1. Introduction

Nowadays, buildings are responsible for about 40% of primary energy consumption and 36% of CO

2 emissions in the EU. As about 35% of the EU building stock is over 50 years old, the improvement of the energy efficiency of buildings could lead to a significant reduction of the total EU energy consumption and CO

2 emissions [

1]. Space heating in apartment buildings is usually provided by outdated central heating systems, characterized by vertical hydraulic distributions with water radiators connected to the main risers. The refurbishment or the improvement of these types of heating system represents one of the main tasks towards the reduction of CO

2 emissions and can be pursued both by replacing older thermal-hydraulic components and devices and by optimizing their operation and control.

The heat cost allocation in apartment buildings, based on the assessment of the actual individual thermal energy consumptions, represents a forceful driver for the residents in order to optimize their household heating management, saving energy and money.

In central heating systems characterized by vertical hydraulic distributions with water radiators of different apartments connected to the same feeding riser, direct heat metering is not feasible for the measurement of individual thermal energy consumptions. Therefore, the indirect estimation of radiator thermal power represents the basis for heat cost allocation, as well as for the design of the heating plant.

The European Standard EN 442 [

2,

3] identifies the measurement model, defines the requirements of the measurement system and describes the procedure to characterize the thermal power exchanged by water radiators. The characteristic coefficients of the radiators, obtained by regression analysis of the experimental data as measured in a thermal chamber [

4,

5] compliant with the European Standard EN 442, enables an indirect estimate of the steady-state thermal power transferred from the radiator surface to the surrounding environment, once the water mean temperature and the air temperature in proximity of the heating surface are known.

In apartment buildings, characterized by a central heating system with vertical feeding risers, the most widespread method for cost allocation of heating consumption makes use of electronic Heat Cost Allocators (HCAs). These devices indirectly estimate the heat consumption of each water radiator by implementing the radiator characteristic coefficients determined according to the EN 442 and by measuring the temperature difference between a specified point on the radiator surface and the surrounding indoor environment. The requirements and the test methods for these kinds of heat cost allocation devices are specified by the European Standard EN 834 [

6].

Other heat cost allocation methods, based on the availability of radiator characteristic coefficients, rely on the use of suitable radiator valves for the measurement of the insertion time of each heating body, e.g., according to the Italian standard UNI/TR 11388 [

7].

Nowadays, the use of direct or indirect thermal energy measurement devices for the evaluation of individual heating consumptions in apartment buildings, as well as of other sub-metering systems for water, gas and electricity consumptions, is becoming more and more related to the framework of Building Energy Management Systems (BEMS) and the Internet of Things (IoT). Several systems for automatic remote meter readings, centralization and processing of individual heat and water consumptions are commercially available on the market and allow real-time monitoring and management of energy flows. Integrated smart sensor networks provide the necessary measurement data to efficiently manage building energy systems by means of optimization algorithms. Along this line, K2n Ltd., in cooperation with Cardiff University, has produced a powerful cloud-based energy reporting and optimization system, characterized by a different approach to existing meter-based energy monitoring systems, that has been exploited in the framework of the iSERVcmb project to provide the configuration, analysis and optimization of about 2800 HVAC systems throughout Europe [

8]. Another example is given by the structure of wireless sensors and actuators and cloud-based algorithms developed by Enerbrain to optimize the operation of HVAC systems, saving energy and improving indoor comfort [

9].

The application of the radiator characteristic coefficients when installation and heat transfer conditions significantly differ from the EN 442 reference testing method may lead to significant errors on the estimation of heating consumption. As it is not possible, in real applications, to reproduce the reference installation and heat transfer conditions for water radiators, it is necessary to know the errors and the uncertainty contributions associated with the various heat cost allocation methods, due to the large variety of installation effects [

10]. Several in-the-field works were carried out, concerning experimental analyses of heat allocation systems [

11,

12], focusing on the installation effects on the thermal output of water radiators due to different hydraulic connections, shelves, cavities and obstructions.

This work deals with the experimental analysis of an indirect method for the evaluation of individual heat consumptions, carried out at the INRIM central heating system test facility [

13]. The proposed method is based on the steady-state indirect estimation of radiator thermal power and exploits the results of the EcoThermo virtual flow sensor [

14,

15] to estimate the water flow rates circulating through each water radiator. Namely, the method allows evaluating the thermal energy exchanged by water radiators by measuring the opening time of radiator valves and by determining the water temperature at radiator outflow from the EcoThermo flow rate estimation, the indoor ambient temperature measurement, the radiator characteristic coefficients and the measurement of main water supply temperature. Although the radiator characteristic coefficients are used for the indirect thermal energy estimation, the proposed method does not rely on temperature measurement at the radiator surface, avoiding some of the drawbacks associated with the on-site installation.

