Seismic Performance of Composite Shear Walls Filled with Demolished Concrete Lumps and Self-Compacting Concrete after Fire

Abstract

:1. Introduction

2. Experimental Program

2.1. Specimen Design and Material Properties

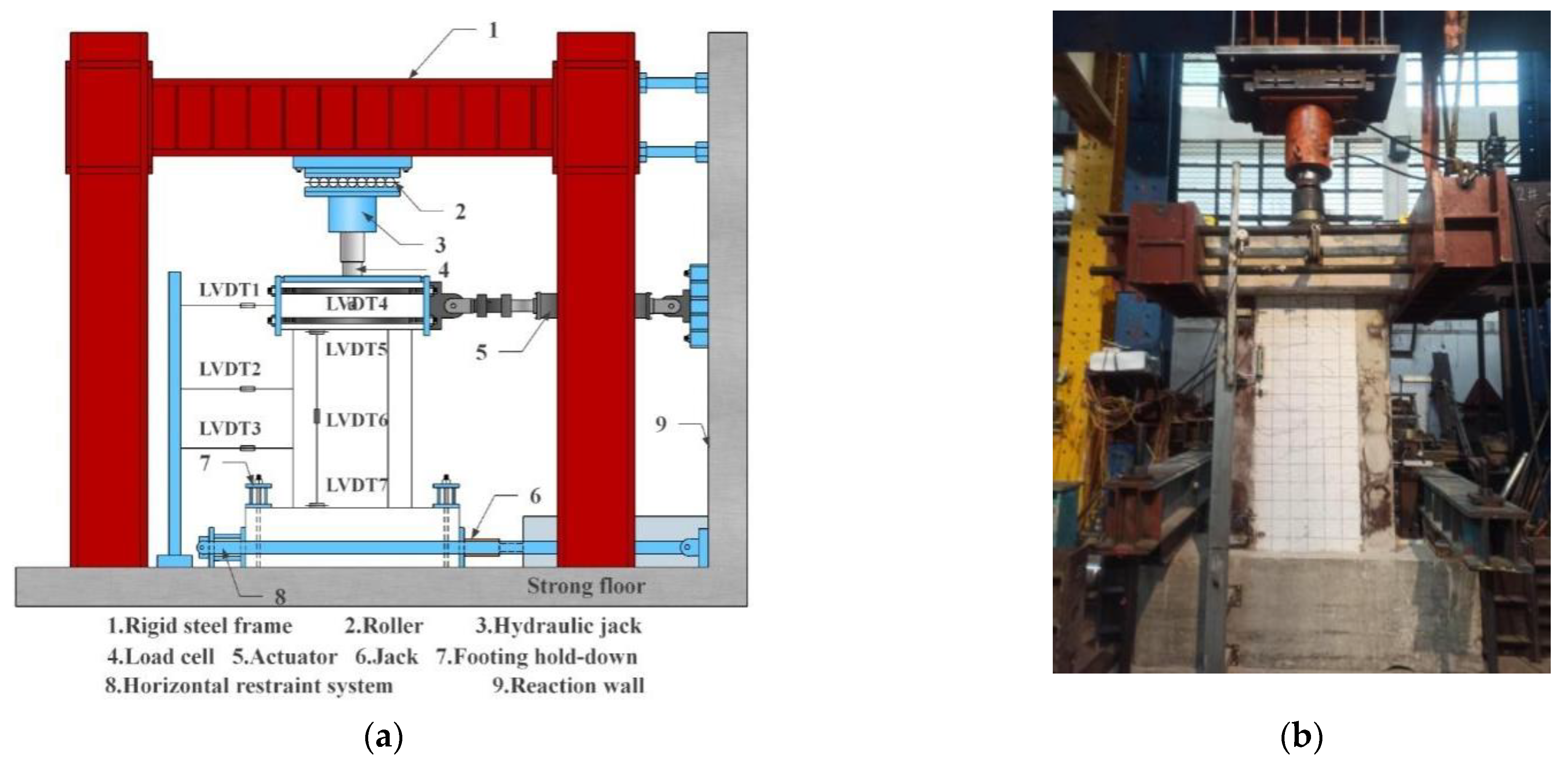

