Development of a Staggered PCD End Mill for Carbon Fiber Reinforced Plastic

Abstract

:1. Introduction

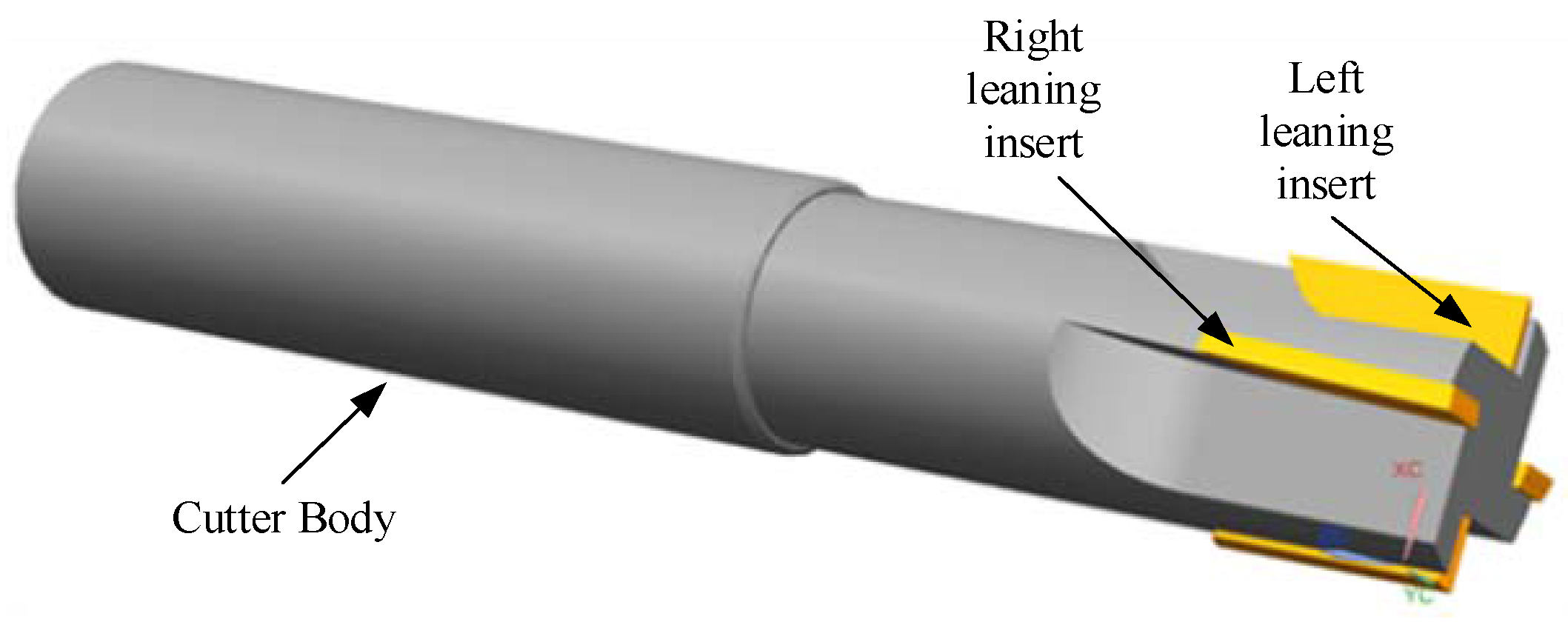

2. Design of Staggered PCD End Mill

2.1. Structural Design

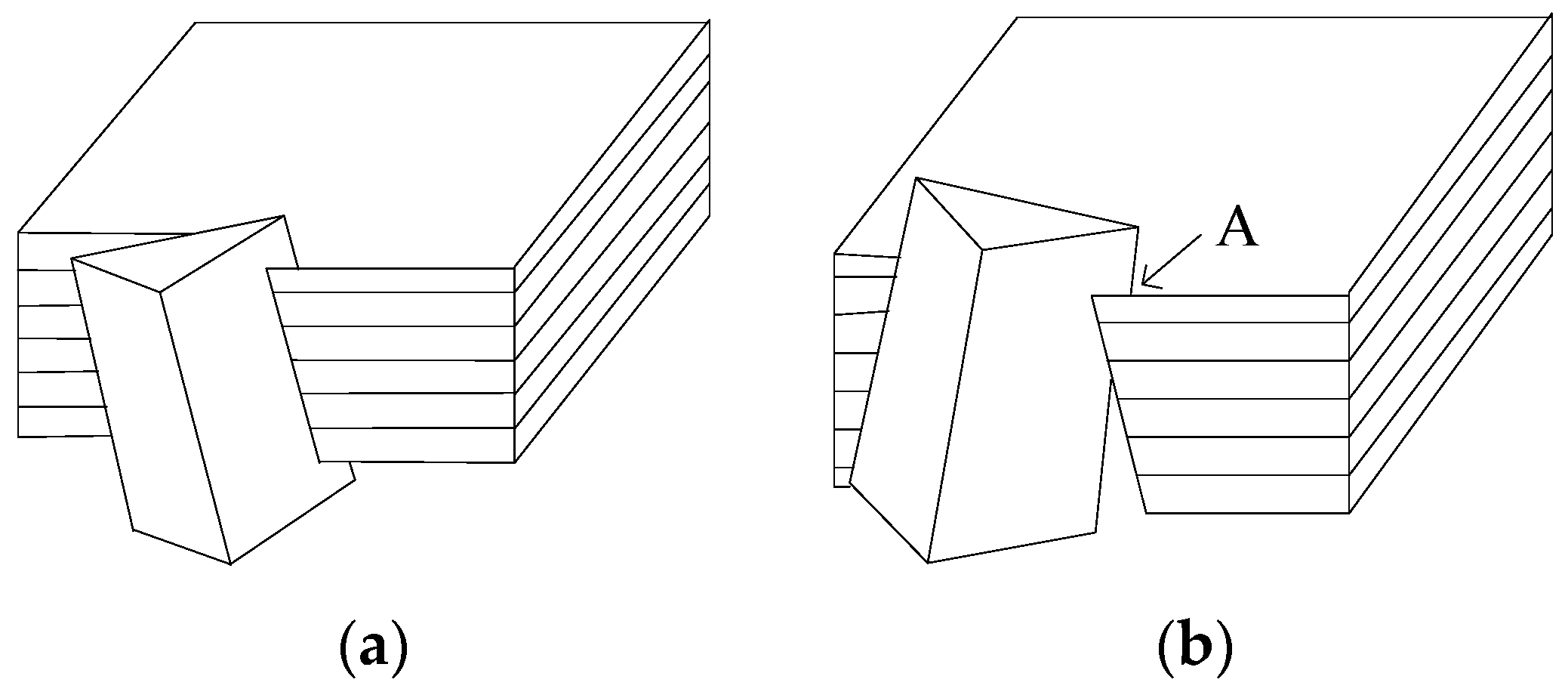

2.2. Design of Flute and Insert Pocket

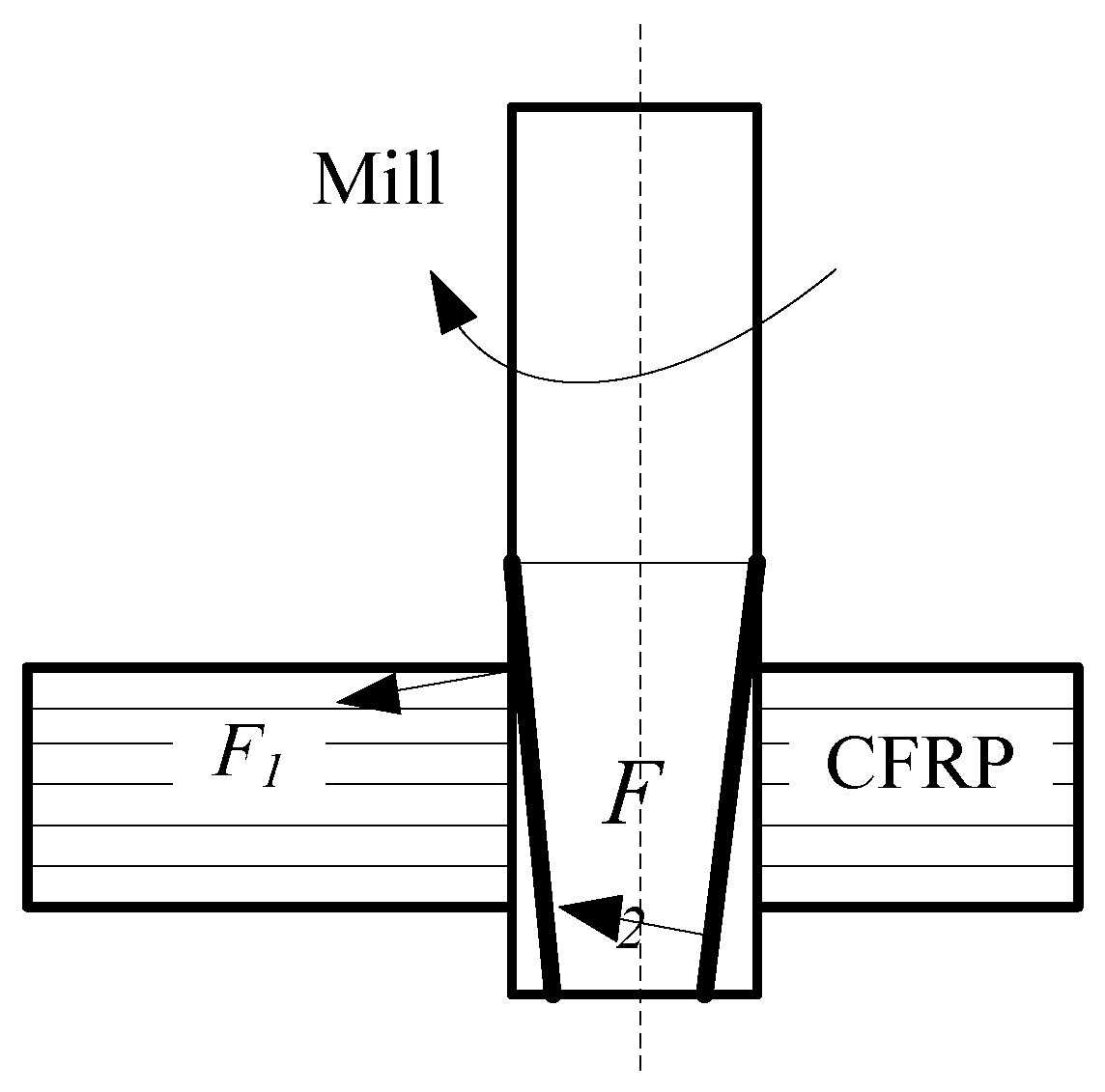

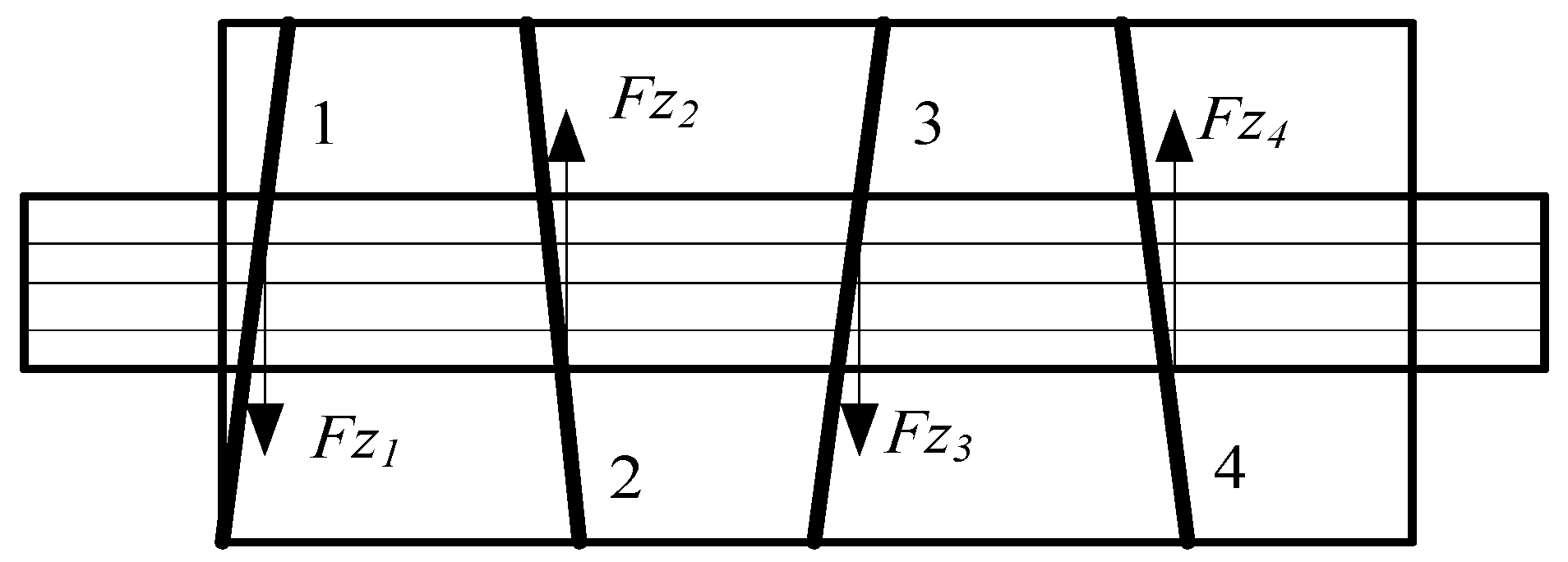

2.3. Analysis of Milling Process

2.4. Analysis of Machining Defects

2.5. Material of the Staggered PCD End Mill

2.6. Structural Parameters of the Staggered PCD End Mill

3. Fabrication of the Staggered PCD End Mill

- (1)

- Preparation and cutting of PCD composite film: according to the shape of the flute, the PCD composite film is cut into the designed shape by wire cutting.

- (2)

- NC machining of flute and insert pockets for the cemented carbide tool body: A 5-axis CNC grinding center is used to process the flute and insert pockets according to the design requirements.

- (3)

- Welding of PCD insert: Using high frequency induction brazing, silver-based solder and QJ102 silver brazing flux are used to weld the PCD inserts to the cemented carbide cutter tool body.

- (4)

- Grinding and passivation of the PCD cutting edges: The EWAG super-hard tool grinder is used to grind the flank of the PCD tool.

