Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine

Abstract

:1. Introduction

2. Equipment and Experiments

2.1. Test Fuel and Operating Conditions

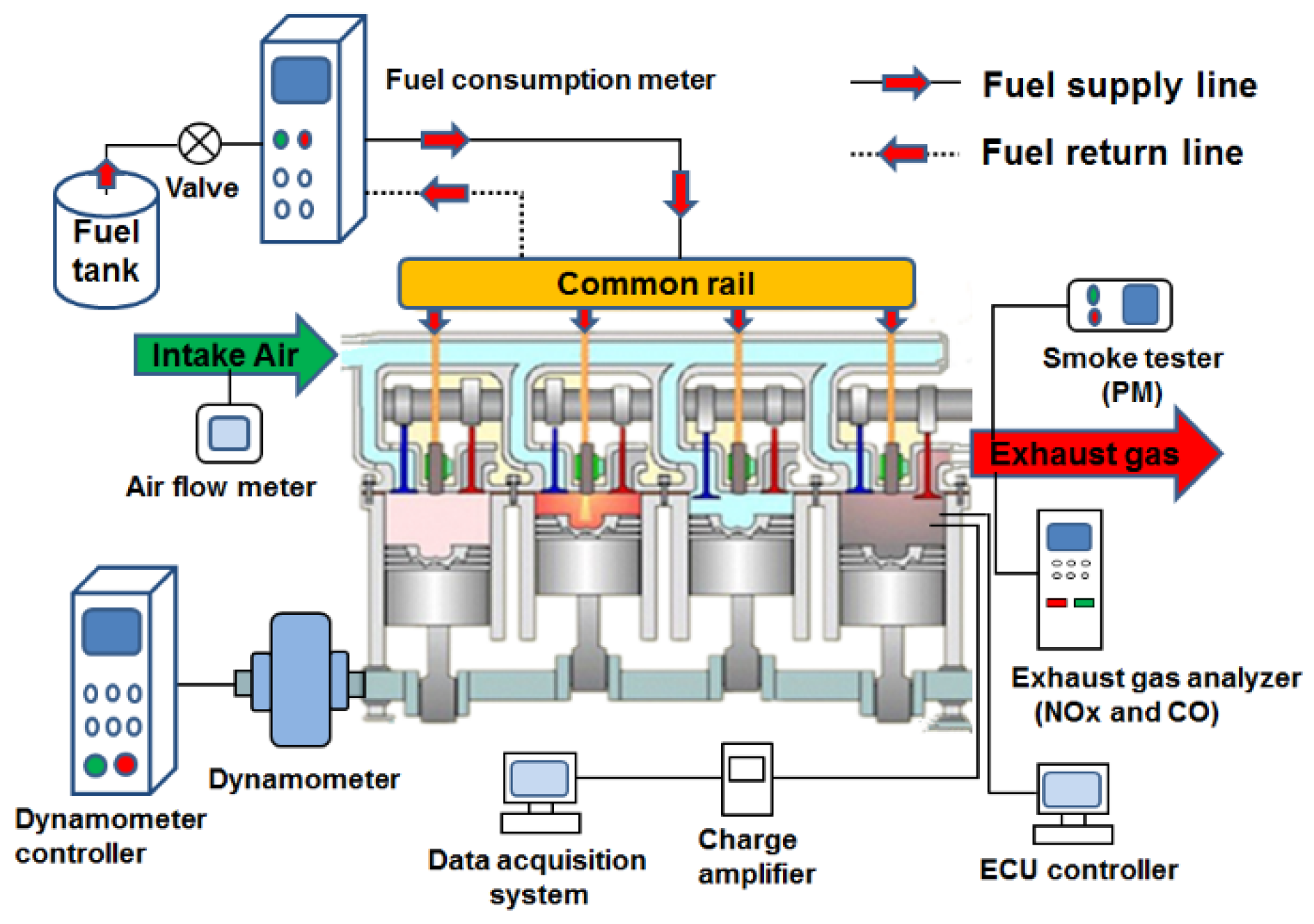

2.2. Test Engine and Experimental Procedure

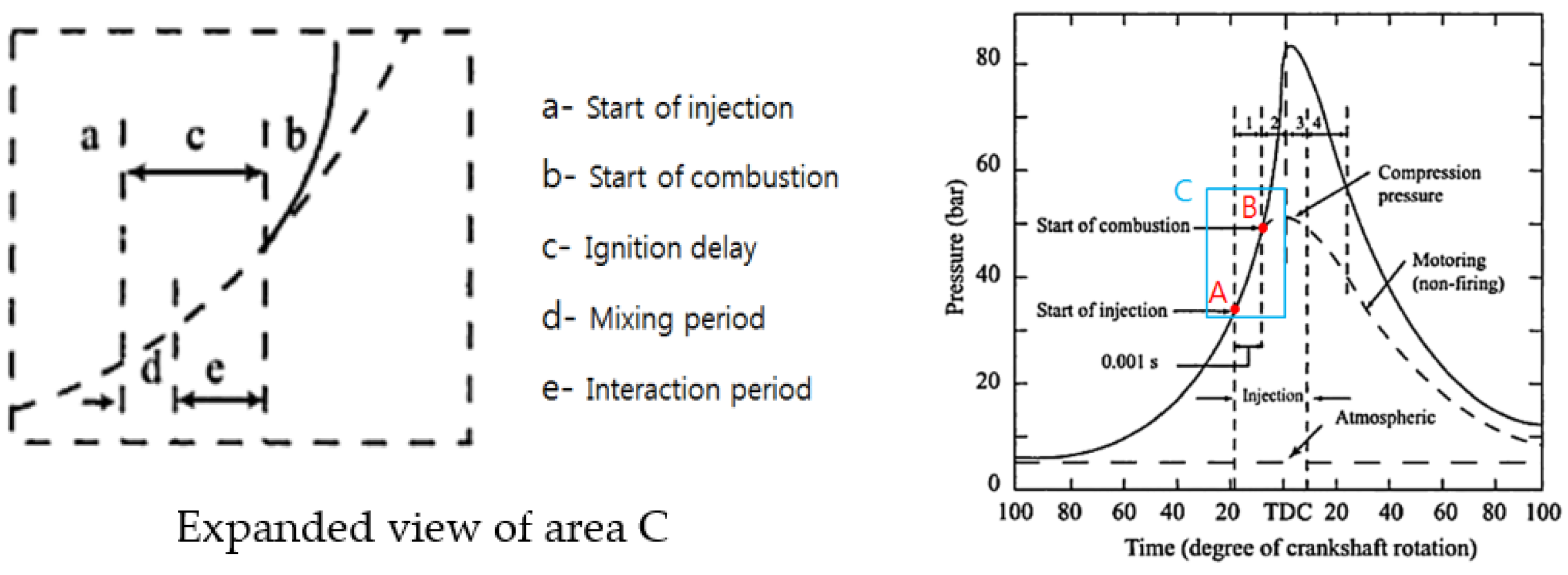

2.3. Ignition Delay in CI Engines

2.3.1. Physical Delay

2.3.2. Chemical Delay

3. Results and Discussion

3.1. Combustion Characteristics

3.1.1. Combustion Pressure and Rate of Heat Release (ROHR)

3.1.2. Brake Specific Fuel Consumption and Brake Specific Energy Consumption

3.1.3. Coefficient of Variation in Indicated Mean Effective Pressure

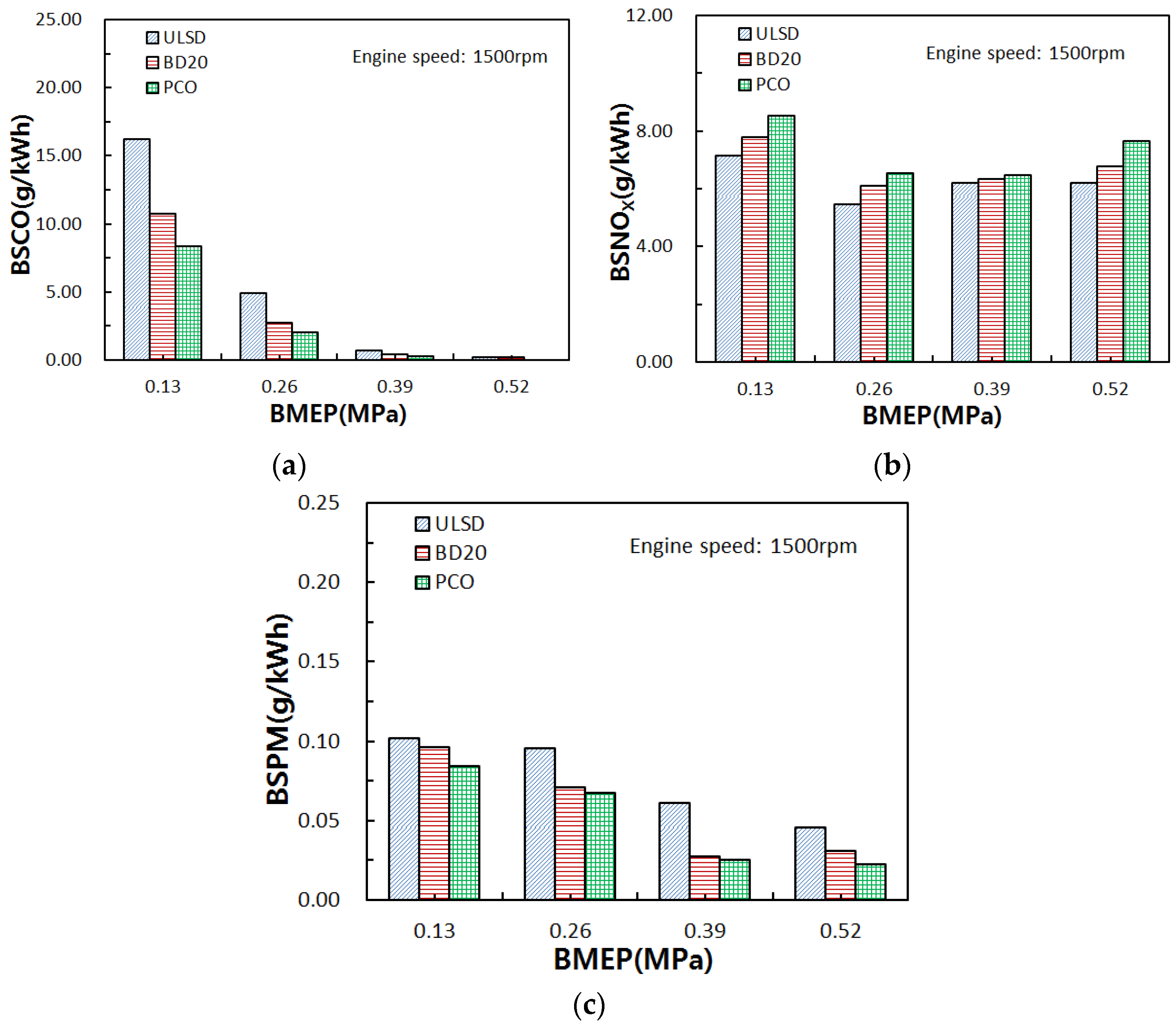

3.2. Emission Characteristics

4. Conclusions

- Canola oil biodiesel is an oxygenated fuel, and the oxygen components have played an important role in the combustion process.

