An Experimental Study on Mechanical Modeling of Ceramics Based on Microstructure

Abstract

:1. Introduction

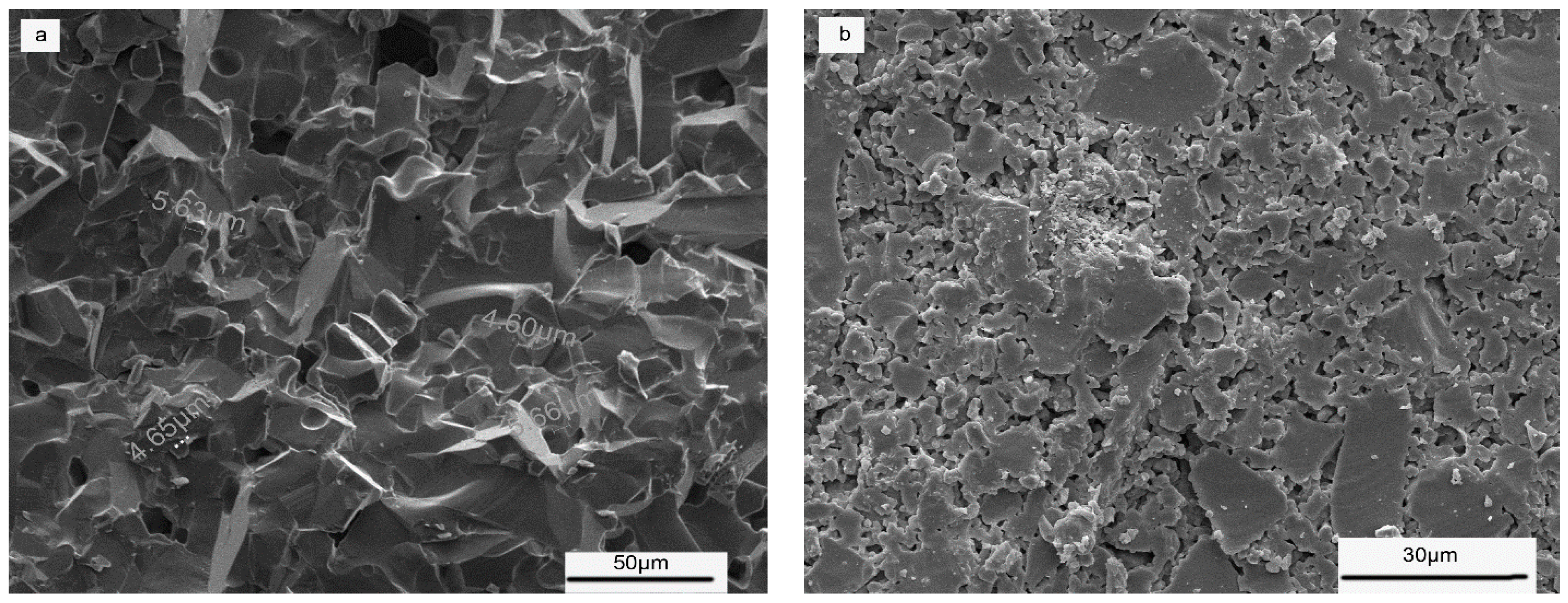

2. Experiment Details

2.1. Properties of Workpieces

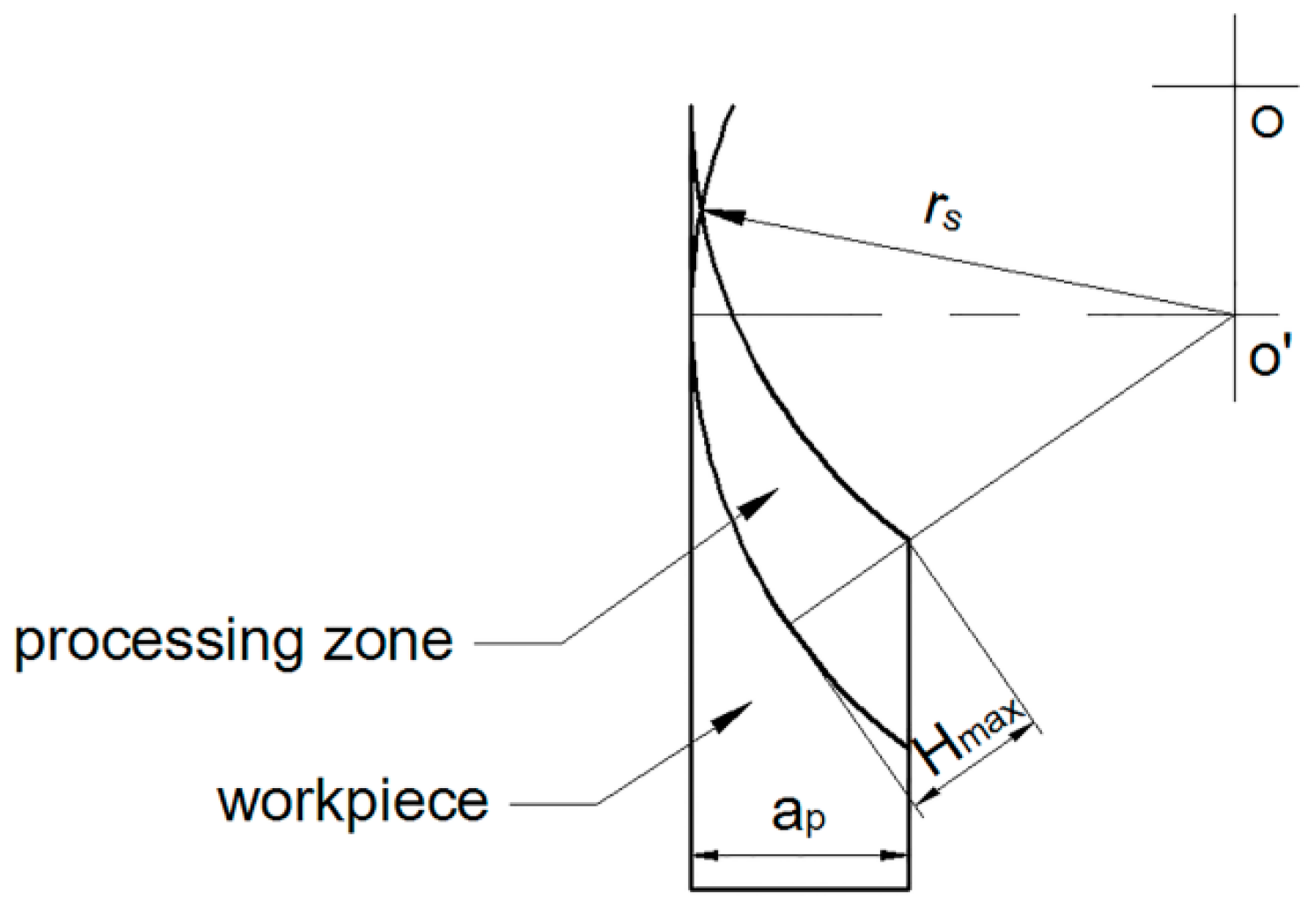

2.2. Grinding Experiment

| No. | Mesh Size M/# | Mean Grit Size/μm | Grit Surface Density C/#·mm−2 |

|---|---|---|---|

| 1 | 60 | 253 | 3.82 |

| 2 | 120 | 127 | 15.15 |

| 3 | 180 | 84 | 34.6 |

| No. | Mesh Size/# | Depth of Cut/μm | Wheel Speed /m·s−1 | Work Speed/m·s−1 | Max Undeformed Chip Thickness Hmax/μm |

