Comparative Investigation of Tungsten Fibre Nets Reinforced Tungsten Composite Fabricated by Three Different Methods

Abstract

:1. Introduction

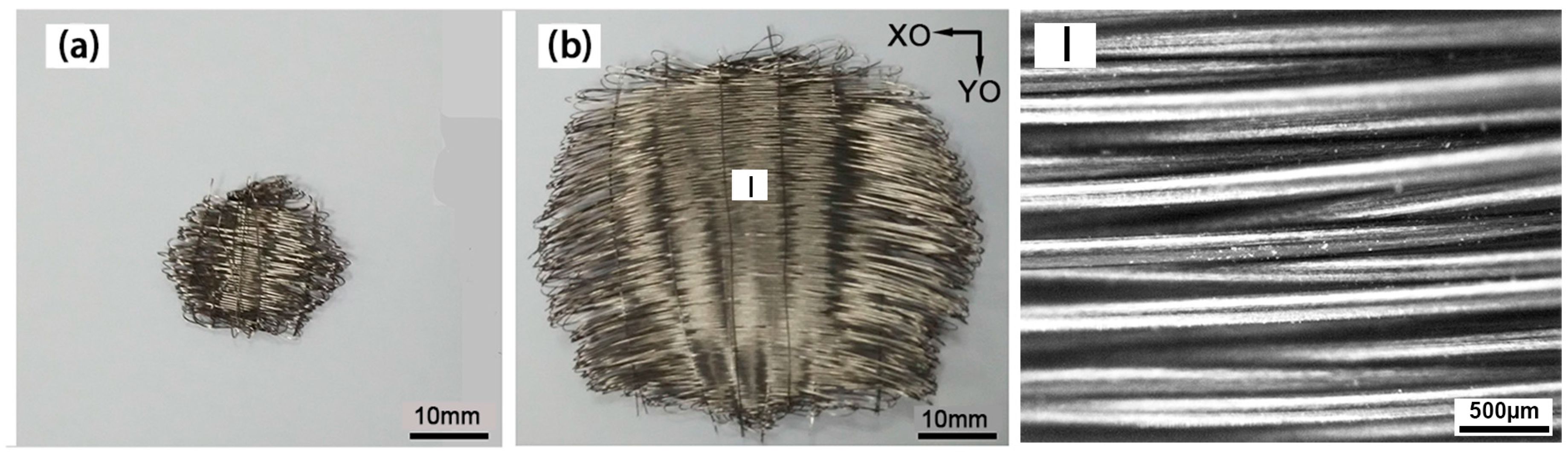

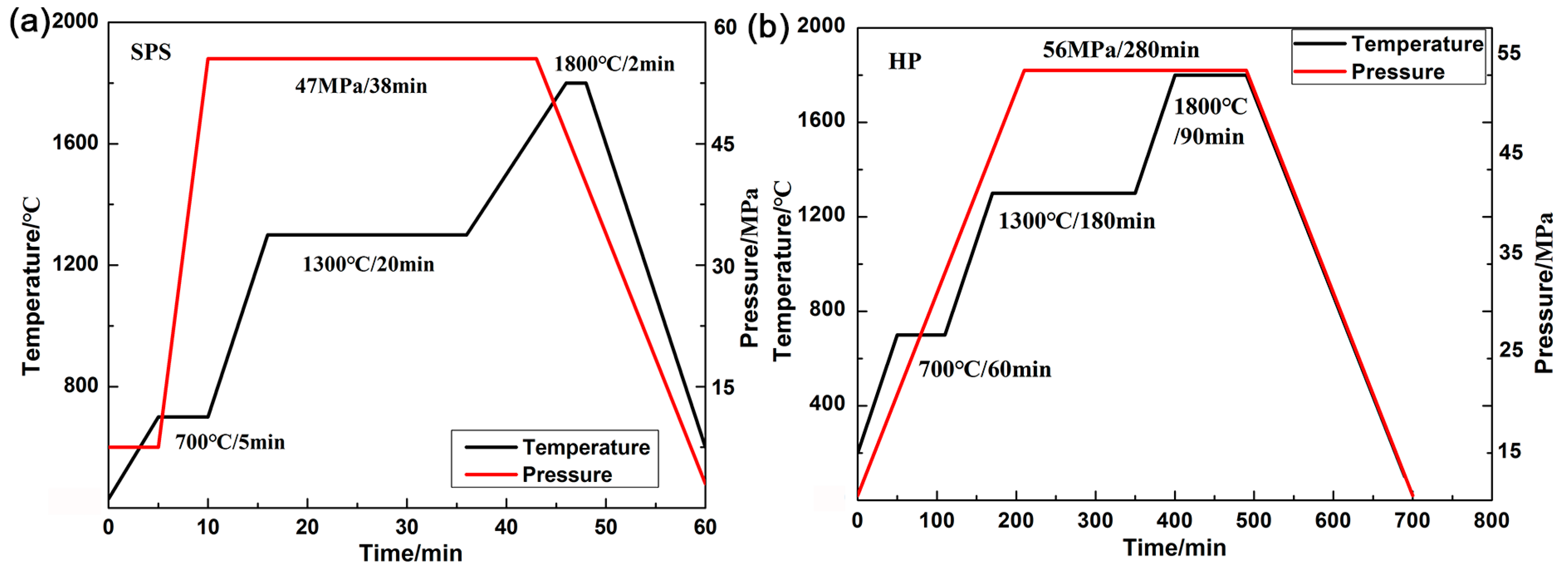

2. Experimental Section

2.1. Preparation and Characterization

2.2. Testing Procedure

3. Results and Discussion

3.1. Density and Vickers Hardness

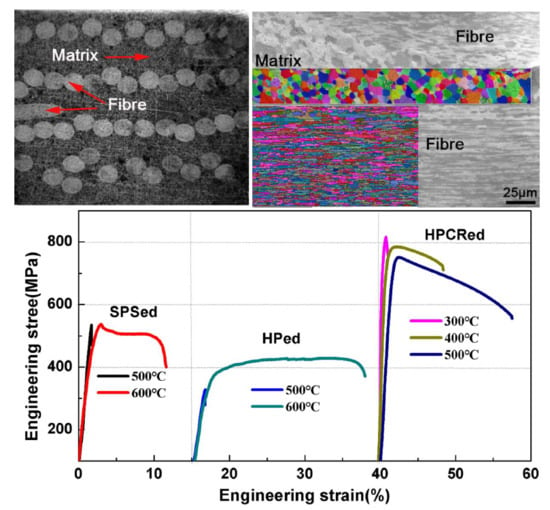

3.2. Distribution of Fibres

3.3. Microstructure of the Original and Sintered Fibres

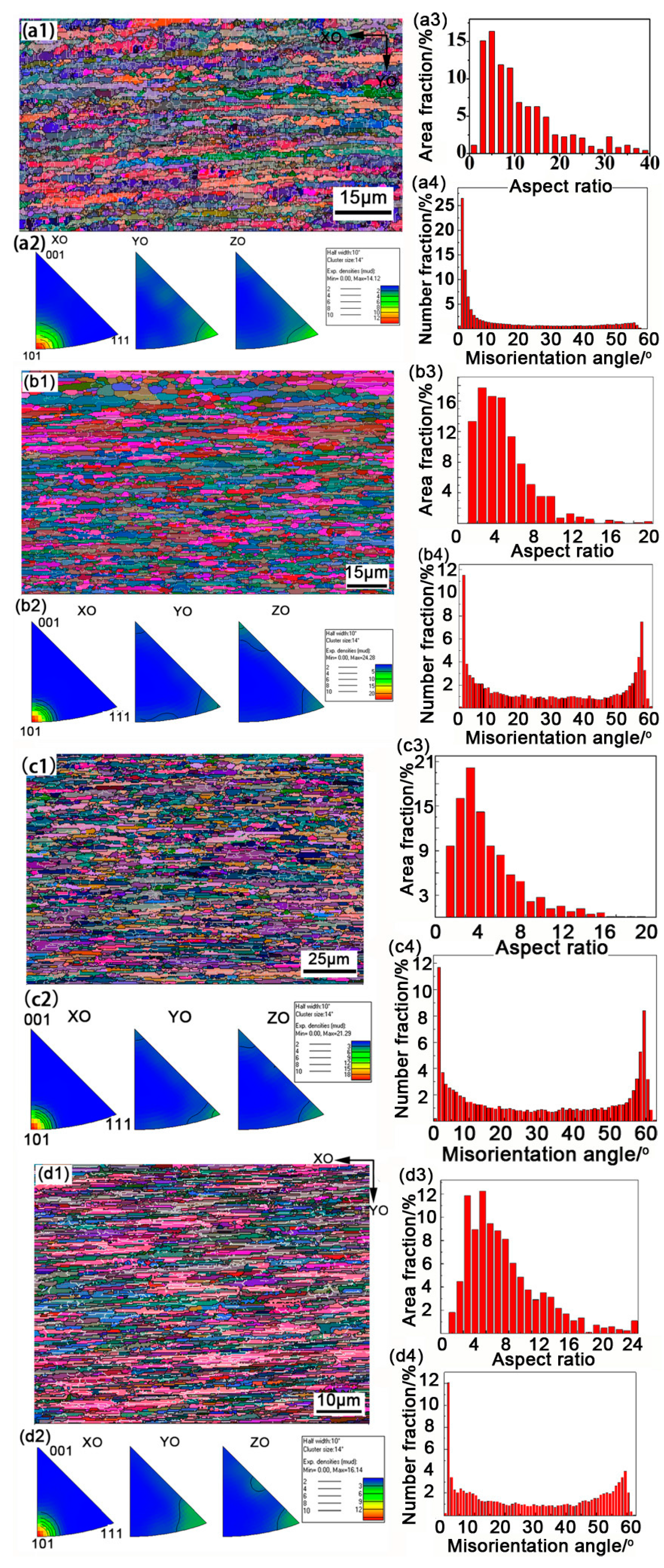

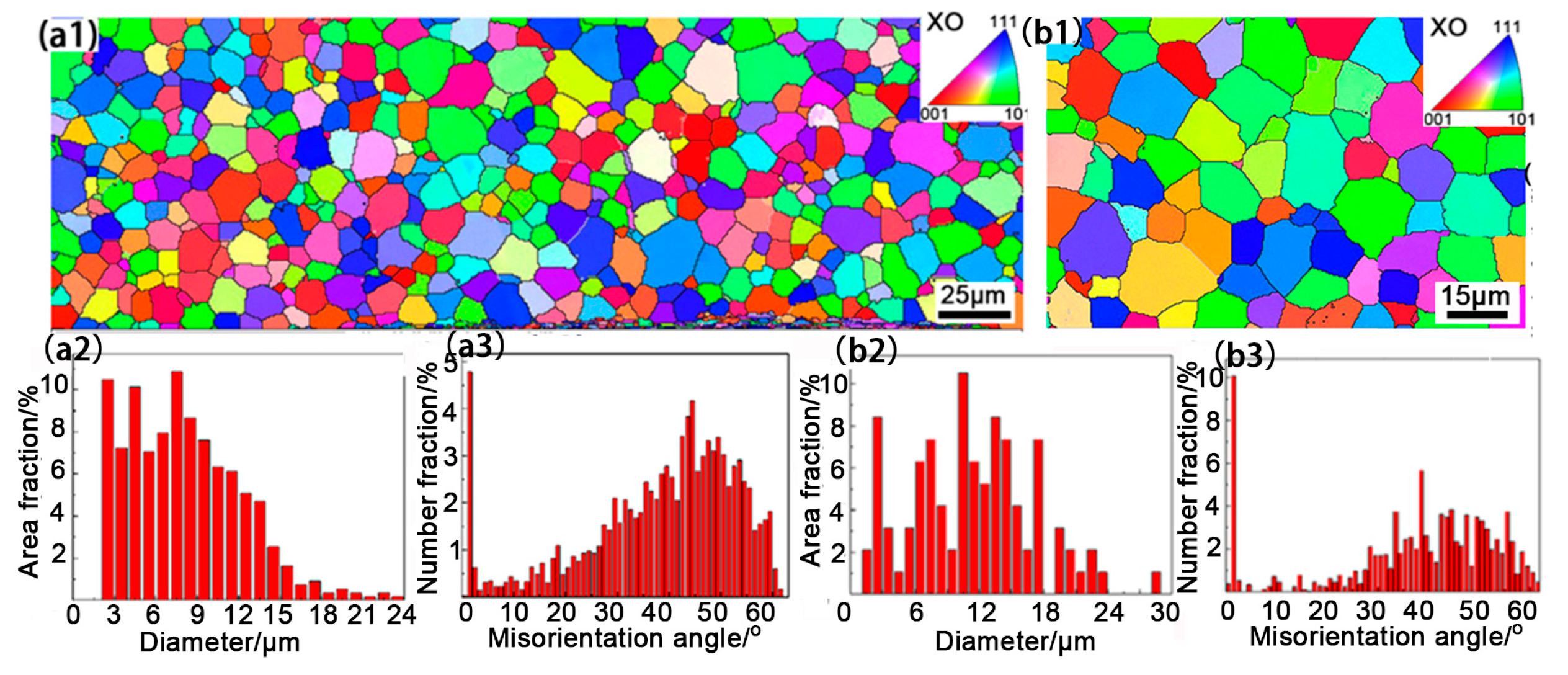

