The Influence of Forming Directions and Strain Rate on Dynamic Shear Properties of Aerial Aluminum Alloy

Abstract

:1. Introduction

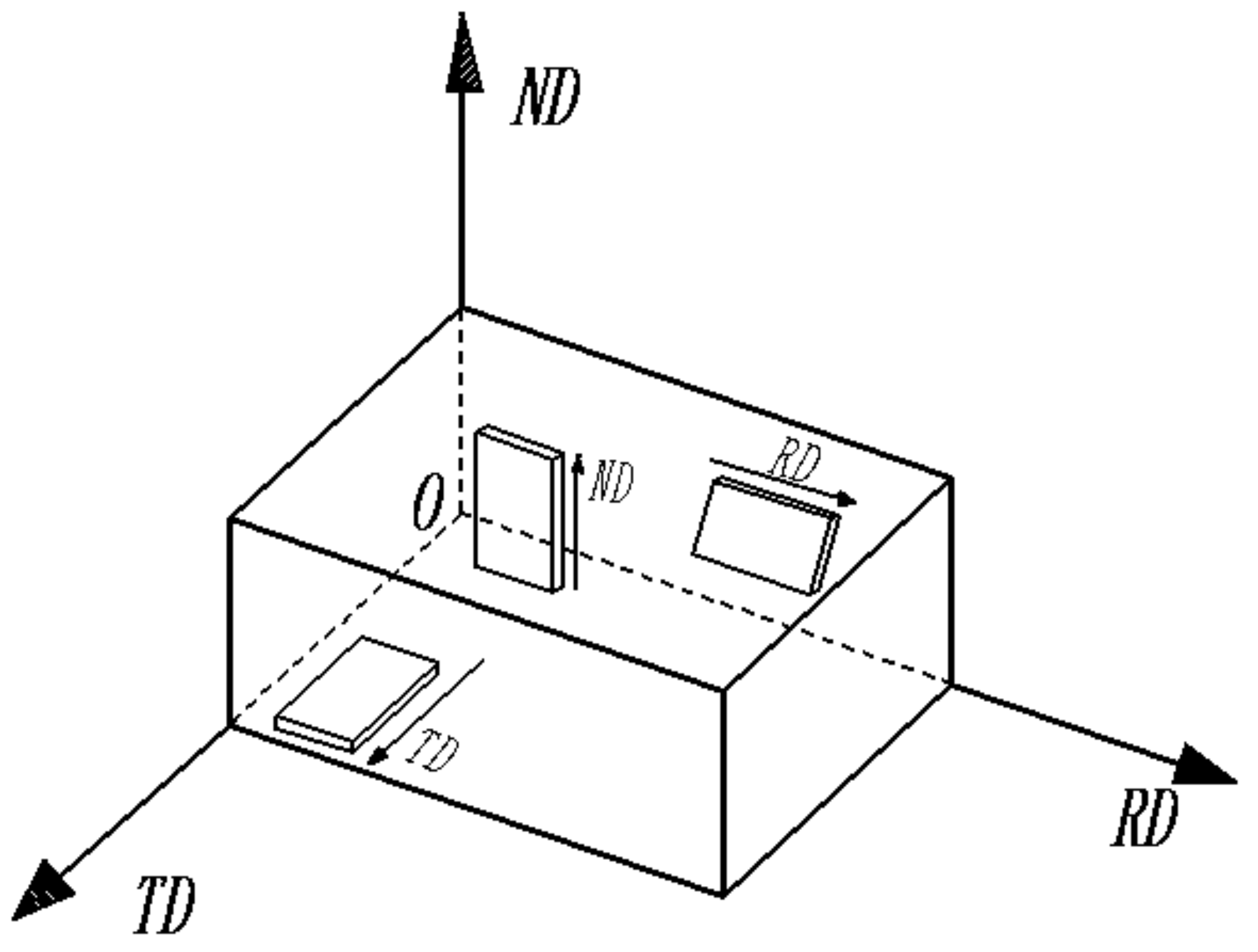

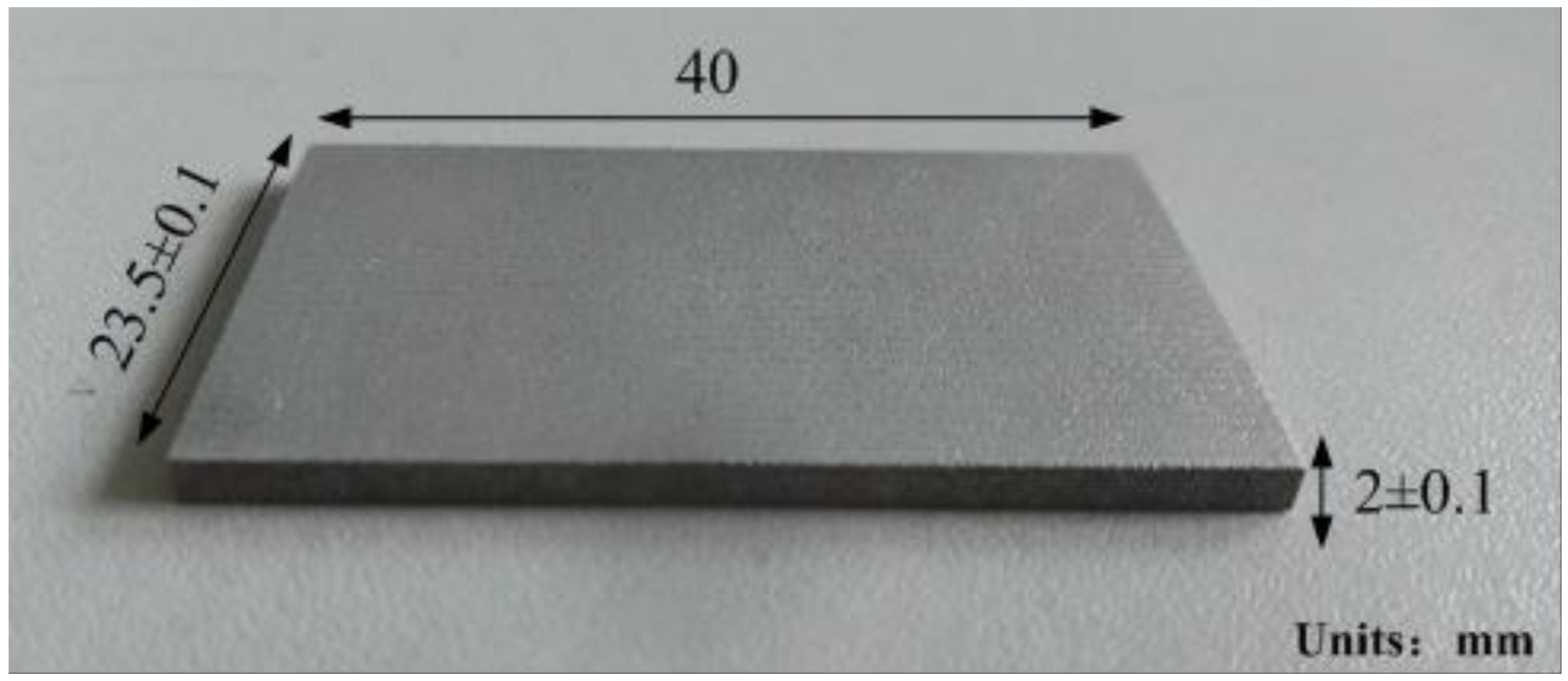

2. Experimental Procedures

2.1. Experimental Material

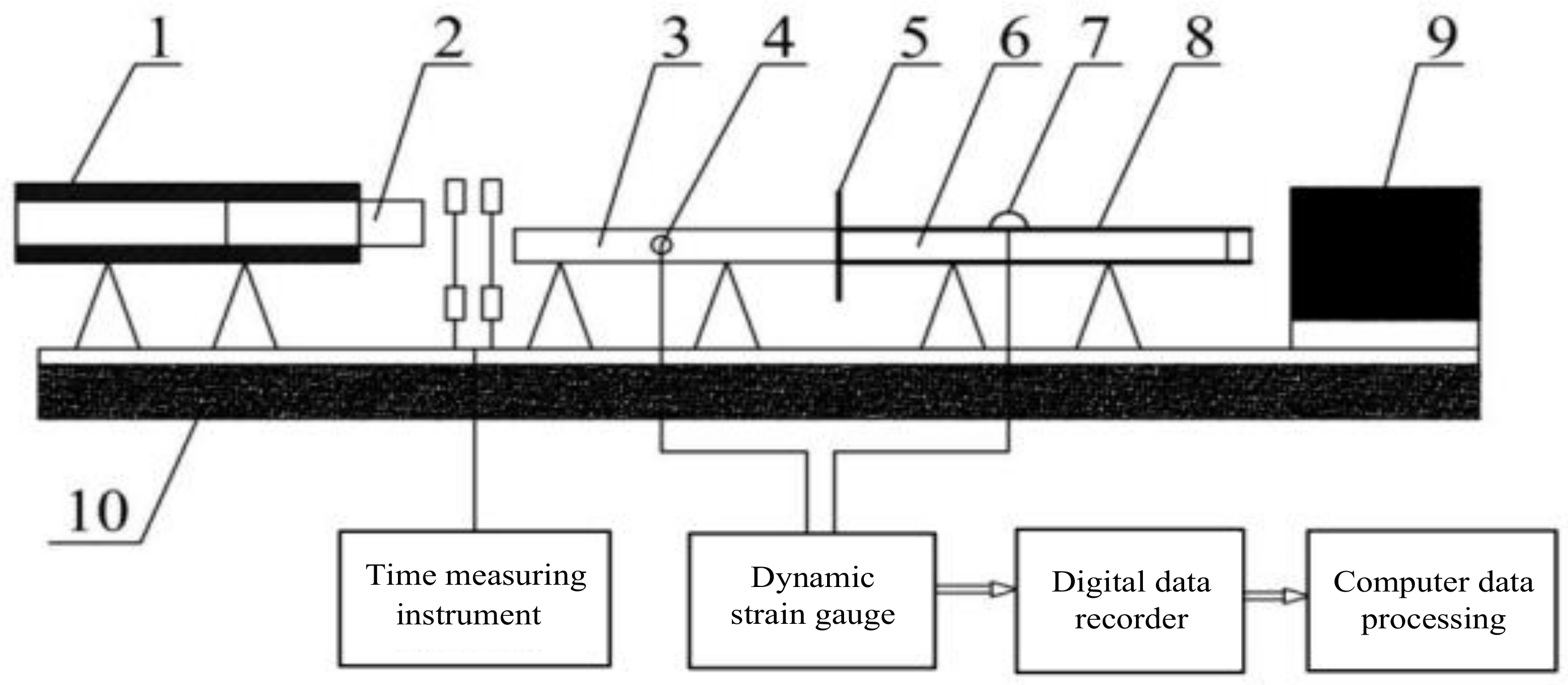

