Researching a Fuzzy- and Performance-Based Optimization Method for the Life-Cycle Cost of SRHPC Frame Structures

Abstract

:1. Introduction

2. Experimental Study on Seismic Performance of SRHPC Frame Columns

2.1. Determination of Performance Objectives

2.2. The Selection of a Performance Index

2.3. Quantization of SRHPC Framework Seismic Performance Index

2.3.1. The Performance Index Quantization of SRHPC Frame Structures

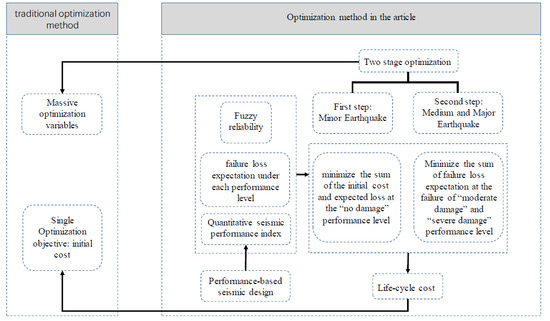

3. Performance-Based Optimization Model for the Life-Cycle Cost of SRHPC Frame Structures

3.1. Performance-Based Life-Cycle SRHPC Frame Optimization Mathematical Model

3.2. The Calculation Method of SRHPC Frame Structure’s Optimization in Stages

3.2.1. The First Optimization Stage under a Minor Earthquake

3.2.2. The Second Optimization Stage under a Medium or Major Earthquake

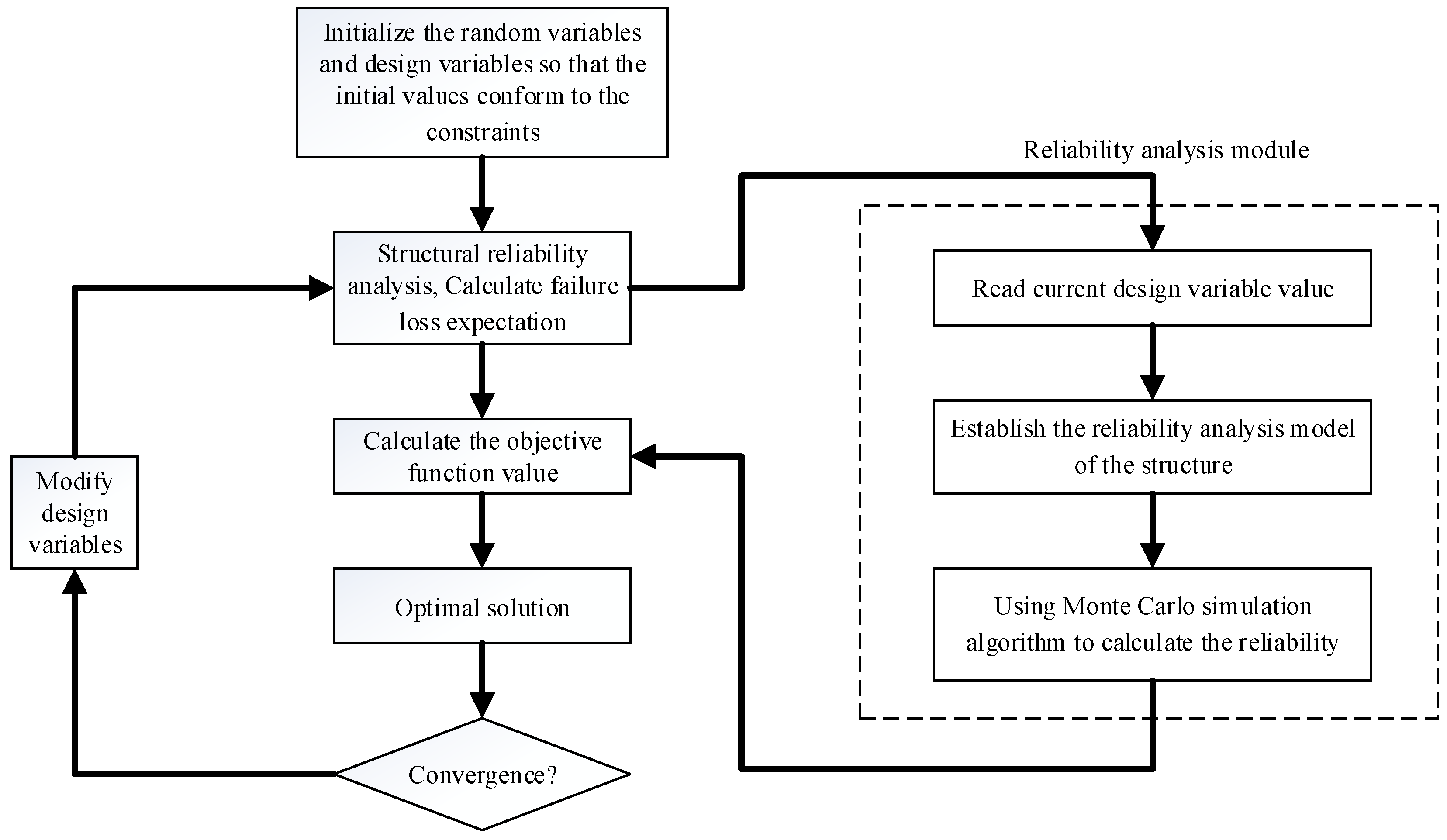

4. The Calculation of Reliability Based on Fuzzy Mathematics

4.1. The Calculation Method of Fuzzy Reliability

4.2. The Calculation Method of Structural Reliability

4.3. Fuzzy Seismic Spectra

4.3.1. Fuzziness of Seismic Intensity

4.3.2. Fuzziness of Site Category

4.3.3. Fuzzy Comprehensive Evaluation of Site Classification

- (1)

- Obtain the maximum value of horizontal earthquake influence coefficient αmax from Equation (26).

- (2)

- Identify the depth of site overburden layer d based on the site drilling geological data, and calculate the equivalent shear wave velocity vs according to formula .

- (3)

- Calculate single factor fuzzy relation vector in accordance with the membership function of equivalent shear wave velocity in Equation (28). During first-step evaluation, there is just one evaluation factor, which is equivalent shear wave velocity, so the fuzzy relation mentioned above is also the membership degree of the mean shear wave velocity to every site classification evaluation grade, that is V = A, .

- (4)

