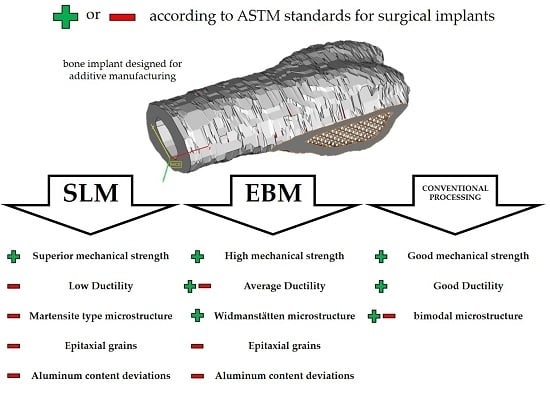

Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants

Abstract

:Featured Application

Abstract

1. Introduction

1.1. Laser and Electron Rapid Prototyping Methods

1.2. SLM and EBM Differences

1.3. Titanium Alloys in the Biomedical Field

1.4. Mechanical Properties of Ti-6Al-4V Alloys

1.5. Microstructures of the Ti-6Al-4V Alloys

2. Materials and Methods

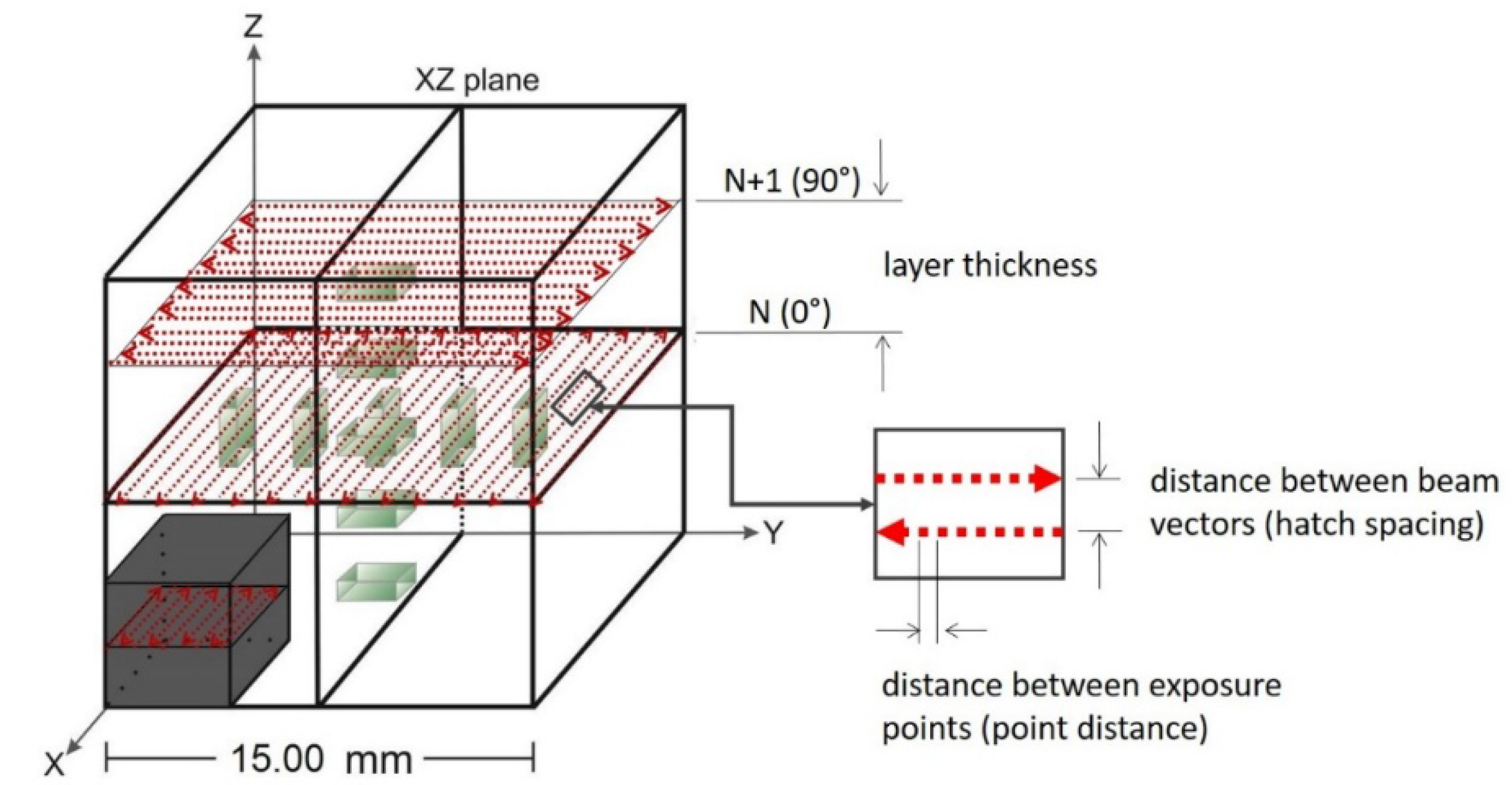

2.1. Fabrication of Solid Samples

2.1.1 Optimization Procedure for the SLM Samples

2.2. Characterization of the Microstructure and Phase Composition

