Comparison between Laser and Stamping without Die (SWD) for Micro Tapered Hole Forming

Abstract

:1. Introduction

2. Finite Element Software DEFORM-3D

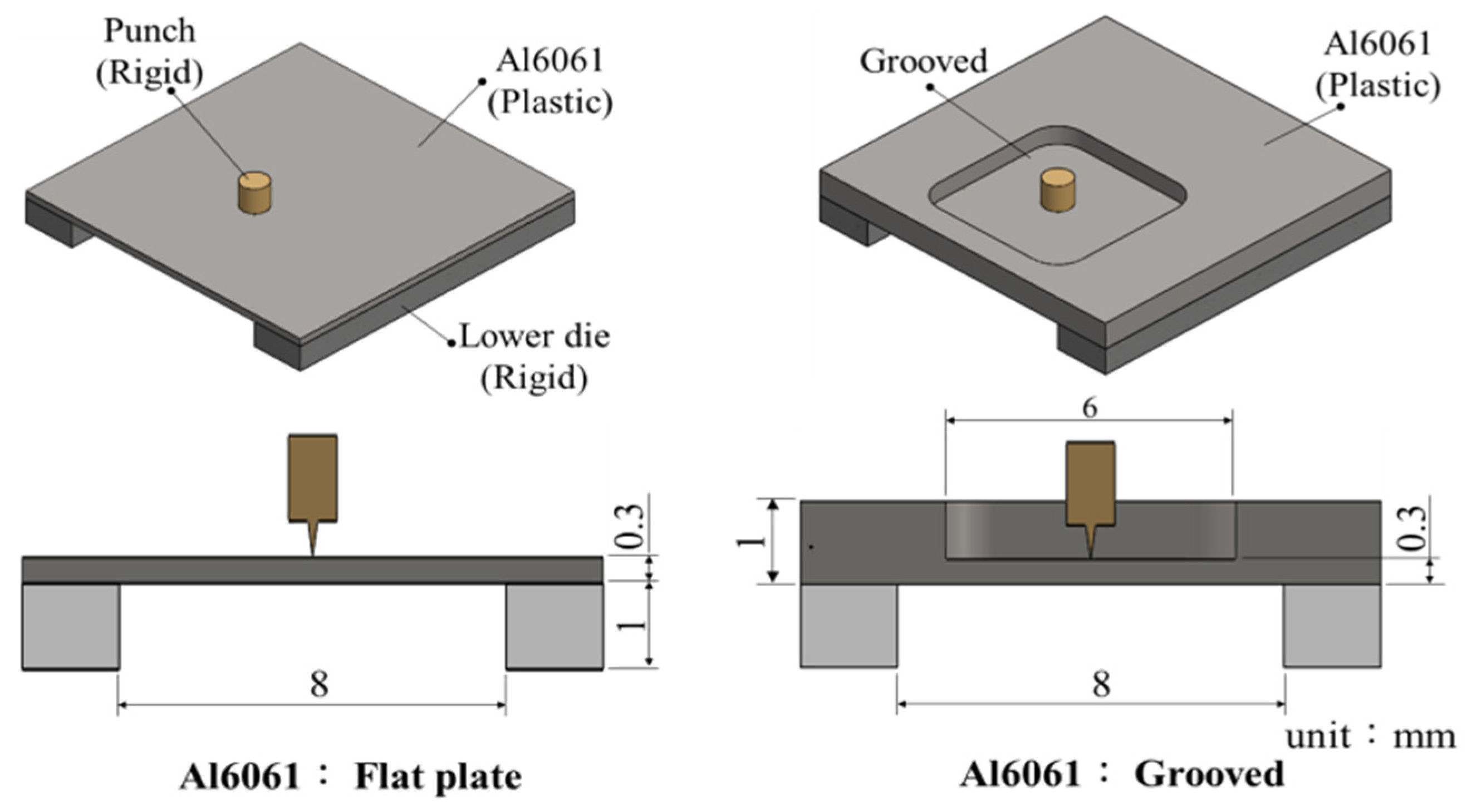

2.1. Computer Aided Design Geometric Modeling

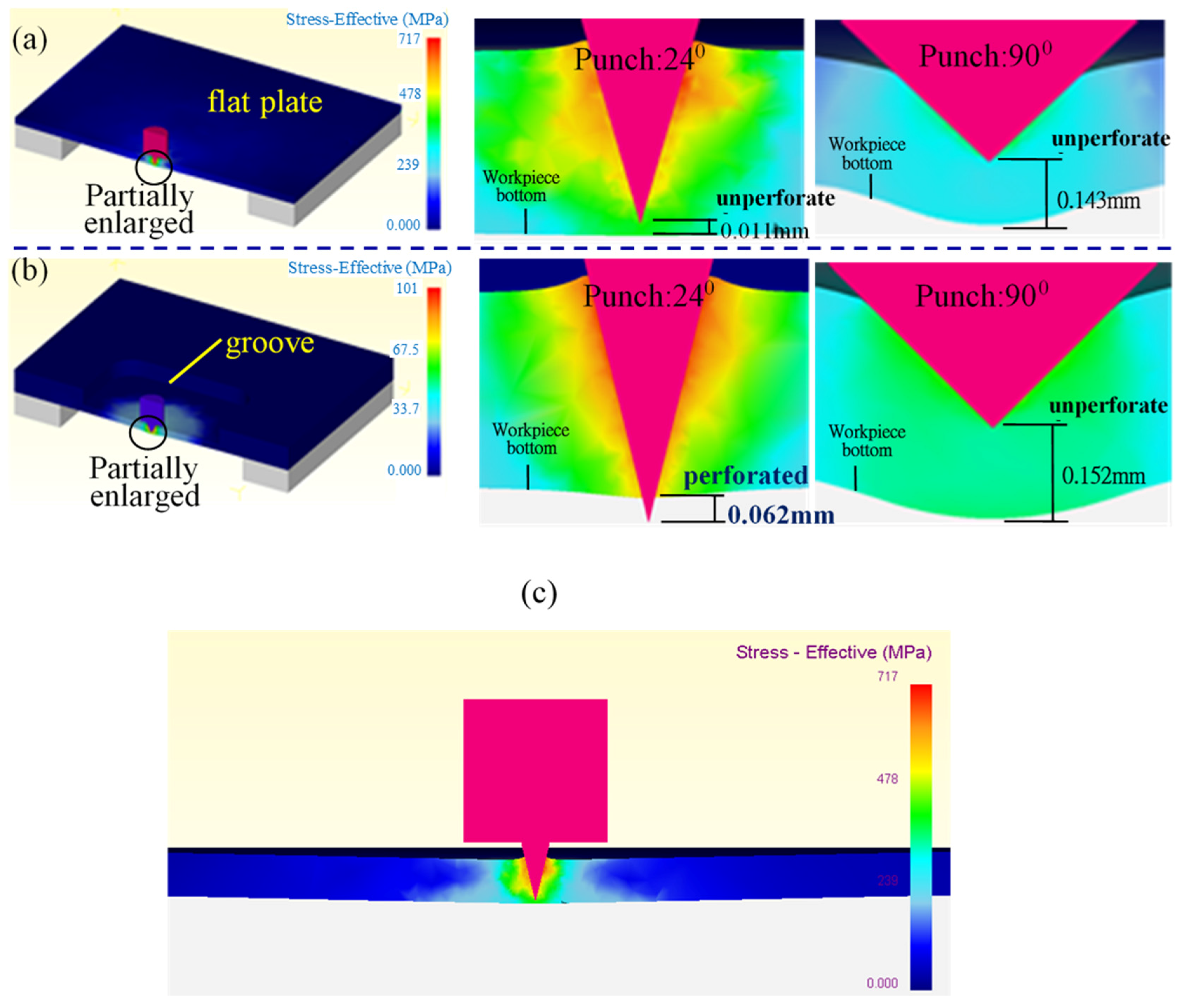

