High Field X-ray Diffraction Study for Ni46.4Mn38.8In12.8Co2.0 Metamagnetic Shape Memory Film

Abstract

:1. Introduction

2. Materials and Methods

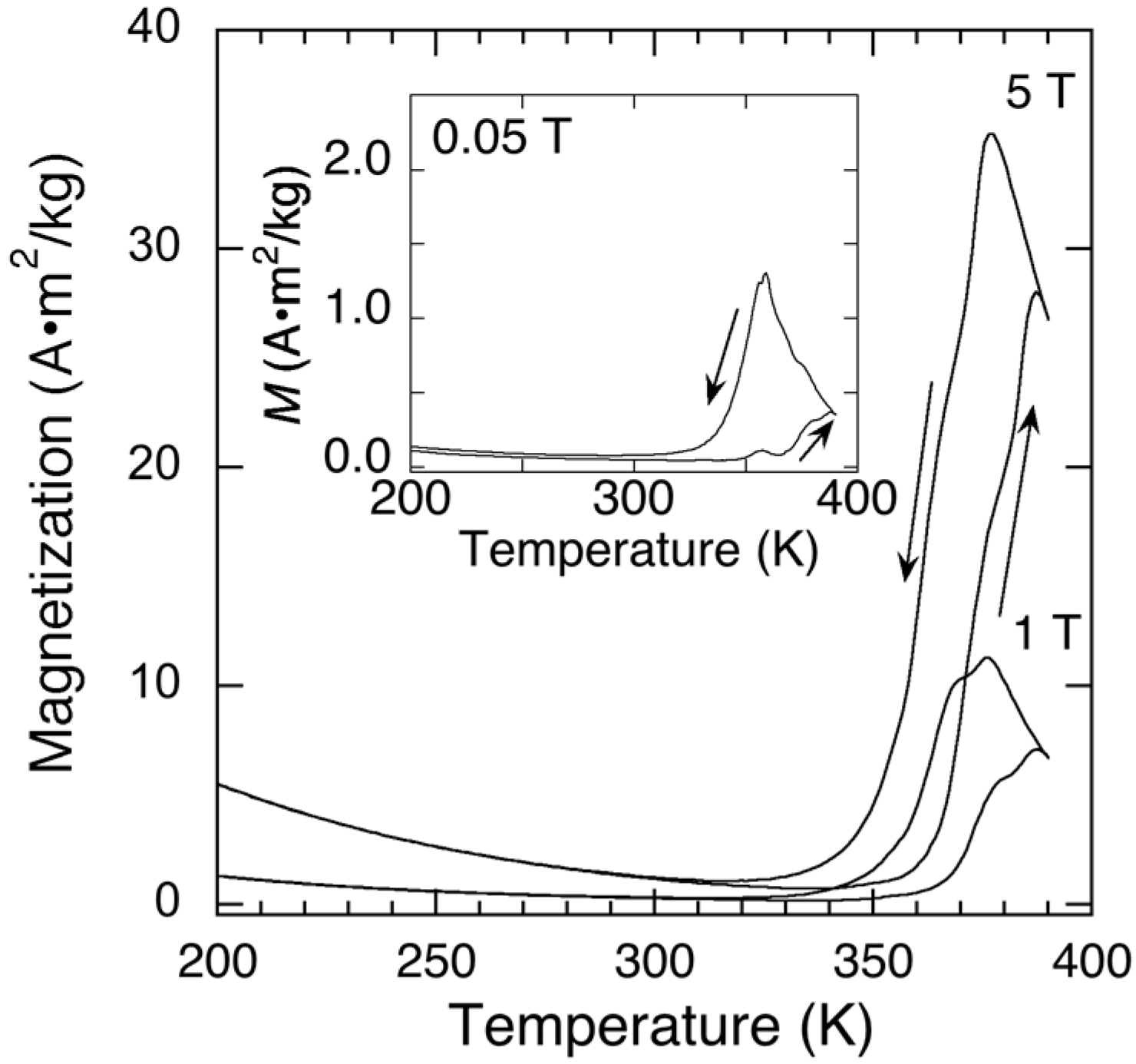

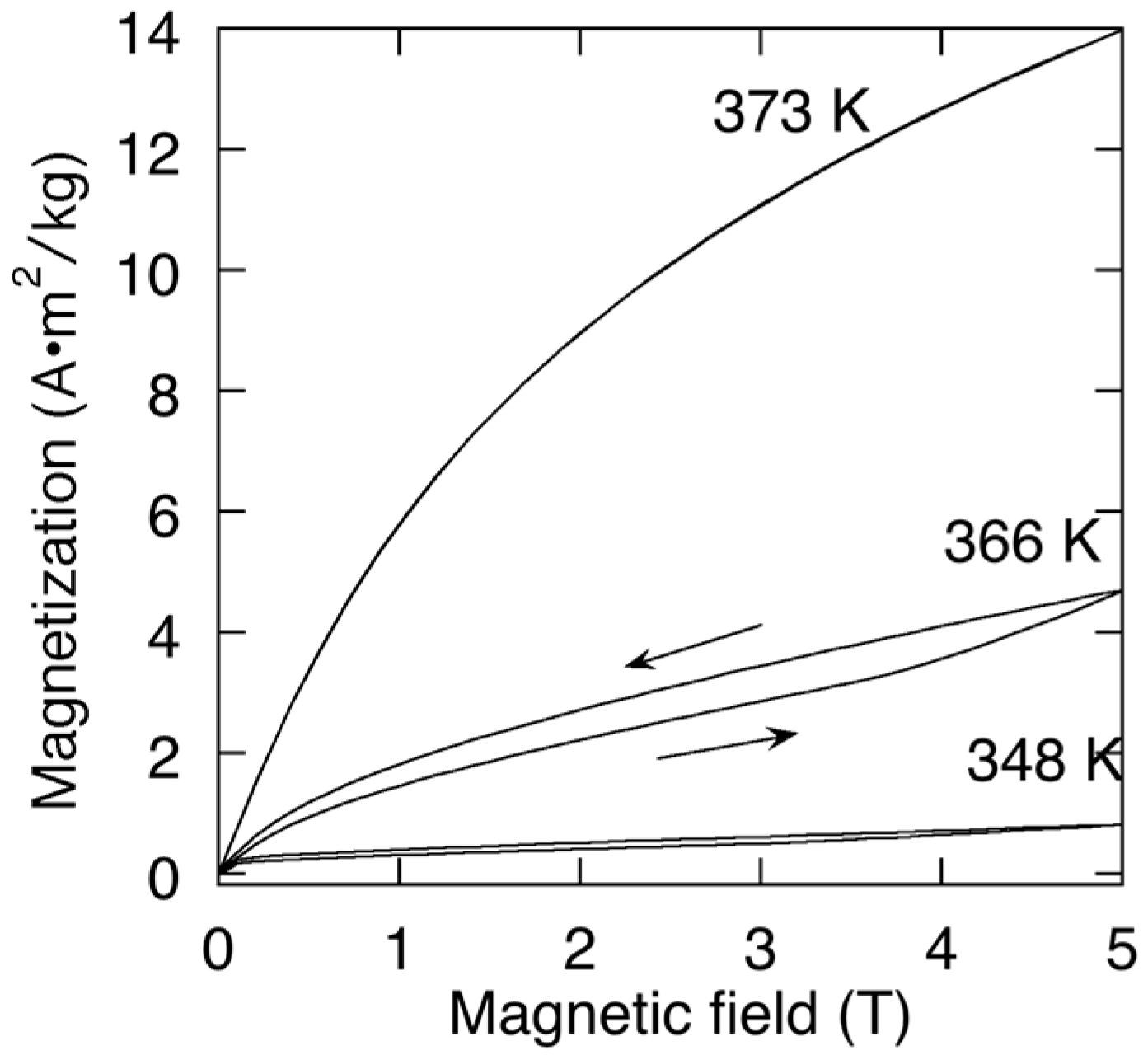

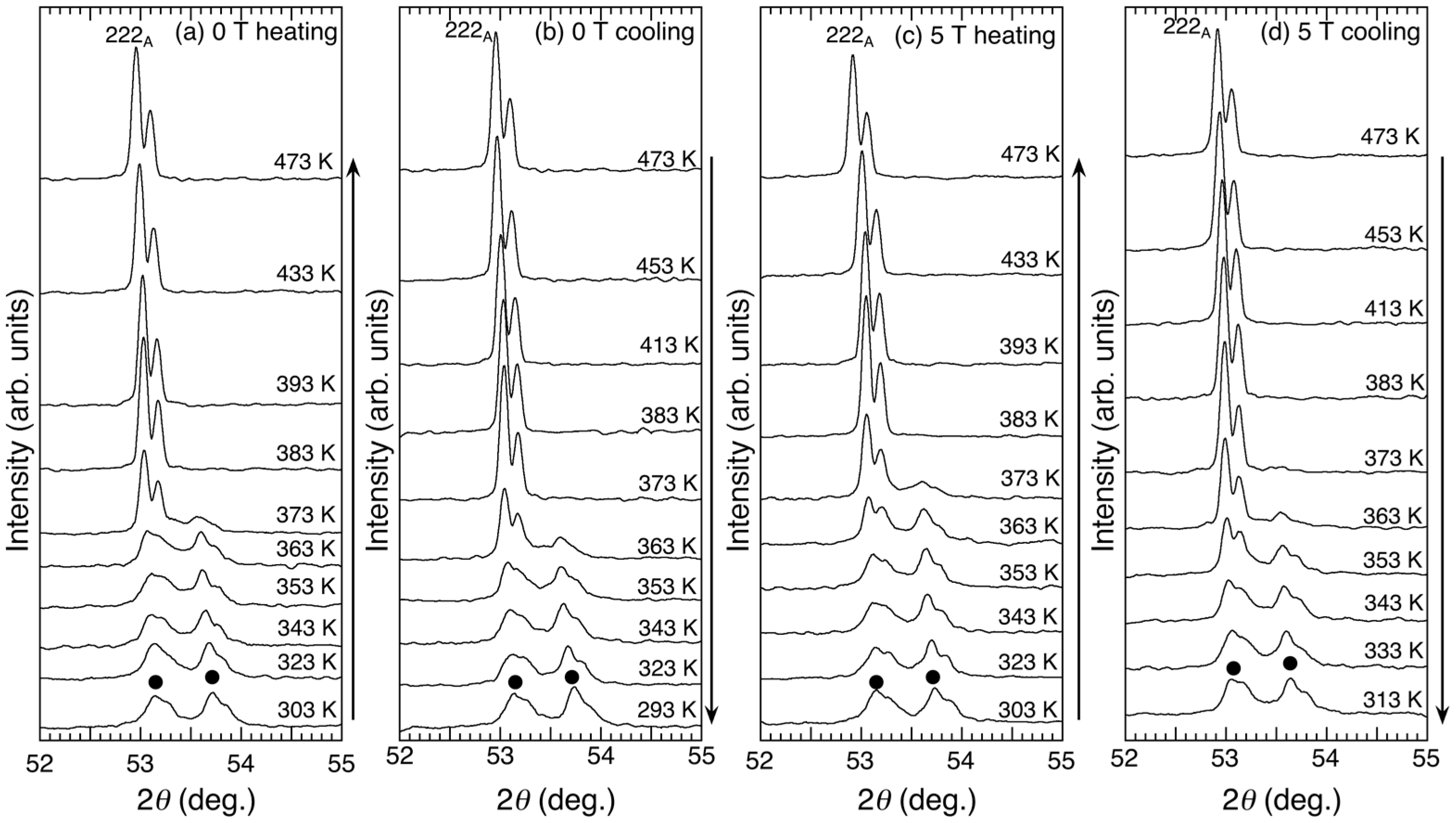