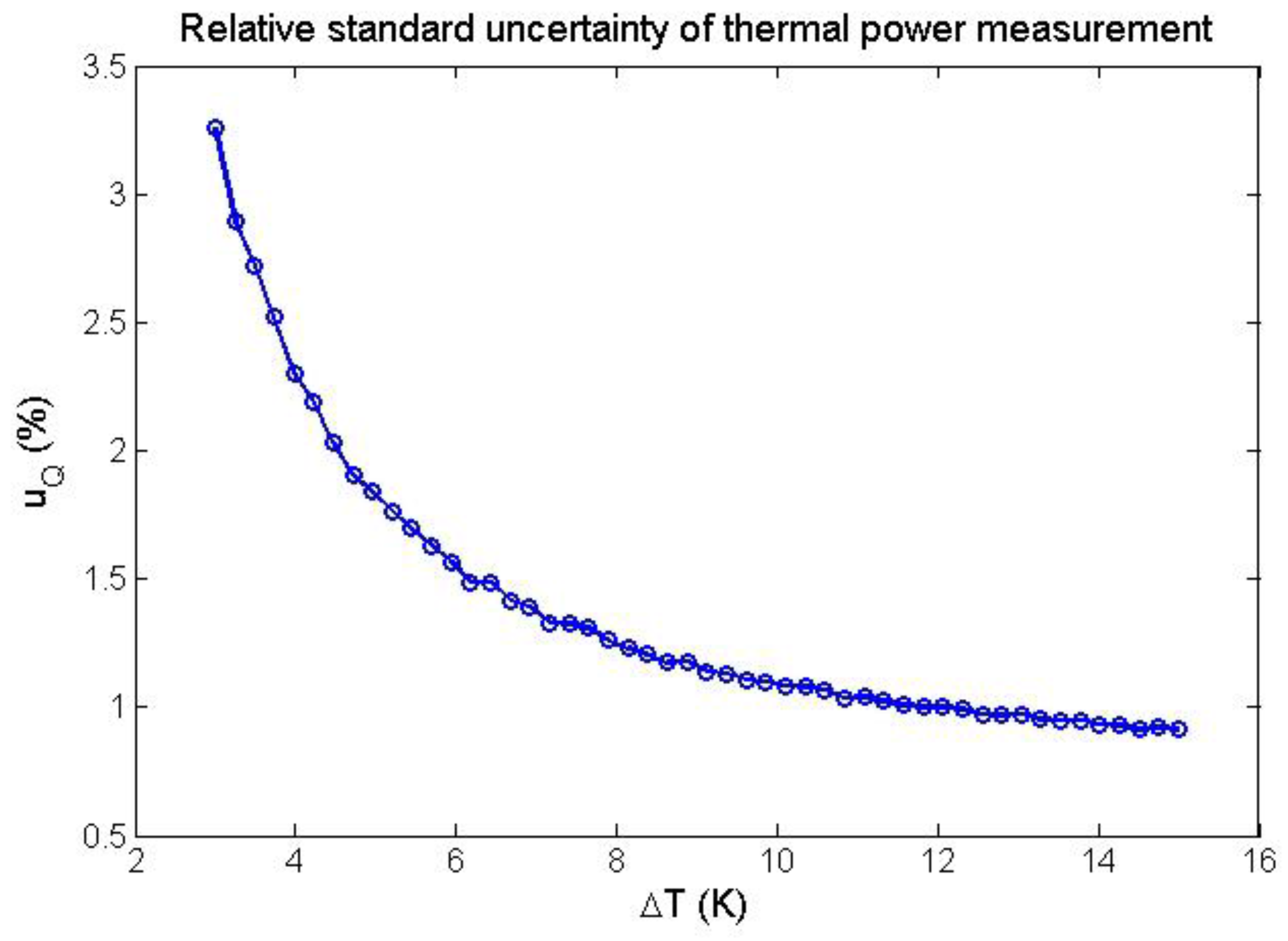

A sensitivity analysis of the measurement model of the heat cost allocation method has been carried out, pointing out the potential effects of the uncertainties associated with input quantities on thermal power estimation. As endorsed by the typical flow rate dependence of radiator thermal power and by the results of the sensitivity analysis, the accuracy of the EcoThermo virtual flow sensor, whose typical errors settle within ±5%, is adequate for thermal power estimation. For instance, considering a water flow rate equal to 80 L/h, an uncertainty of 5% on flow rate estimation entails a corresponding uncertainty contribution on thermal power estimation of about 0.7%.

The results provided by the heat cost allocation method were compared against a reference method, which gives the fractions of heating consumption, as obtained by means of direct heat meters installed on each water radiator. The installation effects associated with water radiators at the INRIM central heating system test facility, which affect the accuracy of any indirect method for thermal power estimation based on radiator characteristic coefficients, are considered by evaluating the deviation between reference direct heat metering and the EN 442 model applied to each water radiator in steady-state conditions. The sharing of thermal energy consumption obtained by the proposed allocation method was observed to be in good agreement (within a maximum deviation of about 10%) with the best indirect estimation of the fractions of heating consumption, which is based on the EN 442 model and takes into account the inherent installation effects that characterize the water radiators at the INRIM test facility. Furthermore, a comparison between the proposed heat cost allocation method and conventional HCAs has been carried out.

3. Characterization of the Proposed Heat Cost Allocation Method

A fair heat cost allocation in apartment buildings, where the individual thermal energy consumptions can only be estimated indirectly by means of the semi-empirical relations associated with each water radiator according to the EN 442 model, is strongly dependent on:

the correct identification of the thermal characteristics of each water radiator,

the accurate evaluation of the temperature difference between the heat-conveying fluid flowing through each radiator and the ambient air in proximity of the radiator surface.

While the identification of the characteristic coefficients of water radiators represents a common task for the heat cost allocation methods available on the market, the main difference between the indirect solutions for the assessment of individual heat consumptions consists of how they estimate or approximate the temperature difference between the heat-conveying fluid inside the radiator and the surrounding air. In particular, HCAs approximate the fluid-air temperature difference with the measurement of the temperature difference between a specified point of the radiator surface and the surrounding air temperature (close to the radiator surface). Such a temperature difference measurement is properly corrected by suitable “coupling coefficients” that depend on the type of HCA (single sensor or double sensor) and the type of radiator on which the HCA is installed [

6]. Other heat cost allocation methods, like the ones based on insertion time counters [

7], do not use temperature measurements at the radiator surface, but make proper approximations about the mean water temperature inside the radiators and the indoor air temperatures.

The heat cost allocation method proposed in this work allows assessing the individual fractions of thermal energy consumption by means of:

the measurement of the opening time and opening degree of radiator valves,

the identification of the characteristic coefficients of each water radiator,

the measurements of the indoor air temperature at each living unit where the radiators are installed,

the measurement of the hot water supply temperature at the boiler room,

the estimation of the water flow rate circulating through each water radiator, depending on the opening degree of radiator valves, the total water flow rate flowing through the thermal-hydraulic circuit and the overall hydraulic head loss.

The EcoThermo virtual flow sensor provides the estimate of radiator volumetric flow rates, by solving the network model of the thermal-hydraulic circuit, whose branches are preliminarily identified in terms of head loss coefficients.

3.1. Measurement Model

The measurement model adopted by the proposed method for the assessment of the thermal power exchanged by each water radiator, in steady-state conditions, can be described as follows:

In Equation (3), the input quantities of the model are the radiator characteristic coefficients and , the indoor air temperature measurement near the radiator surface (air temperature measured in the living unit where the radiator is installed), the estimation of radiator water inlet temperature (approximately equal to the hot water supply temperature at the boiler room) and the estimate of water volumetric flow rate passing through the radiator (which depends on the opening degree of the radiator valve).

The solution of the measurement model, which is expressed in the form of a non-linear system of Equation (3), gives the estimation of the two unknowns: the thermal power

and the water outlet temperature

of the radiator. Water density

and specific heat capacity

are functions of temperatures

and

and pressure, according to the water equation of state [

17]; because of the slight pressure dependence of water thermodynamic properties within the thermal-hydraulic operating range of centralized heating systems, water density and specific heat capacity can be evaluated at a rough estimate of the mean absolute water pressure inside the thermal-hydraulic circuit. The thermal energy exchanged by the water radiator is obtained by the time integration of the thermal power during the opening time of the radiator valve.