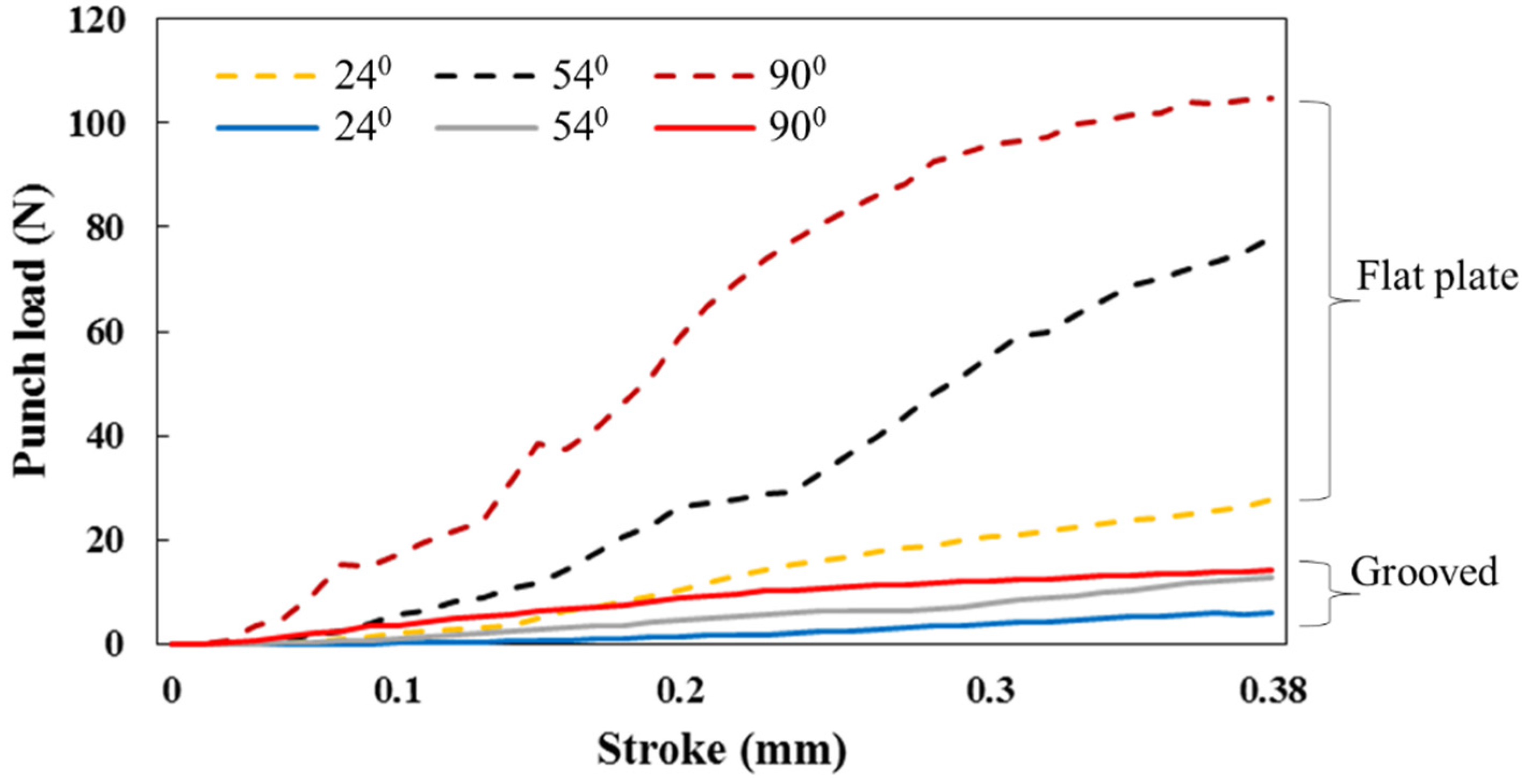

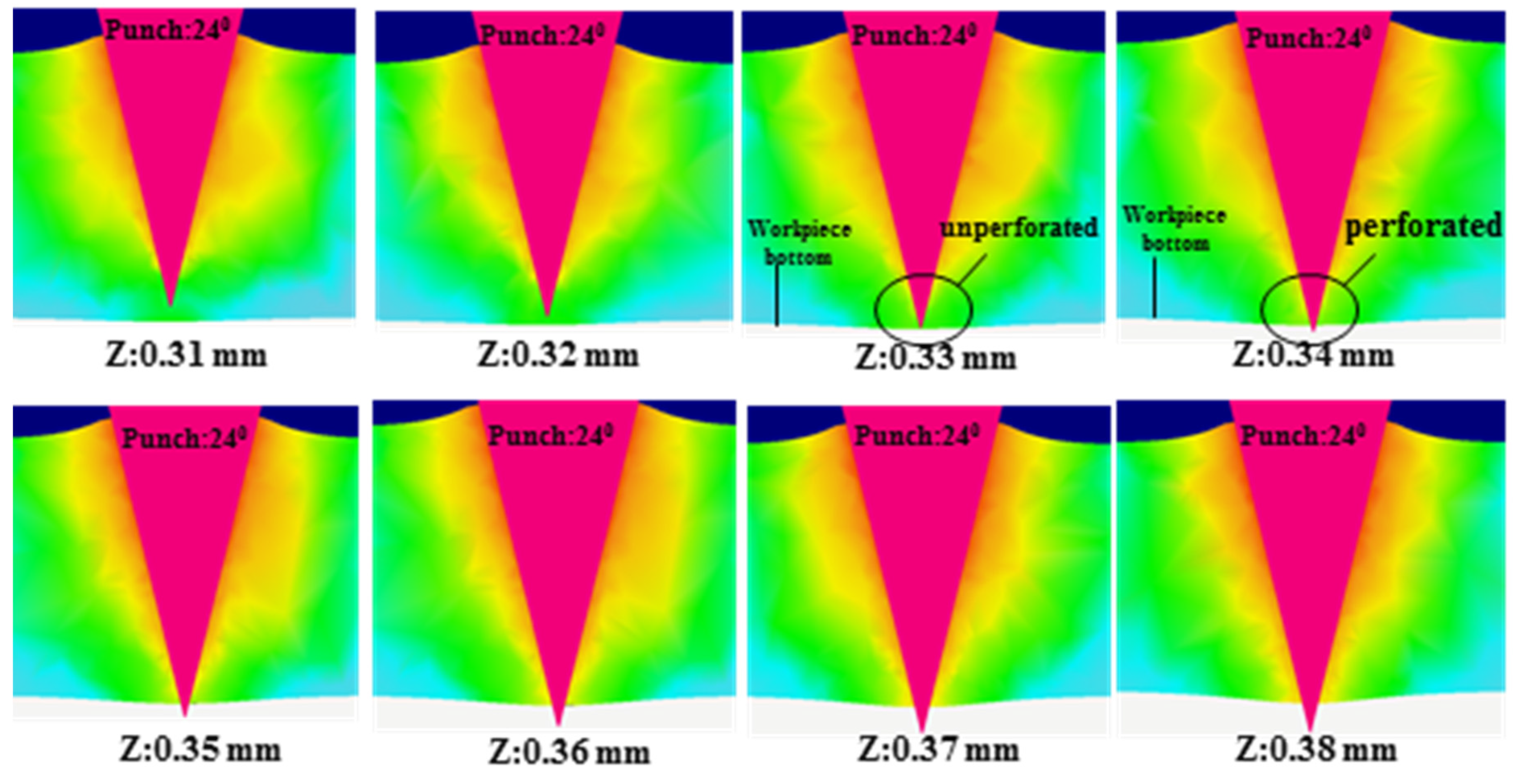

2.2. Simulation Results and Discussion

3. Experimental Method and Procedure

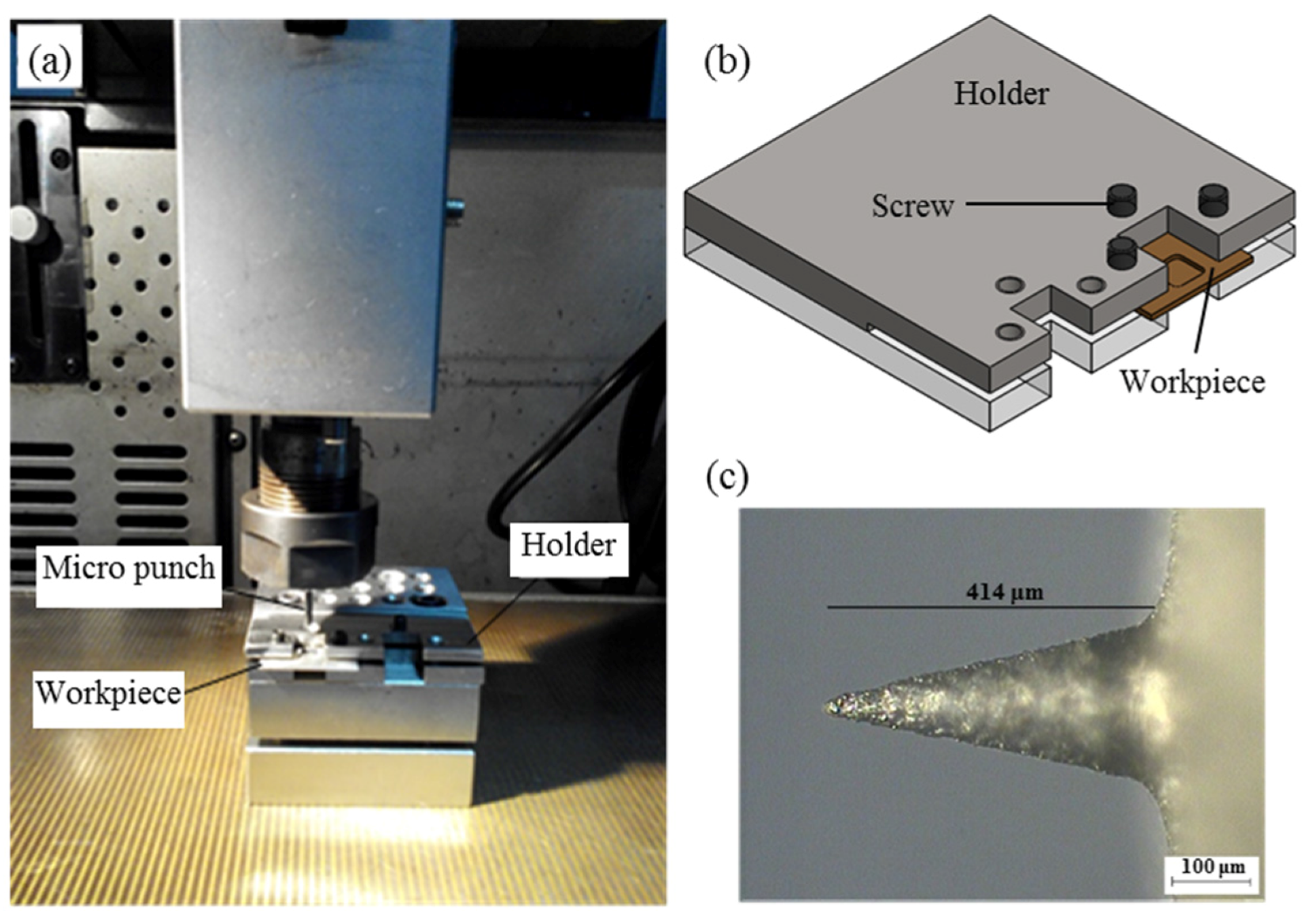

3.1. Micro Stamping

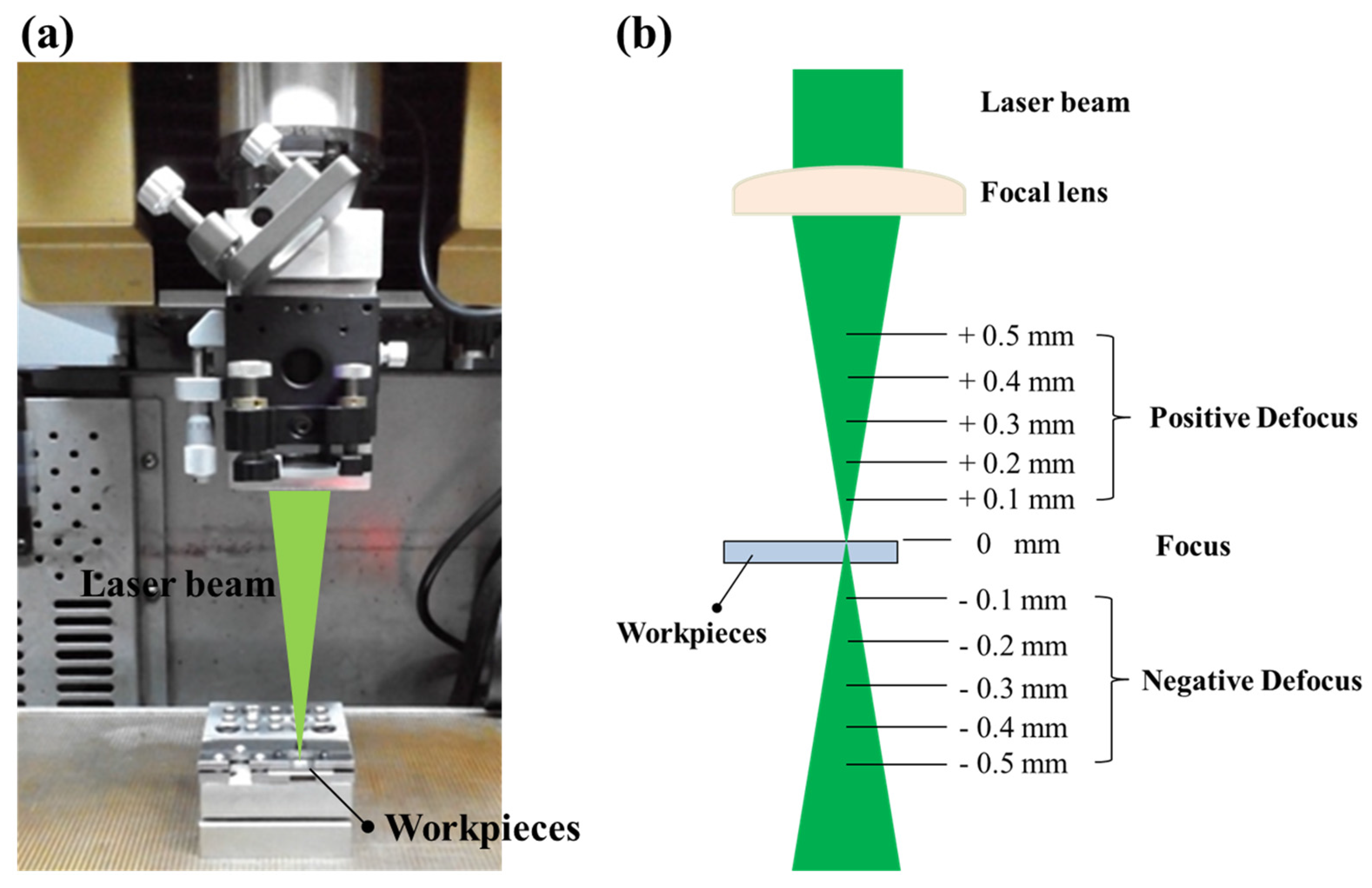

