5.5.1. Resistance to Rutting at High Temperature

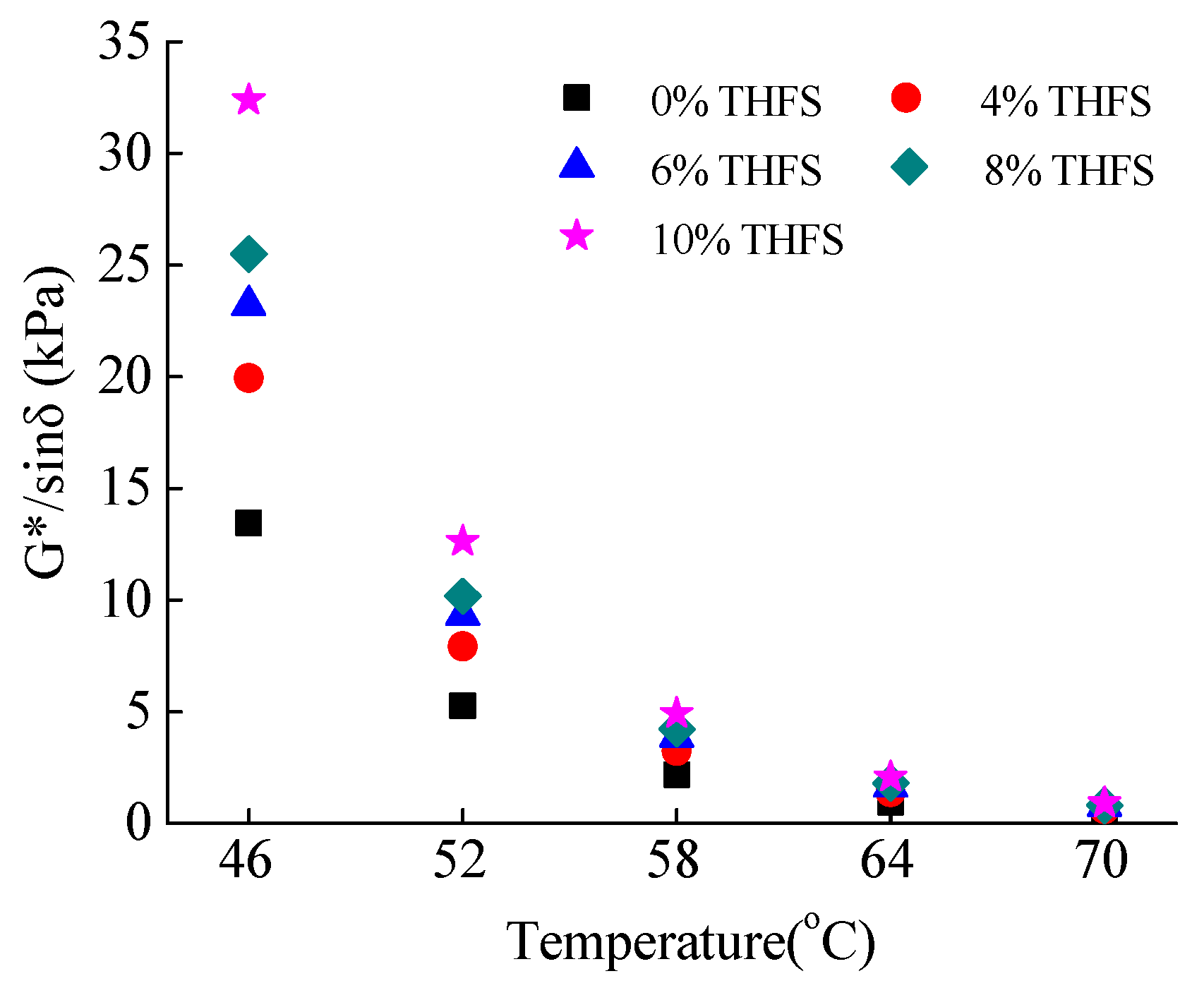

Figure 3 illustrates the

G*/sinδ values of asphalt binders versus test temperatures.

