Experimental Studies on the Spraying Pattern of a Swirl Nozzle for Coal Dust Control

Abstract

:1. Introduction

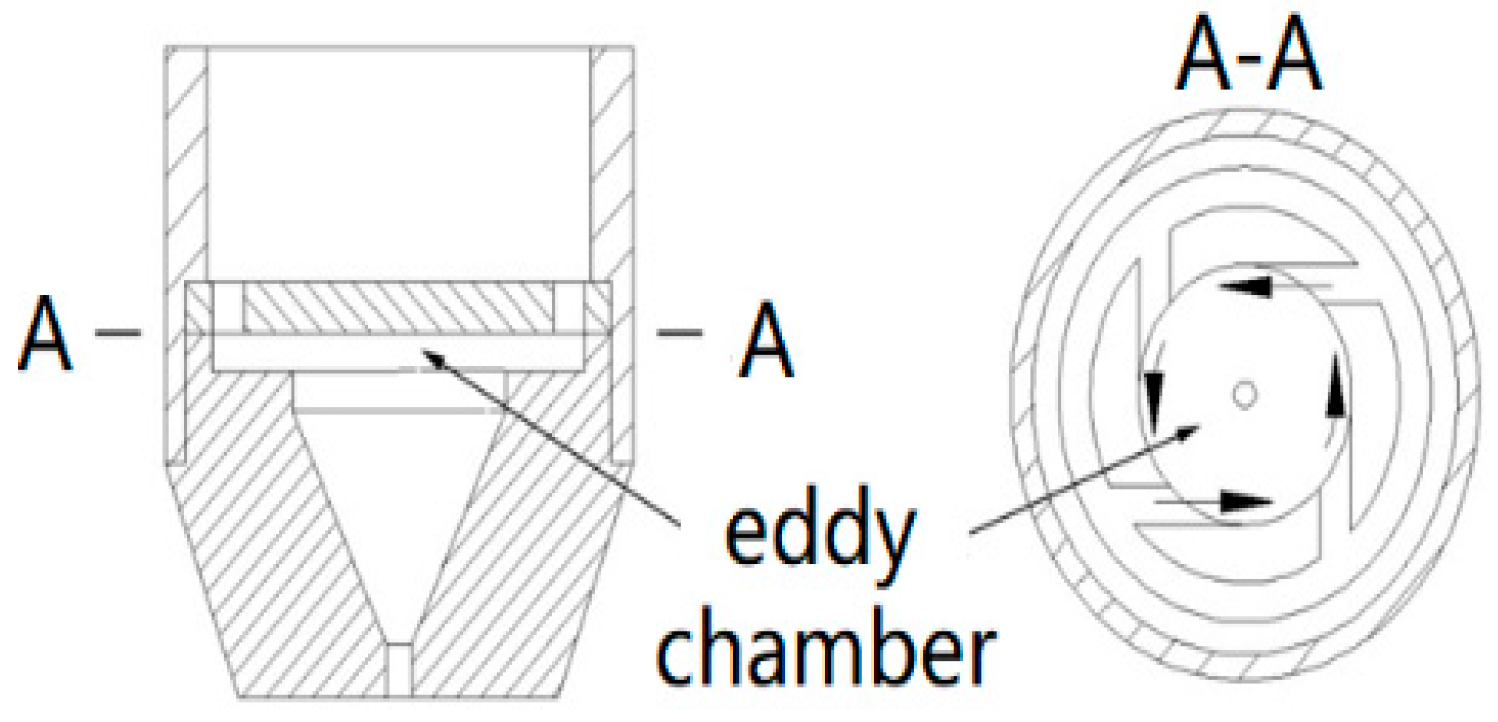

2. Research Method

2.1. Numerical Study of Both Spray Nozzles

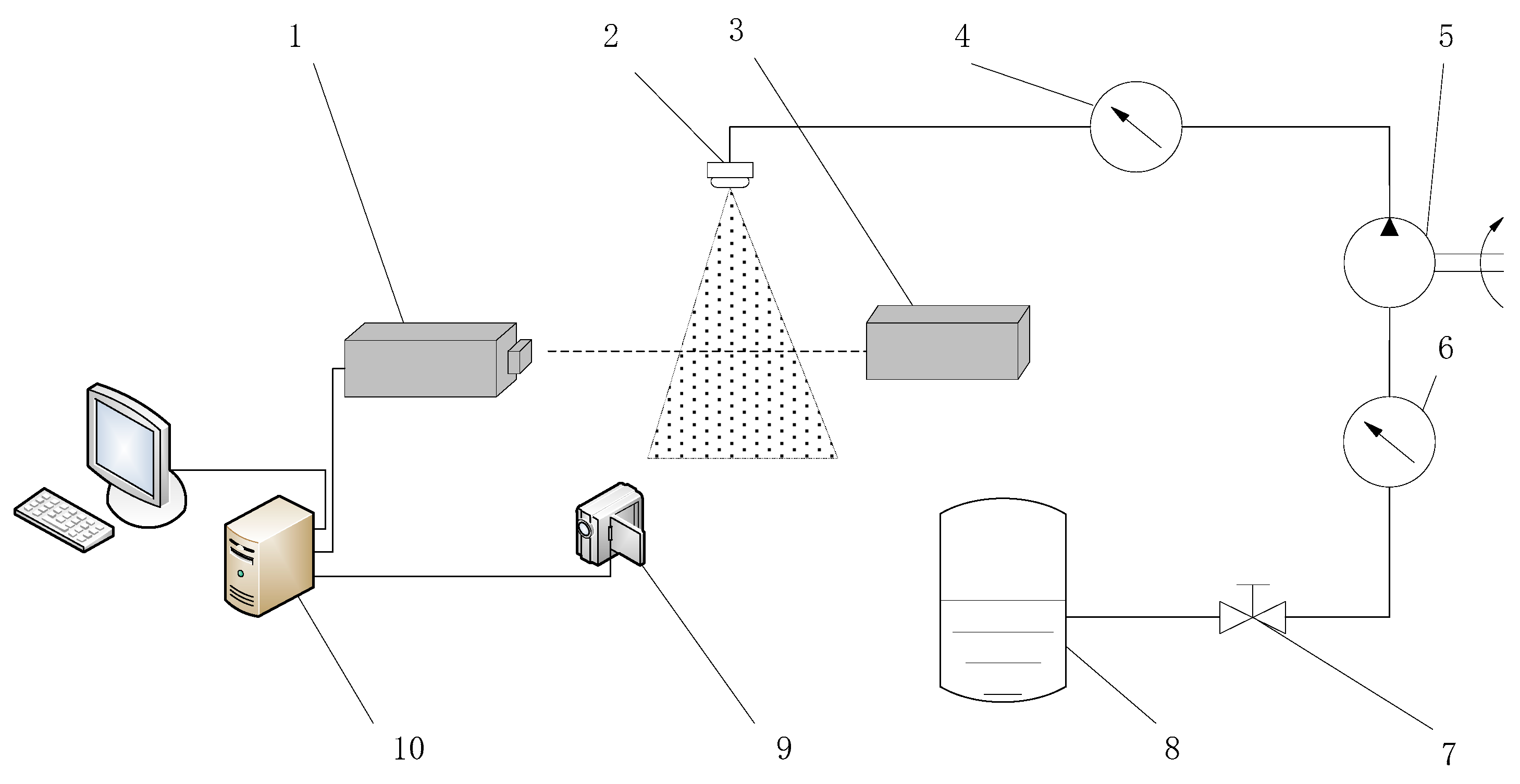

