Interfacial Microstructure and Shear Strength of Brazed Cu-Cr-Zr Alloy Cylinder and Cylindrical Hole by Au Based Solder

Abstract

:1. Introduction

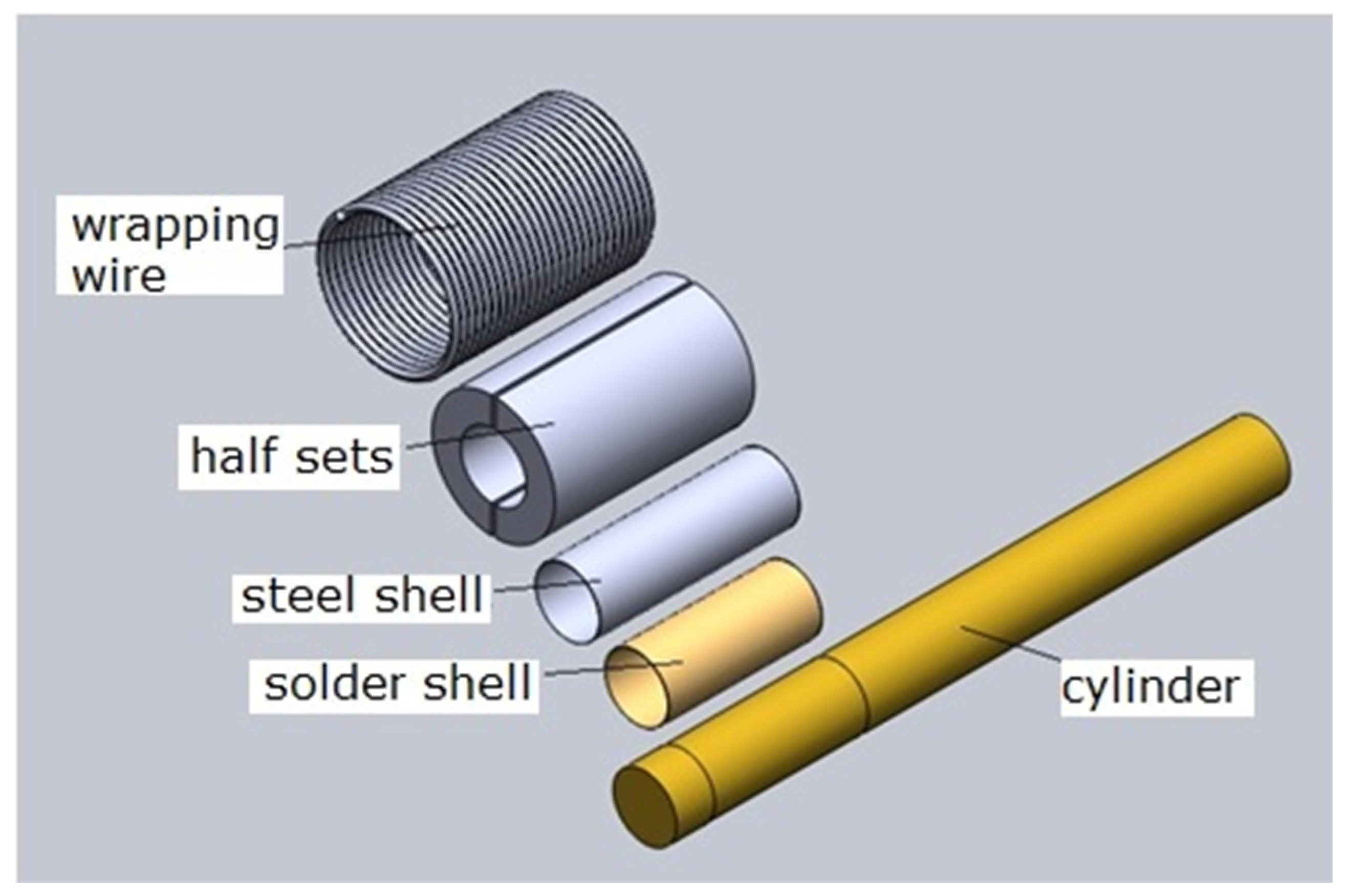

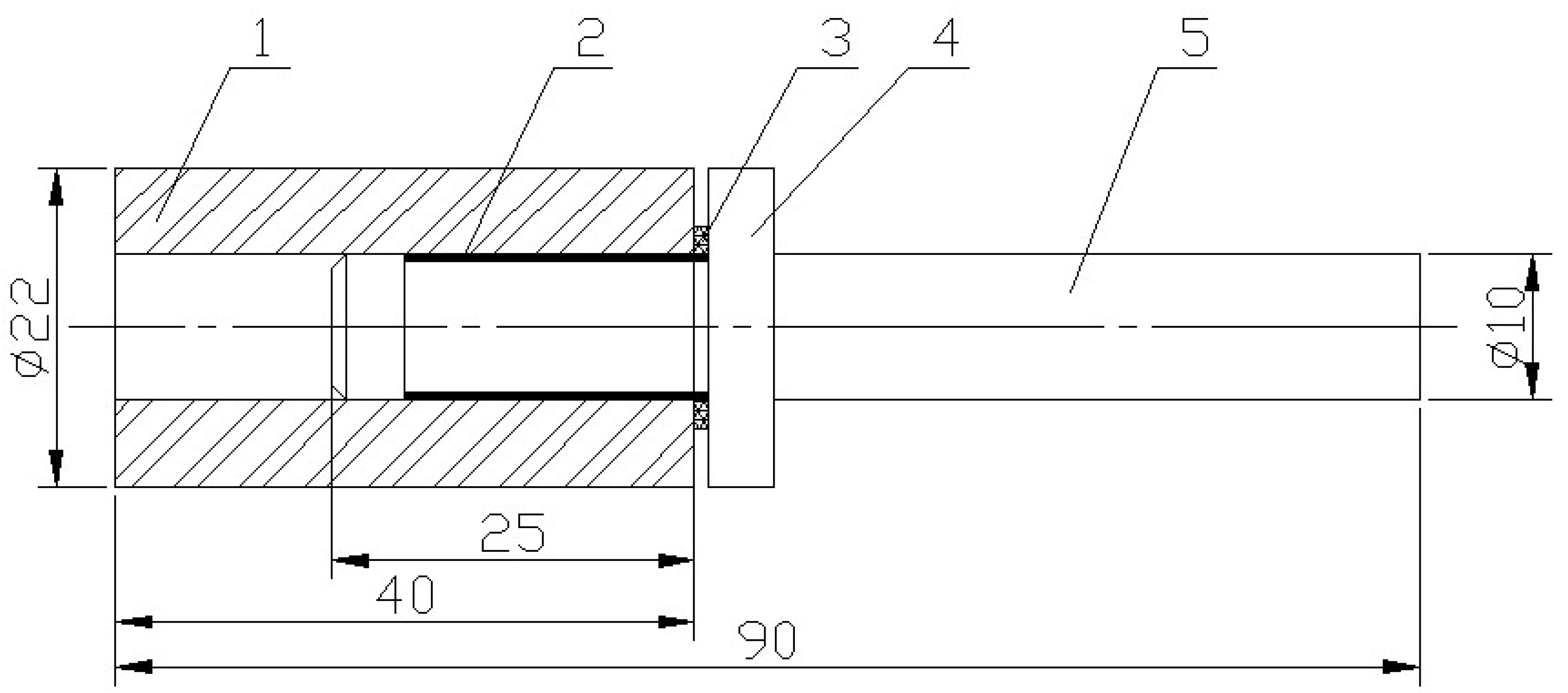