According to the test results in

Figure 3, the

G*/sinδ values of asphalt binders decreased across the test temperature ranges(46 °C to 76 °C with a 6 °C increment). Under the identical condition of THFS content, there was a major decrease in

G*/sinδ value at low temperatures, but a minor decrease was observed at high temperatures. Moreover, the

G*/sinδ had a good exponential correlation with the test temperature with a high correlation coefficient

R2 ranging from 0.9981 to 0.9989 and is given in Equation (1)

where:

G*/sinδ is the rutting parameter of asphalt binder, kPa;

T is the temperature, °C;

A and B are the regression coefficients.

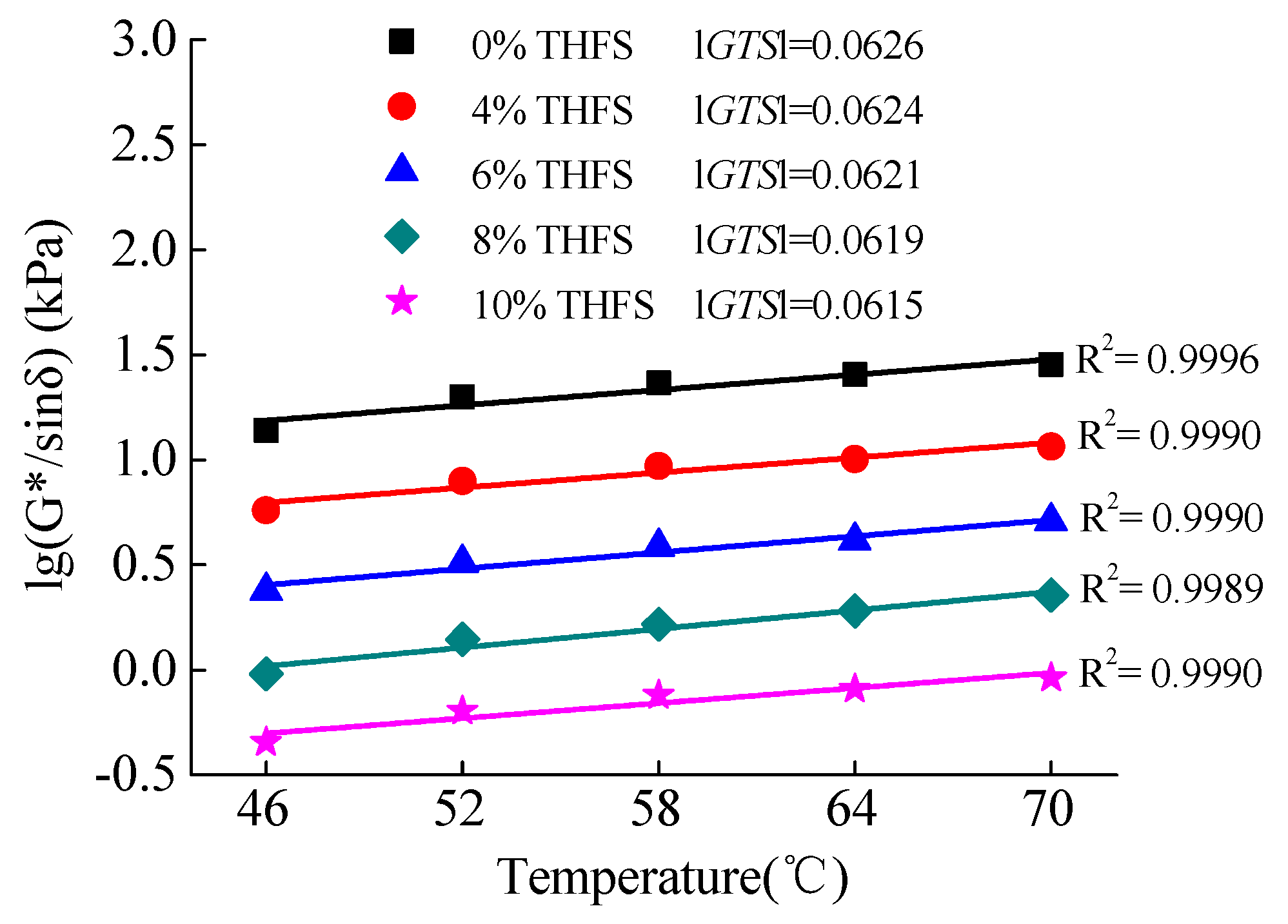

When taking the logarithm of Equation (1), there was a good linear relationship between

lg (G*/sinδ) and test temperature

T and is shown in Equations (2) and (3).