- According to the membership functions Equations (30)–(33) of overburden thickness, calculate the evaluation factors of the fuzzy relation matrix for B. The calculation formula of the fuzzy vector of evaluation grade for site classification is .

- (5)

- Calculate the comprehensive evaluation value of site characteristic period according to Equation (34).

- (6)

- After obtaining parameters αmax and , which are given full consideration of fuzziness, use the parameters of the earthquake response spectrum curve from the Chinese seismic design specifications [21] before the fuzzy earthquake response spectrum can be obtained.

4.4. A Simplified Method for the Calculation of Reliability

- (1)

- Obtain the probability statistic characteristics of the structural resistance term and the seismic effect term, which mainly includes the distribution pattern, the mean value, and the variable coefficient. This paper assumes the resistance term and seismic effect term expressed in the inter-story drift form and their distribution type is lognormal distribution [29,30].

- (2)

- Calculate the standard values of the SRHPC frame structural seismic effect according to the fuzzy seismic response spectrum, then obtain the average values of the earthquake effect according to Step (1). The standard values of the SRHPC frame structural resistance term are the quantitative values of the performance index, which were obtained in Section 2.3.1 and shown in Table 3. Next, the mean value of the resistance item can be obtained by Step (1).

- (3)

- After obtaining the types of probability distribution, average and the variation coefficient of the resistance and seismic effect items, an explicit performance function was established, as shown in Equation (35). The fuzzy reliability degree of the frame structure under different performance levels can be calculated according to the improved Monte Carlo simulation method mentioned in Section 4.