- At high engine load (0.52 MPa), the combustion pressure of ULSD, BD20, and PCO increases 34.6%, 47.1%, and 72.4% compared with that of at low engine load (0.13 MPa), respectively.

- The ignition delay of PCO and BD20 are shorter than that of ULSD by about 5.5° CA and 3.25° CA.

- The CO and PM emissions decreased considerably, but the NOx emission increased only slightly by 6% and 14% at 0.39 MPa and 0.52 MPa compared with 0.26 MPa.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Graboski, M.S.; McCormick, R.L. Combustion of fat and vegetable oil derived fuels in diesel engines. Prog. Energy Combust. Sci. 1998, 24, 125–164. [Google Scholar] [CrossRef]

- Buyukkaya, E.; Cerit, M. Experimental study of NOx emissions and injection timing of a low heat rejection diesel engine. Int. J. Therm. Sci. 2008, 47, 1096–1106. [Google Scholar] [CrossRef]

- Yoon, S.H.; Park, S.H.; Lee, C.S. Experimental investigation on the fuel properties of biodiesel and its blends at various temperatures. Energy Fuels 2008, 22, 652–656. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Dhar, A.; Gupta, J.G.; Kim, W.I.; Choi, K.; Lee, C.S.; Park, S. Effect of fuel injection pressure and injection timing of Karanja biodiesel blends on fuel spray, engine performance, emissions and combustion characteristics. Energy Convers. Manag. 2015, 91, 302–314. [Google Scholar] [CrossRef]

- Miyamoto, T.; Hasegawa, H.; Mikami, M.; Kojima, N.; Kabashima, H.; Urata, Y. Effect of hydrogen addition to intake gas on combustion and exhaust emission characteristics of a diesel engine. Int. J. Hydrogen Energy 2011, 36, 13138–13149. [Google Scholar] [CrossRef]

- Lee, C.S.; Choi, N.J. Effect of air injection on the characteristics of transient response in a turbocharged diesel engine. Int. J. Therm. Sci. 2002, 41, 63–71. [Google Scholar] [CrossRef]