GTS is the slope of

lg (

G*/sinδ) with respect to the test temperature

T, which can be used to characterize the temperature susceptibility of asphalt binder at high temperatures. A higher absolute

GTS value indicates that asphalt binder is more sensitive to high temperatures. The

GTS values of asphalt binders are listed in

Figure 4.

From the test results in

Figure 4, it could be observed that the absolute

GTS values of THFS modified asphalt binders were lower than that of SK-90 and decreased with the increase in THFS content. It showed that the addition of THFS resulted in decreased temperature susceptibility of asphalt binder. The asphalt binder with higher THFS content was less sensitive to temperature. However, for THFS modified asphalt binders, the

G*/sinδ values were higher than that of SK-90 under identical conditions of temperature and increased gradually as THFS content increased. This observation could be attributed to THFS had a higher asphaltene content, resulting in asphalt binder with a higher RV, greater stiffness, and hardness compared to SK-90, which improved the resistance to permanent deformation.

5.5.2. Resistance to Fatigue at Intermediate Temperature

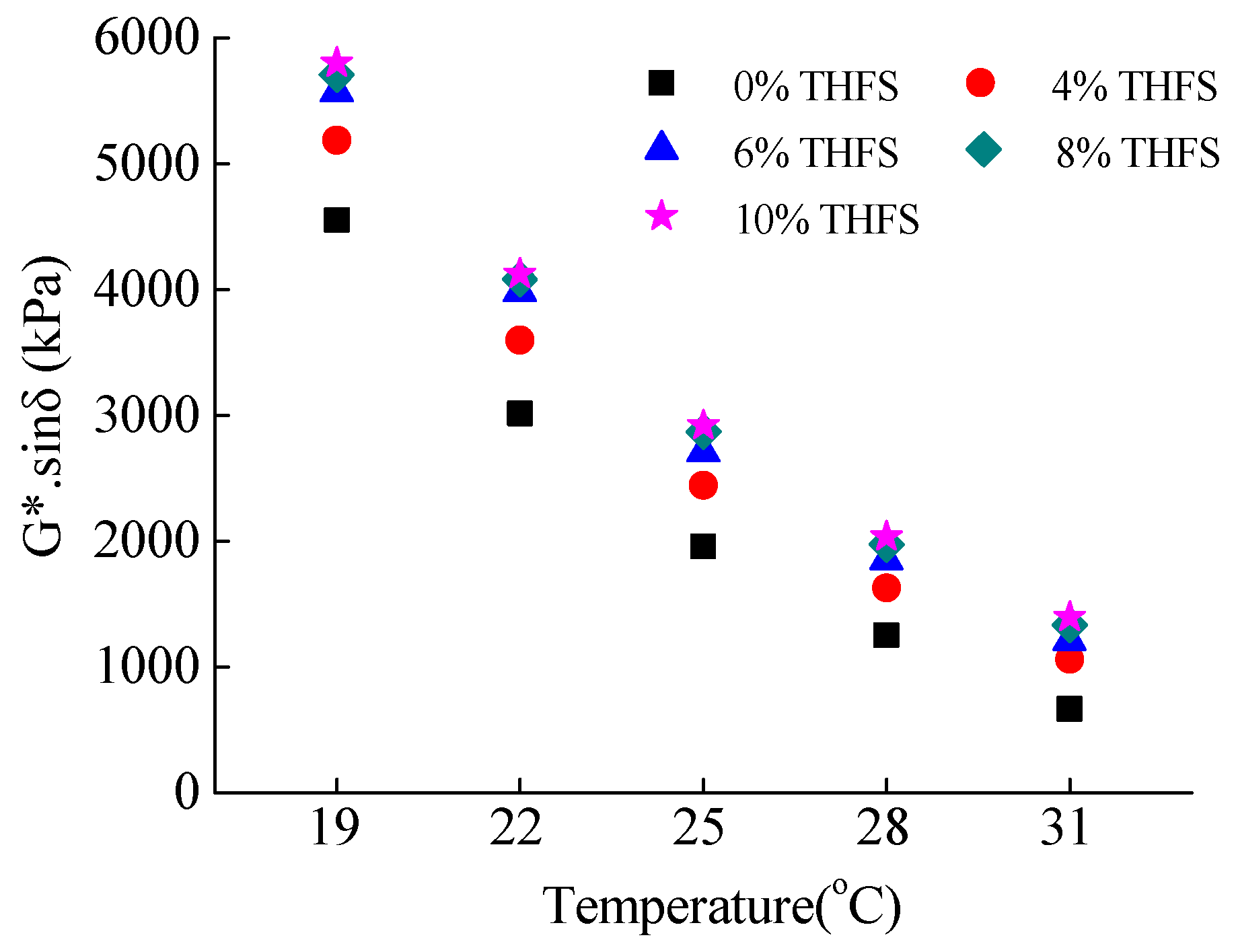

Figure 5 represents the

G*·

sinδ values of asphalt binders versus test temperatures.

From the test results in

Figure 5, it could be observed the

G*·

sinδ values of asphalt binders decreased across the test temperature ranges. The decrease in

G*·

sinδ value was nearly identical in the range of test temperature from 19 °C to 31 °C. Moreover, the

G*·

sinδ had a good linear correlation with test temperature with a high correlation coefficient

R2 ranging from 0.9981 to 0.9989. This phenomenon could be explained by the addition of THFS, which reduced the potential for fatigue cracking at intermediate temperatures due to lower malthene and higher asphaltene contents. Subsequently, for THFS modified asphalt binders, the

G*·

sinδ values were higher than that of SK-90 under identical conditions of test temperature and increased as THFS content increased.

5.5.3. Resistance to Thermal Cracking at Low Temperature

Figure 6 reports the