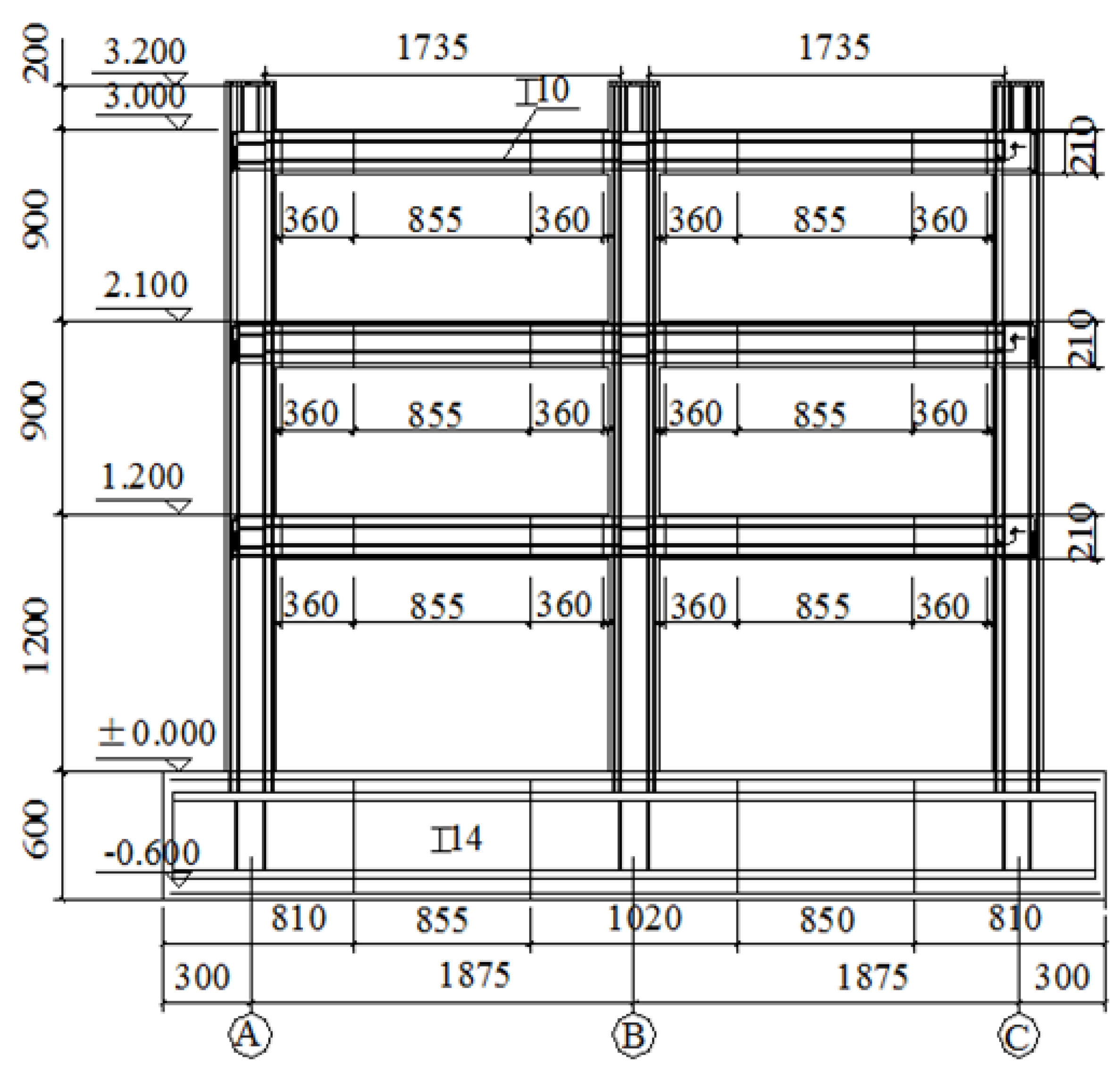

5. Optimization Example

5.1. Example

- Concrete: 1.0 × 10−3 RMB/(mm2·m);

- Section steel: 2.886 × 102 RMB/(mm2·m);

- Longitudinal reinforcement: 2.340 × 10−2 RMB/(mm2·m);

- Stirrup: 2.106 × 10−2 RMB/(mm2·m).

