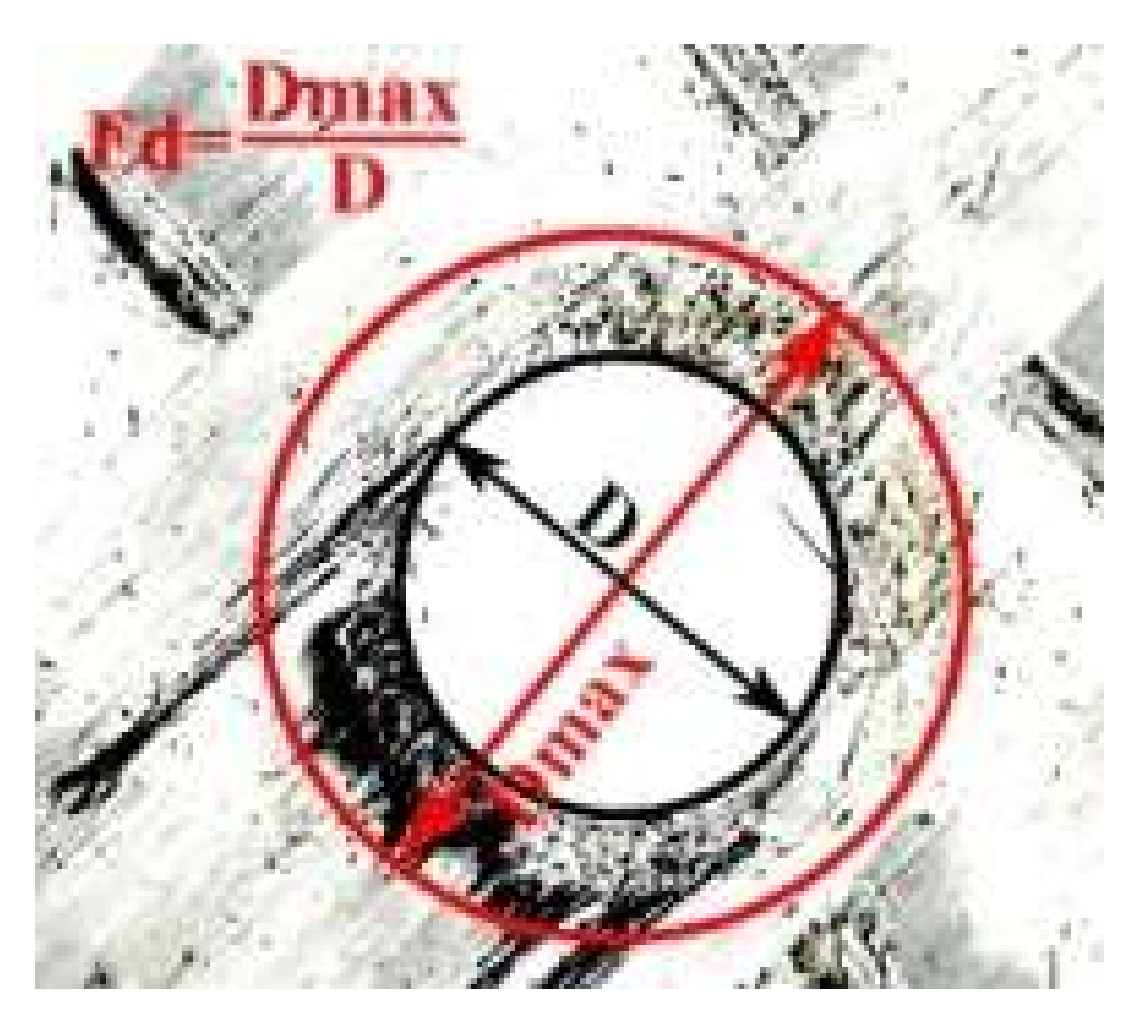

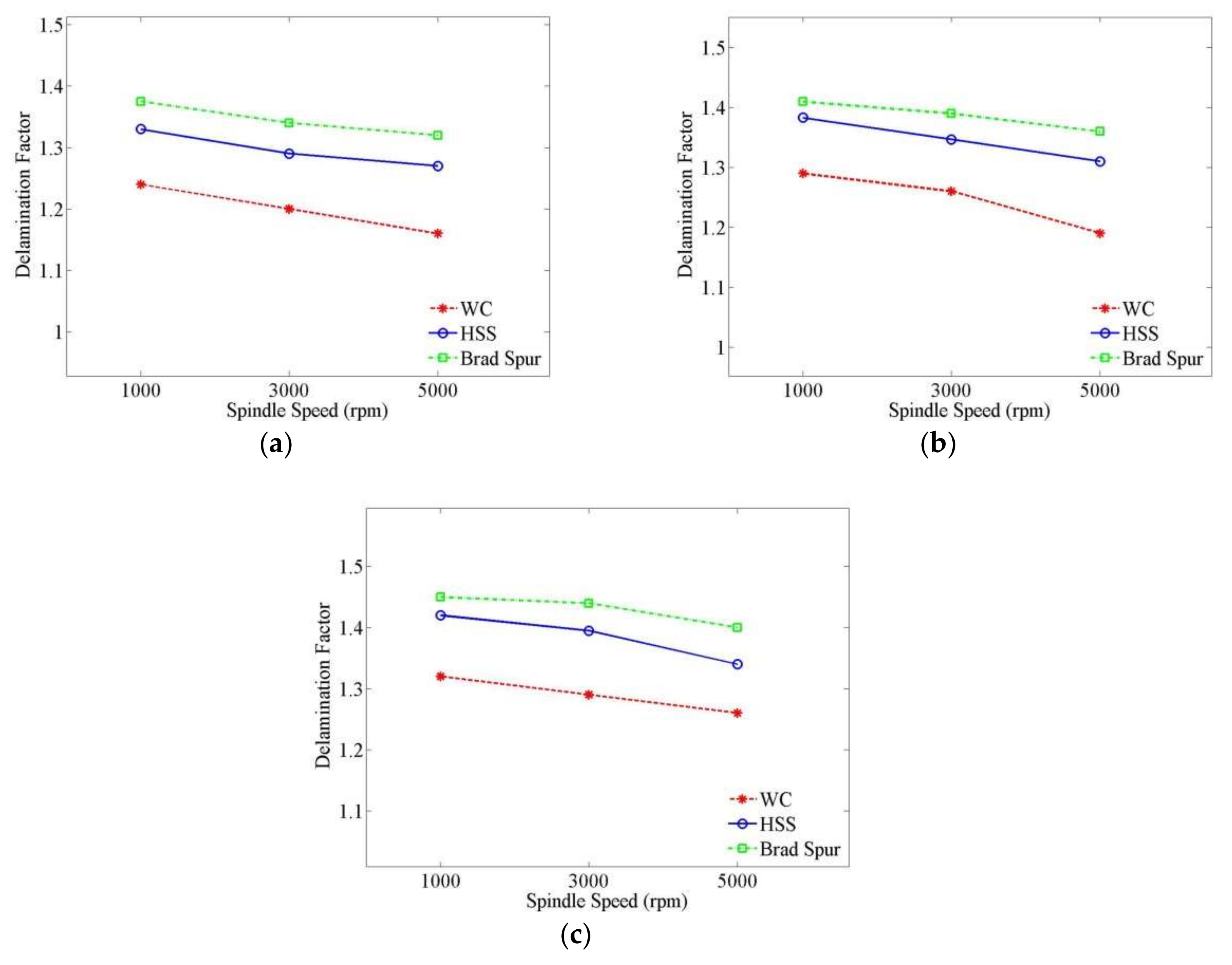

3.3. Delamination Analyses

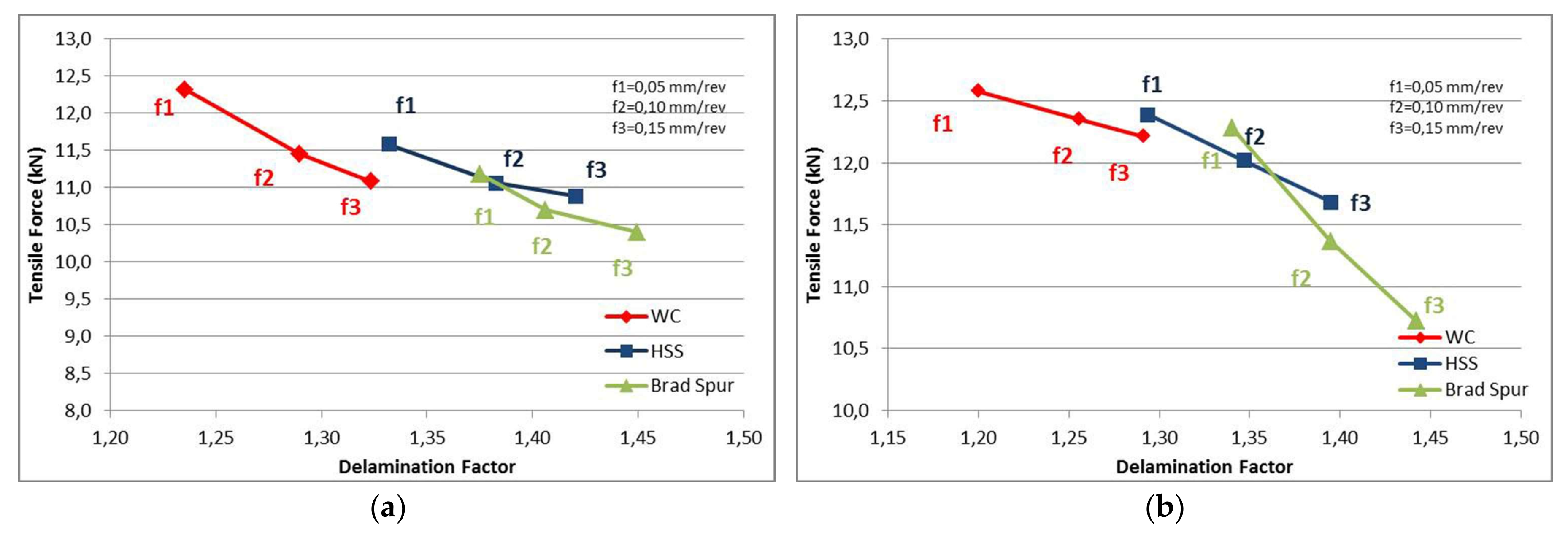

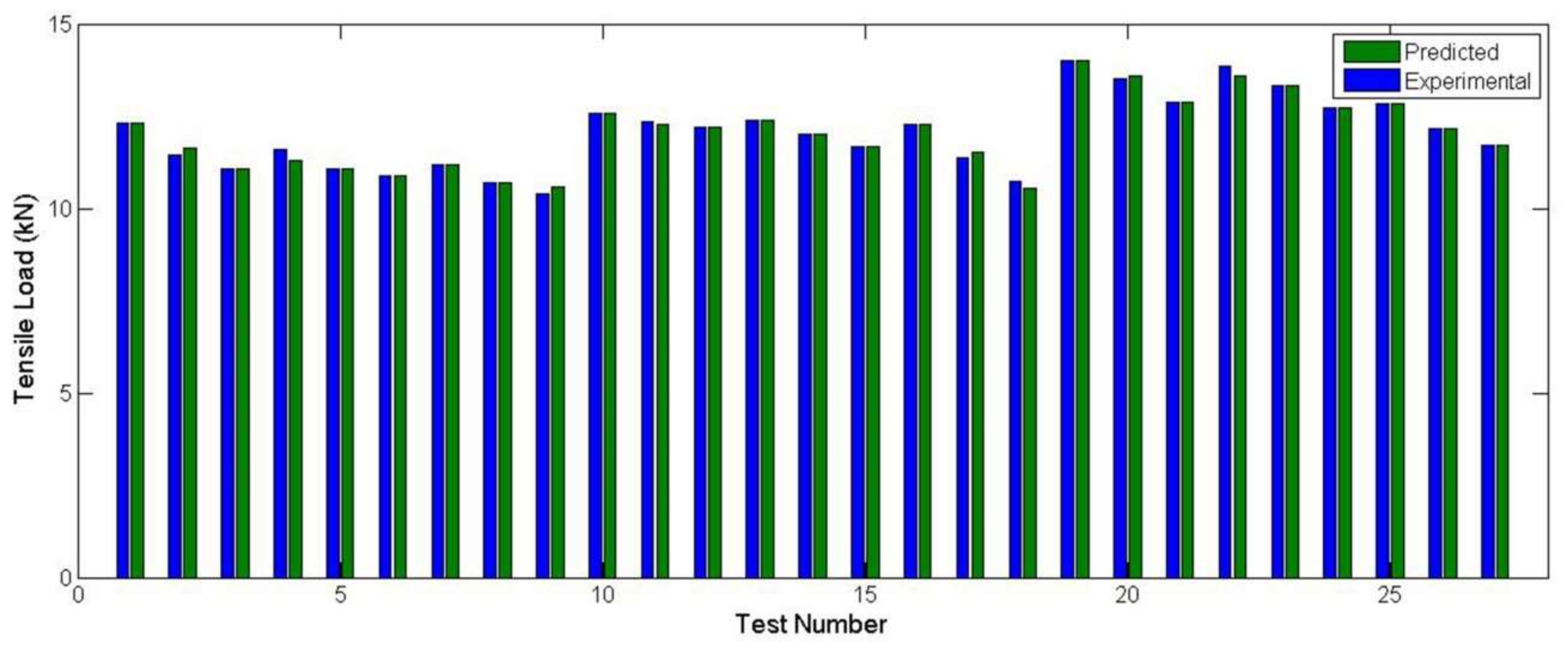

3.4. Influence of Delamination on Tensile Load

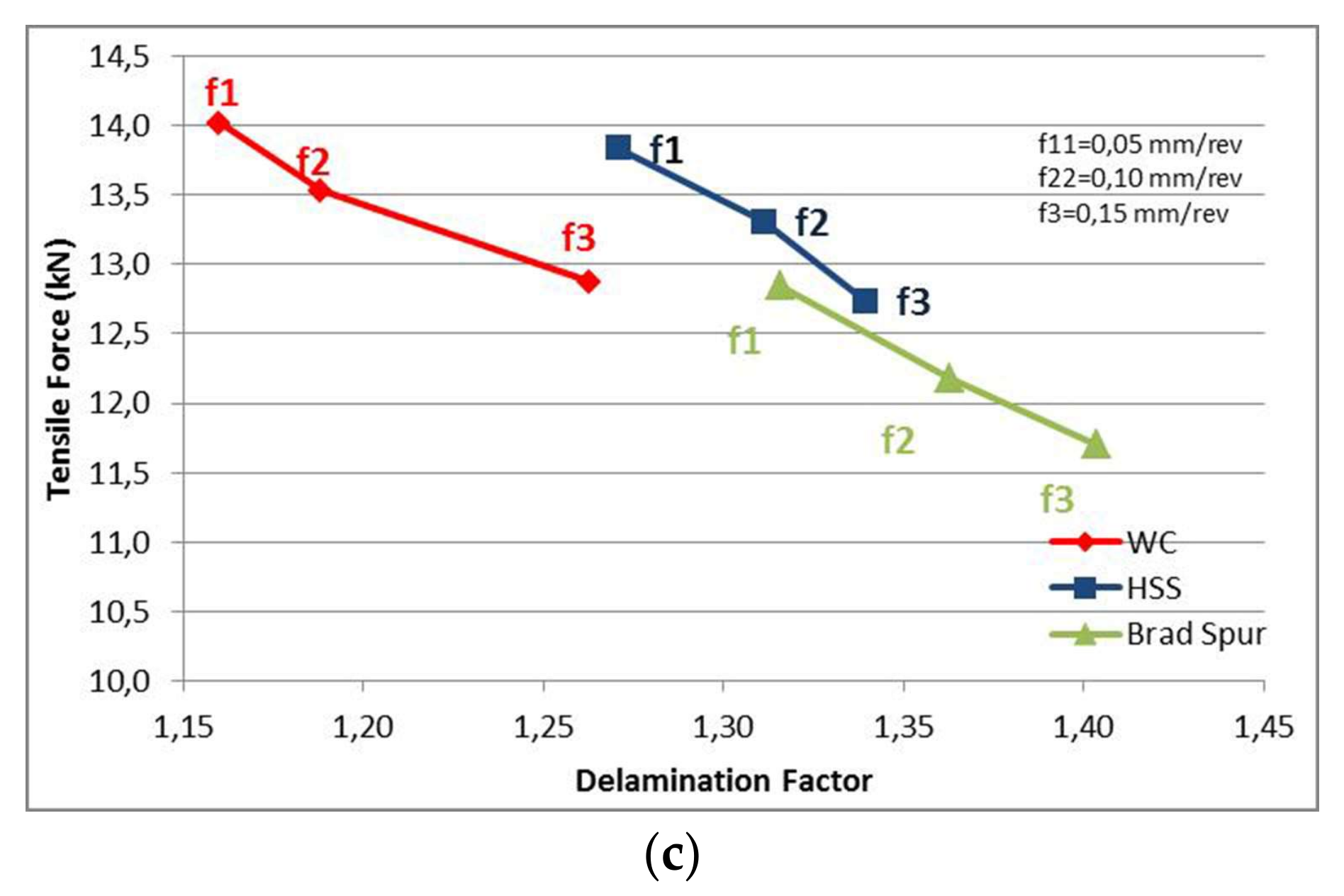

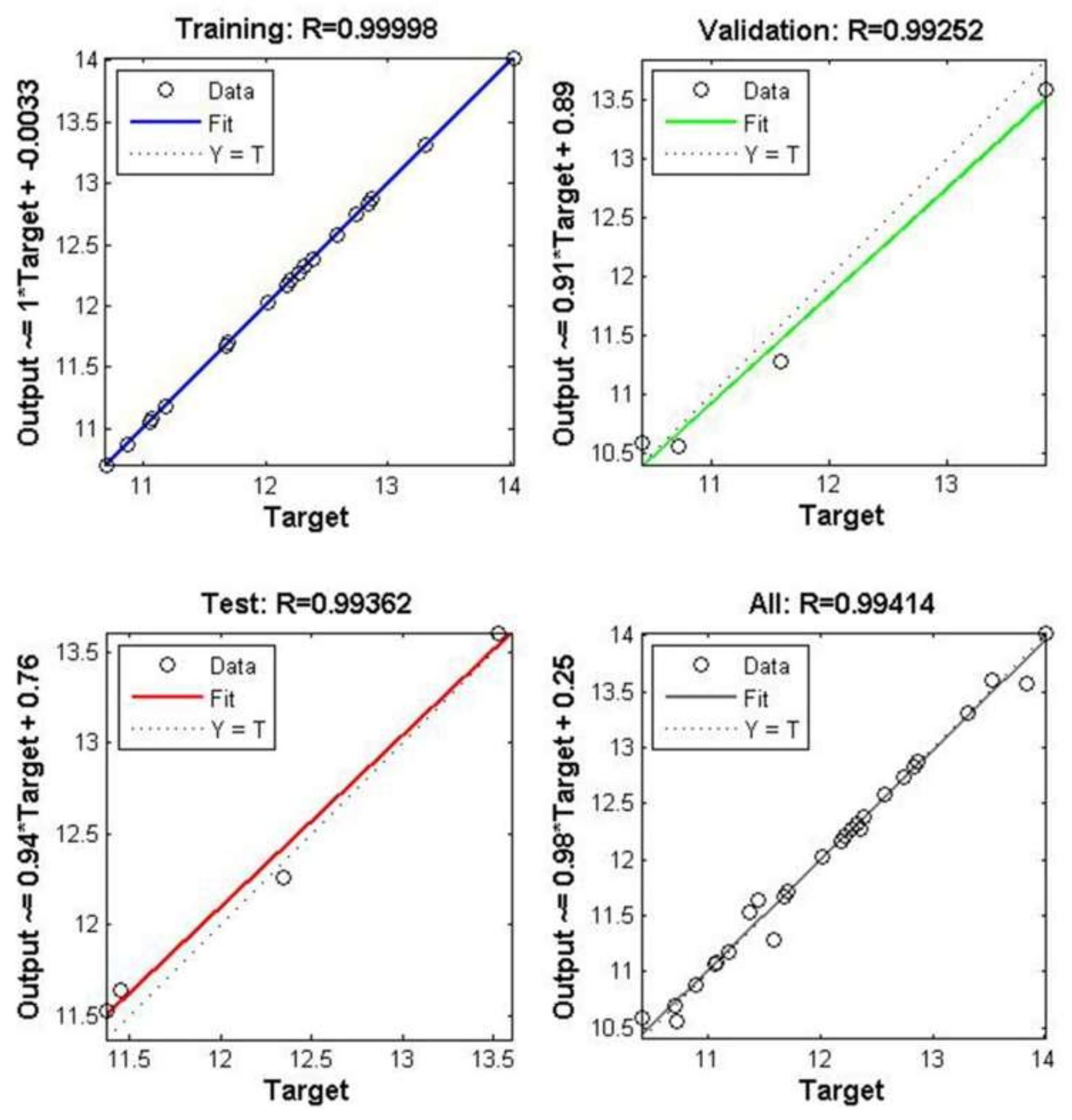

3.5. Prediction of Tensile Load with ANN

4. Conclusions

- The drilling parameters caused a significant change in the tensile load of the CFRP.

- For all drill bits, increasing of feed rate caused increase of delamination, surface roughness, thrust force, and loss in force, but increasing spindle speed caused decrease of them.

