1. Introduction

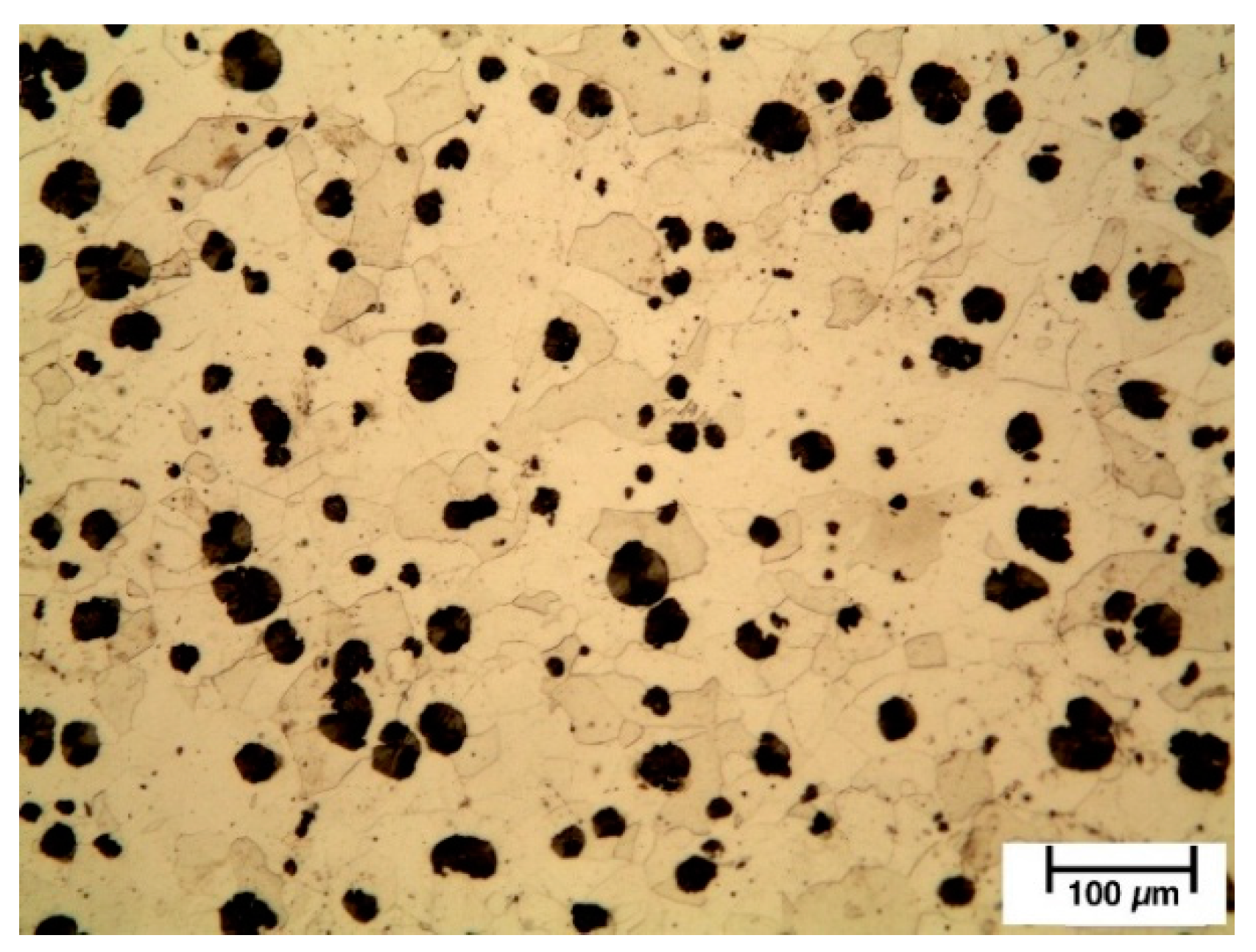

Ductile cast irons (DCI), also known as nodular cast irons or spheroidal graphite irons, are widely used in complex shaped structural parts that need to obey simultaneously to specific requirements such as high mechanical strength, high fatigue resistance, wear resistance and ease of castability [

1,

2,

3,

4,

5]. A compilation of a few interesting properties of cast irons can be found in [

5,

6,

7]. Indeed, DCIs allow combining some interesting properties seen in grey cast irons (such as very good castability) with additional properties presented by other cast steels (e.g., grey cast iron and compacted graphite iron), namely toughness. This set of properties allows the creation of parts with similar characteristics to those made with other cast irons but with the added bonus of having high performance mechanical properties. These properties depend mainly on the iron’s chemical composition, inoculation method, ferrite content of the matrix, size and shape of the graphite nodules, among others [

8]. The relation between properties and microstructure for DCIs and other cast irons is investigated in [

9]. Some heat treatments such as austempering, carried out after the casting process, can increase mechanical properties (such as mechanical strength and fatigue resistance) of certain DCIs, having given rise to the Austempered Ductile Irons (ADIs) (extensive literature about these kinds of cast irons can be seen in [

10,

11,

12,

13,

14]). The heat treatments usually applied to ADIs are properly described in [

15] and related sources. A specific structure combined with the proper heat treatment confer to ADIs a unique set of properties that relate to acicular ferrite and high carbon residual austenite, usually called ausferrite [

16]. Several studies about ADIs structure have been carried out, as described by Chaengkham and Srichandr [

17]. More recently, some high-strength and ultra-high-strength ductile cast irons have been developed based on solid solution strengthened ductile iron, mainly to satisfy the increasingly demanding requirements set by the automotive industry [

18]. Improvements regarding mechanical characteristics (when compared to aluminum alloys) and search for decreasing overall weight of parts relatively to other ferrous alloys are the mains drivers for these advances.

It is well-known that weldability of the DCIs depends on several factors, namely the chemical composition of parent materials and filler metals used, mechanical properties, type of microstructure, adopted welding process and working conditions [

19]. DCIs usually present high amounts of carbon in their structure, which diffuses and promotes the formation of austenite during welding operations, allowing the appearance of brittle phases in the joint’s interface [

20]. Indeed, DCIs usually present carbon equivalents between 2.0% and 4.0% [

21]. Furthermore, welding of DCI alloys is somewhat uncommon due to their well-known poor weldability [

