Comparison of Laser-Engraved Hole Properties between Cold-Rolled and Laser Additive Manufactured Stainless Steel Sheets

Abstract

:1. Introduction

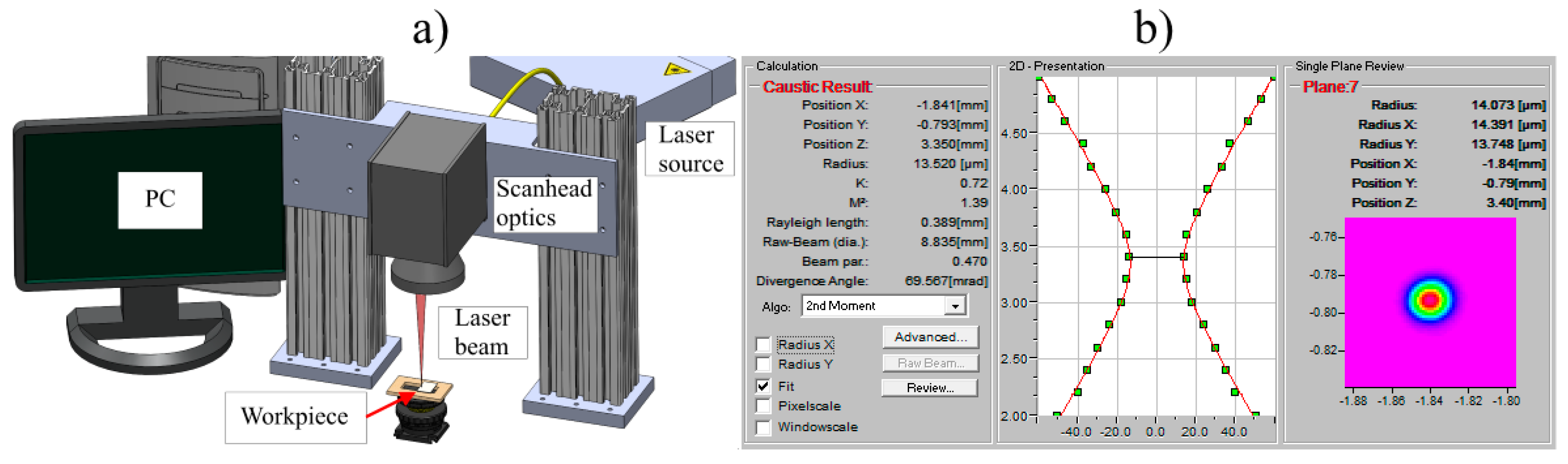

2. Materials and Methods

2.1. Test Sample Materials and Manufacture of PBF Sheet

2.2. Differences in Physical Properties

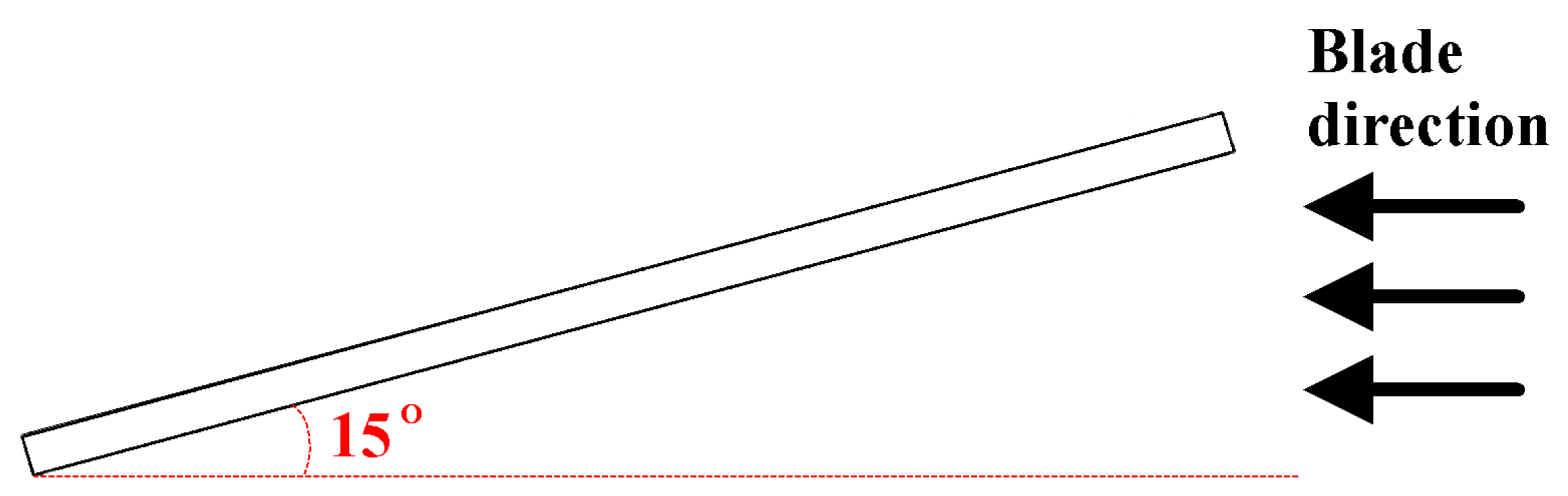

2.3. Drilling Procedure and Parameters

2.4. Measured Properties

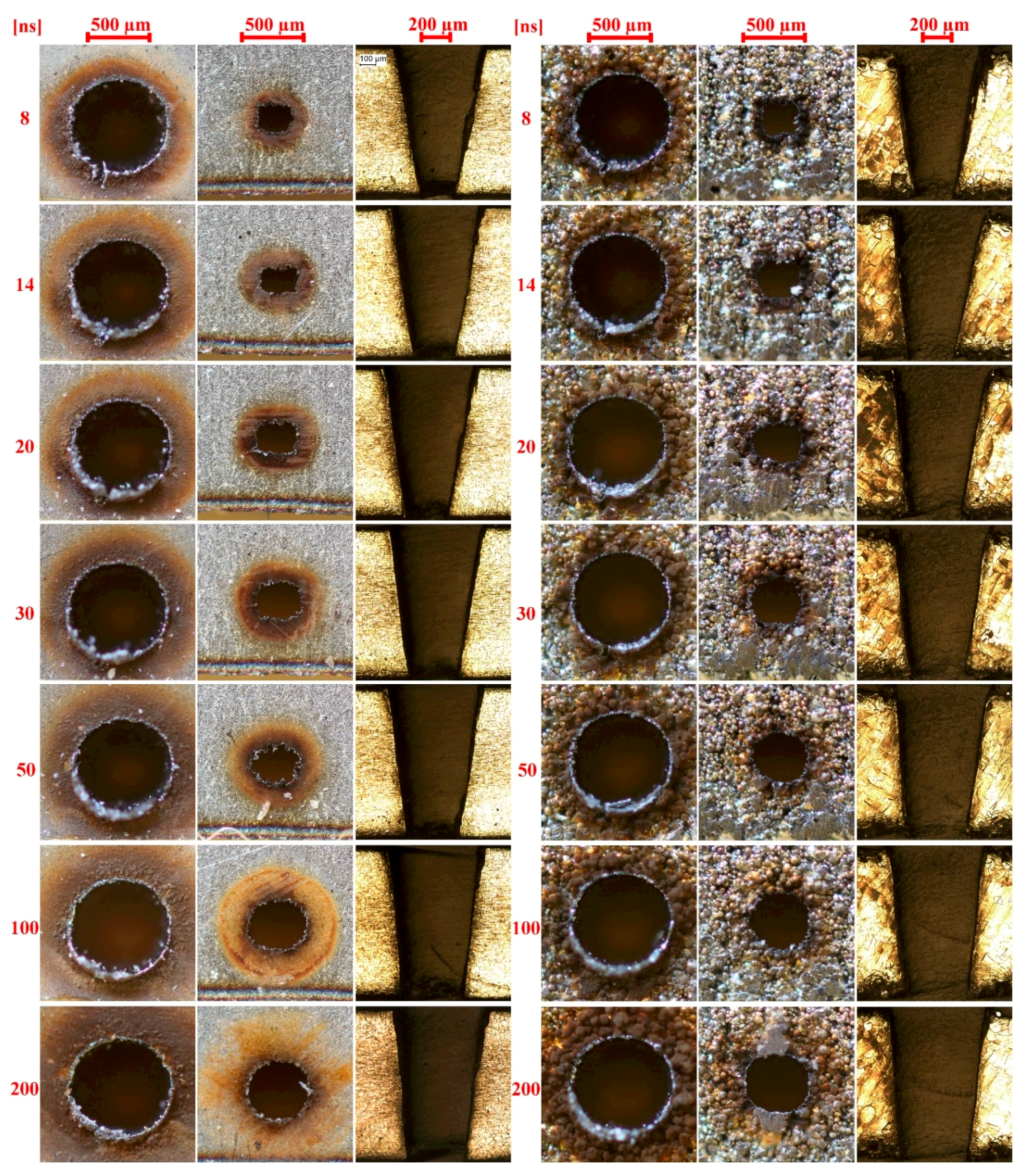

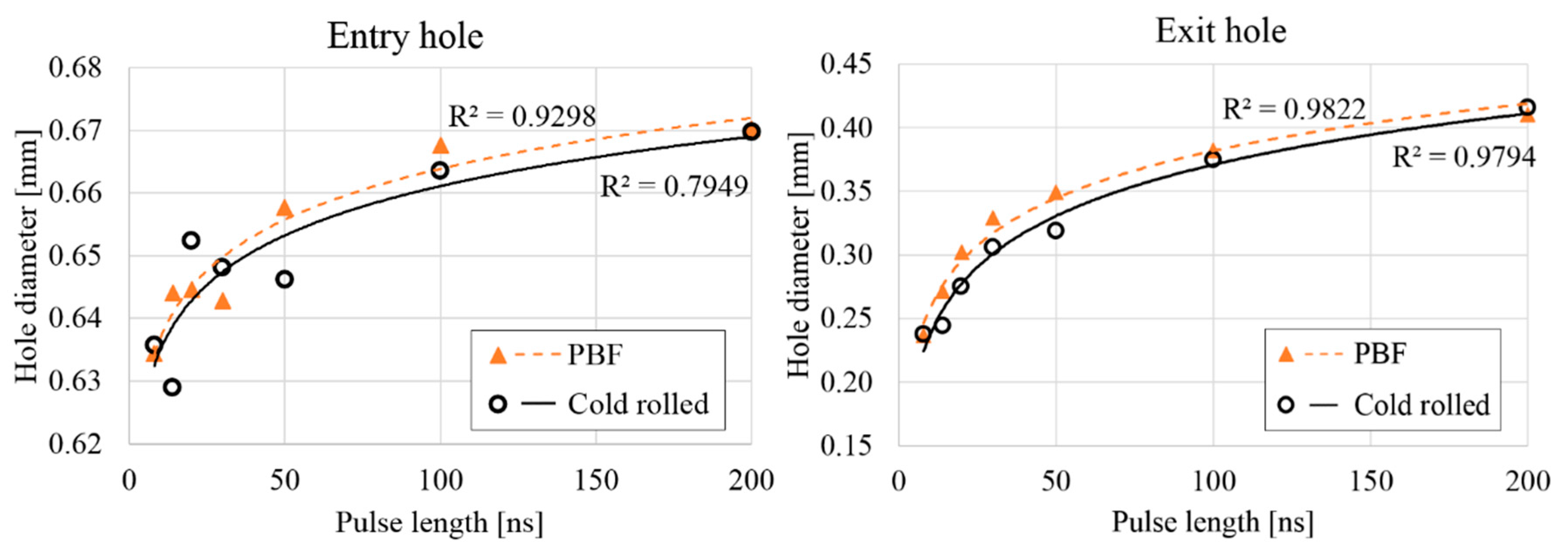

3. Results and Discussion

3.1. Hole Diameters