- The maximum tensile load of the CFRP was observed at low feed rate, and high spindle speed drilled with the WC drill bit and the lowest tensile load was observed at the high feed rate, and low spindle speed drilled with the Brad Spur drill bit.

- The drilling parameters showed similar effects on surface roughness, delamination, thrust force and reduction of tensile load. At the same time, it has been shown that these parameters have a linear relationship among themselves.

- If the correct drilling parameters are selected, the decrease in tensile load of CFRP can be up to 25%.

- The results of the ANN model are a match for the experimental results. The ANN model will help engineers to determine correct drilling parameters for maximizing tensile load of CFRP.

Author Contributions

Conflicts of Interest

References

- Kilickap, E.; Yardımeden, A.; Celik, Y.H. Investigation of experimental study of end milling of CFRP composite. Sci. Eng. Compos. Mater. 2015, 22, 89–95. [Google Scholar] [CrossRef]

- Solmaz, M.Y.; Topkaya, T. Progressive Failure Analysis in Adhesively, Riveted, and Hybrid Bonded Double-Lap Joints. J. Adhes. 2013, 89, 822–836. [Google Scholar] [CrossRef]

- Government Accountability Office. GAO Status of FAA’s Actions to Oversee the Safety of Composite Airplanes; AVIATION SAFETY; Government Accountability Office: Washington, DC, USA, 2011.

- Huang, Z.; Wu, Y.J.; Zhang, C. Bamboo strengthened with carbon fiber reinforced polymer for the substitutes of steel substructures. Key Eng. Mater. 2012, 17, 233–237. [Google Scholar] [CrossRef]

- Celik, Y.H.; Kilickap, E.; Yardımeden, A. Estimate of cutting forces and surface roughness in end milling of glass fiber reinforced plastic composites using fuzzy logic system. Sci. Eng. Compos. Mater. 2014, 21, 435–443. [Google Scholar] [CrossRef]