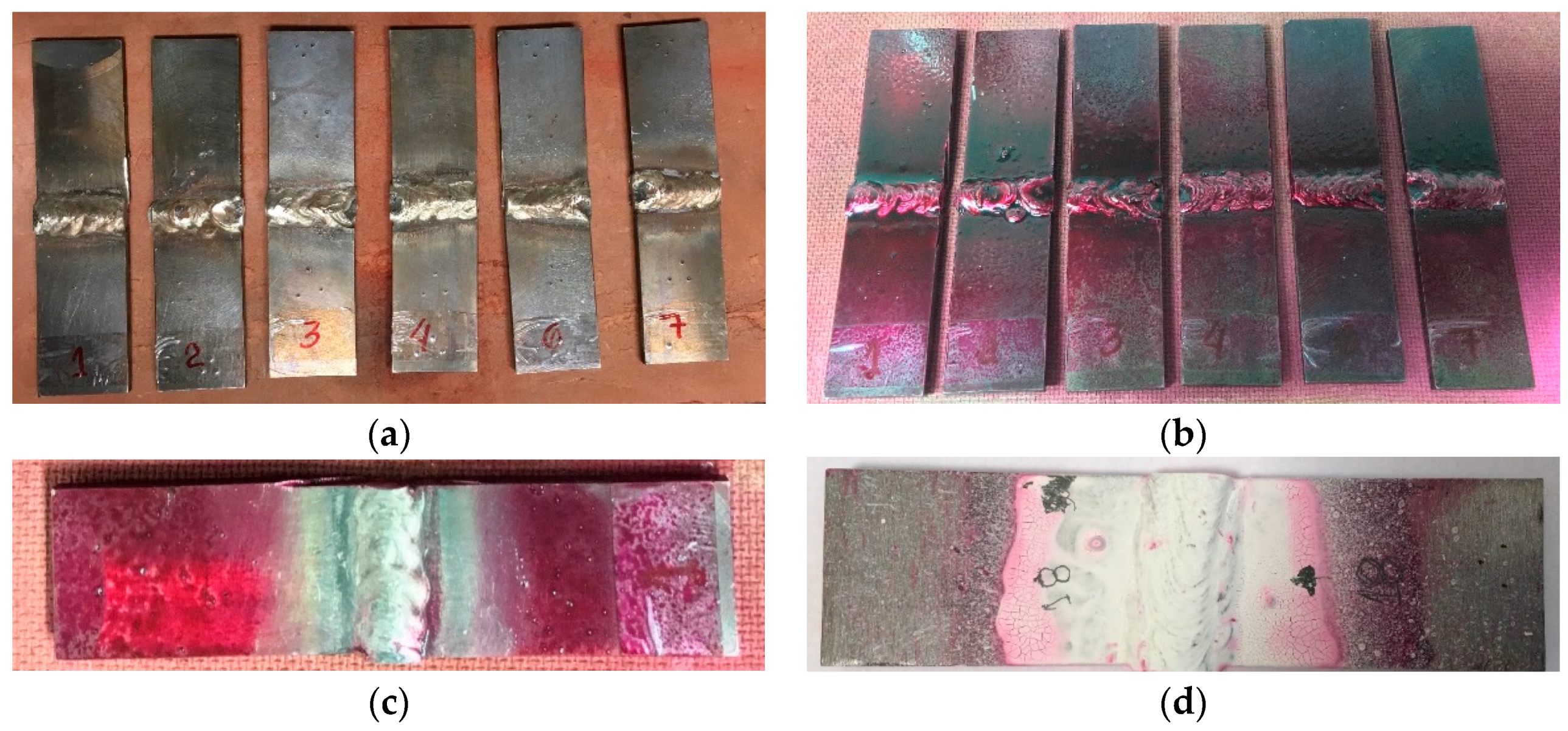

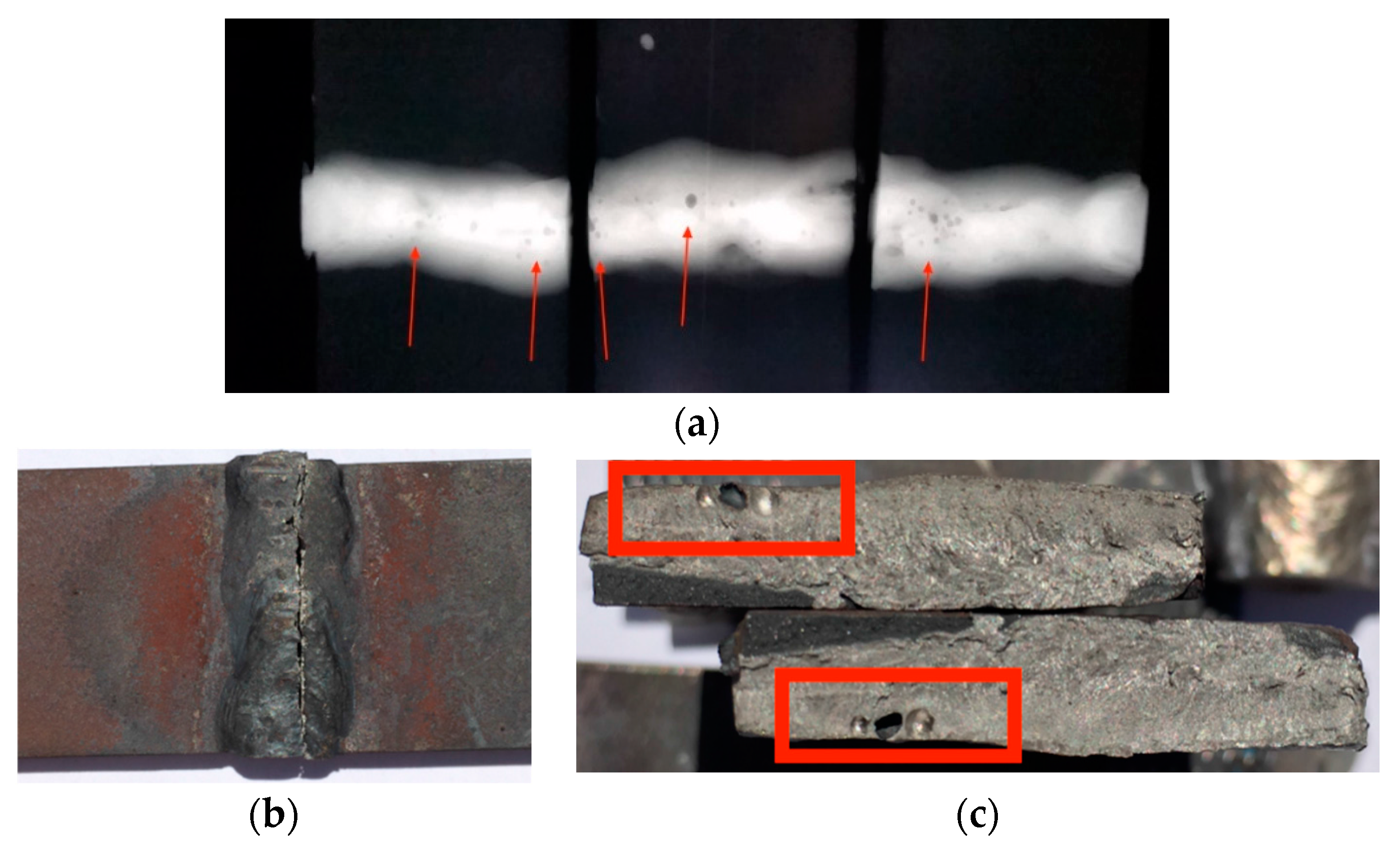

1]. However, welding processes may be used to repair machining errors, casting defects in areas with no functionally requirements, existing cracks in large components such as engine blocks or even hard to replace broken parts [

2].

Several arc welding technologies have been successfully used to join DCIs, such as Manual Shielded Metal Arc Welding (SMAW), Flux Cored Arc Welding (FCAW), Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW) and Laser Welding (LW) [

2,

19], as well as Oxyacetylene Welding (OAW). As one of the main reasons for welding ductile cast irons is usually to perform repairs, as opposed to being a construction method, parts presenting casting defects such as cracks/fissures or shrinkages in non-functional areas can be easily repaired by the use of welding. SMAW is one of the most utilized method for welding DCIs [

22] and is an ideal candidate for this application, mainly for allowing easier maneuverability and access of welding electrodes (essential factor for performing repairs). It is also one of the most common and economical methods of welding in the industry. Furthermore, highly productive or automated welding processes such as GMAW and FCAW are not advantageous to perform arbitrary and interrupted tasks such as repairs. Other methods such as GTAW, although being able to promote higher quality weld finishes (which may be considered of low importance for cast parts), have a higher heat input during welding, which is highly detrimental to cast irons by promoting the appearance of brittle microstructures such as martensite and ledeburite. However, welding processes must be used under some restrictions, as the structure of DCIs tends to change during the solidification process, with the formation of martensite mainly in the Heat Affected Zone (HAZ), iron carbides in the interface between the weld bead and parent metal [