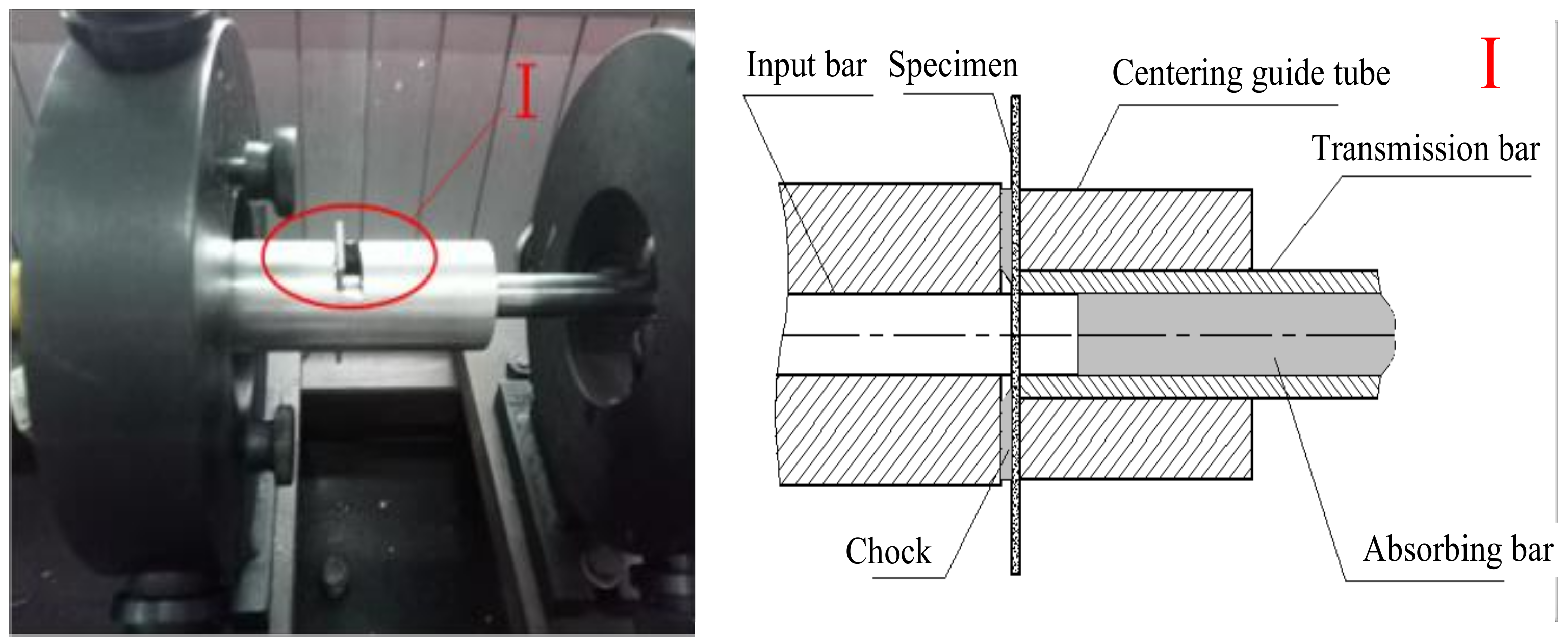

2.2. Experimental Device

2.3. Experimental Process and Microstructure Observation

3. Results and Discussions

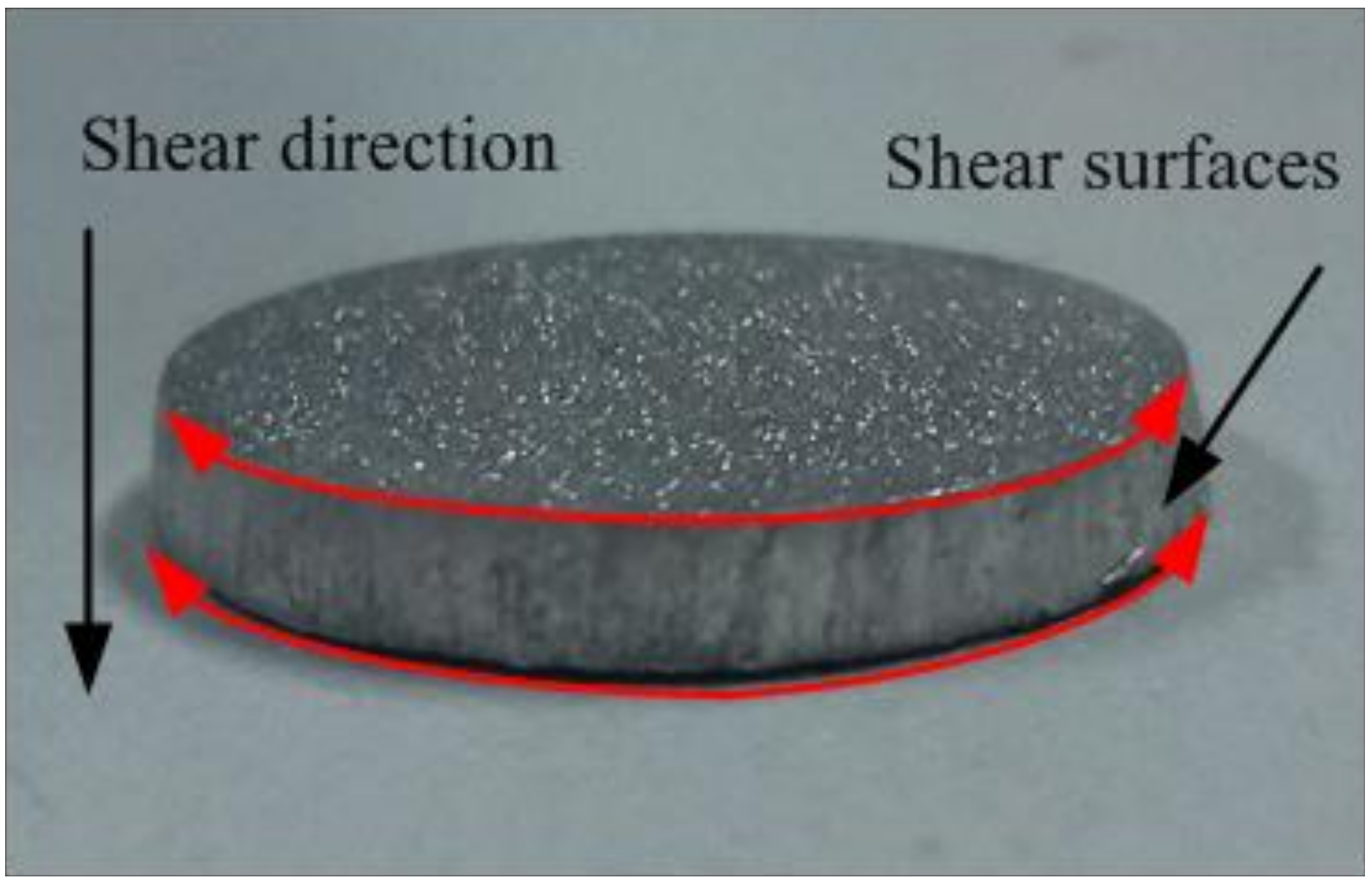

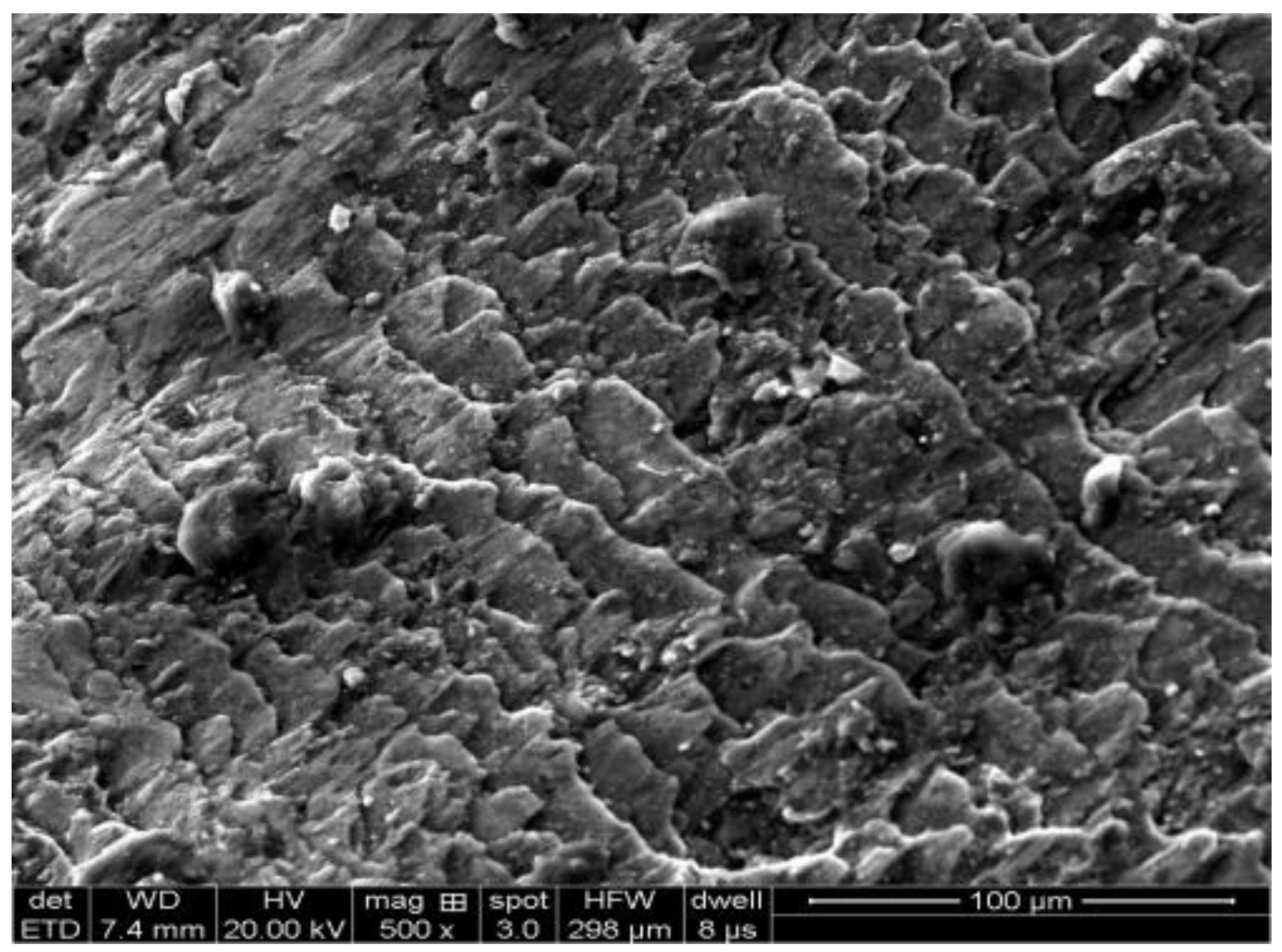

3.1. The Change of Specimens

3.2. The Results of the Stress-Strain Curves