2.2. Experimental Setup

3. Results and Discussion

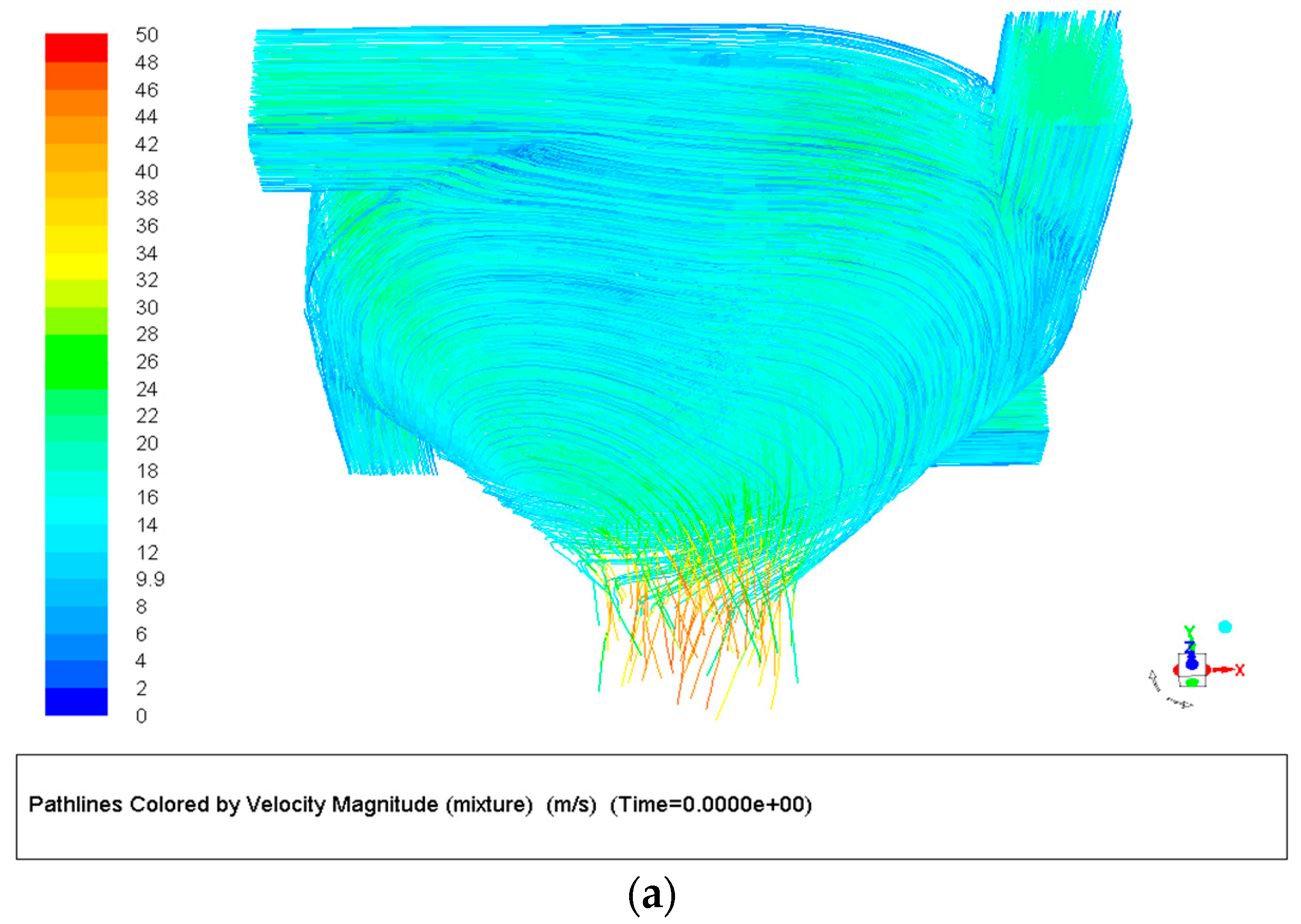

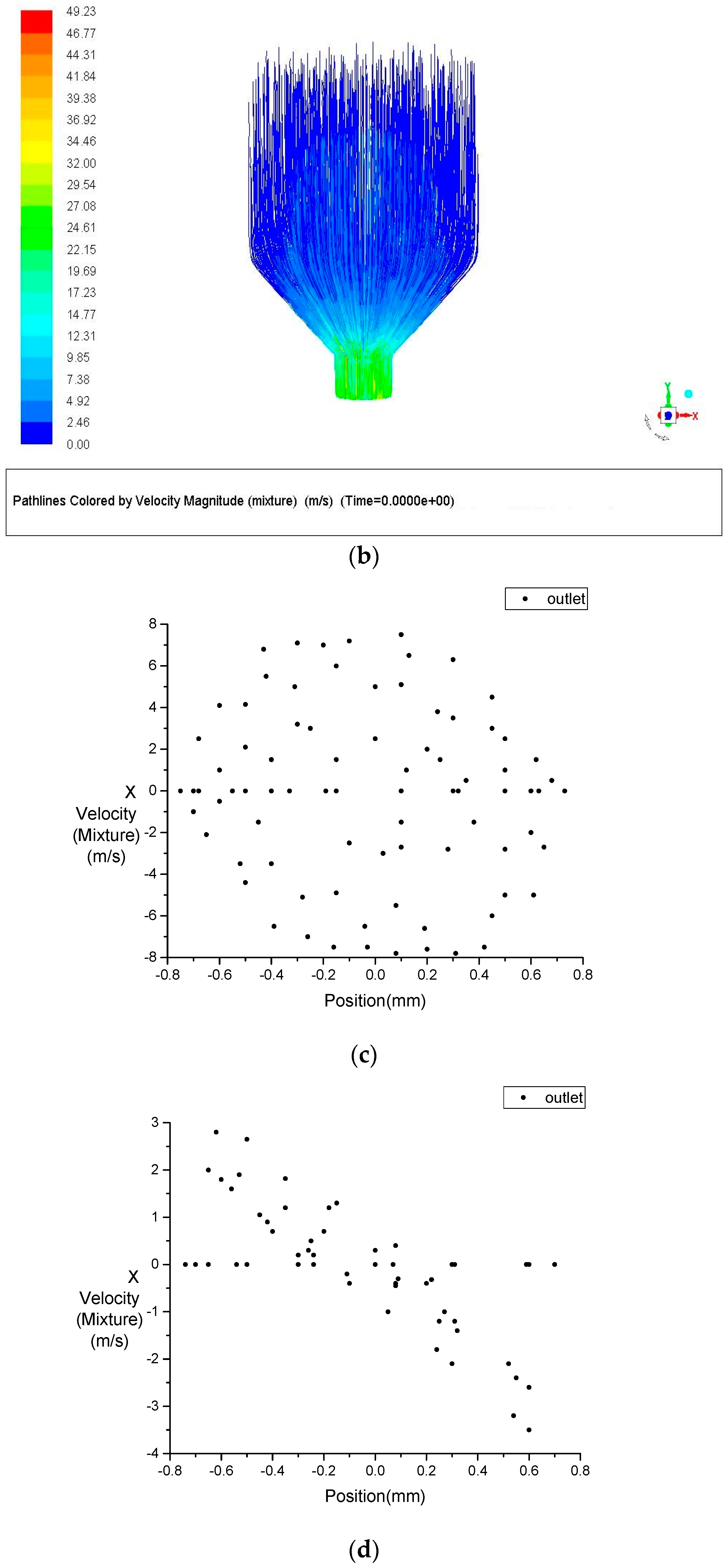

3.1. Numerical Simulation Results

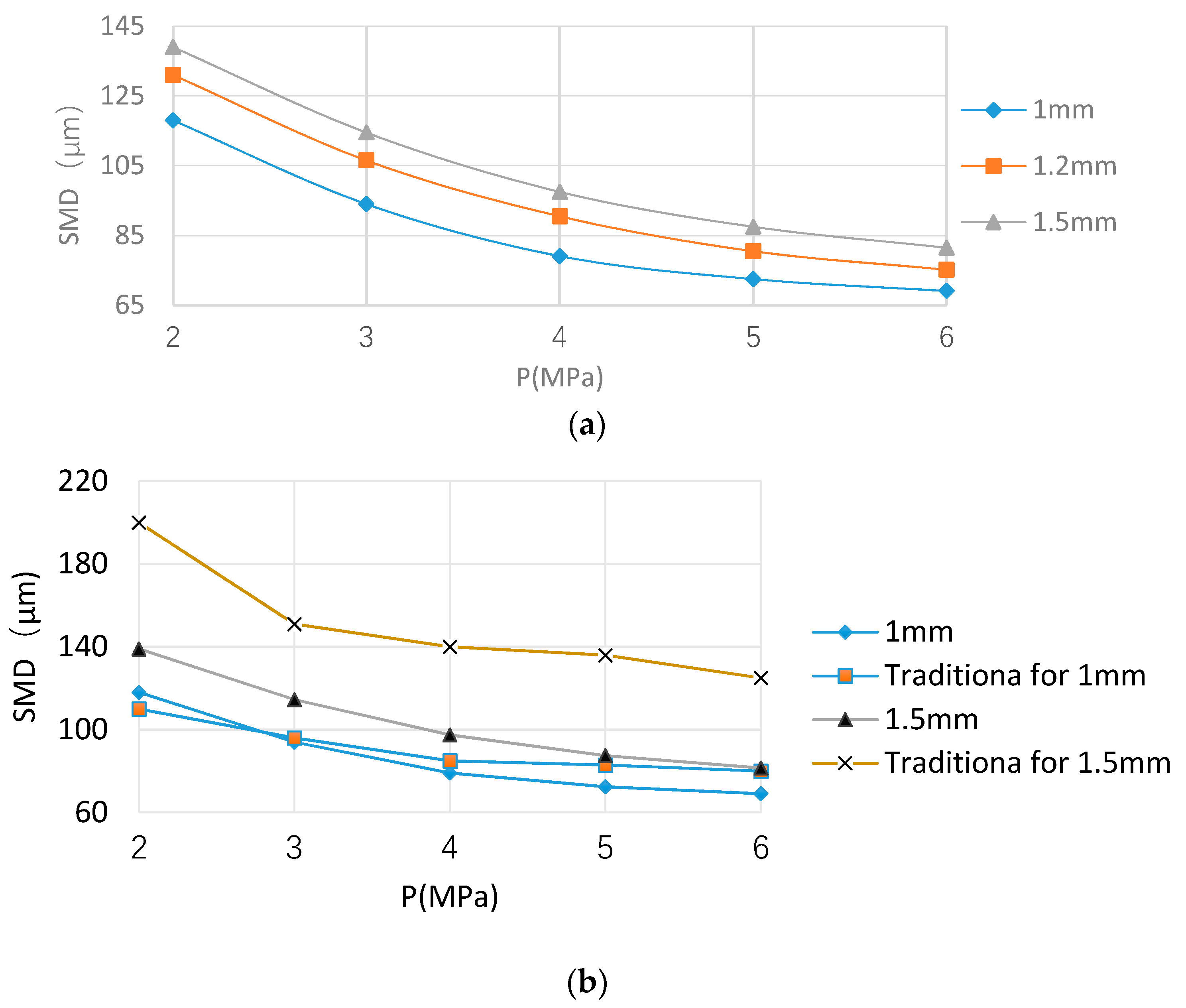