- Hocheng, H.; Tsao, C. Effects of Special Drill Bits on Drilling-Induced Delamination of Composite Materials. Int. J. Mach. Tools Manuf. 2006, 46, 1403–1416. [Google Scholar] [CrossRef]

- Kilickap, E. Analysis and Modeling of Delamination Factor in Drilling Glass Fiber Reinforced Plastic Using Response Surface Methodology. J. Compos. Mater. 2011, 45, 727–736. [Google Scholar] [CrossRef]

- Wong, T.L.; Wu, S.M.; Croy, G.M. An analysis of delamination in drilling composite materials. In Proceedings of the 14th National SAMPE Technical Conference, Atlanta, GA, USA, 12 October 1982; Volume 47, pp. 481–483. [Google Scholar]

- Tao, C.; Qiu, J.; Yao, W.; Ji, H. The effect of drilling-induced delamination on tensile strength and prediction of residual strength of carbon fiber-reinforced polymer laminate. J. Compos. Mater. 2016, 50, 3373–3384. [Google Scholar] [CrossRef]

- Langella, A.; Durante, M. Comparison of tensile strength of composite material elements with drilled and molded-in holes. Appl. Compos. Mater. 2008, 15, 227–239. [Google Scholar] [CrossRef]

- Dilli Babu, G.; Sivaji Babu, K.; Uma Maheswar Gowd, B. Determination of delamination and tensile strength of drilled natural fiber reinforced composites. Appl. Mech. Mater. 2014, 592, 134–138. [Google Scholar] [CrossRef]