2.3. Mechanical Properties

2.4. Cytotoxicity Tests

3. Results

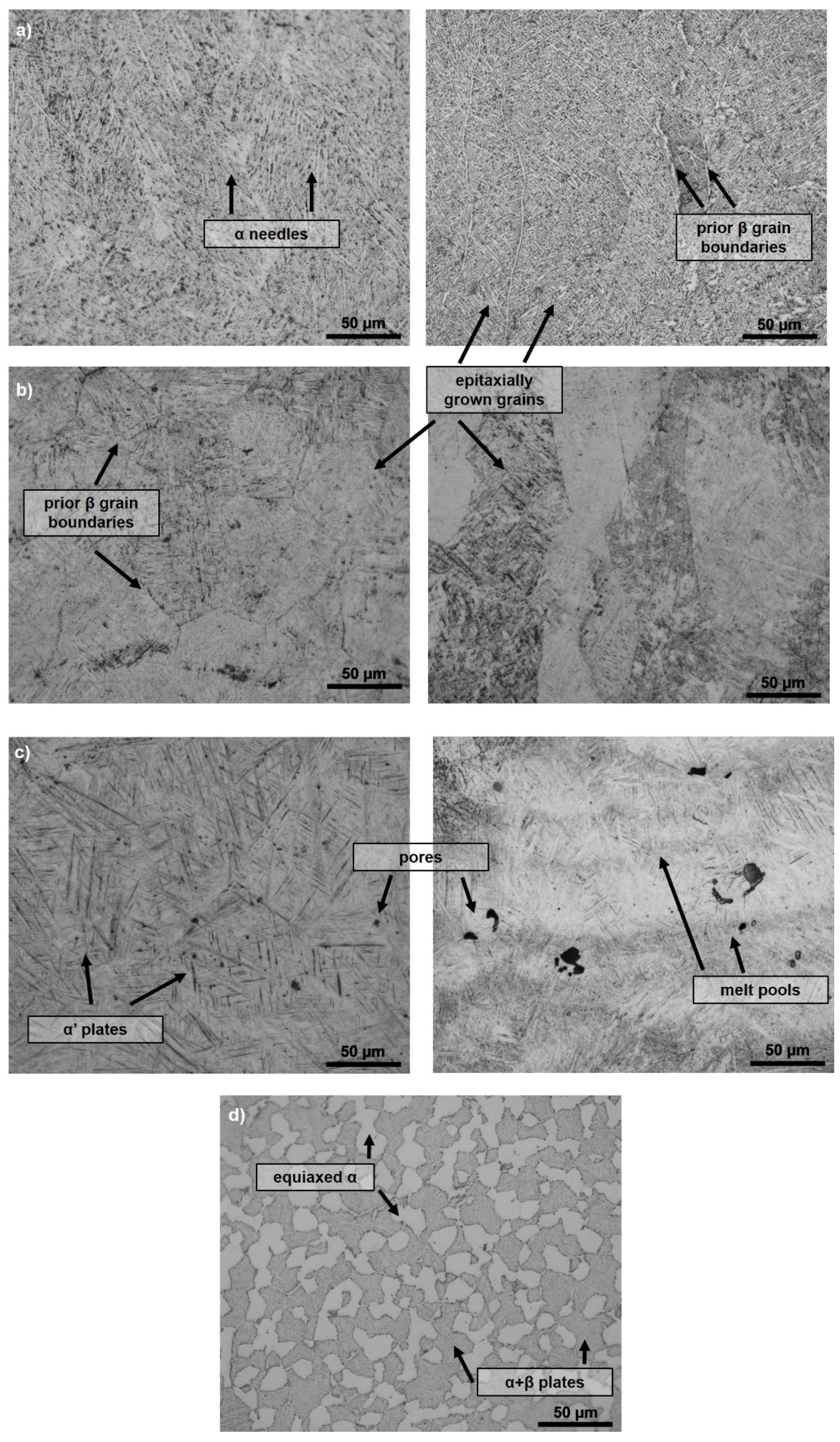

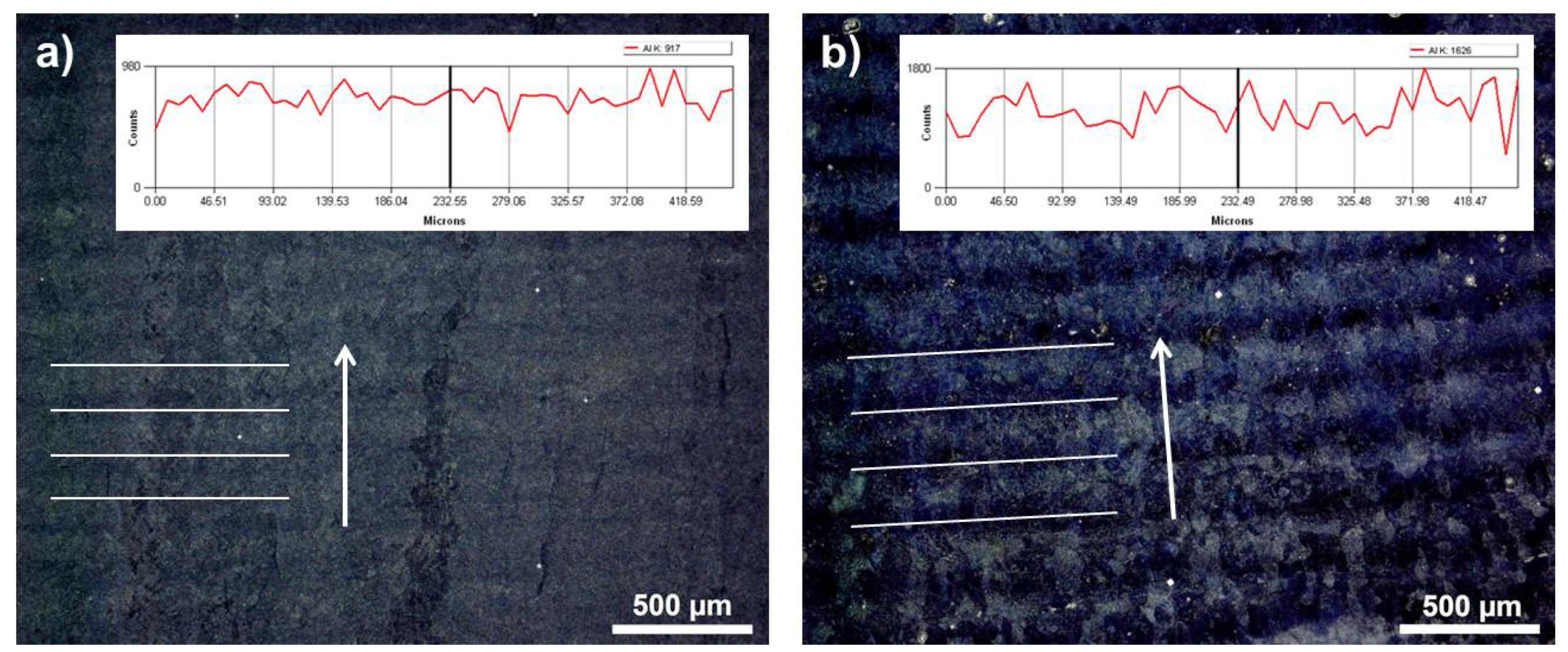

3.1. Light Microscopy

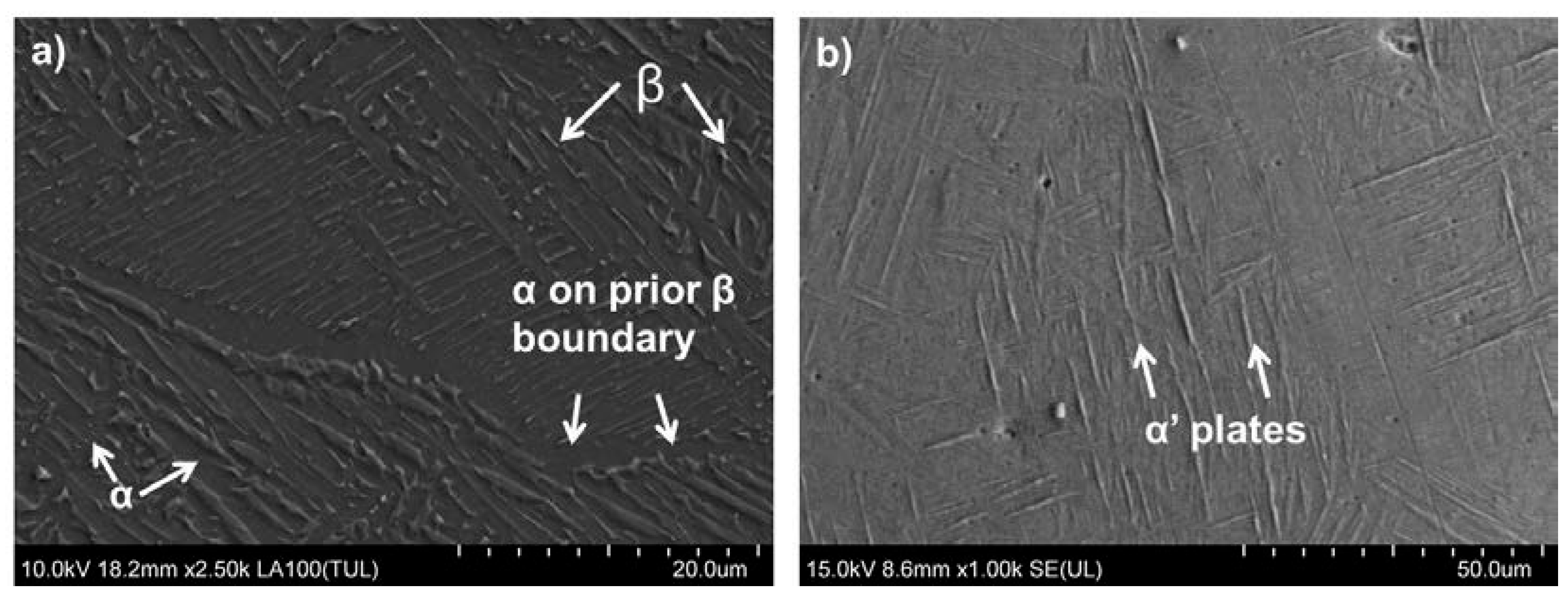

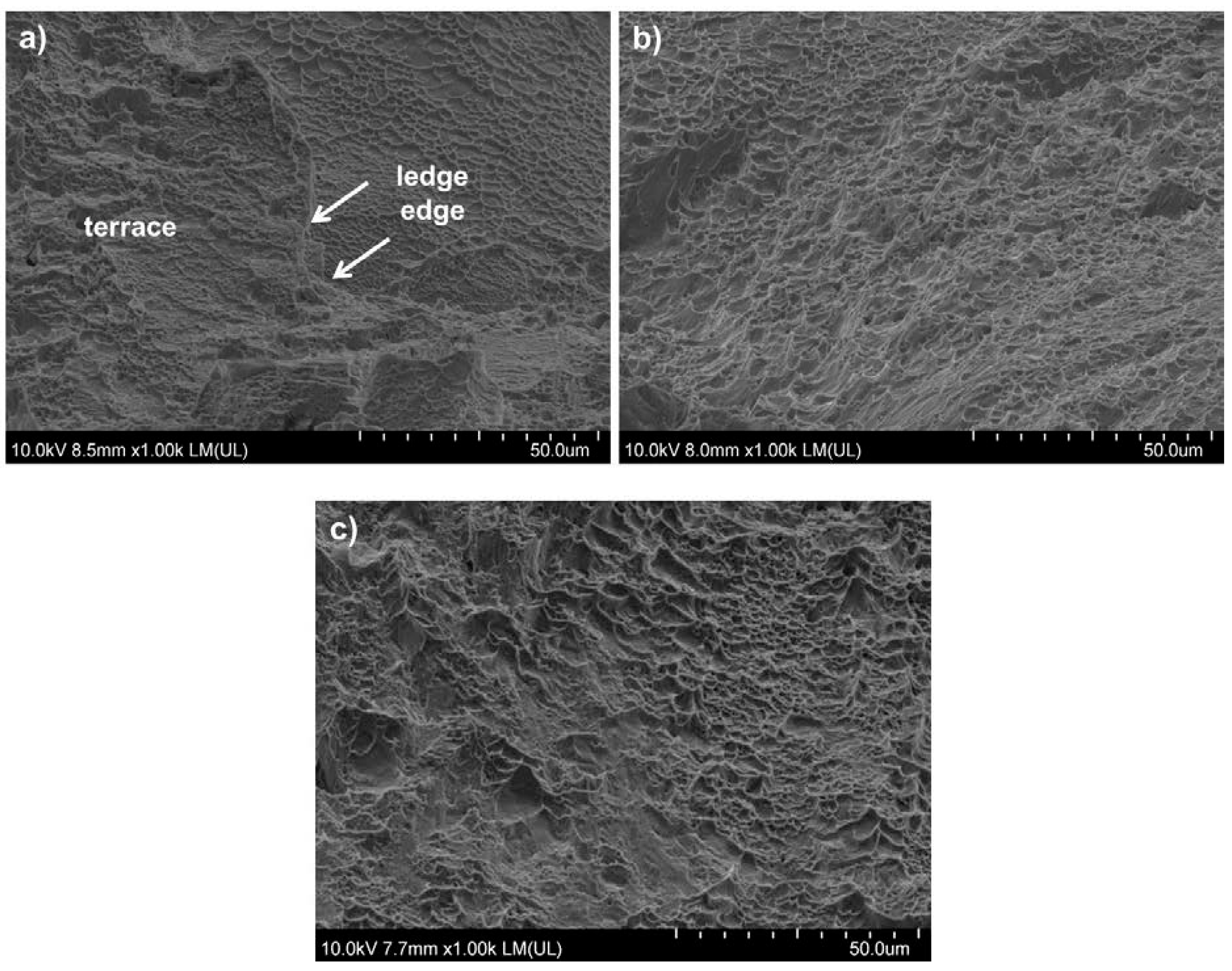

3.2. Scanning Electron and Transmission Electron Microscopy