4. Milling Experiment of CFRP

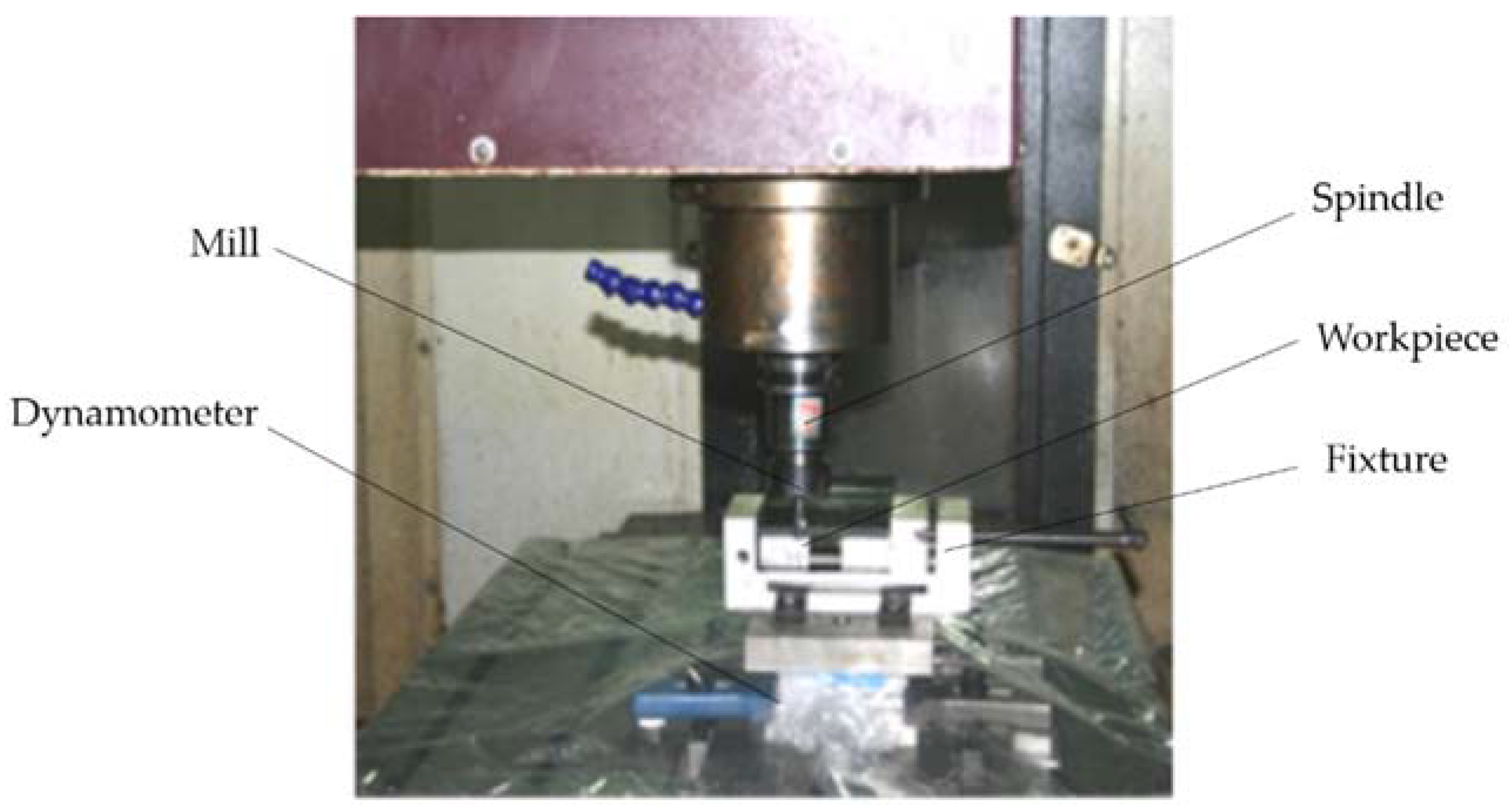

4.1. Experimental Setup

4.2. Design of Experiment with the Staggered PCD End Mill

4.2.1. Design of Experiment

4.2.2. Range Analysis

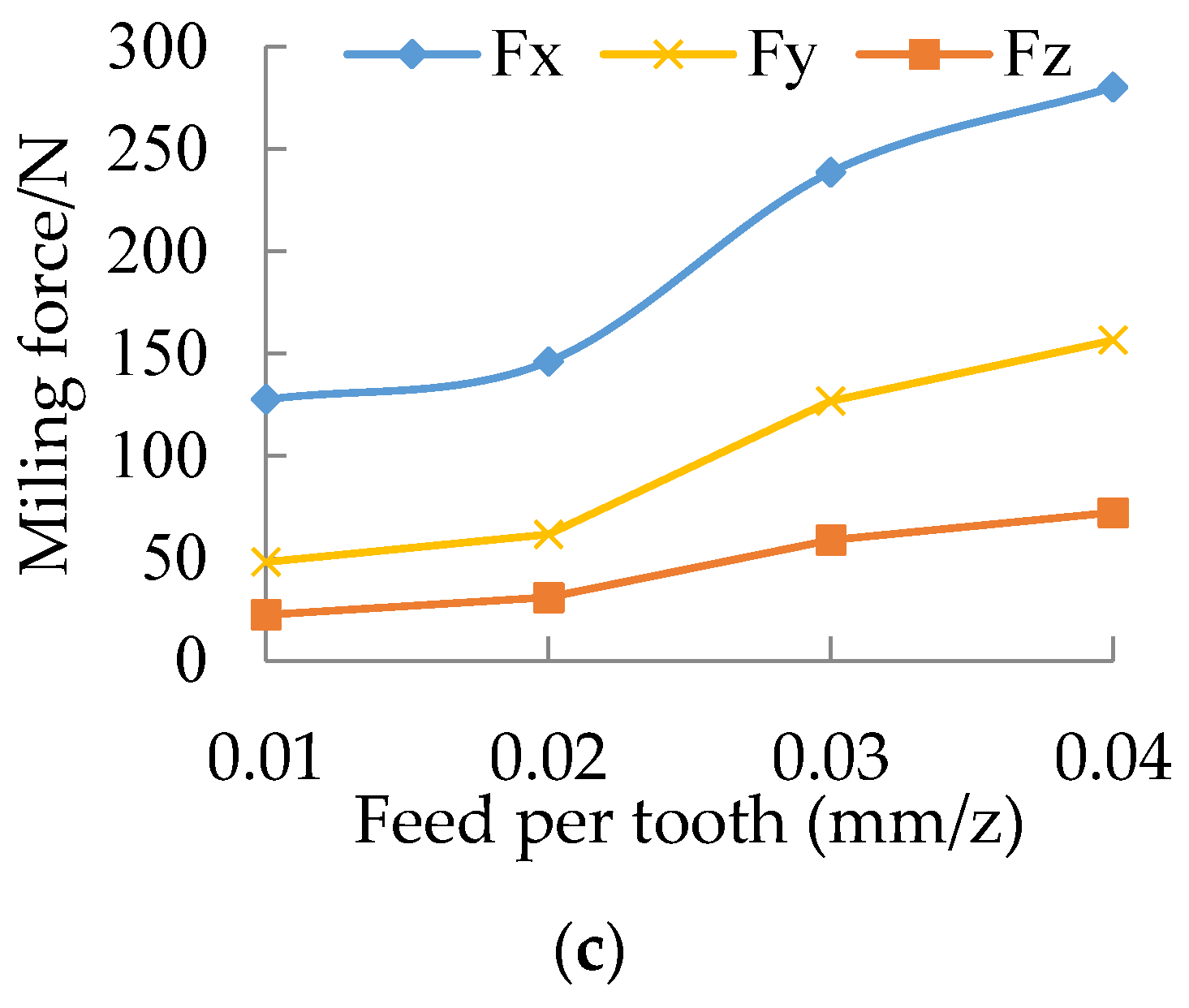

4.3. Influence of Milling Parameters on Milling Force

5. Regression Model of Milling Force

5.1. Regression Model

5.2. Significance Test of Regression Model

5.3. Experimental Verification

6. Effects of Fiber Cutting Angle on Milling Force

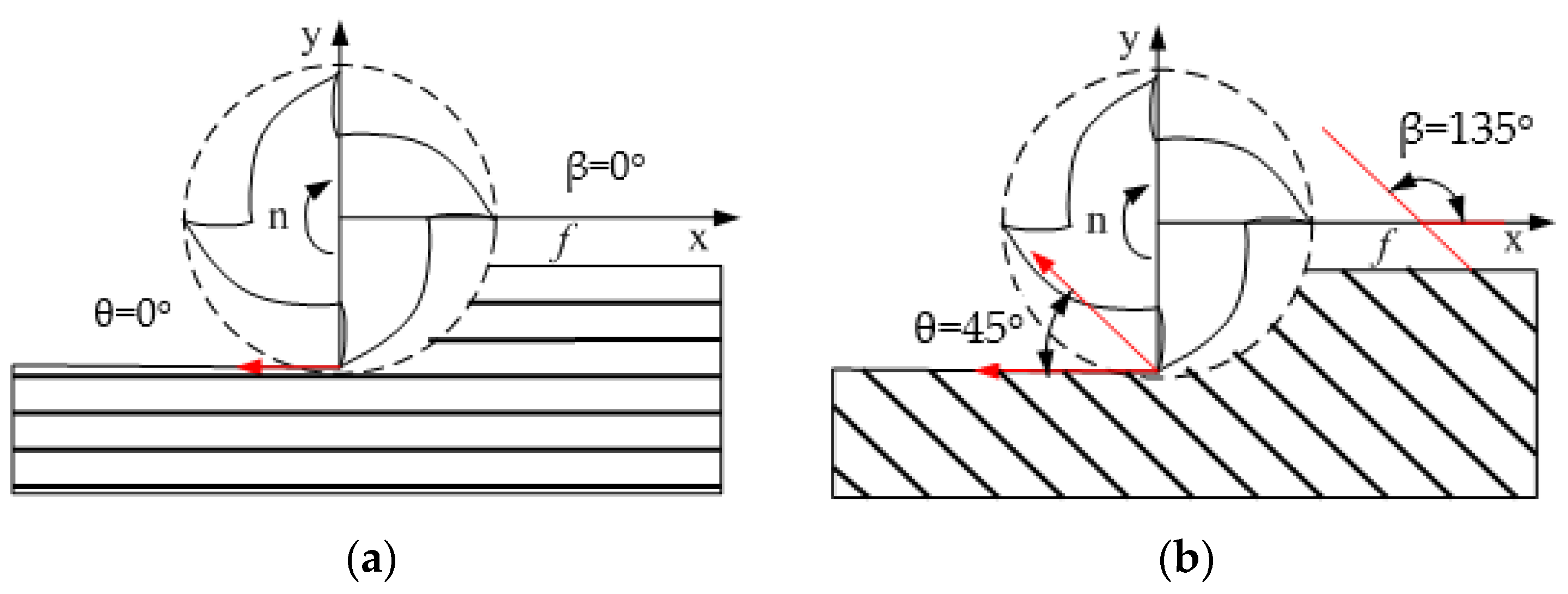

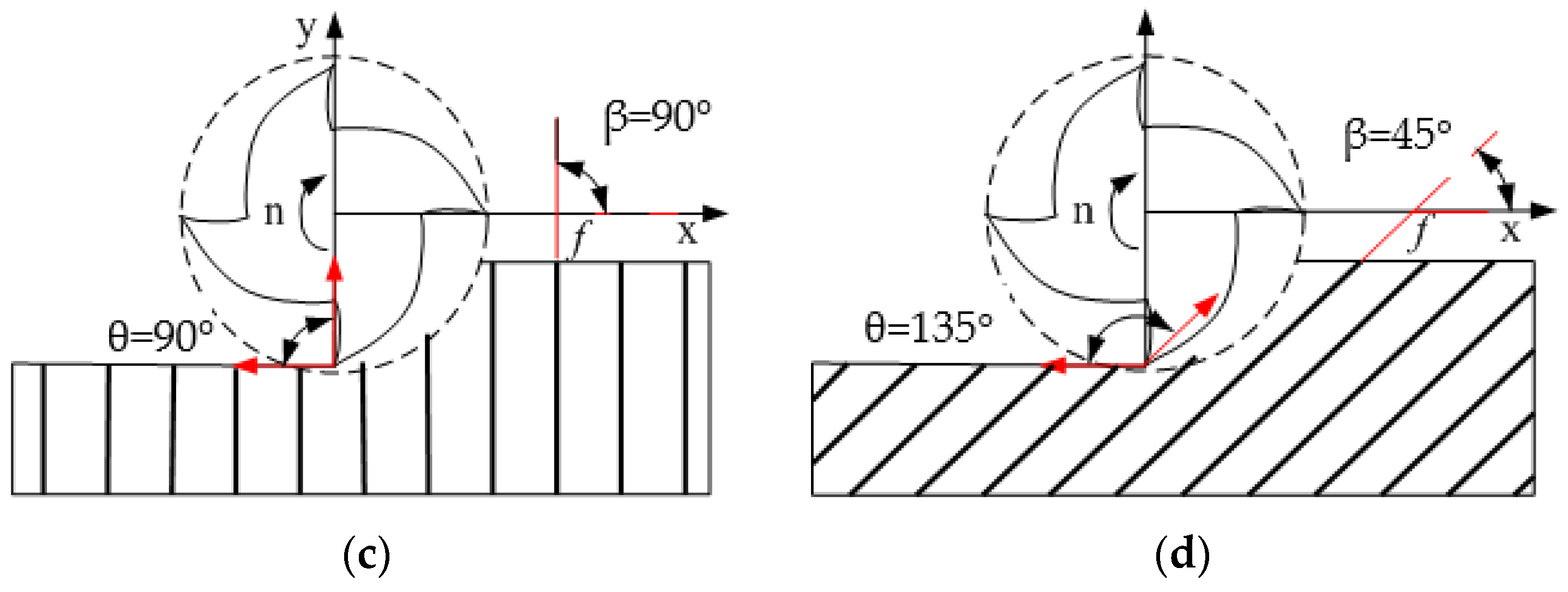

6.1. Definition of Fiber-Cutting Angle

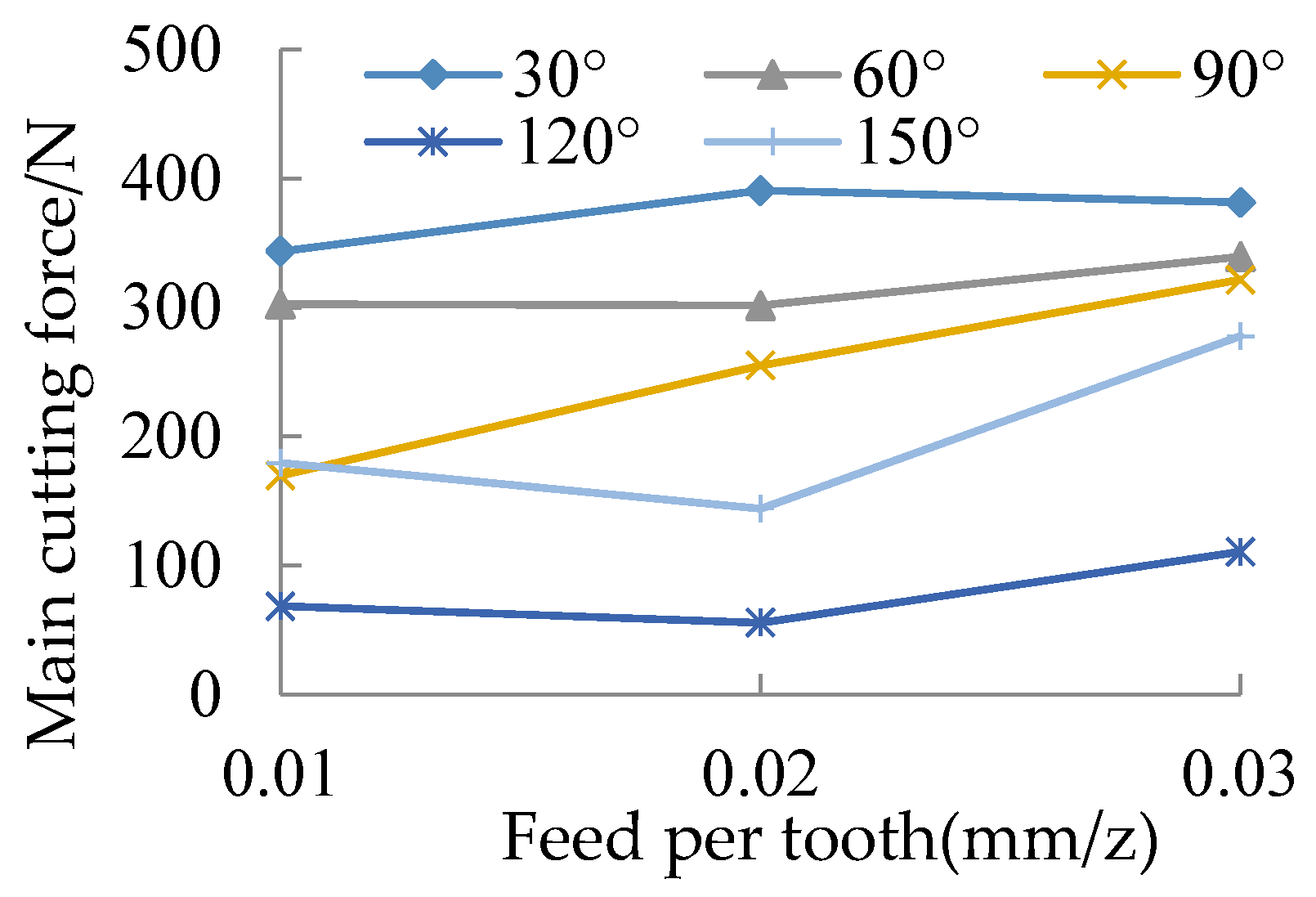

6.2. Influence of Trimming Fiber Orientation on Milling Force

7. Conclusions

- (1)

- A staggered PCD end mill is designed for CFRP milling. The milling process of the staggered PCD end mill is analyzed, and the structural parameters of the tool are designed as the tool diameter is 12 mm, the rake angle is 3°, the rear angle is 10° and the inclination angle is 3°. The cemented carbide K40UF is selected as the tool body material.

- (2)

