An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties

Abstract

:1. Introduction

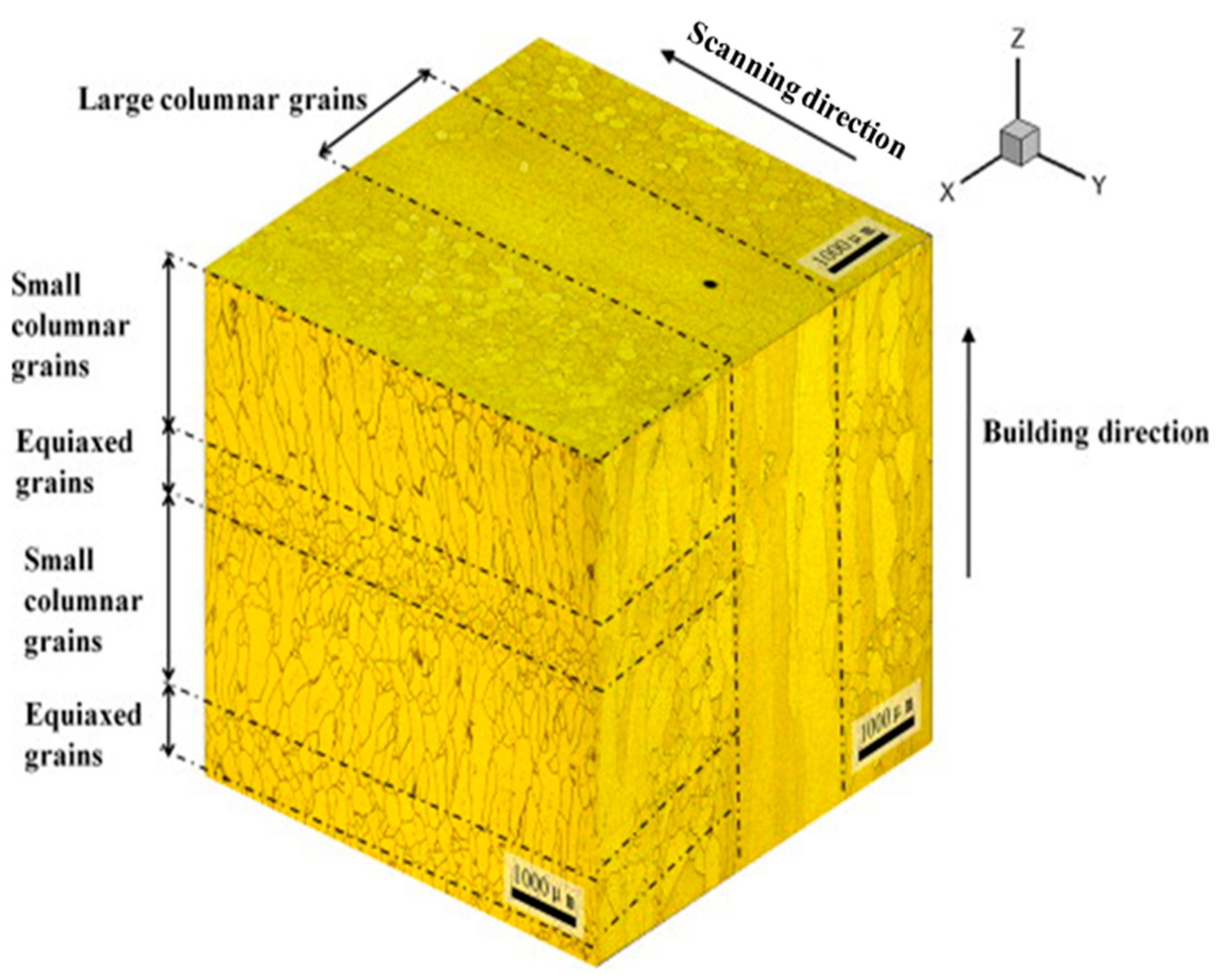

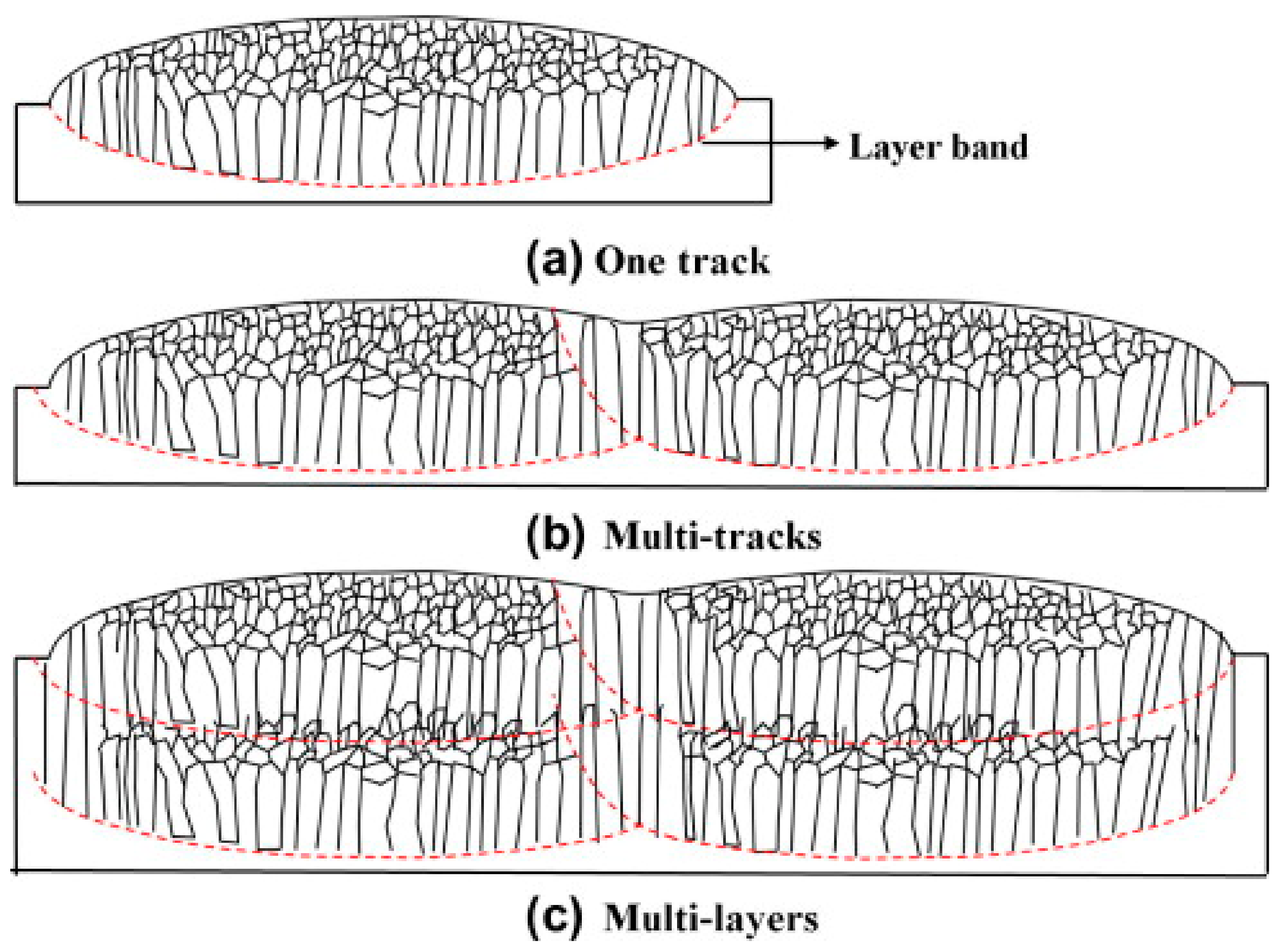

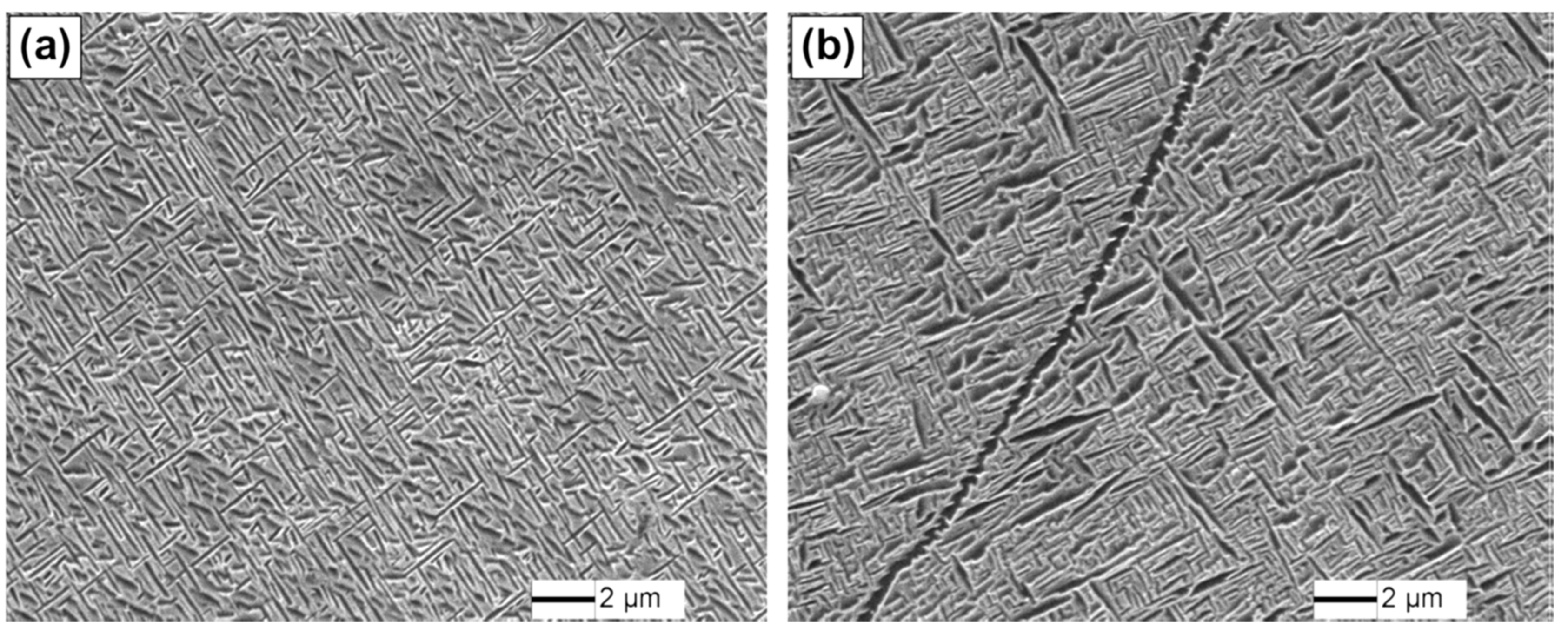

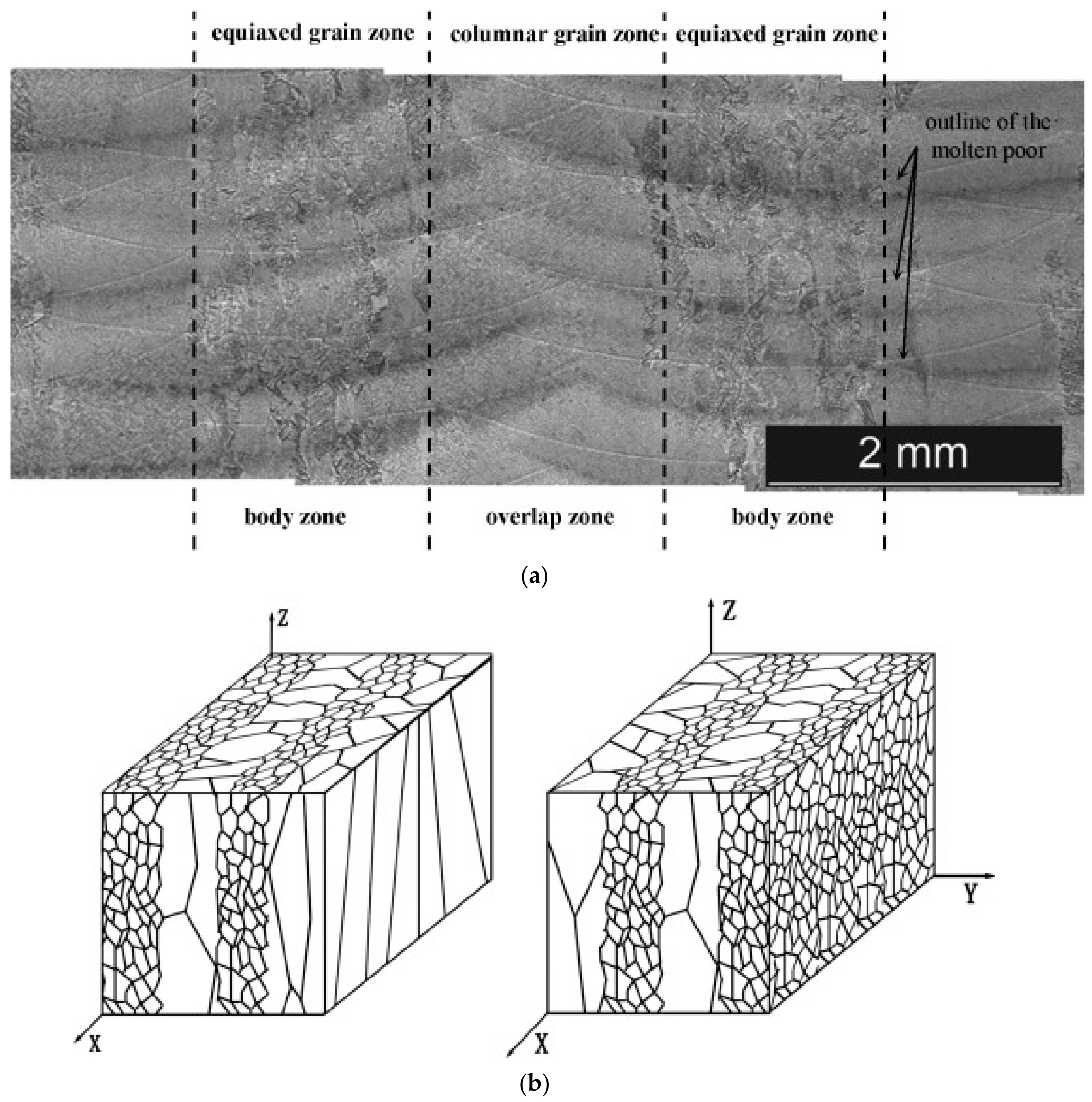

2. Microstructure

3. Mechanical Properties

4. Conclusions

- Finding a proper combination of process parameters such as laser power, powder feeding rate, and Z step is vital for successful deposition of Ti alloys.