|---|---|---|---|---|---|

| 1 | 60 | 100 | 10.5 | 0.2 | 7.94 |

| 2 | 100 | 15 | 0.2 | 6.64 | |

| 3 | 100 | 15 | 0.1 | 4.70 | |

| 4 | 100 | 20 | 0.1 | 4.07 | |

| 5 | 100 | 30 | 0.1 | 3.32 | |

| 6 | 50 | 30 | 0.1 | 2.79 | |

| 7 | 30 | 30 | 0.1 | 2.46 | |

| 8 | 120 | 100 | 30 | 0.1 | 1.67 |

| 9 | 50 | 30 | 0.1 | 1.40 | |

| 10 | 30 | 30 | 0.1 | 1.23 | |

| 11 | 10 | 30 | 0.1 | 0.94 | |

| 12 | 10 | 30 | 0.07 | 0.78 | |

| 13 | 10 | 30 | 0.05 | 0.66 | |

| 14 | 180 | 50 | 30 | 0.07 | 0.78 |

| 15 | 30 | 30 | 0.07 | 0.68 | |

| 16 | 10 | 30 | 0.07 | 0.52 | |

| 17 | 100 | 30 | 0.07 | 0.44 |

2.3. Grinding Force and Specific Grinding Energy Measurements and Surface Morphology Observations

3. Results and Discussion

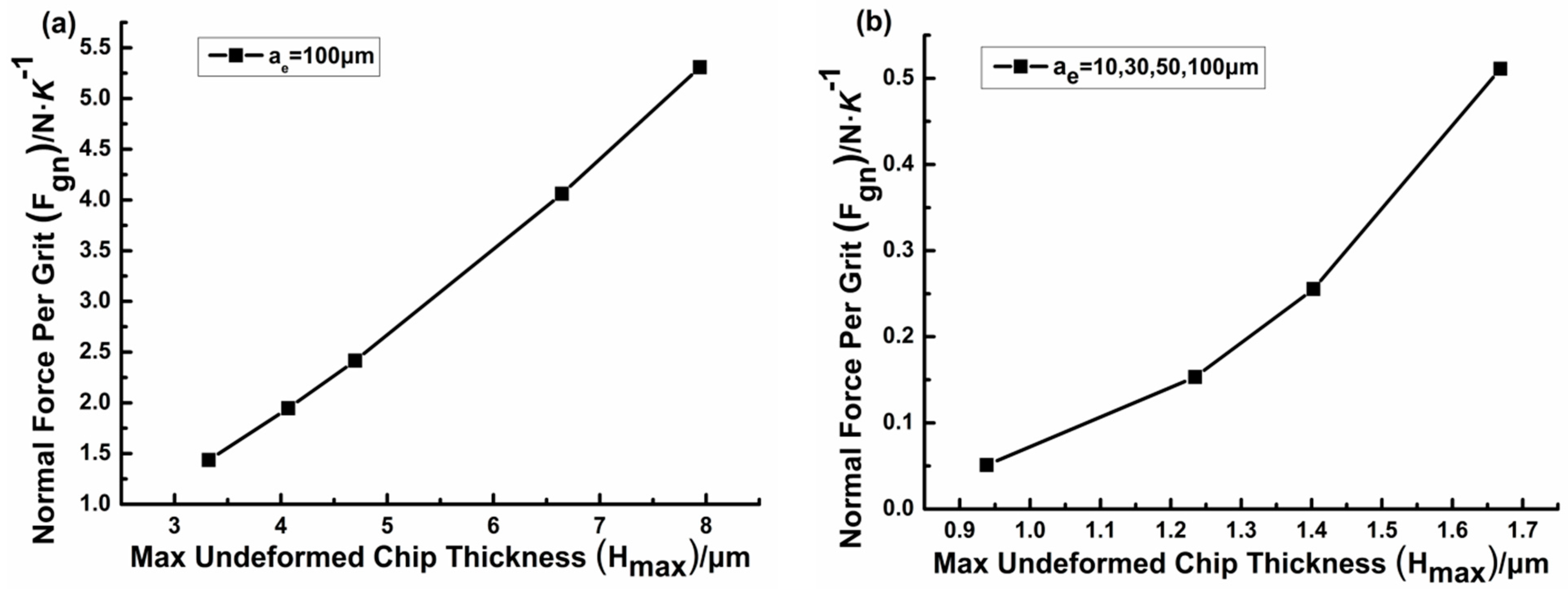