- Nasir, A.A.; Azmi, A.I.; Khalil, A.N.M. Measurement and optimisation of residual tensile strength and delamination damage of drilled flax fibre reinforced composites. Measurement 2015, 75, 298–307. [Google Scholar] [CrossRef]

- Mishra, R.; Malik, J.; Singh, I.; Davim, J.P. Neural network approach for estimating the residual tensile strength after drilling in uni-directional glass fiber reinforced plastic laminates. Mater. Des. 2010, 31, 2790–2795. [Google Scholar] [CrossRef]

- De Filippis, L.A.C.; Serio, L.M.; Facchini, F.; Mummolo, G.; Ludovico, A.D. Prediction of the vickers microhardness and ultimate tensile strength of AA5754 H111 friction stir welding butt joints using artificial neural network. Materials 2016, 9, 915. [Google Scholar] [CrossRef] [PubMed]

- Sevim, D.; Fidan, Ş.; Polat, S.; Oktay, H. Experimental and Articial Neural Network Based Studies on Thermal Conductivity of Lightweight Building Materials. Eur. J. Tech. 2017, 7, 33–41. [Google Scholar] [CrossRef]

- Behera, R.R.; Ghadai, R.K.; Kalita, K.; Banerjee, S. Simultaneous prediction of delamination and surface roughness in drilling GFRP composite using ANN. Int. J. Plast. Technol. 2016, 20, 424–450. [Google Scholar] [CrossRef]

- Sahin, Y. Yapay Sinir Ağları ile Al/Sic Kompozit Malzemenin Yüzey Pürüzlülüğünün Tahmini. Gazi Üniversitesi Mühendislik-Mimarlık Fakültesi Dergisi. 2014, 29. [Google Scholar] [CrossRef]

- Kilickap, E.; Yardimeden, A.; Çelik, Y.H. Mathematical Modelling and Optimization of Cutting Force, Tool Wear and Surface Roughness by Using Artificial Neural Network and Response Surface Methodology in Milling of Ti-6242S. Appl. Sci. 2017, 7, 1064. [Google Scholar] [CrossRef]

- Liu, D.; Tang, Y.; Cong, W.L. A review of mechanical drilling for composite laminates. Compos. Struct. 2012, 94, 1265–1279. [Google Scholar] [CrossRef]

- Shah, D.U.; Schubel, P.J.; Clifford, M.J. Can flax replace E-glass in structural composites? A small wind turbine blade case study. Compos. Part B Eng. 2013, 52, 172–181. [Google Scholar] [CrossRef]

- Palanikumar, K.; Prakash, S.; Shanmugam, K. Evaluation of delamination in drilling GFRP composites. Mater. Manuf. Process. 2008, 23, 858–864. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H. Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int. J. Mach. Tools Manuf. 2005, 45, 1282–1287. [Google Scholar] [CrossRef]

- Singh, I.; Bhatnagar, N.; Viswanath, P. Drilling of uni-directional glass fiber reinforced plastics: Experimental and finite element study. Mater. Des. 2008, 29, 546–553. [Google Scholar] [CrossRef]

- Tsao, C.C.; Hocheng, H.; Chen, Y.C. Delamination reduction in drilling composite materials by active backup force. CIRP Ann. Manuf. Technol. 2012, 61, 91–94. [Google Scholar] [CrossRef]

- Arul, S.; Vijayaraghavan, L.; Malhotra, S.K.; Krishnamurthy, R. Influence of tool material on dynamics of drilling of GFRP composites. Int. J. Adv. Manuf. Technol. 2006, 29, 655–662. [Google Scholar] [CrossRef]

- Jain, S.; Yang, D.C. Effects of feed rate and chisel edge on delamination in composites drilling. J. Eng. Ind. 1993, 115, 398–405. [Google Scholar] [CrossRef]

- Koenig, W.; Wulf, C.; Grass, P.; Willerscheid, H. Machining of fibre reinforced plastics. CIRP Ann. Manuf. Technol. 1985, 34, 537–548. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Fangmann, S.; Rentsch, R. Drilling of composites and resulting surface integrity. CIRP Ann. Manuf. Technol. 2011, 60, 57–60. [Google Scholar] [CrossRef]