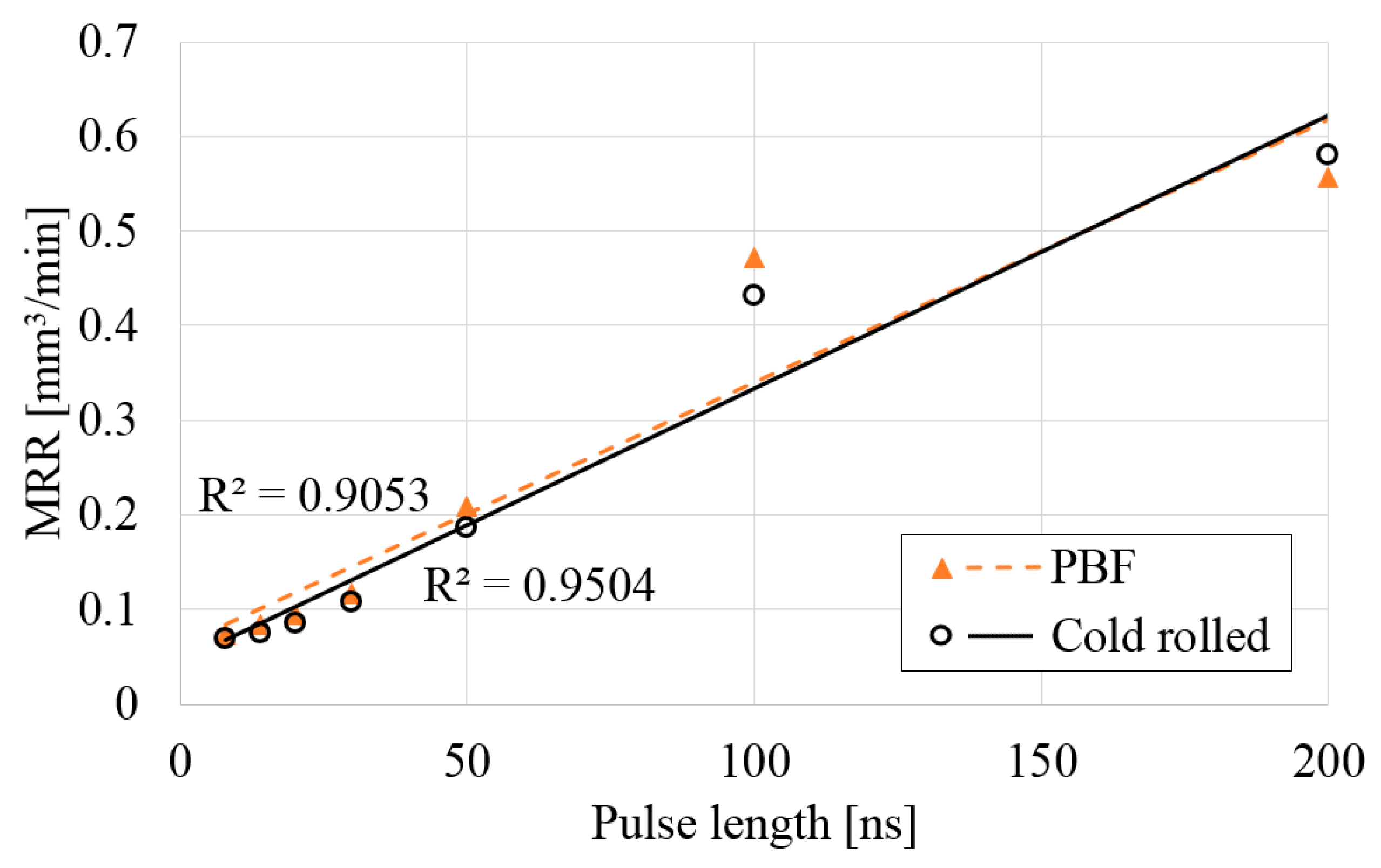

3.2. Material Removal Rate

3.3. Burning Effect Width

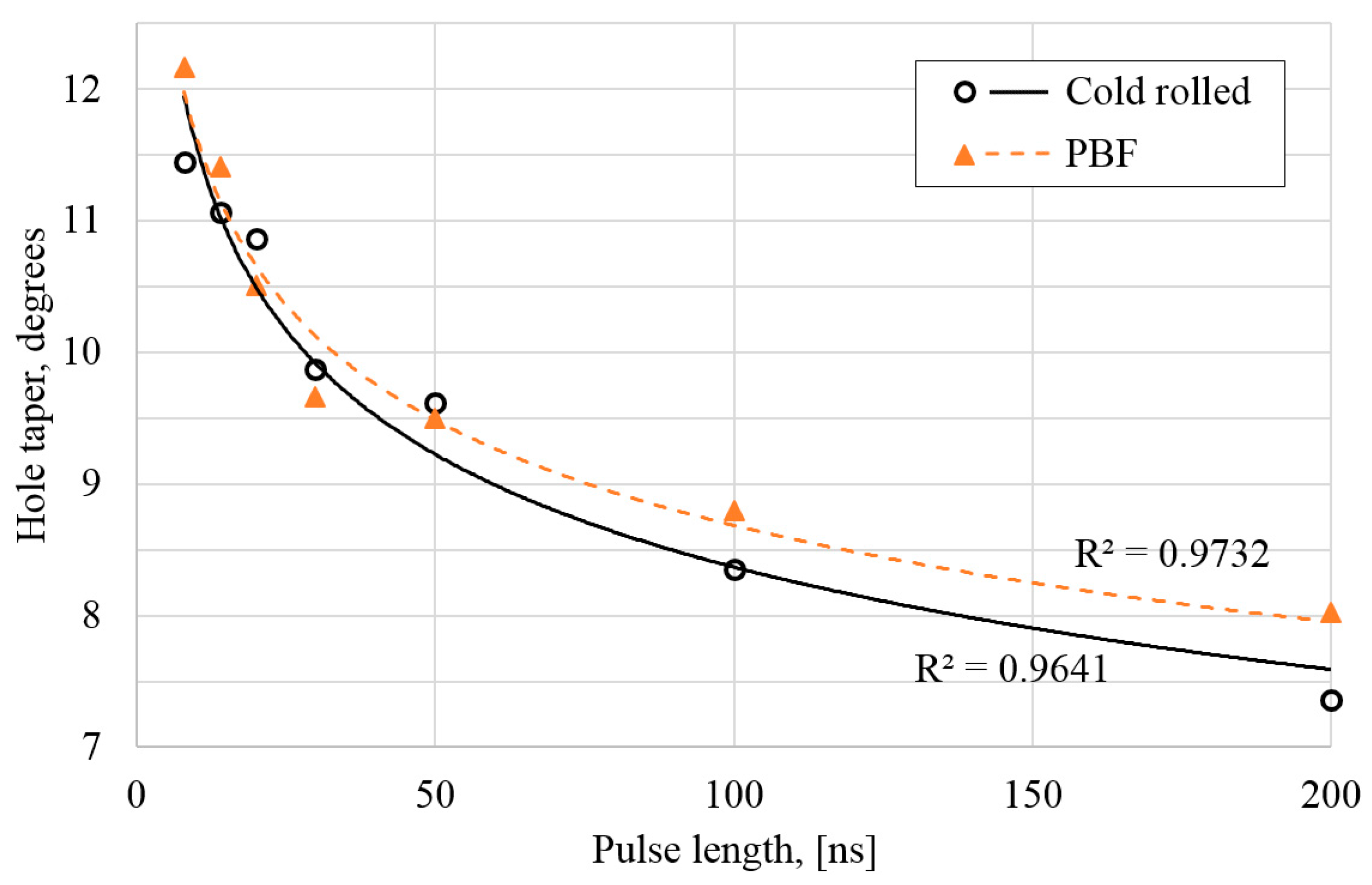

3.4. Hole Taper

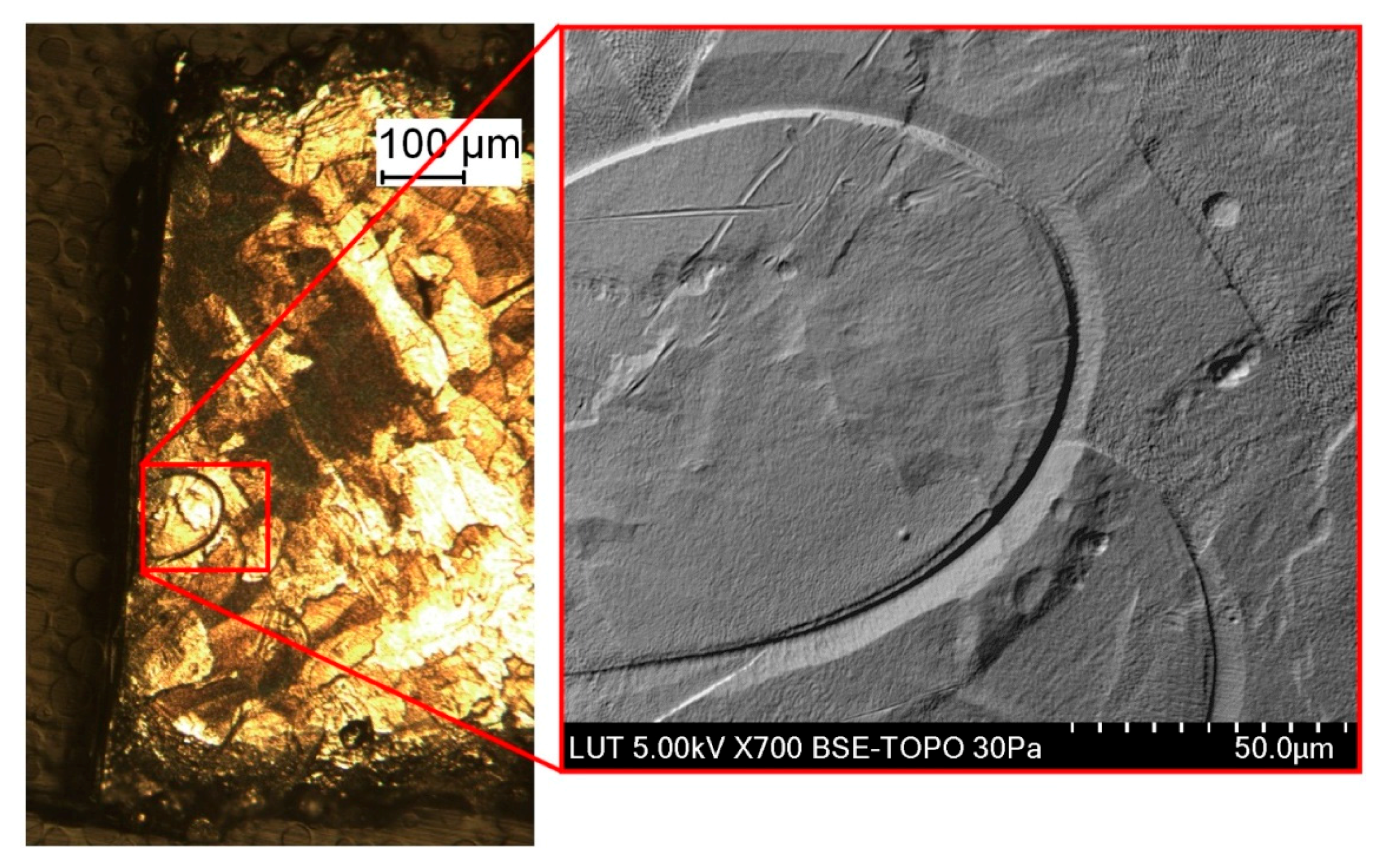

3.5. Evaluation of the Microstructures

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Schulz, W.; Eppelt, U.; Poprawe, R. Review on laser drilling I. Fundamentals, modeling, and simulation. J. Laser Appl. 2013, 24, 1–17. [Google Scholar] [CrossRef]

- Rohde, H. Drilling of Metals. In LIA Handbook of Laser Materials Processing, 1st ed.; Ready, J.F., Farson, D.F., Eds.; Magnolia