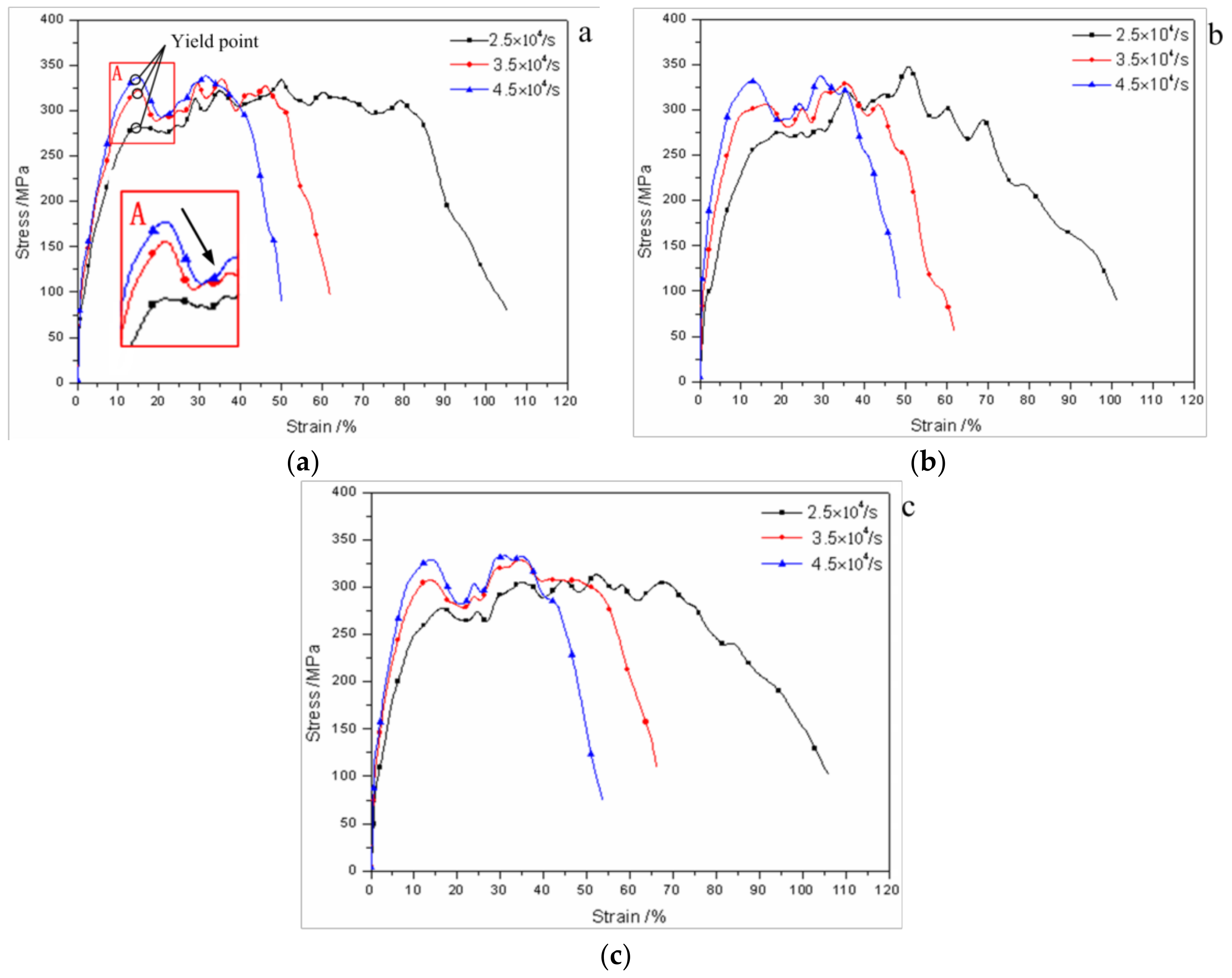

3.2.1. The Influence of Different Strain Rates on Dynamic Impact Shear Properties

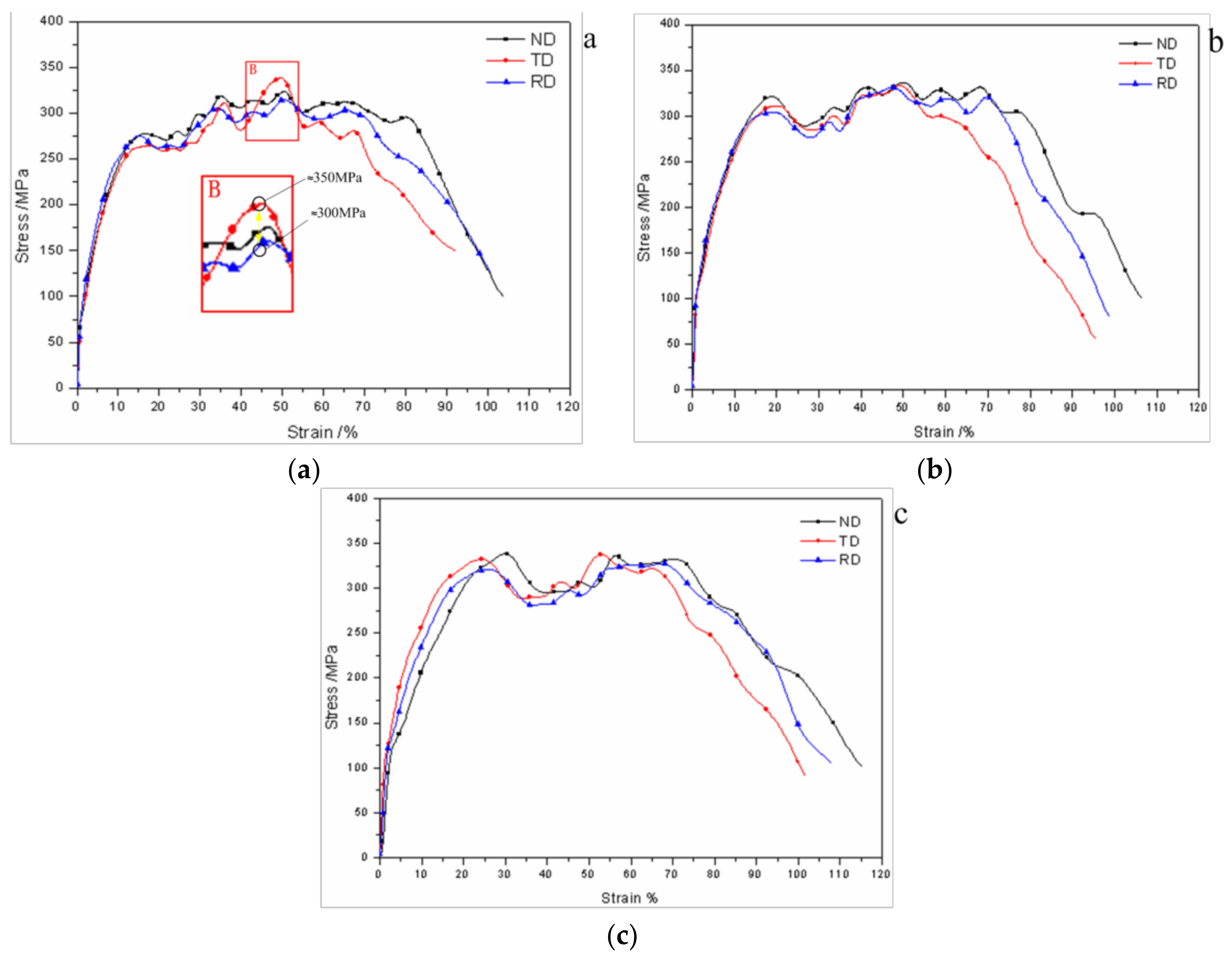

3.2.2. The Influence of Different Forming Directions on Dynamic Impact Shear Properties

4. Conclusions

- (1)

- At the same forming direction, the dynamic shear stress-strain curves of aluminum alloy 7050-T7451 were mainly divided into three deformation stages at different strain rates, the material showed a certain strain rate sensitivity and a positive strain rate strengthening effect, and the strain strengthening effect was not obvious;

- (2)

- At the strain rate range of 2.5 × 104 s−1–4.5 × 104 s−1, it had a significant difference in the dynamic shear mechanical properties of the material at different forming directions. The shear stress in ND was the largest, followed by that in RD, and the lowest was that in TD, and the strain of TD showed a more sensitive characteristic of thermal softening.