S values of asphalt binders over test temperatures.

Figure 6 demonstrates that the

S values of asphalt binders increased, compared to SK-90 under an identical test temperature. It showed that THFS modified asphalt binder was more prone to thermal cracking at low temperatures compared to SK-90. A possible explanation for this tendency was THFS with a higher asphaltene and lower malthene content reduced the flexibility and elasticity of asphalt binder at low temperatures.

Under the identical conditions of THFS content, the

S values of asphalt binders decreased as the test temperature increased and had a good linear correlation with temperature with a high correlation coefficient

R2 ranging from 0.9646 to 0.9853. If taking the logarithm of

S and temperature

T, it was found that the

lg(S) had a good linear correlation with test temperature, and is given as Equations (4) and (5).

in which:

S is creep stiffness (MPa);

T is the test temperature (°C);

C is the regression coefficient;

STS is the slope of lg (S) to the test temperature.

The

STS is the slope of

lg (S) to the test temperature and is followed in Equation (5), which can be used to detect the temperature susceptibility of asphalt binder at low temperatures. A higher absolute

STS value indicates that asphalt binder is more sensitive to thermal cracking at low temperatures. The

STS values of asphalt binders are listed in

Figure 7.

According to the test results in

Figure 7, it could be found that the absolute

STS values of asphalt binders were lower than that of SK-90 and 10% THFS modified asphalt binder had the lowest absolute

STS value. It showed that the addition of THFS resulted in a decrease in the temperature susceptibility of asphalt binder at low temperatures. The asphalt binder with a higher THFS content was less sensitive to thermal cracking at low temperatures.

5.5.4. Frequency Susceptibility of the THFS Modified Asphalt Binder

On the basis of time-temperature equivalence principle and through curve fitting using Sigmoidal function, the

G* and

δ master curves of asphalt binders with respect to frequencies ranging from 0.01 Hz to 50 Hz were regressed. The

G* and

δ master curves are plotted in

Figure 8.