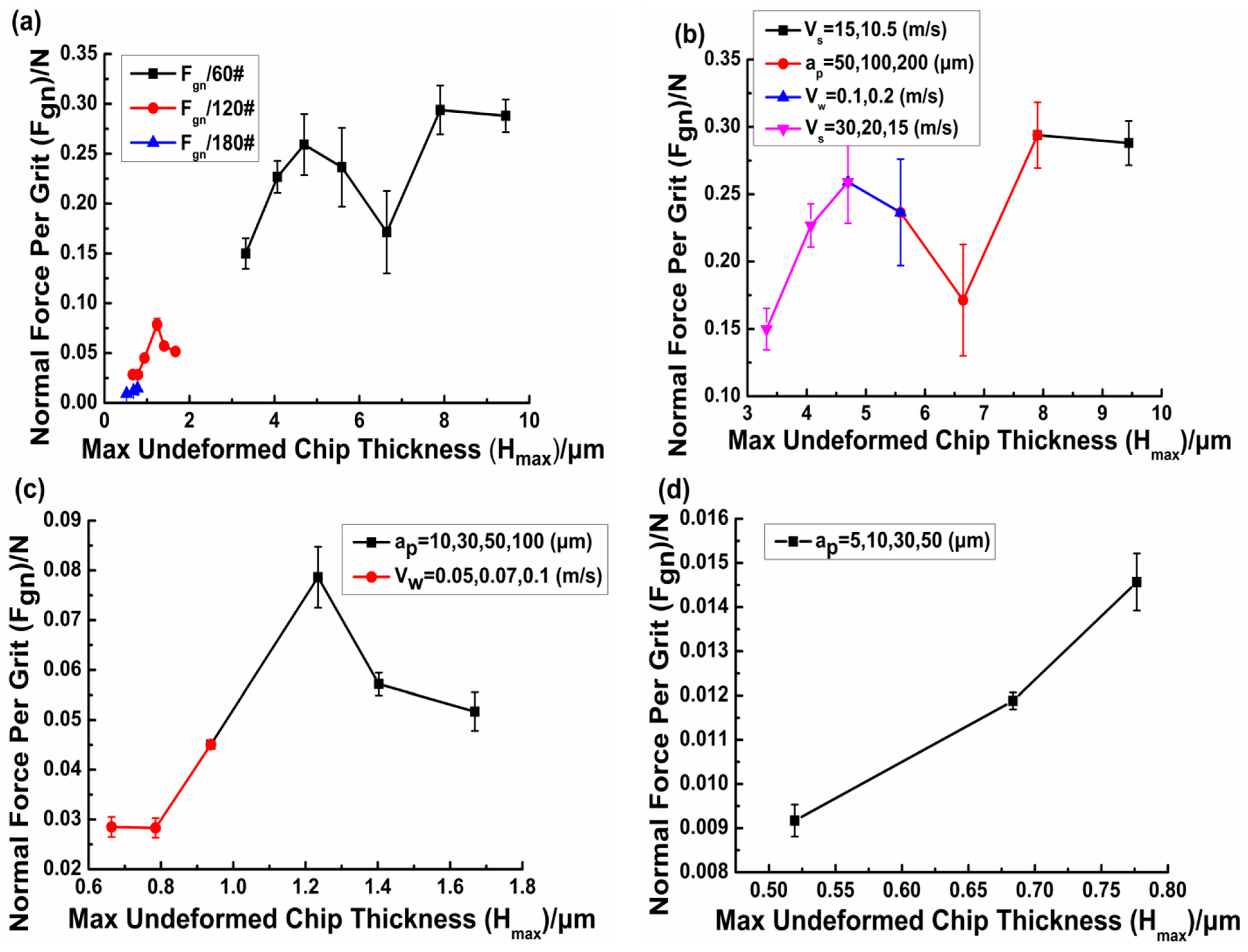

3.1. The Normal Force per Grit vs. Maximum Undeformed Chip Thickness

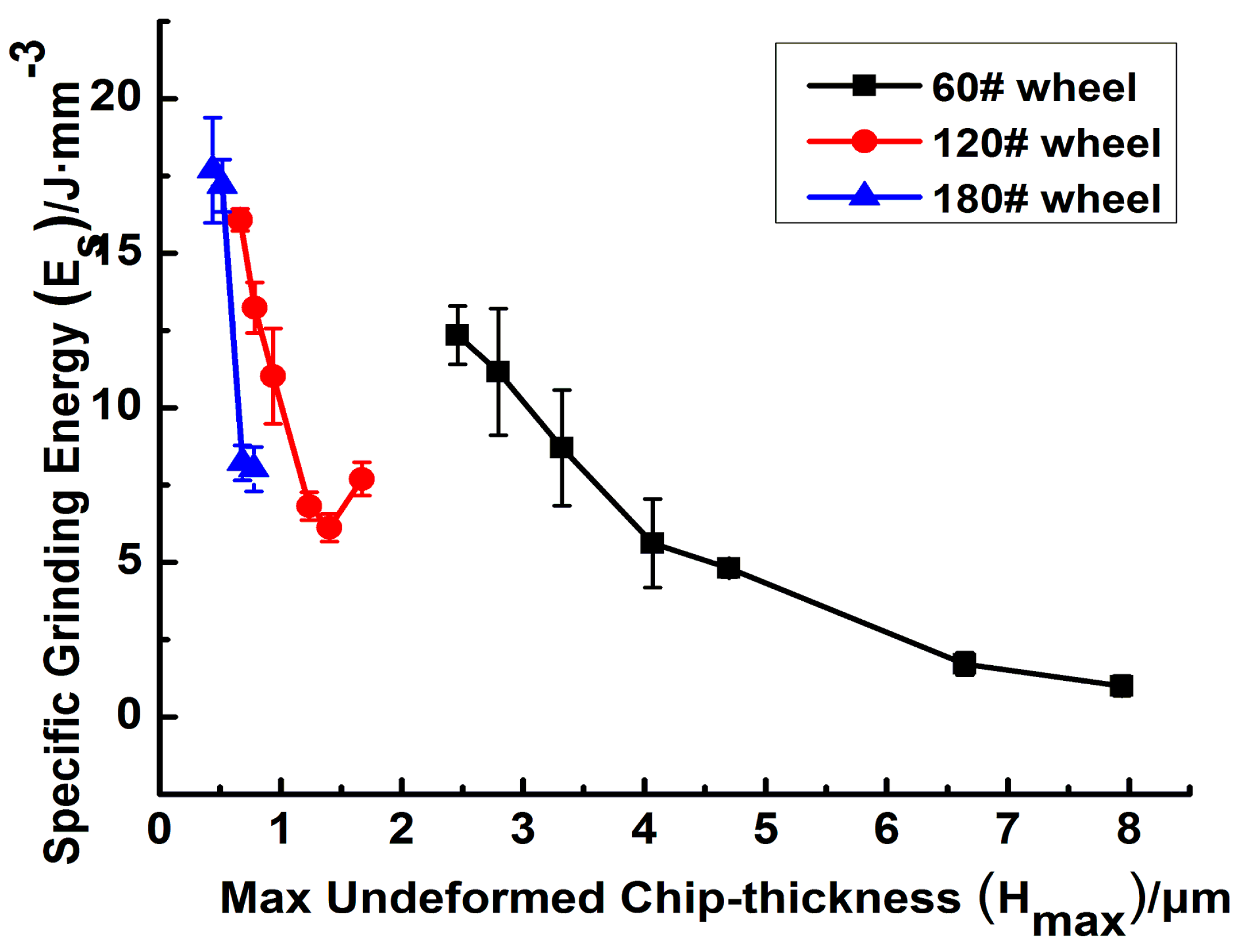

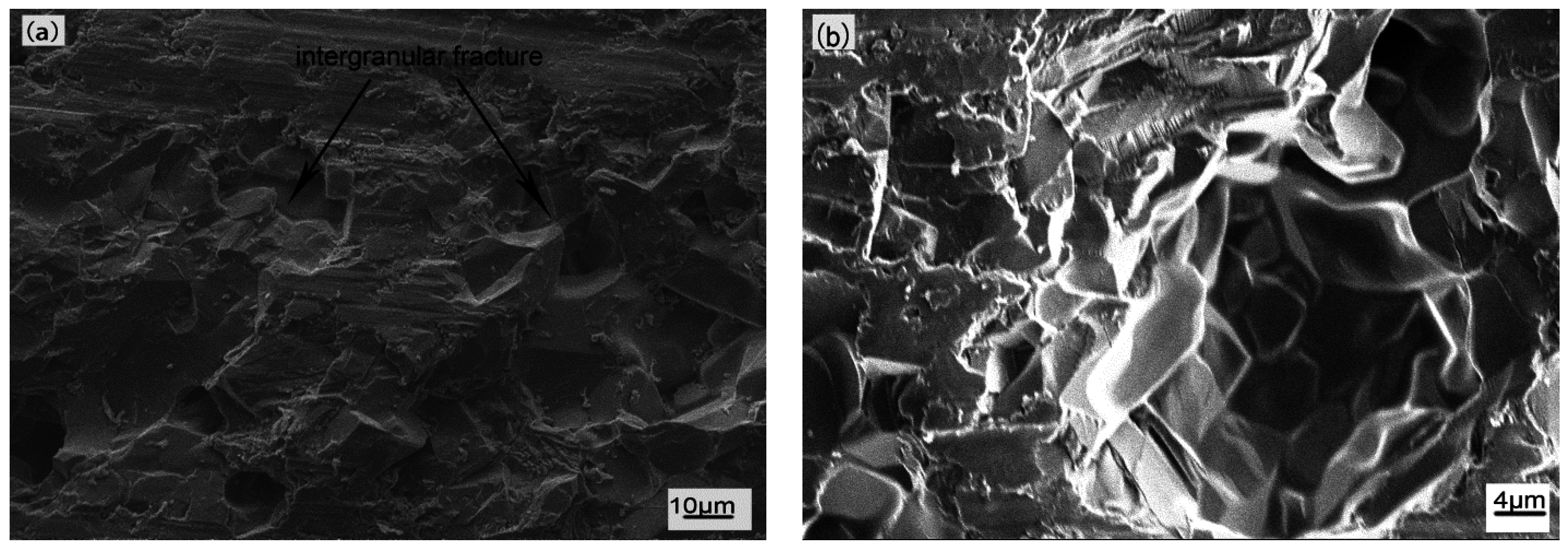

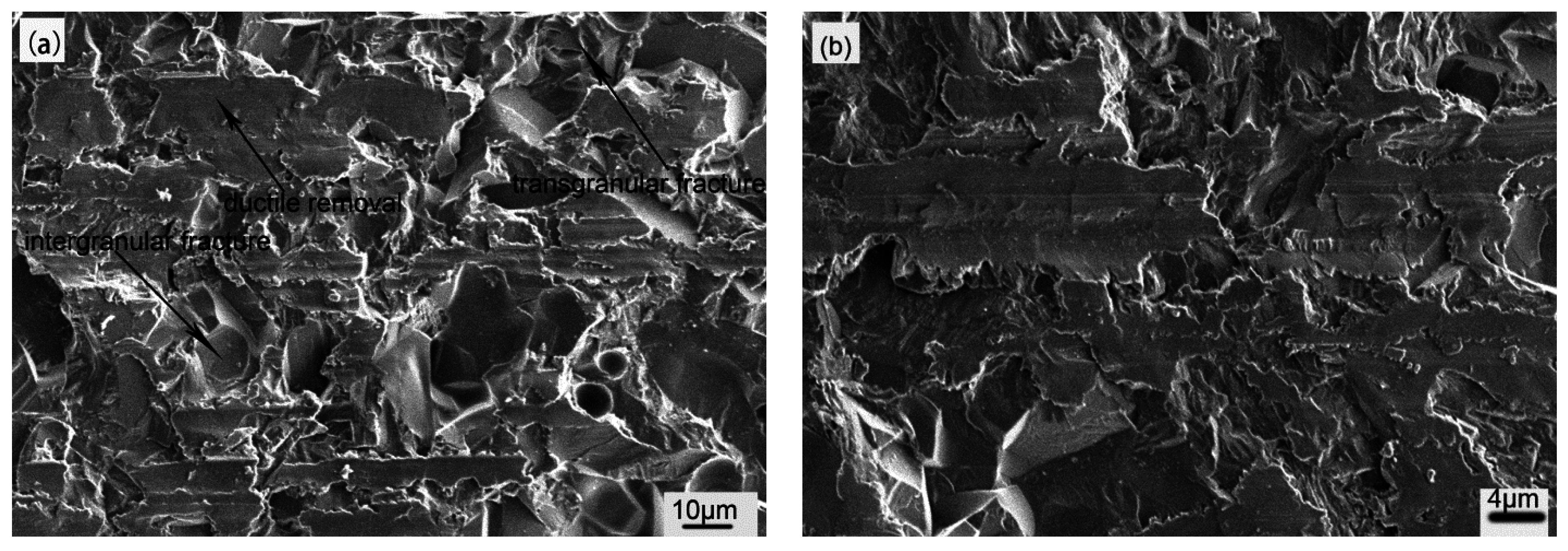

3.2. The Specific Grinding Energy vs. Maximum Undeformed Chip Thickness and SEM Observations

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Werner, G. Influence of work material on grinding forces. Ann. CIRP 1978, 27, 243–248. [Google Scholar]

- Malkin, S.; Cook, N.H. The wear of grinding wheels: Part 1—Attritious wear. J. Eng. Ind. 1971, 93, 1120–1128. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Jahanmir, S.; Ives, L.K. Mechanisms of material removal in abrasive machining of ceramics. Interceram 1998, 47, 380–385. [Google Scholar]