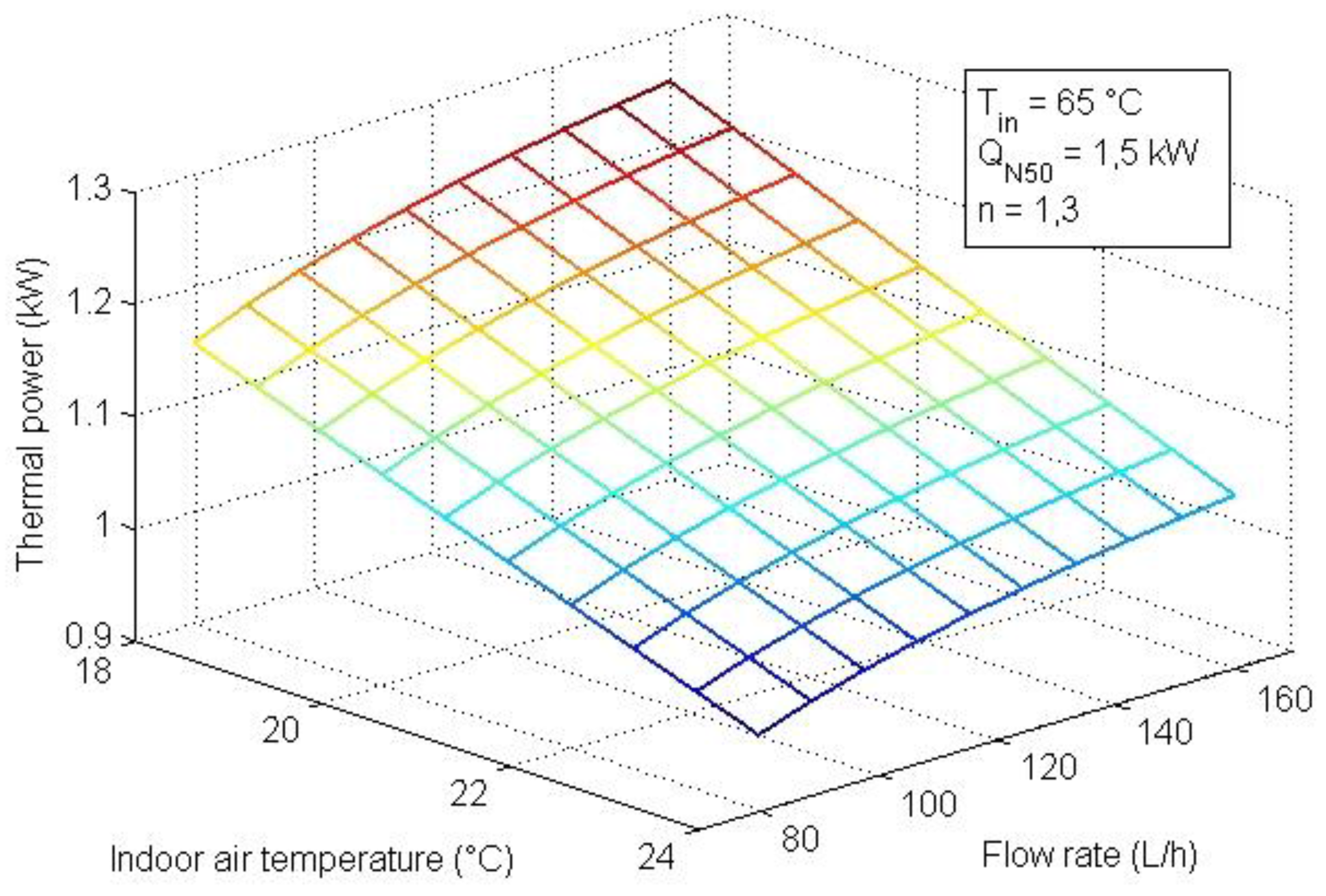

Figure 3 shows the dependence of the thermal power exchanged by a generic water radiator, in steady-state conditions, from the indoor air temperature and the water flow rate, as determined by the model described in Equation (3).

The use of the steady-state model also for transient operating conditions, for instance when the radiator surface is warming up, can lead to the overestimation of the thermal power transferred to the surrounding environment, which is balanced out by the heat transfer occurring during the cooling down phase.

3.2. Sensitivity Analysis

Measurements and estimations for indoor air temperature, hot water supply temperature, radiator characteristic coefficients and water flow rate circulating through the radiator are essential for the accurate evaluation of the temperature of the fluid at the outlet section of the radiator. Anyway, not the same degree of accuracy is required for the assessment of the mentioned quantities. In order to obtain a ranking of the input quantities of the measurement model in terms of influence on the estimated thermal power exchanged by the water radiator, a sensitivity analysis has been carried out.

According to the measurement model described by the system of Equation (3), the output quantity thermal power can be expressed as a function of several input quantities:

The evaluation of the gradient of

allows one to get useful information about the impact of each input quantity on thermal power, since the components of the gradient represent the sensitivity coefficients that characterize the allocation model:

The gradient

has been evaluated numerically by changing one-factor-at-a-time (OFAT) at each point within the multi-dimensional space of the input variables of the model. Moreover, the gradient of the thermal power has been normalized to the thermal power itself, in order to get the relative variation of

with respect to the unit variation of the input quantities.

Table 2 shows the results of the analysis in terms of sensitivity coefficients associated with a specific point within the space of the input variables and an example of evaluation of the uncertainty budget resulting from typical uncertainties assigned to the input quantities.

Because of the variety of installation and operating conditions for water radiators in real applications, a larger uncertainty has been assigned to the estimations of the radiator characteristic coefficients (higher than 7% for both the radiator nominal thermal power and the radiator exponent). As a consequence of the corresponding sensitivity coefficients, the uncertainty contributions on thermal power are, respectively, around 6% due to the radiator nominal thermal power and 2% due to the radiator exponent. Moreover, as endorsed by the results of the sensitivity analysis, a lower accuracy can be accepted for water flow rate estimation, while particular care should be taken for the evaluation of indoor air temperature and hot water inlet temperature.

3.3. Estimation of Water Flow Rates Circulating through the Radiators

In order to estimate the water flow rates circulating through the radiators, the proposed heat cost allocation method uses the results of the soft-sensor EcoThermo, which is applied to the thermal-hydraulic network of the central heating system, where the water radiators are installed.

The EcoThermo soft-sensor has been developed and tested in the context of the EU 7thFramework Program for Small and Medium-sized Enterprises FP7-SME-2012 “Innovative green technology for smart energy saving on existing residential buildings with centralized heating/cooling generators” [

14]. It is based on the network modelling of the thermal-hydraulic circuit of a generic central heating system, where the hydraulic characteristics (head loss coefficients) of each branch are preliminarily estimated by means of a suitable algorithm for the mathematical identification of the network.

The procedure for the mathematical identification of the hydraulic circuit is the core of EcoThermo and consists of the characterization of the minimum number of hydraulic subsystems in which the network can be divided. Namely, the head loss coefficients of each subsystem or closed branch are estimated by non-linear regression of the measurements of water flow rate and corresponding head loss, respectively provided by a fixed volumetric flow meter and two pressure transducers installed at the main supply and return pipe flows in the boiler room. The mathematical relation used to describe the dependence between head loss

and volumetric flow rate

in a generic branch of the hydraulic network can be expressed as follows:

where

and

are the characteristic hydraulic coefficients of the branch. The use of a suitable pump equipped with an inverter or other flow rate control systems is necessary in order to generate a representative set of water flow rates and head losses for the hydraulic characterization of the branches.

Once the hydraulic circuit has been identified, the water volumetric flow rates circulating through each open radiator can be estimated from the overall volumetric flow rate and head loss measurements at the main pipe flow, by solving the network model.

The EcoThermo soft-sensor has been validated at the INRIM central heating system test facility, in a wide set of network topologies and operating conditions [

14,

15].