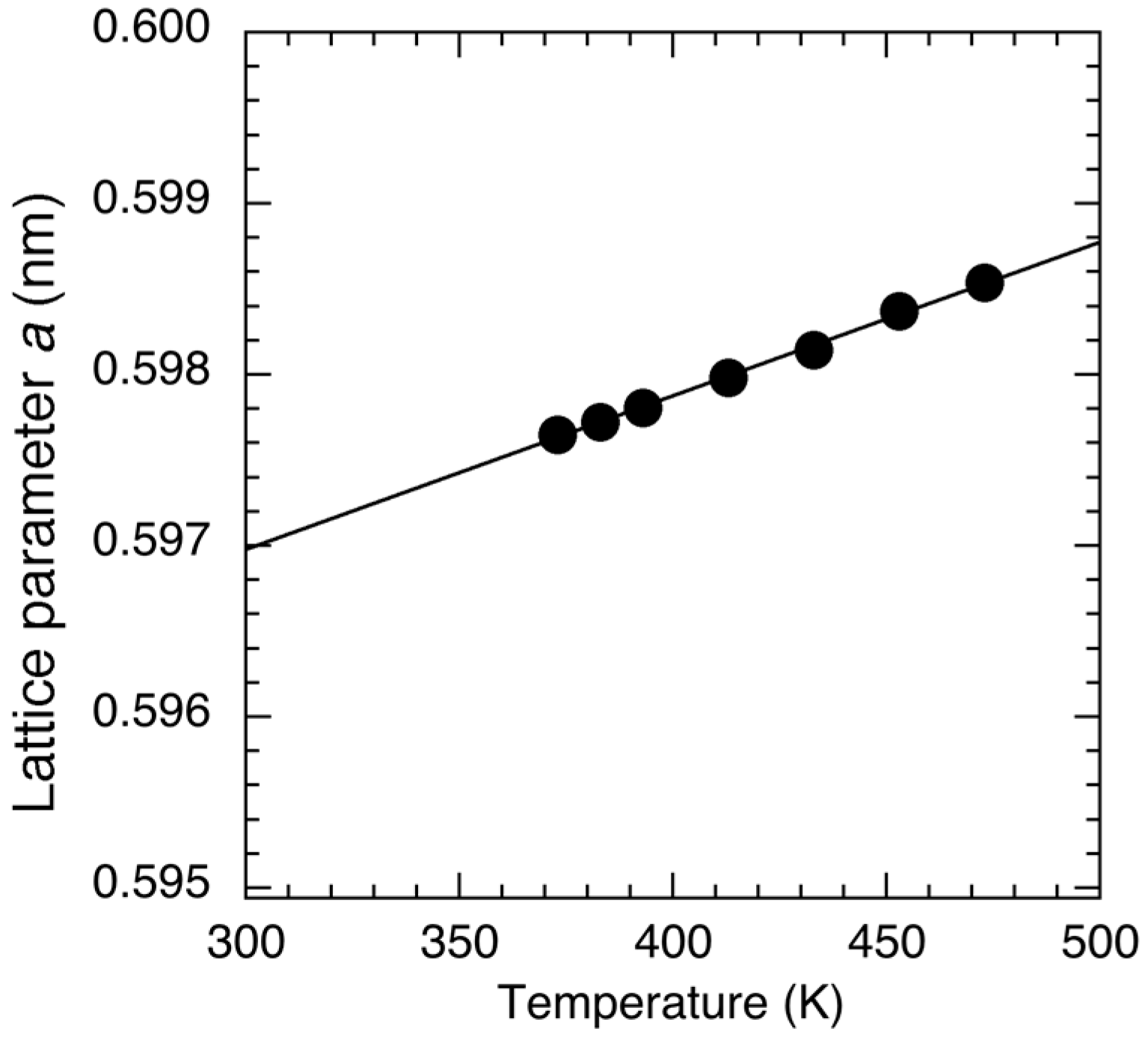

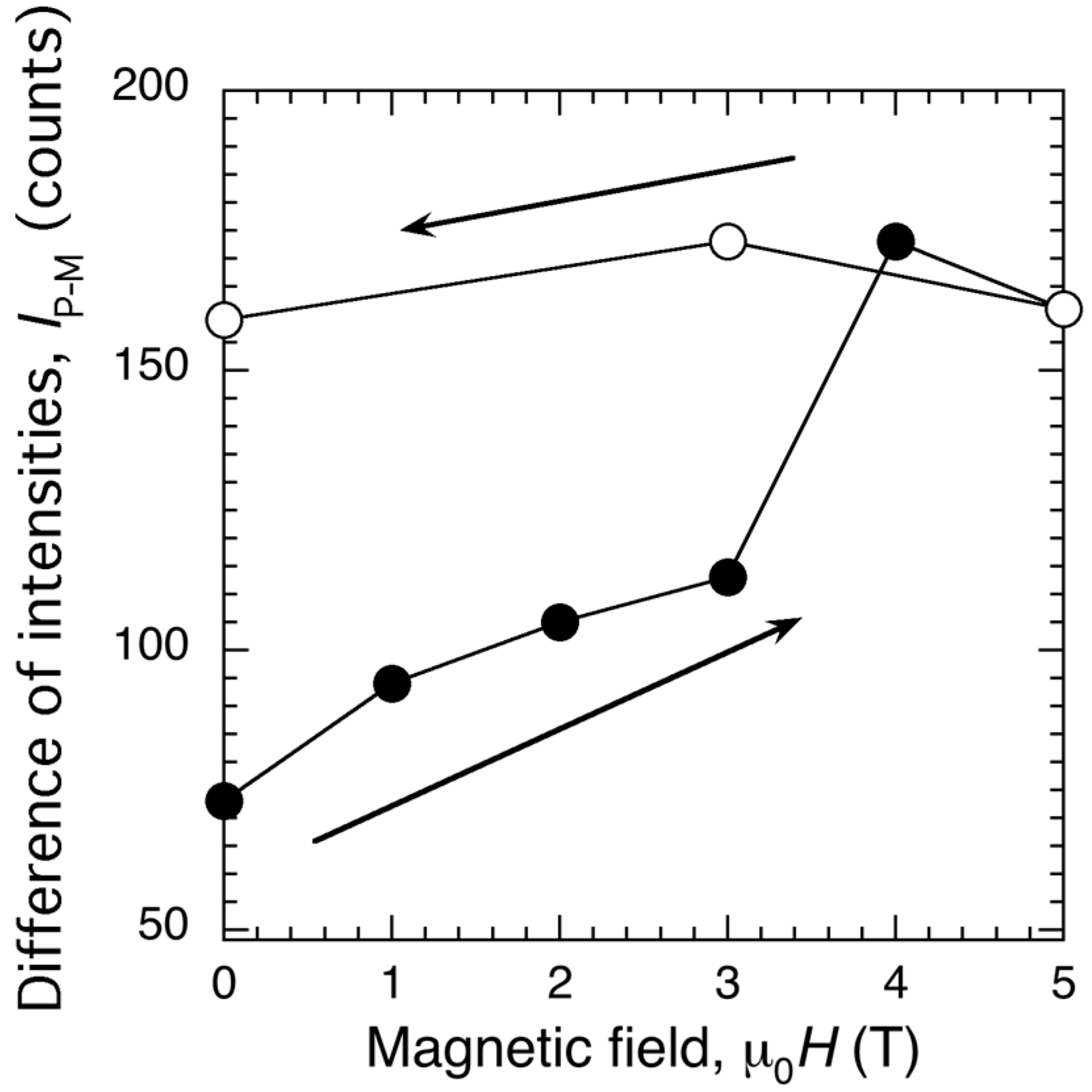

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in Ni2MnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kokorin, V.V.; O’Handley, R.C. Magnetically controlled shape memory effect in Ni2MnGa intermetallics. Scr. Mater. 1997, 36, 1133–1138. [Google Scholar] [CrossRef]