- (3)

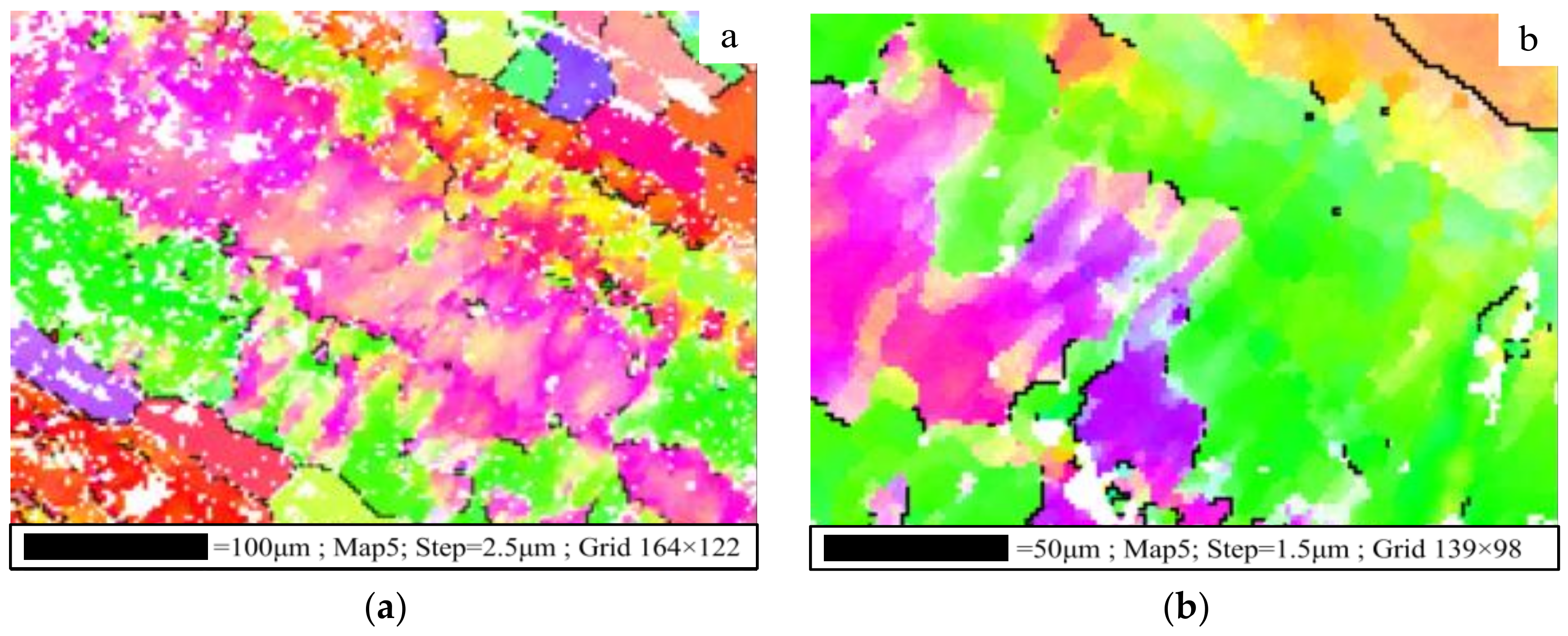

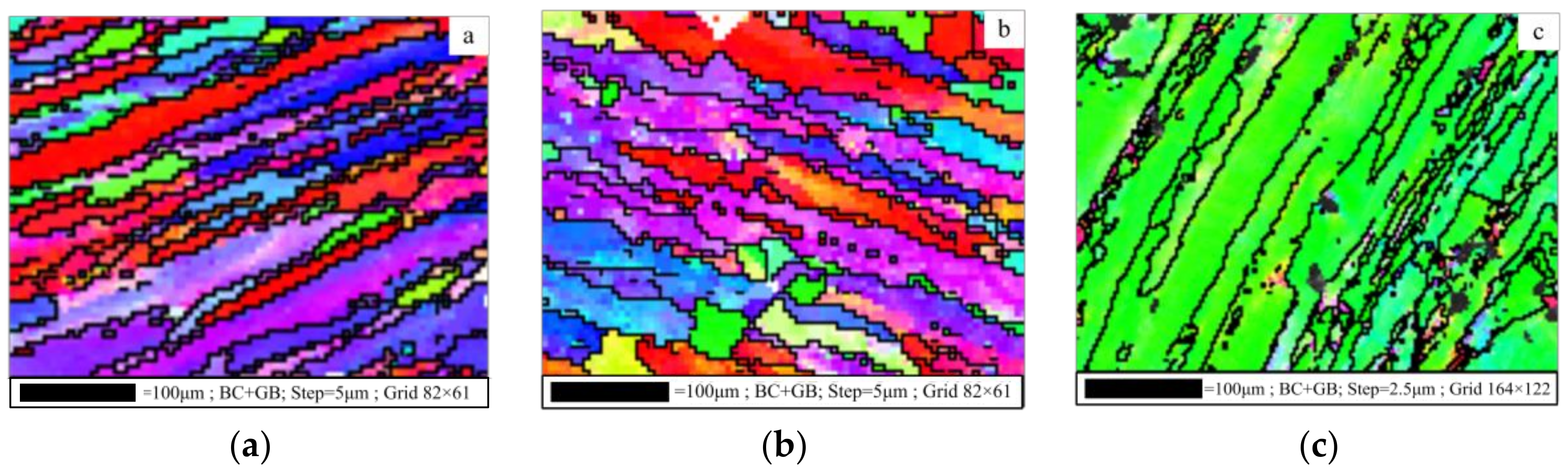

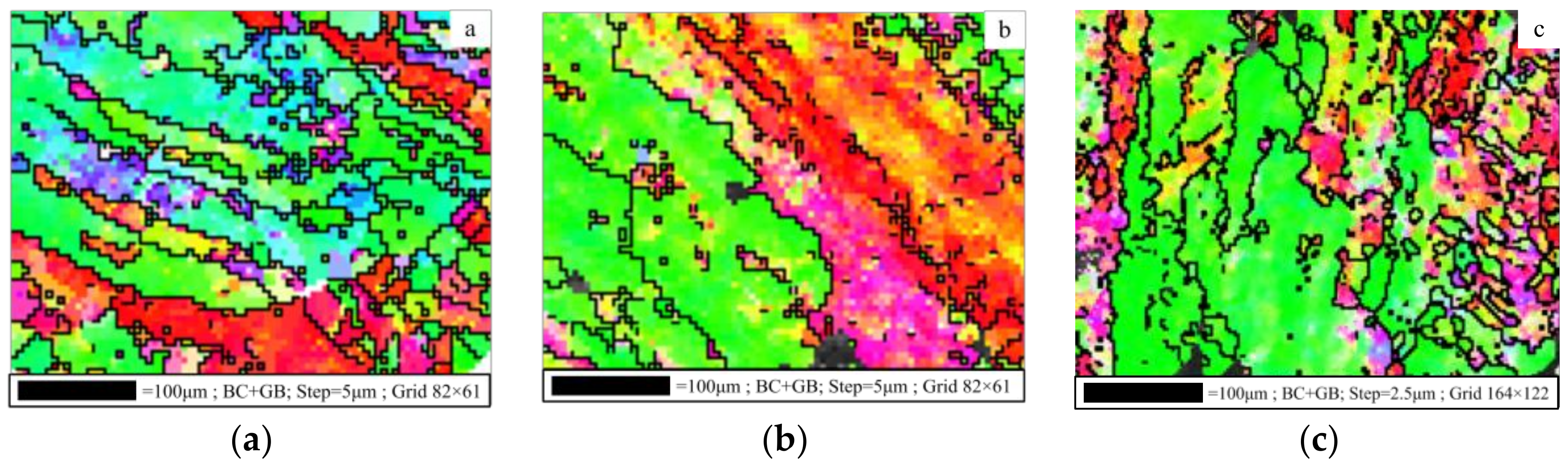

- The microstructure observation showed that the grains in ND of the material were mostly long axial grain, the grains in RD were coarse, flat and non equiaxed shape, and the grains in TD were recrystallized and approximately equiaxed shape. The grain structure showed a certain preferential orientation, and the dynamic shear properties of material showed obvious anisotropic characteristics.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Fu, X.L.; Pan, Y.Z.; Ai, X.; Wan, Y. Research on material constitutive model at large range of strain and strain rate. J. Harbin Inst. Technol. 2010, 17, 37–40. [Google Scholar]

- Zhang, Z.; Jiang, Z.; Wei, Q. Dynamic mechanical properties and constitutive equation of 2219 aluminum alloy. J. Mater. Eng. 2017, 10, 47–51. [Google Scholar]

- Xie, C.; Tongm, M.; Liu, F.; Zhi-Gang, L.I.; Guo, Y.Z.; Liu, X.C. Dynamic tests and constitutive model for 7075-T6 aluminum alloy. J. Vib. Shock 2014, 33, 110–114. [Google Scholar]

- Chen, Y.; Li, Y.; Cheng, X.; Wu, C.; Cheng, B.; Xu, Z. The Microstructure and Mechanical Properties of refractory High-Entropy Alloys with High Plasticity. Materials 2018, 11, 208. [Google Scholar] [CrossRef] [PubMed]

- Yu, J.; Jiang, F.; Rong, Y. Experimental research on mechanical property size effects of AISI D2 steel. Mater. Sci. Technol. 2012, 20, 83–88. [Google Scholar]

- Liu, W.; Ma, M.; Yang, F. Effect of the Heat Treatment on the Cube Recrystallization Texture of Al-Mn-Mg Aluminum Alloy. Metall. Mater. Trans. A 2013, 44, 2857–2868. [Google Scholar] [CrossRef]