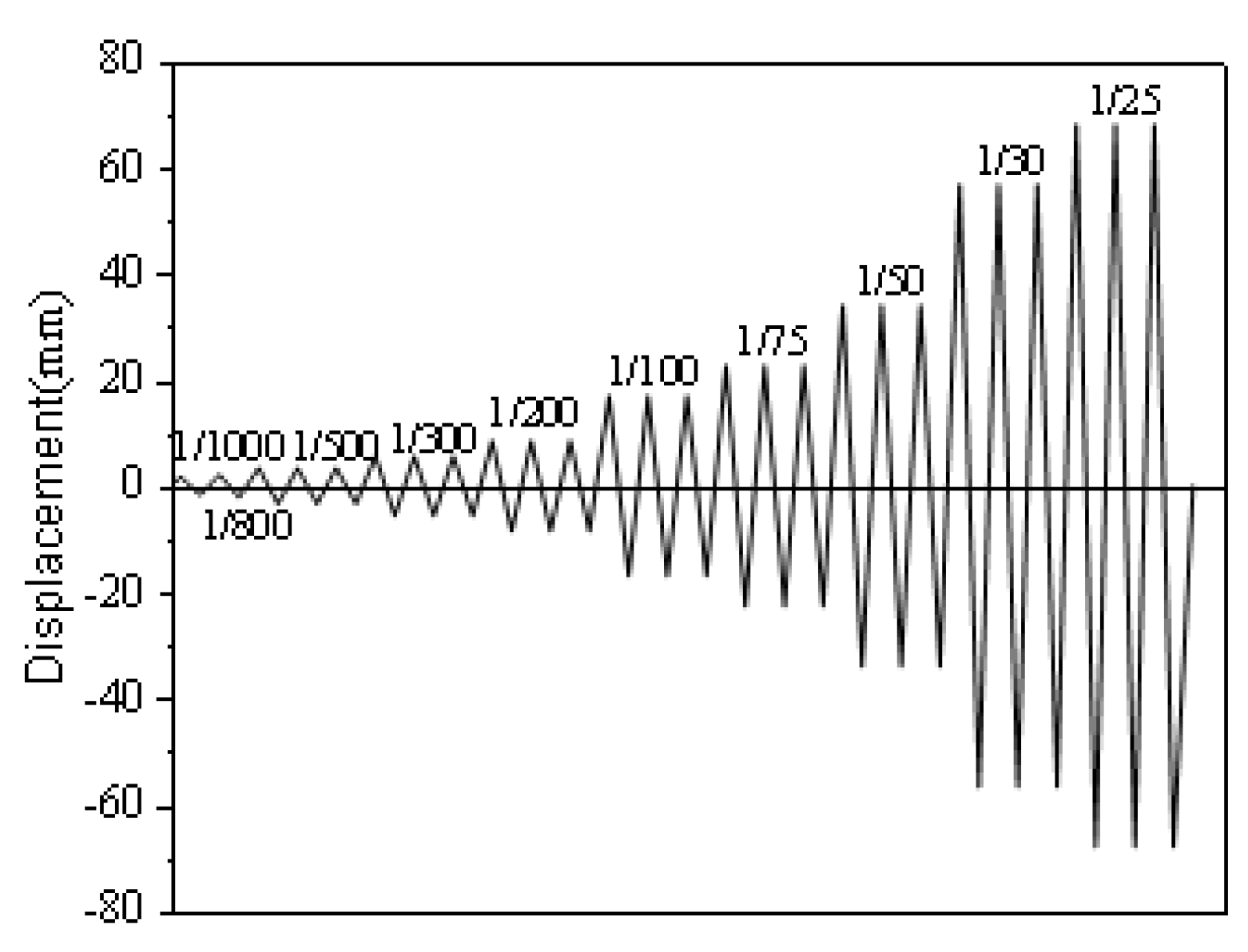

2.2. Test Setup and Loading Process

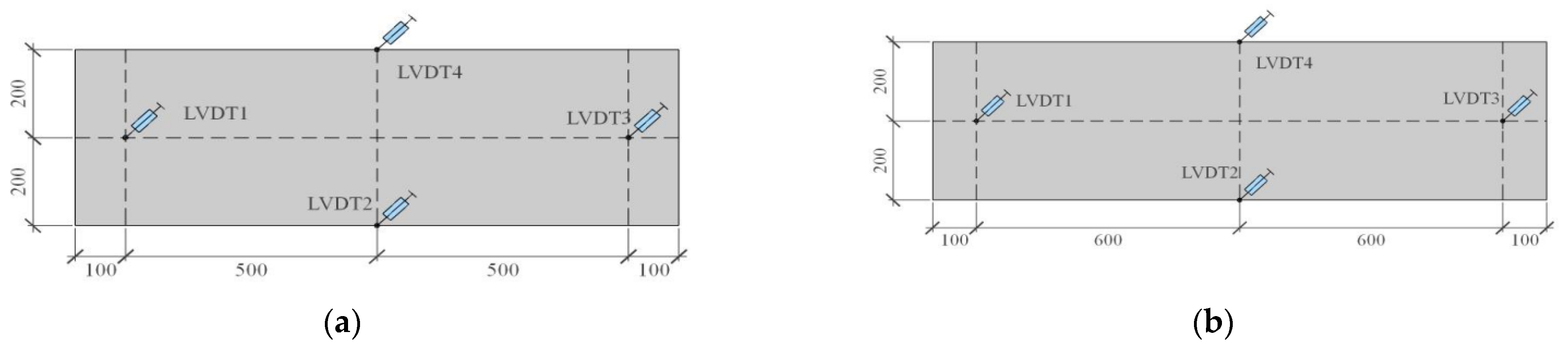

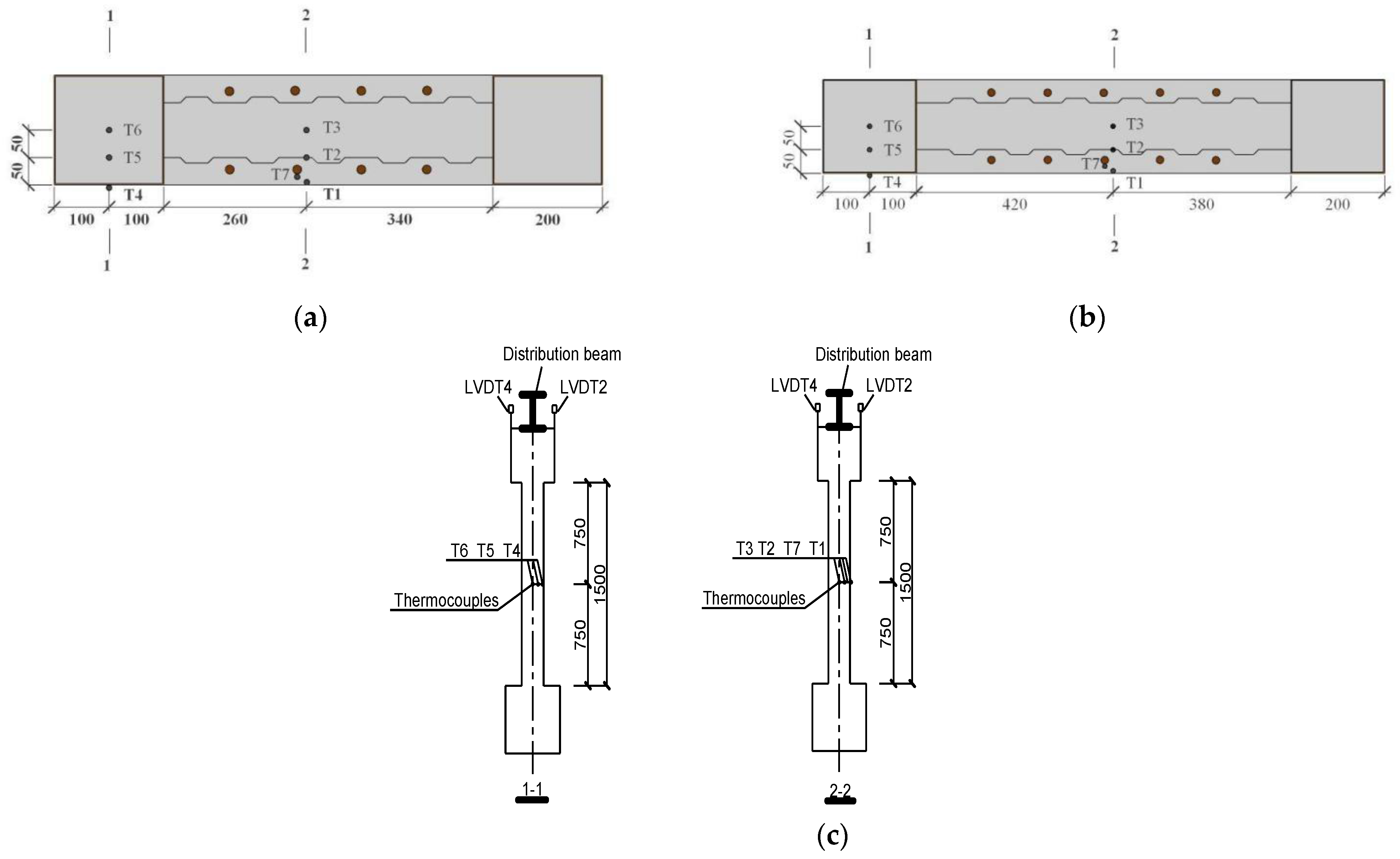

2.3. Monitoring Point Arrangement

3. Test Results

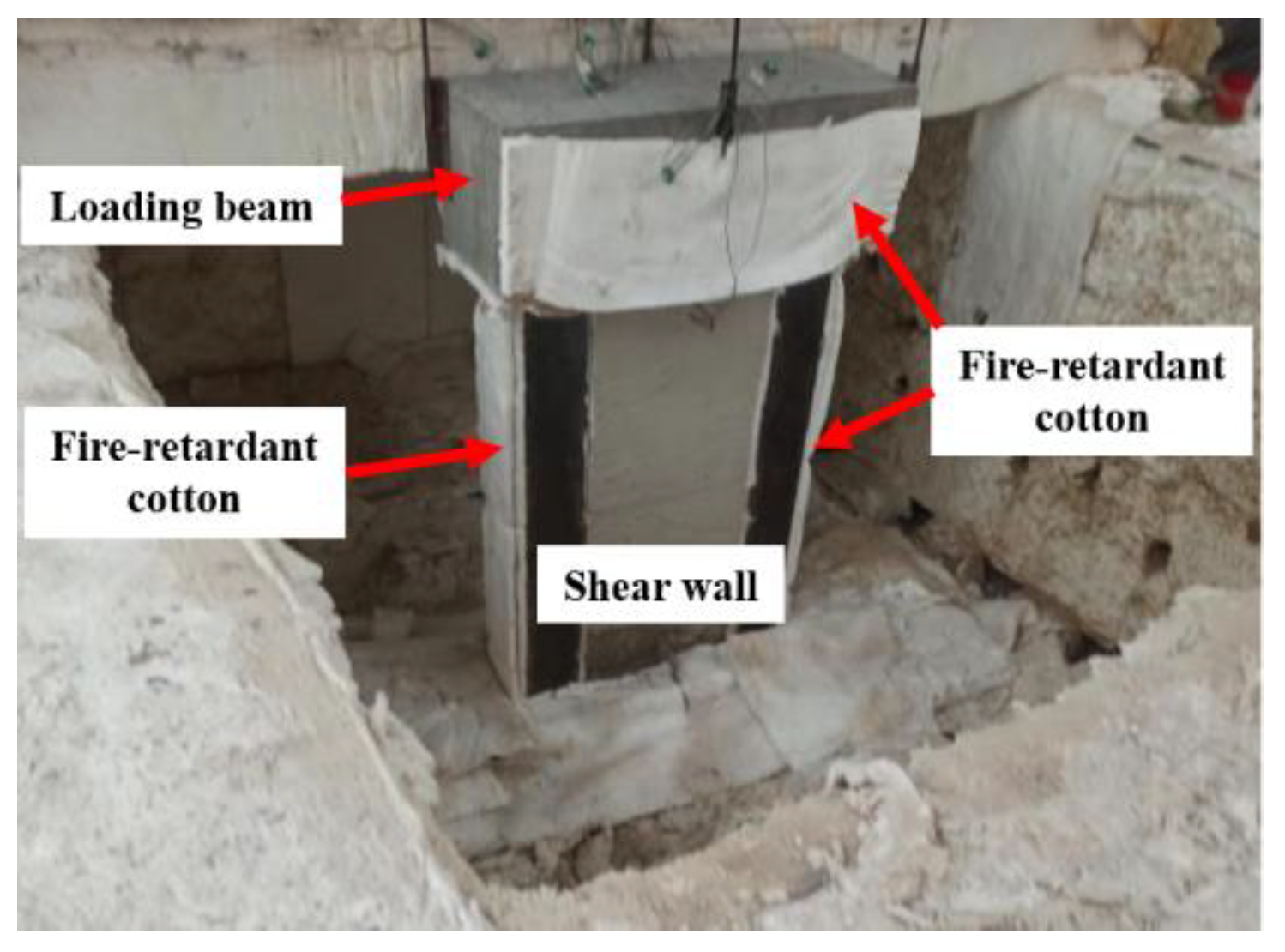