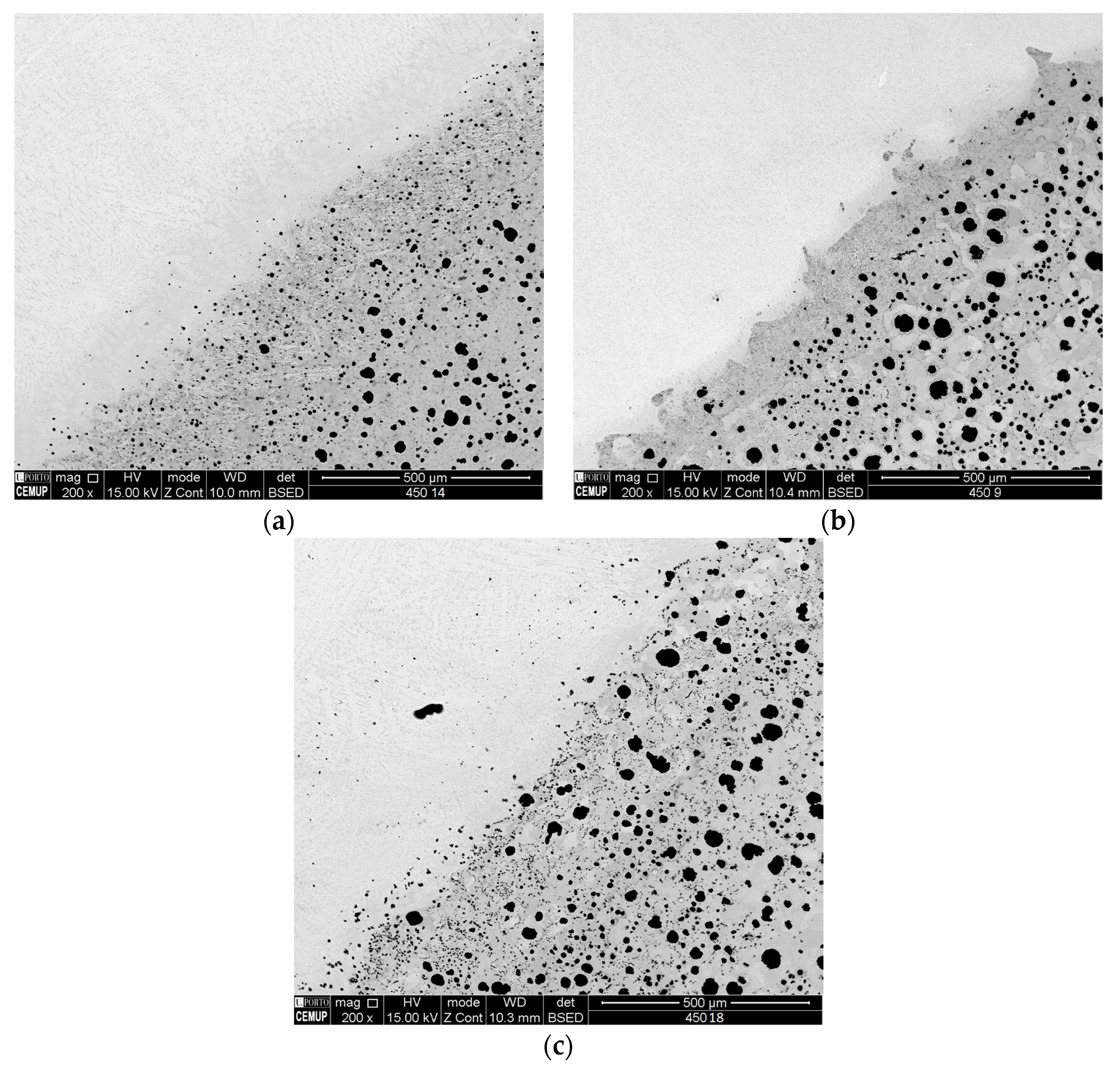

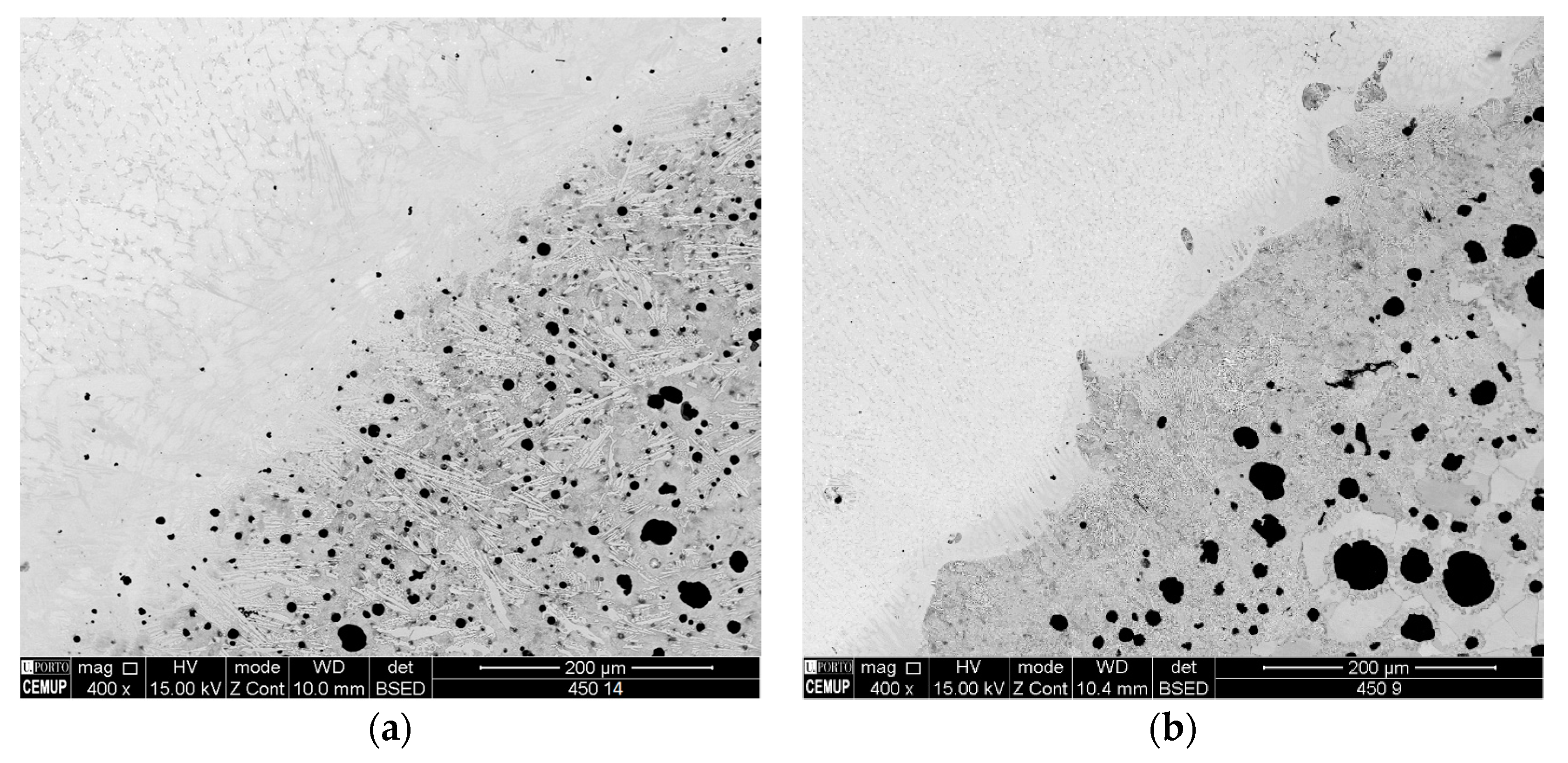

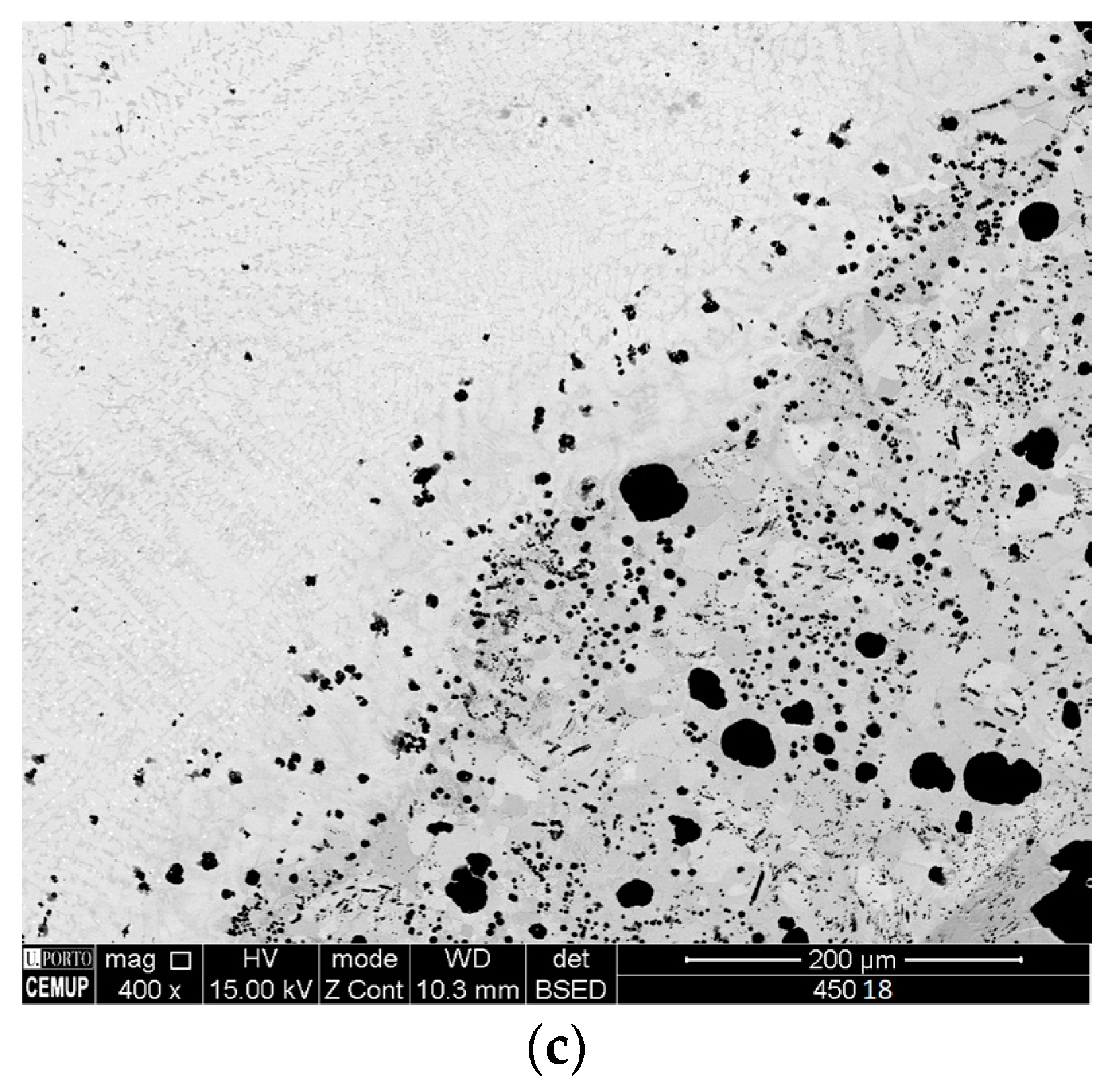

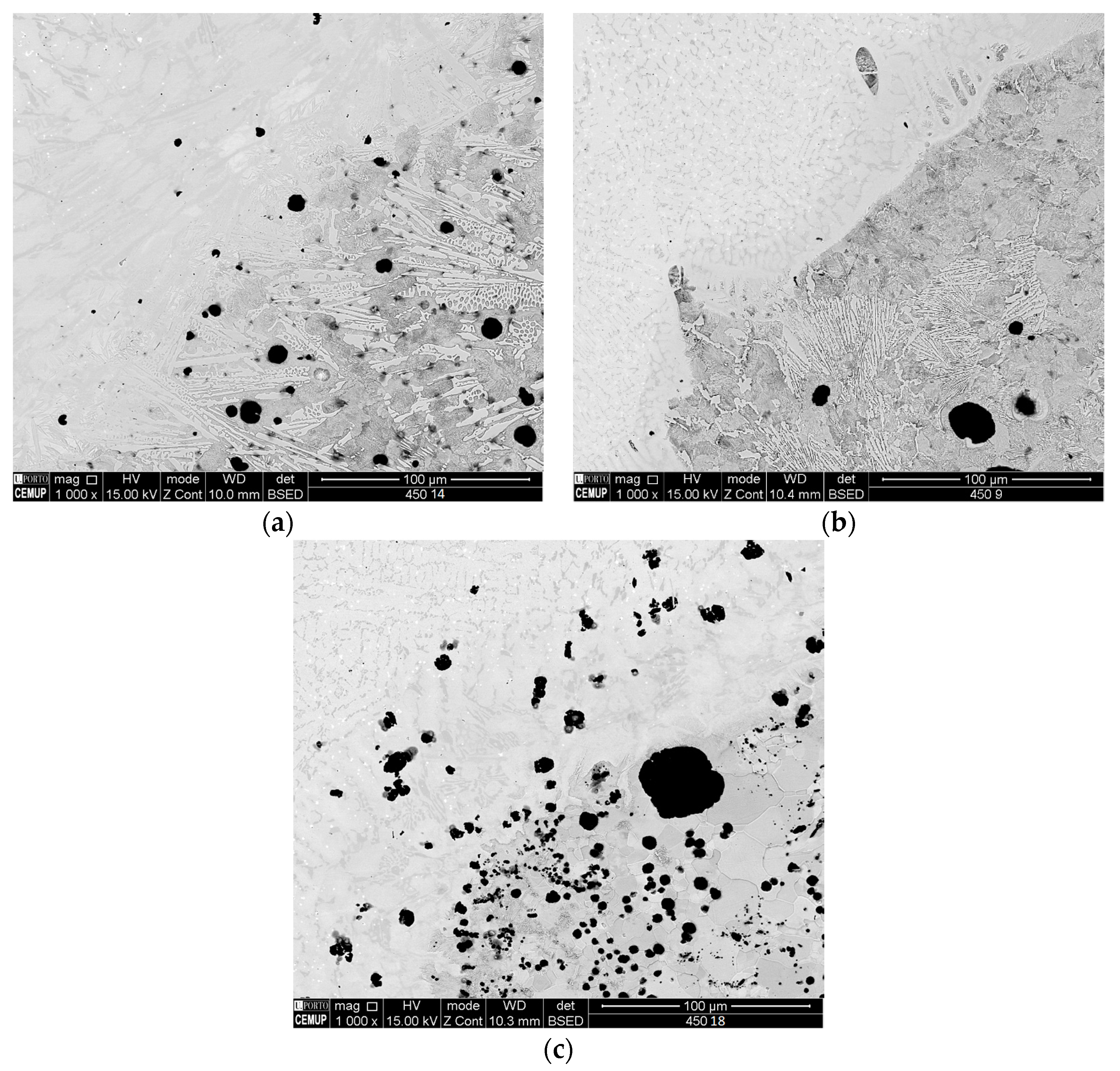

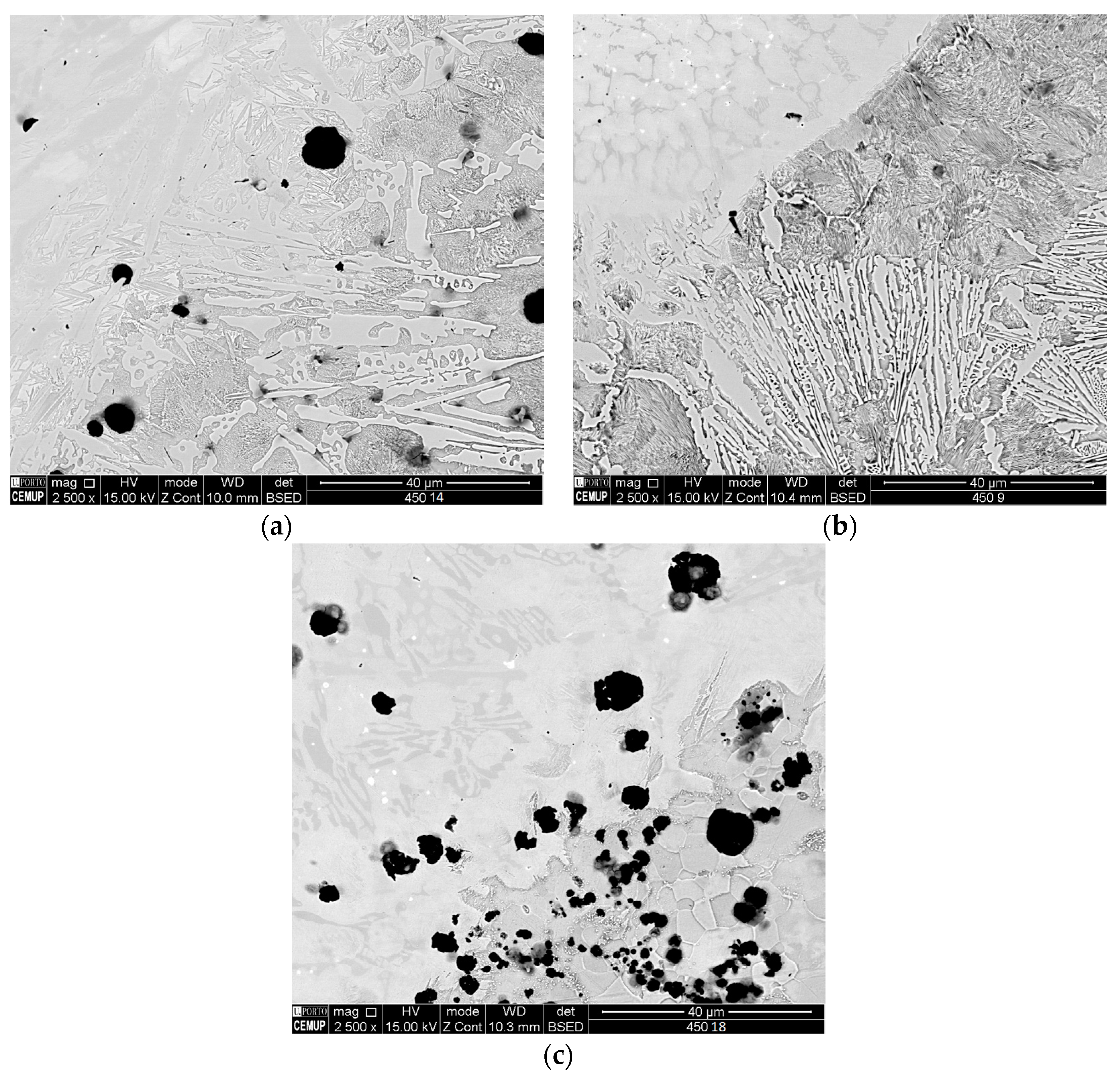

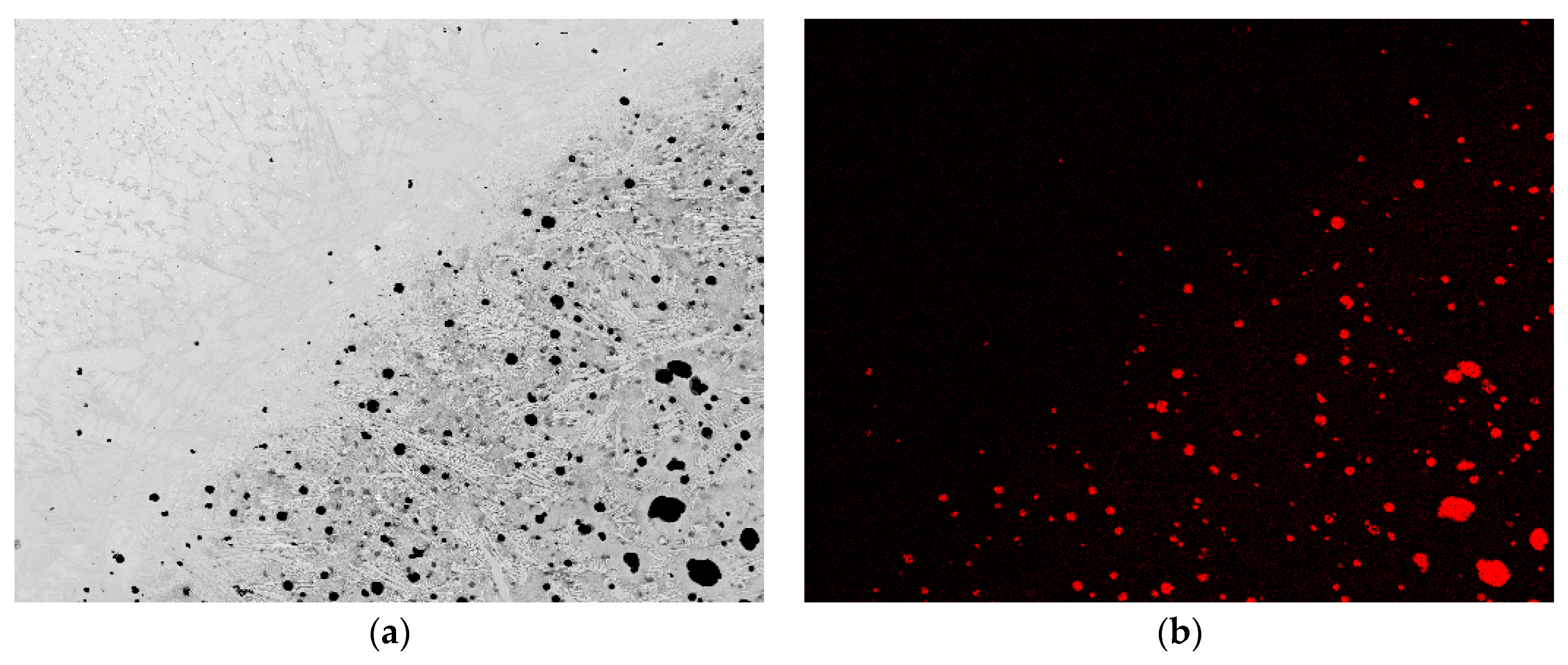

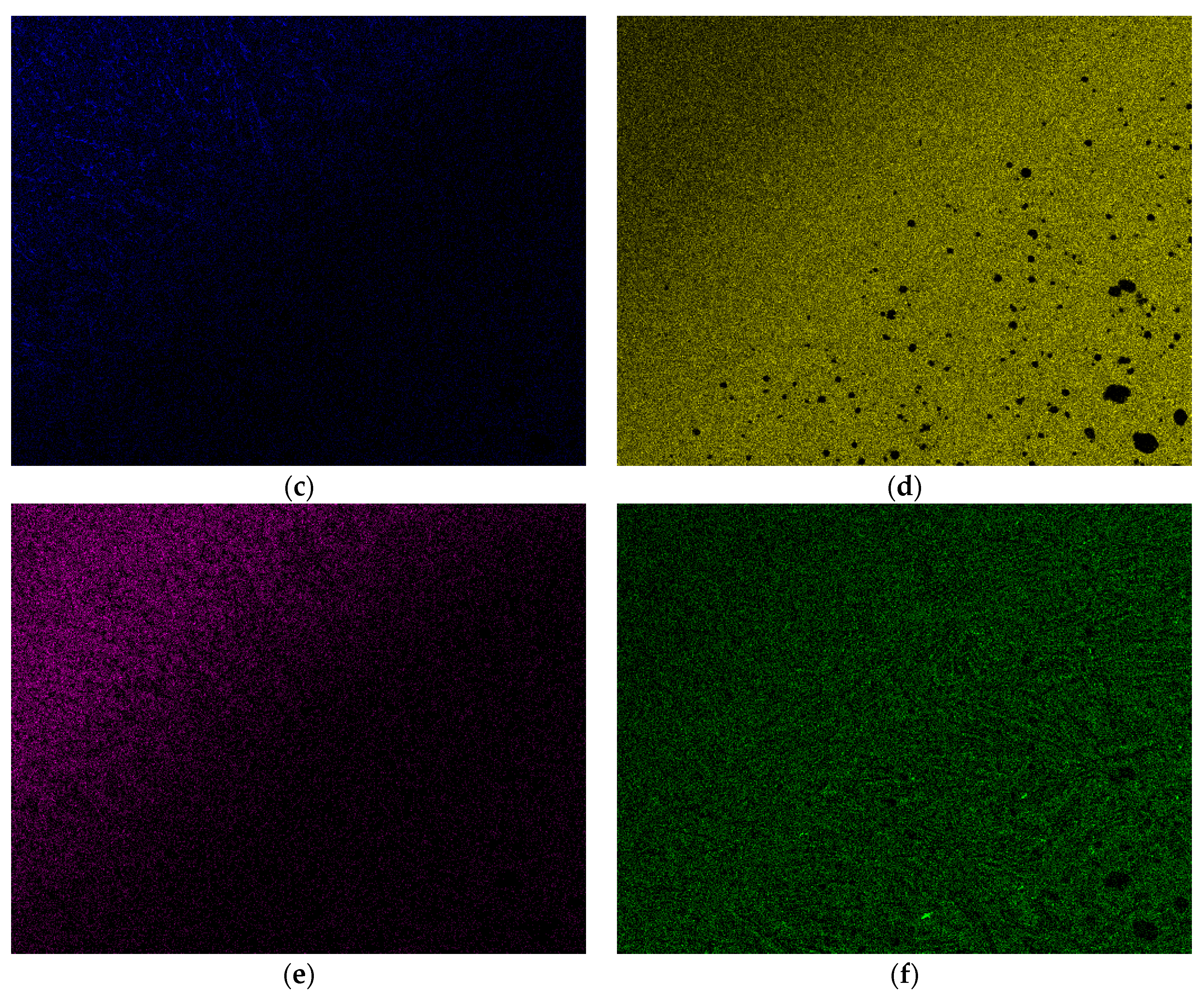

23] and very hard ledeburite in the Partially Melt Zone (PMZ) [

19]. The appearance of such structures negatively affects mechanical properties of the joint and gives rise to a higher probability of crack formation, as described by other authors [

24,

25,

26,

27]. Even when using Nickel-iron alloys as a filler metal, these authors found that grey cast irons still demonstrated poor weldability due to the formation of hard/brittle iron carbides in the PMZ as well as due to the high carbon and carbon equivalent content present in the iron’s structure (which may be the main cause of the formation of hard phases in the HAZ and weld interface during the cooling process).