3.2. The Relationship between Droplet SMD and Spray Pressure and Nozzle Diameter

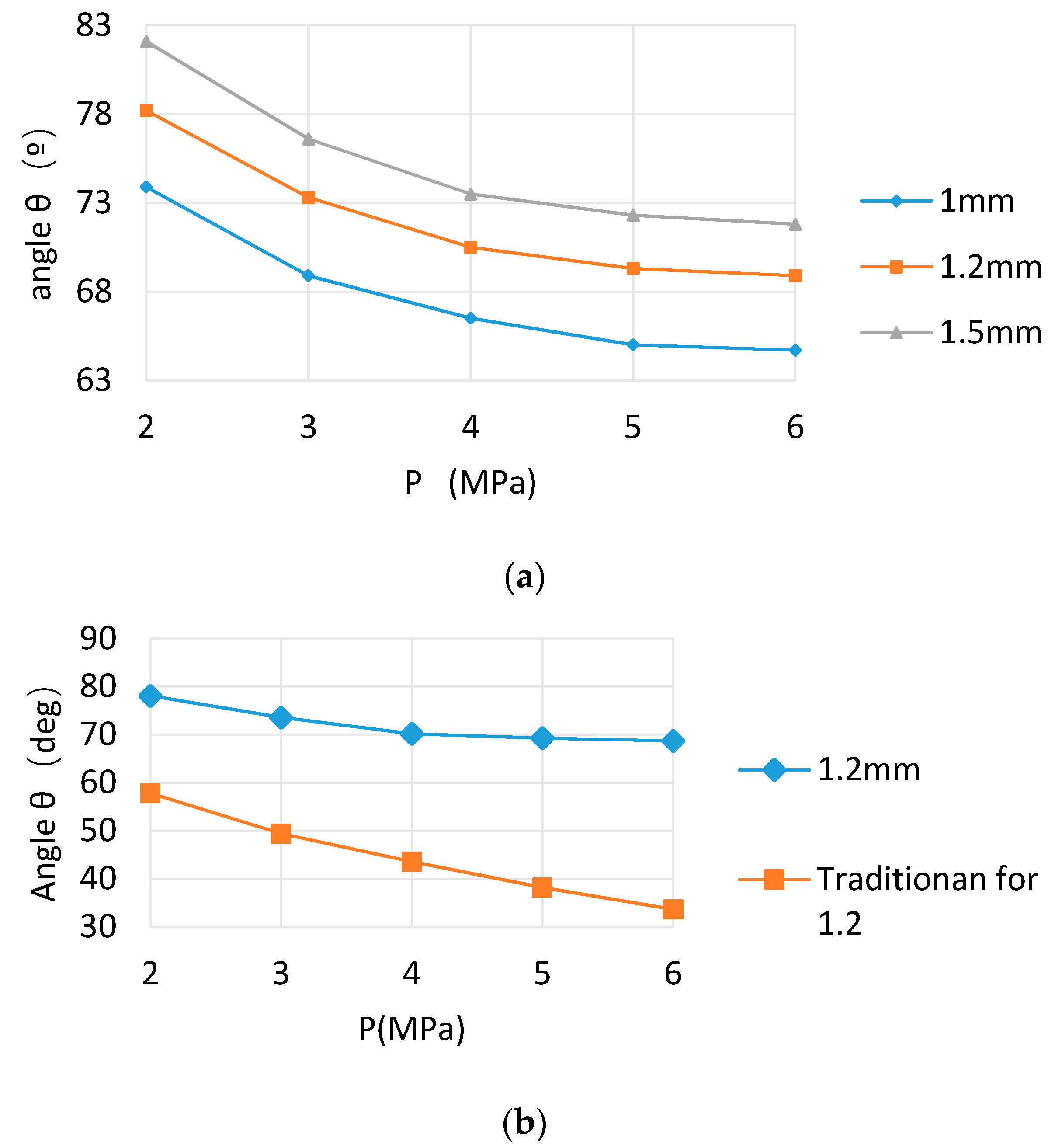

3.3. The Relationship between Atomization Angle and Spray Pressure and Nozzle Aperture

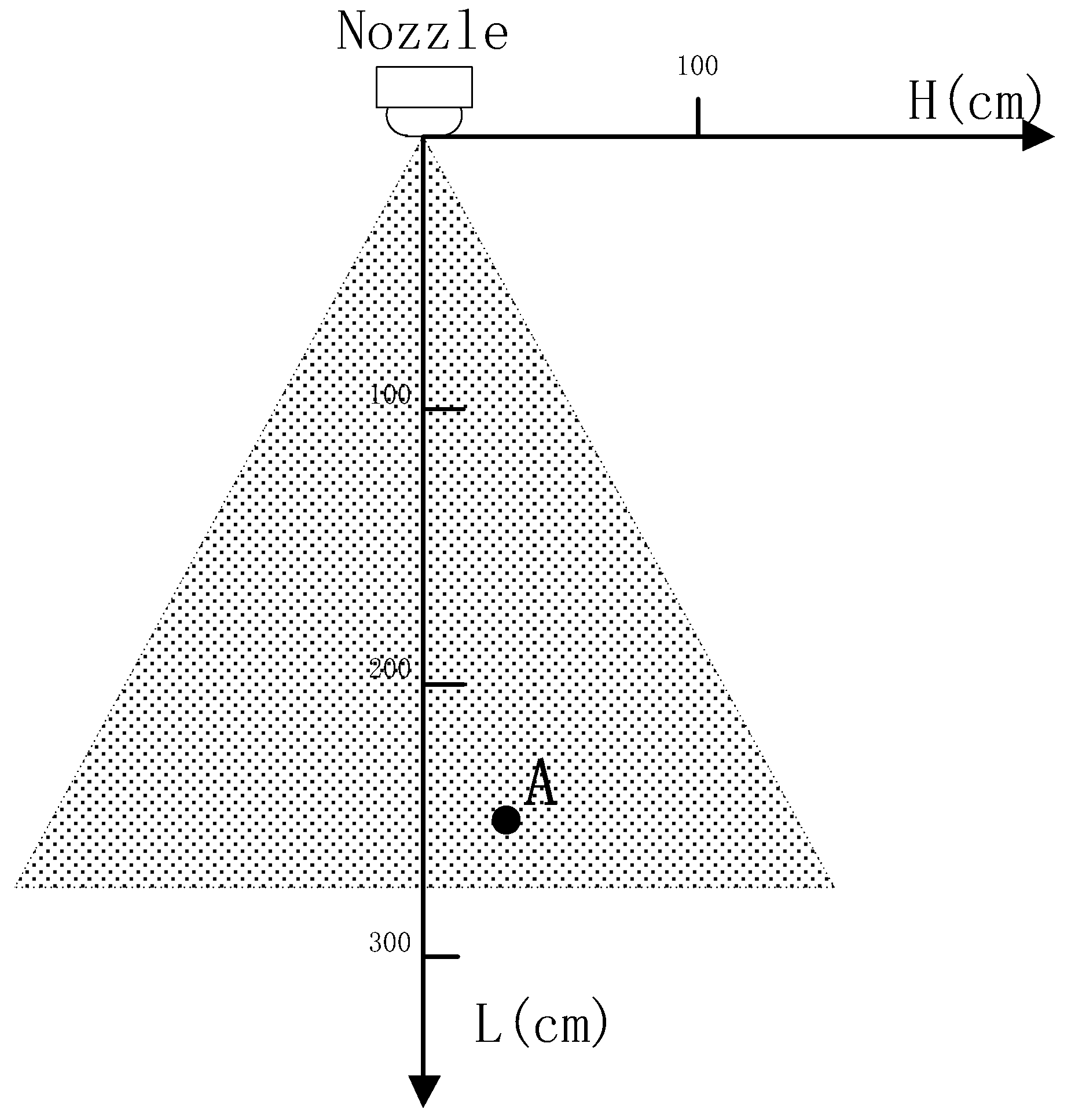

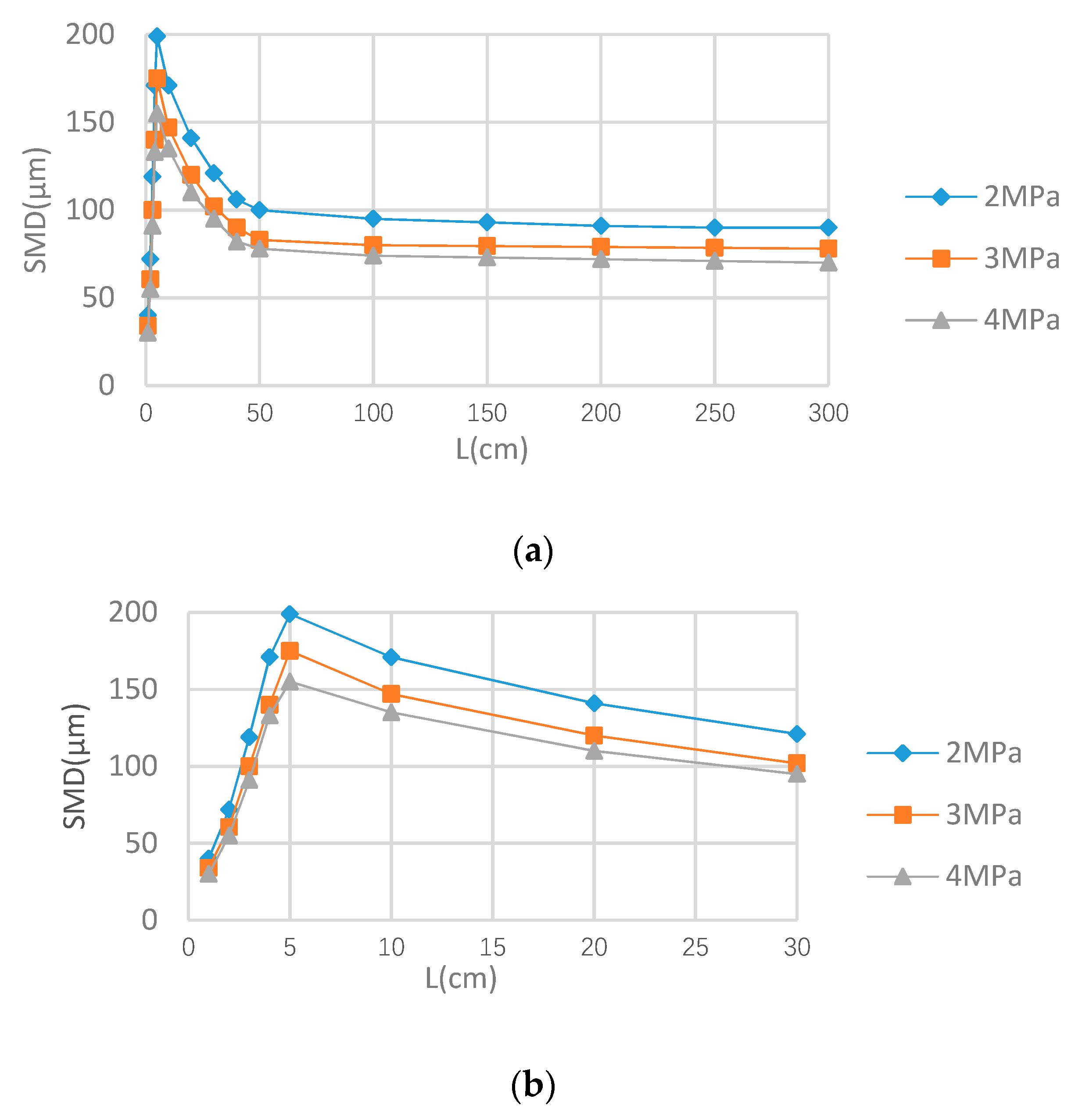