3.1. Open Fire Test Results Analysis

3.1.1. Phenomenon

3.1.2. Temperature Field Analysis

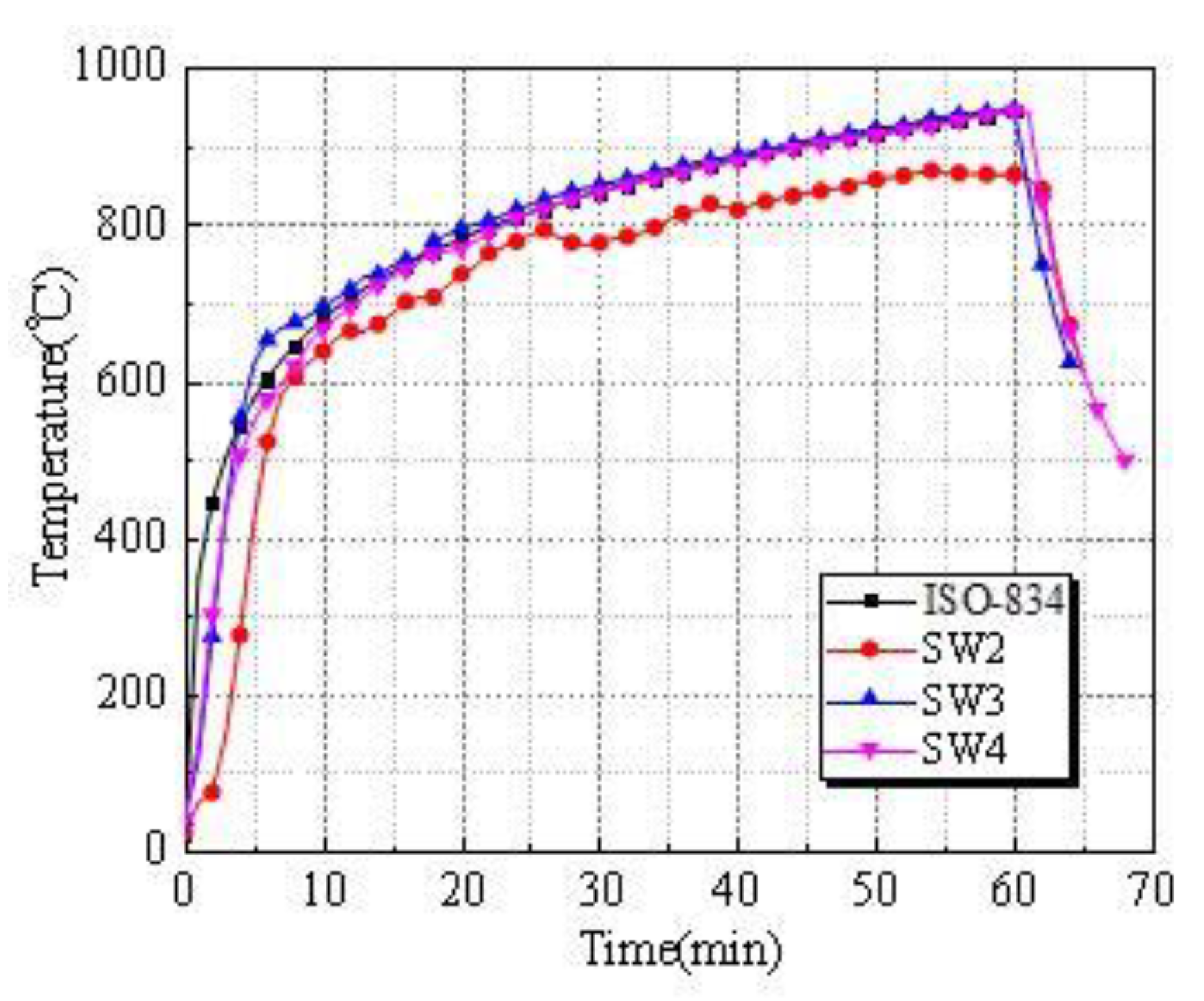

Furnace Temperature

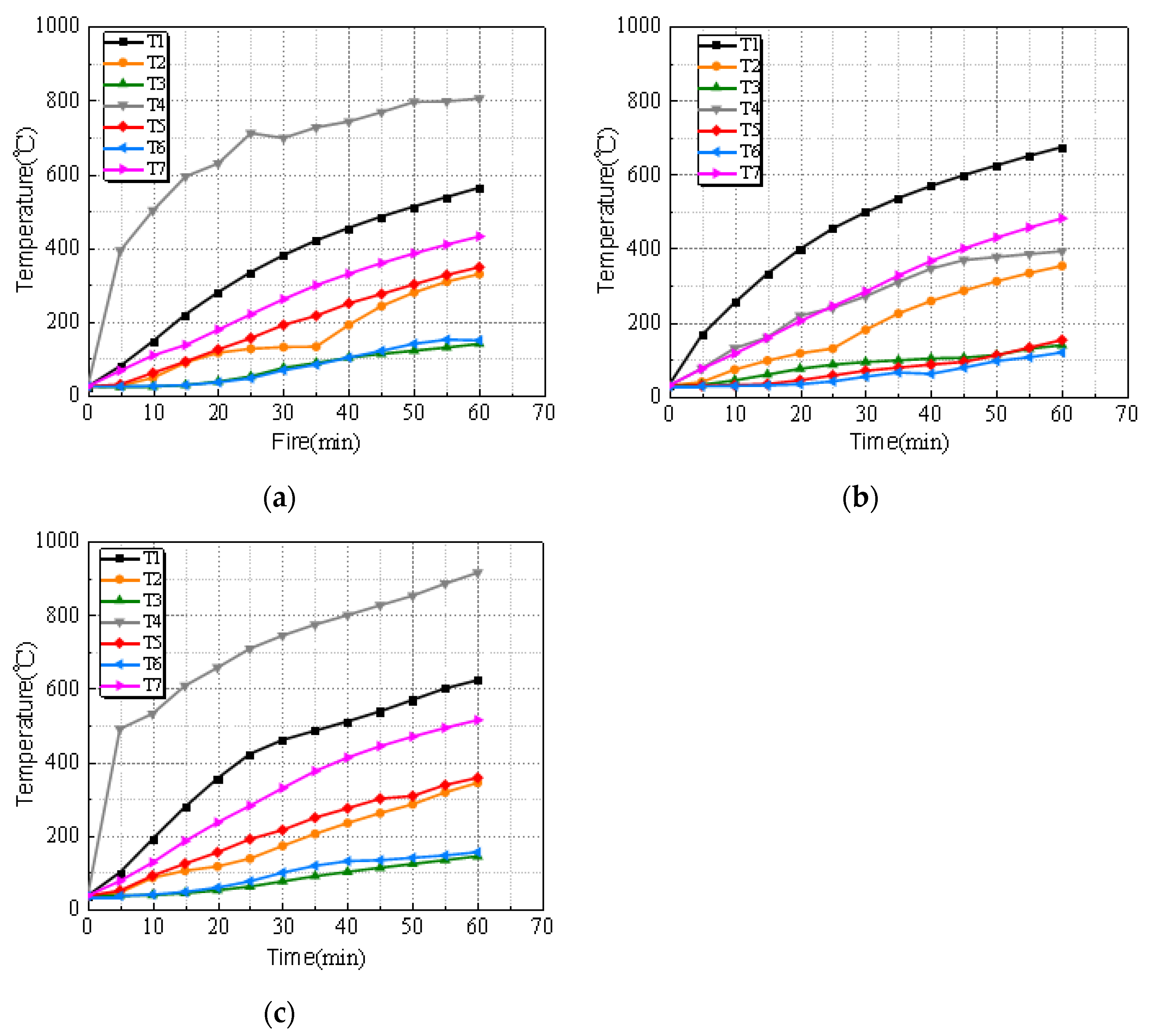

Measured Temperature-Time Curve

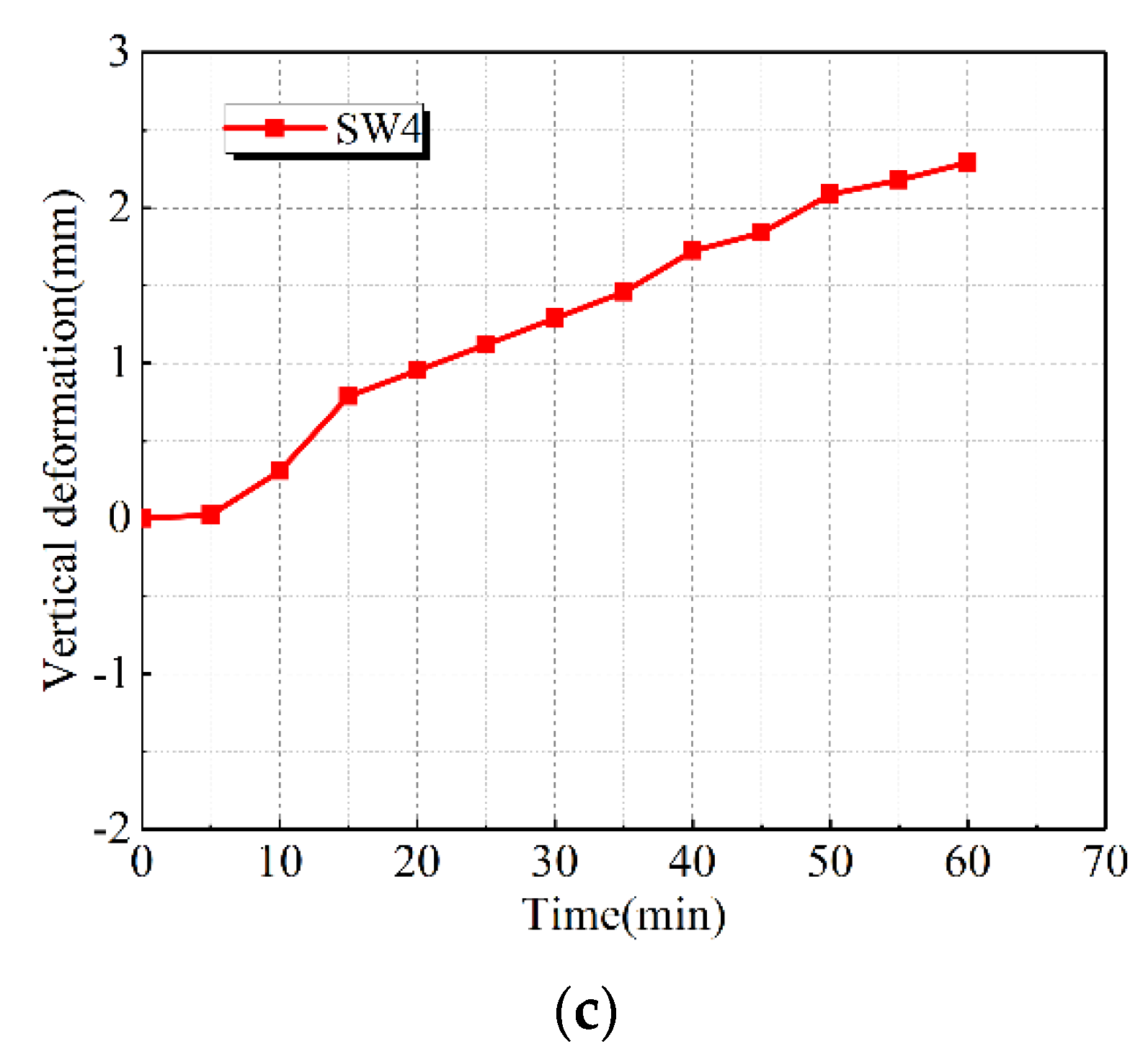