- Premkumar, M.; Himabindu, V.S.; Banumathy, S.; Bhattacharjee, A.; Singh, A.K. Effect of mode of deformation by rolling on texture evolution and yield locus anisotropy in a multifunctional β titanium alloy. Mater. Sci. Eng. A 2012, 552, 15–23. [Google Scholar] [CrossRef]

- Ling, L.; Tang, J.; Liu, W.; Zhang, X.; Liang, C.; Deng, Y. Numerical simulation evolution of shear strain of crystallographic textures during snake rolling of Al-Mg-Si alloy plate. J. Cent. South Univ. 2017, 48, 2279–2287. [Google Scholar]

- Feng, D.; Zhang, X.; Liu, S.; Wu, S.; Guo, Y.; Yu, C. Inhomogeneity of microstructure and properties od 7A55 aluminum alloy thick plate. J. Cent. South Univ. 2015, 8, 2824–2830. [Google Scholar]

- Wei, P.; Lu, C.; Liu, H.; Su, L.; Deng, G.; Tieu, K. Study of Anisotropic Plastic Behavior in High Pressure Torsion of Aluminum Single Crystal by Crystal Plasticity Finite Element Method. Crystals 2017, 7, 362. [Google Scholar] [CrossRef]

- Xiong, C.; Deng, Y.; Wang, L. Evolutions of microstructure and textures of 7050 Al alloy plate during solution heat treatment. Chin. J. Nonferr. Met. 2010, 20, 427–434. [Google Scholar]

- You, Z.; Hui, S.; Ye, W.; Yu, Y.; Liu, R. Effect of texture on dynamic mechanical property of TC4 rolled plate. Chin. J. Rare Met. 2012, 1, 31–35. [Google Scholar]

- Wang, X.; Huang, C.; Zou, B.; Liu, H.; Zhu, H.; Wang, J. Dynamic behavior and a modified Johnson-Cook constitutive model of Inconel 718 at high strain rate and elevated temperature. Mater. Sci. Eng. A 2013, 580, 385–390. [Google Scholar] [CrossRef]