- Tool grinding and PCD composite cutting are conducted, and the welding process of the staggered PCD end mill is proposed. The tool fabrication is done using high-frequency induction brazing and cutting-edge grinding.

- (3)

- An empirical prediction model of milling force is established, and the significance test of the regression model is verified. It is found that the milling force decreases with the milling speed and increases with the feed per tooth and milling width.

- (4)

- In unidirectional CFRP milling, the main cutting force in down milling (0° < θ < 90°) is larger than that in up milling (90° < θ < 180°). During down milling, the cutting force increases first and then decreases with the increase in feed per tooth; during up milling, the cutting force decreases first and then increases with the increase in feed per tooth.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Abena, A.; Soo, S.L.; Essa, K. A finite element simulation for orthogonal cutting of UD-CFRP incorporating a novel fibre-matrix interface model. Procedia CIRP 2015, 31, 539–544. [Google Scholar] [CrossRef]

- Slamani, M.; Gauthier, S.; Chatelain, J.F. A study of the combined effects of machining parameters on cutting force components during high speed robotic trimming of CFRPs. Measurement 2015, 59, 268–283. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, K.; Cheng, H.; Qi, Z.; Meng, Q. A cutting force predicting model in orthogonal machining of unidirectional CFRP for entire range of fiber orientation. Int. J. Adv. Manuf. Technol. 2017, 89, 833–846. [Google Scholar] [CrossRef]

- Yuan, S.; Zhang, C.; Amin, M.; Fan, H.; Liu, M. Development of a cutting force prediction model based on brittle fracture for carbon fiber reinforced polymers for rotary ultrasonic drilling. Int. J. Adv. Manuf. Technol. 2015, 81, 1223–1231. [Google Scholar] [CrossRef]

- Khairusshima, M.K.N.; Hassan, C.H.C.; Jaharah, A.G.; Amin, A.K.M.; Idriss, A.N.M. Effect of chilled air on tool wear and workpiece quality during milling of carbon fibre-reinforced plastic. Wear 2013, 302, 1113–1123. [Google Scholar] [CrossRef]

- Uhlmann, E.; Schröer, N. Advances in tool grinding and development of end mills for machining of fibre reinforced plastics. Procedia CIRP 2015, 35, 38–44. [Google Scholar] [CrossRef]

- Tanaka, H.; Kitamura, M.; Sai, T. An Evaluation of cutting edge and machinability of inclined planetary motion milling for difficult-to-cut materials. Procedia CIRP 2015, 35, 96–100. [Google Scholar] [CrossRef]

