Optical Cutting Interruption Sensor for Fiber Lasers

Abstract

:1. Introduction

2. Experimental Section

2.1. Laser Cutting System

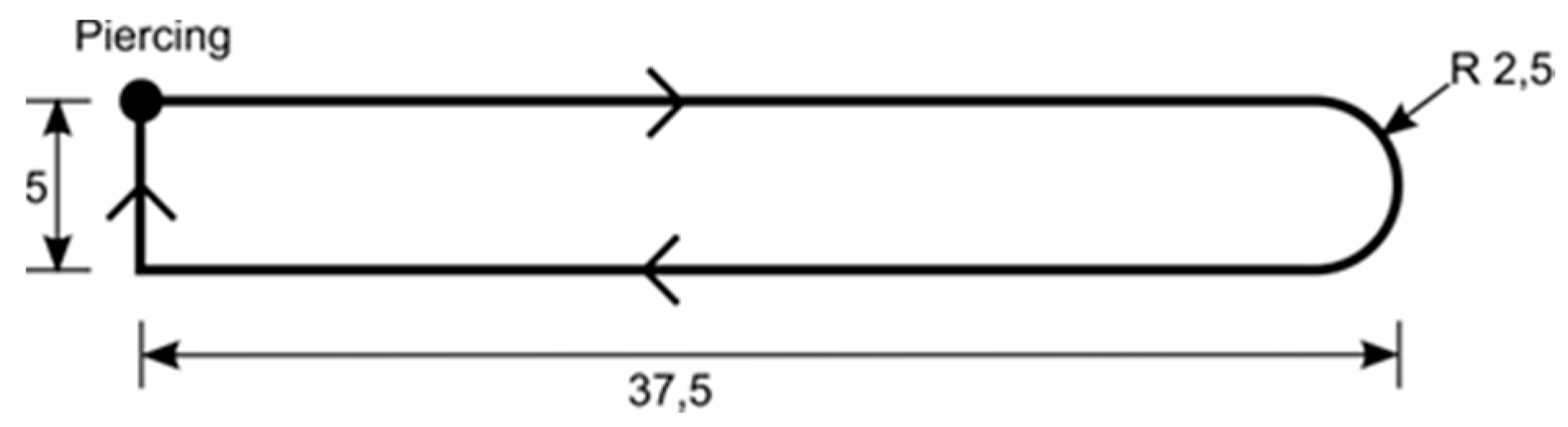

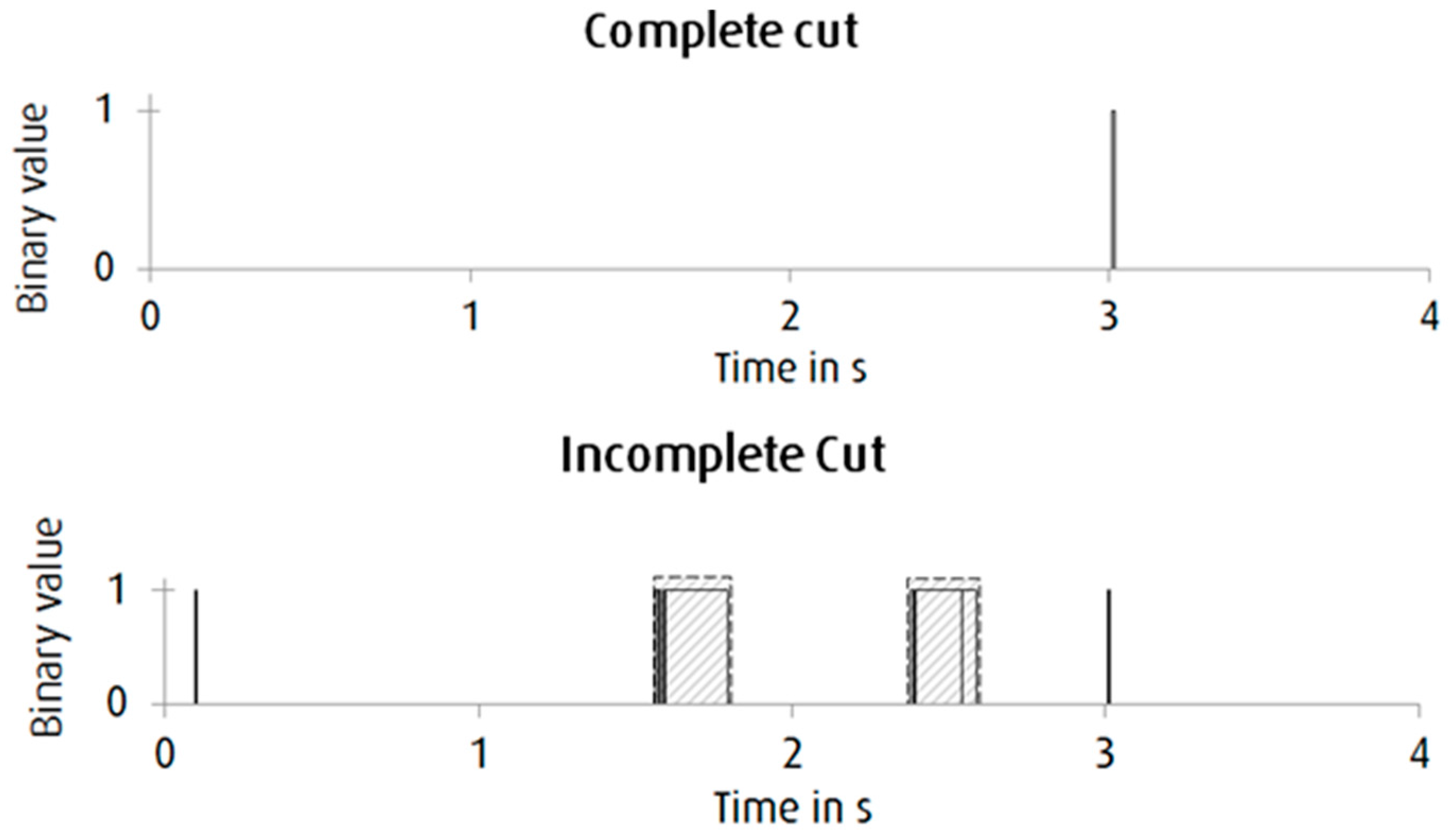

2.2. Cut Design

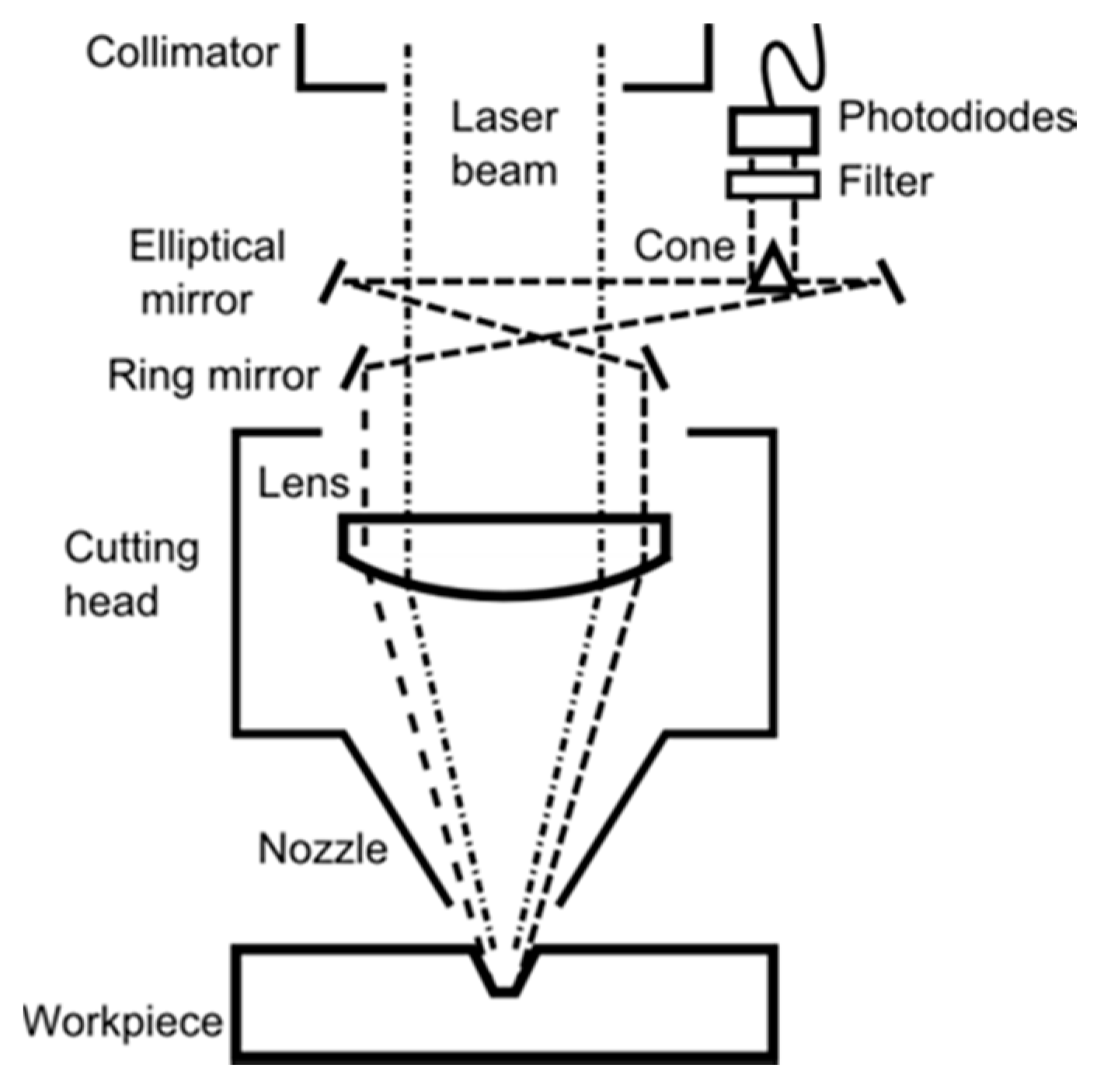

2.3. Design of the Sensor System

3. Results and Discussion

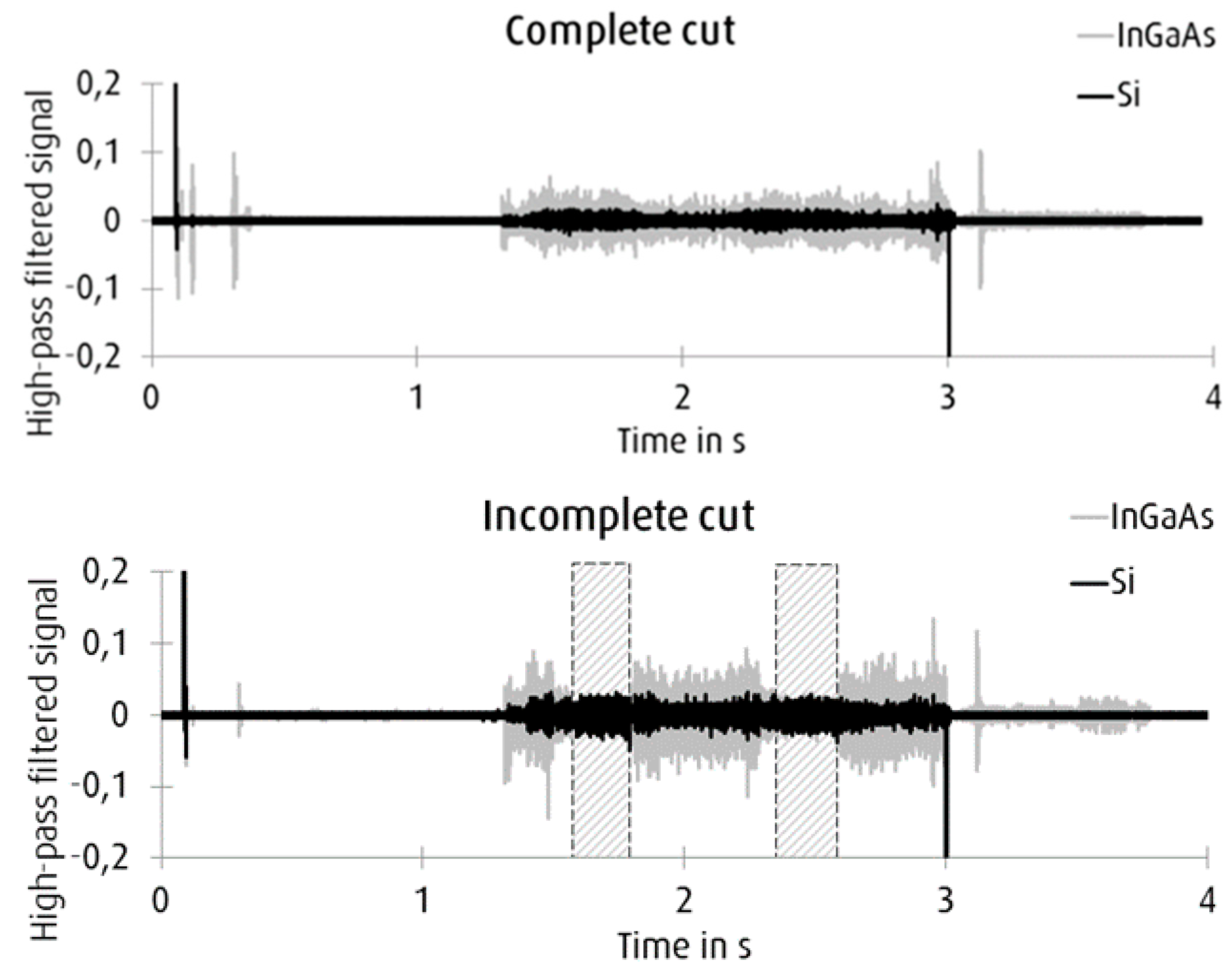