Regarding the welding of DCI, there are mainly three types of alloys considered suitable as filler metals: cast iron filler metal, Ni filler metal and Ni-Fe filler metal alloy [

19]. Likewise, mild steel is sometimes considered as suitable mainly due to its reduced cost, but due to different contraction coefficients, mild steel shrinks more than cast iron during the solidification process, generating residual stress in the weld interface [

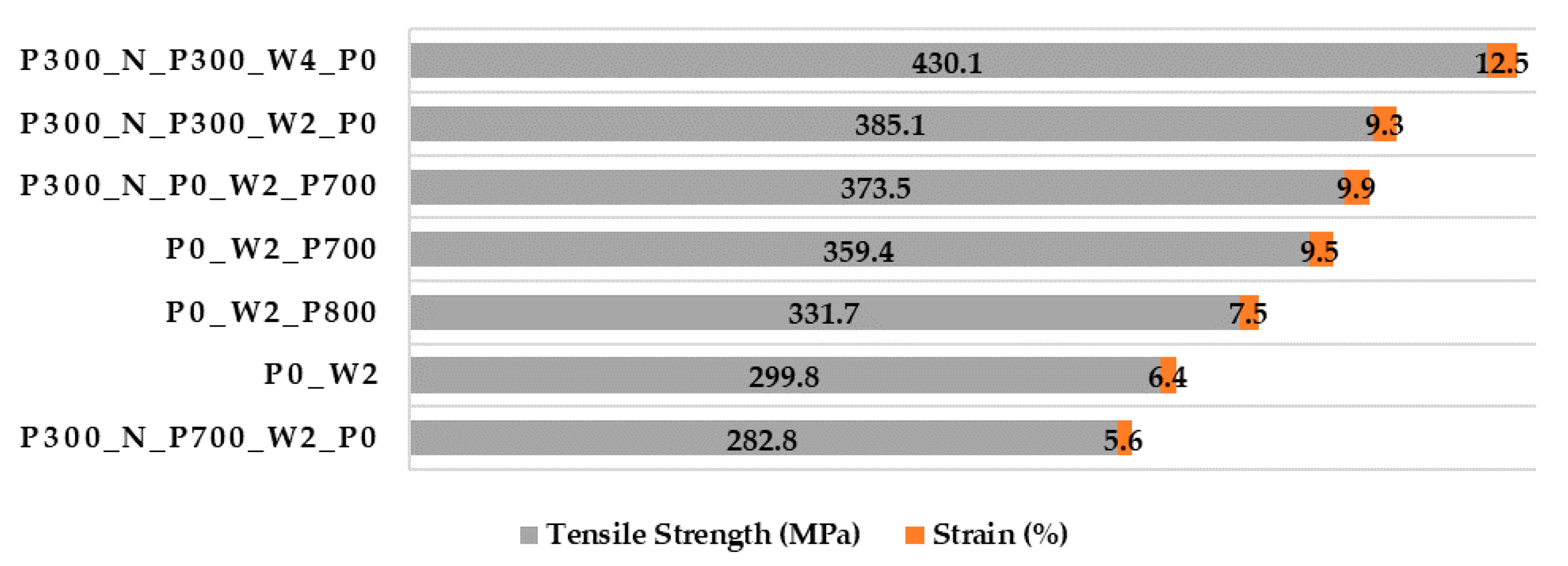

19]. Experiences carried out by Pascual et al. [

23] allow observing that the use of cast-iron as a filler metal gave rise to the worse mechanical properties when welding DCIs using SMAW or OAW technologies, while Ni-Fe and Ni alloys led to the best results in terms of mechanical resistance as well as ensuring good strain values and a non-fragile behavior [

23].

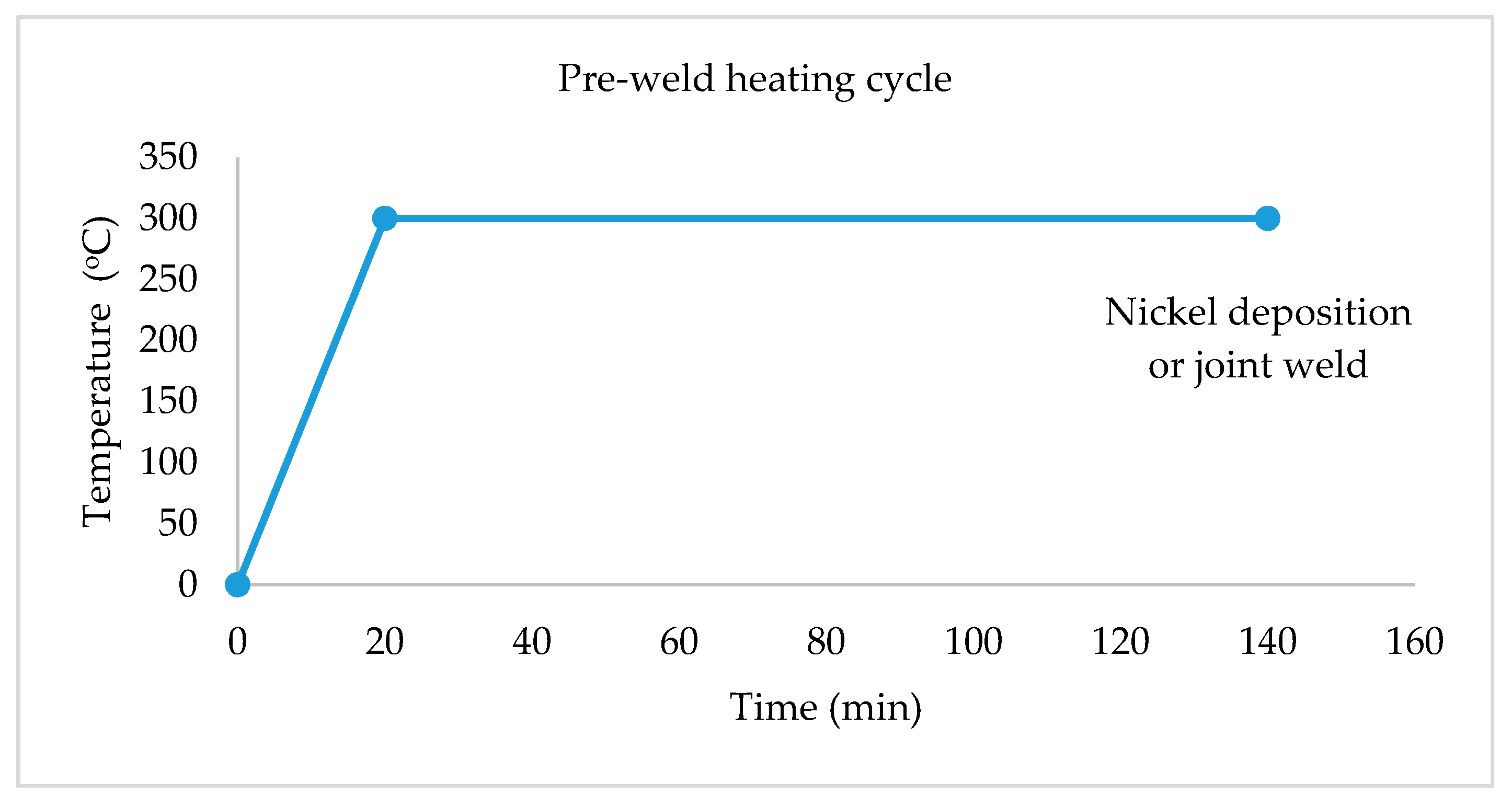

Heat treatments are the most used method to avoid crack formation on DCIs during the solidification process, mainly pre-heating treatments and sometimes post welding heat treatment (PWHT). Other processes have also been implemented with success, such as buttering [