- Mathivanan, N.R.; Mahesh, B.S.; Shetty, H.A. An Experimental investigation on the process parameters influencing machining forces during milling of carbon and glass fiber laminates. Measurement 2016, 91, 39–45. [Google Scholar] [CrossRef]

- Gao, C.; Xiao, J.; Xu, J.; Ke, Y. Factor analysis of machining parameters of fiber-reinforced polymer composites based on finite element simulation with experimental investigation. Int. J. Adv. Manuf. Technol. 2016, 83, 1113–1125. [Google Scholar] [CrossRef]

- Ghafarizadeh, S.; Chatelain, J.F.; Lebrun, G. Finite element analysis of surface milling of carbon fiber-reinforced composites. Int. J. Adv. Manuf. Technol. 2016, 87, 399–409. [Google Scholar] [CrossRef]

- Hosokawa, A.; Hirose, N.; Ueda, T.; Furumoto, T. High-quality machining of CFRP with high helix end mill. CIRP Ann. Manuf. Technol. 2014, 63, 89–92. [Google Scholar] [CrossRef]

- Pecat, O.; Rentsch, R.; Brinksmeier, E. Influence of milling process parameters on the surface integrity of CFRP. Procedia CIRP 2012, 1, 466–470. [Google Scholar] [CrossRef]