3.1. Raw Data of the Sensor in Cutting Application

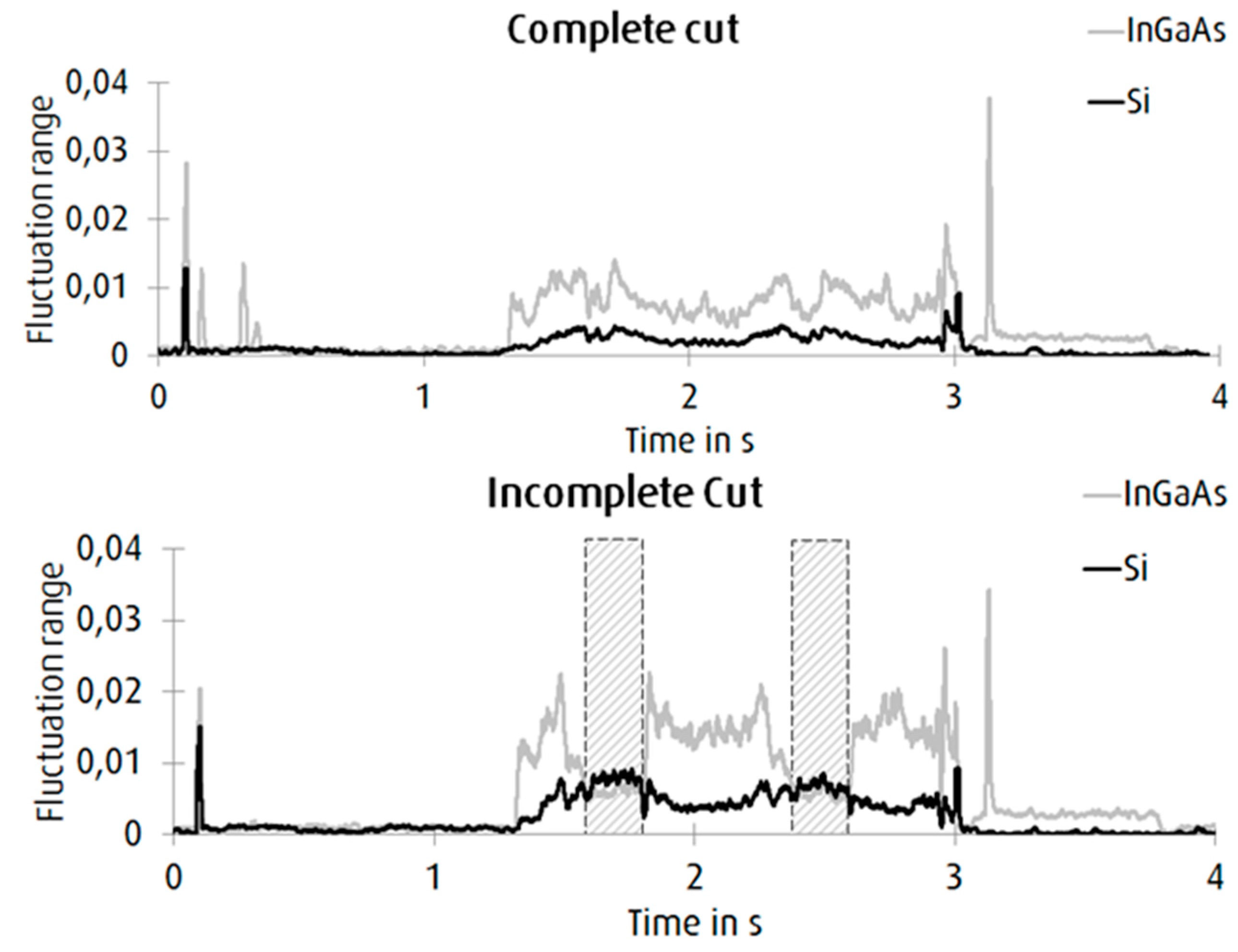

3.2. Signal Processing

3.3. Evaluation and Discussion of the Sensor and Algorithm

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Wandera, A.; Salminen, A.; Olsen, F.; Kujanpaa, V. Inert gas cutting of thick section stainless steel and medium section aluminum using a high power fiber laser. J. Laser Appl. 2009, 21, 154–161. [Google Scholar] [CrossRef]