3.2. Laser Processing

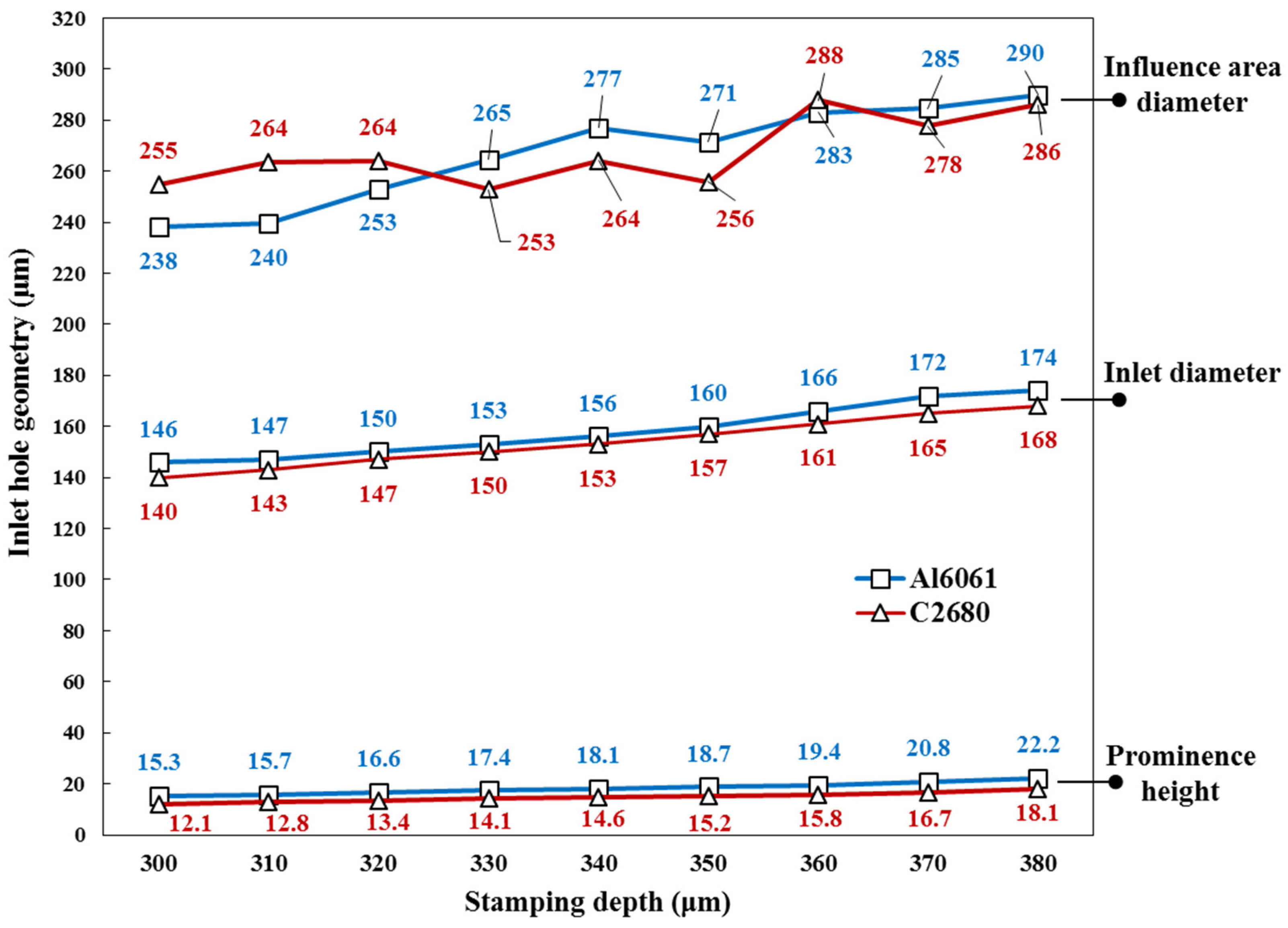

4. Experimental Results and Discussion

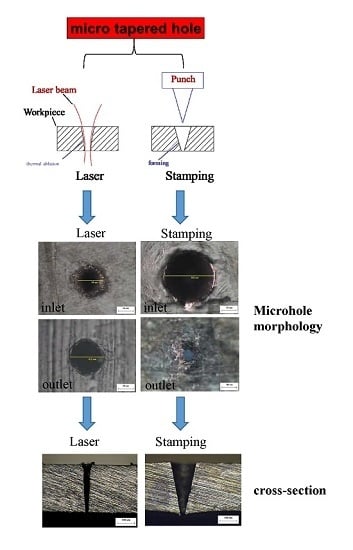

4.1. Microhole Morphology

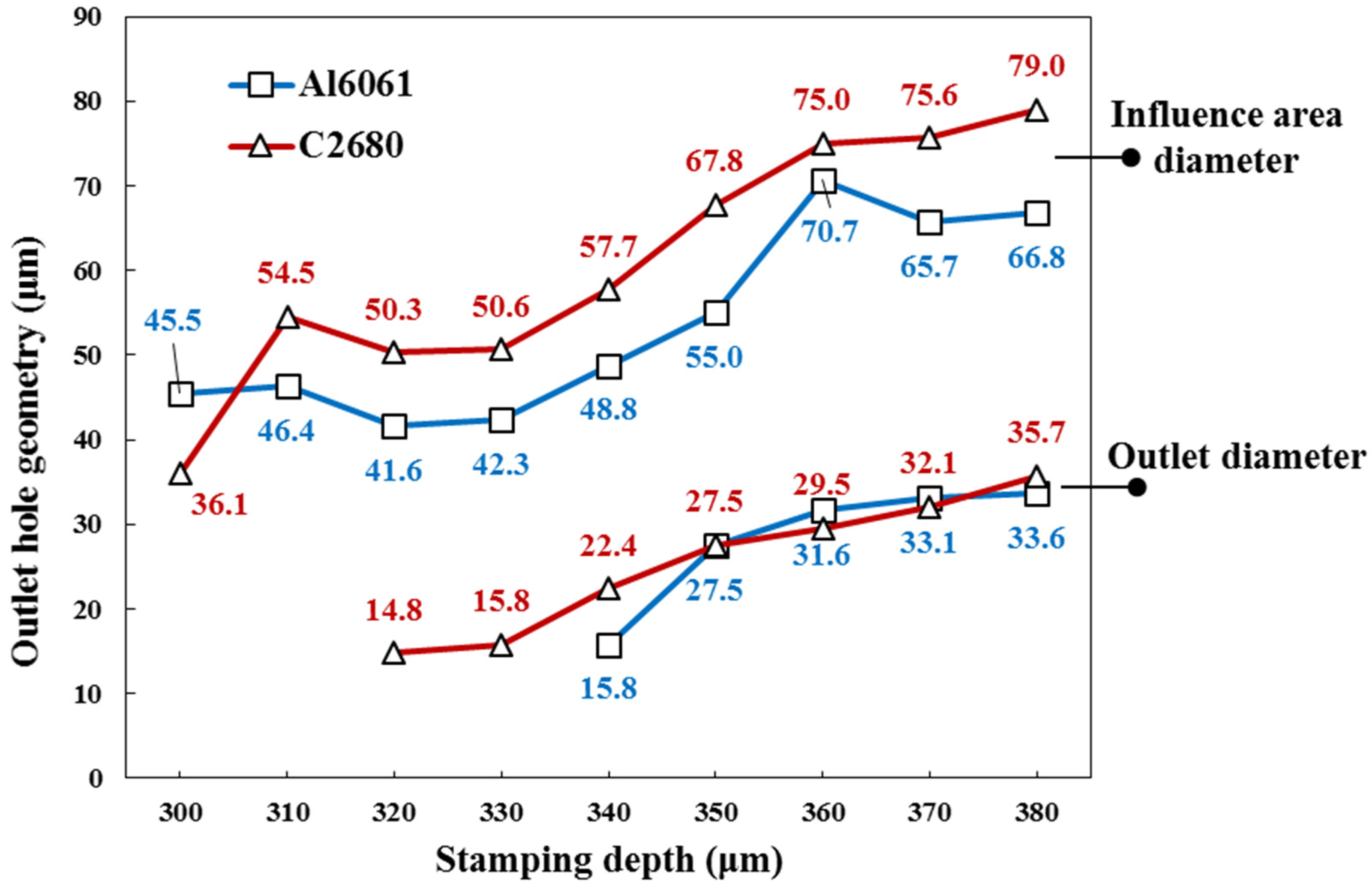

4.1.1. Micro Stamping

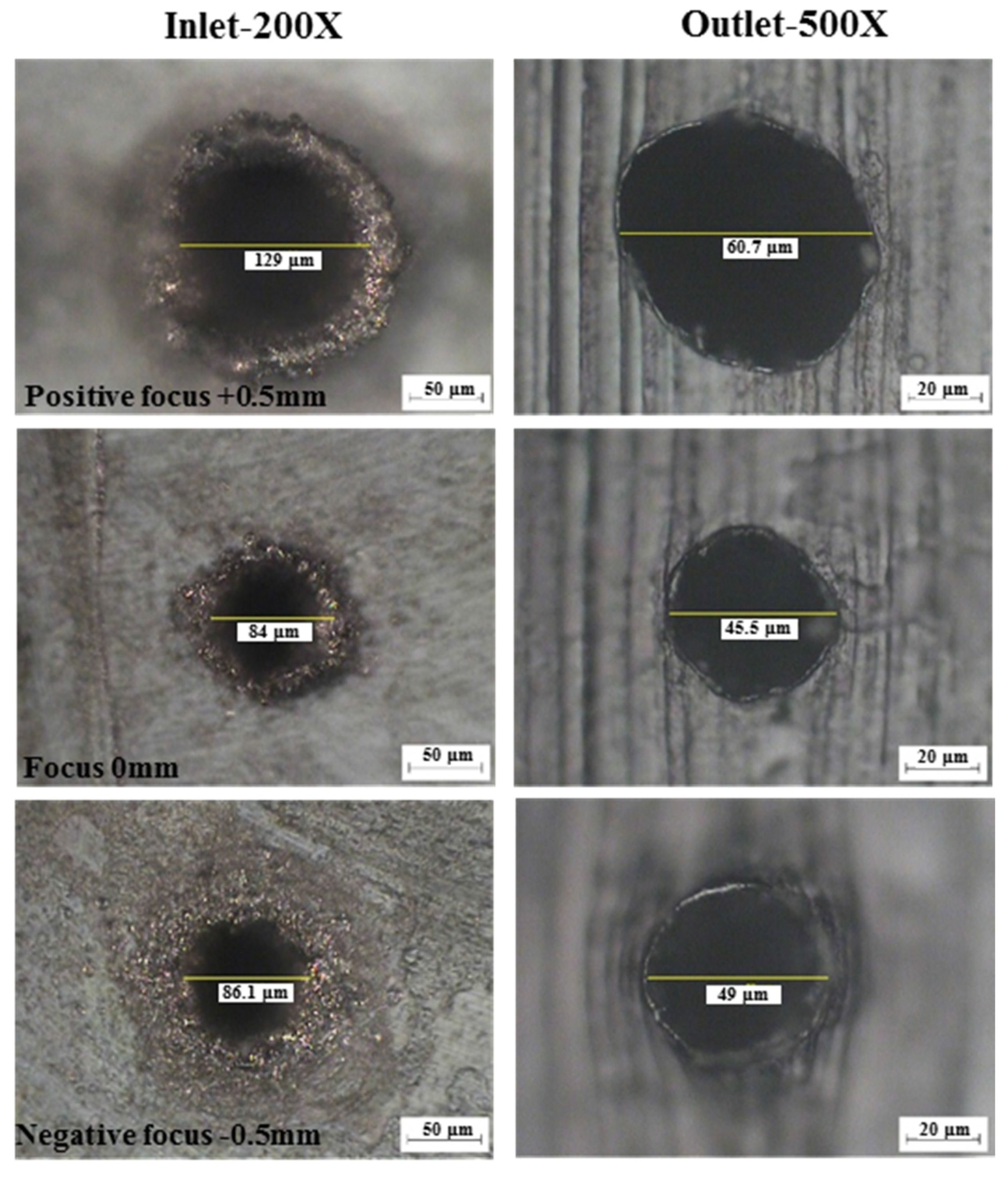