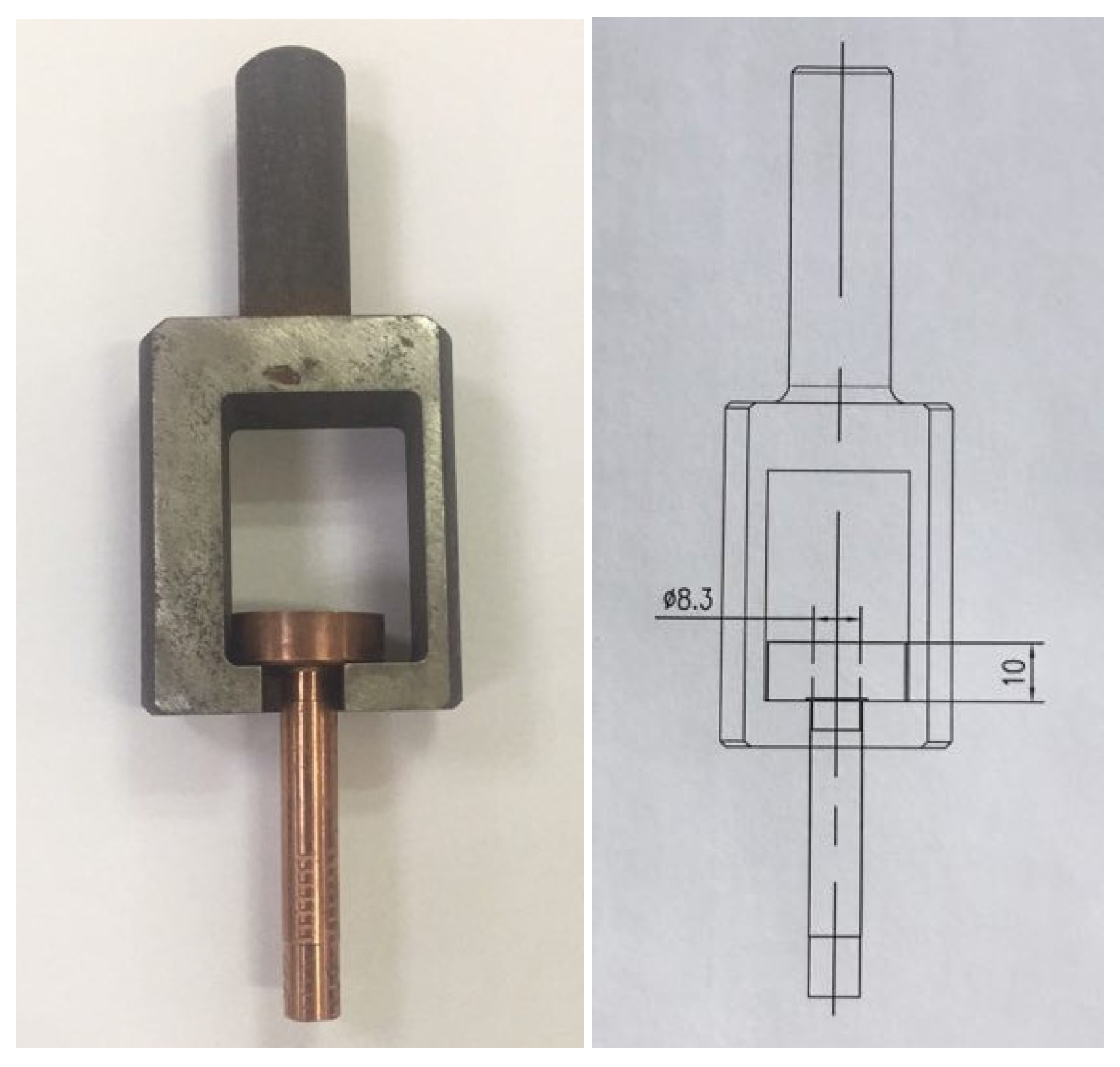

2. Materials and Methods

3. Results and Discussion

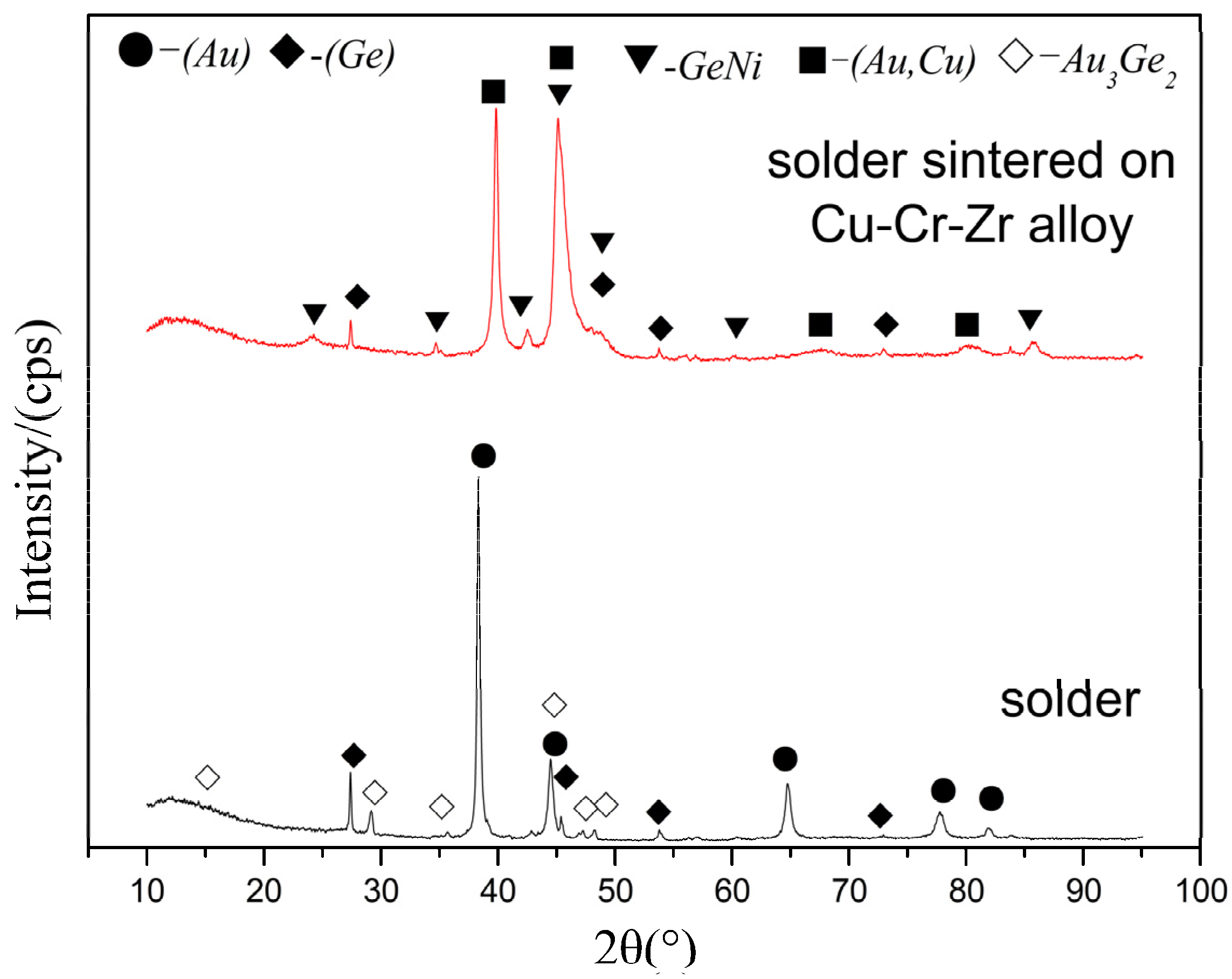

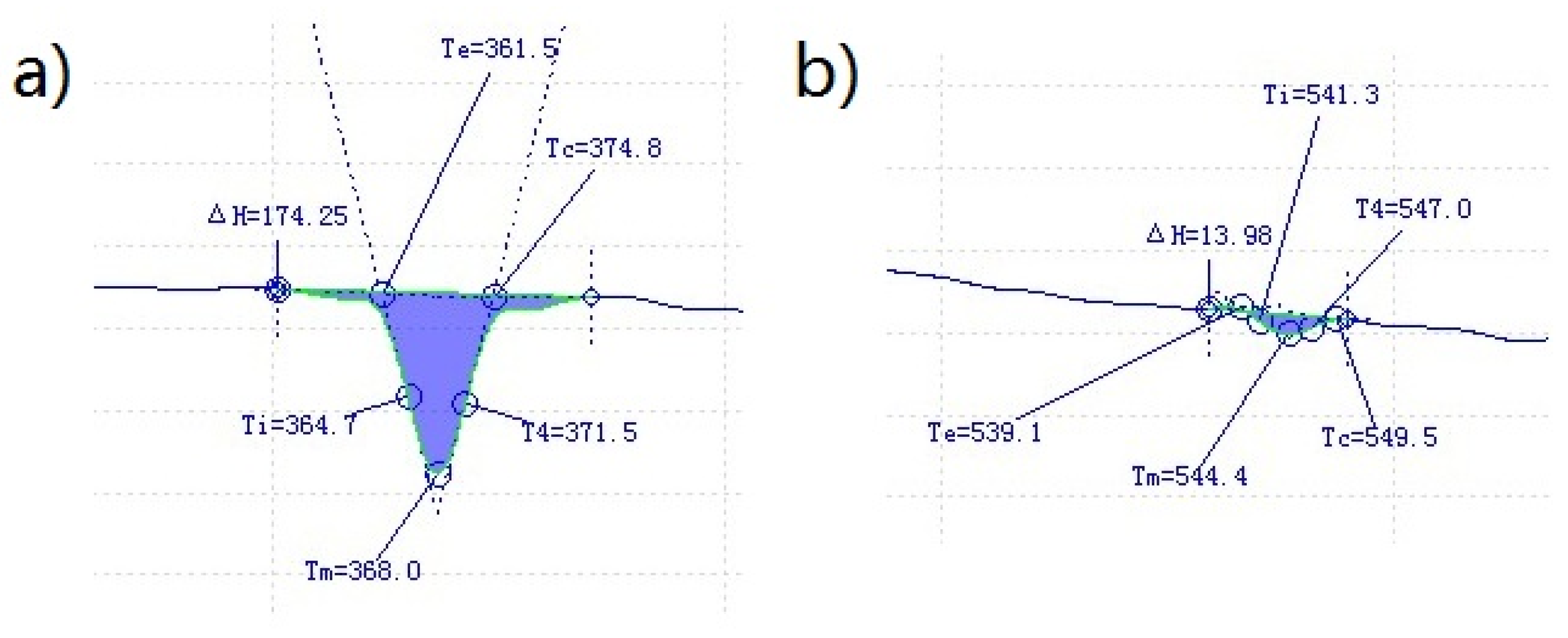

3.1. Properties of the Au Based Solder