There was a similar increase in G* value and decrease in δ value for asphalt binders across frequencies ranging from 0.01 Hz to 50 Hz. This could be because the pavement response and deformation were instantaneous and small caused by a higher frequency, which indicates a shorter loading time. The increase in G* values and decrease in δ values resulted in an improved frequency and exhibited elastic behavior during shorter loading times because asphalt binder would recover from some deformations due to elastic stored energy. Under identical frequencies, the G* values of THFS modified asphalt binders were higher than that of SK-90, but the δ values were lower than that of SK-90, which indicated that at a constant frequency, the addition of THFS could improve the stiffness and elastic characteristics as well as the potential resistance to permanent deformation.

Moreover, for THFS modified asphalt binder, there was a slight increment in G* values and a minor reduction in δ values as THFS content increased at the same frequency. This can be attributed to the interaction of THFS and asphalt binder that form more and more large molecules and limit the movement of molecular chains of asphalt binder. The increase in G* values and decrease in δ values were statistically significant at the 5% significance level, which indicated that THFS content had a significant effect on the frequency susceptibility of THFS modified asphalt binder.

5.5.5. Frequency susceptibility based on CAM model

The Christensen-Andersen-Marasteanu (CAM) model is a kind of rheological model adding a parameter,

me, on the basis of basic shape parameters of the CA model [

30,

31,

32,

33]. Most rheological models are mainly focused on researching the rheological properties of asphalt, however, the CAM model can not only describe the rheological properties of asphalt but also analyze the rheological properties of mixtures. The CAM model includes four equations: the complex modulus master curve equation, the storage modulus master curve equation, the phase angle equation and temperature shift factor equation. These equations characterize the proportion of viscosity and elasticity of asphalt, and also exhibit the temperature sensitivity of viscoelastic properties of asphalt. The equation of the CAM model is shown in Equation (6)

where:

Ge* is the equilibrium complex modulus of asphalt (kPa). It is

G* when frequency reaches zero or the temperature is very high;

Gg* is the glassy complex modulus (kPa). It is G* when frequency reaches infinity or the temperature is very low;

fc is the elastic limit threshold (Hz);

f’ is the reduced frequency, related to temperature and strain (Hz);

k and me are shape parameters, without sizes.

The zones beyond the threshold frequency are the low-frequency stable zone and high-frequency stable zone. Correspondingly, it is called equilibrium complex modulus

Ge* and glassy complex modulus

Gg*. The breakpoint is called the low-frequency break point when the low-frequency stable zone changes into the rheological zone. The break point symbolizes the change in physical form of asphalt. The intercept between

Gg* (

fc) and

Gg* is recorded as

R, which is related to shape parameters

k and

me. R refers to the width of the relaxation spectrum. A larger value of

R indicates that it is easy to change from elastic to viscous behaviors. It also indicates less sensitivity to frequency changes. The parameter R is shown in Equation (7).

Since

Ge* = 0 for asphalt binder, the equation of

R is as follows (8):

Table 9 lists the fitting parameters of asphalt binders based on the CAM model.

The test results in

Table 9 presented that the correlation coefficients

R2 were higher than 0.9990, very close to 1, which indicated that the CAM model was very reliable in predicting the rheological behavior and frequency susceptibility of asphalt binder. In the CAM model, the

Gg* values of asphalt binders were higher than that of SK-90, and 10% THFS modified asphalt binder had the highest

Gg* value. It showed that THFS modified asphalt binder had more resistance to permanent deformation at frequencies ranging from 0.1 Hz to 50 Hz. Subsequently, asphalt binder with higher

fc value indicates it had a good resistance to thermal cracking at low temperatures. Compared with SK-90, the

fc value of THFS modified asphalt binder decreased and 10% THFS modified asphalt binder had the lowest

fc value. It could be predicted that THFS modified asphalt binder was more prone to thermal cracking at low temperatures. This remark was similar to the BBR test results.

Furthermore, asphalt binder with a higher

RG value represented that the ratio of elastic to viscous was high and less sensitive to frequency. According to the test results in

Table 9, it could be observed that 10% THFS modified asphalt binder had the highest

RG and lowest

me, and

k, which indicated that 10% THFS modified asphalt binder had a wider relaxation spectrum and less sensitivity to frequency. It also could be predicted that THFS modified asphalt binder had a better temperature and frequency susceptibility compared to SK-90. In other words, the addition of THFS could decrease the temperature and frequency susceptibility of asphalt binder.