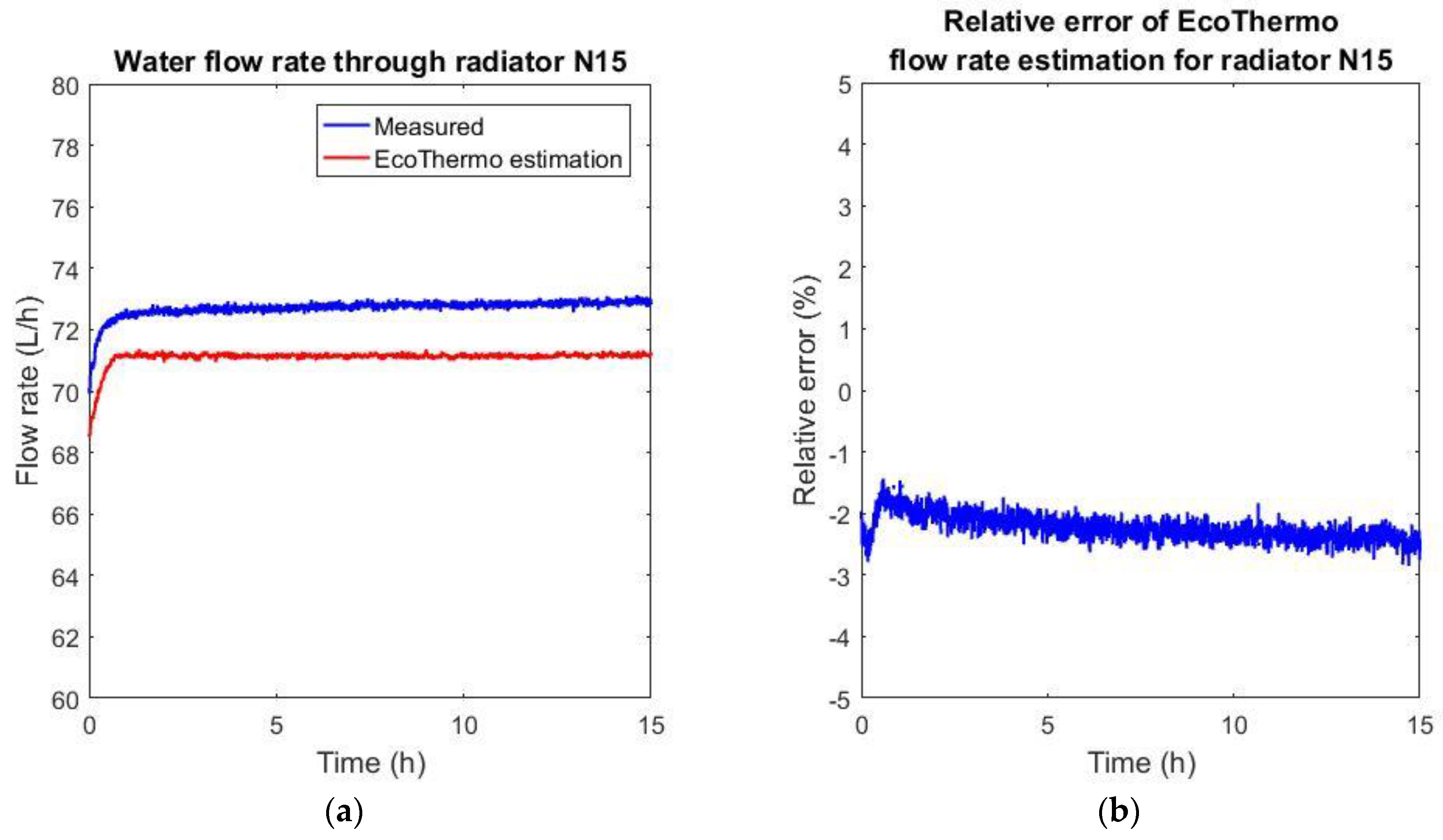

Figure 4 shows an example of the results obtained by EcoThermo for the estimation of the water flow rate through a particular radiator of the thermal-hydraulic circuit.

The soft-sensor EcoThermo could also be used as an effective tool for the optimal management of central heating systems; for instance, it could enable the dynamic balancing of the hydraulic circuit, preventing either too high or too low flow rates at each water radiator. Moreover, it could ensure that radiator valves operate with a stable and predictable hydraulic response, in terms of fixed dependence between water flow rate and opening degree.

4. Results of the Experimental Analysis

The proposed heat cost allocation method has been tested at the INRIM central heating system test facility, where each water radiator is equipped with a reference direct heat meter for thermal energy measurement. A set of 11 water radiators, which consists of 7 aluminum, 2 cast iron and 2 tubular steel radiators distributed on four different risers, as shown in

Figure 5, has been selected for the tests.

The pump and the heater have been programmed to feed the 11 radiators of the thermal-hydraulic circuit with the desired water flow rate and temperature, and the motorized radiator valves have been automatically controlled to set the desired opening/closing times. The task for the heat cost allocation method is to provide the individual fractions of thermal energy consumption for each water radiator, defined as:

where

is the thermal energy exchanged by the

i-th water radiator, calculated by the time integration of the thermal power estimated by means of the model described by the system of Equation (3). The characteristic thermal coefficients of water radiators, which are used by the allocation method to estimate the individual thermal energy consumptions, are obtained from the radiator datasheets and are listed in

Table 3.

The proposed method has been tested by evaluating, for each water radiator, the deviation between the estimated fraction of thermal energy consumption and the one measured by the reference direct heat meters. The relative deviations from the reference measurements of the individual fractions of heat consumption (

) can be expressed as follows:

Moreover, the heat cost allocation method has been compared against conventional HCAs installed on the set of selected radiators (

Figure 6), based on the relative deviations from the reference fractions of heat consumption provided by direct heat meters. HCAs have been programmed using the radiator characteristic coefficients listed in

Table 3 and the rating factors for the device-radiator coupling provided by the manufacturer, according to the EN 834 standard [

6].

The indoor air temperature measurements, which are needed by the proposed heat cost allocation method to estimate the fractions of thermal energy consumption, are provided by five Pt100 temperature sensors placed at different heights, corresponding to the position of water radiators on the risers, at about 1.5 m from the nearest heating surfaces (

Figure 6).

