Dry Sintered Metal Coating of Halloysite Nanotubes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Metal Sintering of Halloysite Nanotubes

2.2.2. Scanning Electron Microscopy (SEM)

2.2.3. Transmission Electron Microscopy (TEM)

2.2.4. Energy Dispersive X-ray Spectroscopy (EDS)

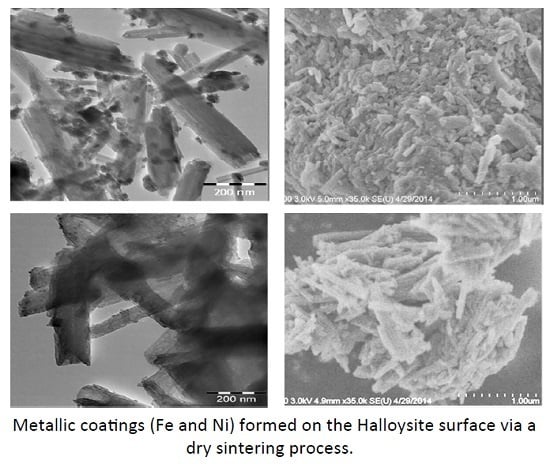

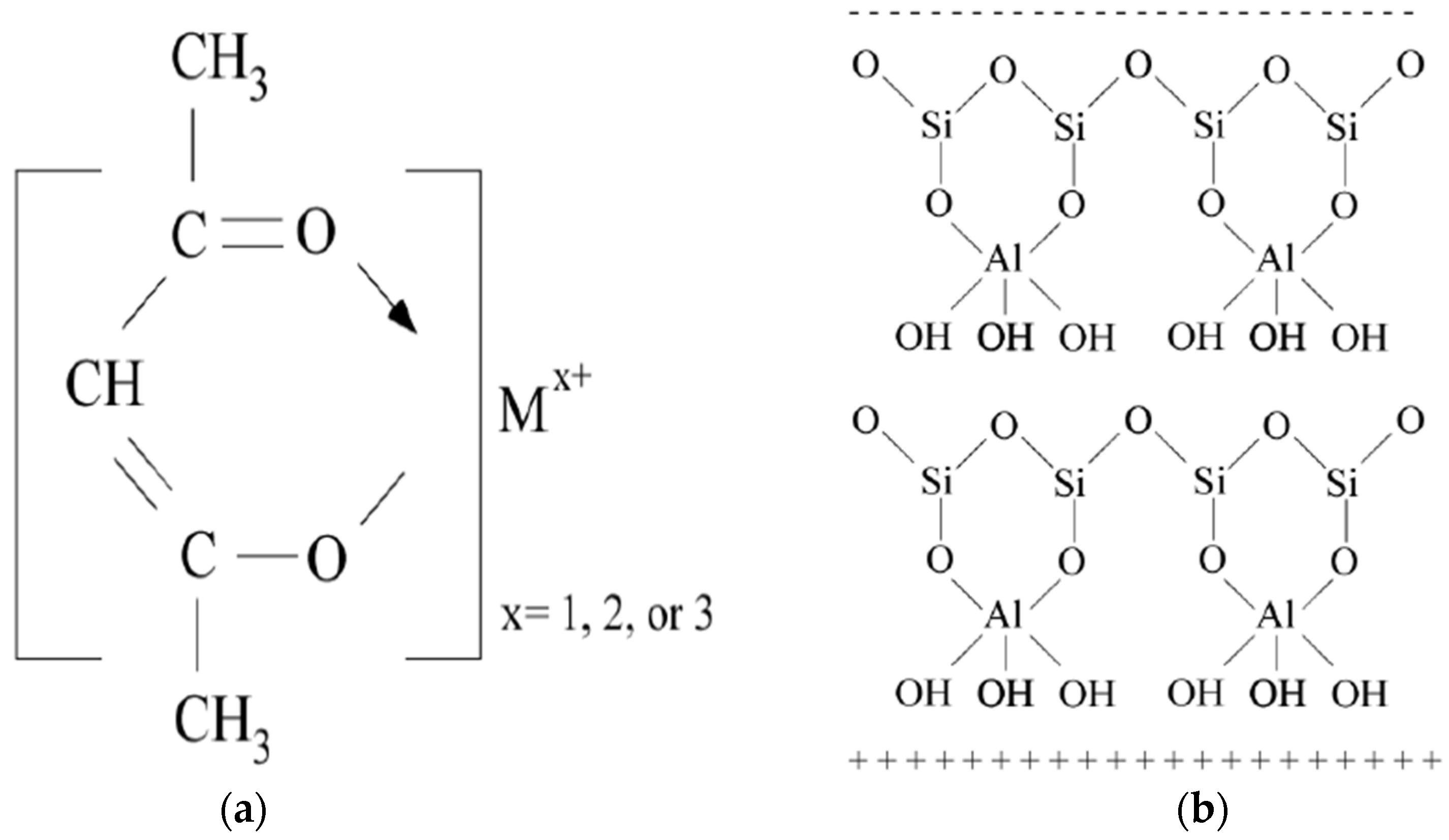

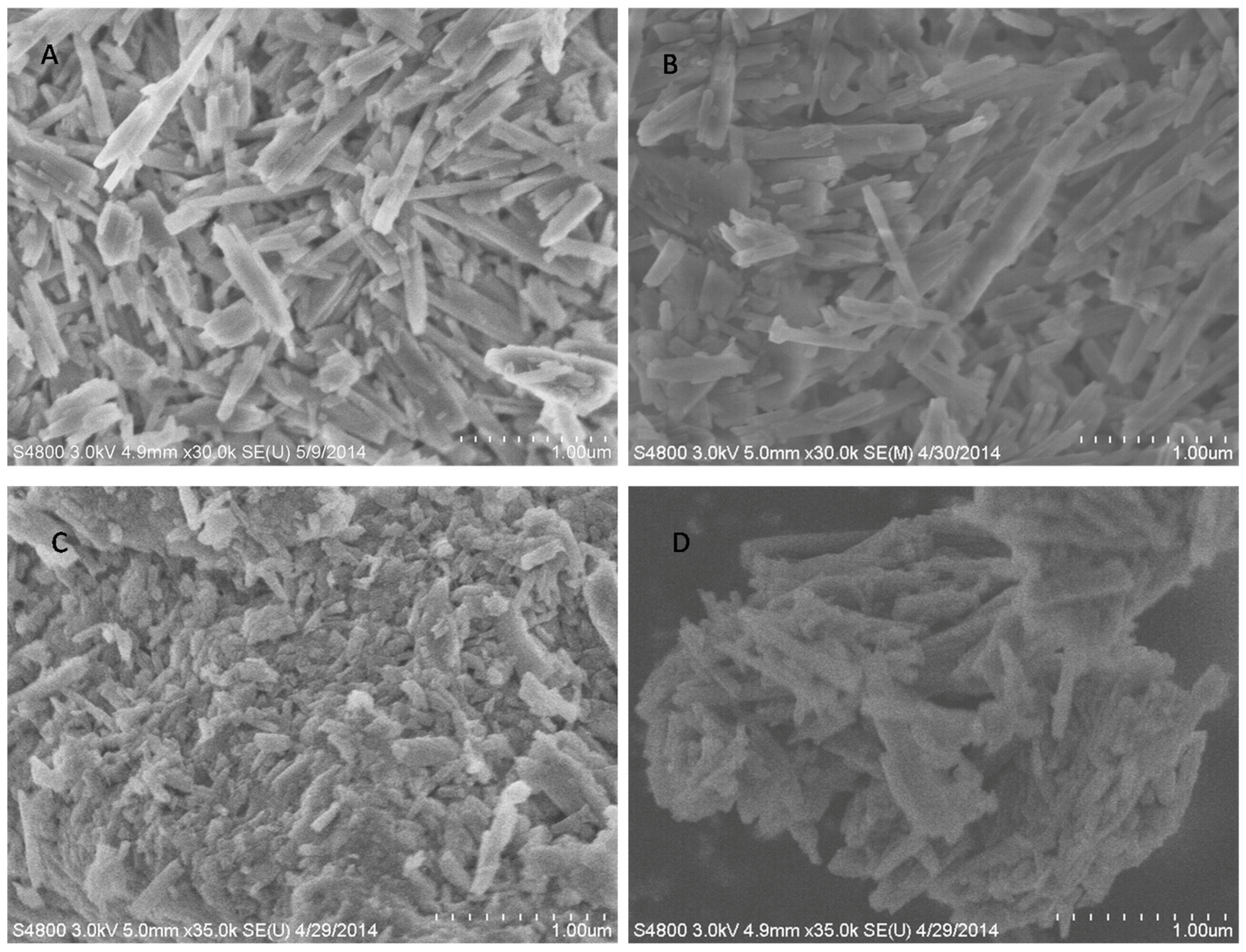

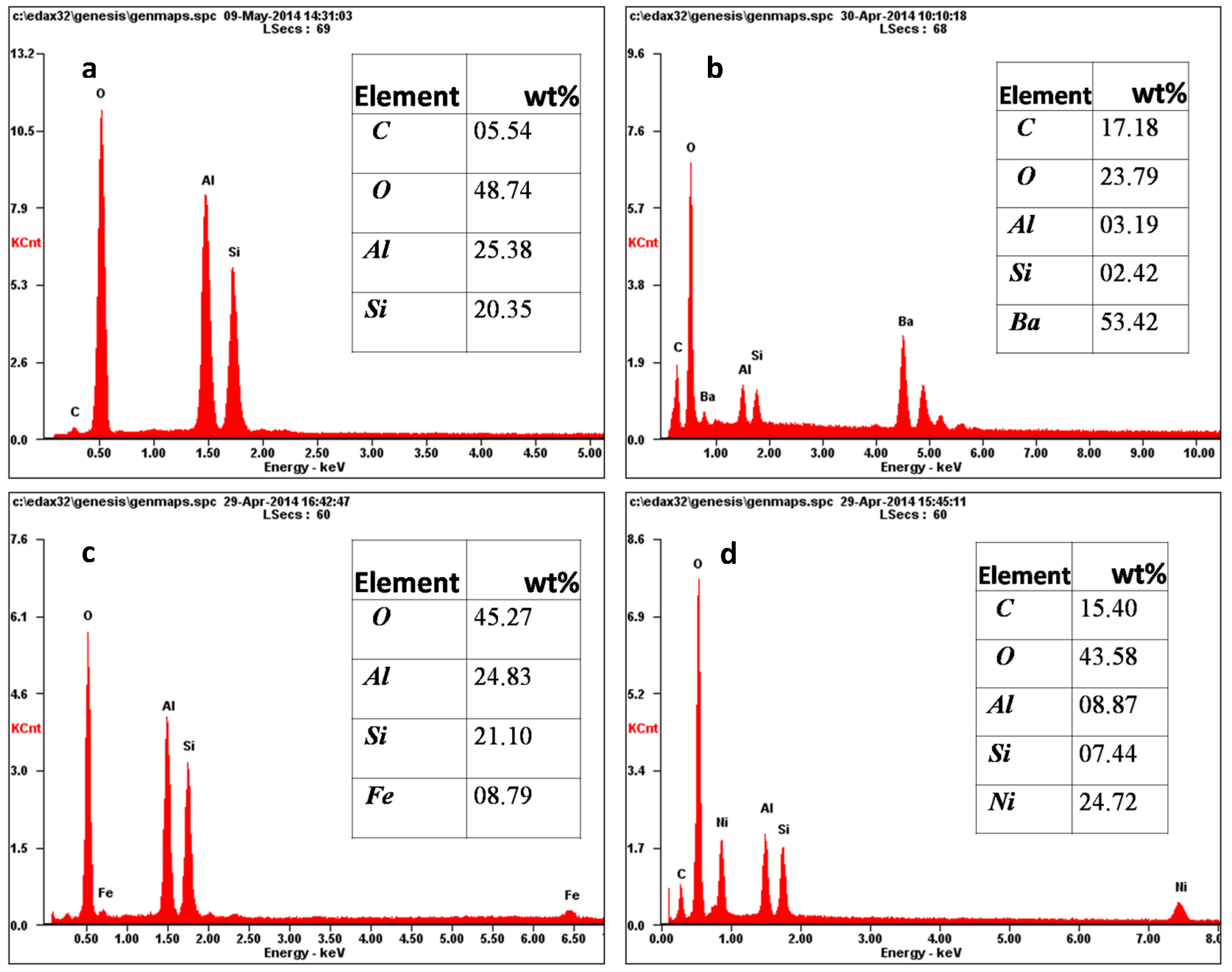

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| EDS | Energy Dispersive X-ray Spectroscopy |

| HNT | halloysite nanotube |

| NMR | Nuclear Magnetic Resonance |

| SEM | Scanning Electron Microscopy |