3.1.3. Axial Deformation Analysis

3.2. Analysis of Seismic Test Results after Fire

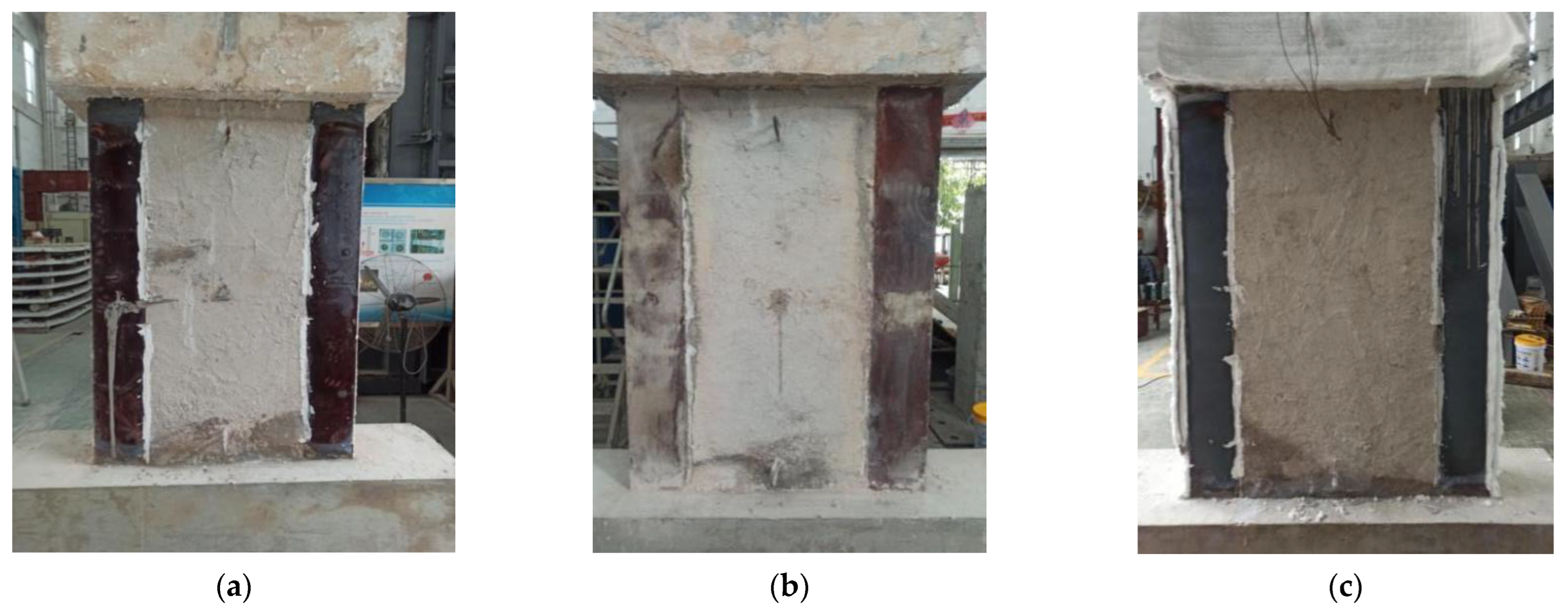

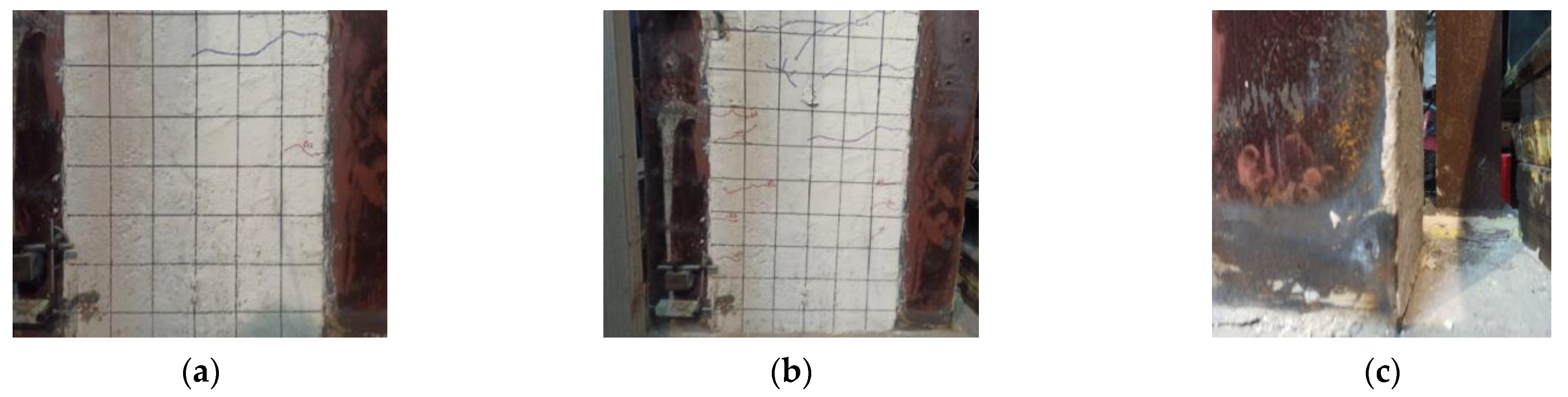

3.2.1. Phenomenon

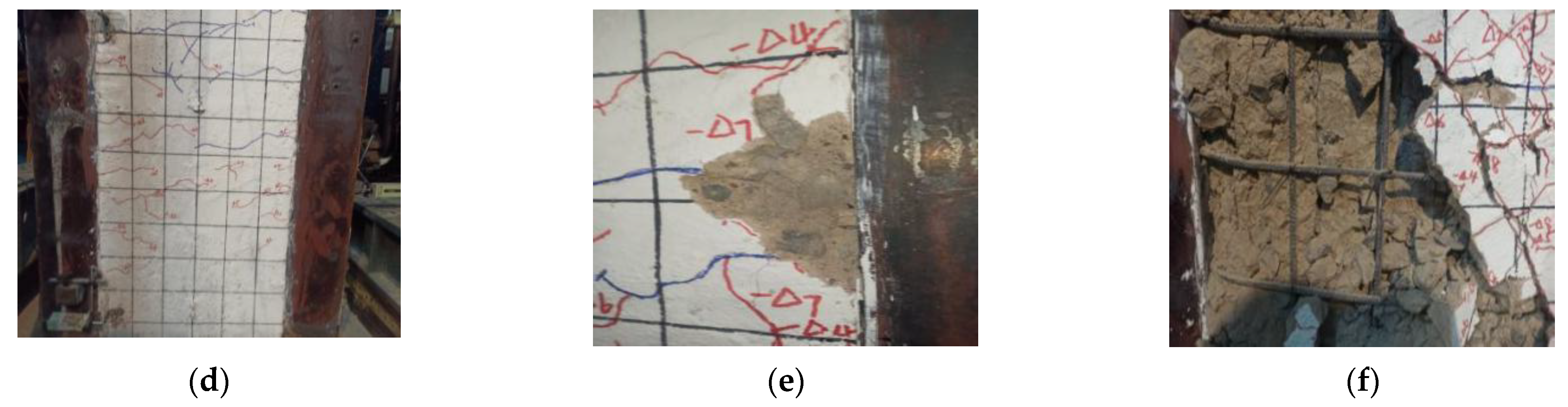

3.2.2. Hysteretic Loop