- Jouneghani, F.Z.; Dimitri, R.; Bacciocchi, M.; Tornabene, F. Free Vibration Analysis of Functionally Graded Porous Doubly-Curved Shells Based on the First-Order Shear Deformation Theory. Appl. Sci. 2017, 7, 1–20. [Google Scholar] [CrossRef]

- Zhou, G.; Dong, X.; Fu, Y. An experimental study of adiabatic shear behavior of TA2 titanium alloy subject to different loading condition. Chin. J. Theor. Appl. Mech. 2016, 48, 1353–1361. [Google Scholar]

- Shi, C.; Xu, S.; Shan, J.; Wang, P.; Hu, S. Plastic instability of LY12 aluminum alloy ring under longitudinal impact compression. Explos. Shock Waves 2017, 37, 471–478. [Google Scholar]

- Zhang, C.; Xie, L.; Chen, M.; Shang, G.Q. Dynamic mechanical property and plastic constitutive relation of TC4-DT Ti alloy under high strain rate. Chin. J. Nonferr. Met. 2015, 25, 323–329. [Google Scholar]

- Gu, L.; Wang, M.; Sun, C. Experimental study on characteristics of adiabatic shear localization fracture in high speed machining. J. Mech. Eng. 2014, 50, 166–171. [Google Scholar] [CrossRef]

- Ma, X.Q.; Han, F. High Speed Collision Dynamics; National Defense Industry Press: Beijing, China, 1998. [Google Scholar]

- Liu, W.; He, Z.; Chen, Y.; Tang, S.W. Dynamic mechanical properties and constitutive equations of 2519A aluminum alloy. Trans. Nonferr. Met. Soc. China 2014, 24, 2179–2186. [Google Scholar] [CrossRef]

- Gao, Z.; Zhang, X.; Chen, M.; Zhao, Y.; Li, H.; Liu, B. Effect of temperature on dynamic yield stress and microstructure of 2519A aluminum aloy at high strain rate. Chin. J. Rare Met. 2009, 38, 881–886. [Google Scholar]

- Ferreira, N.; Antunes, P.; Ferreira, J.A.M.; Costa, J.D.M.; Capela, C. Effects of Shot-Peening and Stress Ratio on the Fatigue Crack Propagation of AL 7475-T7351 Specimens. Appl. Sci. 2018, 8, 375. [Google Scholar] [CrossRef]

- Li, D.; Xu, L.; Huang, X.; Dai, G. Investigation on critical strain of dynamic recrystallization for 7A04 aluminum alloy. J. Mater. Eng. 2013, 4, 23–27. [Google Scholar]

- Zhang, Y.; Wang, X.; Kong, F.; Chen, Y. Dynamic Recrystallization of the Constituent γ Phase and Mechanical Properties of Ti-43Al-9V-0.2Y Alloy Sheet. Materials 2017, 10. [Google Scholar] [CrossRef] [PubMed]

- Tang, W.; Zhang, S.; Fan, X.; Li, F.Y.; Peng, Y.H. Texture and its effect on mechanical properties of AZ31 magnesium alloy. Chin. J. Nonferr. Met. 2010, 3, 371–377. [Google Scholar]

- Zhang, K.; Zhang, J.; Liu, Y.; Zhong, L.; University, C.J. Microstructure and texture variation of 6016 aluminum alloy during cold rolling. Rare Met. Mater. Eng. 2017, 6, 1559–1565. [Google Scholar]

- Yang, L.; Hui, S.; Ye, W.; Huang, L. Texture and EBSD of TA18 titanium alloys tubes. Chin. J. Rare Met. 2011, 35, 928–933. [Google Scholar]

- Mao, L.; Yu, J.; Liu, Z.; Dong, Y.; Xi, T. Dynamic mechanical property and failure behavior of extruded Mg-Gd-Y alloy under high strain rate compression. Chin. J. Nonferr. Met. 2013, 4, 889–897. [Google Scholar]

- Chen, J.; Duan, Y.; Peng, X.; Cao, X.; Xu, G.; Yin, Z. Fracture toughness of 7475-T7351 aluminum alloy thick plate. J. Cent. South Univ. 2015, 2, 437–443. [Google Scholar]

| Zn | Cu | Mg | Zr | Mn | Si | Fe | Ti | Al |

| 6.70 | 2.50 | 2.30 | 0.12 | 0.10 | 0.12 | 0.13 | 0.06 | Bal. |

| Forming Direction | Desired Strain Rate(s−1) |

| RD, TD, ND | 2.5 × 104 ; 3.5 × 104 ; 4.5 × 104 |

| Shear Modulus/(GPa) | ND | TD | RD |

| 2.5 × 104 s−1 | 20 | 15 | 15 |

| 3.5 × 104 s−1 | 21 | 19 | 20 |

| 4.5 × 104 s−1 | 22 | 24 | 22 |

| Shear Modulus/(GPa) | 2.5 × 104 s−1 | 3.5 × 104 s−1 | 4.5 × 104 s−1 |

| ND | 18 | 20 | 11 |

| TD | 17 | 16 | 14 |

| RD | 18 | 19 | 13 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, Y.; Wang, X.; Zongcheng, H.; Fu, X. The Influence of Forming Directions and Strain Rate on Dynamic Shear Properties of Aerial Aluminum Alloy. Appl. Sci. 2018, 8, 520. https://doi.org/10.3390/app8040520

Meng Y, Wang X, Zongcheng H, Fu X. The Influence of Forming Directions and Strain Rate on Dynamic Shear Properties of Aerial Aluminum Alloy. Applied Sciences. 2018; 8(4):520. https://doi.org/10.3390/app8040520

Chicago/Turabian StyleMeng, Ying, Xiangyu Wang, Hao Zongcheng, and Xiuli Fu. 2018. "The Influence of Forming Directions and Strain Rate on Dynamic Shear Properties of Aerial Aluminum Alloy" Applied Sciences 8, no. 4: 520. https://doi.org/10.3390/app8040520

APA StyleMeng, Y., Wang, X., Zongcheng, H., & Fu, X. (2018). The Influence of Forming Directions and Strain Rate on Dynamic Shear Properties of Aerial Aluminum Alloy. Applied Sciences, 8(4), 520. https://doi.org/10.3390/app8040520