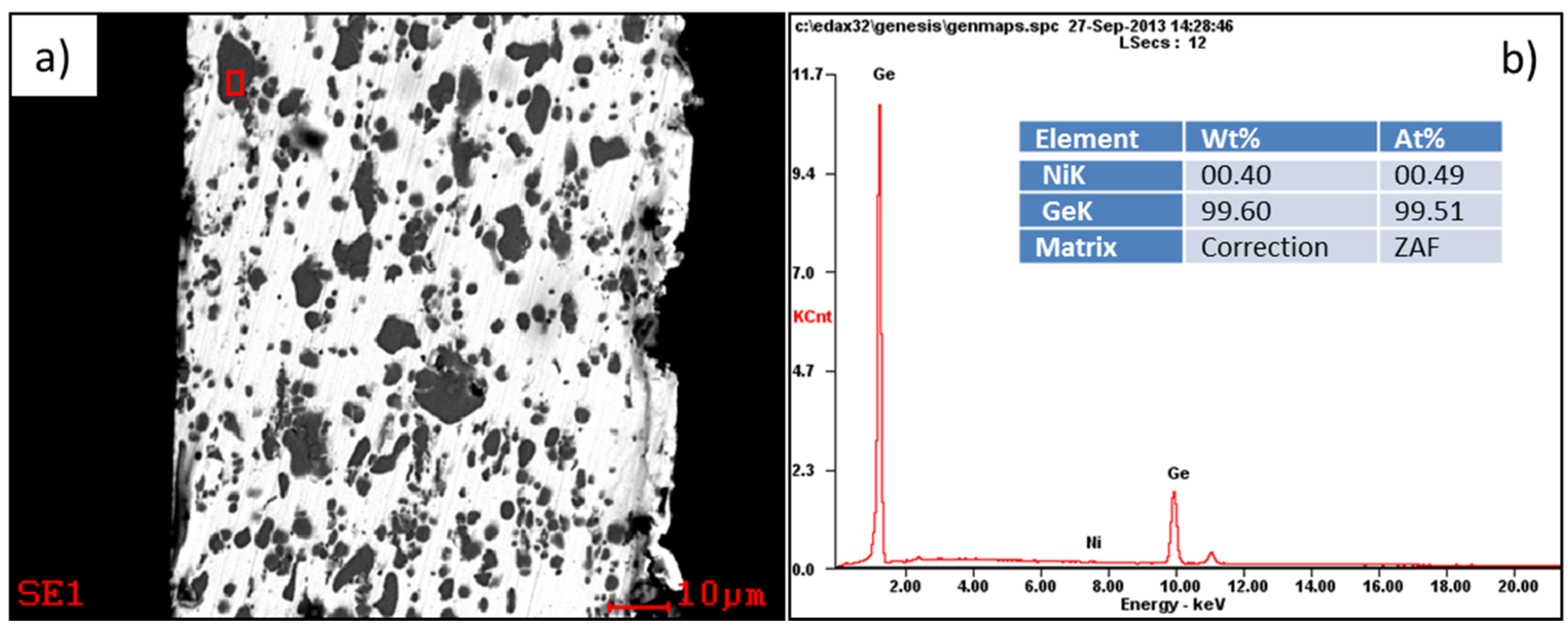

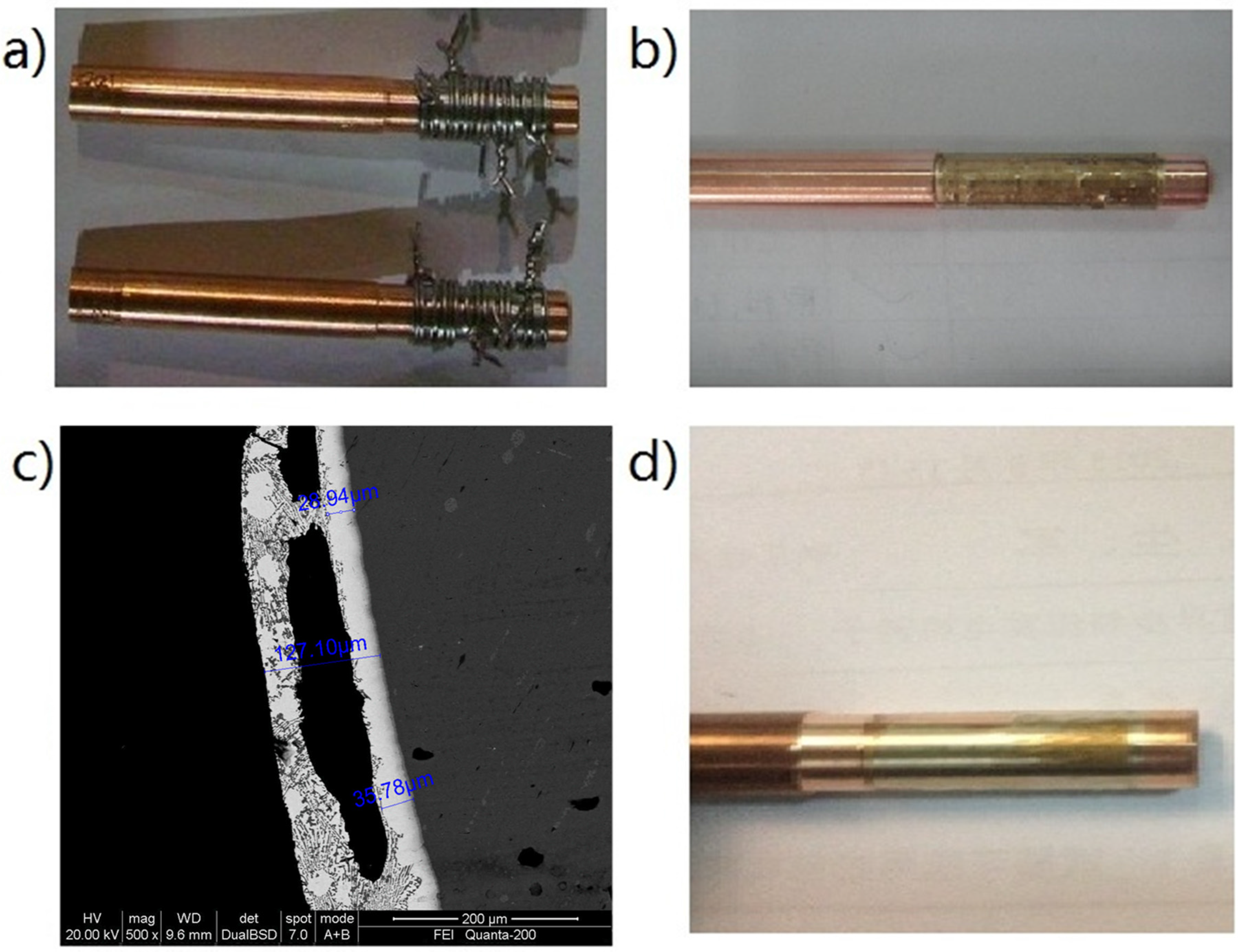

3.2. Sintering of the Solder to the Surface of the Cu-Cr-Zr Cylinder and the Microstructure

3.3. The Brazed Microstructure and Shear Strength