3.2.3. Horizontal Bearing Capacity

3.2.4. Skeleton Curve

3.2.5. Ductility Analysis

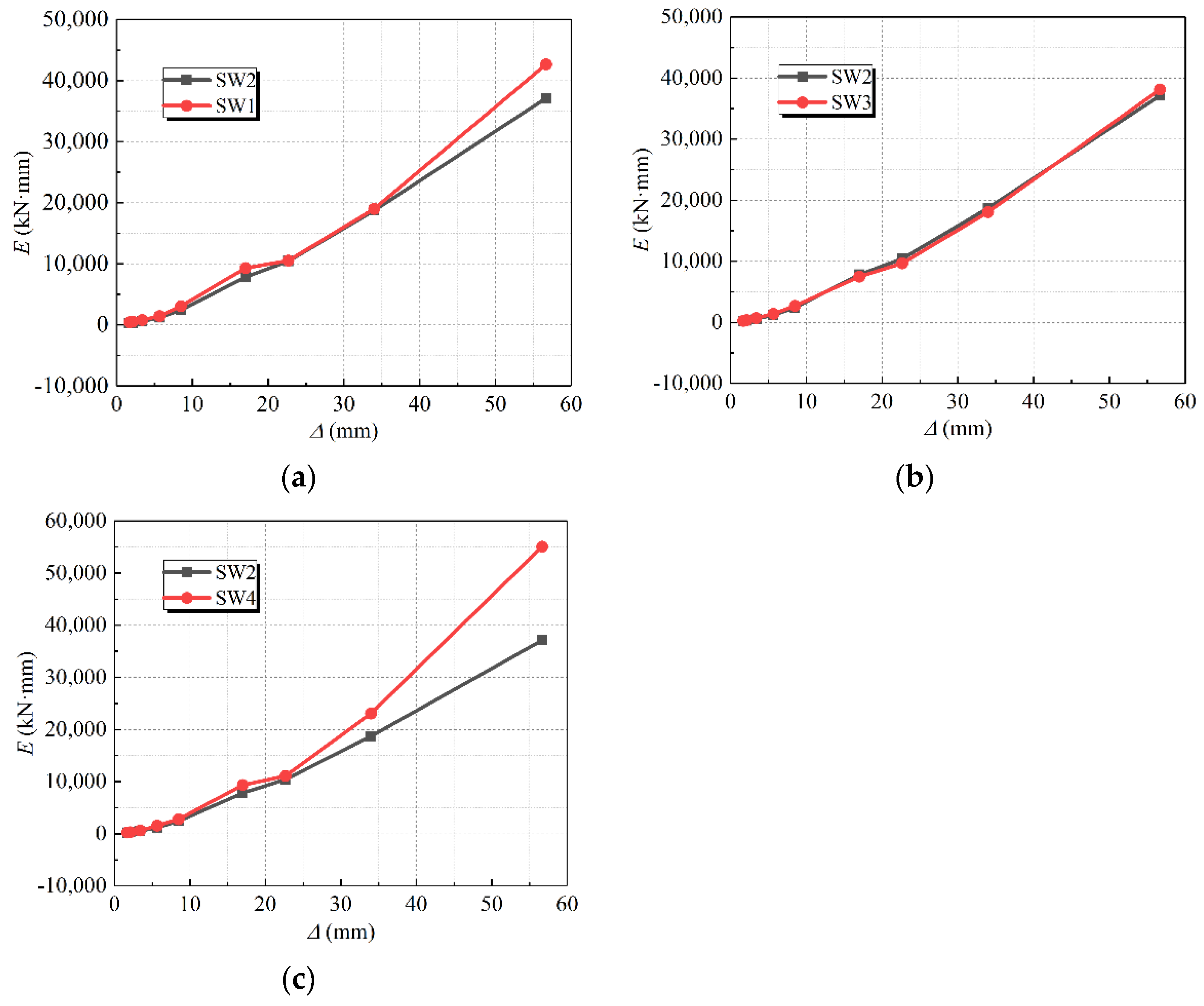

3.2.6. Energy Dissipation Capacity

3.2.7. Stiffness Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Redling, A. Construction Debris Volume to Surge in Coming Years. Construction & Demolition Recycling. Construction & Demolition Recycling Magazine, Ohio, United States. 2018. Available online: https://www.cdrecycler.com/Article/Global-Volumeconstruction-Demolition-Waste/ (accessed on 30 April 2020).