- Vasil’ev, A.N.; Bozhko, A.D.; Khvailo, V.V.; Dikshtein, I.E.; Shavrov, V.G.; Buchelnikov, V.D.; Matsumoto, M.; Suzuki, S.; Takagi, T.; Tani, J. Structural and magnetic phase transitions in shape-memory alloys Ni2+xMn1-xGa. Phys. Rev. B 1999, 59, 1113–1120. [Google Scholar] [CrossRef]

- Xu, X.; Nagasako, M.; Ito, W.; Umetsu, R.Y.; Kanomata, T.; Kainuma, R. Magnetic properties and phase diagram of Ni50Mn50-xGax ferromagnetic shape memory alloys. Acta Mater. 2013, 61, 6712–6723. [Google Scholar] [CrossRef]

- Sutou, Y.; Imano, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K.; Oikawa, K. Magnetic and martensitic transformation of NiMnX (X = In, Sn, Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 2004, 85, 4358–4360. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Kanomata, T.; Tanaka, T.; Nakashima, M.; Amako, Y.; Kainuma, R.; Umetsu, R.Y.; Morito, H.; Miki, H. Magnetic properties of Ni50Mn34.8In15.2 probed by Mössbauer spectroscopy. Phys. Rev. B 2009, 80, 144409. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Sano, K.; Fukushima, K.; Kanomata, T.; Taniguchi, Y.; Amako, Y.; Kainuma, R. Mössbauer spectroscopy studies on magnetic properties for 57Fe-substituted Ni-Mn-Sn metamagnetic shape memory alloys. Metals 2013, 3, 225–236. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Kainuma, R.; Imano, Y.; Ito, W.; Morito, H.; Sutou, Y.; Oikawa, K.; Fujita, A.; Ishida, K.; Okamoto, S.; Kitakami, O.; et al. Metamagnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy. Appl. Phys. Lett. 2006, 88, 192513. [Google Scholar] [CrossRef]

- Ito, W.; Imano, Y.; Kainuma, R.; Sutou, Y.; Oikawa, K.; Ishida, K. Martensitic and Magnetic transformation behaviors in Heusler-Type NiMnIn and NiCoMnIn metamagnetic shape memory alloys. Metall. Mater. Trans. A 2007, 38A, 759–766. [Google Scholar] [CrossRef]

- Wang, Y.D.; Ren, Y.; Huang, E.W.; Nie, Z.H.; Wang, G. Direct evidence on magnetic-field-induced phase transition in a NiCoMnIn ferromagnetic shape memory alloy under a stress field. Appl. Phys. Lett. 2007, 90, 101917. [Google Scholar] [CrossRef]

- Kohl, M.; Brugger, D.; Ohtsuka, M.; Takagi, T. A novel actuation mechanism on the basis of ferromagnetic SMA thin films. Sens. Actuators A 2004, 114, 445–450. [Google Scholar] [CrossRef]

- Kohl, M.; Krevet, B.; Ohtsuka, M.; Brugger, D.; Liu, Y. Ferromagnetic shape memory actuators. Mater. Trans. 2006, 47, 639–644. [Google Scholar]

- Rumpf, H.; Craciunescu, C.M.; Modrow, H.; Olimov, H.M.; Quandt, E.; Wuttig, M. Successive occurrence of ferromagnetic and shape memory properties during crystallization of NiMnGa freestanding films. J. Magn. Magn. Mater. 2006, 302, 421–428. [Google Scholar] [CrossRef]

- Liu, J.; Scheerbaum, N.; Hinz, D.; Gutfleisch, O. Magnetostructural transformation in Ni-Mn-In-Co ribbons. Appl. Phys. Lett. 2008, 92, 162509. [Google Scholar] [CrossRef]

- Rios, S.; Karaman, I.; Zhang, X. Crystallization and high temperature shape memory behavior of sputter-deposited NiMnCoIn thin films. Appl. Phys. Lett. 2010, 96, 173102. [Google Scholar] [CrossRef]

- Gueltig, M.; Ossmer, H.; Ohtsuka, M.; Miki, H.; Tsuchiya, K.; Takagi, T.; Kohl, M. High frequency thermal energy harvesting using magnetic shape memory films. Adv. Energy Mater. 2014, 4, 1400751. [Google Scholar] [CrossRef]