22]. Usually, the selected pre-heating temperature depends on the chemical composition or carbon equivalent (CE) of the iron, which conditions the hardenability of the DCI [

20]. Ebrahimnia et al. [

26] achieved good results in terms of avoiding crack formation by performing a local pre-heat treatment with a temperature of 300 °C before welding large forming dies (found in presses for the production of vehicle body panels), as well as a PWHT 400–500 °C with different cooling rates when powder welding DCIs. On the other hand, El-Banna [

20] tested four preheating temperatures (25 °C, 200 °C, 300 °C and 400 °C), concluding that the best range of temperatures for these types of irons is between 200 °C and 300 °C. Moreover, Bęczkowski [

28] refers that the control of interpass temperatures (up to 300 °C) and pre-heating temperatures (up to 200 °C) promotes the quality of the welds when repairing massive castings. Special care regarding the duration of pre-heating treatments must be given to avoid martensite formation and prevent secondary graphite formation in multi-passes welds [

20]. Moreover, special care is needed to closely match thermal coefficients of filler and parent metals to decrease stress formation during the solidification process. Askari-Paykani et al. [

22] referred that when preheating is used for DCI welding, cooling conditions did not present a significant influence on the Ultimate Tensile Strength (UTS) value of the joined part. However, rapid cooling rates are known for increasing the probability of martensite appearance in the HAZ. According to Mandal [

29] and Connor [

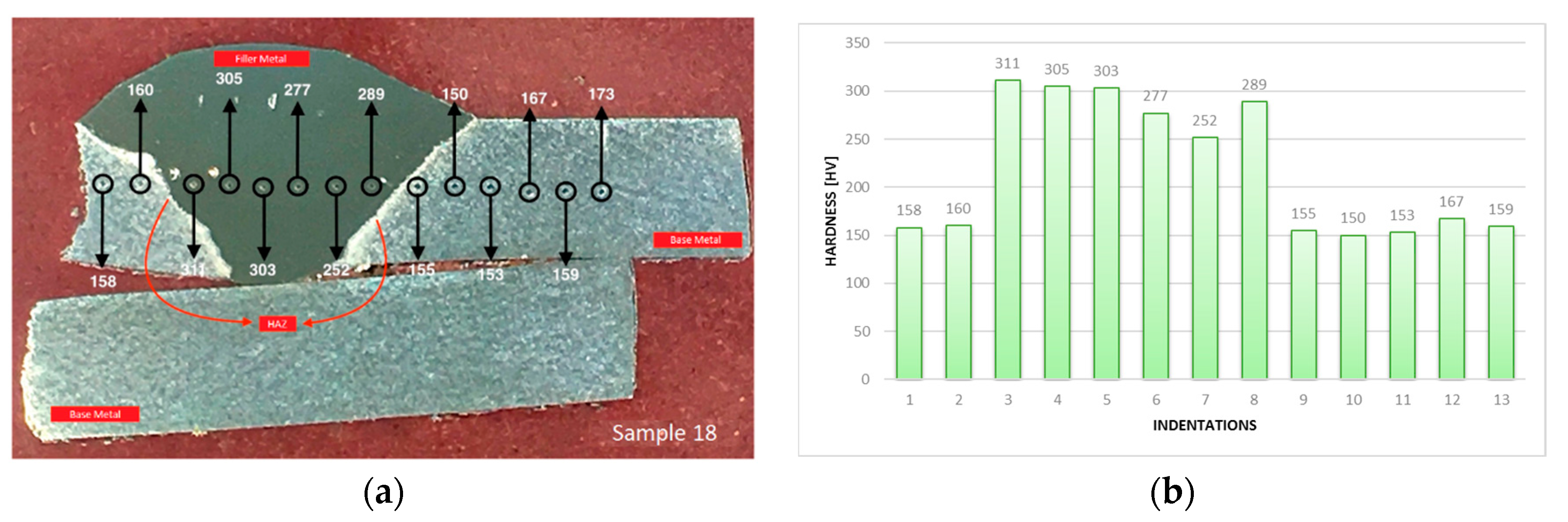

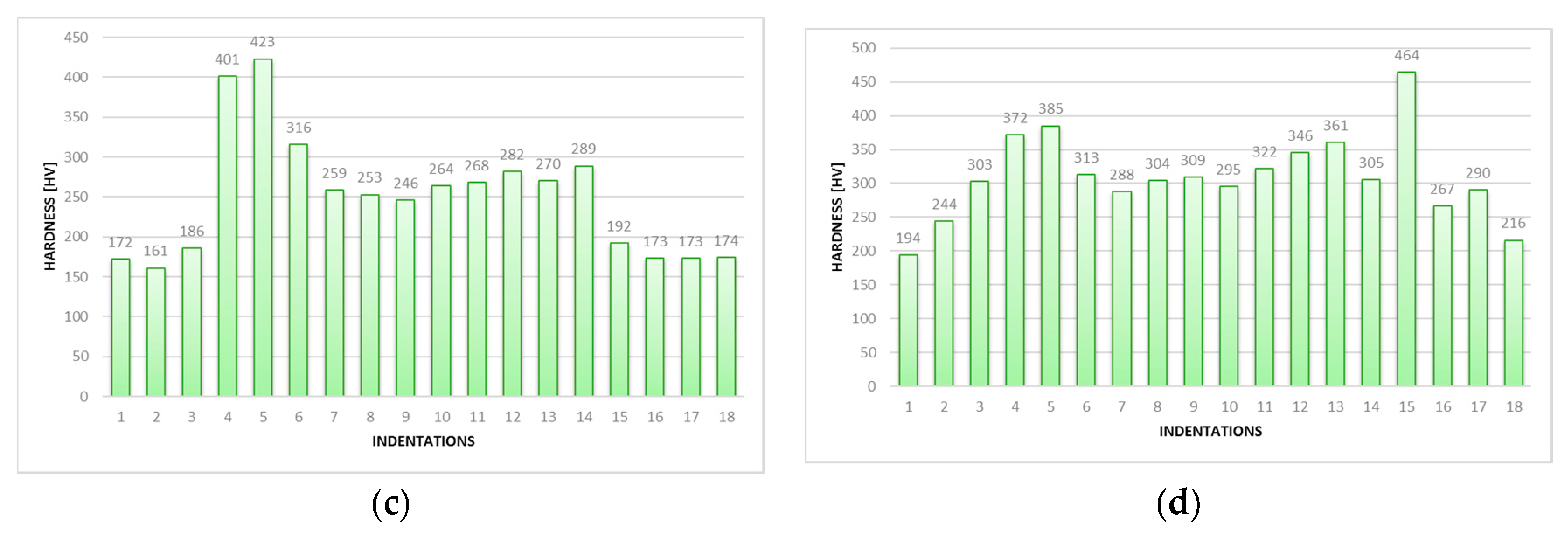

30] cooling rates should never exceed 6 °C/s at 550 °C as this speed seems to promote satisfactory results for most steels. Cooling rates usually depend on many factors such as the thickness of the part to weld, welding speeds, pre-heating temperatures and interpass temperatures. Another important parameter that directly impacts the properties of the HAZ is the peak temperature achieved during welding, as the higher the peak temperatures achieved, the wider the HAZ area. Moreover, the hardness achieved in the Fusion Zone (FZ) is proportional to the martensite and bainite that is formed, the hardness obtained in the HAZ is proportional to the perlite and martensite generated and in the PMZ the hardness is proportional to the ledeburite and martensite created.