- National Bureau of Statistics of China. China Statistical Yearbook; China Statistic Publishing House: Beijing, China, 2020. (In Chinese)

- Velay-Lizancos, M.; Martinez-Lage, I.; Azenha, M.; Granja, J.; Vazquez-Burgo, P. Concrete with Fine and Coarse Recycled Aggregates: E-Modulus Evolution, Compressive Strength and Non-Destructive Testing at Early Ages. Constr. Build. Mater. 2018, 193, 323–331. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A. Structural Recycled Aggregate Concrete Made with Precast Wastes. Constr. Build. Mater. 2016, 114, 536–546. [Google Scholar] [CrossRef]

- Ahmad, S.; Umar, A.; Masood, A. Properties of Normal Concrete, Self-Compacting Concrete and Glass Fibre-Reinforced Self-Compacting Concrete: An Experimental Study. Procedia Eng. 2017, 173, 807–813. [Google Scholar] [CrossRef]

- Kumar, R.D. Self-Compacted Concrete Mix Design and Its Comparison with Conventional Concrete (M-40). J. Civ. Environ. Eng. 2015, 5, 1. [Google Scholar] [CrossRef]

- Khayat, K.H.; De Schutter, G. Mechanical Properties of Self-Compacting Concrete; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Alhussainy, F.; Hasan, H.A.; Rogic, S.; Sheikh, M.N.; Hadi, M.N. Direct Tensile Testing of Self-Compacting Concrete. Constr. Build. Mater. 2016, 112, 903–906. [Google Scholar] [CrossRef]

- Negro, P.; Tornaghi, M.L. Seismic Response of Precast Structures with Vertical Cladding Panels: The safecladding Experimental Campaign. Eng. Struct. 2017, 132, 205–228. [Google Scholar] [CrossRef]

- Belleri, A.; Torquati, M.; Marini, A.; Riva, P. Horizontal Cladding Panels: In-Plane Seismic Performance in Precast Concrete Buildings. Bull. Earthq. Eng. 2016, 14, 1103–1129. [Google Scholar] [CrossRef]

- Brunesi, E.; Nascimbene, R.; Peloso, S. Evaluation of the Seismic Response of Precast Wall Connections: Experimental Observations and Numerical Modeling. J. Earthq. Eng. 2020, 24, 1057–1082. [Google Scholar] [CrossRef]

- Titi, A.; Biondini, F.; Toniolo, G. Seismic Assessment of Existing Precast Structures with Dry-Friction Beam-to-Column Joints. Bull. Earthq. Eng. 2018, 16, 2067–2086. [Google Scholar] [CrossRef]

- Wright, H.; Evans, R.; Gallocher, S. Composite walling. In Composite Construction in Steel and Concrete II; ASCE: Reston, VA, USA, 1992; pp. 783–797. [Google Scholar]

- Sener, K.C.; Varma, A.H.; Ayhan, D. Steel-Plate Composite (SC) Walls: Out-of-Plane Flexural Behavior, Database, and Design. J. Constr. Steel Res. 2015, 108, 46–59. [Google Scholar] [CrossRef]

- Pons, O. Assessing the sustainability of prefabricated buildings. In Eco-Efficient Construction and Building Materials; Woodhead Publishing: Sawston, UK, 2014; pp. 434–456. [Google Scholar]

- Vostrikova, E.V.; Gayevskaya, Z.A. Modernization of residential buildings of the 1960s. In Advanced Materials Research; Trans Tech Publications Ltd.: Bäch, Switzerland, 2014; Volume 941, pp. 858–863. [Google Scholar]

- Boafo, F.E.; Kim, J.H.; Kim, J.T. Performance of Modular Prefabricated Architecture: Case Study-Based Review and Future Pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Moradibistouni, M.; Vale, B.; Isaacs, N. Evaluating Sustainability of Prefabrication Methods in Comparison with Traditional Methods. In Proceedings of the International Conference on Sustainability in Energy and Buildings, Gold Coast, QLD, Australia, 20–22 June 2018; Springer: Cham, Switzerland, 2018; pp. 228–237. [Google Scholar]

- Shafaei, S.; Ayazi, A.; Farahbod, F. The Effect of Concrete Panel Thickness upon Composite Steel Plate Shear Walls. J. Constr. Steel Res. 2016, 117, 81–90. [Google Scholar] [CrossRef]

- Kisa, M.H.; Yuksel, S.B.; Caglar, N. Experimental Study on Hysteric Behavior of Composite Shear Walls with Steel Sheets. J. Build. Eng. 2021, 33, 101570. [Google Scholar] [CrossRef]

- Shafaei, S.; Farahbod, F.; Ayazi, A. The Wall–Frame and the Steel–Concrete Interactions in Composite Shear Walls. Struct. Des. Tall Spec. Build. 2018, 27, e1476. [Google Scholar] [CrossRef]

- Farzam, M.; Hoseinzade, F. Effect of Type and Distribution of Shear Studs on the Behavior of Composite Steel-Concrete Shear Walls. J. Rehabil. Civ. Eng. 2019, 7, 154–167. [Google Scholar]

- Huang, S.T.; Huang, Y.S.; He, A.; Tang, X.L.; Chen, Q.J.; Liu, X.; Cai, J. Experimental Study on Seismic Behavior of an Innovative Composite Shear Wall. J. Constr. Steel Res. 2018, 148, 165–179. (In Chinese) [Google Scholar] [CrossRef]

- Szolomicki, J.; Golasz-Szolomicka, H. Technological Advances and Trends in Modern High-Rise Buildings. Buildings 2019, 9, 193. [Google Scholar] [CrossRef]

- Sarcheshmehpour, M.; Estekanchi, H.E.; Moosavian, H. Optimum Seismic Design of Steel Framed-Tube and Tube-in-Tube Tall Buildings. Struct. Des. Tall Spec. Build. 2020, 29, e1782. [Google Scholar] [CrossRef]

- Molina Hutt, C.; Hulsey, A.M.; Kakoty, P.; Deierlein, G.G.; Eksir Monfared, A.; Wen-Yi, Y.; Hooper, J.D. Toward Functional Recovery Performance in the Seismic Design of Modern Tall Buildings. Earthq. Spectra 2022, 38, 283–309. [Google Scholar] [CrossRef]

- Gentili, F.; Giuliani, L.; Bontempi, F. Structural Response of Steel High Rise Buildings to Fire: System Characteristics and Failure Mechanisms. J. Struct. Fire Eng. 2013, 4, 9–26. [Google Scholar] [CrossRef]

- Andres, B.; Hoehler, M.S.; Bundy, M.F. Fire Resistance of Cold-Formed Steel Framed Shear Walls under Various Fire Scenarios. Fire Mater. 2020, 44, 352–364. [Google Scholar] [CrossRef] [PubMed]