- Miki, H.; Tsuchiya, K.; Ohtsuka, M.; Gueltig, M.; Kohl, M.; Takagi, T. Structural and magnetic properties of magnetic shape memory alloys on Ni-Mn-Co-In self-standing films. In Advances in Shape Memory Materials; Springer: Basel, Switzerland, 2017; Volume 73, pp. 149–160. [Google Scholar]

- Pecharsky, V.K.; Holm, A.P.; Gschneider, K.A., Jr.; Rink, R. Massive magnetic-field-induced structural transformation in Gd5Ge4 and the nature of the giant magnetocaloric effect. Phys. Rev. Lett. 2003, 91, 197204. [Google Scholar] [CrossRef] [PubMed]

- Fujita, A.; Fukamichi, K.; Koyama, K.; Watanabe, K. X-ray diffraction study in high magnetic fields of magnetovolume effect in itinerant-electron metamagnetic La(Fe0.88Si0.12)13 compound. J. Appl. Phys. 2004, 95, 6687–6689. [Google Scholar] [CrossRef]

- Koyama, K.; Kanomata, T.; Matsukawa, T.; Watanabe, K. Magnetic field effect on structural property of MnFeP0.5As0.5. Mater. Trans. 2005, 46, 1753–1756. [Google Scholar] [CrossRef]

- Ma, Y.; Awaji, S.; Watanabe, K.; Matsumoto, M.; Kobayashi, N. Effect of high magnetic field on the two-step martensitic-phase transition in Ni2MnGa. Appl. Phys. Lett. 2000, 76, 37–39. [Google Scholar] [CrossRef]

- Koyama, K.; Watanabe, K.; Kanomata, T.; Kainuma, R.; Oikawa, K.; Ishida, K. Observation of field-induced reverse transformation in ferromagnetic shape memory alloy Ni50Mn36Sn14. Appl. Phys. Lett. 2006, 88, 132505. [Google Scholar] [CrossRef]

- Ito, W.; Ito, K.; Umetsu, R.Y.; Kainuma, R.; Koyama, K.; Watanabe, K.; Fujita, A.; Oikawa, K.; Ishida, K.; Kanomata, T. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett. 2008, 92, 021908. [Google Scholar] [CrossRef]

- Mitsui, Y.; Koyama, K.; Watanabe, K. X-ray diffraction measurements in high magnetic fields and at high temperatures. Sci. Technol. Adv. Mater. 2009, 9, 014612. [Google Scholar] [CrossRef] [PubMed]

- Mitsui, Y.; Koyama, K.; Ito, W.; Umetsu, R.Y.; Kainuma, R.; Watanabe, K. Observation of reverse transformation in metamagnetic shape memory alloy Ni40Co10Mn34Al16 by high-field X-Ray diffraction measurements. Mater. Trans. 2010, 51, 1648–1650. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mitsui, Y.; Koyama, K.; Ohtsuka, M.; Umetsu, R.Y.; Kainuma, R.; Watanabe, K. High Field X-ray Diffraction Study for Ni46.4Mn38.8In12.8Co2.0 Metamagnetic Shape Memory Film. Metals 2017, 7, 364. https://doi.org/10.3390/met7090364

Mitsui Y, Koyama K, Ohtsuka M, Umetsu RY, Kainuma R, Watanabe K. High Field X-ray Diffraction Study for Ni46.4Mn38.8In12.8Co2.0 Metamagnetic Shape Memory Film. Metals. 2017; 7(9):364. https://doi.org/10.3390/met7090364

Chicago/Turabian StyleMitsui, Yoshifuru, Keiichi Koyama, Makoto Ohtsuka, Rie Y. Umetsu, Ryosuke Kainuma, and Kazuo Watanabe. 2017. "High Field X-ray Diffraction Study for Ni46.4Mn38.8In12.8Co2.0 Metamagnetic Shape Memory Film" Metals 7, no. 9: 364. https://doi.org/10.3390/met7090364