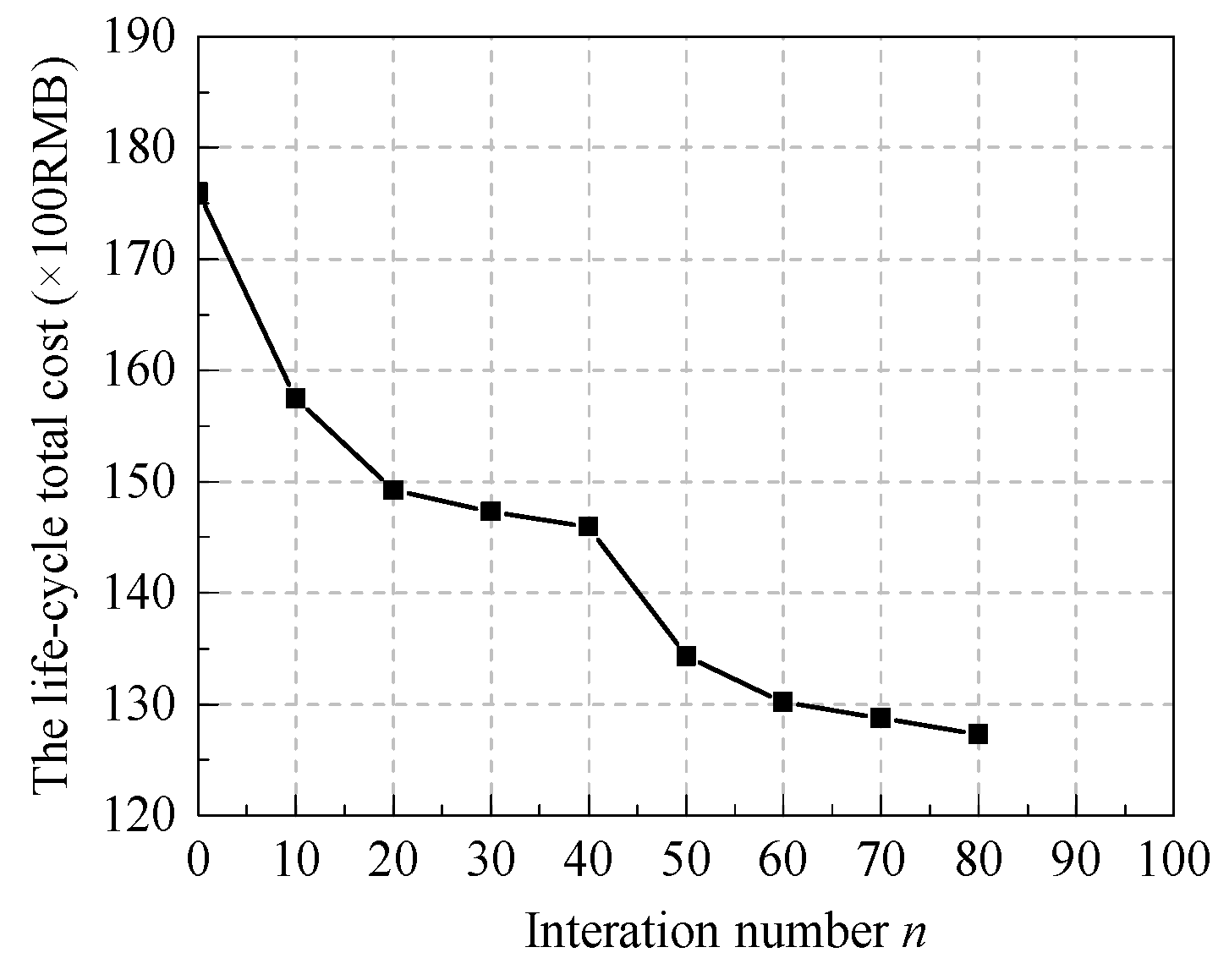

5.2. Optimization Program

6. Conclusions and Future Research

- (1)

- A fuzzy mathematics and performance-based optimization method for the life-cycle cost of SRHPC frame structures was proposed that can not only obtain good economic benefits, but also guarantee the performance of the structure so that the structure design can achieve a balance between economy and reliability.

- (2)

- After considering the complexity of the design optimization of SRHPC frame structures, a two-stage optimization calculation method was proposed. This method can effectively reduce the number of design variables and constraints in the optimization process as well as simplify the optimization process.

- (3)

- The fuzzy reliability theory was proposed to consider the fuzziness existing in the failure of the SRHPC frame. Fuzzy mathematics was adopted to develop the fuzzy seismic response spectra to consider the fuzziness existing in seismic intensity and site classification.