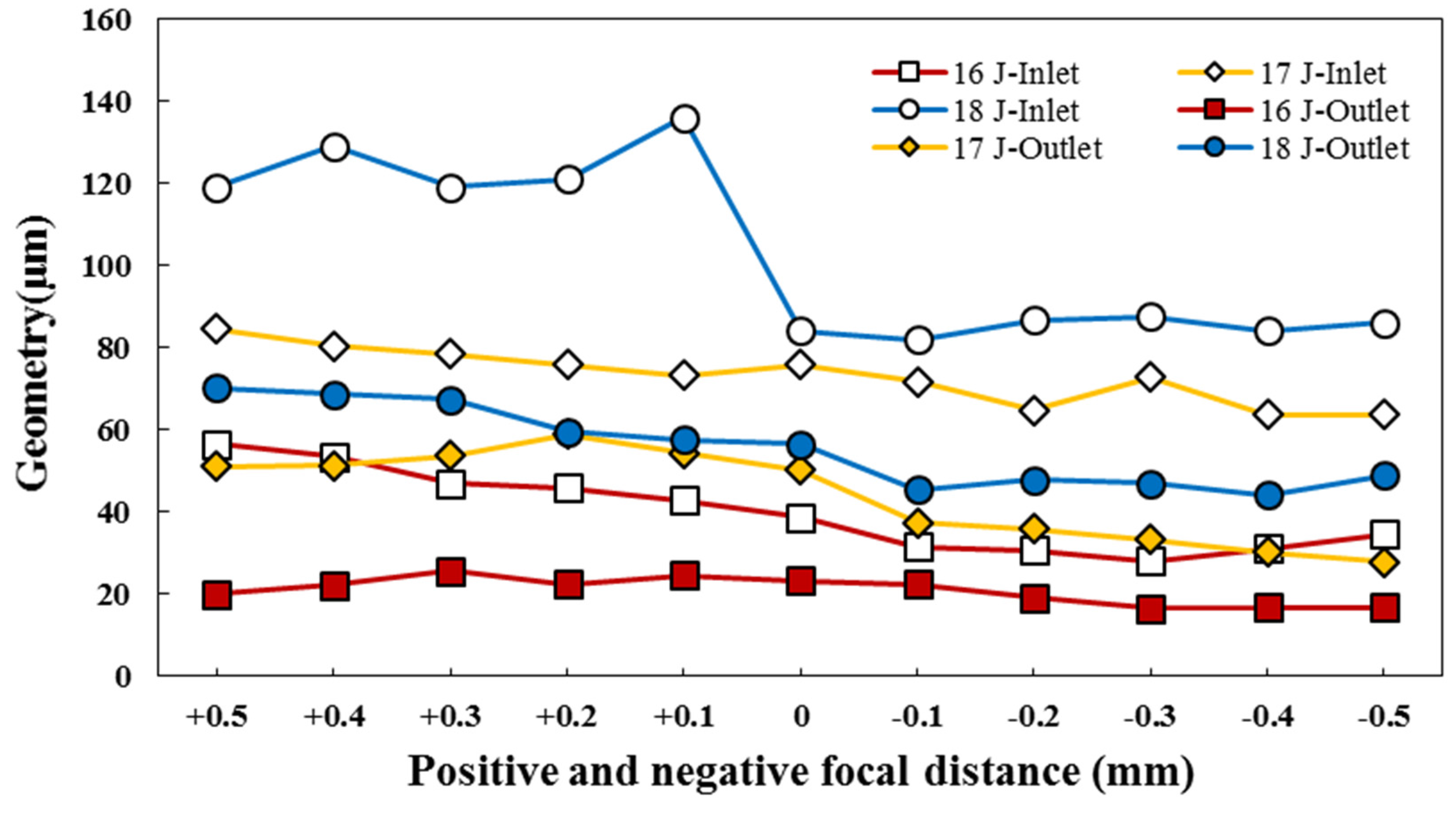

4.1.2. Laser Processing

4.2. Microhole Cross-Section Analysis

4.3. Punch Morphology after Stamping

5. Conclusions

- (1)

- We have demonstrated the feasibility of stamping process by a micro-scale tapered punch head and the micro punch head is not apparently worn in the stamping process.

- (2)

- Micro stamping produces a better micro tapered hole wall quality with Ra value of 0.8 μm than by laser processing.

- (3)

- The stamping results of Al6061 and C2680 workpieces show that, with the same stamping depth, the prominence height at the inlet of the C2680 is lower than Al6061 (~20%). The results show that the C2680 workpiece has better micro tapered hole wall quality than Al6061.

- (4)

- The required tapered hole morphology and size can be accurately obtained by controlling the stamping depth. The inlet and outlet diameter of microholes can be adjusted by the stamping depth or punch head angle.

- (5)

- The micro tapered hole depth is 300 μm, and the maximum ratio of inlet to outlet diameter is 18:1.