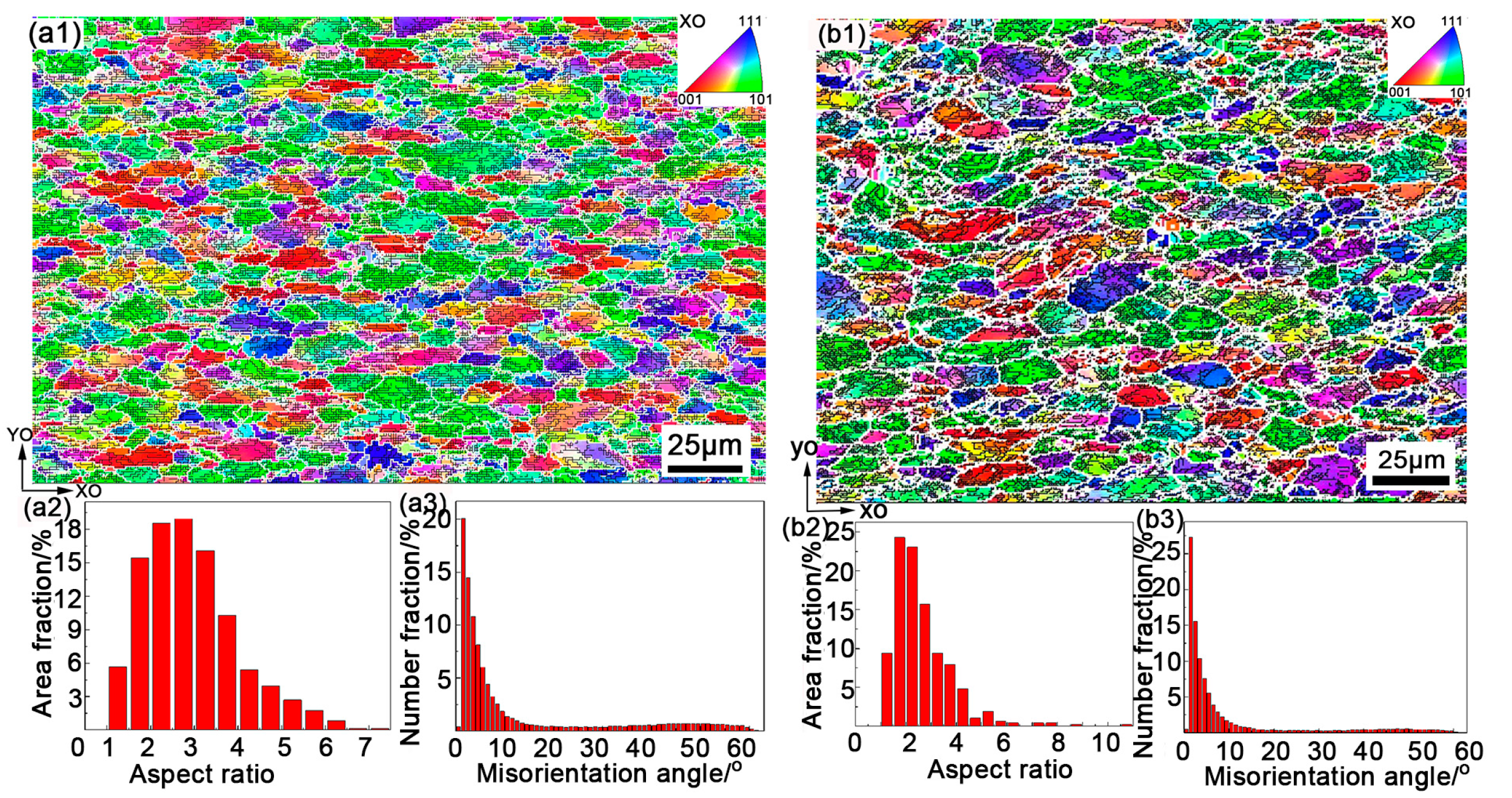

3.4. Grains of Matrix

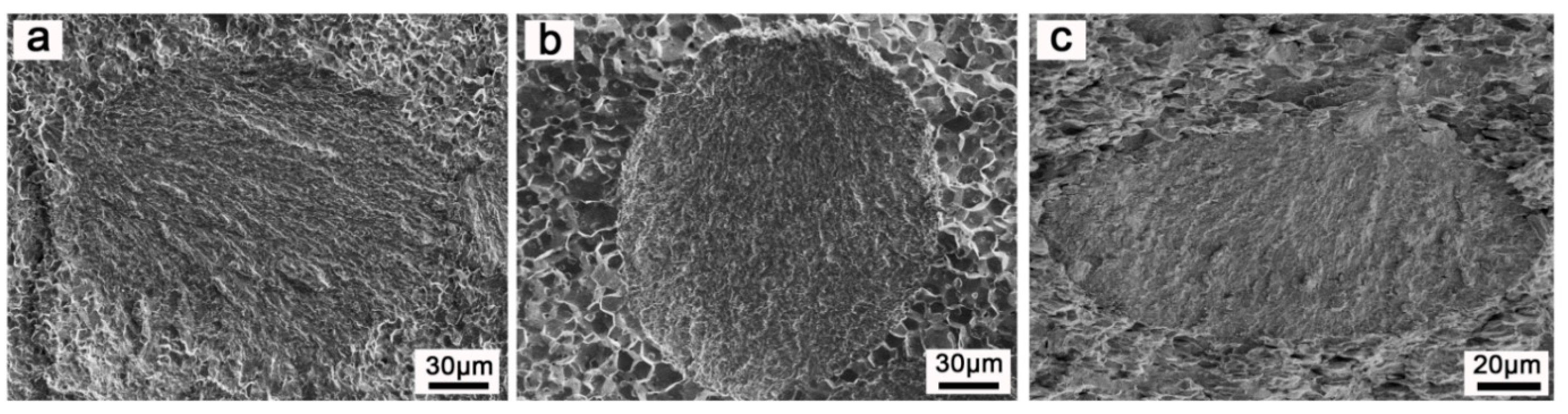

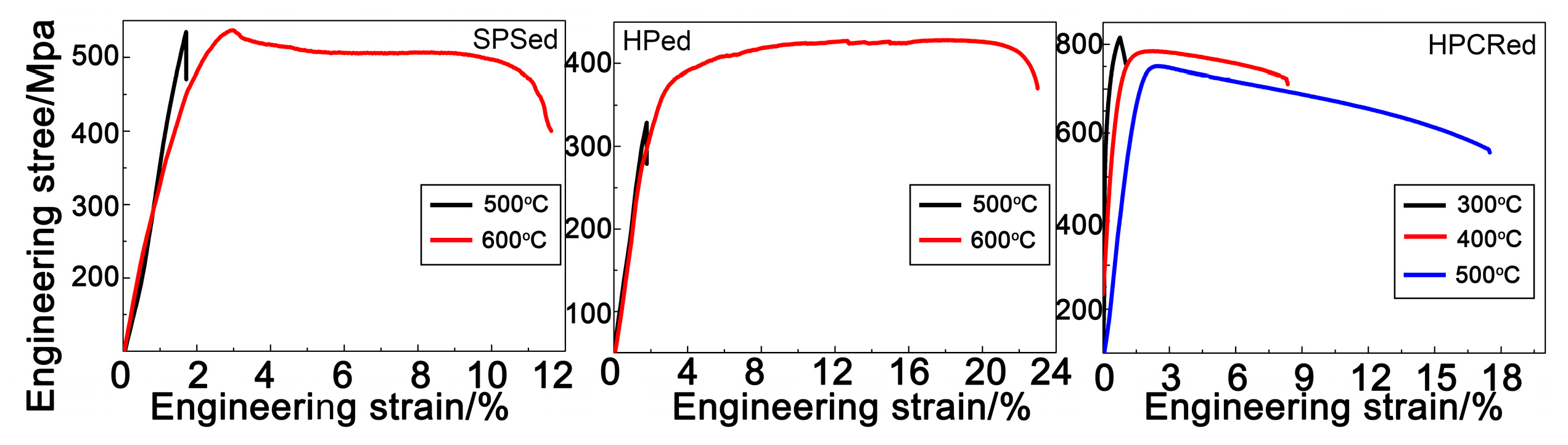

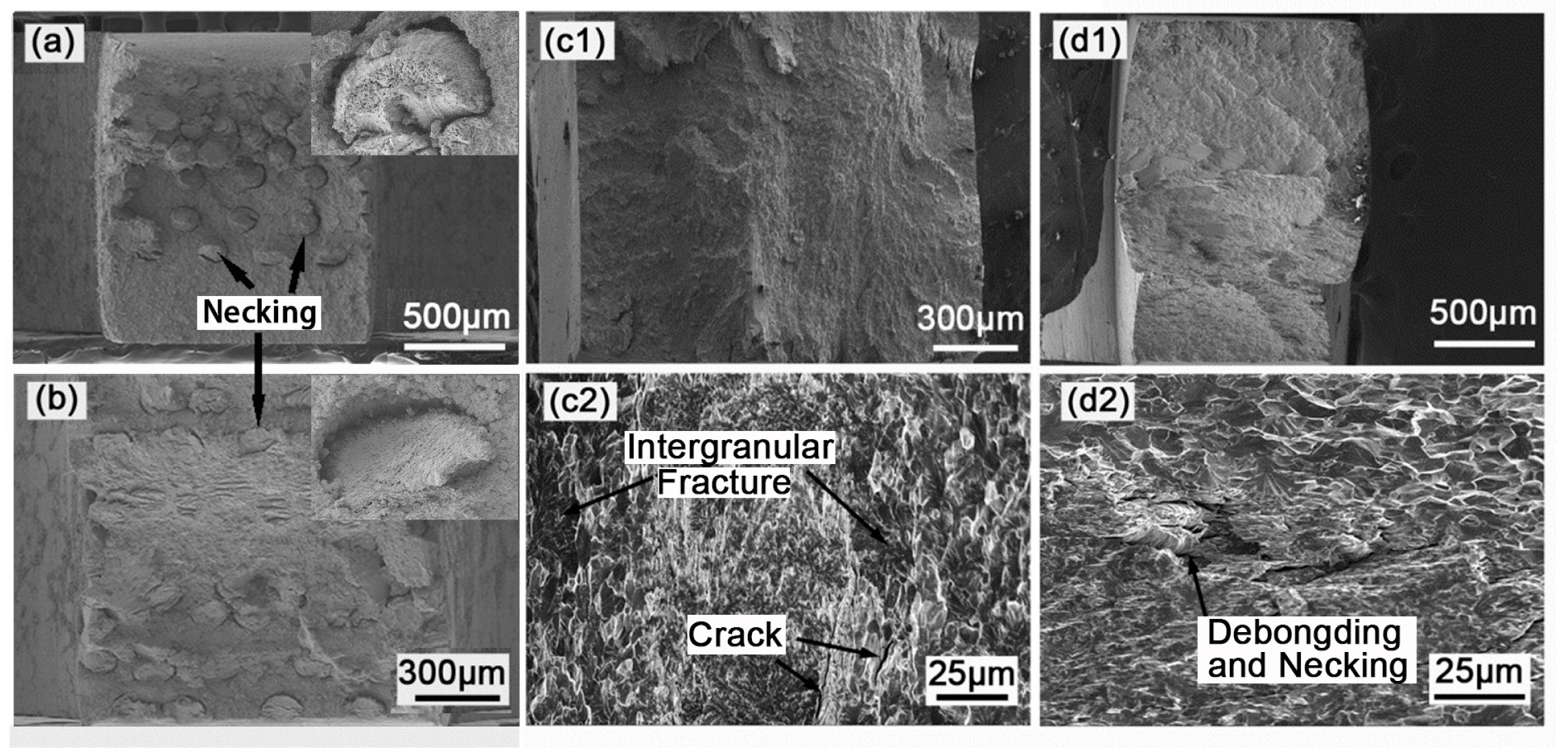

3.5. Tensile Properties and Fracture Microstructure

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chong, F. Feasibility of employing tungsten for plasma facing material in fusion devices. Mater. Rev. 2016, 30, 39–41. [Google Scholar]

- Hao, J.; Shu, X.; Jin, S.; Zhang, X.; Zhang, Y.; Lu, G.-H. A comparison of interatomic potentials for modeling tungsten nanocluster structures. