Study of the Microstructure Evolution and Properties Response of a Friction-Stir-Welded Copper-Chromium-Zirconium Alloy

Abstract

:1. Introduction

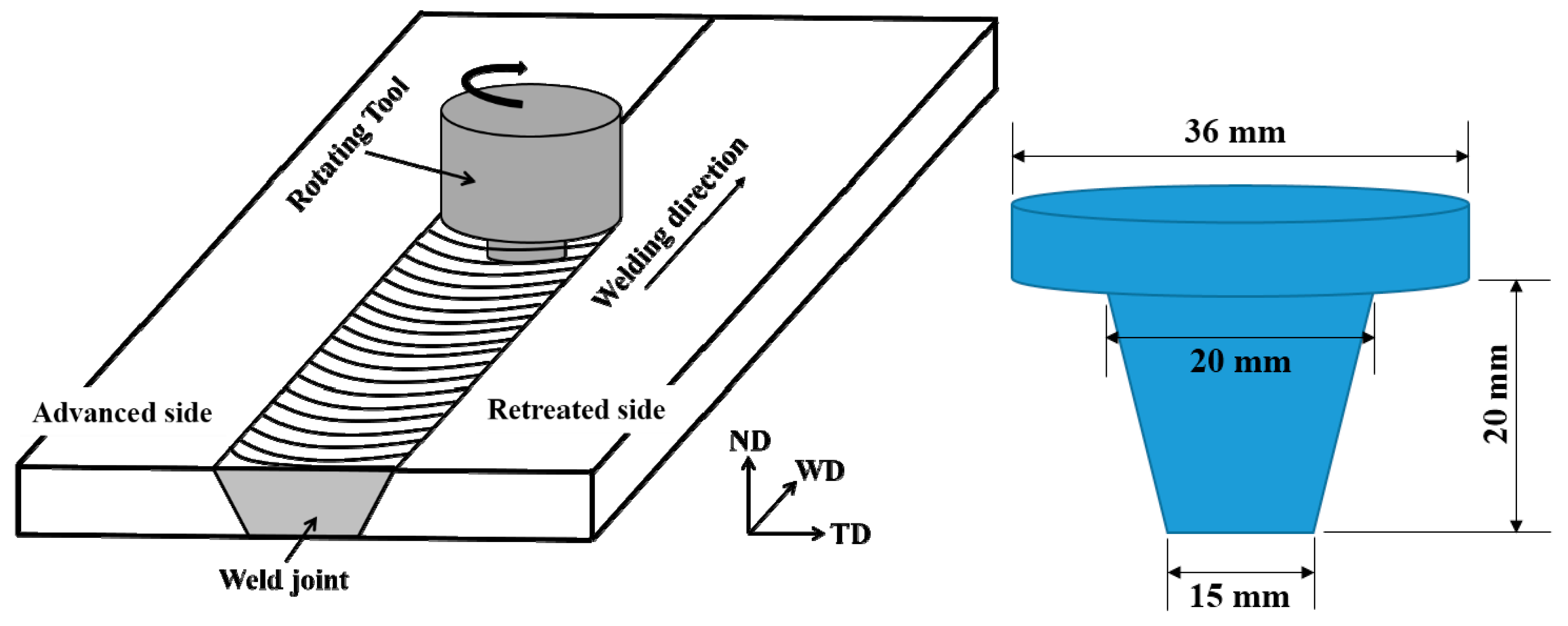

2. Materials and Methods

3. Results and Discussions

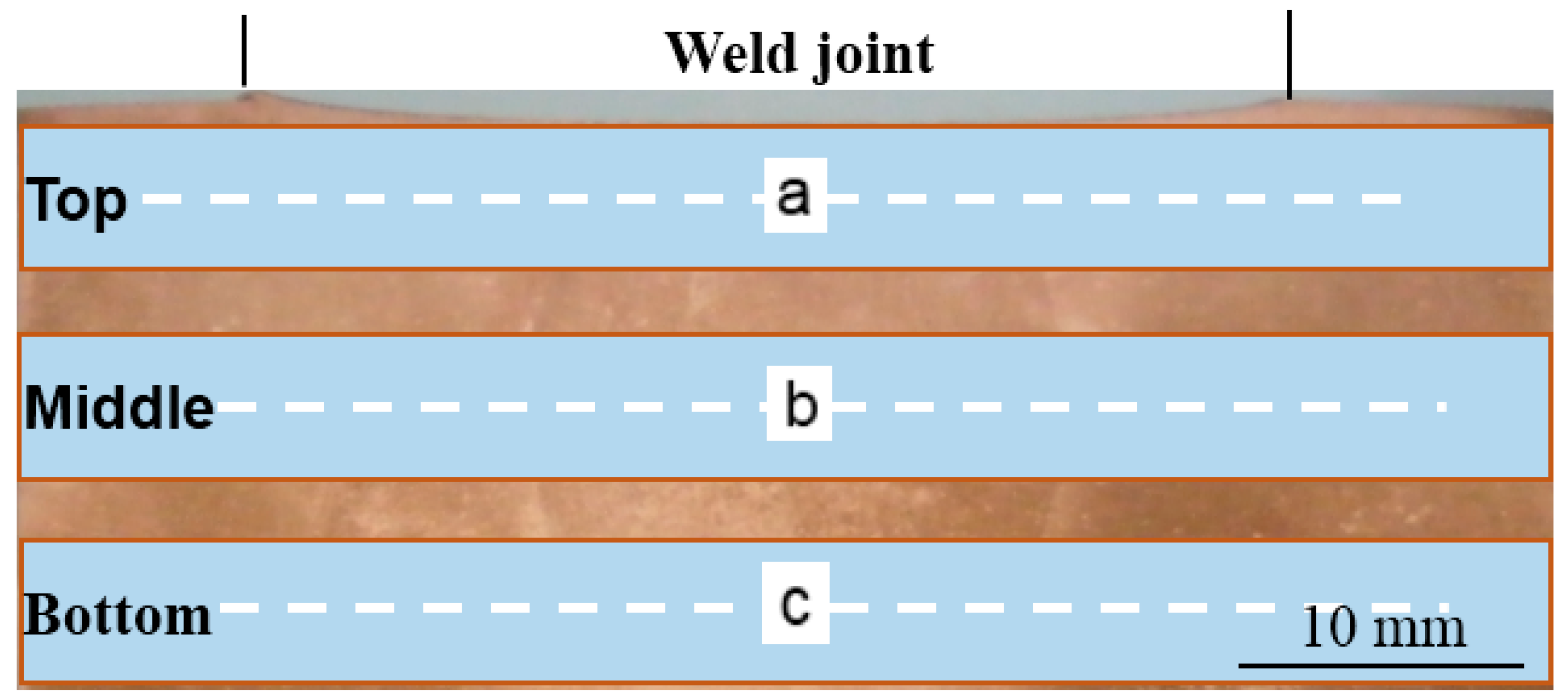

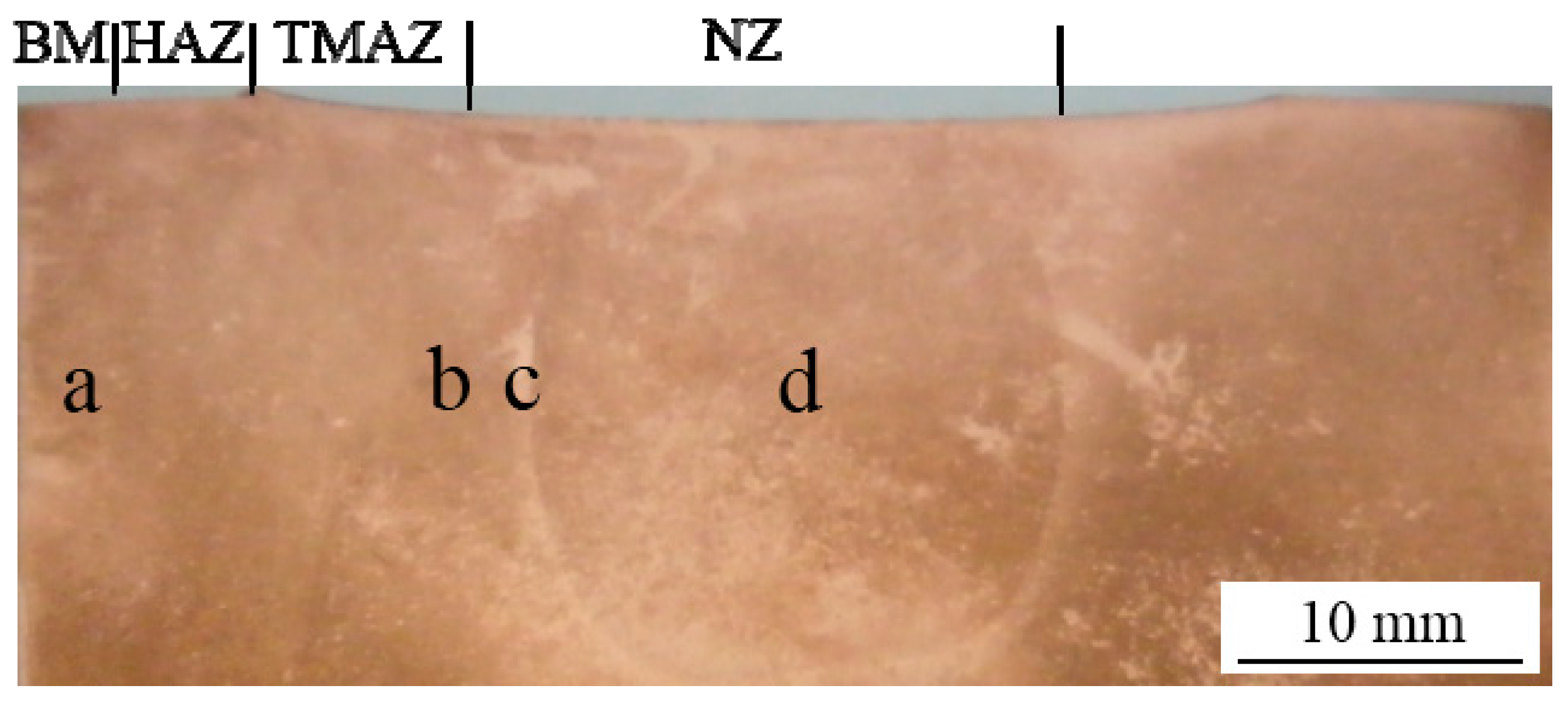

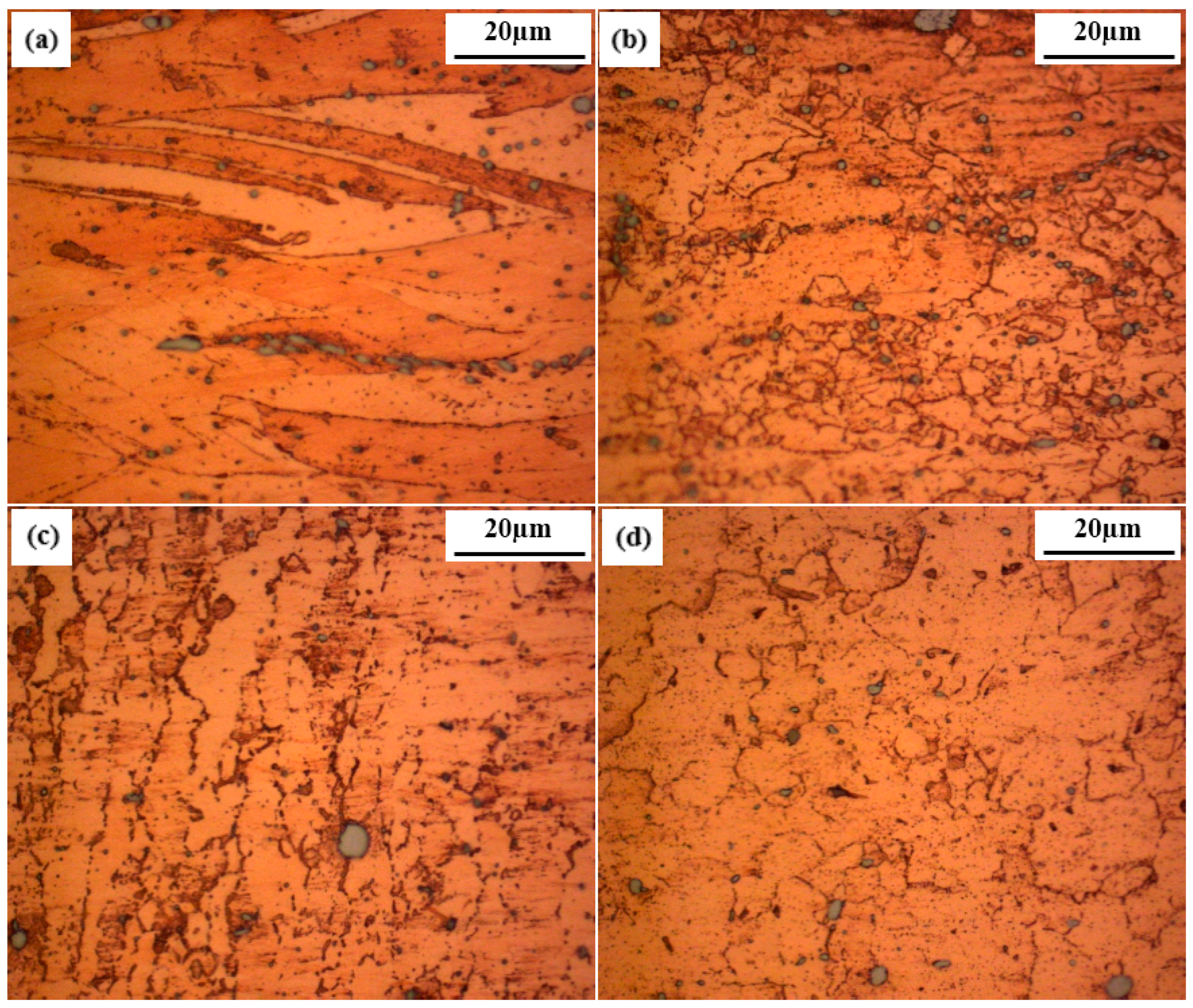

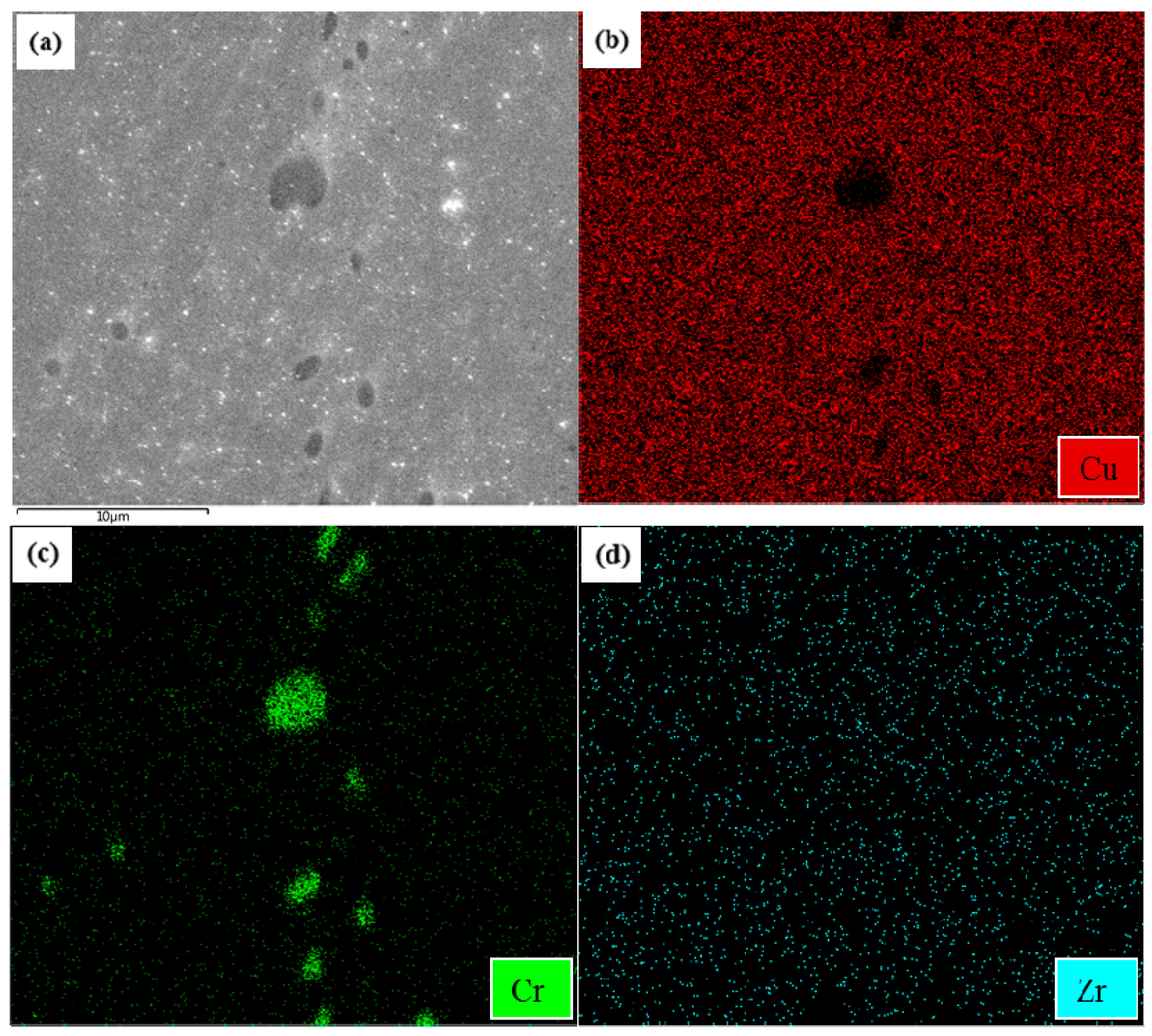

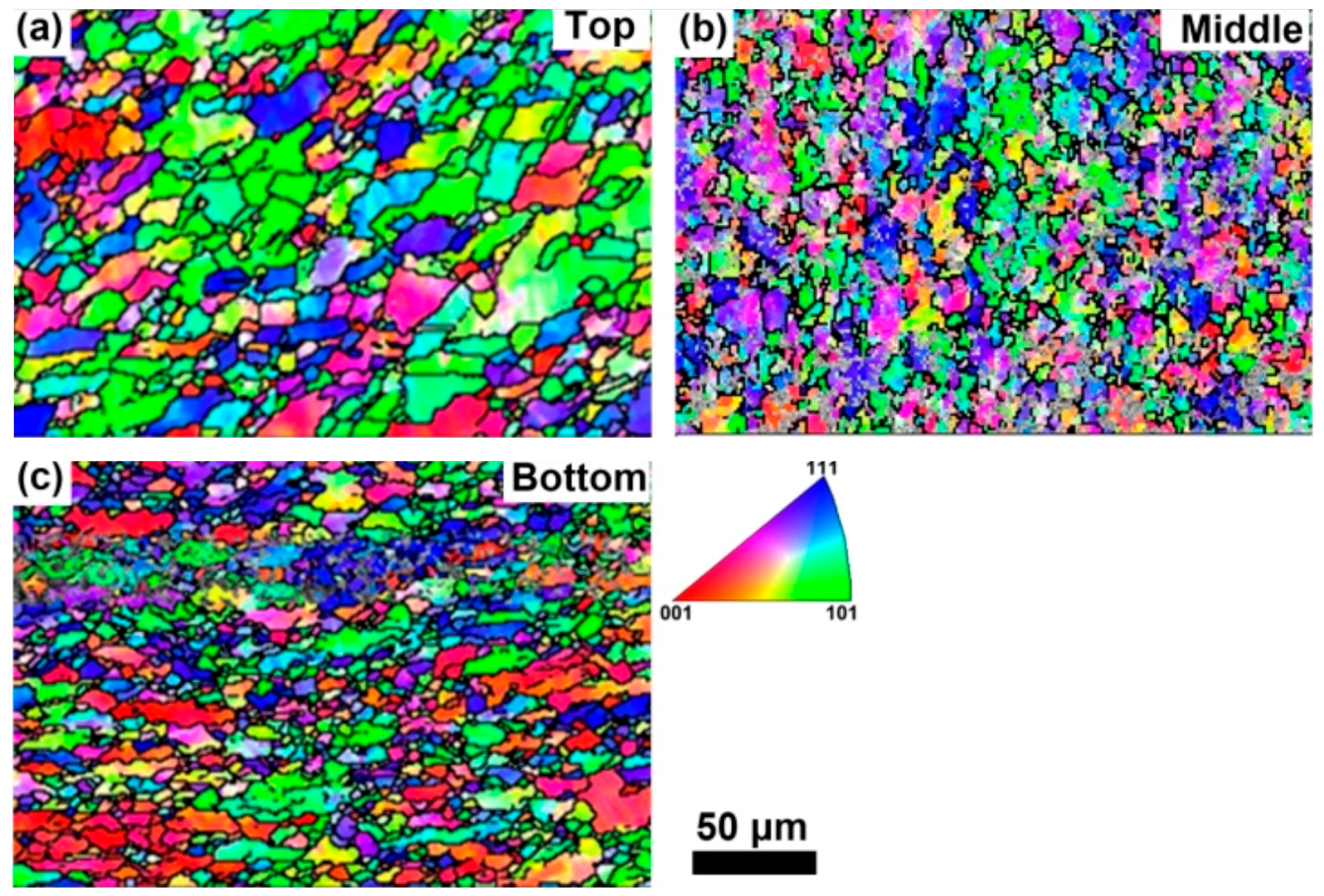

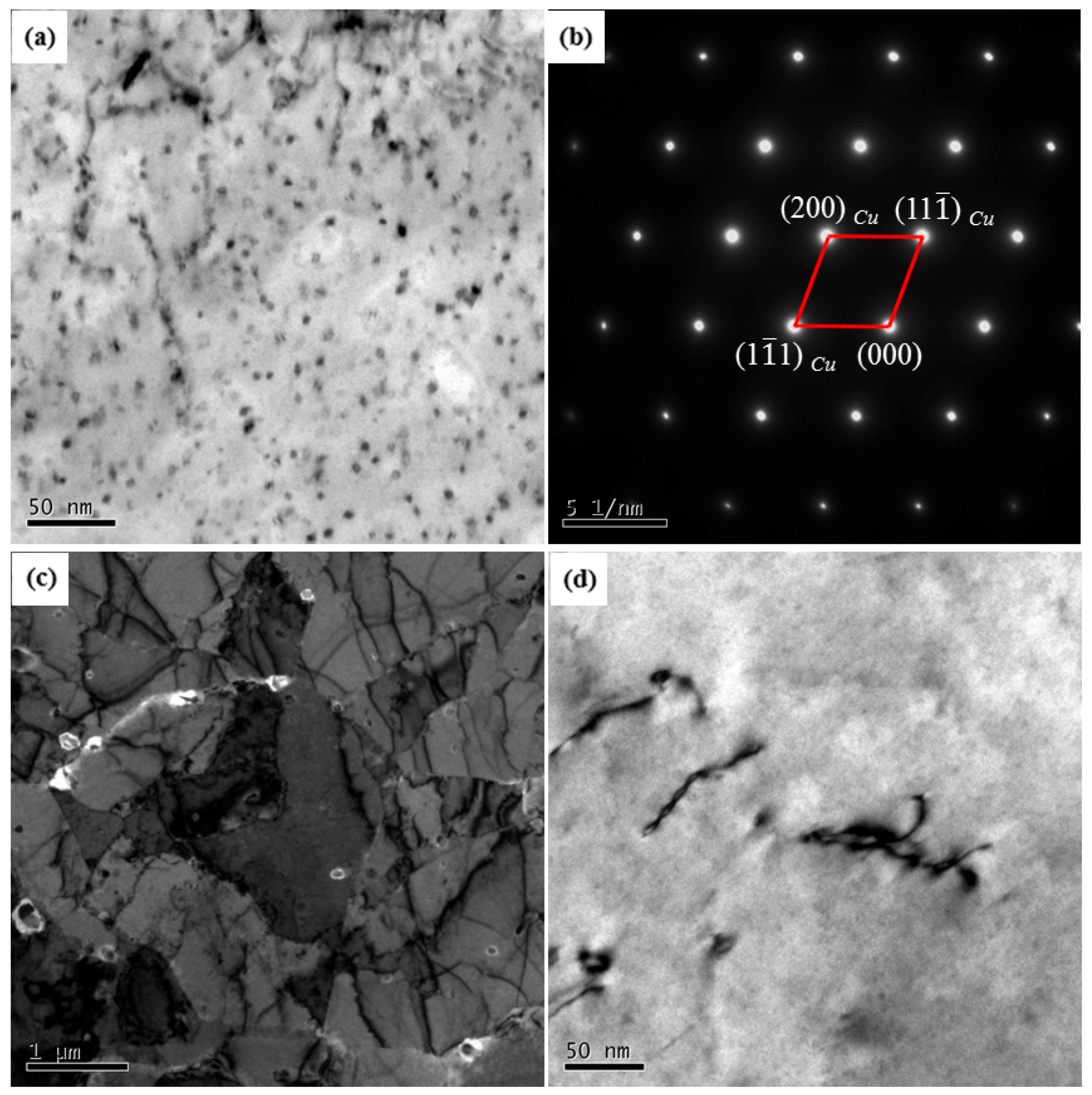

3.1. Microstructure of FSW Joints

3.2. Properties

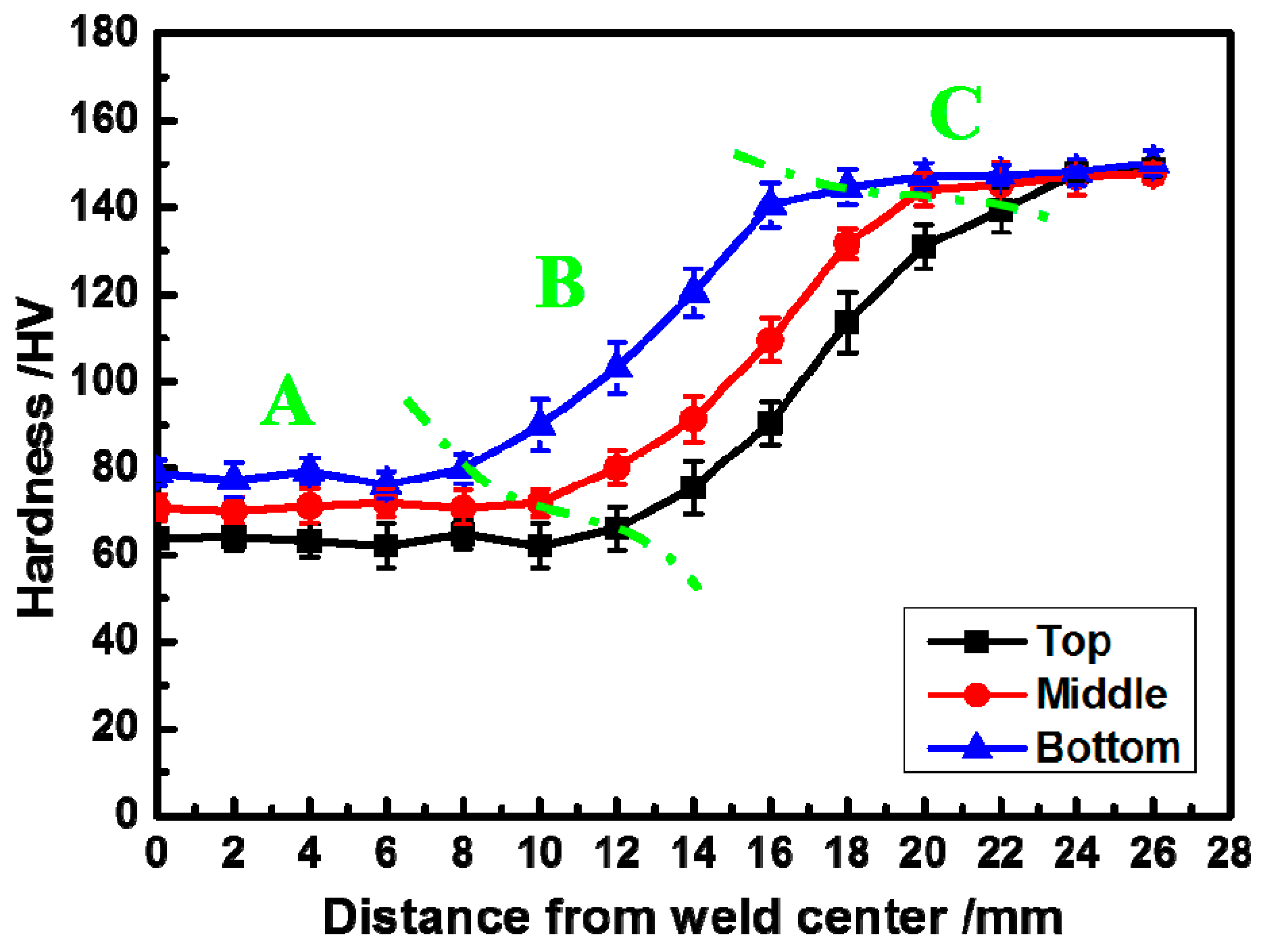

3.2.1. Micro-Hardness

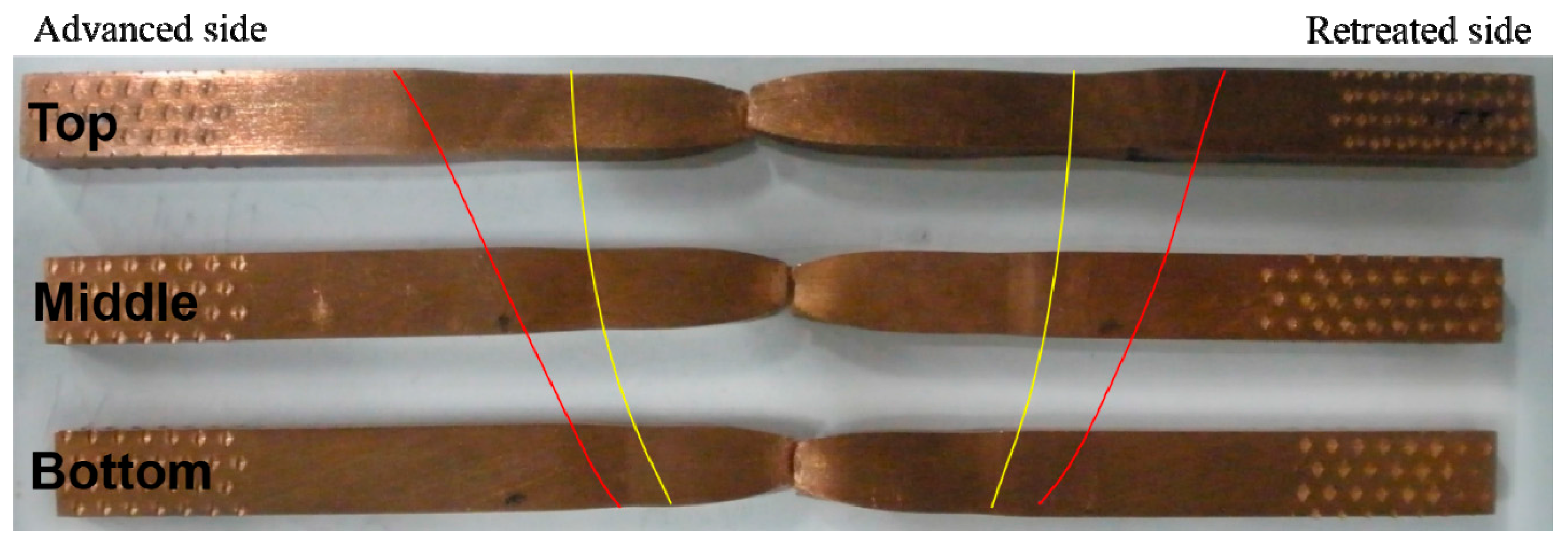

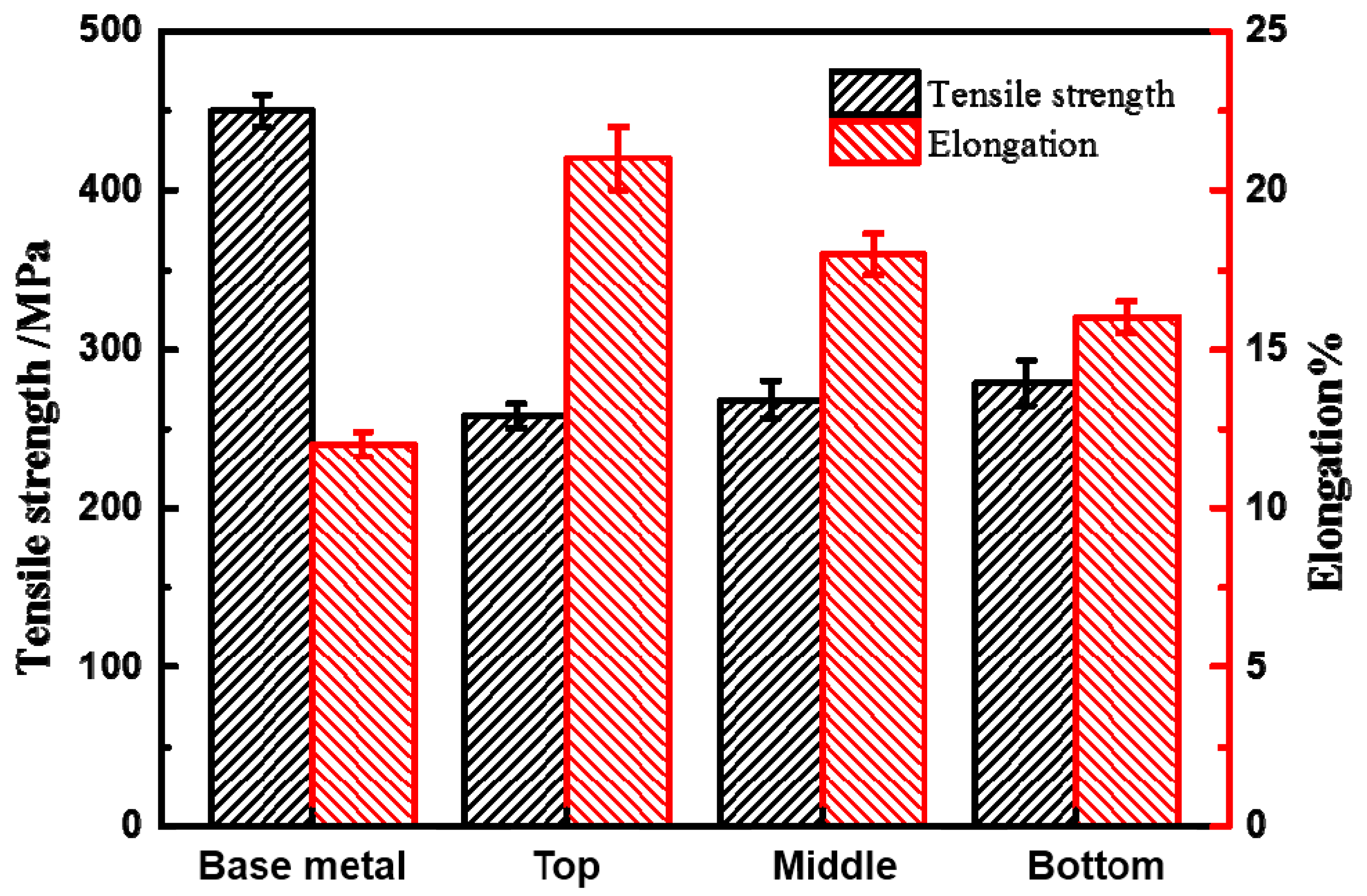

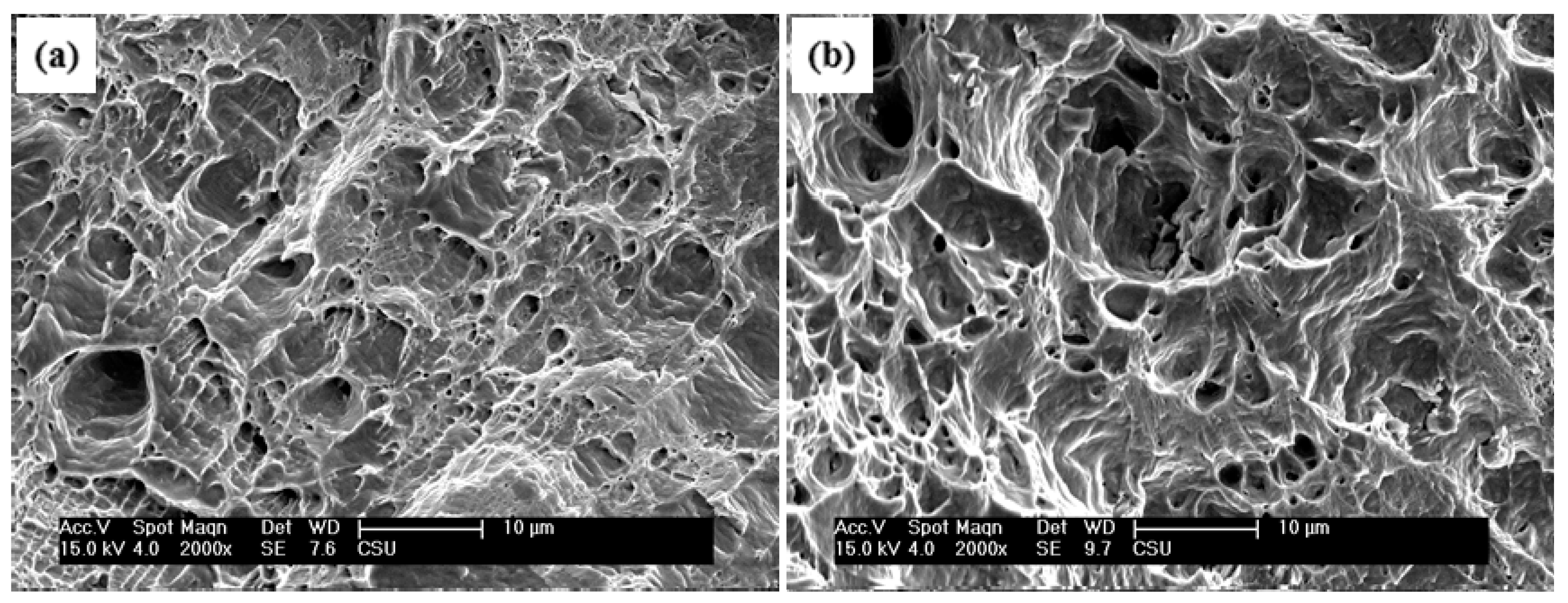

3.2.2. Tensile Strength

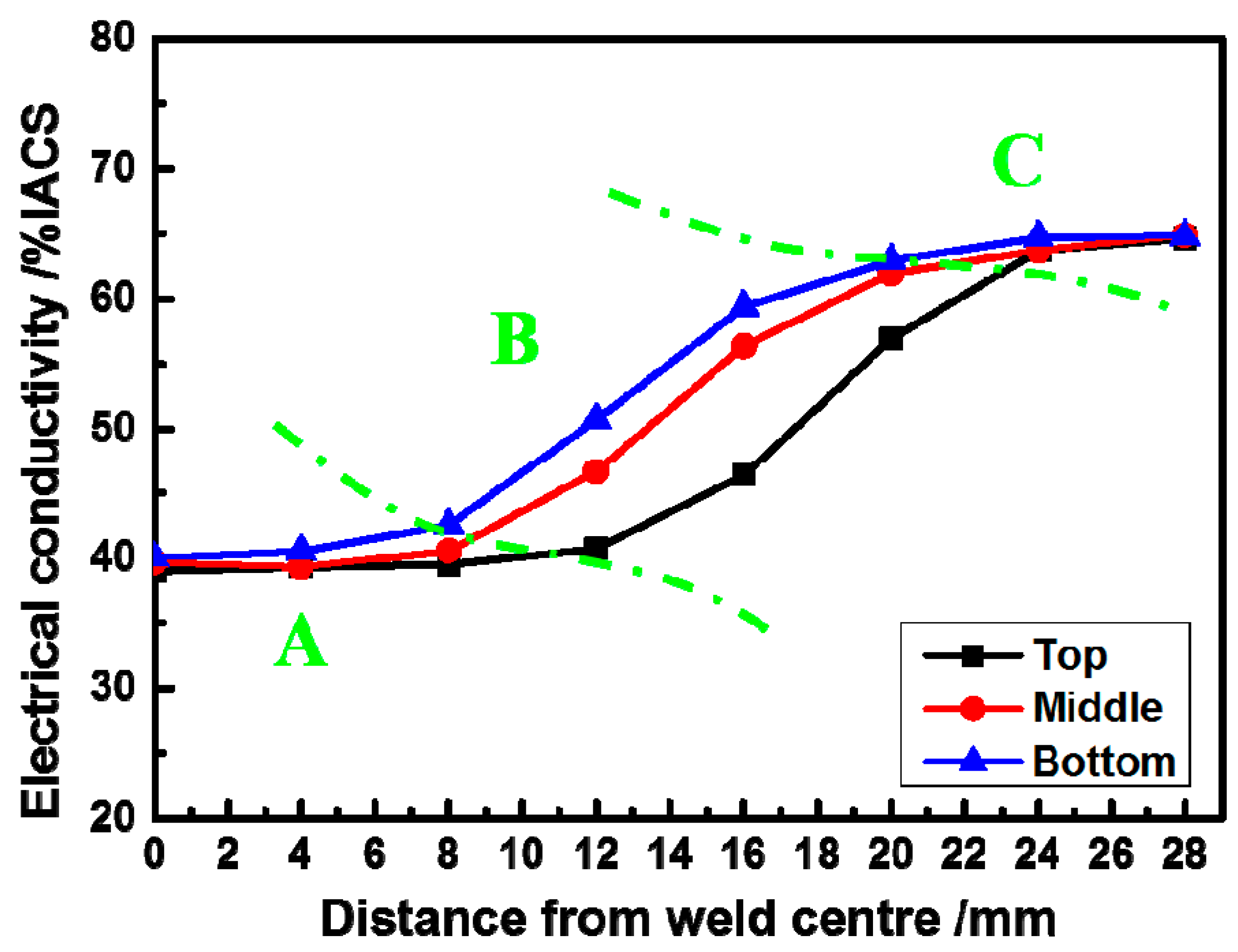

3.2.3. Electrical Conductivity

4. Conclusions