| TEM | Transmission Electron Microscopy |

References

- Bordeepong, S.; Bhongsuwan, D.; Pungrassami, D.; Bhongsuwan, T. Characterization of halloysite from Thung Yai District, Nakhon Si Thammarat Province, in Southern Thailand. J. Sci. Technol. 2011, 33, 599–607. [Google Scholar]

- Churchman, J.; Theng, B.K.G. Interactions of halloysites with amides: mineralogical factors affecting complex formation. Clay Miner. 1984, 19, 161–175. [Google Scholar] [CrossRef]

- Alexander, L.T.; Faust, G.T.; Hendricks, S.B.H.; Insley, H.; McMurdie, H.F. Relationship of the clay minerals halloysite and endellite. Am. Miner. 1943, 28, 1–18. [Google Scholar]

- Joussein, E.; Petit, S.; Churchman, J.; Theng, B.; Righi, D.; Delvaux, B. Halloysite clay minerals-a review. Clay Miner. 2005, 40, 383–426. [Google Scholar] [CrossRef]

- Yah, W.O.; Takahara, A.; Lvov, Y.M. Selective Modification of Halloysite Lumen with Octadecylphosphonic Acid: New Inorganic Tubular Micelle. J. Am. Chem. Soc. 2012, 134, 1853–1859. [Google Scholar] [CrossRef] [PubMed]

- Nitya, G.; Nair, G.T.; Mony, U.; Chennazhi, K.P.; Nair, S.V. In vitro evaluation of electrospun PCL/nanoclay composite scaffold for bone tissue engineering. J. Mater. Sci. Mater. Med. 2012, 23, 1749–1761. [Google Scholar] [CrossRef] [PubMed]

- Prashantha, K.; Shmitt, H.; Lacrampe, M.F.; Krawczak, P. Mechanical behavior and essential work of fracture of halloysite nanotubes filled polyaminde 6 nanocomposites. Comp. Sci. Technol. 2011, 71, 1859–1866. [Google Scholar] [CrossRef]

- Ning, N.; Yin, Q.; Luo, F.; Zhang, Q.; Du, R.; Fu, Q. Crystallization behavior and mechanical properties of polypropropylene/halloysite composites. Polymer 2007, 48, 7374–7384. [Google Scholar] [CrossRef]

- Liu, M.; Guo, B.; Du, M.; Lei, Y.; Jia, D. Natural inorga nic nanotubes reinforced epoxy resin nanocomposites. J. Polym. Res. 2008, 15, 205–212. [Google Scholar] [CrossRef]