Publishing Inc.: Pineville, LA, USA, 2001; pp. 474–477. ISBN 0-941463-02-8. [Google Scholar]

- Gower, M. Industrial applications of laser micromachining. Opt. Express 2000, 7, 56–67. [Google Scholar] [CrossRef] [PubMed]

- Uchtmann, H.; He, C.; Gillner, A. High precision and high aspect ratio laser drilling—Challenges and Solutions. In Proceedings of the SPIE 9741, High-Power Laser Materials Processing: Lasers, Beam Delivery, Diagnostics, and Applications V, San Francisco, CA, USA, 13 February 2016; Volume 974106, pp. 1–12. [Google Scholar]

- Weck, A.; Crawford, T.H.R.; Wilkinson, D.S.; Haugen, H.K.; Preston, J.S. Laser drilling of high aspect ratio holes in copper with femtosecond, picosecond and nanosecond pulses. Appl. Phys. A 2008, 90, 537–543. [Google Scholar] [CrossRef]

- Patwa, R.; Herfurth, H.; Flaig, R.; Christophersen, M.; Phlips, B.F. Laser Drilling for High Aspect Ratio Holes and a High Open Area Fraction for Space Applications. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics, ICALEO, San Diego, CA, USA, 19–23 October 2014; Paper No. M1101. pp. 204–210. [Google Scholar]