- Hintze, W.; Cordes, M.; Koerkel, G. Influence of weave structure on delamination when milling CFRP. J. Mater. Process. Technol. 2015, 216, 199–205. [Google Scholar] [CrossRef]

- Leone, C.; Papa, I.; Tagliaferri, F.; Lopresto, V. Investigation of CFRP laser milling using a 30 W Q-switched Yb:YAG fiber laser: Effect of process parameters on removal mechanisms and HAZ formation. Compos. A Appl. Sci. Manuf. 2013, 55, 129–142. [Google Scholar] [CrossRef]

- Jeyapaul, R.; Jenarthanan, M.P. Machinability study of carbon fibre reinforced polymer (CFRP) composites using design of experiment technique. Pigment Resin Technol. 2013, 43, 35–44. [Google Scholar]

- Maegawa, S.; Morikawa, Y.; Hayakawa, S.; Itoigawa, F.; Nalamura, T. Mechanism for changes in cutting forces for down-milling of unidirectional carbon fiber reinforced polymer laminates: Modeling and experimentation. Int. J. Mach. Tools Manuf. 2015, 100, 7–13. [Google Scholar] [CrossRef]

- Karpat, Y.; Polat, N. Mechanistic force modeling for milling of carbon fiber reinforced polymers with double helix tools. CIRP Ann. Manuf. Technol. 2013, 62, 95–98. [Google Scholar] [CrossRef] [Green Version]

- Karpat, Y.; Bahtiyar, O.; Değer, B. Mechanistic force modeling for milling of unidirectional carbon fiber reinforced polymer laminates. Int. J. Mach. Tools Manuf. 2012, 56, 79–93. [Google Scholar] [CrossRef]

- Wang, H.; Sun, J.; Li, J.; Li, W. Roughness modelling analysis for milling of carbon fibre reinforced polymer composites. Mater. Technology 2015, 30, A46–A50. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Kumar, M.S. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Chibane, H.; Morandeau, A.; Serra, R.; Bouchou, A.; Leroy, R. Optimal milling conditions for carbon/epoxy composite material using damage and vibration analysis. Int. J. Adv. Manuf. Technol. 2013, 68, 1111–1121. [Google Scholar] [CrossRef]

- Jenarthanan, M.P.; Jeyapaul, R. Analysis and optimisation of machinability behaviour of CFRP composites using fuzzy logic. Pigment Resin Technol. 2015, 44, 48–55. [Google Scholar] [CrossRef]

- Haddad, M.; Zitounea, R.; Bougherara, H.; Eyma, F.; Castanié, B. Study of trimming damages of CFRP structures in function of the machining processes and their impact on the mechanical behavior. Compos. B Eng. 2014, 57, 136–143. [Google Scholar] [CrossRef]

- Haddad, M.; Zitounea, R.; Eyma, F.; Castanié, B. Machinability and surface quality during high speed trimming of multi directional CFRP. Int. J. Mach. Machinability Mater. 2013, 13, 289–310. [Google Scholar] [CrossRef]

- Haddad, M.; Zitounea, R.; Eyma, F.; Castanié, B. Influence of machining process and machining induced surface roughness on mechanical properties of continuous fiber composites. Exp. Mech. 2015, 55, 519–528. [Google Scholar] [CrossRef]

- Haddad, M.; Zitounea, R.; Eyma, F.; Castanié, B. Study of the surface defects and dust generated during trimming of CFRP: Influence of tool geometry, machining parameters and cutting speed range. Compos. A Appl. Sci. Manuf. 2014, 66, 142–154. [Google Scholar] [CrossRef]

- Çolak, O.; Sunar, T. Cutting Forces and 3D surface analysis of CFRP milling with PCD cutting tools. Procedia CIRP 2016, 45, 75–78. [Google Scholar] [CrossRef]

- Maegawa, S.; Hayakawa, S.; Itoigawa, F.; Nakamura, T. Development of novel tool for cutting of carbon-fiber-reinforced plastics (Positive use of abrasive wear at tool edge for reduction in cutting force). Mech. Eng. J. 2015, 2, 15-00295. [Google Scholar] [CrossRef]

- Wang, D.H.; Ramulu, M.; Arola, D. Orthogonal cutting mechanisms of graphite/epoxy composite. Part I: Unidirectional laminate. Int. J. Mach. Tools Manuf. 1995, 35, 1623–1638. [Google Scholar] [CrossRef]

- Wern, C.W.; Ramulu, M.; Shukla, A. Investigation of stresses in he orthogonal cutting of fiber-reinforced plastics. Exp. Mech. 1996, 36, 33–41. [Google Scholar] [CrossRef]

- Zitoune, R.; Collombet, F.; Lachaud, F.; Piquet, R.; Pasquet, P. Experiment–calculation comparison of the cutting conditions representative of the long fiber composite drilling phase. Compos. Sci. Technol. 2005, 65, 455–466. [Google Scholar] [CrossRef]

- Yashiro, T.; Ogawa, T.; Sasahara, H. Temperature measurement of cutting tool and machined surface layer in milling of CFRP. Int. J. Mach. Tools Manuf. 2013, 70, 63–69. [Google Scholar] [CrossRef]

- Senthilkumar, M.; Prabukarthi, A.; Krishnaraj, V. Study on tool wear and chip formation during drilling carbon fiber reinforced polymer (CFRP)/titanium alloy (Ti6Al4 V) stacks. Procedia Eng. 2013, 64, 582–592. [Google Scholar] [CrossRef]

| Rake Angle | Relief Angle | Inclination Angle | Tool Length | Tool Diameter | Edge Radius |

|---|---|---|---|---|---|

| 3°/3° | 10°/10° | Staggered 3° | 70 mm | 12 mm | 10 μm |

| Filament Count | Filament Radius | Longitudinal Young Modulus | Transversal Young Modulus | Shear Modulus | Elongation | Density |

|---|---|---|---|---|---|---|

| 12,000 | 7 µm | 142 GPa | 8.4 GPa | 3.8 GPa | 2.11% | 1.8 g/cm3 |

| Ply Orientations | Volume Ratio of Carbon Fiber | Reinforcing Material | Matrix Material | Size (mm) |