- Teti, R. Machining of composite materials. CIRP Ann. Manuf. Technol. 2002, 51, 611–634. [Google Scholar] [CrossRef]

- Franke, V. Drilling of long fiber reinforced thermoplastics—Influence of the cutting edge on the machining results. CIRP Ann. Manuf. Technol. 2011, 60, 65–68. [Google Scholar] [CrossRef]

- Schulze, V.; Becke, C.; Pabst, R. Specific machining forces and resultant force vectors for machining of reinforced plastics. CIRP Ann. Manuf. Technol. 2011, 60, 69–72. [Google Scholar] [CrossRef]

- Stein, J.M.; Dornfeld, D.A. Burr formation in drilling miniature holes. CIRP Ann. Manuf. Technol. 1997, 46, 63–66. [Google Scholar] [CrossRef]

- Pierson, H.O. Handbook of Refractory Carbides & Nitrides: Properties, Characteristics. Processing and Applications; William Andrew: Park Ridge, NJ, USA, 1996. [Google Scholar]

- Shackelford, J.F.; Alexander, W. CRC Materials and Engineering Handbook, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Schultrich, B.; Poebnecker, W. Thermal conductivity of cemented carbides. J. Therm. Anal. Calorim. 1988, 33, 305–310. [Google Scholar] [CrossRef]

- Wang, H.; Webb, T.; Bitler, J.W. Study of thermal expansion and thermal conductivity of cemented WC–Co composite. Int. J. Refract. Met. Hard Mater. 2015, 49, 170–177. [Google Scholar] [CrossRef]

- Ketin, M. Sirius-High Speed Steel. Available online: www.mkb.be/Qualities/MK-Sirius.pdf (accessed on 5 November 2017).

- Bosco, M.A.J.; Palanikumar, K.; Prasad, B.D.; Velayudham, A. Influence of machining parameters on delamination in drilling of GFRP-armour steel sandwich composites. Procedia Eng. 2013, 51, 758–763. [Google Scholar] [CrossRef]

| Properties. | Fiber | Resin |

|---|---|---|

| Type | Carbon | Polyester |

| Volume Rate (%) | 55 | 45 |

| Tensile Strength (Mpa) | 66.47 | |

| Number of Layers | 11 | |

| Ply Thickness (mm) | 0.545 | |

| Fiber Orientation | (+45/−45) | |

| Properties | High Speed Steel | Brad Spur | Tungsten Carbide |

|---|---|---|---|

| Drill Bit Type | Twist | Twist | Twist |

| Point Angle (°) | 118 | - | 140 |

| Helix Angle (°) | 30 | 30 | 30 |

| Material | High Speed Steel | Tungsten Carbide | |

| Level | Feed Rate(mm/rev) | Spindle Speed (rev/min) |

|---|---|---|

| 1 | 0.05 | 1000 |

| 2 | 0.10 | 3000 |

| 3 | 0.15 | 5000 |

| Drill Bit | Rpm | 0.05 mm/rev | 0.10 mm/rev | 0.15 mm/rev | |||

|---|---|---|---|---|---|---|---|

| Entrance | Exit | Entrance | Exit | Entrance | Exit | ||

| Brad Spur | 1000 |  |  |  |  |  |  |

| 3000 |  |  |  |  |  |  | |

| 5000 |  |  |  |  |  |  | |

| HSS | 1000 |  |  |  |  |  |  |

| 3000 |  |  |  |  |  |  | |

| 5000 |  |  |  |  |  |  | |

| WC | 1000 |  |  |  |  |  |  |

| 3000 |  |  |  |  |  |  | |

| 5000 |  |  |  |  |  |  | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yenigun, B.; Kilickap, E. Prediction of the Tensile Load of Drilled CFRP by Artificial Neural Network. Appl. Sci. 2018, 8, 549. https://doi.org/10.3390/app8040549

Yenigun B, Kilickap E. Prediction of the Tensile Load of Drilled CFRP by Artificial Neural Network. Applied Sciences. 2018; 8(4):549. https://doi.org/10.3390/app8040549

Chicago/Turabian StyleYenigun, Burak, and Erol Kilickap. 2018. "Prediction of the Tensile Load of Drilled CFRP by Artificial Neural Network" Applied Sciences 8, no. 4: 549. https://doi.org/10.3390/app8040549