- The weld zone that is defect-free is formed in the condition of 1500 rpm and 150 mm/min. The microstructure near the weld zone is very different from that of the base metal. HAZ is characterized by some newly formed grains around the large grains. TMAZ is characterized by a highly deformed structure with an upward flowing pattern, and the fine and equaxed grain structure is apparently found in the NZ.

- The strengthening precipitates with a range of 2 nm–5 nm in diameter are coherently exhibited with the Cu matrix in the BM. After FSW, however, all the nano-strengthening precipitates are dissolved into the Cu matrix in the NZ. Also, the grains’ size is significantly refined owing to the occurrence of DRX. The coarse chromium-rich particles are crushed into finer ones, which distribute more uniformly in the NZ.

- Along the thickness direction, the microstructure distribution is inhomogeneous and the size of the equiaxed grains in the NZ is decreased gradually from the top to the bottom area of the welds because of the distinctive heat production and the heat dissipation on the welding joint. That led to the micro-hardness and tensile strength of the welds, which are slightly increased from the top to the bottom area of the welds.

- Decreases in hardness, tensile strength, and electrical conductivity are detected in the welded NZ, which result from the comprehensive effect of the dissolution of the nano-strengthening precipitates into the supersaturation matrix and severe DRX.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Davis, J.W.; Kalinin, G.M. Material properties and design requirements for copper alloys used in ITER. J. Nucl. Mater. 1998, 258–263, 323–328. [Google Scholar] [CrossRef]