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2017, 393, 180–185. [Google Scholar] [CrossRef]

- Wang, K.; Bannister, M.E.; Meyer, F.W.; Parish, C.M. Effect of starting microstructure on helium plasma-materials interaction in tungsten. Acta Mater. 2017, 124, 556–567. [Google Scholar] [CrossRef]

- Hu, X.; Koyanagi, T.; Fukuda, M.; Kumar, N.A.P.K.; Snead, L.L.; Wirth, B.D.; Katoh, Y. Irradiation hardening of pure tungsten exposed to neutron irradiation. J. Nucl. Mater. 2016, 480, 235–243. [Google Scholar] [CrossRef]

- Khan, A.; Elliman, R.; Corr, C.; Lim, J.J.H.; Forrest, A.; Mummery, P.; Evans, L.M. Effect of rhenium irradiations on the mechanical properties of tungsten for nuclear fusion applications. J. Nucl. Mater. 2016, 477, 42–49. [Google Scholar] [CrossRef]

- Van Renterghem, W.; Uytdenhouwen, I. Investigation of the combined effect of neutron irradiation and electron beam exposure on pure tungsten. J. Nucl. Mater. 2016, 477, 77–84. [Google Scholar] [CrossRef]

- Cui, K.; Shen, Y.Z.; Yu, J.; Ji, B. Microstructural characteristics of commercial purity W and W-1% La2O3 alloy. Int. J. Refract. Met. Hard Mater. 2013, 41, 143–151. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.M.; Hao, T.; Zhou, Y.; Wang, X.P.; Fang, Q.F.; Liu, C.S. Fabricating high performance tungsten alloys through zirconium micro-alloying and nano-sized yttria dispersion strengthening. J. Nucl. Mater. 2014, 451, 35–39. [Google Scholar] [CrossRef]

- Miao, S.; Xie, Z.M.; Yang, X.D.; Liu, R.; Gao, R.; Zhang, T.; Wang, X.P.; Fang, Q.F.; Liu, C.S.; Luo, G.N.; et al. Effect of hot rolling and annealing on the mechanical properties and thermal conductivity of W-0.5 wt. % TaC alloys. Int. J. Refract. Met. Hard Mater. 2016, 56, 8–17. [Google Scholar] [CrossRef]

- Xie, Z.M.; Liu, R.; Miao, S.; Yang, X.D.; Zhang, T.; Fang, Q.F.; Wang, X.P.; Liu, C.S.; Lian, Y.Y.; Liu, X.; et al. High thermal shock resistance of the hot rolled and swaged bulk W-ZrC alloys. J. Nucl. Mater. 2016, 469, 209–216. [Google Scholar] [CrossRef]

- Kanerva, M.; Johansson, L.S.; Campbell, J.M.; Revitzer, H.; Sarlin, E.; Brander, T.; Saarela, O. Hydrofluoric-nitric-sulphuric-acid surface treatment of tungsten for carbon fibre-reinforced composite hybrids in space applications. Appl. Surf. Sci. 2015, 328, 418–427. [Google Scholar] [CrossRef]