- Xu, H.H.K.; Jahanmir, S. Transitions in the mechanism of material removal in abrasive wear of alumina. Wear 1996, 192, 228–232. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Jahanmir, S. Microfracture and material removal in scratching of alumina. J. Mater. Sci. 1995, 30, 2235–2247. [Google Scholar] [CrossRef]

- Li, L.J.; Fu, J.C. Study on grinding force model. J. Hunan Univ. 1979, 3, 44–55. [Google Scholar]

- Li, K.; Liao, W. Modelling of ceramic grinding processes part I. Number of cutting points and grinding forces per grit. J. Mater. Process. Technol. 1997, 65, 1–10. [Google Scholar] [CrossRef]

- Hecker, R.L.; Liang, S.Y.; Wu, X.J.; Xia, P.; Jin, D.G.W. Grinding force and power modeling based on chip thickness analysis. Int. J. Adv. Manuf. Technol. 2007, 33, 449–459. [Google Scholar] [CrossRef]

- Wang, J.M.; Ye, R.Z.; Tang, Y.P.; Bing, H.Z. Research on the grinding force model of steel 55 during surface grinding with CBN wheel. Diam. Abras. Eng. 2010, 30, 67–70. [Google Scholar]

- Agarwal, S.; Rao, P.V. Predictive modeling of force and power based on a new analytical undeformed chip thickness model in ceramic grinding. Int. J. Mach. Tools Manuf. 2013, 65, 68–78. [Google Scholar] [CrossRef]

- Agarwal, S.; Rao, P.V. Predictive modeling of undeformed chip thickness in ceramic grinding. Int. J. Mach. Tools Manuf. 2012, 56, 59–68. [Google Scholar] [CrossRef]

- Xie, G.Z.; Shang, Z.T.; Sheng, X.M.; Wu, Y.; Yu, J.W. Grinding force modeling for high-speed deep grinding of engineering ceramics. J. Mech. Eng. 2011, 47, 169–176. [Google Scholar] [CrossRef]

- Xu, H.H.K.; Jahanmir, S. Effect of grain size on scratch damage and hardness of alumina. J. Mater. Sci. Lett. 1995, 14, 736–739. [Google Scholar] [CrossRef]

- Klecka, M.; Subhash, G. Grain size dependence of scratch-induced damage in alumina ceramics. Wear 2008, 265, 612–619. [Google Scholar] [CrossRef]

- Jin, Z.H. Engineering Ceramics; Xi′an Jiao Tong University Press: Xi′an, China, 2000; p. 385. [Google Scholar]

- Mayer, J.E.; Fang, G.P. Effect of grinding parameters on surface finish of ground ceramics. CIRP Ann. Manuf. Technol. 1995, 44, 279–282. [Google Scholar] [CrossRef]

- Zhu, A.J. Research on Surface Grinding of SCFS with Diamond Wheel. Master Thesis, Tianjin University, China, 2005. [Google Scholar]

- Li, W.; Wang, Y.; Fan, S.H.; Xu, J.F. Wear of diamond grinding wheels and material removal rate of silicon nitrides under different machining conditions. Mater. Lett. 2007, 61, 54–58. [Google Scholar] [CrossRef]

- Kannappan, S.; Malkin, S. Effects of grain size and operating parameters on the mechanics of grinding. J. Eng. Ind. 1972, 94, 833–842. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.-N.; Lin, B.; Liu, J.-J.; Song, X.-F.; Key, J.Y. An Experimental Study on Mechanical Modeling of Ceramics Based on Microstructure. Appl. Sci. 2015, 5, 1337-1349. https://doi.org/10.3390/app5041337

Zhang Y-N, Lin B, Liu J-J, Song X-F, Key JY. An Experimental Study on Mechanical Modeling of Ceramics Based on Microstructure. Applied Sciences. 2015; 5(4):1337-1349. https://doi.org/10.3390/app5041337

Chicago/Turabian StyleZhang, Ya-Nan, Bin Lin, Jian-Jun Liu, Xiao-Fei Song, and Jie Yang Key. 2015. "An Experimental Study on Mechanical Modeling of Ceramics Based on Microstructure" Applied Sciences 5, no. 4: 1337-1349. https://doi.org/10.3390/app5041337