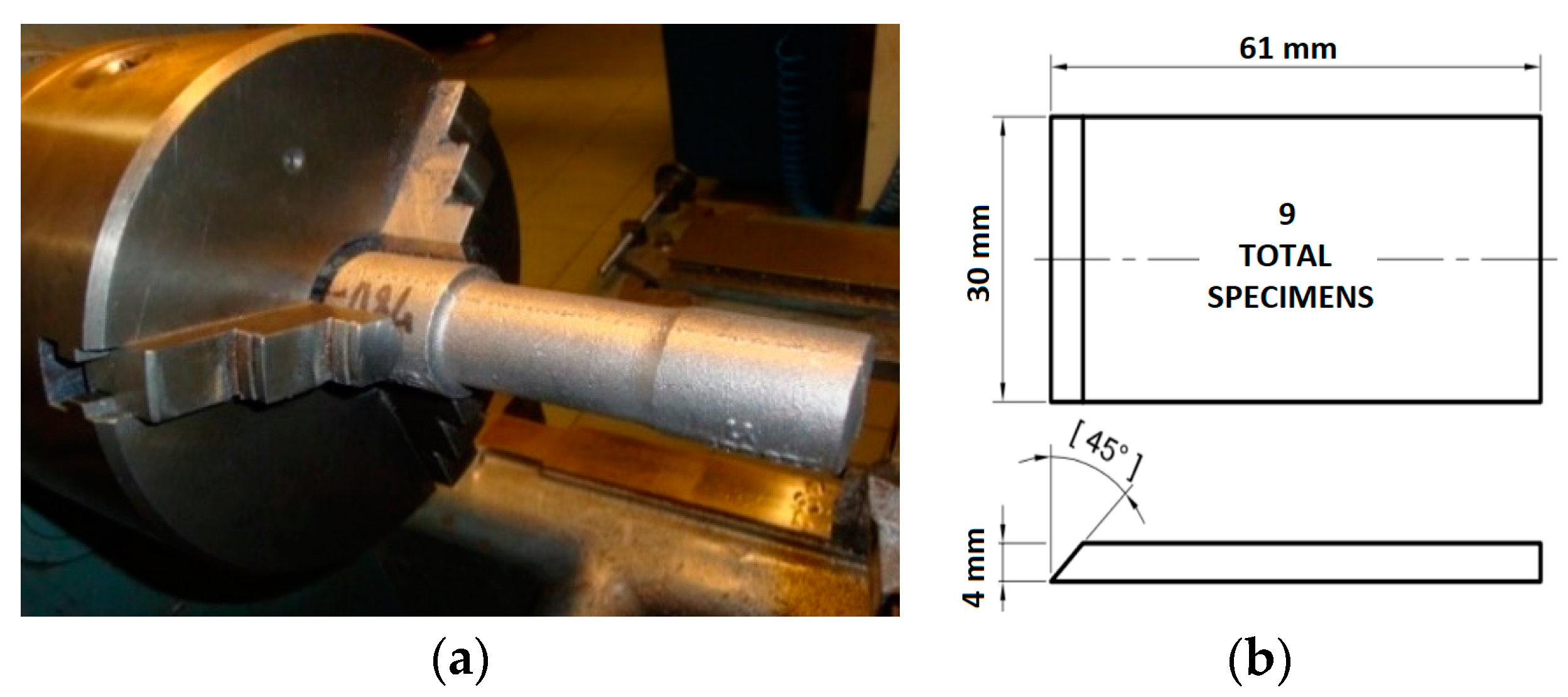

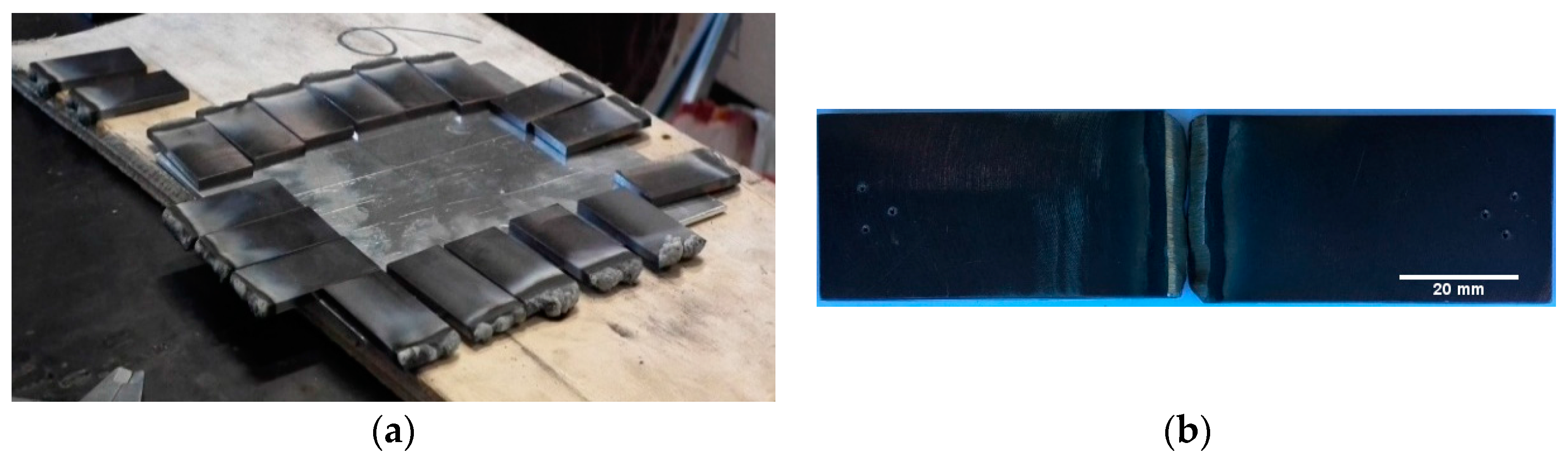

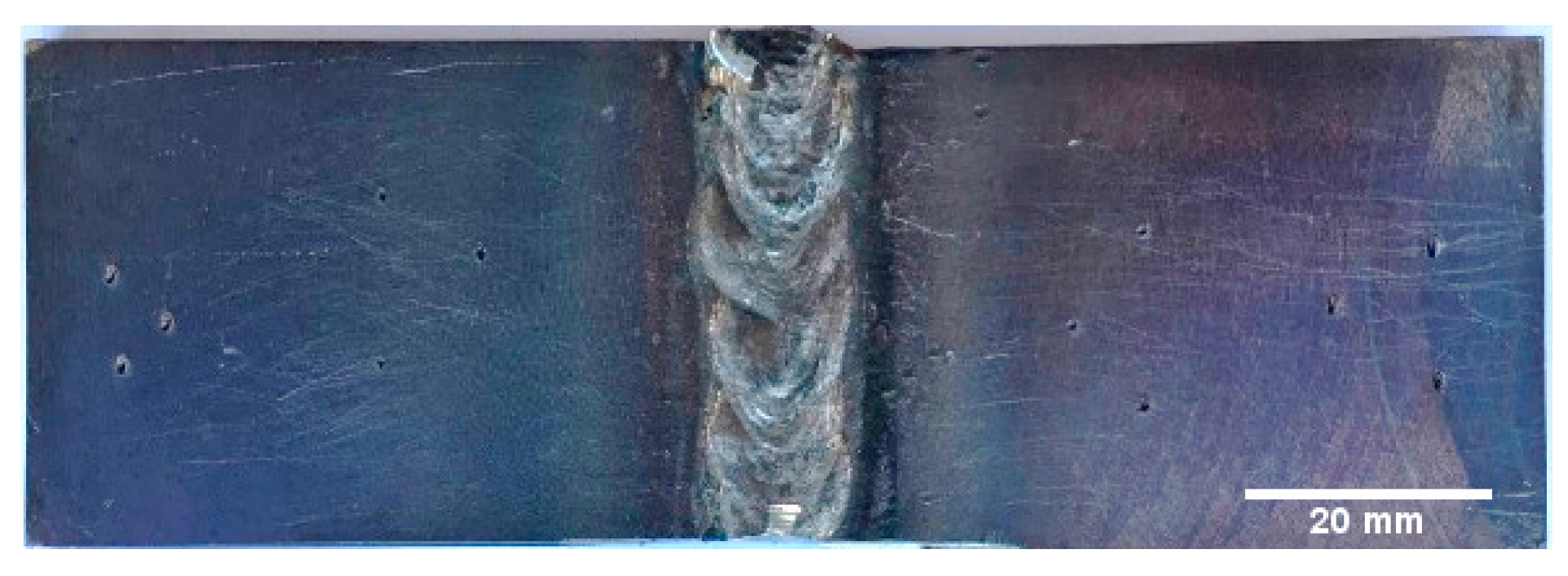

Thus, this work intends to evaluate the effects of heat treatments performed at different temperatures (by the implementation of thermal cycles before and/or after welding) on welded joints of a high-strength ductile cast iron (SiboDur® 450, similar to EN-GJS-450-10, following the DIN EN 1563:2012 standard) used in automotive industry, using SMAW as the joining process and Ni-Fe as a filler metal. It also intends to determine the mechanical properties of welded joints as well as observe changes in the iron’s microstructure, correlating the obtained results with the joint’s hardness profile.