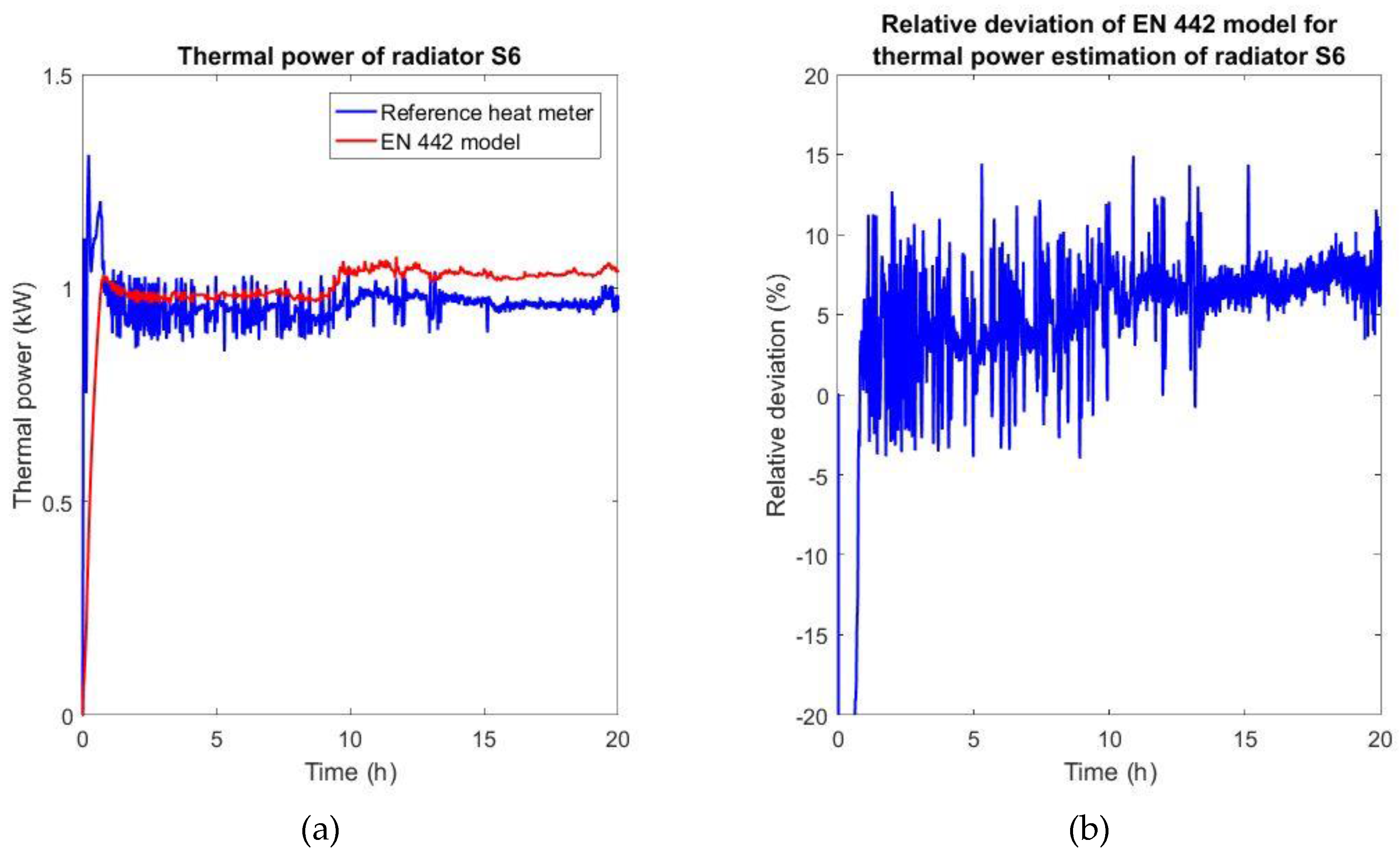

Furthermore, the indoor air temperature measurements are used to evaluate the individual fractions of thermal energy consumption by means of the EN 442 model. Such a model, in addition to the indoor air temperature measurements and the characteristic thermal coefficients of each radiator, uses the reference temperature sensors directly immersed at the inlet and outlet flow sections of each water radiator to evaluate the water mean temperatures. As discussed in

Section 2.2, the comparison between the indirect estimation of radiator thermal power by means of the EN 442 model and the reference direct measurement of the thermal power exchanged by the heat-conveying fluid passing through the radiator in steady-state conditions allows one to evaluate the uncertainty contribution due to the particular installation and operating conditions in the laboratory during the tests. As well as in real applications, the installation and operating conditions at the INRIM central heating system may be significantly different from the ones to which the characteristic thermal coefficients of the radiators refer. For this reason, the performance of any heat cost allocation method based on the EN 442 model must take into account the inherent limit due to the particular installation and operating conditions at the test facility, which is highlighted by the deviation between the individual heat consumptions provided by the EN 442 model and the reference direct heat metering in steady-state conditions.

A Pt100 temperature sensor directly immersed in the main hot water supply flow exiting from the heater gives the estimation of radiator inlet temperatures, which are needed by the heat cost allocation method to evaluate the fractions of thermal energy consumption. Such an approximation is justified, in real applications, by the economic and practical constraints related to the installation of thermometers at the inlet sections of each water radiator of the central heating system.

The experiments for testing the proposed heat cost allocation method are characterized by the following operating conditions:

Balanced hydraulic network: the thermal-hydraulic circuit of the central heating system has been preliminarily balanced, as should be recommended in real applications, in order to obtain a uniform flow rate distribution among the water radiators;

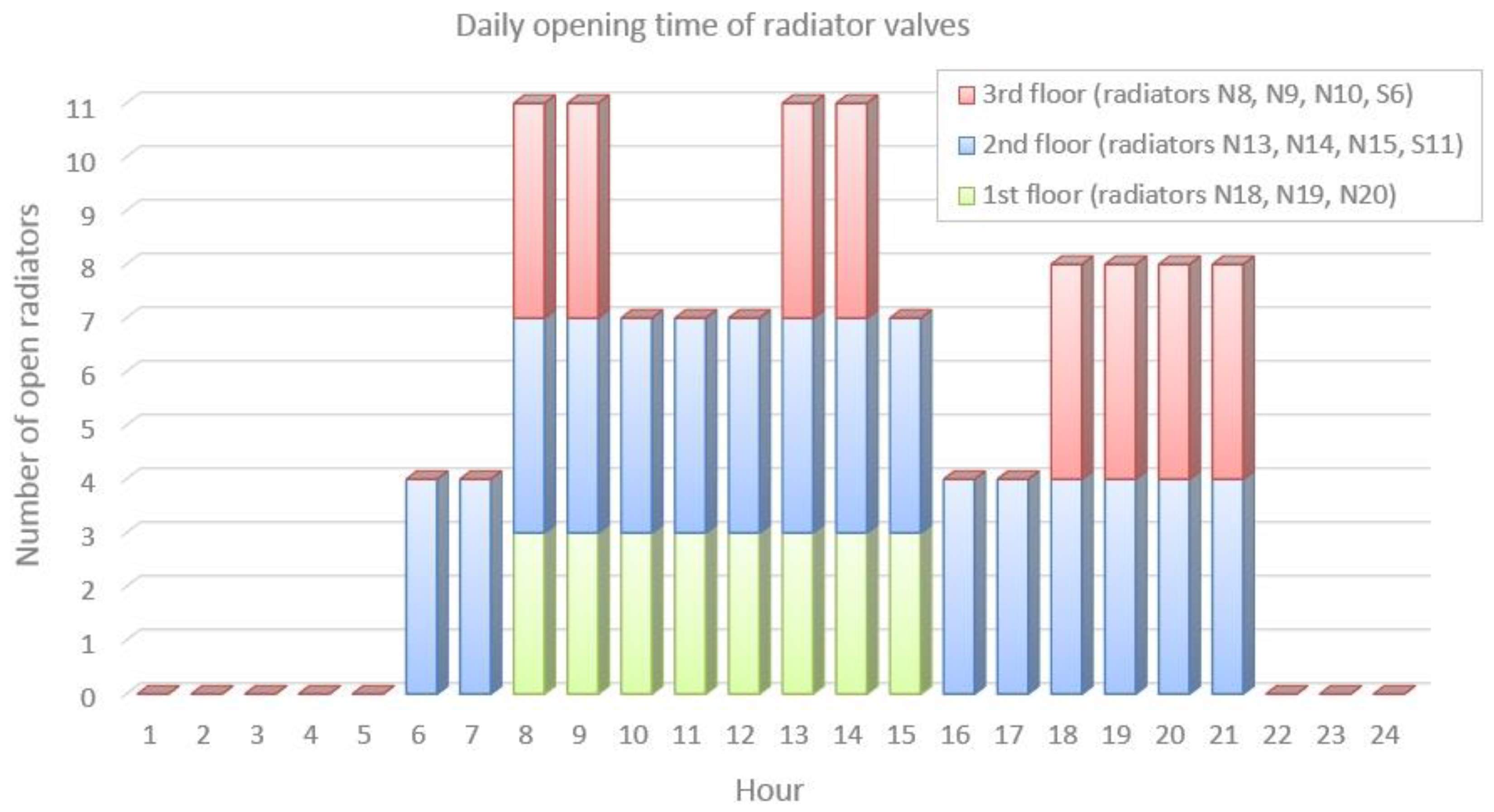

Automatic control of the opening/closing time of radiator valves: the motorized supply valves of the 11 water radiators, which can only set on their fully-open/closed state, are preliminarily programmed in terms of opening/closing times, simulating typical daily occupancy behaviors, as shown in

Figure 7;

Constant water supply temperature and constant pump speed: the heater is set to ensure a constant hot water supply temperature of 65 °C, and the pump is set to operate at 45% of its maximum speed;

Cooling down of radiator surfaces: the tests include the time needed for the complete natural cooling down of the heat transfer surface of radiators after either the closing of radiator valves or the shutdown of the heater; this is necessary in order to compare the heat cost allocation obtained by means of HCAs and the EN 442 model, with the one provided by reference direct heat meters;

Long time duration of the tests: the tests are characterized by long-time recording, such that the resolution error of the 11 HCAs becomes negligible if compared to the corresponding amount of totalized units of heating consumption.