- Hedicke-Höchstötter, K.; Lim, G.T.; Altstädt, V. Novel polyaminde nanocomposites based on silicate nanotubes of the mineral halloysite. Comp. Sci. Technol. 2009, 69, 330–334. [Google Scholar] [CrossRef]

- Shchukin, D.G.; Mohwald, H. Surface-engineered nanocontainers for entrapment of corrosion inhibitors. Adv. Funct. Mater. 2007, 17, 1451–1458. [Google Scholar] [CrossRef]

- Kelly, H.M.; Deasy, P.B.; Ziaka, E.; Claffey, N. Formulation and preliminary in vivo dog studies of a novel drug delivery system for the treatment of periodontitis. Intern. J. Pharm. 2004, 274, 167–183. [Google Scholar] [CrossRef] [PubMed]

- Veerabadran, N.G.; Price, R.R.; Lvov, Y. Clay nanotubes for the encapsulation and sustained release of drugs. Nano 2007, 2, 115–121. [Google Scholar] [CrossRef]

- Karnik, S.; Jammalamadaka, U.; Tappa, K.; Mills, D.K. Performance evaluation of nanoclay enriched anti-microbial hydrogels for biomedical applications. Heliyon 2016, 2. [Google Scholar] [CrossRef] [PubMed]

- Karnik, S.; Mills, D.K. Nanoenhanced hydrogel system with sustained release capabilities. J. Biomed. Mater. A 2015, 103, 2416–2426. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.J.; Meng, J.; Zhou, Y.B.; Wu, H.C.; Bie, Y.Q.; Liao, Z.M.; Yu, D.P. Layer-by-layer assembly of vertically conducting graphene devices. Nat. Commun. 2013, 4. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Boyer, C.; Grimes, R.; Mills, D.K. Drug coated clay nanoparticles for delivery of chemotherapeutics. Curr. Nanosci. 2016, 12, 207–214. [Google Scholar] [CrossRef]

- Chen, S.; Li, J.; Zhang, Y.; Zhang, D.; Zhu, J. Effect of preparation method on halloysite supported cobalt catalysts for Fischer-Tropsch synthesis. J. Nat. Gas Chem. 2012, 21, 426–430. [Google Scholar] [CrossRef]

- Liu, M.; Guo, B.; Du, M.; Jia, D. Natural inorganic nanotubes reinforced epoxy resin nanocomposites. J. Polym. Res. 2008, 15, 205–212. [Google Scholar] [CrossRef]

- Guo, B.; Zou, Q.; Lei, Y.; Jia, D. Structure and performance of polyamide 6/halloysite nanotubes nanocomposites. Polym. J. 2009, 41, 835–842. [Google Scholar] [CrossRef]

- Wilkie, C.A.; Harworth, D.T. Non-aqueous routes to crystalline metal oxide nanoparticles: Formation mechanisms and applications. Prog. Solid State Chem. 2005, 33, 59–70. [Google Scholar]

- Koka, A.; Sodano, H.A. Vertically aligned arrays of BaTiO3 nanowires. Appl. Mater. Interface 2013, 5, 11894–11899. [Google Scholar]

- Fu, Y.; Zhang, L. Optimal activation of carboxyl-superparamagnetic iron oxide nanoparticles bioconjugated with antibody using orthogonal array design. J. Nanosci. Nanotechnol. 2005, 5, 8137–8143. [Google Scholar]

- Pan, J.; Hang, H.; Dai, X; Dai, J.; Huo, P.; Yan, Y. Switched recognition and release ability of temperature responsive molecularly imprinted polymers based on magnetic halloysite nanotubes. J. Mater. Chem. 2012, 22, 17167–17175. [Google Scholar] [CrossRef]

- Wang, H.; Liang, Y.; Gong, M.; Li, Y.; Chang, W.; Mefford, T.; Zhou, J.; Wang, J.; Regier, T.; Wei, F.; et al. An ultrafast nickel–iron battery from strongly coupled inorganic nanoparticle/nanocarbon hybrid materials. Nat. Commun. 2002, 3. [Google Scholar] [CrossRef] [PubMed]