- Fornaroli, C.; Holtkamp, J.; Gillner, A. Laser-beam helical drilling of high quality micro holes. Phys. Procedia 2013, 41, 661–669. [Google Scholar] [CrossRef]

- Stephen, A.; Schrauf, G.; Mehrafsun, S.; Vollertsen, F. High speed laser micro drilling for aerospace applications. Procedia CIRP 2014, 24, 130–133. [Google Scholar] [CrossRef]

- Duan, W.; Wang, K.; Dong, X. Experimental characterizations of burr deposition in Nd:YAG laser drilling: A parametric study. Int. J. Adv. Des. Manuf. Technol. 2015, 76, 1529–1542. [Google Scholar] [CrossRef]

- Ghoreishi, M.; Low, D.K.Y.; Li, L. Comparative statistical analysis of hole taper and circularity in laser percussion drilling. Int. J. Mach. Tools Manuf. 2002, 42, 985–995. [Google Scholar] [CrossRef]

- Goyal, R.; Dubey, A.K. Modeling and optimization of geometrical characteristics in laser trepan drilling of titanium alloy. J. Mech. Sci. Technol. 2016, 30, 1281–1293. [Google Scholar] [CrossRef]

- Begic-Hajdarevic, D.; Bijelonja, I. Experimental and numerical Investigation of Temperature Distribution and Hole Geometry during Laser Drilling Process. Procedia Eng. 2014, 100, 384–393. [Google Scholar] [CrossRef]