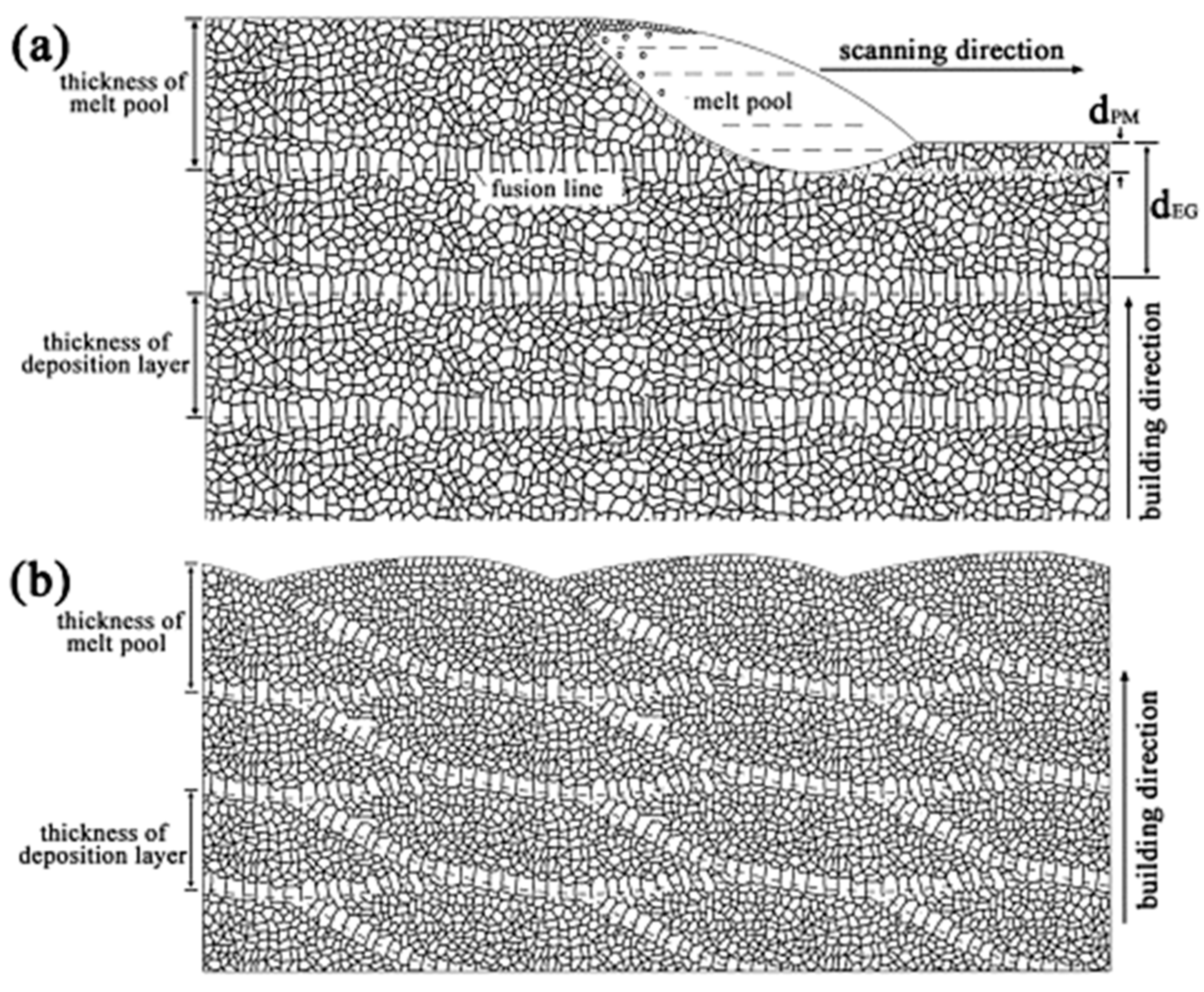

- Two different mechanisms of solidification (heterogeneous nucleation of equiaxed grains on partially melted particles and/or epitaxial growth of parent grains) can take place in the melt pool during the DED process and define the final microstructures.

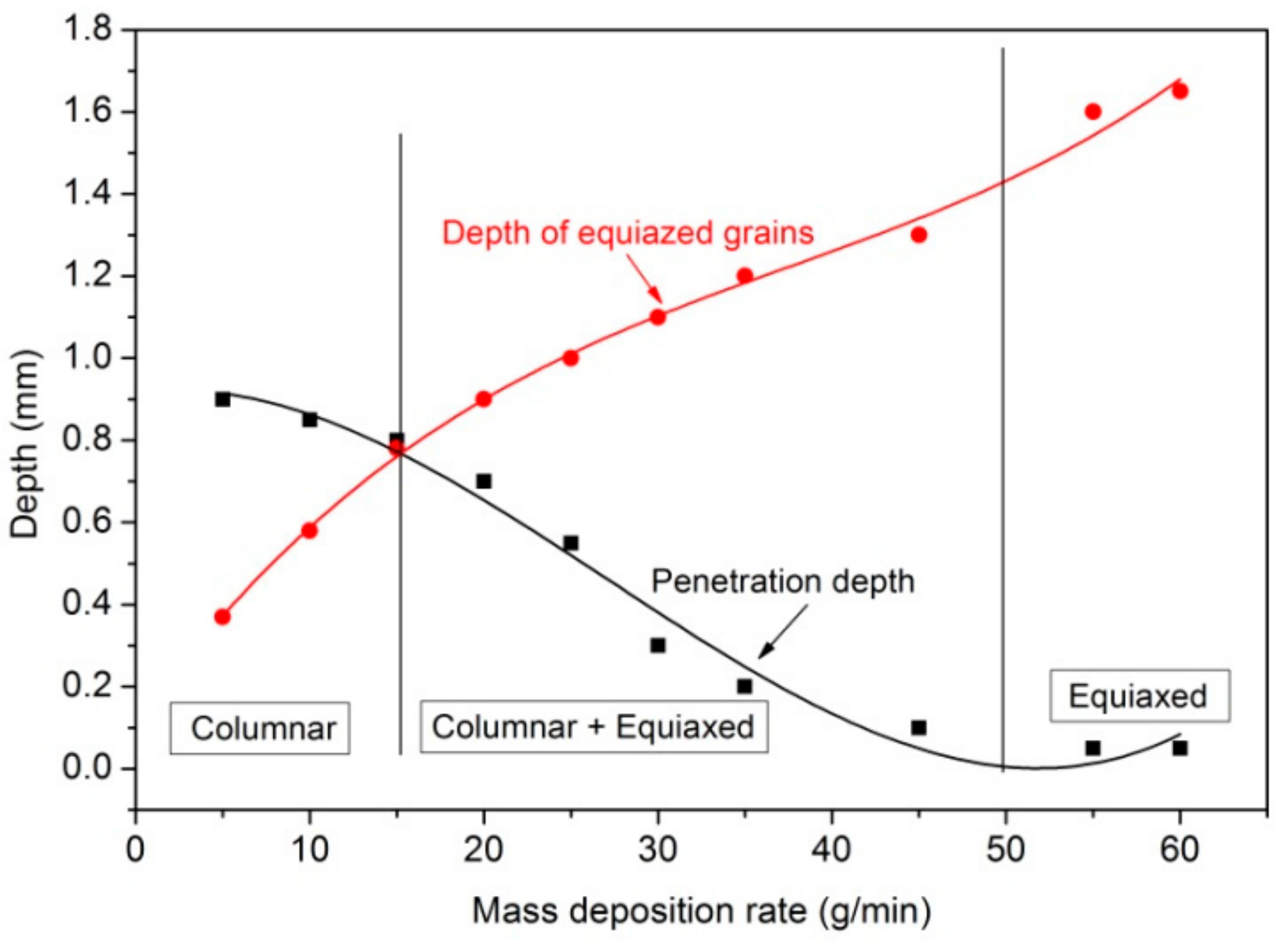

- At constant parameters of the laser manufacturing process, the mass deposition rate plays a key role in the thermal gradient, heterogeneous nucleation sites, and penetration melting depth, determining the final microstructure of the DED parts. As a matter of fact, low specific mass deposition rate promotes the formation of columnar grains, whereas with high specific mass deposition rates fine near equiaxed grains are the predominate microstructure.