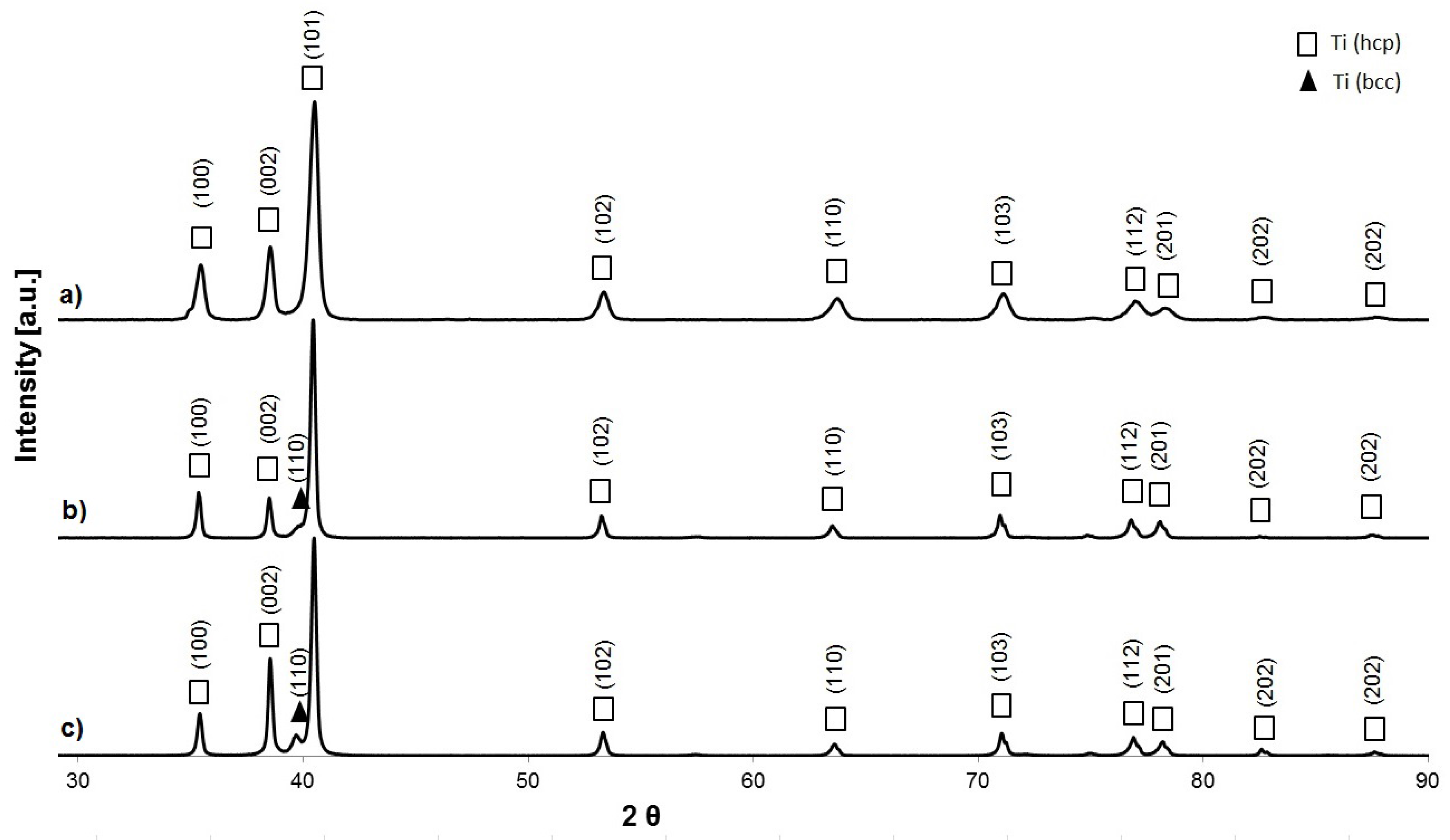

3.3. X-ray Diffraction

3.4. Mechanical Tests

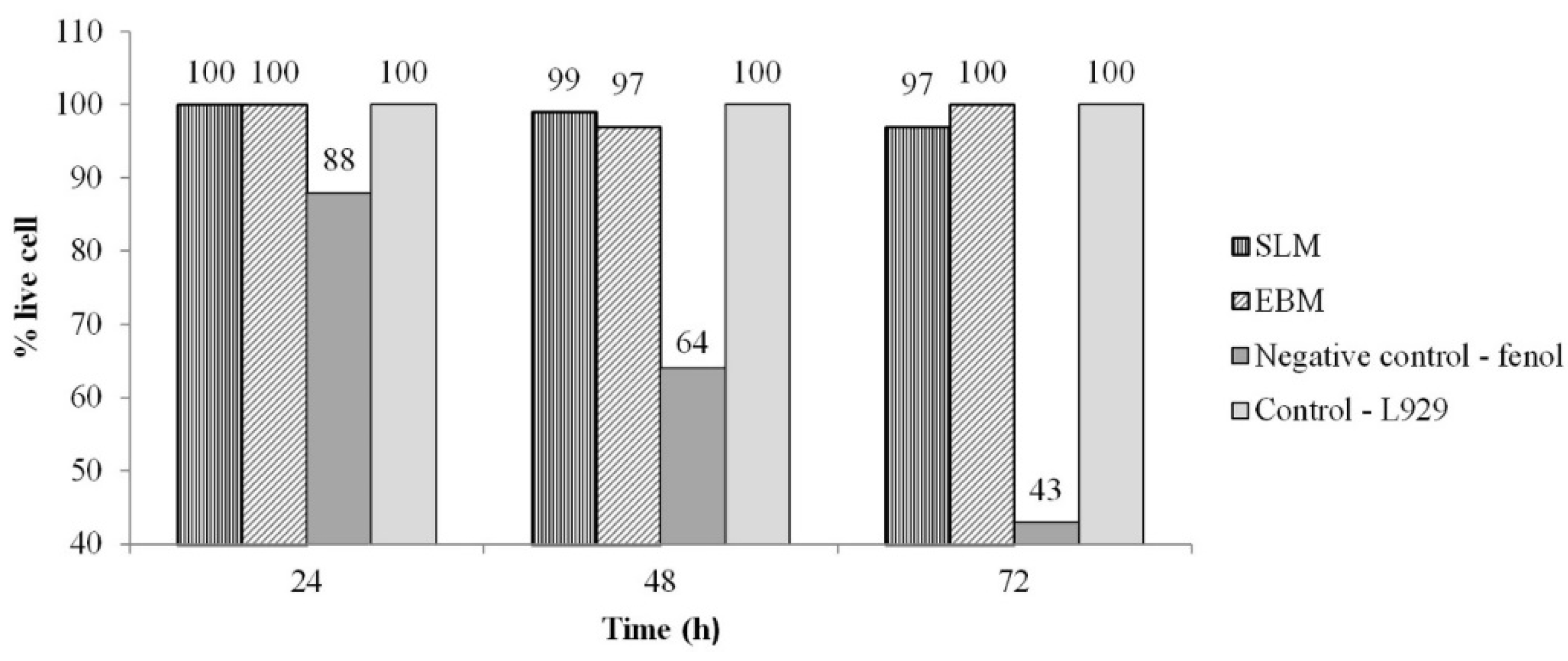

3.5. Cytotoxicity

4. Discussion

4.1. Process Condition

4.2. Microstructural Analysis

4.3. X-ray Diffraction Results

4.4. Mechanical Properties

5. Conclusions

- (1)