- (6)

- Laser processing is used to form tapered holes. Although the energy and defocusing distance can be adjusted, the largest taper angle in the experiments was 9.7°, which was smaller than the angle of 23.5° produced by the stamping process.

- (7)

- The surface roughness of micro stamping is 33% lower than laser processing.

- (8)

- SWD, as proposed in this study, can make the required taper angle by changing the punch angle.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Derzija, B.H.; Izet, B. Experimental and numerical investigation of temperature distribution and hole geometry during laser drilling process. Procedia Eng. 2015, 100, 384–393. [Google Scholar]

- Ahn, D.G.; Jung, G.W. Influence of process parameters on drilling characteristics of Al 1050 sheet with thickness of 0.2 mm using pulsed Nd:YAG laser. Trans. Nonferr. Met. Soc. China 2009, 19, s157–s163. [Google Scholar] [CrossRef]

- Yao, K.C.; Lin, J. The characterization of the hole-contour and plume ejection in the laser drilling with various inclination angles. Opt. Laser Technol. 2013, 48, 110–116. [Google Scholar] [CrossRef]

- Masuzawa, T.; Fujino, M.; Kobayashi, K. Wire electro-discharge grinding for micro-machining. CIRP Ann. Manuf. Technol. 1985, 34, 431–434. [Google Scholar] [CrossRef]

- Fujino, M.; Yamamoto, M.; Masuzawa, T. Micro-Punching System as an Application of WEDG; Institute of Industrial Science, The University of Tokyo SEISAN-KENKYU: Tokyo, Japan, 1987; Volume 39, pp. 277–280. (In Japanese) [Google Scholar]

- Chern, G.L.; Wang, S.D. Punching of noncircular micro-holes and development of micro-forming. Precis. Eng. 2007, 31, 210–217. [Google Scholar] [CrossRef]

- Joo, B.Y.; Oh, S.I.; Jeon, B.H. Development of micro punching system. CIRP Ann. Manuf. Technol. 2001, 50, 191–194. [Google Scholar] [CrossRef]

- Joo, B.Y.; Rhim, S.H.; Oh, S.I. Micro-hole fabrication by mechanical punching process. J. Mater. Process. Technol. 2005, 170, 593–601. [Google Scholar] [CrossRef]

- Hwang, Y.L.; Kuo, C.L.; Hwang, S.F. Fabrication of a micro-pin array with high density and high hardness by combining mechanical peck-drilling and reverse-EDM. J. Mater. Process. Technol. 2010, 210, 1103–1130. [Google Scholar] [CrossRef]

- Xu, J.; Guo, B.; Shan, D.; Wang, C.; Li, J.; Liu, Y.; Qu, D. Development of a micro-forming system for micro-punching process of micro-hole arrays in brass foil. J. Mater. Process. Technol. 2012, 212, 2238–2246. [Google Scholar] [CrossRef]

- Kibe, Y.; Okada, Y.; Mitsui, K. Machining accuracy for shearing process of thin-sheet metals—Development of initial tool position adjustment system. Int. J. Mach. Tools Manuf. 2007, 47, 1728–1737. [Google Scholar] [CrossRef]

- Oh, S.I.; Wu, W.T.; Tang, J.P. Simulations of cold forging processes by the DEFORM system. J. Mater. Process. Technol. 1992, 35, 357–370. [Google Scholar] [CrossRef]

- Nagao, Y.; Knoerr, M.; Altan, T. Improvement of tool life in cold forging of complex automotive parts. J. Mater. Process. Technol. 1994, 46, 73–85. [Google Scholar] [CrossRef]

- Kim, H.; Sweeney, K.; Altan, T. Application of computer aided simulation to investigate metal flow in selected forging operations. J. Mater. Process. Technol. 1994, 46, 127–154. [Google Scholar] [CrossRef]

- Kim, H.H.; Kang, C.G. Numerical simulation and experimental study for rheo-forged component using direct and indirect die system. Trans. Nonferr. Met. Soc. China 2010, 20, 1799–1804. [Google Scholar] [CrossRef]

| Parameter | Condition |

|---|---|

| Workpiece | Al6061 |

| Punch angle | 24°, 54°, 90° |

| Workpiece/Die | Plastic/Rigid |

| Stamping speed | 0.5 mm/min |

| Stamping depth (Z) | 0.38 mm |

| Parameter | Condition |

|---|---|

| Workpiece | Al6061 C2680 |

| Punch angle | 23.5° |

| Stamping speed | 0.5 mm/min |

| Stamping depth (Z) | 300, 310, 320, 330, 340, 350, 360, 370, 380 μm |

| Parameter | Condition |

|---|---|

| Workpieces (Al6061) | 300 μm |

| Wavelength | 532 nm |

| Frequency | 15 Hz |

| Pumping lamp energy | 16, 17, 18 J |

| Power (Watt) | 20, 30, 40 mW |

| Focal length | 120 mm |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hung, Y.-C.; Chang, Y.-J.; Kuo, C.-L.; Hsu, J.-C.; Ho, C.-C. Comparison between Laser and Stamping without Die (SWD) for Micro Tapered Hole Forming. Appl. Sci. 2016, 6, 77. https://doi.org/10.3390/app6030077

Hung Y-C, Chang Y-J, Kuo C-L, Hsu J-C, Ho C-C. Comparison between Laser and Stamping without Die (SWD) for Micro Tapered Hole Forming. Applied Sciences. 2016; 6(3):77. https://doi.org/10.3390/app6030077

Chicago/Turabian StyleHung, Yung-Chou, Yuan-Jen Chang, Chia-Lung Kuo, Jin-Chen Hsu, and Chao-Ching Ho. 2016. "Comparison between Laser and Stamping without Die (SWD) for Micro Tapered Hole Forming" Applied Sciences 6, no. 3: 77. https://doi.org/10.3390/app6030077