- Ashkenasi, D.; Kaszemeikat, T.; Mueller, N.; Dietrich, R.; Eichler, H.J.; Illing, G. Laser Trepanning for Industrial Applications. Phys. Procedia 2011, 12, 323–331. [Google Scholar] [CrossRef]

- Jahns, D.; Kaszemeikat, T.; Mueller, N.; Ashkenasi, D.; Dietrich, R.; Eichler, H.J. Laser trepanning of stainless steel. Phys. Procedia 2013, 41, 630–635. [Google Scholar] [CrossRef]

- Li, L.; Diver, C.; Atkinson, J.; Giedl-Wagner, R.; Helml, H.J. Sequential Laser and EDM Micro-drilling for Next Generation Fuel Injection Nozzle Manufacture. CIRP Ann.-Manuf. Technol. 2006, 55, 179–182. [Google Scholar] [CrossRef]

- Uhlmann, E.; Oberschmidt, D.; Langmack, M. Complex bore holes fabricated by combined Helical Laser Drilling and Micro Electrical Discharge Machining. In Proceedings of the 28th Annual Meeting of the American Society for Precision Engineering, ASPE 2013, Saint Paul, MN, USA, 20–25 October 2013; pp. 195–199, ISBN 978-1-887706-63-6. [Google Scholar]

- Luft, A.; Franz, U.; Emsermann, A.; Kaspar, J. A study of thermal and mechanical effects on materials induced by pulsed laser drilling. Appl. Phys. A 1996, 63, 93–101. [Google Scholar] [CrossRef]

- Hidai, H.; Kuroki, Y.; Matsusaka, S.; Chiba, A.N.; Morita, N. Curved drilling via inner hole laser reflection. Precis. Eng. 2016, 46, 96–103. [Google Scholar] [CrossRef]

- Arrizubieta, I.; Lamikiz, A.; Martínez, S.; Ukar, E.; Tabernero, I.; Girot, F. Internal characterization and the hole formation mechanism in the laser percussion drilling process. Int. J. Mach. Tools Manuf. 2013, 75, 55–62. [Google Scholar] [CrossRef]

- Jackson, M.J.; O’Neill, W. Laser micro-drilling of tool steel using Nd:YAG lasers. J. Mater. Process. Technol. 2003, 142, 517–525. [Google Scholar] [CrossRef]

- Voisey, K.T.; Kudesia, S.S.; Rodden, W.S.O.; Hand, D.P.; Jones, J.D.C.; Clyne, T.W. Melt ejection during laser drilling of metals. Mater. Sci. Eng. 2003, A356, 414–424. [Google Scholar] [CrossRef]

- Ho, C.; He, J.; Liao, T. On-Line Estimation of Laser-Drilled Hole Depth Using a Machine Vision Method. Sensors 2012, 12, 10148–10162. [Google Scholar] [CrossRef] [PubMed]

- Casalino, G.; Campanelli, S.L.; Contuzzi, N.; Ludovico, A.D. Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt. Laser Technol. 2015, 65, 151–158. [Google Scholar] [CrossRef]

- Carter, L.N.; Martin, C.; Withers, P.J.; Attallah, M.M. The influence of the laser scan strategy on grain structure and cracking behavior in SLM powder-bed fabricated nickel superalloy. J. Alloys Compd. 2014, 615, 338–347. [Google Scholar] [CrossRef]

- Stainless Steel—1.4542 (Stainless 17.4) Datasheet (Default) by 3D Alchemy. Available online: https://www.3d-alchemy.co.uk/assets/datasheets/3d-Alchemy-Stainless%20Steel%201-4542%20-%2001_13.pdf (accessed on 25 August 2017).

- 1.4542 Steel Datasheet by Lucefin. Available online: http://www.lucefin.com/wp-content/files_mf/1.4542pha63062.pdf (accessed on 25 August 2017).

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation into the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2014, 76, 869–879. [Google Scholar] [CrossRef]

- Spierings, A.B.; Levy, G. Comparison of density of stainless steel 316L parts produced with selective laser melting using different powder grades. In Proceedings of the Twentieth Annual International Solid Freeform Fabrication (SFF) Symposium, Austin, TX, USA, 3–5 August 2009; pp. 342–353. [Google Scholar]

- Think3d Web Page. Available online: https://www.additively.com/en/material/from/eos/eos-stainless-steel-316l (accessed on 25 August 2017, requires login).

- Outokumpu Data Sheet for 316 and 316L. Available online: http://www.outokumpu.com/SiteCollectionDocuments/Datasheet-316-316L-imperial-hpsa-outokumpu-en-americas.pdf (accessed on 25 August 2017).