- Huang, H.Z.; Zhou, C.Z.; Liu, Q.S.; Wang, Q.X.; Wang, X.Q. An experimental study on the combustion and emission characteristics of a diesel engine under low temperature combustion of diesel/gasoline/n-Butanol blends. Appl. Energy 2016, 170, 219–231. [Google Scholar] [CrossRef]

- Agarwal, A.K.; Gupta, T.; Bothra, P.; Shukla, P.C. Emission profiling of diesel and gasoline cars at a city traffic junction. Particuology 2015, 18, 186–193. [Google Scholar] [CrossRef]

- Harris, S.J.; Maricq, M.M. Signature size distributions for diesel and gasoline engine exhaust particulate matter. J. Aerosol Sci. 2001, 32, 749–764. [Google Scholar] [CrossRef]

- Kagawa, J. Health effects of diesel exhaust emissions—A mixture of air pollutants of worldwide concern. Toxicology 2002, 181, 349–353. [Google Scholar] [CrossRef]

- Rahmana, M.M.; Stevanovicb, S.; Brownc, R.J.; Ristovski, Z. Influence of different alternative fuels on particle emission from a turbocharged common-rail diesel engine. Procedia Eng. 2013, 56, 381–386. [Google Scholar] [CrossRef]

- Li, Q.; Backes, F.; Wachtmeister, G. Application of canola oil operation in a diesel engine with common rail system. Fuel 2015, 159, 141–149. [Google Scholar] [CrossRef]

- Chen, P.; Wang, J. Air-fraction modeling for simultaneous Diesel engine NOx and PM emissions control during active DPF regenerations. Appl. Energy 2014, 122, 310–320. [Google Scholar] [CrossRef]

- Bermúdez, V.; Serrano, J.R.; Piqueras, P.; Campos, D. Analysis of the influence of pre-DPF water injection technique on pollutants emission. Energy 2015, 89, 778–792. [Google Scholar] [CrossRef]

- Vallinayagam, R.; Vedharaj, S.; Yang, W.M.; Saravanan, C.G.; Lee, P.S.; Chua, K.J.E.; Chou, S.K. Emission reduction from a diesel engine fueled by pine oil biofuel using SCR and catalytic converter. Atmos. Environ. 2013, 80, 190–197. [Google Scholar] [CrossRef]

- Ge, J.C.; Kim, M.S.; Yoon, S.K.; Choi, N.J. Effects of pilot injection timing and egr on combustion, performance and exhaust emissions in a common rail diesel engine fueled with a canola oil biodiesel-diesel blend. Energies 2015, 8, 7312–7325. [Google Scholar] [CrossRef]

- Parks, J.E.; Prikhodko, V.; Storey, J.M.E.; Barone, T.L.; Sr, S.A.L.; Kass, M.D.; Huff, S.P. Emissions from premixed charge compression ignition (PCCI) combustion and affect on emission control devices. Catal. Today 2010, 151, 278–284. [Google Scholar] [CrossRef]

- Roy, M.M.; Wang, W.; Bujold, J. Biodiesel production and comparison of emissions of a DI diesel engine fueled by biodiesel-diesel and canola oil-diesel blends at high idling operations. Appl. Energy 2013, 106, 198–208. [Google Scholar] [CrossRef]

- Roy, M.M.; Calder, J.; Wang, W.; Mangad, A.; Diniz, F.C.M. Emission analysis of a modern Tier 4 DI diesel engine fueled by biodiesel-diesel blends with a cold flow improver (Wintron Synergy) at multiple idling conditions. Appl. Energy 2016, 179, 45–54. [Google Scholar]

- Roy, M.M.; Calder, J.; Wang, W.; Mangad, A.; Diniz, F.C.M. Cold start idle emissions from a modern Tier-4 turbo-charged diesel engine fueled with diesel-biodiesel, diesel-biodiesel-ethanol, and diesel-biodiesel-diethyl ether blends. Appl. Energy 2016, 180, 52–65. [Google Scholar] [CrossRef]

- Rahman, M.M.; Rasul, M.; Hassan, N.M.S.; Hyde, J. Prospects of biodiesel production from macadamia oil as an alternative fuel for diesel engines. Energies 2016, 9, 403. [Google Scholar] [CrossRef]

- Hou, S.S.; Huang, W.C.; Rizal, F.M.; Lin, T.H. Co-firing of fast pyrolysis bio-oil and heavy fuel oil in a 300-kWth furnace. Appl. Sci. 2016, 6. [Google Scholar] [CrossRef]