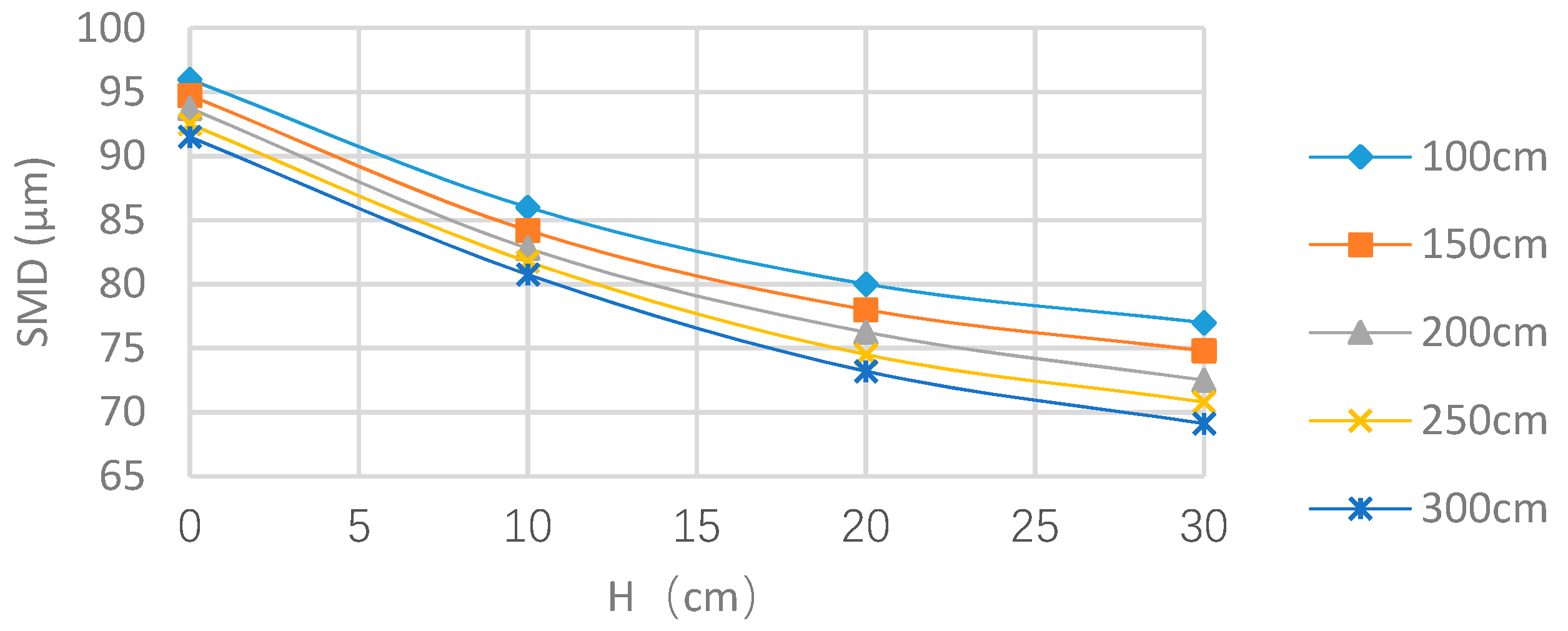

3.4. Axial and Radial Distributions of Particle SMD

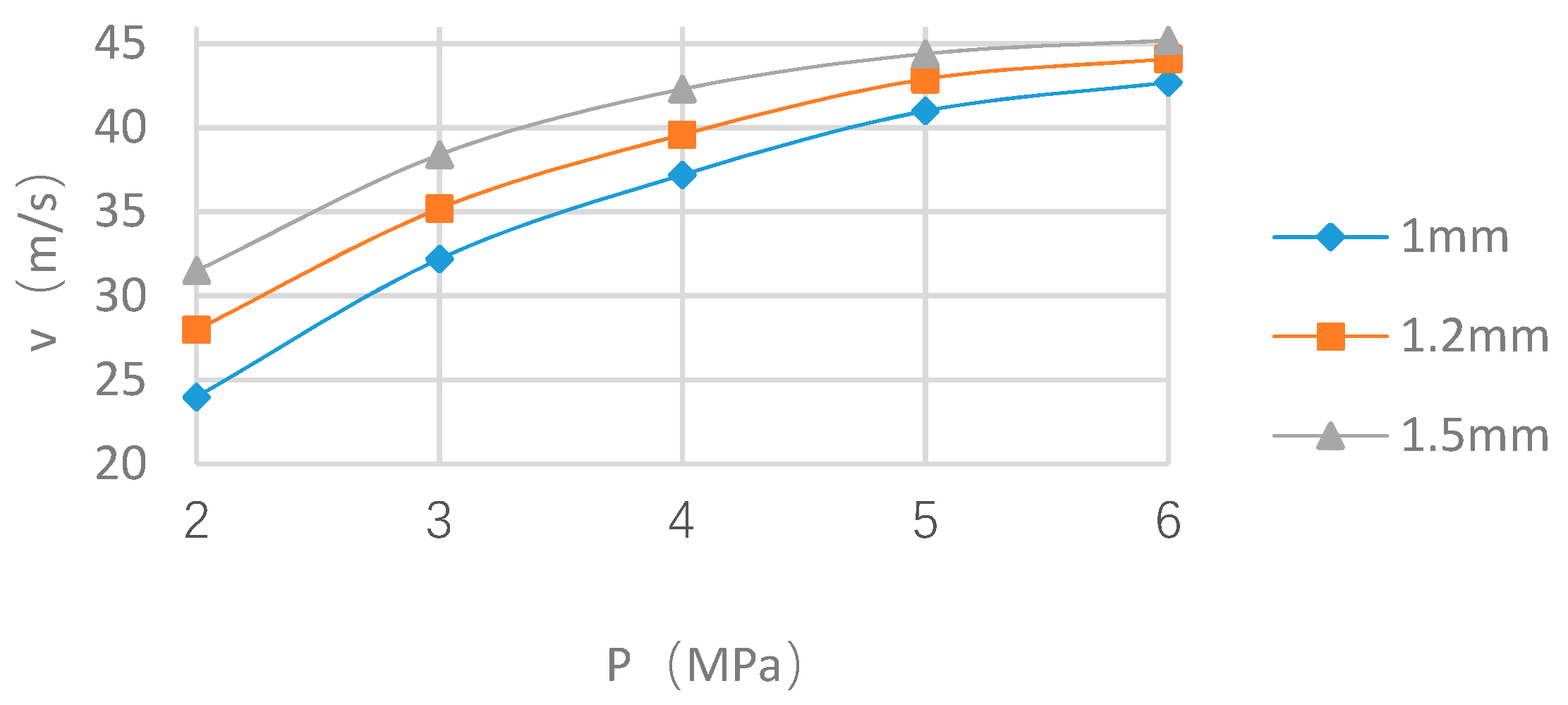

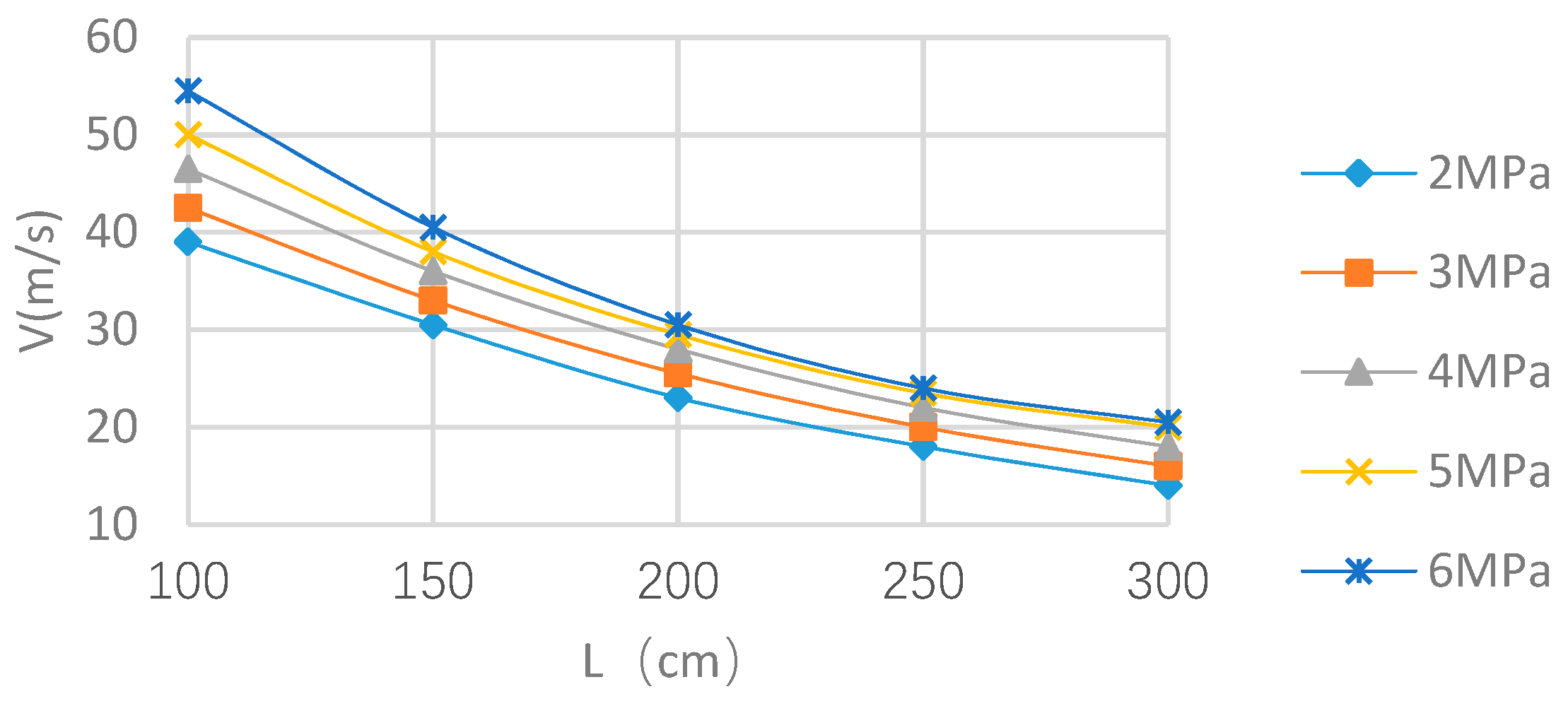

3.5. Speed Distribution of Fog Particles

4. Comparison of the Effects of the Nozzle in Practice

5. Conclusions

- (1)

- For this swirl nozzle, when the spray pressure is low, the particles’ SMD decreases rapidly with the increase of the spray pressure. When the pressure reaches 5 MPa, the particles’ SMD decreases slowly; even if the spray pressure continues to increase, the particles’ SMD reduces very slowly. According to this character, a normal pressure pump can be used in practice instead of an expensive high-pressure pump for cost reduction.