- Correia, J.B.; Davies, H.A.; Sellars, C.M. Strengthening in rapidly solidified age hardened Cu-Cr and Cu-Cr-Zr alloys. Acta Mater. 1997, 45, 177–190. [Google Scholar] [CrossRef]

- Batra, I.; Dey, G.; Kulkarni, U.; Banerjee, S. Microstructure and properties of a Cu–Cr–Zr alloy. J. Nucl. Mater. 2001, 299, 91–100. [Google Scholar] [CrossRef]

- Zhang, D.; Mihara, K.; Tsubokawa, S.; Suzuki, H. Precipitation characteristics of Cu–15Cr–015Zr in situ composite. Mater. Sci. Technol. 2000, 16, 357–363. [Google Scholar] [CrossRef]

- Sakthivel, T.; Mukhopadhyay, J. Microstructure and mechanical properties of friction stir welded copper. J. Mater. Sci. 2007, 42, 8126–8129. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Lee, W.-B.; Jung, S.-B. The joint properties of copper by friction stir welding. Mater. Lett. 2004, 58, 1041–1046. [Google Scholar] [CrossRef]

- Durocher, A.; Ayrault, D.; Chagnot, C.; Lipa, M.; Saikaly, W. CuCrZr alloy hot cracking during electron beam welding. J. Nucl. Mater. 2007, 367, 1208–1212. [Google Scholar] [CrossRef]

- Durocher, A.; Lipa, M.; Chappuis, P.; Schlosser, J.; Huber, T.; Schedler, B. TORE SUPRA experience of copper chromium zirconium electron beam welding. J. Nucl. Mater. 2002, 307, 1554–1557. [Google Scholar] [CrossRef]

- Drezet, J.; Ayrault, D.; Wisniewski, J.; Barras, M.; Pilvin, P.; Carron, D.; Primaux, F. Hot tearing susceptibility of a CuCrZr alloy during electron beam welding. Mater. Tech. 2010, 98, 287–296. [Google Scholar] [CrossRef]

- Gogari, H.J. Materials Characterization of Electron Beam Welded CuCrZr Joint for ITER High Heat Flux Component. Ph.D. Thesis, Institute for Plasma Research, Gandhinagar, India, May 2014. [Google Scholar]