- Alton, R.; Cetinkaya, S.; Yucesu, H.S. The potential of using vegetable oil fuels as fuel for diesel engines. Energy Convers. Manag. 2001, 42, 529–538. [Google Scholar] [CrossRef]

- Basak, A.; Patra, J.; Ganguly, R.; Datta, A. Effect of transesterification of vegetable oil on liquid flow number and spray cone angle for pressure and twin fluid atomizers. Fuel 2013, 112, 347–354. [Google Scholar] [CrossRef]

- Sarin, R.; Kumar, R.; Srivastav, B.; Puri, S.K.; Tuli, D.K.; Malhotra, R.K.; Kumar, A. Biodiesel surrogates: Achieving performance demands. Bioresour. Technol. 2009, 100, 3022–3028. [Google Scholar] [CrossRef] [PubMed]

- He, B.Q. Advances in emission characteristics of diesel engines using different biodiesel fuels. Renew. Sustain. Energy Rev. 2016, 60, 570–586. [Google Scholar] [CrossRef]

- Nalgundwar, A.; Paul, B.; Sharma, S.K. Comparison of performance and emissions characteristics of DI CI engine fueled with dual biodiesel blends of palm and jatropha. Fuel 2016, 173, 172–179. [Google Scholar] [CrossRef]

- Lapuerta, M.; Armas, O.; Fernandez, J.R. Effect of biodiesel fuels on diesel engine emissions. Prog. Energy Combust. Sci. 2008, 34, 198–223. [Google Scholar] [CrossRef]

- Melo-Espinosa, E.A.; Piloto-Rodríguez, R.; Goyos-Pérez, L.; Sierens, R.; Verhelst, S. Emulsification of animal fats and vegetable oils for their use as a diesel engine fuel: An overview. Renew. Sustain. Energy Rev. 2015, 47, 623–633. [Google Scholar] [CrossRef]

- Yahya, A.; Marley, S.J. Performance and exhaust emissions of a compression ignition engine operating on ester fuels at increased injection pressure and advanced timing. Biomass Bioenergy 1994, 6, 297–319. [Google Scholar] [CrossRef]

- Clark, S.J.; Wagner, L.; Schrock, M.D.; Piennaar, P.G. Methyl and ethyl soybean esters as renewable fuels for diesel engines. J. Am. Oil Chem. Soc. 1984, 61, 1632–1643. [Google Scholar] [CrossRef]

- Pestes, M.N.; Stanislao, J. Piston ring deposits when using vegetable oil as a fuel. J. Test. Eval. 1984, 12, 61–68. [Google Scholar]

- Rakopoulos, D.C.; Rakopoulos, C.D.; Giakoumis, E.G. Impact of properties of vegetable oil, bio-diesel, ethanol and n-Butanol on the combustion and emissions of turbocharged HDDI diesel engine operating under steady and transient conditions. Fuel 2015, 156, 1–19. [Google Scholar] [CrossRef]

- Gülüm, M.; Bilgin, A. Density, flash point and heating value variations of corn oil biodiesel-diesel fuel blends. Fuel Process. Technol. 2015, 134, 456–464. [Google Scholar] [CrossRef]

- No, S.Y. Inedible vegetable oils and their derivatives for alternative diesel fuels in CI engines: A review. Renew. Sustain. Energy Rev. 2011, 15, 131–149. [Google Scholar] [CrossRef]

- Atmanli, A.; İleri, E.; Yüksel, B. Effects of higher ratios of n-Butanol addition to diesel-vegetable oil blends on performance and exhaust emissions of a diesel engine. J. Energy Inst. 2015, 88, 209–220. [Google Scholar] [CrossRef]

- Puhan, S.; Vedaraman, N.; Ram, V.B. Mahua oil (Madhucaindica seed oil) methyl ester as biodiesel preparation and emission characteristics. Biomass Bioenergy 2005, 28, 87–93. [Google Scholar] [CrossRef]

- Li, E.; Xu, Z.P.; Rudolph, V. MgCoAl–LDH derived heterogeneous catalysts for the ethanol transesterification of canola oil to biodiesel. Appl. Catal. B Environ. 2009, 88, 42–49. [Google Scholar] [CrossRef]

- Kurre, S.K.; Garg, R.; Pandey, S. A review of biofuel generated contamination, engine oil degradation and engine wear. Biofuels 2016, 1–8. [Google Scholar] [CrossRef]