|---|---|---|---|---|

| 0°/45°/90°/135° | 60% ± 5% | T700 | AG-80 epoxy | 200 × 110 × 5 |

| Level | Cutting Speed (m/min) | Milling Width (mm) | Feed Peer Tooth (mm/z) |

|---|---|---|---|

| 1 | 50 | 0.5 | 0.01 |

| 2 | 100 | 1 | 0.02 |

| 3 | 150 | 1.5 | 0.03 |

| 4 | 200 | 2 | 0.04 |

| No. | (m/min) | (mm) | (mm/z) | (N) | (N) | (N) |

|---|---|---|---|---|---|---|

| 1 | 50 | 0.5 | 0.01 | 93.40 | 41.25 | 15.08 |

| 2 | 50 | 1 | 0.02 | 137.90 | 82.50 | 30.16 |

| 3 | 50 | 1.5 | 0.03 | 365.60 | 171.15 | 89.70 |

| 4 | 50 | 2 | 0.04 | 434.00 | 239.85 | 99.97 |

| 5 | 100 | 0.5 | 0.02 | 117.20 | 51.30 | 24.57 |

| 6 | 100 | 1 | 0.01 | 112.30 | 43.05 | 14.30 |

| 7 | 100 | 1.5 | 0.04 | 394.30 | 217.95 | 92.04 |

| 8 | 100 | 2 | 0.03 | 304.00 | 157.50 | 71.37 |

| 9 | 150 | 0.5 | 0.03 | 119.60 | 96.15 | 41.21 |

| 10 | 150 | 1 | 0.04 | 137.30 | 81.45 | 57.98 |

| 11 | 150 | 1.5 | 0.01 | 176.40 | 79.65 | 43.68 |

| 12 | 150 | 2 | 0.02 | 170.90 | 61.35 | 34.97 |

| 13 | 200 | 0.5 | 0.04 | 155.00 | 87.00 | 39.65 |

| 14 | 200 | 1 | 0.03 | 165.40 | 82.50 | 33.83 |

| 15 | 200 | 1.5 | 0.02 | 158.70 | 51.30 | 34.06 |

| 16 | 200 | 2 | 0.01 | 128.20 | 29.25 | 16.90 |

| No. | A Cutting Speed | B Milling Width | C Feed per Tooth |

|---|---|---|---|

| 1 | 257.73 | 121.30 | 127.58 |

| 2 | 231.95 | 138.23 | 146.18 |

| 3 | 151.05 | 273.75 | 238.65 |

| 4 | 151.83 | 259.28 | 280.15 |

| R(Max. − Min.) | 106.68 | 152.45 | 152.58 |

| Rank of primary-secondary | C, B, A | ||

| No. | A Cutting Speed | B Milling Width | C Feed per Tooth |

|---|---|---|---|

| 1 | 133.69 | 68.93 | 48.30 |

| 2 | 117.45 | 72.38 | 61.61 |

| 3 | 79.65 | 130.01 | 126.83 |

| 4 | 62.51 | 121.99 | 156.56 |

| R(Max. − Min.) | 71.18 | 61.09 | 108.26 |

| Rank of primary-secondary | C, A, B | ||

| No. | A Cutting Speed | B Milling Width | C Feed per Tooth |

|---|---|---|---|

| 1 | 58.73 | 30.13 | 22.49 |

| 2 | 50.57 | 34.07 | 30.94 |

| 3 | 44.46 | 64.87 | 59.03 |

| 4 | 31.11 | 55.80 | 72.41 |

| R(Max. − Min.) | 27.62 | 34.74 | 49.92 |

| Rank of primary-secondary | C, B, A | ||

| Correlation Coefficient R | Adjustment | Standard Error | |

|---|---|---|---|

| 0.905 | 0.820 | 0.776 | 0.099 |

| Variance Source | Degree of Freedom | Sum of Squares (SS) | Mean Square (MS) | F | Significance |

|---|---|---|---|---|---|

| Regression | 3 | 0.536 | 0.179 | 18.182 | 0.000 |

| Residual | 12 | 0.118 | 0.010 | ― | |

| Sum | 15 | 0.654 | ― | ― |

| Coefficien t | b1 | b2 | b3 | Significance of Regression Coefficient |

|---|---|---|---|---|

| t | 2.551 | 5.101 | 4.692 |

| Experiment No. 1 | Experiment No. 2 | Experiment No. 3 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| (m/min) | 75 | 125 | 175 | ||||||

| (mm) | 0.75 | 1.25 | 1.75 | ||||||

| (mm/z) | 0.015 | 0.025 | 0.035 | ||||||

| Milling force (N) | |||||||||

| Experimental (N) | 119.87 | 59.45 | 22.26 | 185.12 | 84.93 | 39.61 | 231.73 | 110.26 | 59.36 |

| Predicted (N) | 129.32 | 61.0 | 24.74 | 193.9 | 90.12 | 43.62 | 253.2 | 116.54 | 65.82 |

| Error (%) | 7.88 | 2.61 | 11.12 | 4.74 | 6.11 | 10.12 | 9.26 | 5.69 | 10.88 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, G.; Qian, X.; Chen, H.; Gao, F.; Chen, T. Development of a Staggered PCD End Mill for Carbon Fiber Reinforced Plastic. Appl. Sci. 2017, 7, 245. https://doi.org/10.3390/app7030245

Liu G, Qian X, Chen H, Gao F, Chen T. Development of a Staggered PCD End Mill for Carbon Fiber Reinforced Plastic. Applied Sciences. 2017; 7(3):245. https://doi.org/10.3390/app7030245

Chicago/Turabian StyleLiu, Guangjun, Xin Qian, Hongyuan Chen, Fei Gao, and Tao Chen. 2017. "Development of a Staggered PCD End Mill for Carbon Fiber Reinforced Plastic" Applied Sciences 7, no. 3: 245. https://doi.org/10.3390/app7030245

APA StyleLiu, G., Qian, X., Chen, H., Gao, F., & Chen, T. (2017). Development of a Staggered PCD End Mill for Carbon Fiber Reinforced Plastic. Applied Sciences, 7(3), 245. https://doi.org/10.3390/app7030245