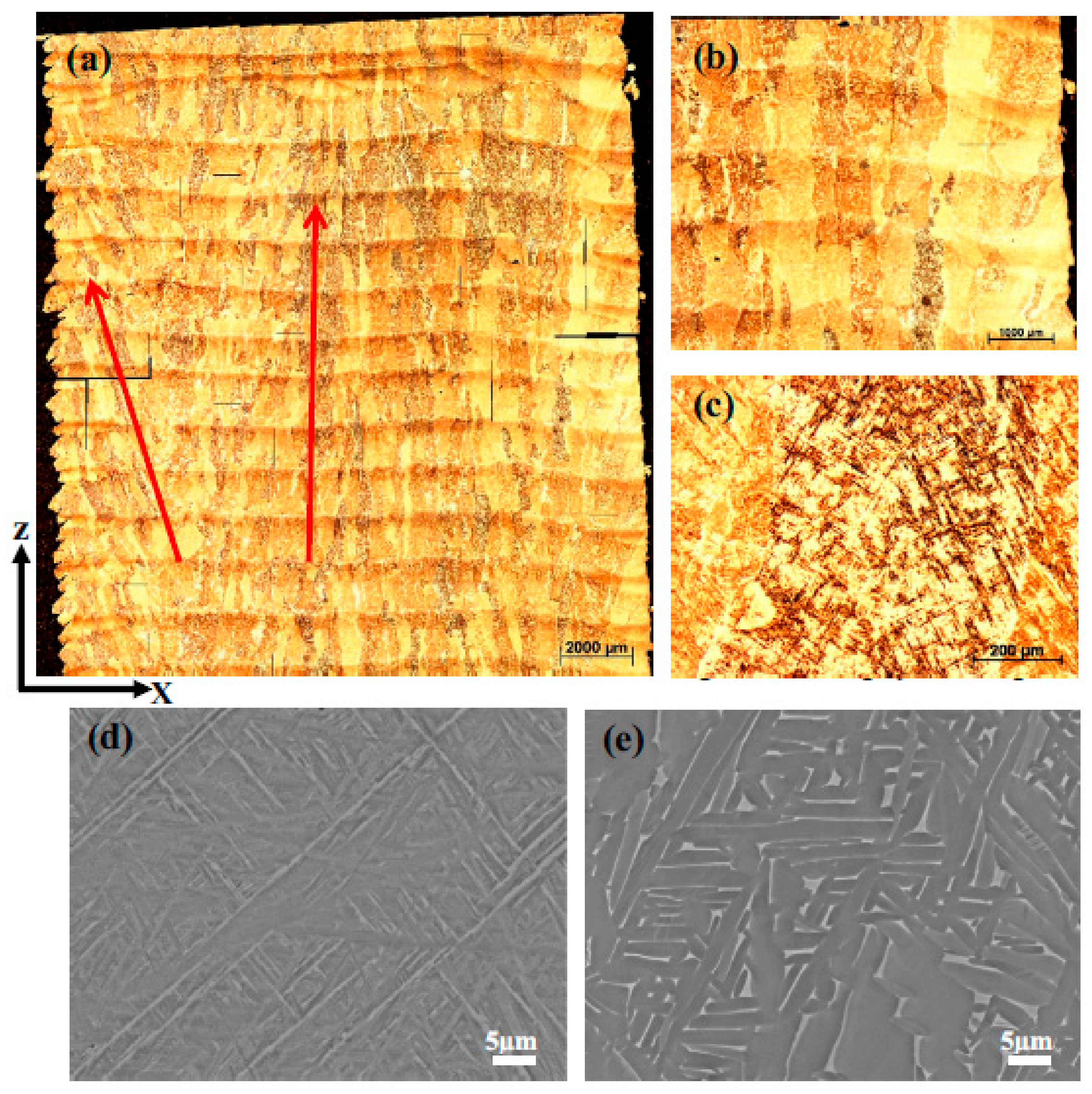

- The DEDed titanium alloys have an ultrafine basket-weave microstructure and columnar grains consist of a much more uniform microstructure in comparison with equiaxed grains.

- The DEDed titanium parts exhibit higher strength and lower ductility values with respect to the conventionally processed parts.

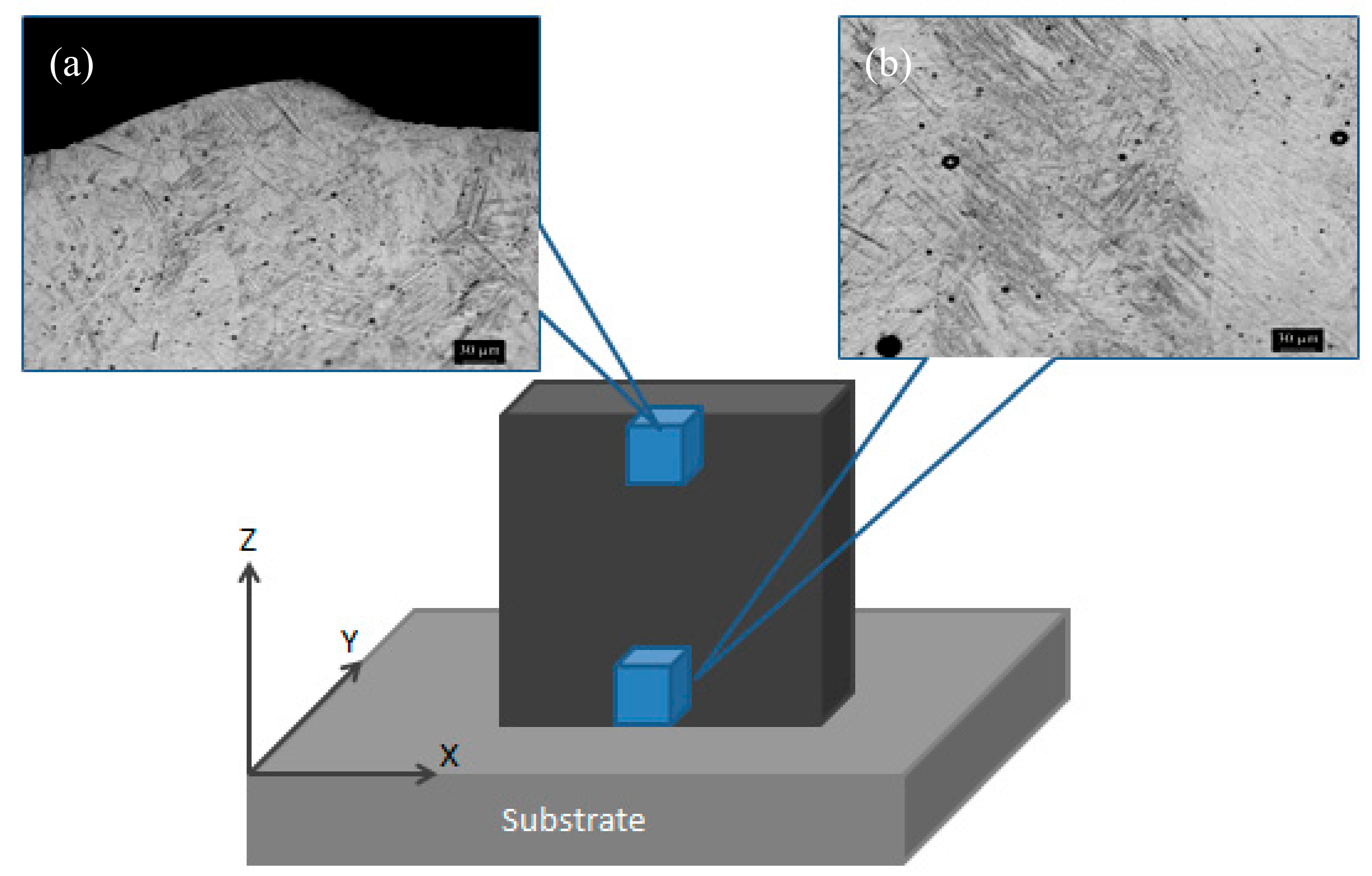

- Anisotropy in the tensile characteristics of DED parts is widely detected: generally samples deposited in the X-direction show higher tensile strengths with respect to the samples deposited in the Y-direction.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Liou, F.; Slattery, K.; Kinsella, M.; Newkirk, J.; Chou, H.; Landers, R. Applications of a hybrid manufacturing process for fabrication of metallic structures. Rapid Prototyp. J. 2007, 13, 236–244. [Google Scholar] [CrossRef]

- Merklein, M.; Junker, D.; Schaub, A.; Neubauer, F. Hybrid additive manufacturing technologies—An analysis regarding potentials and applications. Phys. Procedia 2016, 83, 549–559. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q.; Lu, J.; Liu, Y.; Shi, W. Selective laser melting-wire arc additive manufacturing hybrid fabrication of Ti-6Al-4V alloy: Microstructure and mechanical properties. Mater. Sci. Eng. A 2017, 684, 196–204. [Google Scholar] [CrossRef]