- (2)

- Along the axial distance from the nozzle, the fog particles’ SMD increase rapidly and then decrease rapidly; after 100 cm, it gradually becomes stable. The processes of increase and decrease are relatively short. The particles’ SMD was the largest in the center of the fog field and decreases gradually along the radial direction.

- (3)

- The axial speed of particles increases with the increase of spray pressure, however, the increase rate tends to be slow when the pressure is above 5 MPa. The speed of particles decreases with the increase of aperture under the same spray pressure. The speed of the fog particles decreases gradually with the increase of axial distance in the fog field, and the rate of decrease gradually slows down.

- (4)

- Increasing of spray pressure and decreasing of nozzle aperture will make the fog particles’ size distribution more concentrated and uniform. The fog particles’ size distribution is also more uniform where it is further away from the nozzle axially and radially.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| dpmin | dust particle diameter (m) |

| Δs | distribution of fog particle size |

| U | dynamic viscosity |

| Stk | stokes number |

| ρp | dust density |

| v0 | air flow rate |

| D | nozzle diameter (m) |

| Dw | droplet diameter |

| Q | nozzle flowrate (m3/s) |

| Pw | pressure of water (MPa) |

| k | test coefficient (k = 1.34) |

| v | water jet speed (m/s) |

| dSMD | Sauter mean diameter |

| di | the droplet diameter |

| ni | number of ith segment |

| m | the number of droplet diameter segments |

Abbreviations

| SMD | Sauter mean diameter |

| PIV | Particle image velocimetry |

| PDA | Phase-doppler anemometry |

| CFD | Computational fluid dynamics |

| LDA | Laser doppler anemometry |

References

- Russell, R. Coal dust control. Power Eng. 2013, 117, 28–30. [Google Scholar]

- Li, Y.Q.; Qin, Y.P.; Yang, X.B. New progress on coal mine dust in recent ten years. Procedia Eng. 2011, 26, 738–743. [Google Scholar]

- Wang, J.; Gao, Y. Development of coal mine downhole high-pressure dust reduction and water supply system monitor device. In Proceedings of the 2011 International Conference on Electronics, Communications and Control (ICECC), Ningbo, China, 9–11 September 2011; pp. 2032–2034. [Google Scholar]

- Wang, P.-F.; Liu, R.-H.; Tang, M.; Zhang, W.; Gui, Z. Experimental study on atomization characteristics and dust suppression efficiency of high-pressure spray in underground coal mine. J. Chin. Coal Soc. 2015, 40, 2124–2130. [Google Scholar]

- Pang, J.; Xie, J.; Li, C.; Hao, Y.; Jian, J. Study on dust distribution features of high cutting fully-mechanized coal mining face. Coal Sci. Technol. 2017, 45, 78–83. [Google Scholar]

- Liu, Q.; Kou, Z.; Gao, G.; Hou, T. Experimental research on the comprehensive operating parameters of atomized dust collector. Exp. Therm. Fluid Sci. 2015, 62, 216–221. [Google Scholar] [CrossRef]

- Kudo, T.; Sekiguchi, K.; Sankoda, K.; Namiki, N.; Nii, S. Effect of ultrasonic frequency on size distributions of nano sized mist generated by ultrasonic atomization. Ultrason. Sonochem. 2017, 37, 16–22. [Google Scholar] [CrossRef] [PubMed]

- Chang, P.; Bai, B. An improved method of gas well deliquification using supersonic nozzle. Int. J. Heat Mass Transf. 2017, 108, 2262–2272. [Google Scholar] [CrossRef]

- Wu, D.; Yin, K.; Yin, Q.; Zhang, X.; Cheng, J.; Ge, D.; Zhang, P. Reverse circulation drilling method based on a supersonic nozzle for dust control. Appl. Sci. 2016, 7, 5. [Google Scholar] [CrossRef]

- Charinpanitkul, T.; Tanthapanichakoon, W. Deterministic model of open-space dust removal system using water spray nozzle: Effects of polydispersity of water droplet and dust particle. Sep. Purif. Technol. 2011, 77, 382–388. [Google Scholar] [CrossRef]

- Pollock, D.; Organiscak, J. Airborne dust capture and induced airflow of various spray nozzle designs. Aerosol Sci. Technol. 2007, 41, 711–720. [Google Scholar] [CrossRef]

- Ren, G.; Heo, S.; Kim, T.-H.; Cheong, C. Response surface method-based optimization of the shroud of an axial cooling fan for high performance and low noise. J. Mech. Sci. Technol. 2013, 27, 33–42. [Google Scholar] [CrossRef]

- Liu, J.; Yu, Q.; Guo, Q. Experimental investigation of liquid disintegration by rotary cups. Chem. Eng. Sci. 2012, 73, 44–50. [Google Scholar] [CrossRef]

- Bizjan, B.; Širok, B.; Hočevar, M.; Orbanić, A. Ligament-type liquid disintegration by spinning wheel. Chem. Eng. Sci. 2014, 116, 172–182. [Google Scholar] [CrossRef]

- Kamiya, T.; Kayano, A. Film-type disintegration by rotating disk. J. Chem. Eng. Jpn. 1972, 5, 174–182. [Google Scholar] [CrossRef]

- Liu, X.; Gao, G. Atomization characteristics of ultrasonic nozzle with hartmann whistle structure. Chin. J. Vac. Sci. Technol. 2016, 36, 268–272. [Google Scholar]

- Wilson, J.; Grib, S.; Darwish Ahmad, A.; Renfro, M.; Adams, S.; Salaimeh, A. Study of near-cup droplet breakup of an automotive electrostatic rotary bell (esrb) atomizer using high-speed shadowgraph imaging. Coatings 2016, 8, 174. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Langrish, T.A.G. Spray drying and crystallization of lactose with humid air in a straight-through system. Drying Technol. 2016, 33, 808–816. [Google Scholar] [CrossRef]