In such an experimental test condition, the estimations of the fractions of heating consumption associated with each water radiator, as given by the proposed heat cost allocation method, have been compared to the ones provided by the reference direct heat meters. In order to take into account the installation effects that characterize the particular operation of water radiators at the INRIM test facility, the individual fractions of thermal energy consumption have been evaluated also by means of the EN 442 model.

It is worth noticing how the operating conditions designed for the test may deviate from what usually happens in real applications. For instance, balanced hydraulic networks, although recommended, are not so typical for old buildings, while the control of supply temperature, pump speed and radiator valves may be affected by hysteresis and communication issues or can be designed with different criteria, e.g., supply temperature and flow can be controlled by external ambient temperature measurement. Moreover, the ON-OFF operation of water radiators, as programmed for the test, is getting more and more unusual in current applications, because of the growing use of thermostatic radiator valves, which allows modulating the radiator thermal power according to the desired indoor air temperature.

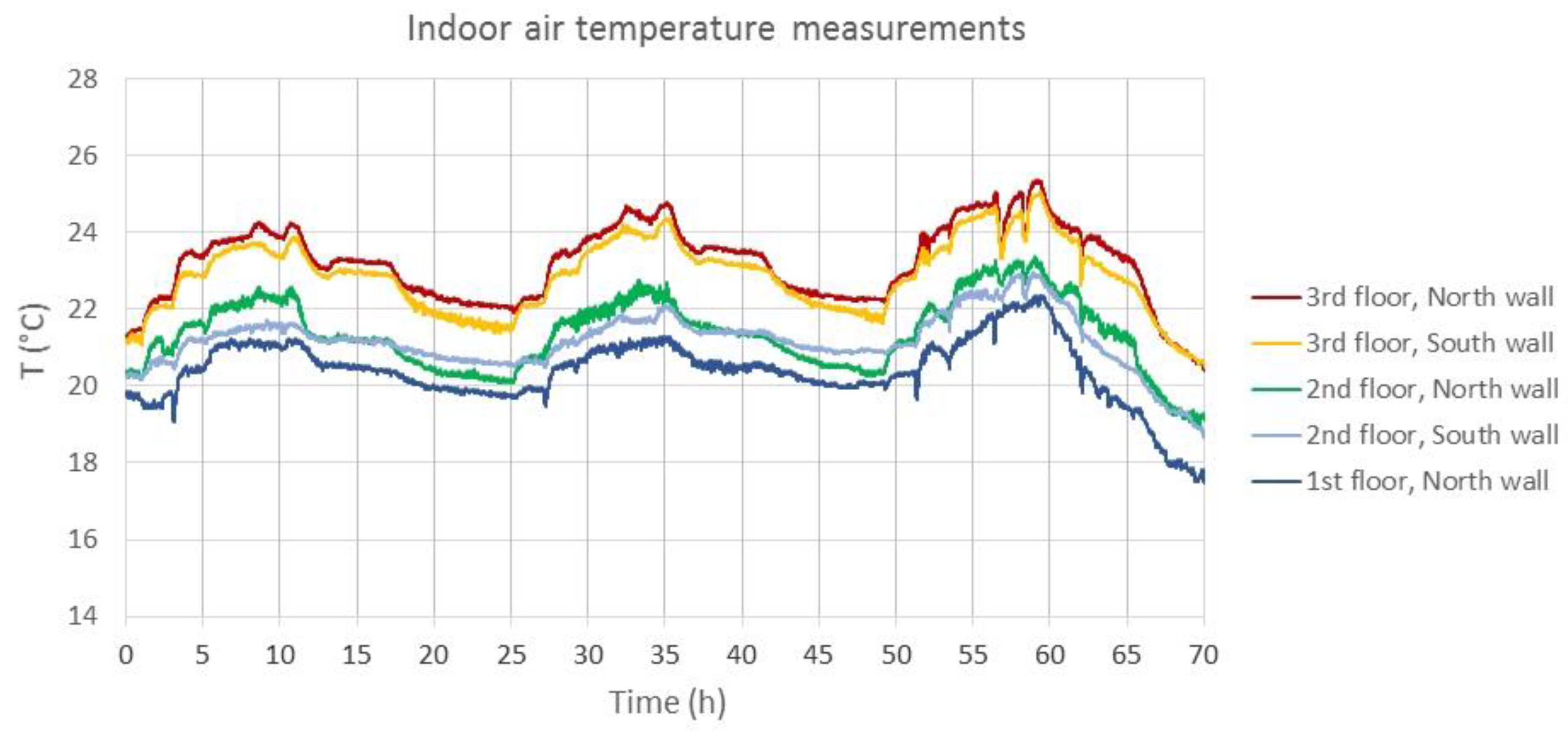

Figure 8 shows the time trend of the indoor air temperature measurements during the test, as given by the five Pt100 thermometers installed at different heights inside the laboratory in proximity of the heating surfaces of the radiators. The time evolution follows the programmed opening/closing times of water radiators and highlights the vertical stratification of air temperatures inside the laboratory. Indoor air temperature has been observed ranging from about 18 °C (at a 1-m height from the floor) to a maximum of about 25 °C (at a 3-m height from the floor). Although the air temperature measurement points are equally spaced on the height of the laboratory, a slightly stronger thermal stratification was observed between the second and third floors, with respect to the first and second ones.