- Tasker, S.T.; Standley, E.A.; Jamison, T.F. Recent advances in homogeneous nickel catalysis. Nature 2014, 509, 299–309. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Yang, H.G.; Wang, X.; Cheng, L.; Pan, J.; Lu, G.Q.; Cheng, H.-M. Visible light responsive nitrogen doped anatase TiO2 sheets with dominant {001} facets derived from TiN. J. Am. Chem. Soc. 2009, 131, 12868–12869. [Google Scholar]

- Geckler, K.; Hassan, S. Gold Nanoparticle-Halloysite Nanotube and Method of Forming the Same. US20090092836 A1, 9 April 2009. [Google Scholar]

- Wagner, A.; Price, R. Radiation Absorptive Composites and Methods for Production. U.S. 20070148457 A1, 28 June 2007. [Google Scholar]

- Chen, Y.; Liu, J.; Zhang, Y.; Wang, K. Preparation and antibacterial property of polyethersulfone ultrafiltration hybrid membrane containing halloysite nanotubes loaded with copper ions. Chem. Eng. J. 2012, 210, 298–308. [Google Scholar] [CrossRef]

- Wei, W.; Abdllayev, E.; Goeders, A.; Hollister, A.; Lvov, L.; Mills, D.K. Clay nanotube/poly(methyl methacrylate) bone cement composite with sustained antibiotic release. Macromol. Mater. Eng. 2012, 297, 645–653. [Google Scholar] [CrossRef]

- Qi, R.; Guo, R.; Shen, M.; Cao, X.; Zhang, L.; Xu, J.; Yu, J.; Shi, X. Electrospun poly(lactic-co-glycolic acid)/halloysite nanotube composite nanofibers for drug encapsulation and sustained release. J. Mater. Chem. 2010, 20, 10622–10629. [Google Scholar] [CrossRef]

- Abdullayev, E.; Price, R.; Schukin, R.; Lovo, Y. Halloysite tubes as nanocontainers for anticorrosion coating with benzotriazole. ACS Appl. Mater. Interface 2009, 1, 1437–1443. [Google Scholar] [CrossRef] [PubMed]

- Liang, Y.; Zhang, Y.; Zhang, B.; Liu, J. Enhanced antibacterial activity of silver nanoparticles/halloysite nanotubes/graphene nanocomposites with sandwich-like structure. Sci. Rep. 2014, 4, 4551–4565. [Google Scholar]

- Wei, W.; Minullina, R.; Abdullayev, E.; Fakhrullin, R.; Mills, D.K.; Lvov, Y. Enhanced efficiency of antiseptics with sustained release from clay nanotubes. RSC Adv. 2014, 4, 488–494. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nicholson, J.C.; Weisman, J.A.; Boyer, C.J.; Wilson, C.G.; Mills, D.K. Dry Sintered Metal Coating of Halloysite Nanotubes. Appl. Sci. 2016, 6, 265. https://doi.org/10.3390/app6090265

Nicholson JC, Weisman JA, Boyer CJ, Wilson CG, Mills DK. Dry Sintered Metal Coating of Halloysite Nanotubes. Applied Sciences. 2016; 6(9):265. https://doi.org/10.3390/app6090265

Chicago/Turabian StyleNicholson, James C., Jeffery A. Weisman, Christen J. Boyer, Chester G. Wilson, and David K. Mills. 2016. "Dry Sintered Metal Coating of Halloysite Nanotubes" Applied Sciences 6, no. 9: 265. https://doi.org/10.3390/app6090265

APA StyleNicholson, J. C., Weisman, J. A., Boyer, C. J., Wilson, C. G., & Mills, D. K. (2016). Dry Sintered Metal Coating of Halloysite Nanotubes. Applied Sciences, 6(9), 265. https://doi.org/10.3390/app6090265