- The manufacturing method influences the equilibrium conditions of the crystallization process. As a result, the microstructure changes can be seen. In the SLM method, only the α’ martensitic phase can be detected, whereas the EBM processed material had a very fine needle-like α + β Widmanstätten microstructure. Additionally, due to non-equilibrium cooling, pores can be seen in the SLM samples that drastically reduce ductility, preventing its use in medical applications. In contrast, the EBM vacuum processed material met the requirements of the ASTM F136-13 standards. For the SLM, additional heat treatment is necessary; however, the issue of pores may be still an obstacle.

- (2)

- Higher temperature gradients in the SLM method in comparison to EBM and wrought material led to high residual stress at the atomic level. The material after the SLM process had the highest UTS (ca. 1300 MPa); however, the elongation was very small (ca. 2%). Furthermore, this changed with the building direction of the sample, which is evidence of significant anisotropy. In the case of EBM and the wrought material, the mechanical properties were homogenous and independent of sample orientation. This factor is especially important for larger sizes of the fabricated elements. Therefore, the size effect should be accounted for and energy dissipation should be considered when planning an AM process.

Supplementary Materials

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Seifi, M.; Salem, A.; Beuth, J.; Harrysson, O.; Lewandowski, J.J. Overview of materials qualification needs for metal additive manufacturing. JOM 2016, 68, 747–764. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: New York, NY, USA, 2010. [Google Scholar]

- Kannan, G.B.; Rajendran, D.K. A review on status of research in metal additive manufacturing. In Advances in 3rd Printing & Additive Manufacturing Technologies; Wimpenny, D.I., Pandey, P.M., Kumar, L.J., Eds.; Springer: Singapore, 2017; pp. 95–100. [Google Scholar]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Murr, L.E.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Rodela, A.; Martinez, E.Y.; Hernandez, D.H.; Martinez, E.; Medina, F.; Wicker, R.B. Microstructure and mechanical behavior of Ti-6Al-4V produced by rapid-layer manufacturing, for biomedical applications. J. Mech. Behav. Biomed. Mater. 2009, 2, 20–32. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.-L.; Li, S.-J.; Yang, R. Biomedical titanium alloys and their additive manufacturing. Rare Metals 2016, 35, 661–671. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Astm f2924-14. Standard Specification for Additive Manufacturing Titanium-6 Aluminum-4 Vanadium Eli with Powder Bed Fusion; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of in738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Niendorf, T.; Leuders, S.; Riemer, A.; Richard, H.A.; Tröster, T.; Schwarze, D. Highly anisotropic steel processed by selective laser melting. Metall. Mater. Trans. B 2013, 44, 794–796. [Google Scholar] [CrossRef]

- Brenne, F.; Leuders, S.; Niendorf, T. On the impact of additive manufacturing on microstructural and mechanical properties of stainless steel and Ni-base alloys. BHM Berg-und Hüttenmännische Monatshefte 2017, 162, 199–202. [Google Scholar] [CrossRef]

- Trevisan, F.; Calignano, F.; Lorusso, M.; Pakkanen, J.; Aversa, A.; Ambrosio, E.; Lombardi, M.; Fino, P.; Manfredi, D. On the selective laser melting (SLM) of the alsi10mg alloy: Process, microstructure, and mechanical properties. Materials 2017, 10, 76. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal additive manufacturing: A review of mechanical properties. Ann. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Zhao, X.; Li, S.; Zhang, M.; Liu, Y.; Sercombe, T.B.; Wang, S.; Hao, Y.; Yang, R.; Murr, L.E. Comparison of the microstructures and mechanical properties of Ti-6Al-4V fabricated by selective laser melting and electron beam melting. Mater. Des. 2016, 95, 21–31. [Google Scholar] [CrossRef]

- Edwards, P.; O’Conner, A.; Ramulu, M. Electron beam additive manufacturing of titanium components: Properties and performance. J. Manuf. Sci. Eng. 2013, 135, 061016. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Taminger, K. Electron beam freeform fabrication. Adv. Mater. Process. 2009, 167, 45. [Google Scholar]

- Gibbons, G.J.; Hansell, R.G. Direct tool steel injection mould inserts through the arcam ebm free-form fabrication process. Assem. Autom. 2005, 25, 300–305. [Google Scholar] [CrossRef]

- Miura, H.; Osada, T.; Ishibashi, H.; Okawachi, K.; Uemura, M.; Fujita, M.; Arimoto, N. Development of selective laser sintering for titanium alloy powder—3rd report. J. Jpn. Soc. Powder Powder Metall. 2008, 55, 738–742. [Google Scholar] [CrossRef]

- Ciocca, L.; Fantini, M.; Crescenzio, F.; Corinaldesi, G.; Scotti, R. Direct metal laser sintering (DMLS) of a customized titanium mesh for prosthetically guided bone regeneration of atrophic maxillary arches. Med. Biol. Eng. Comput. 2011, 49, 1347–1352. [Google Scholar] [CrossRef] [PubMed]

- Chlebus, E.; Kuźnicka, B.; Kurzynowski, T.; Dybała, B. Microstructure and mechanical behaviour of Ti-6Al-7Nb alloy produced by selective laser melting. Mater. Charact. 2011, 62, 488–495. [Google Scholar] [CrossRef]

- Krishna, B.V.; Bose, S.; Bandyopadhyay, A. Low stiffness porous Ti structures for load-bearing implants. Acta Biomater. 2007, 3, 997–1006. [Google Scholar] [CrossRef] [PubMed]

- Dinda, G.P.; Song, L.; Mazumder, J. Fabrication of Ti-6Al-4V scaffolds by direct metal deposition. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2008, 39, 2914–2922. [Google Scholar] [CrossRef]

- Lewis, G.K.; Schlienger, E. Practical considerations and capabilities for laser assisted direct metal deposition. Mater. Des. 2000, 21, 417–423. [Google Scholar] [CrossRef]

- Park, J.; Tari, M.J.; Hahn, H.T. Characterization of the laminated object manufacturing (LOM) process. Rapid Prototyp. J. 2000, 6, 36–49. [Google Scholar] [CrossRef]