- Feng, H.; Jiang, H.; Yan, D.; Rong, L. Microstructure and Mechanical Properties of a CuCrZr Welding Joint After Continuous Extrusion. J. Mater. Sci. Technol. 2015, 31, 210–216. [Google Scholar] [CrossRef]

- Kanigalpula, P.; Chatterjee, A.; Pratihar, D.; Jha, M.; Derose, J. Effects of Electron Beam Welding on Microstructure, Microhardness, and Electrical Conductivity of Cu-Cr-Zr Alloy Plates. J. Mater. Eng. Perform. 2015, 24, 4681–4690. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.; Needham, J.; Murch, M.; Temple-Smith, P.; Dawes, C. Improvements Relating to Friction Welding. Patent EP 0,653,265, 17 May 1995. [Google Scholar]

- Liu, H.; Shen, J.; Huang, Y.; Kuang, L.; Liu, C.; Li, C. Effect of tool rotation rate on microstructure and mechanical properties of friction stir welded copper. Sci. Technol. Weld. Join. 2009, 14, 577–583. [Google Scholar] [CrossRef]

- Xie, G.; Ma, Z.; Geng, L. Development of a fine-grained microstructure and the properties of a nugget zone in friction stir welded pure copper. Scr. Mater. 2007, 57, 73–76. [Google Scholar] [CrossRef]

- Nakata, K. Friction stir welding of copper and copper alloys. Weld. Int. 2005, 19, 929–933. [Google Scholar] [CrossRef]

- Celik, S.; Cakir, R. Effect of friction stir welding parameters on the mechanical and microstructure properties of the Al-Cu butt joint. Metals 2016, 6, 133. [Google Scholar] [CrossRef]

- Källgren, T. Friction Stir Welding of Copper Canisters for Nuclear Waste. Ph.D. Thesis, KTH, Stockholm, Sweden, July 2005. [Google Scholar]

- Cederqvist, L.; Garpinger, O.; Hägglund, T.; Robertsson, A. Cascade control of the friction stir welding process to seal canisters for spent nuclear fuel. Control Eng. Pract. 2012, 20, 35–48. [Google Scholar] [CrossRef]