- Essink, W.P.; Flynn, J.M.; Goguelin, S.; Dhokia, V. Hybrid ants: A new approach for geometry creation for additive and hybrid manufacturing. Procedia CIRP 2017, 60, 199–204. [Google Scholar] [CrossRef]

- Du, W.; Bai, Q.; Zhang, B. A Novel Method for Additive/Subtractive Hybrid Manufacturing of Metallic Parts. Procedia Manuf. 2016, 5, 1018–1030. [Google Scholar] [CrossRef]

- Shim, D.; Baek, G.; Seo, J.; Shin, G.; Kim, K.; Lee, K. Effect of layer thickness setting on deposition characteristics in direct energy deposition (DED) process. Opt. Laser Technol. 2016, 86, 69–78. [Google Scholar] [CrossRef]

- Mazzucato, F.; Tusacciu, S.; Lai, M.; Biamino, S.; Lombardi, M.; Valente, A. Monitoring Approach to Evaluate the Performances of a New Deposition Nozzle Solution for DED Systems. Technologies 2017, 5, 29. [Google Scholar] [CrossRef]

- Weerasinghe, V.M.; Steen, W. Laser cladding by powder injection. In Proceedings of the 1st International Conference on Lasers in Manufacturing, Brighton, UK, 1–3 November 1983. [Google Scholar]

- Weerasinghe, V.M.; Steen, W.M. Laser cladding with blown powder. Met. Constr. 1987, 19, 581–585. [Google Scholar]

- Mazumder, J.; Choi, J.; Nagarathnam, K.; Koch, J.; Hetzner, D. The direct metal deposition of H13 tool steel for 3-D components. JOM 1997, 49, 55–60. [Google Scholar] [CrossRef]

- Milewski, J.O.; Lewis, G.K.; Thoma, D.J.; Keel, G.I.; Nemec, R.B.; Reinert, R.A. Directed light fabrication of a solid metal hemisphere using 5-axis powder deposition. J. Mater. Process. Technol. 1998, 75, 165–172. [Google Scholar] [CrossRef]

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.S.; Voice, W. Microstructures of laser-deposited Ti-6Al-4V. Mater. Des. 2004, 25, 137–144. [Google Scholar] [CrossRef]

- McLean, M.A.; Shannon, G.J.; Steen, W.M. Laser Direct Casting high nickel alloy components. Adv. Powder Metall. Part. Mater. 1997, 3, 21–23. [Google Scholar]

- Arcella, F.G.; Froes, F.H. Producing titanium aerospace components from powder using laser forming. JOM 2000, 52, 28–30. [Google Scholar] [CrossRef]

- Fessler, J.R.; Merz, R.; Nickel, A.H.; Prinz, F.B.; Weiss, L. Laser deposition of metals for shape deposition manufacturing. In Proceedings of the Solid Freeform Fabrication Symposium, Austin, TX, USA, 12 August 1996. [Google Scholar]

- Keicher, D.M.; Miller, W.D. LENSTM moves beyond RP to direct fabrication. Met. Powder Rep. 1998, 53, 26–28. [Google Scholar]

- Shamsaei, N.; Yadollahi, A.; Bian, L.; Thompson, S.M. An overview of Direct Laser Deposition for additive manufacturing; Part II: Mechanical behavior, process parameter optimization and control. Addit. Manuf. 2015, 8, 12–35. [Google Scholar] [CrossRef]

- Choi, J. Process and Properties Control in Laser Aided Direct Metal/Materials Deposition Process. In Proceedings of the ASME 2002 International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 17–22 November 2002. [Google Scholar]

- Dwivedi, R.; Kovacevic, R. An expert system for generation of machine inputs for laser-based multi-directional metal deposition. Int. J. Mach. Tools Manuf. 2006, 46, 1811–1822. [Google Scholar] [CrossRef]

- Dwivedi, R.; Kovacevic, R. Process Planning for Multi-Directional Laser-Based Direct Metal Deposition. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2005, 219, 695–707. [Google Scholar] [CrossRef]

- Zhang, J.; Liou, F. Adaptive Slicing for a Multi-Axis Laser Aided Manufacturing Process. J. Mech. Des. 2004, 126, 254–261. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Scanning speed and powder flow rate influence on the properties of laser metal deposition of titanium alloy. Int. J. Adv. Manuf. Technol. 2017. [Google Scholar] [CrossRef]

- Tan, X.; Kok, Y.; Tan, Y.J.; Descoins, M.; Mangelinck, D.; Tor, S.B.; Leong, K.F.; Chua, C.K. Graded microstructure and mechanical properties of additive manufactured Ti-6Al-4V via electron beam melting. Acta Mater. 2015, 97, 1–16. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, D.; Tian, X.; Tang, H.; Wang, H. Characterization of microstructure and mechanical properties of laser melting deposited Ti-6.5Al-3.5-1.5Zr-0.3Si titanium alloy. Mater. Des. 2014, 56, 445–453. [Google Scholar] [CrossRef]

- Lin, J.; Lv, Y.; Liu, Y.; Sun, Z.; Wang, K.; Li, Z.; Wu, Y. Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment. J. Mech. Behav. Biomed. Mater. 2017, 69, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Brandl, E.; Schoberth, A.; Leyens, C. Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mater. Sci. Eng. A 2012, 532, 295–307. [Google Scholar] [CrossRef]

- Liu, C.M.; Tian, X.J.; Tang, H.B.; Wang, H.M. Microstructural characterization of laser melting deposited Ti-5Al-5Mo-5V-1Cr-1Fe near b titanium alloy. J. Alloys Compd. 2013, 572, 17–24. [Google Scholar] [CrossRef]

- El Kadiri, H.; Wang, L.; Horstemeyer, M.F.; Yassar, R.S.; Berry, J.T.; Felicelli, S.; Wang, P.T. Phase transformations in low-alloy steel laser deposits. Mater. Sci. Eng. A 2008, 494, 10–20. [Google Scholar] [CrossRef]

- Xue, Y.; Pascu, A.; Horstemeyer, M.F.; Wang, L.; Wang, P.T. Microporosity effects on cyclic plasticity and fatigue of LENSTM-processed steel. Acta Mater. 2010, 58, 4029–4038. [Google Scholar] [CrossRef]

- Blackwell, P.L. The mechanical and microstructural characteristics of laser-deposited IN718. J. Mater. Process. Technol. 2005, 170, 240–246. [Google Scholar] [CrossRef]

- Paul, C.P.; Ganesh, P.; Mishra, S.K.; Bhargava, P.; Negi, J.; Nath, A.K. Investigating laser rapid manufacturing for Inconel-625 components. Opt. Laser Technol. 2007, 39, 800–805. [Google Scholar] [CrossRef]

- Amsterdam, E.; Kool, G.A. High Cycle Fatigue of Laser Beam Deposited Ti-6Al-4V and Inconel 718. In ICAF 2009, Bridging the Gap between Theory and Operational Practice: Proceedings of the 25th Symposium of the International Committee on Aeronautical Fatigue, Rotterdam, The Netherlands, 27–29 May 2009; Bos, M.J., Ed.; Springer: Dordrecht, The Netherlands, 2009. [Google Scholar]

- Dinda, G.P.; Dasgupta, A.K.; Mazumder, J. Laser aided direct metal deposition of Inconel 625 superalloy: Microstructural evolution and thermal stability. Mater. Sci. Eng. A 2009, 509, 98–104. [Google Scholar] [CrossRef]

- Ganesh, P.; Kaul, R.; Paul, C.P.; Tiwari, P.; Rai, S.K.; Prasad, R.C.; Kukreja, L.M. Fatigue and fracture toughness characteristics of laser rapid manufactured Inconel 625 structures. Mater. Sci. Eng. A 2010, 527, 7490–7497. [Google Scholar] [CrossRef]