- (4)

- The proposed optimization was programmed by MATLAB, and an example was used to verify the optimization method where the life-cycle cost of the structure dropped by 27.31% after optimization. The results show the effectiveness and feasibility of the optimization method.

- (1)

- In this study, the SRHPC frame columns’ test data were considered the main object of analysis to quantify the performance index of the SRHPC frame structures; the impact of other components on the SRHPC frame structures was not considered.

- (2)

- The actual initial cost of a structure includes not only the cost of materials, but also the machinery costs, labor costs, and so on. This study only considered the loss of the initial material costs of a structure. The impact of the loss of the non-structural and maintenance costs of the structure were not considered.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| X | = | design variable vector; |

| i | = | refer to the ith layer of the SRHPC frame structure; |

| j | = | refer to the jth row column or beam of the given floor; |

| = | life-cycle total cost; | |

| = | initial cost of structure; | |

| = | loss value of structure corresponding to each performance level; | |

| = | fuzzy failure probability of structure corresponding to each performance level; | |

| = | loss expectation of structure corresponding to each performance level; | |

| = | reliability target value corresponding to each performance level; | |

| , | = | the number of constraints in equality and inequality; |

| , | = | weighted coefficient, used to reflect the importance of different structures; |

| bij,c, hij,c | = | the width and height of the SRHPC frame column; |

| hij,b | = | the height of the SRHPC frame beam; |

| , | = | the area of section steel in SRHPC frame column and beam; |

| , | = | the web’s area of section steel in SRHPC frame beam and column; |

| , | = | stirrup’s reinforcement ratio of beam and column; |

| , , | = | the loss value of structure corresponding to “no damage”, “moderate damage”, and “severe damage” performance levels; |

| , , | = | the fuzzy failure probability corresponding to “no damage”, “moderate damage”, and “severe damage” performance levels; |

| = | the shear span ratio of column and beam; | |

| = | the strength grade of concrete; | |

| , | = | the calculated height of frame column; |

| , | = | the yield strength of the stirrup and section steel; |

| = | the design value of axial pressure of frame column considering seismic action combination; | |

| = | the seismic adjustment coefficient of bearing capacity; | |

| , | = | shearing force design value of column and beam; |

| , , , | = | diameter and spacing of stirrups in column and beam; |

| , , | = | story drift of structures corresponding to “no damage”, “moderate damage”, and “severe damage” performance levels; |

| , , | = | threshold for story drift corresponding to “no damage”, “moderate damage”, and “severe damage” performance levels; |

| , | = | the flexural stiffness of the column and beam; |

| , | = | the shear stiffness of the section steel of column and beam; |

| , , , | = | the section steel flange’s width and thickness of column and beam; |

| , , , | = | the section steel web’s height and thickness of column and beam; |

| = | the volume radio of reinforcement; | |

| = | the random variable used to express the structural resistance term, which represents inter-story drift, whose standard value can be seen in Table 3; | |

| = | the load effect term, which represents in-story drift. |

References

- Iannaccone, G.; Salvalai, G.; Sesana, M.M.; Paolini, R. Integrated approaches for large scale energy retrofitting of existing residential building through innovative external insulation prefabricated panels. In Proceedings of the Sustainable Built Environment (SBE) Regional Conference, Zurich, Switzerland, 13–17 June 2016.

- Masera, G.; Iannaccone, G.; Salvalai, G. Retrofitting the existing envelope of residential buildings: Innovative technologies, performance assessment and design methods. In Proceedings of the Advanced Building Skins—9th Energy Forum 2014, Bressanone, Italy, 28–29 October 2014.

- Fragiadakis, M.; Lagaros, N.D.; Papadrakakis, M. Performance-based multiobjective optimum design of steel structures considering life-cycle cost. Struct. Multidiscip. Optim. 2006, 32, 1–11. [Google Scholar] [CrossRef]

- Kaveh, A.; Azar, B.F.; Hadidi, A.; Sorochi, F.R.; Talatahari, S. Performance-based seismic design of steel frames using ant colony optimization. Steel Constr. 2010, 66, 566–574. [Google Scholar] [CrossRef]

- Kaveh, A.; Shojaei, I.; Gholipour, Y.; Rahami, H. Seismic design of steel frames using multi-objective optimization. Struct. Eng. Mech. 2013, 45, 211–232. [Google Scholar] [CrossRef]