- Wandera, A.; Olsen, F.; Salminen, A.; Kujanpaa, V. Cutting of stainless steel with fiber and disk laser. In Proceedings of 25th International Conference on Lasers and Electro Optics, Scottsdale, AZ, USA, 30 October–2 November 2006; pp. 211–220.

- Himmer, T.; Pinder, T.; Morgenthal, L.; Beyer, E. High brightness laser in cutting applications. In Proceedings of 26th International Congress on Applications of Lasers & Electro-Optics, Orlando, FL, USA, 29 October–1 November 2007; pp. 87–91.

- Stelzer, S.; Mahrle, A.; Wetzig, A.; Beyer, E. Experimental Investigations on Fusion Cutting Stainless Steel with Fiber and CO2 Laser Beams. Phys. Procedia 2013, 41, 392–397. [Google Scholar] [CrossRef]

- Adelmann, B.; Hellmann, R. Process optimization of laser fusion cutting of multilayer stacks of electrical sheets. Int. J. Adv. Manuf. Technol. 2013, 68, 2693–2701. [Google Scholar] [CrossRef]

- Lan, H.; Wang, W. Fundamental Studies on High Power Fiber Laser Cutting Performance of 30 mm Thick Carbon Steel Plate. In Proceedings of Strategic Technology (IFOST), 2011 6th International Forum on, Harbin, China, 22–24 August 2011; pp. 6–11.