- Hedges, M.; Calder, N. Near net shape rapid manufacture & repair by LENS. In Proceedings of the NATO AVT-139 Meeting on Cost Effective Manufacture via Net Shape Processing, Amsterdam, The Netherlands, 15–19 May 2006. [Google Scholar]

- Pei, Y.T.; Hosson, J.T. De Functionally graded materials produced by laser cladding. Acta Mater. 2000, 48, 2617–2624. [Google Scholar] [CrossRef]

- Liu, W.; DuPont, J.N. Fabrication of functionally graded TiC/Ti composites by Laser Engineered Net Shaping. Scr. Mater. 2003, 48, 1337–1342. [Google Scholar] [CrossRef]

- Yan, L.; Chen, X.; Li, W.; Newkirk, J.; Liou, F.; Newkirk, J.; Liou, F. Direct laser deposition of Ti-6Al-4V from elemental powder blends. J. Alloys Compd. 2016, 22, 810–816. [Google Scholar] [CrossRef]

- Sing, S.L.; Yeong, W.Y.; Wiria, F.E. Selective laser melting of titanium alloy with 50 wt % tantalum: Microstructure and mechanical properties. J. Alloys Compd. 2016, 660, 461–470. [Google Scholar] [CrossRef]

- Costa, L.; Vilar, R. Laser powder deposition. Rapid Prototyp. J. 2009, 15, 264–279. [Google Scholar] [CrossRef]

- Selcuk, C. Laser metal deposition for powder metallurgy parts. Powder Metall. 2011, 54, 94–99. [Google Scholar]

- Gäumann, M.; Henry, S.; Cléton, F.; Wagnière, J.-D.; Kurz, W. Epitaxial laser metal forming: Analysis of microstructure formation. Mater. Sci. Eng. A 1999, 271, 232–241. [Google Scholar] [CrossRef]

- Xue, L.; Chen, J.; Islam, M.; Pritchard, J. Laser consolidation of Ni-base IN-738superalloy for repairing gas turbine blades. In Proceedings of the International Congress on Applications of Lasers & Electro-Optics (ICALEO), Dearborn, MI, USA, 2–5 October 2000. [Google Scholar]

- Baskes, G.; Kreutz, E.W.; Gasser, A.; Wissenbach, K.; Poprawe, R. Laser-shapereconditioning and manufacturing of tools and machine parts. In Proceedings of the Laser Materials Processing Conference ICALEO’98, Orlando, FL, USA, 16–19 November 1998. [Google Scholar]

- Mazumder, J.; Dutta, D.; Kikuchi, N.; Ghosh, A. Closed loop direct metal deposition: Art to part. Opt. Lasers Eng. 2000, 34, 397–414. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Thermal process maps for predicting solidification microstructure in laser fabrication of thin-wall structures. J. Mater. Process. Technol. 2006, 178, 135–142. [Google Scholar] [CrossRef]

- Bontha, S.; Klingbeil, N.W.; Kobryn, P.A.; Fraser, H.L. Effects of process variables and size-scale on solidification microstructure in beam-based fabrication of bulky 3D structures. Mater. Sci. Eng. A 2009, 513, 311–318. [Google Scholar] [CrossRef]

- Peters, M. Titanium and Titanium Alloys; Leyens, C., Peters, M., Eds.; WILEY-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Kong, H.; Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S. Laser Metal Deposition of Ti6Al4V: A Study on the Effect of Laser Power on Microstructure and Microhardness. In Proceedings of the International Multi Conference of Enginners and Computer Scientist 2013 Volume II, IMECS 2013, Hong Kong, China, 13–15 March 2013; pp. 6–11. [Google Scholar]

- Dutta, B.; Froes, F.H.S. The Additive Manufacturing (AM) of titanium alloys. Met. Powder Rep. 2017, 72, 1–11. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Aversa, A.; Marchese, G.; Lombardi, M.; Biamino, S.; Ugues, D.; Manfredi, D. Additive manufacturing of titanium alloys in the biomedical field: Processes, properties and applications. J. Appl. Biomater. Funct. Mater. 2017, in press. [Google Scholar]

- Vilar, R. Laser cladding. Laser Appl. 2001, 11, 64–79. [Google Scholar] [CrossRef]

- Pouzet, S.; Peyre, P.; Gorny, C.; Castelnau, O.; Baudin, T.; Brisset, F.; Colin, C.; Gadaud, P. Additive layer manufacturing of titanium matrix composites using the direct metal deposition laser process. Mater. Sci. Eng. A 2016, 677, 171–181. [Google Scholar] [CrossRef]

- Carroll, B.E.; Palmer, A.; Beese, A.M. Anisotropic tensile behavior of Ti–6Al–4V components fabricated with directed energy deposition additive manufacturing. Acta Mater. 2015, 87, 309–320. [Google Scholar] [CrossRef]

- Åkerfeldt, P.; Pederson, R.; Antti, M. A fractographic study exploring the relationship between the low cycle fatigue and metallurgical properties of laser metal wire deposited Ti-6Al-4V. Int. J. Fatique 2016, 87, 245–256. [Google Scholar] [CrossRef]

- Mok, S.H.; Bi, G.; Folkes, J.; Pashby, I. Deposition of Ti-6Al-4V using a high power diode laser and wire, Part I: Investigation on the process characteristics. Surf. Coat. Technol. 2008, 202, 3933–3939. [Google Scholar] [CrossRef]

- Baufeld, B.; Van der Biest, O.; Gault, R. Additive manufacturing of Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. Mater. Des. 2010, 31, S106–S111. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Role of geometry on properties of additively manufactured Ti-6Al-4V structures fabricated using laser based directed energy deposition. JMADE 2016, 106, 482–494. [Google Scholar] [CrossRef]

- Åkerfeldt, P.; Antti, M.; Pederson, R. Influence of microstructure on mechanical properties of laser metal wire-deposited Ti-6Al-4V. Mater. Sci. Eng. A 2016, 674, 428–437. [Google Scholar] [CrossRef]

- Baufeld, B.; Brandl, E.; Van der Biest, O. Wire based additive layer manufacturing: Comparison of microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser-beam deposition and shaped metal deposition. J. Mater. Process. Technol. 2011, 211, 1146–1158. [Google Scholar] [CrossRef]

- Hofmeister, W.; Griffith, M.; Ensz, M.; Smugeresky, J. Melt pool imaging for con-trol of LENS processing. In Proceedings of the Conference on Metal Powder Deposition for Rapid Manufacturing, San Antonio, TX, USA, 8–10 April 2002; pp. 188–194. [Google Scholar]

- Hofmeister, W.; Wert, M.; Smugeresky, J.; Philliber, J.A.; Griffith, M.; Ensz, M. Investigation of solidification in the laser engineered net shaping (LENS) process. JOM 1999, 51, 1–6. [Google Scholar]

- Wang, H.M.; Zhang, S.Q.; Wang, X.M. Direct, Progress and challenges of laser manufacturing of large titanium structural components. Chin. J. Lasers 2009, 36, 3204–3209. [Google Scholar] [CrossRef]

- Kobryn, P.A.; Semiatin, S.L. Mechanical properties of laser-deposited Ti-6Al-4V. In Proceedings of the Solid Freeform Fabrication, Austin, TX, USA, 6–8 August 2001. [Google Scholar]

- Tian, X.J.; Zhang, S.Q.; Li, A.; Wang, H.M. Effect of annealing temperature on the notch impact toughness of a laser melting deposited titanium alloy Ti-4Al-1.5Mn. Mater. Sci. Eng. A 2010, 527, 1821–1827. [Google Scholar] [CrossRef]

- Qu, H.P.; Wang, H.M. Microstructure and mechanical properties of laser melting deposited γ-TiAl intermetallic alloys. Mater. Sci. Eng. A 2007, 466, 187–194. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, S.Q.; Li, A.; Wang, H.M. Microstructure and tensile properties of laser melting deposited TiC/TA15 titanium matrix composites. J. Alloys Compd. 2009, 485, 156–162. [Google Scholar] [CrossRef]