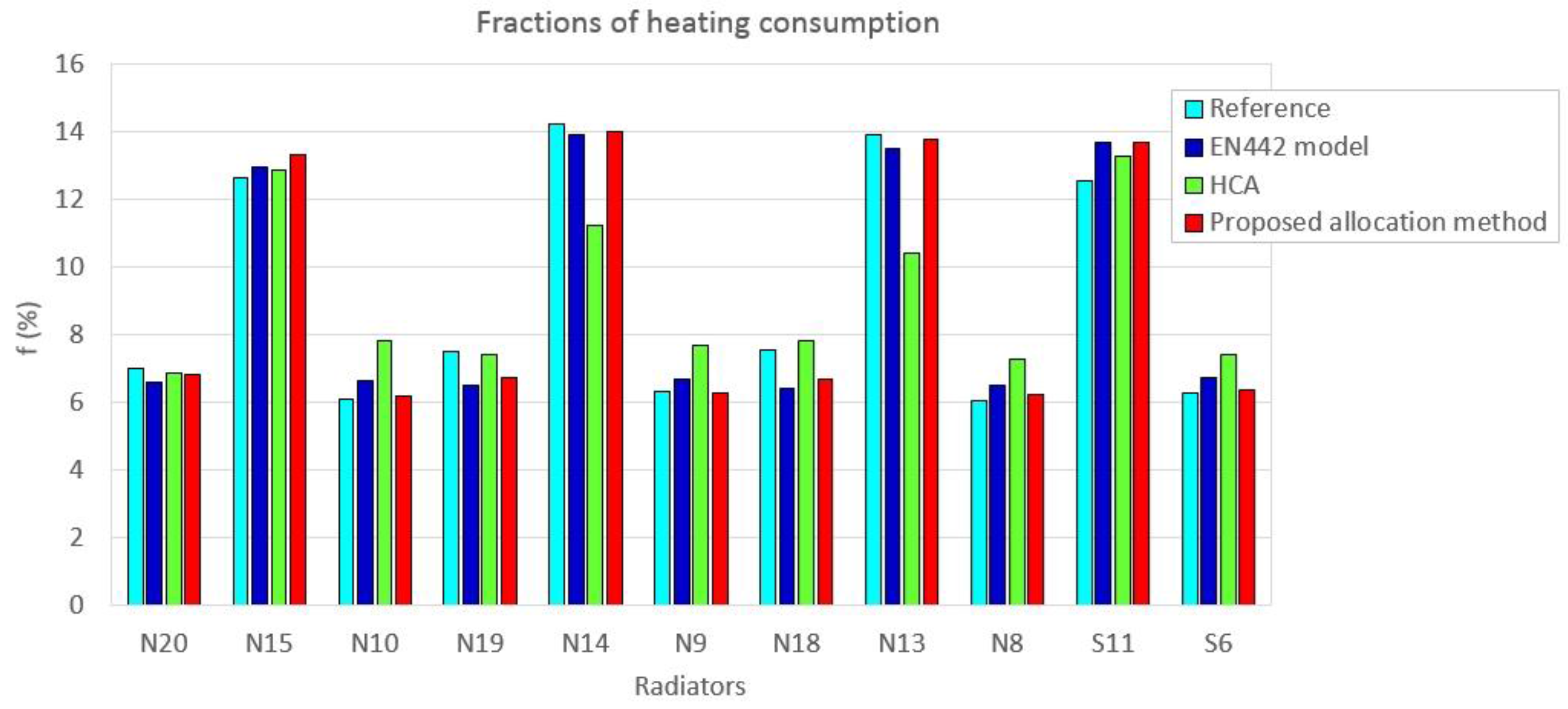

Figure 9 shows the results of the test in terms of fractions of thermal energy consumption, as given by the reference direct heat meters, the EN 442 model applied to each water radiator, the HCAs and the proposed heat cost allocation method. The last, as described in

Section 3.3, exploits the results of the EcoThermo soft-sensor to estimate the water flow rates circulating through each water radiator.

All of the heat cost allocation methods, as well as reference direct heat metering, provide greater fractions of heat consumption for second floor radiators (N13, N14, N15, S11), which are open for a longer time (16 h/day). Focusing on radiators N20 and N10 (same material, shape and dimension), which are installed on the same riser at the first and third floors, respectively, and are characterized by almost the same feeding flow rate and the same opening time (8 h/day), it can be observed that the reference fractions of heat consumption are lower for radiator N10 than for N20 (about 6% for radiator N10 and 7% for N20), mainly because of indoor air temperature stratification. The same behavior cannot be observed for the heat cost allocation provided by indirect methods, like the EN 442 model and HCAs, since their estimates are significantly affected by installation effects, and the fractions of heating consumptions are strongly correlated. The proposed heat cost allocation method is sensitive to installation effects, as well, but the evaluation of the heat output only when the radiator valve is open could slightly improve or decrease the accuracy of the estimated fractions of heat consumption, depending on the frequency of the ON-OFF operation of radiator valves and on the uniformity of installation effects. Moreover, while the accuracy of radiator characteristic coefficients is ensured for describing the heat transfer occurring when water is flowing through the radiator, their use for the estimation of the thermal power transferred from the hot surface to the surrounding air when the radiator valve is closed may lead to errors that cannot be related, exclusively, to installation effects.

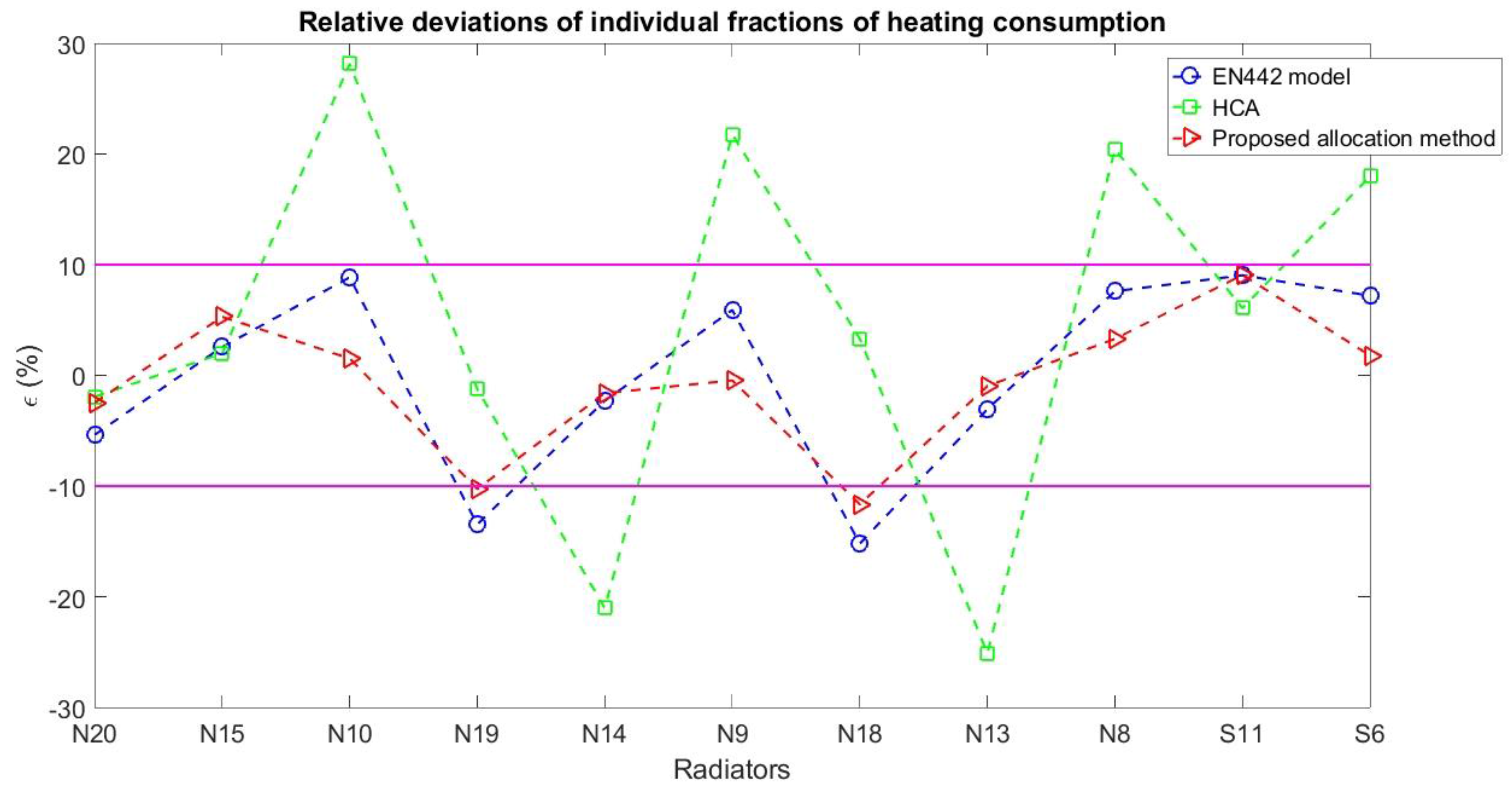

The relative deviations between the individual fractions of heating consumption and the reference ones have been evaluated for the EN 442 model, the HCAs and the proposed allocation method, and the results are shown in

Figure 10. The sharing of thermal energy consumption provided by the proposed allocation method reproduces quite accurately the heat cost allocation obtained by means of the EN 442 model, with slight differences due to the evaluation of radiator thermal power only during the opening time of the corresponding valves and to the assumptions made for estimating the water inlet temperatures and flow rates at each radiator. Such deviations between the proposed heat cost allocation method and the EN 442 model settle within 10% and are greater for third floor radiators (N10, N9, N8 and S6), because of the more frequent ON-OFF operation for such heat delivery points. The contribution of the inherent installation effects that characterize the radiators at the central heating system test facility is such that the relative deviations of the EN 442 model, with respect to the reference fractions of heating consumption, vary within ±10% for most of the radiators, except for radiators N18 and N19, characterized by relative deviations of about −15% and −13%, respectively. As far as the proposed heat cost allocation method is concerned, the modulus of the maximum relative deviation from the reference fraction of heat consumption does not exceed 11%.