- Gong, Y.; Xue, Y.; Xu, L. Optimal capacity design of eccentrically braced steel frameworks using nonlinear response history analysis. Eng. Struct. 2013, 48, 28–36. [Google Scholar] [CrossRef]

- Kaveh, A.; Bakhshpoori, T.; Azimi, M. Seismic optimal design of 3D steel frames using cuckoo search algorithm. Struct. Des. Tall Spec. Build. 2014, 24, 210–227. [Google Scholar] [CrossRef]

- Lu, H. Genetic Algorithm and Optimality Criteria Method Based Optimum Design for Tall Buildings. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 21 September 2009. [Google Scholar]

- Gencturk, B.; Hossain, K.A. Optimal Design of RC Frames Using Nonlinear Inelastic Analysis. In Computational Methods in Earthquake Engineering; Springer: Heidelberg, Germany, 2013; pp. 545–568. [Google Scholar]

- Zou, X.K.; Chan, C.M.; Li, G.; Wang, Q. Multiobjective optimization for performance-based design of reinforced concrete frames. J. Struct. Eng. 2007, 133, 1462–1474. [Google Scholar] [CrossRef]

- Senouci, A.B.; Al-Ansari, M.S. Cost optimization of composite beams using genetic algorithms. Adv. Eng. Softw. 2009, 40, 1112–1118. [Google Scholar] [CrossRef]

- Luo, Y.; Li, A.; Kang, Z. Reliability-based design optimization of adhesive bonded steel-concrete composite beams with probabilistic and non-probabilistic uncertainties. Eng. Struct. 2011, 33, 2110–2119. [Google Scholar] [CrossRef]

- Papavasileiou, G.S.; Charmpis, D.C. Seismic design optimization of multi–storey steel–concrete composite buildings. Comput. Struct. 2016, 170, 49–61. [Google Scholar] [CrossRef]

- Chan, C.M. Optimal lateral stiffness design of tall buildings of mixed steel and concrete construction. Struct. Des. Tall Build. 2001, 10, 155–177. [Google Scholar] [CrossRef]

- Papavasileiou, G.S.; Charmpis, D.C. Design optimization of steel-concrete composite structures with requirements on progressive collapse resistance. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Portugal, 24–28 September 2012; pp. 48–49.

- Shan, S.P. High performance concrete: Past, present and future. In Proceedings of the International Symposium of High Performance Concrete-Workability, Strength and Durability, Hong Kong/Shenzhen, China, 10–15 December 2000; Volume I, pp. 3–30.

- Deng, G. Mechanical Behaviors and Seismic Design of Steel Reinforced High Strength High Performance Concrete Composite Structures. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2008. [Google Scholar]

- Zeng, L.; Parvasi, S.M.; Kong, Q.; Huo, L.; Lim, I.; Li, M.; Song, G. Bond slip detection of concrete-encased composite structure using shear wave based active sensing approach. Smart Mater. Struct. 2015, 24, 125026. [Google Scholar] [CrossRef]

- Xu, C.H.; Zeng, L.; Zhou, Q.; Wu, Y.; Tu, X. Cyclic performance of concrete-encased composite columns with T-shaped steel sections. Int. J. Civ. Eng. 2015, 13, 456–467. [Google Scholar]

- Zeng, L.; Cui, Z.; Xiao, Y.; Jin, S.; Wu, Y. Cyclical behavior of concrete-encased composite frame joints with high strength concrete. Adv. Mater. Sci. Eng. 2015, 2015, 1–13. [Google Scholar] [CrossRef]

- National Standard of the People’s Republic of China: Code for Seismic Design of Buildings. GB 50011–2010, 2010.