- Chai, L.; Luan, B.; Murty, K.L.; Liu, Q. Effect of predeformation on microstructural evolution of a Zr alloy during 550–700 °C aging after β quenching. Acta Mater. 2013, 61, 3099–3109. [Google Scholar] [CrossRef]

- Dinda, G.P.; Song, L.; Mazumder, J. Fabrication of Ti-6Al-4V Scaffolds by Direct Metal Deposition. Metall. Mater. Trans. A 2008, 39, 2914–2922. [Google Scholar] [CrossRef]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comparison of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef]

- Wang, F.; Mei, J.; Wu, X. Microstructure study of direct laser fabricated Ti alloys using powder and wire. Appl. Surf. Sci. 2006, 253, 1424–1430. [Google Scholar] [CrossRef]

- Baufeld, B. Effect of deposition parameters on mechanical properties of shaped metal deposition parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 126–136. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and Mechanical Properties of Wire and Arc Additive Manufactured Ti-6Al-4V. Metall. Mater. Trans. A 2013, 44, 968–997. [Google Scholar] [CrossRef]

- Ren, H.S.; Liu, D.; Tang, H.B.; Tian, X.J.; Zhu, Y.Y.; Wang, H.M. Microstructure and mechanical properties of a graded structural material. Mater. Sci. Eng. A 2014, 611, 362–369. [Google Scholar] [CrossRef]

- Liang, Y.-J.; Liu, D.; Wang, H.-M. Microstructure and mechanical behavior of commercial purity Ti/Ti-6Al-2Zr-1Mo-1V structurally graded material fabricated by laser additive manufacturing. Scr. Mater. 2014, 74, 80–83. [Google Scholar] [CrossRef]

- Qu, H.P.; Li, P.; Zhang, S.Q.; Li, A.; Wang, H.M. Microstructure and mechanical property of laser melting deposition (LMD) Ti/TiAl structural gradient material. Mater. Des. 2010, 31, 574–582. [Google Scholar] [CrossRef]

- Sun, X.; Liu, D.; Tang, H.; Wang, H. Solid-state phase transformation and microstructure of laser direct manufactured TC17 titanium alloy components. Rare Met. Mater. Eng. 2013, 42, 724–729. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T. Scanning Speed Influence on the Microstructure and Micro hardness Properties of Titanium Alloy Produced by Laser Metal Deposition Process. Mater. Today Proc. 2017, 4, 5206–5214. [Google Scholar] [CrossRef]

- Qiu, C.; Ravi, G.A.; Attallah, M.M. Microstructural control during direct laser deposition of a β-titanium alloy. Mater. Des. 2015, 81, 21–30. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, J.; Lin, X.; Tan, H.; Huang, W.D. Grain morphology control and texture characterization of laser solid formed Ti6Al2Sn2Zr3Mo1.5Cr2Nb titanium alloy. J. Mater. Process. Technol. 2016, 238, 202–211. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Development of strength-hardness relationships in additively manufactured titanium alloys. Mater. Sci. Eng. A 2017, 693, 214–224. [Google Scholar] [CrossRef]

- Gharbi, M.; Peyre, P.; Gorny, C.; Carin, M.; Morville, S.; Masson, P.L.; Carron, D.; Fabbro, R. Influence of various process conditions on surface finishes induced by the direct metal deposition laser technique on a Ti-6Al-4V alloy. J. Mater. Process. Technol. 2013, 213, 791–800. [Google Scholar] [CrossRef] [Green Version]

- Blackwell, P.L.; Wisbey, A. Laser-aided manufacturing technologies; their application to the near-net shape forming of a high-strength titanium alloy. J. Mater. Process. Technol. 2005, 170, 268–276. [Google Scholar] [CrossRef]

- Liu, Z.; Qin, Z.-X.; Liu, F.; Lu, X.; Wang, H.-M. The microstructure and mechanical behaviors of the Ti-6.5Al-3.5Mo-1.5Zr-0.3Si alloy produced by laser melting deposition. Mater. Charact. 2014, 97, 132–139. [Google Scholar] [CrossRef]

- Fu, H.Z.; Guo, J.J.; Liu, L.; Li, J.S. Directional Solidification and Processing of Advanced Materials, 1st ed.; Science Press: Beijing, China, 2008. [Google Scholar]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Qiu, C.; Ravi, G.A.; Dance, C.; Ranson, A.; Dilworth, S.; Attallah, M.M. Fabrication of large Ti-6Al-4V structures by direct laser deposition. J. Alloys Compd. 2015, 629, 351–361. [Google Scholar] [CrossRef]

- Baufeld, B.; Van der Biest, O.; Gault, R.; Ridgway, K. Manufacturing Ti-6Al-4V components by shaped metal deposition: Microstructure and mechanical properties. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2011; Volume 26. [Google Scholar]

- ASTM International. ASTM E6-09be1 Standard Terminology Relating to Methodsof Mechanical Testing; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Rangaswamy, P.; Griffith, M.L.; Prime, M.B.; Holden, T.M.; Rogge, R.B.; Edwards, J.M.; Sebring, R.J. Residual stresses in LENS® components using neutron diffraction and contour method. Mater. Sci. Eng. A 2005, 399, 72–83. [Google Scholar] [CrossRef]

- Liu, F.; Lin, X.; Yang, G.; Song, M.; Chen, J.; Huang, W. Microstructure and residual stress of laser rapid formed Inconel 718 nickel-base superalloy. Opt. Laser Technol. 2011, 43, 208–213. [Google Scholar] [CrossRef]