On the other hand, the heat cost allocation obtained by means of HCAs describes a scenario of individual fractions of thermal energy consumption that is very different from the actual one, with relative deviations with respect to reference heat cost allocation up to about 30%. This may be due to the different types of mounting adopted for the installation of HCAs on the different types of water radiators used for the test. In fact, while the same type of installation is more likely to result in the same accuracy on the estimation of individual heat consumptions, the different mountings of HCAs in the same heating system may entail large errors in terms of fractions of thermal energy consumption. In order to evaluate this effect, the heat cost allocation has been carried out considering only the seven aluminum radiators of the selected set, characterized by the same mounting installation of the HCA on the radiator surface. The results in terms of relative deviations from the reference fractions of thermal energy consumption are shown in

Figure 11.

A significant reduction of the relative deviations in particular for HCAs at radiators N10, N9, N8 and S6 can be observed. This is due to the uniformity of the types of mounting installation and to the correlation between the fractions of heating consumption. The maximum relative deviation with respect to the reference heat cost allocation obtained by direct heat meters is about 15% for HCAs (radiator N10), while, as far as the proposed allocation method is concerned, the relative deviations settle within ±6% for all seven aluminum radiators.

Moreover, it is worth noticing that HCAs and the EN 442 model, unlike both the reference direct heat meters and the proposed heat cost allocation method, are able to detect the heat transfer from the radiator surface, even when the water flow rate is not circulating through the radiator. This may happen either when the radiator valve closes and the stagnant hot water remains inside the radiator tubes or when a closed radiator is connected to a riser in which hot water is circulating because of the presence of at least one open radiator; in such a case, depending on the piping connections of the hydraulic circuit and the position of the closed radiator with respect to the open ones, heat is transferred by conduction from the hot riser to the closed radiator (through the pipe wall and the stagnant water). While the additional heat transfer, which occurs because of the presence of stagnant hot water inside a closed radiator, is balanced out by the smaller thermal power transferred to the surrounding air during the warming up of the radiator surface, the heat conduction from the risers behaves as an offset. In order to compare the fractions of heating consumption provided by the EN 442 model with the ones obtained by both the reference direct heat meters and the proposed allocation method, the heat cost allocation evaluated by the EN 442 model has been carried out excluding the contribution due to heat conduction from the risers when the water flow rate is not circulating through the radiators. Such a correction is taken into account since the contribution due to the heat conduction from the hot risers, when the radiator valve is closed, should not be considered as a voluntary individual thermal energy consumption. As far as the heat cost allocation provided by HCAs is concerned, the heat conduction contribution should be taken into account within the uncertainty budget associated with the estimated fractions of heating consumption, since it is not possible to correct the readings of each HCA, by separating the heat conduction contribution from the total amount of units of thermal energy consumption.

5. Conclusions

The method described in this work, for heat accounting in apartment buildings, has provided good results in terms of accuracy on the estimation of individual fractions of thermal energy consumptions, as pointed out by the preliminary experimental analysis carried out at the INRIM central heating system test facility. The sharing of heat consumption evaluated by the proposed method has been observed to be very close to the heat cost allocation provided by the EN 442 model (within a maximum deviation of about 10%), which has been calculated using the characteristic radiator coefficients, the reference inlet and outlet water temperature measurements for each radiator and the air temperature measurements in proximity of the heat transfer surfaces. The contribution of the installation effects that characterize the radiators at the INRIM central heating system test facility is such that the relative deviations between the fractions of heat consumption provided by the EN 442 model and the reference ones given by direct heat meters vary within ±10% for most of the radiators, except for two radiators of the set, characterized by relative deviations of about −15% and −13%. The results of the test show that the proposed method is mainly affected by the inherent installation effects that characterize the test facility, endorsing the effectiveness of the measurement model for the estimation of individual thermal energy consumptions. The approach adopted by the proposed heat cost allocation method, consisting of the evaluation of thermal power only when the radiator valve is open, could slightly improve or decrease the accuracy of the estimated fractions of heat consumption, depending on the frequency of the ON-OFF operation of radiator valves and on the uniformity of installation effects. Moreover, it could avoid possible errors that may result from the application of radiator characteristic coefficients to the evaluation of the exchanged thermal power when water is not flowing through the radiator.

The assumptions made for the approximation of water inlet temperatures of radiators and the use of the EcoThermo soft-sensor for the estimation of radiator flow rates do not entail a significant reduction of the accuracy of the heat cost allocation method, as predicted by the sensitivity analysis. The modulus of the maximum relative deviation from the reference fraction of heating consumption does not exceed 11%.

The proposed method has been compared also with conventional HCAs, and the results of the test have pointed out the importance of ensuring homogeneous mounting installations of these devices on the set of water radiators selected for the test. Namely, the different mounting adopted for tubular steel radiators, with respect to aluminum and cast iron radiators, has led to significant deviations from reference fractions of heat consumption, even up to 30%. In order to verify the effect of the mounting installation on the accuracy of HCAs, the heat cost allocation has been carried out considering only the seven aluminum radiators of the selected set, characterized by the same mounting of HCAs on radiator surfaces. A significant reduction of the relative deviations with respect to the reference fractions of heating consumptions has been observed; namely, a maximum deviation of about 15% has been obtained for HCAs, while, regarding the proposed allocation method, the relative deviations settled within ±6% for all seven aluminum radiators.

As far as the in-the-field application is concerned, the proposed indirect method for heat accounting is safe from some of the installation effects that may affect the accuracy of HCAs, like the on-site mounting of the devices and the identification of the radiator-device coupling coefficients, since it does not rely on the temperature measurement of the radiator external surface. Moreover, in order to ensure the correct application of the heat cost allocation model and the effective use of the EcoThermo soft-sensor, the signals related to the state (opening degree) and opening time of radiator valves, indoor air temperatures, hot water supply temperature, total flow rate and overall head loss, must be transmitted to a suitable data acquisition system and logged at a proper sampling time.

Furthermore, it is worth observing that the deviations between the fractions of heating consumption obtained by indirect heat cost allocation methods and the reference ones provided by direct heat meters can also be influenced by the capability of indirect methods to assess the radiator heat transfer even if no water is circulating. For such a reason, the tests have been carried out either by comparing direct and indirect methods in steady-state operating conditions only or by considering test durations that ensure the indirect estimation of radiator thermal power to balance out the symmetric warming up and cooling down transients. Moreover, as pointed out by the experimental analysis, indirect methods for heat accounting can also detect thermal energy consumptions due to the heat conduction from the hot risers of the thermal-hydraulic circuit, when no water flow rate is passing through the radiator. The consideration of such a contribution, as far as HCAs are concerned, has been regarded as an uncertainty source for the resulting heat cost allocation, since it should not be considered as a voluntary individual consumption of thermal energy.