- Hoehler, M.S.; Smith, C.M.; Hutchinson, T.C.; Wang, X.; Meacham, B.J.; Kamath, P. Behavior of Steel-Sheathed Shear Walls Subjected to Seismic and Fire Loads. Fire Saf. J. 2017, 91, 524–531. [Google Scholar] [CrossRef] [PubMed]

- Hoehler, M.S.; Andres, B.; Bundy, M.F. Lateral Resistance Reduction to Cold-Formed Steel-Framed Shear Walls under Various Fire Scenarios. J. Struct. Eng. 2020, 146. [Google Scholar] [CrossRef]

- Mistri, A.; Davis, R.; Sarkar, P. Condition Assessment of Fire Affected Reinforced Concrete Shear Wall Building—A Case Study. Adv. Concr. Constr. 2016, 4, 89. [Google Scholar] [CrossRef]

- Ambroziak, A.; Piotrkowski, P.; Heizig, T. Assessment of Technical Condition and Repair of Steel Structure Elements on the Example of Fire Damage in a Warehouse Building. In Proceedings of the MATEC Web of Conferences, Miedzyzdroje, Poland, 20–24 May 2019; EDP Sciences: Les Ulys, France, 2019; Volume 284, p. 02001. [Google Scholar]

- Cardoso, R. Haussmannian Building Repair, Rehabilitation and Strengthening: Case Study from France. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2021, 175, 7–20. [Google Scholar] [CrossRef]

- Yan, X.I.O.N.G.; Guowei, Z.H.A.O.; Di, W.U.; Zhuoliang, X.I.A.O.; Yaxin, C.H.E.N. Experimental Study on Seismic Behavior of Composite Shear Walls Filled with Demolished Concrete Lumps and Self-Compacting Concrete. J. Build. Struct. 2022, 43, 114. (In Chinese) [Google Scholar]

- Dey, S.; Bhowmick, A.K. Seismic performance of composite plate shear walls. In Structures; Elsevier: Amsterdam, The Netherlands, 2016; Volume 6, pp. 59–72. [Google Scholar]

- GB/T 9978.3-2008; Fire-Resistance Tests—Elements of Building Construction—Part 3: Commentary on Test Method and Test Data Application. ISO: Geneva, Switzerland, 2008.

- Demir, U.; Goksu, C.; Binbir, E.; Ilki, A. Impact of time after fire on post-fire seismic behavior of RC columns. In Structures; Elsevier: Amsterdam, The Netherlands, 2020; Volume 26, pp. 537–548. [Google Scholar]

- Nguyen, K.T.; Ngo, T.; Mendis, P.; Heath, D. Performance of High-Strength Concrete Walls Exposed to Fire. Adv. Struct. Eng. 2018, 21, 1173–1182. [Google Scholar] [CrossRef]

- Ni, S.; Birely, A.C. Post-Fire Seismic Behavior of Reinforced Concrete Structural Walls. Eng. Struct. 2018, 168, 163–178. [Google Scholar] [CrossRef]

- Li, W.; Guo, Z. Experimental Investigation on Strength and Deformation of Concrete at Elevated Temperature. J. Build. Struct. 1993, 14, 8–16. (In Chinese) [Google Scholar]

- Park, R. Ductility evaluation from laboratory and analytical testing. In Proceedings of the 9th World Conference on Earthquake Engineering, Tokyo-Kyoto, Japan, 1 August 1988; Volume 8, pp. 605–616. [Google Scholar]

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture & Building Press: Beijing, China, 2010. (In Chinese)

| Specimen Number | Replacement Rate of Abandoned Concrete (%) | Wall Limb Width (mm) | Wall Limb Thickness (mm) | Thickness of Fire-Retardant Coating for Steel Pipe (mm) | Fire Exposure Time (min) | Axial Compression Ration |

|---|---|---|---|---|---|---|

| SW1 | 20 | 1000 | 200 | 0 | 0 | 0.18 |

| SW2 | 20 | 1000 | 200 | 0 | 60 | 0.18 |

| SW3 | 20 | 1000 | 200 | 20 | 60 | 0.18 |

| SW4 | 20 | 1200 | 200 | 0 | 60 | 0.18 |

| Steel Type | Nominal Thickness (mm) | Measured Thickness (mm) | Yield Strength (MPa) | Ultimate Strength (MPa) |

|---|---|---|---|---|

| Q235B | 2 | 1.77 | 340.7 | 467.6 |

| HRB400 | 8 | 8 | 430.1 | 594.2 |

| HRB400 | 20 | 20 | 443.6 | 620.2 |

| Series | Displacement Angle | Displacement Values (mm) | Cycles | Series | Displacement Angle | Displacement Values (mm) | Cycles |

|---|---|---|---|---|---|---|---|

| Δ1 | 1/1000 | 1.70 | 1 time | Δ6 | 1/100 | 17.00 | 3 times |

| Δ2 | 1/800 | 2.12 | 1 time | Δ7 | 1/75 | 22.67 | 3 times |

| Δ3 | 1/500 | 3.40 | 3 times | Δ8 | 1/50 | 34.00 | 3 times |

| Δ4 | 1/300 | 5.67 | 3 times | Δ9 | 1/30 | 56.67 | 3 times |

| Δ5 | 1/200 | 8.50 | 3 times | Δ10 | 1/25 | 68 | 3 times |

| Specimen Number | ∆y (mm) | Py (kN) | ∆p (mm) | Pue (KN) | ∆u (mm) | Pul (kN) | μ | ξeq |

|---|---|---|---|---|---|---|---|---|

| SW1 | 8.09 | 422.68 | 33.62 | 510.93 | 50.14 | 434.29 | 6.198 | 0.184 |

| SW2 | 10.94 | 386.36 | 34.39 | 478.99 | 48.51 | 407.14 | 4.434 | 0.182 |

| SW3 | 10.98 | 379.14 | 33.99 | 474.87 | 55.31 | 403.64 | 5.037 | 0.181 |

| SW4 | 14.26 | 588.08 | 50.675 | 707.76 | 54.08 | 601.60 | 3.792 | 0.245 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiong, Y.; Chen, A.; Wu, D.; Zhao, G. Seismic Performance of Composite Shear Walls Filled with Demolished Concrete Lumps and Self-Compacting Concrete after Fire. Buildings 2022, 12, 1308. https://doi.org/10.3390/buildings12091308

Xiong Y, Chen A, Wu D, Zhao G. Seismic Performance of Composite Shear Walls Filled with Demolished Concrete Lumps and Self-Compacting Concrete after Fire. Buildings. 2022; 12(9):1308. https://doi.org/10.3390/buildings12091308

Chicago/Turabian StyleXiong, Yan, Aodong Chen, Di Wu, and Guowei Zhao. 2022. "Seismic Performance of Composite Shear Walls Filled with Demolished Concrete Lumps and Self-Compacting Concrete after Fire" Buildings 12, no. 9: 1308. https://doi.org/10.3390/buildings12091308