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. B 2014, 45, 6260–6270. [Google Scholar] [CrossRef]

- Li, L.; Low, D.K.Y.; Ghoreshi, M.; Crookall, J.R. Hole Taper Characterisation and Control in Laser Percussion Drilling. CIRP Ann.-Manuf. Technol. 2002, 51, 153–156. [Google Scholar] [CrossRef]

- Chickov, B.N.; Momma, C.; Nolte, S.; von Alvensleben, F.; Tünnermann, A. Femtosecond, picosecond and nanosecond laser ablation of solids. Appl. Phys. A 1996, 63, 109–115. [Google Scholar] [CrossRef]

- Von Allmen, M. Laser drilling velocity in metals. J. Appl. Phys. 1976, 47, 5460–5463. [Google Scholar] [CrossRef]

- Manninen, M.; Hirvimäki, M.; Poutiainen, I.; Salminen, A. Effect of Pulse Length on Engraving Efficiency in Nanosecond Pulsed Laser Engraving of Stainless Steel. Metall. Mater. Trans. B 2015, 46, 2129–2136. [Google Scholar] [CrossRef]

- British Stainless Steel Association. Available online: http://www.bssa.org.uk/topics.php?article=140 (accessed on 15 April 2017).

- Bandyopadhyay, S.; Sarin Sundar, J.K.; Sundararajan, G.; Joshi, S.V. Geometrical features and metallurgical characteristics of Nd:YAG laser drilled holes in thick IN718 and Ti-6Al-4V sheets. J. Mater. Process. Technol. 2002, 127, 83–95. [Google Scholar] [CrossRef]

| Material | C | Cr | Ni | Mo | Mn | Cu | Si | P | S | N | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CR1 1 | <0.03 | 17.2 | 10.1 | 2.1 | <2 | <0.5 | <0.75 | <0.045 | <0.03 | <0.1 | bal. |

| CR2 2 | - | 18.4 | 9.5 | 2.3 | 2.1 | - | 0.6 | - | - | - | 66.7 |

| PBF1 3 | <0.03 | 17–19 | 13–15 | 2.25–3 | <2 | <0.5 | <0.75 | <0.025 | <0.01 | <0.1 | bal. |

| PBF2 4 | - | 18.4 | 11.4 | 2.4 | 1.3 | - | 0.7 | - | - | - | 65.5 |

| Material | Ultimate Tensile Strength, MPa | Hardness, Rockwell B | Density, g/cm3 | Coef. of Thermal Exp., °C−1 | Thermal Conductivity, W/(m °C) | Heat Capacity, J/(g °C) |

|---|---|---|---|---|---|---|

| 316L | 586 | 81 | 7.9 | 1.602 × 10−5 | 15.1 | 0.502 |

| 3D printed 316L | 640 ± 50 (horizontal) 540 ± 55 (vertical) | 85 | min. 7.9 | - | - | - |

| # | Pulse Length, ns | Pulse Energy, mJ | PRR, kHz | Pulse Overlap, % | Beam Speed, mm/s | Waveform |

|---|---|---|---|---|---|---|

| 1 | 8 | 0.100 | 200 | 75 | 2000 |  |

| 2 | 14 | 0.160 | 125 | 60 | 2000 |  |

| 3 | 20 | 0.190 | 105 | 52 | 2000 |  |

| 4 | 30 | 0.235 | 85 | 50 | 1700 |  |

| 5 | 50 | 0.333 | 60 | 50 | 1200 |  |

| 6 | 100 | 0.500 | 40 | 50 | 800 |  |

| 7 | 200 | 1.000 | 20 | 50 | 400 |  |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manninen, M.; Hirvimäki, M.; Matilainen, V.-P.; Salminen, A. Comparison of Laser-Engraved Hole Properties between Cold-Rolled and Laser Additive Manufactured Stainless Steel Sheets. Appl. Sci. 2017, 7, 913. https://doi.org/10.3390/app7090913

Manninen M, Hirvimäki M, Matilainen V-P, Salminen A. Comparison of Laser-Engraved Hole Properties between Cold-Rolled and Laser Additive Manufactured Stainless Steel Sheets. Applied Sciences. 2017; 7(9):913. https://doi.org/10.3390/app7090913

Chicago/Turabian StyleManninen, Matti, Marika Hirvimäki, Ville-Pekka Matilainen, and Antti Salminen. 2017. "Comparison of Laser-Engraved Hole Properties between Cold-Rolled and Laser Additive Manufactured Stainless Steel Sheets" Applied Sciences 7, no. 9: 913. https://doi.org/10.3390/app7090913