- Reham, S.S.; Masjuki, H.H.; Kalam, M.A.; Shancita, I.; Fattah, I.M.R.; Ruhul, A.M. Study on stability, fuel properties, engine combustion, performance and emission characteristics of biofuel emulsion. Renew. Sustain. Energy Rev. 2015, 52, 1566–1579. [Google Scholar] [CrossRef]

- Yoon, S.K.; Kim, M.S.; Kim, H.J.; Choi, N.J. Effects of canola oil biodiesel fuel blends on combustion, performance, and emissions reduction in a common rail diesel engine. Energies 2014, 7, 8132–8149. [Google Scholar] [CrossRef]

- Ganesan, V. Internal Combustion Engines, 2nd ed.; Tata McGraw-Hill: New York, NY, USA, 2004. [Google Scholar]

- Shahabuddin, M.; Liaquat, A.M.; Masjuki, H.H.; Kalam, M.A.; Mofijur, M. Ignition delay, combustion and emission characteristics of diesel engine fueled with biodiesel. Renew. Sustain. Energy Rev. 2013, 21, 623–632. [Google Scholar] [CrossRef]

- Oo, C.W.; Shioji, M.; Nakao, S.; Dung, N.N.; Reksowardojo, I.; Roces, S.A.; Dugos, N.P. Ignition and combustion characteristics of various biodiesel fuels (BDFs). Fuel 2015, 158, 279–287. [Google Scholar] [CrossRef]

- Fattah, I.M.R.; Masjuki, H.H.; Kalam, M.A.; Wakil, M.A.; Ashraful, A.M.; Shahir, S.A. Experimental investigation of performance and regulated emissions of a diesel engine with Calophyllum inophyllum biodiesel blends accompanied by oxidation inhibitors. Energy Convers. Manag. 2014, 83, 232–240. [Google Scholar] [CrossRef]

- Rahim, N.A.; Jaafar, M.N.M.; Sapee, S.; Elraheem, H.F. Effect on particulate and gas emissions by combusting biodiesel blend fuels made from different plant oil feedstocks in a liquid fuel burner. Energies 2016, 9. [Google Scholar] [CrossRef]

| Properties | ULSD | BD20 | PCO |

|---|---|---|---|

| Density at 15 °C (kg/m3) | 836.8 | 846 | 880 |

| Viscosity at 40 °C (mm2/s) | 2.719 | 2.991 | 4.290 |

| Lower calorific value (MJ/kg) | 43.96 | 42.71 | 39.49 |

| Catane number | 55.8 | - | 61.5 |

| Flash point (°C) | 55 | - | 182 |

| Pour point (°C) | −21 | - | −8 |

| Oxidation stability (h/110 °C) | 25 | - | 15 |

| Ester content (%) | - | - | 98.9 |

| Oxygen (%) | 0 | - | 10.8 |

| Test Parameters | Operating Conditions |

|---|---|

| Engine speed (rpm) | 1500 |

| BMEP 1 (MPa) | 0.13, 0.26, 0.39, 0.52 |

| Test fuels | ULSD, BD20, PCO |

| Cooling water temp. (°C) | 70 ± 3 |

| Intake air temp. (°C) | 20 ± 3 |

| Main injection timing (degree) | TDC 0 |

| Number of Cylinders | 4 |

|---|---|

| Cylinder diameter | 81 mm |

| Stroke | 96 mm |

| Displacement | 1979 cm3 |

| Compression ratio | 17.7:1 |

| Max. power | 82 kW at 4000 rpm |

| Max. torque | 260 Nm at 2000 rpm |

| Max. fuel pressure | 145 MPa |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ge, J.C.; Yoon, S.K.; Kim, M.S.; Choi, N.J. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Appl. Sci. 2017, 7, 34. https://doi.org/10.3390/app7010034

Ge JC, Yoon SK, Kim MS, Choi NJ. Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Applied Sciences. 2017; 7(1):34. https://doi.org/10.3390/app7010034

Chicago/Turabian StyleGe, Jun Cong, Sam Ki Yoon, Min Soo Kim, and Nag Jung Choi. 2017. "Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine" Applied Sciences 7, no. 1: 34. https://doi.org/10.3390/app7010034

APA StyleGe, J. C., Yoon, S. K., Kim, M. S., & Choi, N. J. (2017). Application of Canola Oil Biodiesel/Diesel Blends in a Common Rail Diesel Engine. Applied Sciences, 7(1), 34. https://doi.org/10.3390/app7010034