- Shi, X.L.; Wang, M.; Zhang, S.; Zhang, Q.X. Fabrication and properties of W-20Cu alloy reinforced by titanium nitride coated SiC fibers. Int. J. Refract. Met Hard Mater. 2013, 41, 60–65. [Google Scholar] [CrossRef]

- Guo, C.Y.; Zhang, C.B.; He, L.L.; Jin, B.H.; Shi, N.L. Microstructure characterization of long W core SiC fiber. J. Mater. Sci. Technol. 2007, 23, 677–684. [Google Scholar]

- Livramento, V.; Nunes, D.; Correia, J.; Carvalho, P.; Mateus, R.; Hanada, K.; Shohoji, N.; Fernandes, H.; Silva, C.; Alves, E. Tungsten-tantalum composites for plasma facing components. Mater. Energy 2010, 4–8. [Google Scholar]

- Riesch, J.; Buffiere, J.Y.; Hoschen, T.; di Michiel, M.; Scheel, M.; Linsmeier, C.; You, J.H. In situ synchrotron tomography estimation of toughening effect by semi-ductile fibre reinforcement in a tungsten-fibre-reinforced tungsten composite system. Acta Mater. 2013, 61, 7060–7071. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, L.H.; Fang, Q.F.; Zhang, T.; Wang, X.P.; Hao, T.; Liu, C.S. Toughness enhancement of tungsten reinforced with short tungsten fibres. Mater. Sci. Eng. A 2017, 690, 208–213. [Google Scholar] [CrossRef]

- Riesch, J.; Hoschen, T.; Linsmeier, C.; Wurster, S.; You, J.H. Enhanced toughness and stable crack propagation in a novel tungsten fibre-reinforced tungsten composite produced by chemical vapor infiltration. Phys. Scr. 2014, T159, 1–8. [Google Scholar] [CrossRef]

- Riesch, J.; Aumann, M.; Coenen, J.W.; Gietl, H.; Holzner, G.; Höschen, T.; Huber, P.; Li, M.; Linsmeier, C.; Neu, R. Chemically deposited tungsten fibre-reinforced tungsten—The way to a mock-up for divertor applications. Nucl. Mater. Energy 2016, 9, 75–83. [Google Scholar] [CrossRef]

- Du, J.; Hoschen, T.; Rasinski, M.; You, J.H. Interfacial fracture behavior of tungsten wire/tungsten matrix composites with copper-coated interfaces. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2010, 527, 1623–1629. [Google Scholar] [CrossRef]

- Du, J.; Hoschen, T.; Rasinski, M.; Wurster, S.; Grosinger, W.; You, J.H. Feasibility study of a tungsten wire-reinforced tungsten matrix composite with ZrOx interfacial coatings. Compos. Sci. Technol. 2010, 70, 1482–1489. [Google Scholar] [CrossRef]

- Du, J.; Hoeschen, T.; Rasinski, M.; You, J.H. Shear debonding behavior of a carbon-coated interface in a tungsten fiber-reinforced tungsten matrix composite. J. Nucl. Mater. 2011, 417, 472–476. [Google Scholar] [CrossRef]

- Jasper, B.; Coenen, J.W.; Riesch, J.; Höschen, T.; Bram, M.; Linsmeier, C. Powder metallurgical tungsten fiber-reinforced tungsten. Mater. Sci. Forum 2015, 825–826, 125–133. [Google Scholar] [CrossRef]

- Coenen, J.W.; Mao, Y.; Almanstötter, J.; Calvo, A.; Sistla, S.; Gietl, H.; Jasper, B.; Riesch, J.; Rieth, M.; Pintsuk, G.; et al. Advanced materials for a damage resilient divertor concept for DEMO: Powder-metallurgical tungsten-fibre reinforced tungsten. Fusion Eng. Des. 2016. [Google Scholar] [CrossRef]

- Zhang, L.H.; Jiang, Y.; Fang, Q.F.; Zhang, T.; Wang, X.P.; Liu, C.S. Toughness and microstructure of tungsten fibre net-reinforced tungsten composite produced by spark plasma sintering. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2016, 659, 29–36. [Google Scholar] [CrossRef]

- Huang, Q.Y.; Tang, A.T.; Ma, S.D.; Pan, H.C.; Song, B.; Gao, Z.Y.; Rashad, M.; Pan, F.S. Enhancing thermal conductivity of Mg-Sn alloy sheet by cold rolling and aging. J. Mater. Eng. Perform. 2016, 25, 2356–2363. [Google Scholar] [CrossRef]

- Xie, Z.M.; Liu, R.; Fang, Q.F.; Zhou, Y.; Wang, X.P.; Liu, C.S. Spark plasma sintering and mechanical properties of zirconium micro-alloyed tungsten. J. Nucl. Mater. 2014, 444, 175–180. [Google Scholar] [CrossRef]