- Orishich, A.; Malikov, A.; Shulyatyev, V.; Golyshev, A. Experimental Comparison of Laser Cutting of Steel with Fiber and CO2 Lasers on the Basis of Minimal Roughness. Phys. Procedia 2014, 56, 875–884. [Google Scholar] [CrossRef]

- Kratky, A.; Schuöcker, D.; Liedl, G. Processing with kW fibre lasers-advantages and limits. Proc. SPIE 2008. [Google Scholar] [CrossRef]

- Park, Y.W.; Park, H.; Rhee, S.; Kang, M. Real time estimation of CO2 laser weld quality for automotive industry. Opt. Laser Technol. 2002, 34, 135–142. [Google Scholar] [CrossRef]

- Sun, A.; Kannatey-Asibu, E., Jr.; Gartner, M. Sensor systems for real-time monitoring of laser weld quality. J. Laser Appl. 1999, 11, 153–168. [Google Scholar] [CrossRef]

- Ancona, A.; Spagnolo, V.; Lugara, P.M.; Ferrara, M. Optical Sensor for real-time Monitoring of CO2 Laser Welding Process. Appl. Opt. 2001, 40, 6019–6025. [Google Scholar] [CrossRef] [PubMed]

- Sichani, E.; de Keuster, J.; Kruth, J.P.; Duflou, J.R. Monitoring and adaptive controll of CO2 laser flame cutting. Phys. Procedia 2010, 5, 483–492. [Google Scholar] [CrossRef]

- Sichani, E.F.; de Keuster, J.; Kruth, J.; Duflou, J. Real-time monitoring, control and optimization of CO2 laser cutting of mild steel plates. In Proceedings of the 37th International MATADOR Conference, Manchester, UK, 14 May 2012; pp. 177–181.

- Ermolaev, G.V.; Yudin, P.V.; Briand, F.; Zaitsev, A.V.; Kovalev, O.B. Fundamental study of CO2-and fiber laser cutting of steel plates with high speed visualization technique. J. Laser Appl. 2014, 26, 042004. [Google Scholar] [CrossRef]

- Alippi, C.; Bono, V.; Piuri, V.; Scotti, F. Toward real-time quality analysis measurement of metal laser cutting. In Proceedings of Virtual and Intelligent Measurement Systems, 2002. VIMS '02. 2002 IEEE International Symposium on, Mt Alyeska Resort, AK, USA, 19–20 May 2002; pp. 39–44.

- Kaierle, S.; Abels, P.; Kratzsch, C. Process Monitoring and Control for Laser Materials Processing—An Overview. In WLT-Conference on Lasers in Manufacturing. In Proceedings of the Third International WLT-Conference Lasers in Manufacturing, LIM 2005, Munich, Germany, 13–16 June 2005; pp. 101–105.

- Jurca, M.; Langer, H.J. Temperature field measurement as quality assurance measure in case of laser material processing. Phys. Procedia 2010, 5, 473–481. [Google Scholar] [CrossRef]

- Golubev, Y.; Dubrov, A.; Zavalov, Y.N.; Dubrovin, N.G. Diagnostics of laser radiance penetration into material by multi-channel pyrometer. In Proceedings of Advanced Optoelectronics and Lasers (CAOL), 2010 International Conference on, Sevastopol, Ukraine, 10–14 September 2010; pp. 182–184.

- Kek, T.; Grum, J. Use of AE monitoring in laser cutting and resistance spot welding. In Proceedings of EWGAE, Vienna, Austria, 8–10 September 2010.

- Arnold, P. Apparatus for collecting process light during laser machining, comprises lens in machining head, narrow annular mirror over lens edge and reflective ellipse for directing light to detector. Patent DE 102008015133A1, 24 September 2009. [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adelmann, B.; Schleier, M.; Neumeier, B.; Wilmann, E.; Hellmann, R. Optical Cutting Interruption Sensor for Fiber Lasers. Appl. Sci. 2015, 5, 544-554. https://doi.org/10.3390/app5030544

Adelmann B, Schleier M, Neumeier B, Wilmann E, Hellmann R. Optical Cutting Interruption Sensor for Fiber Lasers. Applied Sciences. 2015; 5(3):544-554. https://doi.org/10.3390/app5030544

Chicago/Turabian StyleAdelmann, Benedikt, Max Schleier, Benedikt Neumeier, Eugen Wilmann, and Ralf Hellmann. 2015. "Optical Cutting Interruption Sensor for Fiber Lasers" Applied Sciences 5, no. 3: 544-554. https://doi.org/10.3390/app5030544