- Taminger, K.M.B.; Harley, R.A. Characterization of 2219 aluminium produced by electron beam freeform fabrication. In Proceedings of the 13th Solid Freeform Fabrication Symposium, Austin, TX, USA, 5–7 August 2002; University of Texas at Austin: Austin, TX, USA, 2002. [Google Scholar]

- Harrysson, O.L.A.; Cansizoglu, O.; Marcellin-Little, D.J.; Cormier, D.R.; West, H.A., II. Direct metal fabrication of titanium implants with tailored materials and mechanical properties using electron beam melting technology. Mater. Sci. Eng. C 2008, 28, 366–373. [Google Scholar] [CrossRef]

- Wysocki, B.; Chmielewska, A.; Szlązak, K. Druk 3D implantów na wymiar metodami SLM oraz FDM. Tworzywa Sztuczne w Przemysle 2017, 3, 13–14. [Google Scholar]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti-6Al-4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef] [PubMed]

- Sallica-Leva, E.; Jardini, A.L.; Fogagnolo, J.B. Microstructure and mechanical behavior of porous Ti-6Al-4V parts obtained by selective laser melting. J. Mech. Behav. Biomed. Mater. 2013, 26, 98–108. [Google Scholar] [CrossRef] [PubMed]

- Bobbio, L.D.; Qin, S.; Dunbar, A.; Michaleris, P.; Beese, A.M. Characterization of the strength of support structures used in powder bed fusion additive manufacturing of Ti-6Al-4V. Addit. Manuf. 2017, 14, 60–68. [Google Scholar] [CrossRef]

- Mower, T.M.; Long, M.J. Mechanical behavior of additive manufactured, powder-bed laser-fused materials. Mater. Sci. Eng. A 2016, 651, 198–213. [Google Scholar] [CrossRef]

- Smith, C.J.; Derguti, F.; Hernandez Nava, E.; Thomas, M.; Tammas-Williams, S.; Gulizia, S.; Fraser, D.; Todd, I. Dimensional accuracy of Electron Beam Melting (EBM) additive manufacture with regard to weight optimized truss structures. J. Mater. Process. Technol. 2017, 229, 128–138. [Google Scholar] [CrossRef]

- Yves-Christian, H.; Jan, W.; Wilhelm, M.; Konrad, W.; Reinhart, P. Net shaped high performance oxide ceramic parts by selective laser melting. Phys. Procedia 2010, 5, 587–594. [Google Scholar] [CrossRef]

- Shishkovskii, I.V.; Yadroitsev, I.A.; Smurov, I.Y. Selective laser sintering/melting of nitinol–hydroxyapatite composite for medical applications. Powder Metall. Met. Ceram. 2011, 50, 275–283. [Google Scholar] [CrossRef]

- Wysocki, B.; Maj, P.; Krawczyńska, A.; Rożniatowski, K.; Zdunek, J.; Kurzydłowski, K.J.; Święszkowski, W. Microstructure and mechanical properties investigation of CP titanium processed by selective laser melting (SLM). J. Mater. Process. Technol. 2017, 241, 13–23. [Google Scholar] [CrossRef]

- Hanzl, P.; Zetek, M.; Bakša, T.; Kroupa, T. The influence of processing parameters on the mechanical properties of slm parts. Procedia Eng. 2015, 100, 1405–1413. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti-6Al-4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1, 87–98. [Google Scholar] [CrossRef]

- Wang, X.; Gong, X.; Chou, K. Scanning speed effect on mechanical properties of Ti-6Al-4V alloy processed by electron beam additive manufacturing. Procedia Manuf. 2015, 1, 287–295. [Google Scholar] [CrossRef]

- Żrodowski, Ł.; Wysocki, B.; Wróblewski, R.; Kurzydłowski, K.; Święszkowski, W. The novel scanning strategy for fabrication metallic glasses by selective laser melting. In Fraunhofer Direct Digital Manufacturing Conference; Fraunhofer Additive Manufacturing Alliance: Berlin, Germany, 2016. [Google Scholar]

- Kruth, J.-P.; Vandenbroucke, B.; Vaerenbergh, V.J.; Mercelis, P. Benchmarking of Different SLS/SLM Processes as Rapid Manufacturing Techniques. In Proceedings of the International Conference on Polymers and Moulds Innovations (PMI), Gent, Belgium, 20–23 April 2005. [Google Scholar]

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425. [Google Scholar] [CrossRef]

- Sidambe, A.T. Biocompatibility of advanced manufactured titanium implants—A review. Materials 2014, 7, 8168–8188. [Google Scholar] [CrossRef]

- Niinomi, M.; Nakai, M. Titanium-based biomaterials for preventing stress shielding between implant devices and bone. Int. J. Biomater. 2011, 2011. [Google Scholar] [CrossRef] [PubMed]

- Kováčik, J. Correlation between young’s modulus and porosity in porous materials. J. Mater. Sci. Lett. 1999, 18, 1007–1010. [Google Scholar] [CrossRef]

- Oldani, C.; Dominguez, A. Titanium as a biomaterial for implants. In Recent Advances in Arthroplasty; Fokter, S., Ed.; InTech: Rijeka, Croatia, 2012. [Google Scholar]

- Dabrowski, B.; Swieszkowski, W.; Godlinski, D.; Kurzydlowski, K.J. Highly porous titanium scaffolds for orthopaedic applications. J. Biomed. Mater. Res. Part B Appl. Biomater. 2010, 95B, 53–61. [Google Scholar] [CrossRef] [PubMed]

- Sumner, D.R.; Turner, T.M.; Igloria, R.; Urban, R.M.; Galante, J.O. Functional adaptation and ingrowth of bone vary as a function of hip implant stiffness. J. Biomech. 1998, 31, 909–917. [Google Scholar] [CrossRef]

- Gaggl, A.; Schultes, G.; Müller, W.D.; Kärcher, H. Scanning electron microscopical analysis of laser-treated titanium implant surfaces—A comparative study. Biomaterials 2000, 21, 1067–1073. [Google Scholar] [CrossRef]

- Van Blitterswijk, C.A.; Grote, J.J.; Kuijpers, W. Macropore tissue ingrowth: A quantitative and qualitative study on hydroxyapatite ceramic. Biomaterials 1986, 7, 137–143. [Google Scholar] [CrossRef]

- Schliephake, H.; Neukam, F.W.; Klosa, D. Influence of pore dimensions on bone ingrowth into porous hydroxylapatite blocks used as bone graft substitutes. A histometric study. Int. J. Oral Maxillofac. Surg. 1991, 20, 53–58. [Google Scholar] [CrossRef]