- Mei, Z.; Guobiao, L.; Zidong, W.; Maokui, Z. Analysis of precipitation in a Cu-Cr-Zr alloy. Res. Dev. 2008, 5, 268–271. [Google Scholar]

- Deng, J.Q.; Zhang, X.Q.; Shang, S.Z.; Zhao, Z.X.; Ye, Y.F. Deformation Processing and Mechanical Properties of Cu-10Cr-0.4Zr In Situ Composite Microwires. Mater. Sci. Forum Trans. Tech. Publ. 2011, 682, 89–95. [Google Scholar] [CrossRef]

- Mahoney, M.; Rhodes, C.; Flintoff, J.; Bingel, W.; Spurling, R. Properties of friction-stir-welded 7075 T651 aluminum. Metall. Mater. Trans. A 1998, 29, 1955–1964. [Google Scholar] [CrossRef]

- Ma, Z.; Mishra, R.S.; Mahoney, M.W. Superplastic deformation behaviour of friction stir processed 7075Al alloy. Acta Mater. 2002, 50, 4419–4430. [Google Scholar] [CrossRef]

- Rhodes, C.; Mahoney, M.; Bingel, W.; Spurling, R.; Bampton, C. Effects of friction stir welding on microstructure of 7075 aluminum. Scr. Mater. 1997, 36, 69–75. [Google Scholar] [CrossRef]

- Li, Y.; Murr, L.; McClure, J. Flow visualization and residual microstructures associated with the friction-stir welding of 2024 aluminum to 6061 aluminum. Mater. Sci. Eng. A 1999, 271, 213–223. [Google Scholar] [CrossRef]

- Kwon, Y.; Saito, N.; Shigematsu, I. Friction stir process as a new manufacturing technique of ultrafine grained aluminum alloy. J. Mater. Sci. Lett. 2002, 21, 1473–1476. [Google Scholar] [CrossRef]

- Tang, W.; Guo, X.; McClure, J.; Murr, L.; Nunes, A. Heat input and temperature distribution in friction stir welding. J. Mater. Process. Manuf. Sci. 1998, 7, 163–172. [Google Scholar] [CrossRef]

- Abdollah-Zadeh, A.; Saeid, T.; Sazgari, B. Microstructural and mechanical properties of friction stir welded aluminum/copper lap joints. J. Alloys Compd. 2008, 460, 535–538. [Google Scholar] [CrossRef]

- Heinz, B.; Skrotzki, B. Characterization of a friction-stir-welded aluminum alloy 6013. Metall. Mater. Trans. B 2002, 33, 489–498. [Google Scholar] [CrossRef]

- Murr, L.; Liu, G.; McClure, J. Dynamic recrystallization in friction-stir welding of aluminium alloy 1100. J. Mater. Sci. Lett. 1997, 16, 1801–1803. [Google Scholar] [CrossRef]

- Sato, Y.S.; Park, S.H.C.; Kokawa, H. Microstructural factors governing hardness in friction-stir welds of solid-solution-hardened Al alloys. Metall. Mater. Trans. A 2001, 32, 3033–3042. [Google Scholar] [CrossRef]

- Salem, H.G.; Reynolds, A.P.; Lyons, J.S. Microstructure and retention of superplasticity of friction stir welded superplastic 2095 sheet. Scr. Mater. 2002, 46, 337–342. [Google Scholar] [CrossRef]

- Su, J.-Q.; Nelson, T.; Mishra, R.; Mahoney, M. Microstructural investigation of friction stir welded 7050-T651 aluminium. Acta Mater. 2003, 51, 713–729. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S.; Mahoney, M.W. Multi-sheet structures in 7475 aluminum by friction stir welding in concert with post-weld superplastic forming. Scr. Mater. 2002, 47, 631–636. [Google Scholar] [CrossRef]

- Ma, Z.; Mishra, R.S.; Mahoney, M.W.; Grimes, R. High strain rate superplasticity in friction stir processed Al–Mg–Zr alloy. Mater. Sci. Eng. A 2003, 351, 148–153. [Google Scholar] [CrossRef]

- Saeid, T.; Abdollah-Zadeh, A.; Sazgari, B. Weldability and mechanical properties of dissimilar aluminum–copper lap joints made by friction stir welding. J. Alloys Compd. 2010, 490, 652–655. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T. Prediction of mechanical properties in friction stir welds of pure copper. Mater. Des. 2013, 52, 1077–1087. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural evolution of 6063 aluminum during friction-stir welding. Metall. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Liu, G.; Murr, L.; Niou, C.; McClure, J.; Vega, F. Microstructural aspects of the friction-stir welding of 6061-T6 aluminum. Scr. Mater. 1997, 37, 355–361. [Google Scholar] [CrossRef]

- Jata, K.; Sankaran, K.; Ruschau, J. Friction-stir welding effects on microstructure and fatigue of aluminum alloy 7050-T7451. Metall. Mater. Trans. A 2000, 31, 2181–2192. [Google Scholar] [CrossRef]

- Chang, C.; Lee, C.; Huang, J. Relationship between grain size and Zener–Holloman parameter during friction stir processing in AZ31 Mg alloys. Scr. Mater. 2004, 51, 509–514. [Google Scholar] [CrossRef]

- Balcerek, K.; Marucha, C.; Rafalowicz, J.; Wawryk, R. Deviation from matthiessen’s rule for thermal conductivity of quenched Zn-doped Cd crystals in the temperature range 5–20 K. Int. J. Thermophys. 1993, 14, 1229–1234. [Google Scholar] [CrossRef]

- Xie, H.; Mi, X.; Huang, G.; Gao, B.; Yin, X.; Li, Y. Effect of thermomechanical treatment on microstructure and properties of Cu-Cr-Zr-Ag alloy. Rare Met. 2011, 30, 650–656. [Google Scholar] [CrossRef]

| Cu | Cr | Zr | Al | Mg | Fe | Si | Pb |

|---|---|---|---|---|---|---|---|

| Bal. | 0.8 | 0.3 | 0.25 | 0.1 | 0.09 | 0.04 | 0.02 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lai, R.; He, D.; He, G.; Lin, J.; Sun, Y. Study of the Microstructure Evolution and Properties Response of a Friction-Stir-Welded Copper-Chromium-Zirconium Alloy. Metals 2017, 7, 381. https://doi.org/10.3390/met7090381

Lai R, He D, He G, Lin J, Sun Y. Study of the Microstructure Evolution and Properties Response of a Friction-Stir-Welded Copper-Chromium-Zirconium Alloy. Metals. 2017; 7(9):381. https://doi.org/10.3390/met7090381

Chicago/Turabian StyleLai, Ruilin, Diqiu He, Guoai He, Junyuan Lin, and Youqing Sun. 2017. "Study of the Microstructure Evolution and Properties Response of a Friction-Stir-Welded Copper-Chromium-Zirconium Alloy" Metals 7, no. 9: 381. https://doi.org/10.3390/met7090381