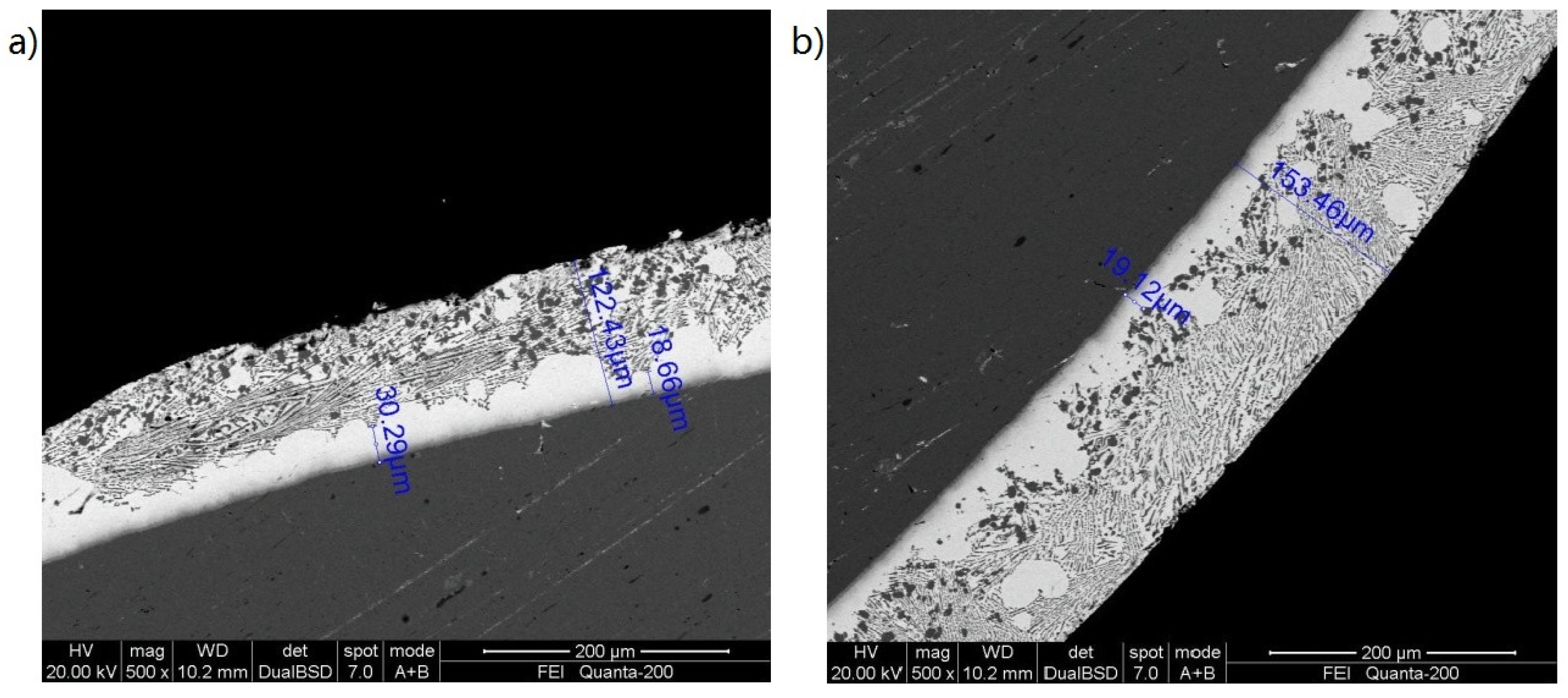

3.3.1. Effect of the Brazing Temperature and the Holding Time

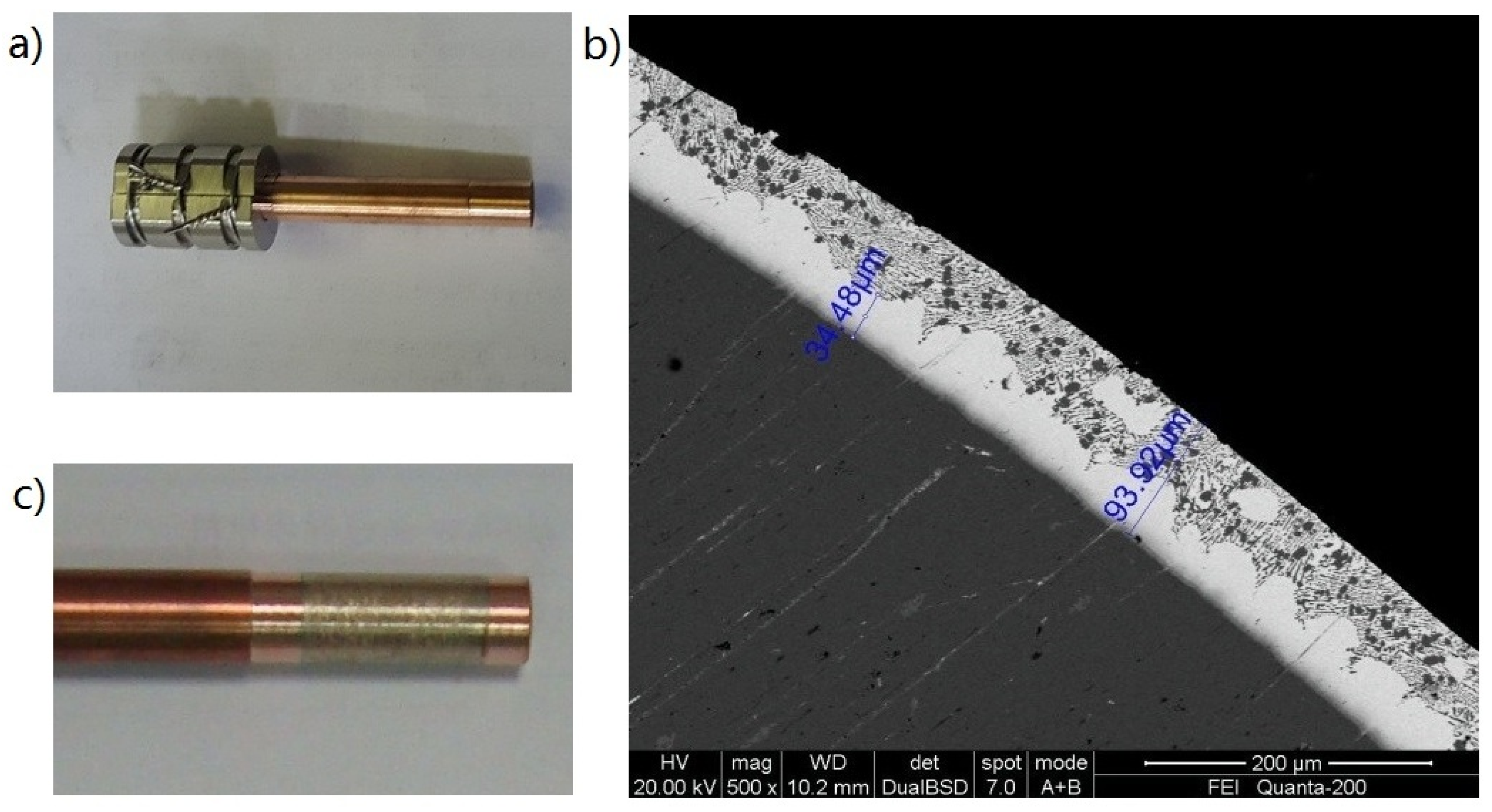

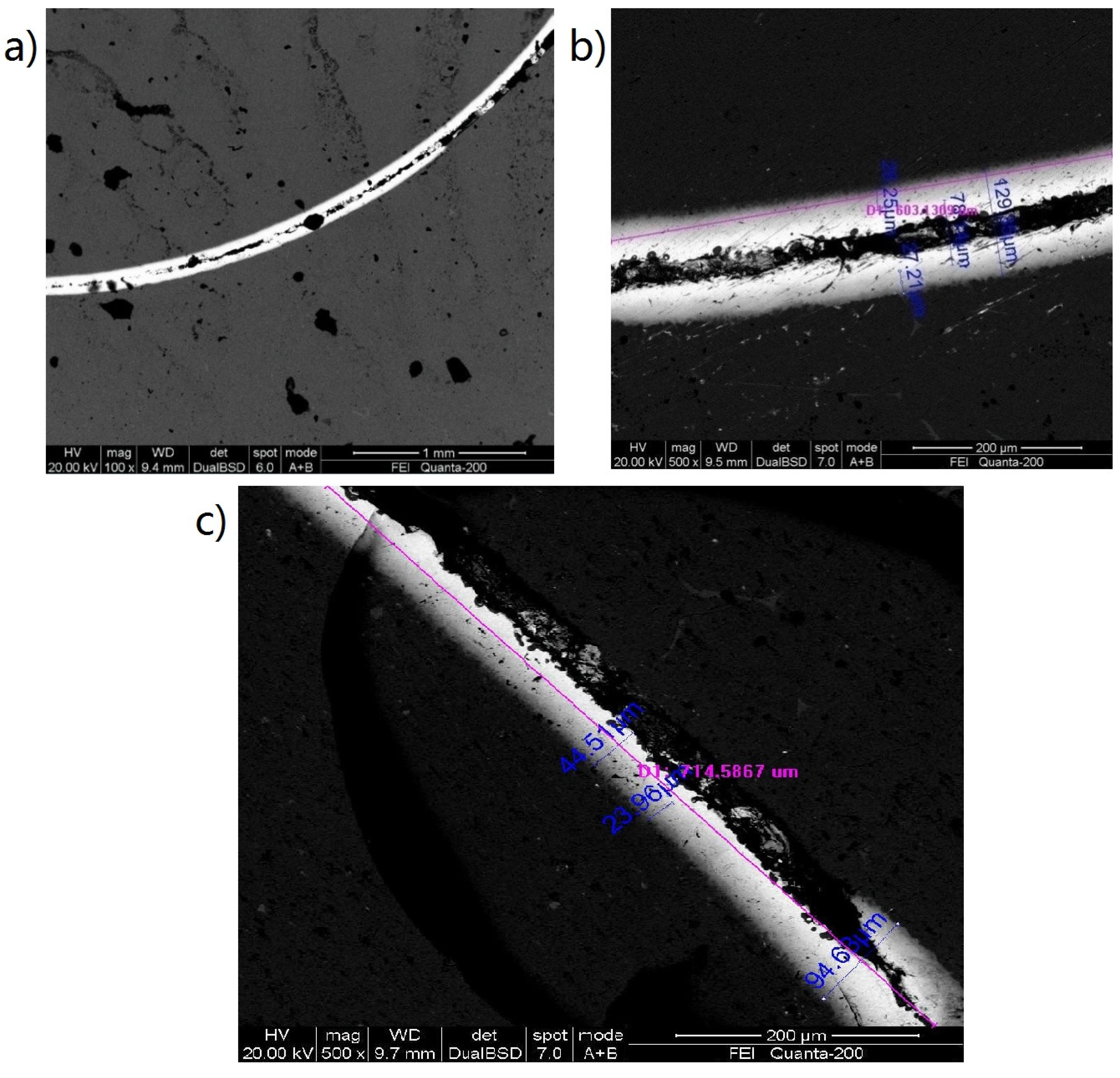