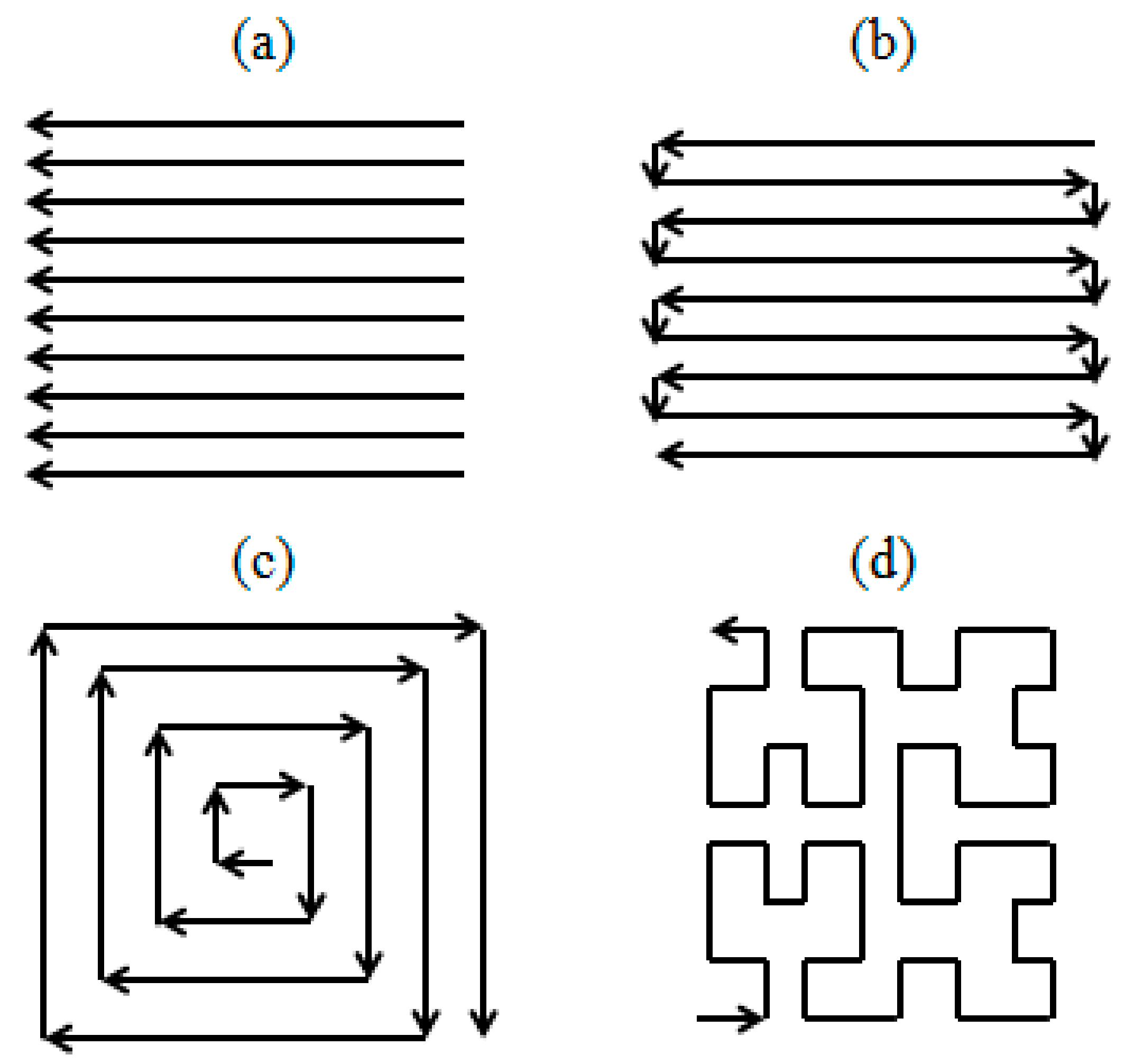

- Dai, K.; Shaw, L. Distortion minimization of laser-processed components through control of laser scanning patterns. Rapid Prototyp. J. 2002, 8, 270–276. [Google Scholar] [CrossRef]

- Shuangyin, Z.; Xin, L.; Jing, C.; Weidong, H. Influence of heat treatment on resid-ual stress of Ti-6Al-4V alloy by laser solid forming. Rare Met. Mater. Eng. 2009, 38. [Google Scholar]

- Beuth, J.; Klingbeil, N. The role of process variables in laser-based direct metal solid freeform fabrication. JOMJ. Miner. Mater. Soc. 2001, 53, 36–39. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Pinkerton, A.J.; Moat, R.J.; Shackleton, J. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti-6Al-4V powders. Mater. Sci. Eng. A 2011, 528, 7648–7657. [Google Scholar] [CrossRef]

- Moat, R.J.; Pinkerton, A.J.; Li, L.; Withers, P.J.; Preuss, M. Residual stresses in laser direct metal deposited Waspaloy. Mater. Sci. Eng. A 2011, 528, 2288–2298. [Google Scholar] [CrossRef]

- Griffith, M.L.; Schlienger, M.E.; Harwell, L.D.; Oliver, M.S.; Baldwin, M.D.; Ensz, M.T.; Essien, M.; Brooks, J.; Robino, C.V.; Smugeresky, J.E.; et al. Understanding thermal behavior in the LENS process. Mater. Des. 1999, 20, 107–113. [Google Scholar] [CrossRef]

- Li, Y.; Yang, H.; Lin, X.; Huang, W.; Li, J.; Zhou, Y. The influences of processing parameters on forming characterizations during laser rapid forming. Mater. Sci. Eng. A 2003, 360, 18–25. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Ma, L.; Wang, J.; Fu, X.; Chen, J.; Huang, W. Influence of laser deposition patterns on part distortion, interior quality and mechanical properties by laser solid forming (LSF). Mater. Sci. Eng. A 2011, 528, 1094–1104. [Google Scholar] [CrossRef]

- Nickel, A.H.; Barnett, D.M.; Prinz, F.B. Thermal stresses and deposition patterns in layered manufacturing. Mater. Sci. Eng. A 2001, 317, 59–64. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, S.; Tian, X.; Wang, H. High-cycle fatigue crack initiation and propagation in laser melting deposited TC18 titanium alloy. Int. J. Miner. Metall. Mater. 2013, 20, 665–670. [Google Scholar] [CrossRef]

- Li, Z.; Tian, X.; Tang, H.; Wang, H. Low cycle fatigue behavior of laser melting deposited TC18 titanium alloy. Trans. Nonferr. Met. Soc. China 2013, 23, 2591–2597. [Google Scholar] [CrossRef]

- Wolff, S.; Lee, T.; Faierson, E.; Ehmann, K.; Cao, J. Anisotropic properties of directed energy deposition (DED)-processed Ti-6Al-4V. J. Manuf. Process. 2016, 24 Pt 2, 397–405. [Google Scholar] [CrossRef]

- Alcisto, J.O.J.; Enriquez, A.; Garcia, H.; Hinkson, S.; Steelman, T.; Silverman, E.; Valdovino, P.; Gigerenzer, H.; Foyos, J.; Dorey, J.; et al. Tensile properties and microstructures of laser-formed Ti-6Al-4V. JMEPEG 2011, 20, 203–212. [Google Scholar]

| Technique | Acronym | Reference |

|---|---|---|

| Laser cladding | LC | [9,10] |

| Direct metal deposition | DMD | [11] |

| Direct light fabrication | DLF | [12,13] |

| Laser direct casting | LDC | [14] |

| Laser forming | Lasform | [15] |

| Shape deposition manufacturing | SDM | [16] |

| Laser engineer net shaping | LENS | [17] |

| Laser powder fusion | LPF | [18] |

| Laser-aided direct-metal deposition | LADMD | [19] |

| Laser-based multi-directional metal deposition | LBMDMD | [20,21] |

| Laser aided manufacturing process | LAMP | [2,22] |

| Alloy | Examples | Reference |

|---|---|---|

| Titanium alloy | Ti-22Al-23Nb, Ti-6Al-4V, Ti-6.5Al-3.5Mo-1.5Zr-0.3Si, Ti-5Al-5Mo-4V-1Cr-1Fe | [13,15,23,24,25,26,27,28] |

| Steel | 10V, 15-5 PH, 410, AISI 309Aremet 10, A2, MM10 | [11,29,30] |

| Nickel based superalloy | CMSX-3, Haynes188, Haynes230, IN600, IN690, IN713, Rene 142, Rene N5 | [31,32,33,34,35] |

| Aluminum alloy | CP Al, 6061, 2024 | [36] |

| Item | Material ($/pound) | ||

|---|---|---|---|

| Steel | Aluminum | Titanium | |

| Ore | 0.02 | 0.01 | 0.22 |

| Metal | 0.10 | 1.10 | 5.44 |

| Ingot | 0.15 | 1.15 | 9.07 |

| Sheet | 0.30–0.60 | 1.00–5.00 | 15.00–50.00 |

| Ultimate Tensile Strength (MPa) | Yield Strength (MPa) | ε (%) | |

|---|---|---|---|

| DLD | 931 | 855 | 10 |

| Wrought | 900 | 850 | 12 |

| UTS (MPa) | YS (MPa) | ε (%) | |

|---|---|---|---|

| X-direction | 1073 | 973 | 10 |

| Y-direction | 1065 | 941 | 11.6 |

| Condition | YS (MPa) | UTS (MPa) | ε (%) |

|---|---|---|---|

| As-DED Vertical | 950 | 1025 | 5 |

| As-DED Horizontal | 950 | 1025 | 12 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saboori, A.; Gallo, D.; Biamino, S.; Fino, P.; Lombardi, M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Appl. Sci. 2017, 7, 883. https://doi.org/10.3390/app7090883

Saboori A, Gallo D, Biamino S, Fino P, Lombardi M. An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Applied Sciences. 2017; 7(9):883. https://doi.org/10.3390/app7090883

Chicago/Turabian StyleSaboori, Abdollah, Donato Gallo, Sara Biamino, Paolo Fino, and Mariangela Lombardi. 2017. "An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties" Applied Sciences 7, no. 9: 883. https://doi.org/10.3390/app7090883

APA StyleSaboori, A., Gallo, D., Biamino, S., Fino, P., & Lombardi, M. (2017). An Overview of Additive Manufacturing of Titanium Components by Directed Energy Deposition: Microstructure and Mechanical Properties. Applied Sciences, 7(9), 883. https://doi.org/10.3390/app7090883