- Vision, S. Performance based seismic engineering of building. Struct. Eng. Assoc. Calif. (SEAOC) 1995. [Google Scholar]

- Zheng, S.S. Experimental Study Report on Seismic Behaviors of Steel Reinforced High Strength and High Performance Concrete Frame’s Beams, Columns, and Joints; Research Data of College of Civil Engineering Xi’an University of Architecture and Technology: Xi’an, China, 2007. (In Chinese) [Google Scholar]

- Vatn, J. A discussion of the acceptable risk problem. Reliab. Eng. Syst. Saf. 1998, 61, 11–19. [Google Scholar] [CrossRef]

- Cheng, G.D. Introduction to Optimum Design of Engineering Structures; China Water & Power Press: Beijing, China, 1993. [Google Scholar]

- Gao, X. Anti-Seismic Levels for Buildings of Various Importance; Building Science: Westford, MA, USA, 1999. [Google Scholar]

- Unified Standard for Reliability Design of Building Structures. GB50068, 2001.

- Wang, G.Y. Exploration of Structural Soft Design; Harbin Civil Engineering Institute Press: Harbin, China, 1987. [Google Scholar]

- Wu, B.; Li, Y.H. Determination of representative value of target displacement in displacement reliability-based seismic design method. Earthq. Eng. Eng. Vib. 2002, 22, 44–51. [Google Scholar]

- Wei, C.J.; Gao, L.; Gao, X.W.; Li, W.Z. Seismic reliability analysis of structure based upon limit elasto-plastic story drift. Eng. Mech. 1986, 3, 60–70. [Google Scholar]

- He, W. Research of Performance-Based Optimization Method for the Life-Cycle Cost of SRHPC Frame Structures. Master’s Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2013. [Google Scholar]

| Performance Levels | No Damage | Repairable | No Collapse | |

|---|---|---|---|---|

| Seismic risk level | Frequent earthquake | 1 | — | — |

| Occasional earthquake | 2 | 1 | — | |

| Rare earthquake | 3 | 2 | 1 | |

| Failure Stage | Failure Patterns | |||||

|---|---|---|---|---|---|---|

| Bending Failure | Shear Bond Failure | Shear Diagonal Compression Failure | ||||

| I | m | I | m | I | m | |

| component cracking | [1/300, 1/190] | 1/242 | [1/205, 1/101] | 1/151 | [1/135, 1/110] | 1/123 |

| component yielded | [1/160, 1/115] | 1/141 | [1/115, 1/78] | 1/110 | [1/90, 1/60] | 1/71 |

| ultimate load | [1/108, 1/60] | 1/78 | [1/83, 1/51] | 1/63 | [1/59, 1/31] | 1/35 |

| component failure | [1/55, 1/32] | 1/39 | [1/38, 1/21] | 1/30 | [1/25, 1/18] | 1/21 |

| Earthquake Intensity | Minor Earthquake | Medium Earthquake | Major Earthquake |

|---|---|---|---|

| performance level | no damage | repairable | no collapse |

| economic acceptability for renovation of building | complete acceptance | acceptable | unacceptable |

| safety | safe | safe | life safe |

| threshold for story drift angle | 1/450 | 1/135 | 1/50 |

| Damage Degree | Intact | Slight | Moderate | Extensive | Collapse |

|---|---|---|---|---|---|

| Ratio | 0.02 | 0.105 | 0.3 | 0.7 | 1.0 |

| Cost | Initial Cost/RMB | Failure Loss Expectation/RMB | Life-Cycle Cost/RMB |

|---|---|---|---|

| Before optimization | 13,377 | 4227 | 17,604 |

| After optimization | 9261 | 3535 | 12,796 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, J.; Dong, L.-g.; Zheng, S.-s.; Zeng, L.; Xiang, Z.-h.; He, W. Researching a Fuzzy- and Performance-Based Optimization Method for the Life-Cycle Cost of SRHPC Frame Structures. Appl. Sci. 2017, 7, 269. https://doi.org/10.3390/app7030269

Zheng J, Dong L-g, Zheng S-s, Zeng L, Xiang Z-h, He W. Researching a Fuzzy- and Performance-Based Optimization Method for the Life-Cycle Cost of SRHPC Frame Structures. Applied Sciences. 2017; 7(3):269. https://doi.org/10.3390/app7030269

Chicago/Turabian StyleZheng, Jie, Li-guo Dong, Shan-suo Zheng, Lei Zeng, Ze-hui Xiang, and Wei He. 2017. "Researching a Fuzzy- and Performance-Based Optimization Method for the Life-Cycle Cost of SRHPC Frame Structures" Applied Sciences 7, no. 3: 269. https://doi.org/10.3390/app7030269