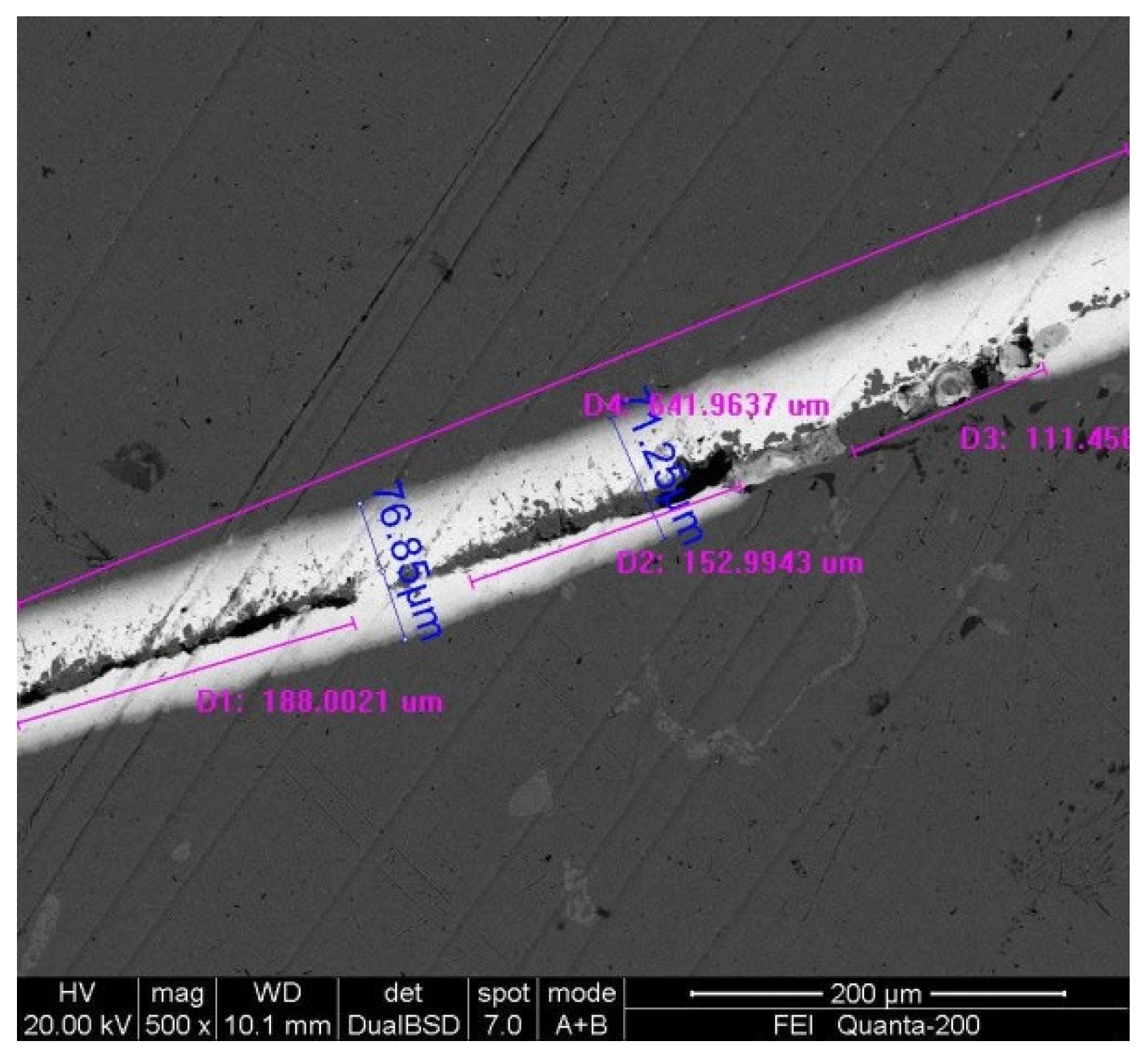

3.3.2. Effect of the Brazing with Side Solder Feeding

4. Conclusions

- (1)

- The proper process parameters for sintering of a Au-Ge solder on the surface of the Cu-Cr-Zr cylinder by half sets are, first, heating the temperature to 320 °C at the rate of 180 °C/h and holding at the temperature for 20 min, then, heating the temperature to 420 °C at the rate of 200 °C/h and holding at the temperature for 15 min.

- (2)