- Vasconcellos, L.M.R.D.; Leite, D.O.; Oliveira, F.N.D.; Carvalho, Y.R.; Cairo, C.A.A. Evaluation of bone ingrowth into porous titanium implant: Histomorphometric analysis in rabbits. Braz. Oral Res. 2010, 24, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Wysocki, B.; Idaszek, J.; Szlązak, K.; Strzelczyk, K.; Brynk, T.; Kurzydłowski, K.; Święszkowski, W. Post processing and biological evaluation of the titanium scaffolds for bone tissue engineering. Materials 2016, 9, 197. [Google Scholar] [CrossRef]

- Koike, M.; Greer, P.; Owen, K.; Lilly, G.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Okabe, T. Evaluation of titanium alloys fabricated using rapid prototyping technologies—Electron beam melting and laser beam melting. Materials 2011, 4, 1776–1792. [Google Scholar] [CrossRef]

- Song, B.; Dong, S.; Liao, H.; Coddet, C. Process parameter selection for selective laser melting of Ti-6Al-4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Tech. 2012, 61, 967–974. [Google Scholar] [CrossRef]

- Puebla, K.; Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Effect of melt scan rate on microstructure and macrostructure for electron beam melting of Ti-6Al-4V. Mater. Sci. Appl. 2012, 3, 259–264. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Medina, F.; Martinez, E.; Martinez, J.L.; Hernandez, D.H.; Machado, B.I.; Ramirez, D.A.; Wicker, R.B. Characterization of Ti-6Al-4V open cellular foams fabricated by additive manufacturing using electron beam melting. Mater. Sci. Eng. A 2010, 527, 1861–1868. [Google Scholar] [CrossRef]

- Hollander, D.A.; Von Walter, M.; Wirtz, T.; Sellei, R.; Schmidt-Rohlfing, B.; Paar, O.; Erli, H.J. Structural, mechanical and in vitro characterization of individually structured Ti-6Al-4V produced by direct laser forming. Biomaterials 2006, 27, 955–963. [Google Scholar] [CrossRef] [PubMed]

- Murr, L.E.; Esquivel, E.V.; Quinones, S.A.; Gaytan, S.M.; Lopez, M.I.; Martinez, E.Y.; Medina, F.; Hernandez, D.H.; Martinez, E.; Martinez, J.L.; et al. Microstructures and mechanical properties of electron beam-rapid manufactured Ti-6Al-4V biomedical prototypes compared to wrought Ti-6Al-4V. Mater. Charact. 2009, 60, 96–105. [Google Scholar] [CrossRef]

- Facchini, L.; Magalini, E.; Robotti, P.; Molinari, A.; Höges, S.; Wissenbach, K. Ductility of a Ti-6Al-4V alloy produced by selective laser melting of prealloyed powders. Rapid Prototyp. J. 2010, 16, 450–459. [Google Scholar] [CrossRef]

- Koike, M.; Martinez, K.; Guo, L.; Chahine, G.; Kovacevic, R.; Okabe, T. Evaluation of titanium alloy fabricated using electron beam melting system for dental applications. J. Mater. Process. Technol. 2011, 211, 1400–1408. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Astm f136-13. Standard Specification for Wrought Titanium-6Aluminum-4Vanadium Eli (Extra Low Interstitial) Alloy for Surgical Implant Applications (UNS R56401); ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Xu, W.; Lui, E.W.; Pateras, A.; Qian, M.; Brandt, M. In situ tailoring microstructure in additively manufactured Ti-6Al-4V for superior mechanical performance. Acta Mater. 2017, 125, 390–400. [Google Scholar] [CrossRef]

- Safdar, A.; Wei, L.Y.; Snis, A.; Lai, Z. Evaluation of microstructural development in electron beam melted Ti-6Al-4V. Mater. Charact. 2012, 65, 8–15. [Google Scholar] [CrossRef]

- Fischer, P.; Leber, H.; Romano, V.; Weber, H.P.; Karapatis, N.P.; André, C.; Glardon, R. Microstructure of near-infrared pulsed laser sintered titanium samples. Appl. Phys. A Mater. Sci. Process. 2004, 78, 1219–1227. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, B.; Zhao, W.S.; Li, D.X.; Sui, M.L. Formation of novel β-Ti martensites in Ti-6Al-4V under an electric-current-pulse heat treatment. Mater. Sci. Eng. A 2006, 438–440, 320–323. [Google Scholar] [CrossRef]

- Murr, L.E.; Amato, K.N.; Li, S.J.; Tian, Y.X.; Cheng, X.Y.; Gaytan, S.M.; Martinez, E.; Shindo, P.W.; Medina, F.; Wicker, R.B. Microstructure and mechanical properties of open-cellular biomaterials prototypes for total knee replacement implants fabricated by electron beam melting. J. Mech. Behav. Biomed. Mater. 2011, 4, 1396–1411. [Google Scholar] [CrossRef] [PubMed]

- Nalla, R.; Boyce, B.; Campbell, J.; Peters, J.; Ritchie, R. Influence of microstructure on high-cycle fatigue of Ti-6Al-4V: Bimodal vs. Lamellar structures. Metall. Mater. Trans. A 2002, 33, 899–918. [Google Scholar] [CrossRef]

- Sonntag, R.; Reinders, J.; Gibmeier, J.; Kretzer, J.P. Fatigue performance of medical Ti-6Al-4V alloy after mechanical surface treatments. PLoS ONE 2015, 10, e0121963. [Google Scholar] [CrossRef] [PubMed]

- Molak, R.M.; Kartal, M.; Pakiela, Z.; Manaj, W.; Turski, M.; Hiller, S.; Gungor, S.; Edwards, L.; Kurzydłowski, K.J. Use of Micro Tensile Test Samples in Determining the Remnant Life of Pressure Vessel Steels. Appl. Mech. Mater. 2007, 7–8, 187–194. [Google Scholar] [CrossRef]

- International Organization for Standardization. Biological Evaluation of Medical Devices—Part 5: Tests for in Vitro Cytotoxicity (ISO 10993-5:2009); Polski Komitet Normalizacyjny: Warsaw, Poland, 2009. [Google Scholar]

- International Organization for Standardization. Biological Evaluation of Medical Devices—Part 12: Sample Preparation and Reference Materials (ISO 10993-12:2012); Polski Komitet Normalizacyjny: Warsaw, Poland, 2012. [Google Scholar]

- Thijs, L.; Verhaeghe, F.; Craeghs, T.; Humbeeck, J.V.; Kruth, J.-P. A study of the microstructural evolution during selective laser melting of Ti-6Al-4V. Acta Mater. 2010, 58, 3303–3312. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Sailer, R.; McCarthy, G. Icdd Grant-in-Aid; North Dakota State University: Fargo, ND, USA, 1993. [Google Scholar]