- Koschel, D.; Stark, W.; Karmann, F.; Sennekamp, J.; Müller-Wening, D. Extrinsic allergic alveolitis caused by misting fountains. Respir. Med. 2005, 99, 943–947. [Google Scholar] [CrossRef] [PubMed]

- Avvaru, B.; Patil, M.N.; Gogate, P.R.; Pandit, A.B. Ultrasonic atomization: effect of liquid phase properties. Ultrasonics 2006, 44, 146–158. [Google Scholar] [CrossRef] [PubMed]

- Barreras, F.; Amaveda, H.; Lozano, A. Transient high-frequency ultrasonic water atomization. Exp. Fluids 2002, 33, 405–413. [Google Scholar] [CrossRef]

- Yang, Y.; Wen, C. CFD modeling of particle behavior in supersonic flows with strong swirls for gas separation. Sep. Purif. Technol. 2017, 174, 22–28. [Google Scholar] [CrossRef]

- Wen, C.; Yang, Y.; Walther, J.H.; Pang, K.M.; Feng, Y. Effects of delta wing on the particle flow in a gas supersonic separator. Powder Technol. 2016, 304, 261–267. [Google Scholar] [CrossRef]

- Wen, C.; Li, A.; Walther, J.H.; Yang, Y. Effect of swirling device on flow behavior in a supersonic separator for natural gas dehydration. Sep. Purif. Technol. 2016, 115, 1357–1362. [Google Scholar] [CrossRef] [Green Version]

- Wen, C.; Cao, X.; Yang, Y.; Zhang, J. Evaluation of natural gas dehydration in supersonic swirling separators applying the discrete particle method. Adv. Powder Technol. 2012, 23, 228–233. [Google Scholar] [CrossRef]

- Yang, Y.; Li, A.; Wen, C. Optimization of static vanes in a supersonic separator for gas purification. Fuel Process. Technol. 2017, 156, 265–270. [Google Scholar] [CrossRef]

- Benajes, J.; Pastor, J.V.; Payri, R.; Plazas, A.H. Analysis of the influence of diesel nozzle geometry in the injection rate characteristics. J. Fluids Eng. 2004, 126, 63–71. [Google Scholar] [CrossRef]

- Payri, R.; Salvador, F.J.; Gimeno, J.; Zapata, L.D. Diesel nozzle geometry influence on spray liquid-phase fuel penetration in evaporative conditions. Fuel 2008, 87, 1165–1176. [Google Scholar] [CrossRef]

- Hadef, R.; Lenze, B. Measurements of droplets characteristics in a swirl-stabilized spray flame. Exp. Therm. Fluid Sci. 2005, 30, 117–130. [Google Scholar] [CrossRef]

- Husted, B.P.; Petersson, P.; Lund, I.; Holmstedt, G. Comparison of PIV and PDA droplet velocity measurement techniques on two high-pressure water mist nozzles. Fire Saf. J. 2009, 44, 1030–1045. [Google Scholar] [CrossRef]

- Rashad, M.; Yong, H.; Zheng, Z. Effect of geometric parameters on spray characteristics of pressure swirl atomizers. Int. J. Hydrogen Energy 2016, 41, 15790–15799. [Google Scholar] [CrossRef]

- Soltani, M.R.; Ghorbanian, K.; Ashjaee, M.; Morad, M.R. Spray characteristics of a liquid–liquid coaxial swirl atomizer at different mass flow rates. Aerosp. Sci. Technol. 2005, 9, 592–604. [Google Scholar] [CrossRef]

- Jiang, Z.; Wang, M.; Chen, J.; Lin, M. Atomization characteristics and dust suppression mechanism of a gas water nozzle. J. Harbin Inst. Technol. 2017, 49, 151–157. [Google Scholar]

- Cheng, W.-M.; Nie, W.; Zhou, G.; Zuo, Q.-M. Study of dust suppression by atomized water from high-pressure sprays in mines. J. China Univ. Min. Technol. 2011, 40, 185–190. [Google Scholar]

- Fletcher, D.F.; Guo, B.; Harvie, D.J.E.; Langrish, T.A.G.; Nijdam, J.; Williams, J. What is important in the simulation of spray dryer performance and how do current CFD models perform. Appl. Math. Model. 2006, 30, 1281–1292. [Google Scholar] [CrossRef]

- Launder, B.E.; Sharma, B.I. Application of the energy dissipation model of turbulence to the calculation of flow near a spinning disc. Lett. Heat Mass Transf. 1974, 1, 131–138. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Z.-G.; Li, Q.; Zhang, J. Investigations on the droplet distributions in the atomization of kerosene jets in supersonic crossflows. Appl. Phys. Lett. 2015, 107, 104103. [Google Scholar] [CrossRef]

- Kowalczuk, P.B.; Drzymala, J. Physical meaning of the Sauter mean diameter of spherical particulate matter. Part. Sci. Technol. 2016, 34, 645–647. [Google Scholar] [CrossRef]

- Zhou, Y. An Investigation of Droplet Behavior during Spray-Based Manufacturing Processes. Ph.D. Thesis, University of California, Irvine, CA, USA, 1999. [Google Scholar]

- Cheng, W.-M.; Zhou, G.; Zuo, Q.-M.; Nie, W.; Wang, G. Experimental research on the relationship between nozzle spray pressure and atomization particle size. J. China Univ. Min. Technol. 2010, 35, 1308–1313. [Google Scholar]

- Faeth, G.M.; Hsiang, L.-P.; Wu, P.-K. Structure and breakup properties of sprays. Int. J. Multiphase Flow 1995, 21, 99–127. [Google Scholar] [CrossRef]

- Yi, Y. Numerical Modeling of Spray Primary Breakup with Application to Diesel Engines. Ph.D. Thesis, University of Wisconsin-Madison, Madison, WI, USA, 2002. [Google Scholar]

| Location | Traditional Nozzle | Swirl Nozzle | Reduction |

|---|---|---|---|

| 1035 East tunnel | 8.5 mg/m3 | 6.51 mg/m3 | 23% |

| Belt tunnel | 13 mg/m3 | 11 mg/m3 | 15% |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, G.; Wang, C.; Kou, Z. Experimental Studies on the Spraying Pattern of a Swirl Nozzle for Coal Dust Control. Appl. Sci. 2018, 8, 1770. https://doi.org/10.3390/app8101770

Gao G, Wang C, Kou Z. Experimental Studies on the Spraying Pattern of a Swirl Nozzle for Coal Dust Control. Applied Sciences. 2018; 8(10):1770. https://doi.org/10.3390/app8101770

Chicago/Turabian StyleGao, Guijun, Changjiang Wang, and Ziming Kou. 2018. "Experimental Studies on the Spraying Pattern of a Swirl Nozzle for Coal Dust Control" Applied Sciences 8, no. 10: 1770. https://doi.org/10.3390/app8101770