- Zeng, L.F.; Gao, R.; Fang, Q.F.; Wang, X.P.; Xie, Z.M.; Miao, S.; Hao, T.; Zhang, T. High strength and thermal stability of bulk Cu/Ta nanolamellar multilayers fabricated by cross accumulative roll bonding. Acta Mater. 2016, 110, 341–351. [Google Scholar] [CrossRef]

- Zhang, B.; Fu, H.M.; Sha, P.F.; Zhu, Z.W.; Dong, C.; Zhang, H.F.; Hu, Z.Q. Anisotropic compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2013, 566, 16–21. [Google Scholar] [CrossRef]

- Chen, Z.C.; Zuo, T.Y.; Zhou, M.L. The recrystallization mechanism of doped tungsten wire. J. Mater. Sci. Lett. 1990, 9, 782–784. [Google Scholar]

- Xia, F.; Wang, M.; Li, Z.; Wei, H.; Chen, C.; Jia, Y.; Lei, Q. Recrystallization and texture of tungsten strip. J. Cent. South Univ. Sci. Technol. 2013, 44, 1359–1366. [Google Scholar]

- Reiser, J.; Hoffmann, J.; Jantsch, U.; Klimenkov, M.; Bonk, S.; Bonnekoh, C.; Rieth, M.; Hoffmann, A.; Mrotzek, T. Ductilisation of tungsten (W): On the shift of the brittle-to-ductile transition (BDT) to lower temperatures through cold rolling. Int. J. Refract. Met. Hard Mater. 2016, 54, 351–369. [Google Scholar] [CrossRef]

- Xie, Z.M.; Zhang, T.; Liu, R.; Fang, Q.F.; Miao, S.; Wang, X.P.; Liu, C.S. Grain growth behavior and mechanical properties of zirconium microalloyed and nano-size zirconium carbide dispersion strengthened tungsten alloys. Int. J. Refract. Met. Hard Mater. 2015, 51, 180–187. [Google Scholar] [CrossRef]

| Different Samples | Mass Fraction of Fibre | Relative Density (%) | Vickers Hardness/HV0.2 | |

|---|---|---|---|---|

| Fibre | Matrix | |||

| Original fibre | 100% | 100% | 623.6 ± 11 | - |

| SPSed | 17.4 ± 0.1% | 97.5 ± 0.3% | 537.4 ± 9 | 431.3 ± 8 |

| HPed | 10.5 ± 0.1% | 95.1 ± 0.2% | 538.5 ± 7 | 331.9 ± 6 |

| HPCRed | 10.5 ± 0.1% | 99.8 ± 0.1% | 536.4 ± 5 | 476.4 ± 2 |

| Fibre | The Share of Small Angle Grain Boundaries θ < 10°/% | Average Length-Diameter Ratio | ||||

|---|---|---|---|---|---|---|

| 60.1 ± 0.2 | 5.2 ± 0.1 | |||||

| Fibre | Near the Fibre | Away from the Fibre | Fibre | Near the Fibre | Away from the Fibre | |

| SPSed | 31.5 ± 0.1 | 6.8 ± 0.2 | 4.2 ± 0.1 | 3.7 ± 0.1 | 4.3 ± 0.3 μm (grain size) | 3.6 ± 0.2 μm (grain size) |

| HPed | 26.8 ± 0.2 | 7.8 ± 0.1 | 12.0 ± 0.2 | 3.2 ± 0.1 | 8.1 ± 0.2 μm (grain size) | 11.4 ± 0.2 μm (grain size) |

| HPCRed | 31.6 ± 0.3 | 72.7 ± 0.3 | 78.3 ± 0.2 | 5.8 ± 0.2 | 2.6 ± 0.1 | 2.1 ± 0.2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Jiang, Y.; Fang, Q.; Liu, R.; Xie, Z.; Zhang, T.; Wang, X.; Liu, C. Comparative Investigation of Tungsten Fibre Nets Reinforced Tungsten Composite Fabricated by Three Different Methods. Metals 2017, 7, 249. https://doi.org/10.3390/met7070249

Zhang L, Jiang Y, Fang Q, Liu R, Xie Z, Zhang T, Wang X, Liu C. Comparative Investigation of Tungsten Fibre Nets Reinforced Tungsten Composite Fabricated by Three Different Methods. Metals. 2017; 7(7):249. https://doi.org/10.3390/met7070249

Chicago/Turabian StyleZhang, Linhui, Yan Jiang, Qianfeng Fang, Rui Liu, Zhuoming Xie, Tao Zhang, Xianping Wang, and Changsong Liu. 2017. "Comparative Investigation of Tungsten Fibre Nets Reinforced Tungsten Composite Fabricated by Three Different Methods" Metals 7, no. 7: 249. https://doi.org/10.3390/met7070249