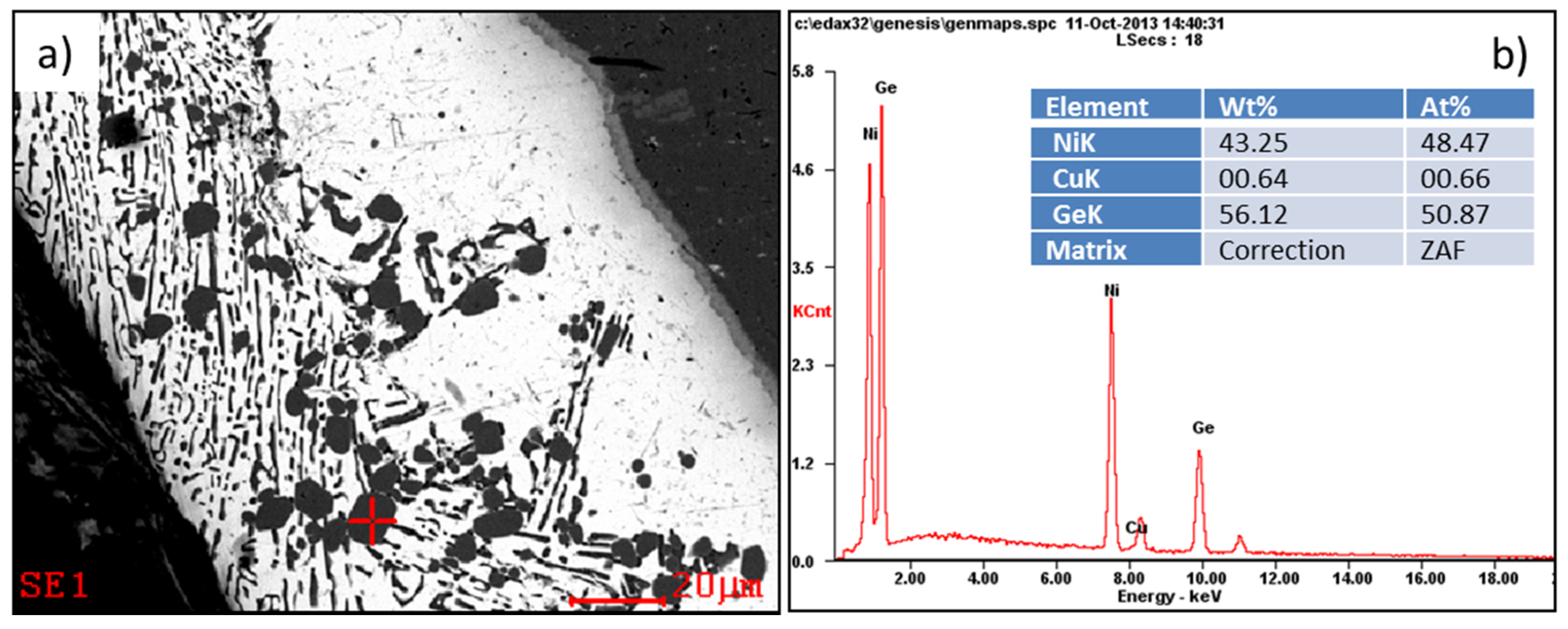

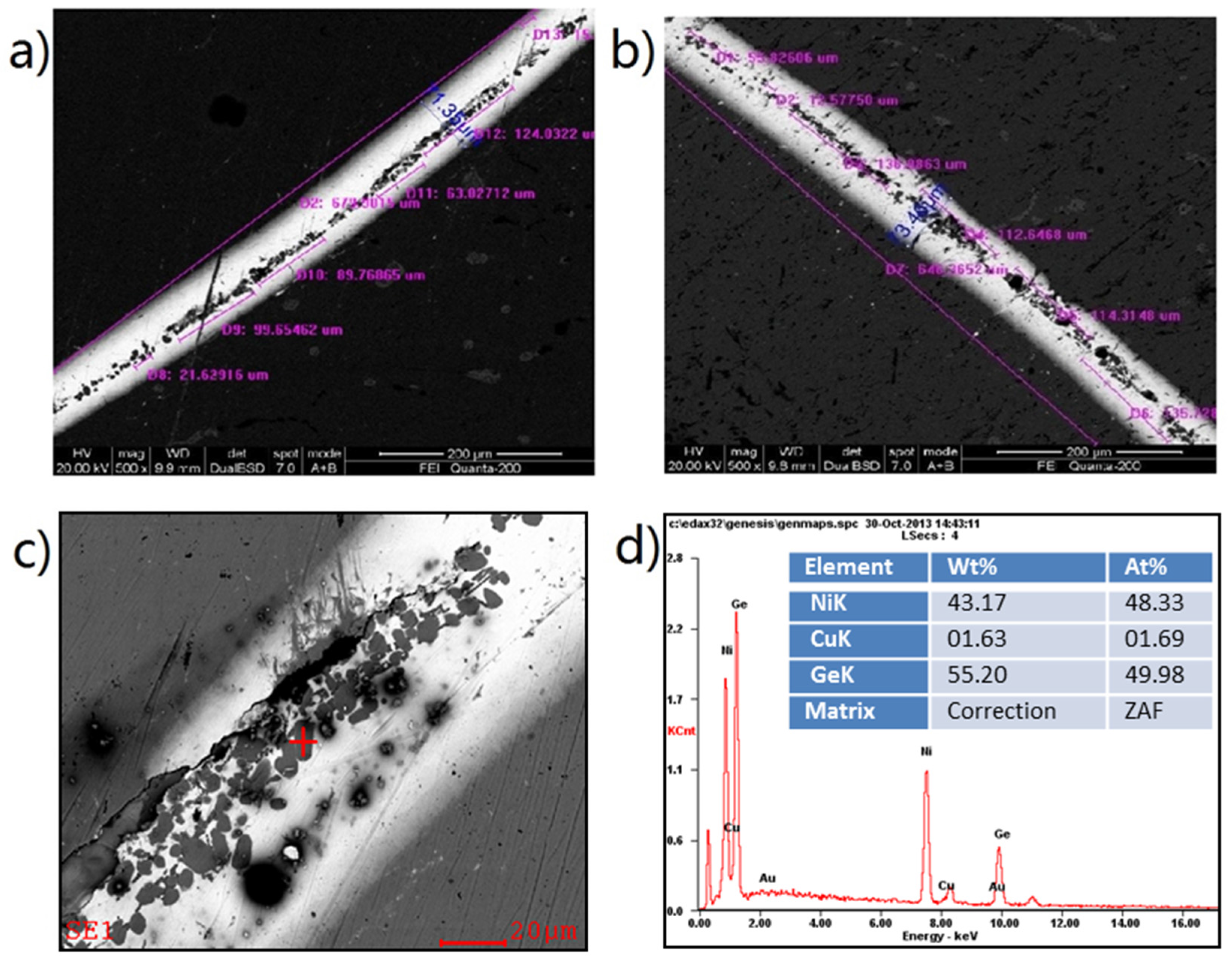

- For brazing without side solder melt feeding, the highest brazed shear strength was 87.05 MPa. There were a number of voids and micro cracks along the interface of the cylinder and the sleeve due to lack of enough melt feeding and the congregation of large amounts of Ge-Ni particles with about 55.2 wt % Ge and 43.17 