- Wyckoff, R.W.G. Crystal Structures, 2nd ed.; John Wiley & Sons, Inc.: New Yoor, NY, USA, 1963. [Google Scholar]

- Murr, L.E.; Gaytan, S.M.; Martinez, E.; Medina, F.; Wicker, R.B. Next generation orthopaedic implants by additive manufacturing using electron beam melting. Int. J. Biomater. 2012, 2012, 14. [Google Scholar] [CrossRef] [PubMed]

- Das, S. Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 2003, 5, 701–711. [Google Scholar] [CrossRef]

- American Society for Testing Materials. Astm f1108-14. Standard Specification for Titanium-6Aluminum-4Vanadium Alloy Castings for Surgical Implants (UNS R56406); ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- American Society for Testing Materials. Astm f620-11. Standard Specification for Titanium Alloy Forgings for Surgical Implants in the Alpha Plus Beta Condition; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Xu, W.; Brandt, M.; Sun, S.; Elambasseril, J.; Liu, Q.; Latham, K.; Xia, K.; Qian, M. Additive manufacturing of strong and ductile Ti-6Al-4V by selective laser melting via in situ martensite decomposition. Acta Mater. 2015, 85, 74–84. [Google Scholar] [CrossRef]

- Christensen, A.; Kircher, R.; Lippincott, A. Medical Device Materials IV. In Qualification of Electron Beam Melted (EBM) Ti-6Al-4V-Eli for Orthopaedic Applications, Proceedings of the Materials & Processes for Medical Devices Conference, Palm Desert, CA, USA, 23–27 September 2007; ASTM International: West Conshohocken, PA, USA, 2007; p. 48. [Google Scholar]

- Jordan, D. Study of alpha case formation heat treated Ti-6-4 alloy. Heat Treat. Prog. 2008, 8, 45–47. [Google Scholar]

- Thijs, L.; Montero Sistiaga, M.L.; Wauthle, R.; Xie, Q.; Kruth, J.-P.; Van Humbeeck, J. Strong morphological and crystallographic texture and resulting yield strength anisotropy in selective laser melted tantalum. Acta Mater. 2013, 61, 4657–4668. [Google Scholar] [CrossRef]

- Rafi, H.K.; Karthik, N.V.; Gong, H.; Starr, T.L.; Stucker, B.E. Microstructures and mechanical properties of Ti-6Al-4V parts fabricated by selective laser melting and electron beam melting. J. Mater. Eng. Perform. 2013, 22, 3872–3883. [Google Scholar] [CrossRef]

- Kwasniak, P.; Garbacz, H.; Kurzydlowski, K.J. Solid solution strengthening of hexagonal titanium alloys: Restoring forces and stacking faults calculated from first principles. Acta Mater. 2016, 102, 304–314. [Google Scholar] [CrossRef]

- Sun, B.; Li, S.; Imai, H.; Mimoto, T.; Umeda, J.; Kondoh, K. Fabrication of high-strength ti materials by in-process solid solution strengthening of oxygen via p/m methods. Mater. Sci. Eng. A 2013, 563, 95–100. [Google Scholar] [CrossRef]

- Kwasniak, P.; Muzyk, M.; Garbacz, H.; Kurzydlowski, K.J. Influence of oxygen content on the mechanical properties of hexagonal Ti—First principles calculations. Mater. Sci. Eng. A 2014, 590, 74–79. [Google Scholar] [CrossRef]

- Vrancken, B. Study of Residual Stresses in Selective Laser Melting; KU Luven: Leuven, Belgium, 2016. [Google Scholar]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of slm Ti-6Al-4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef]

| Parameter | Realizer SLM50 | Arcam EBM S12 |

|---|---|---|

| Environment | argon | Vacuum 10−4–10−5 (mbar) |

| Preheating (°C) | 200 (building table resistive heating) | 700 (powder bed heating by defocused electron beam) |

| Maximum beam power (W) | 120 | 3500 |

| Laser/electron beam spot (μm) | 30–250 | 200–1000 |

| Average powder layer thickness (μm) | 20–100 | 50–200 |

| Beam scan speed (m/s) | 0.3–1.0 | >1000 |

| Parameter | Realizer SLM50 | Arcam EBM S12 |

|---|---|---|

| Beam power (W) | 110 | 50–3500 * |

| Layer thickness (µm) | 50 | 50 |

| Scan speed (m/s) | 0.5 | 0.5 |

| Atmosphere | 0.4–0.6 vol. O2 | Vacuum 10−4–10−5 mbar |

| Process | Powder Supplier | Percentage by Weight | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Al | V | O | C | N | H | Other Max. | Ti | ||

| SLM | AP&C | 5.50–6.75 | 3.50–4.50 | 0.12–0.15 | 0.02 | 0.02 | 0.005 | 0.65 | bal. |

| EBM | ARCAM | 6.00 | 4.00 | 0.15 | 0.03 | 0.01 | 0.003 | 0.10 | bal. |

| Process | Cutting Direction | R02 (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|

| ASTM F136 | >795 | >860 | >10 | |

| Wrought | XY | 832 ± 10 | 933 ± 7 | 13.0 ± 1.5 |

| XZ | 836 ± 9 | 942 ± 8 | 12.5 ± 1.2 | |

| EBM | XY | 846 ± 7 | 976 ± 11 | 15.0 ± 2.0 |

| XZ | 845 ± 9 | 972 ± 14 | 14.2 ± 1.5 | |

| SLM | XY | 1273 ± 53 | 1421 ± 120 | 3.2 ± 0.5 |

| XZ | 1150 ± 67 | 1246 ± 134 | 1.4 ± 0.5 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wysocki, B.; Maj, P.; Sitek, R.; Buhagiar, J.; Kurzydłowski, K.J.; Święszkowski, W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Appl. Sci. 2017, 7, 657. https://doi.org/10.3390/app7070657

Wysocki B, Maj P, Sitek R, Buhagiar J, Kurzydłowski KJ, Święszkowski W. Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Applied Sciences. 2017; 7(7):657. https://doi.org/10.3390/app7070657

Chicago/Turabian StyleWysocki, Bartłomiej, Piotr Maj, Ryszard Sitek, Joseph Buhagiar, Krzysztof Jan Kurzydłowski, and Wojciech Święszkowski. 2017. "Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants" Applied Sciences 7, no. 7: 657. https://doi.org/10.3390/app7070657

APA StyleWysocki, B., Maj, P., Sitek, R., Buhagiar, J., Kurzydłowski, K. J., & Święszkowski, W. (2017). Laser and Electron Beam Additive Manufacturing Methods of Fabricating Titanium Bone Implants. Applied Sciences, 7(7), 657. https://doi.org/10.3390/app7070657