wt % Ni during solidification of the solder melt. High brazing temperature and long holding time at the temperature accelerate formation of these micro defects. One suitable condition was brazing at a temperature of 535 °C and holding at this temperature for 10 min.

- (3)

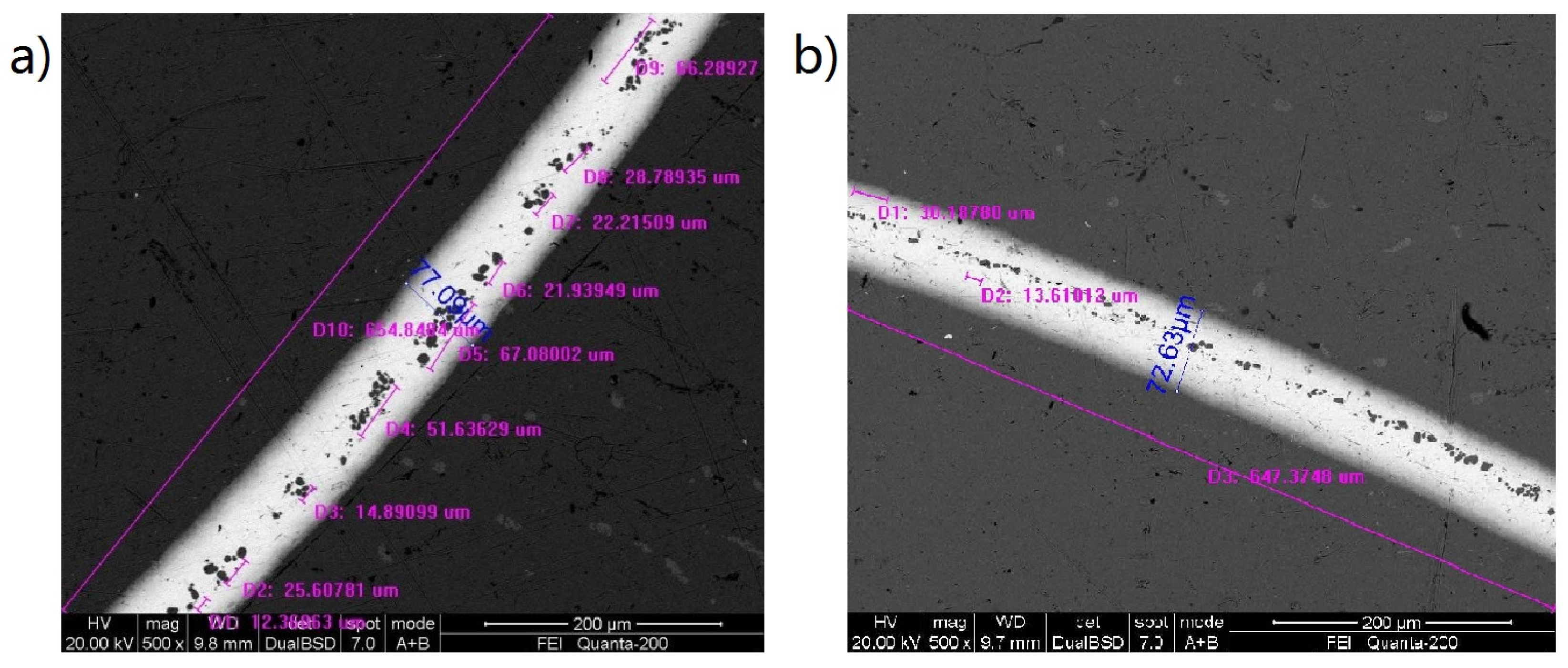

- For brazing by side solder melt feeding, the brazed shear strength was increased to 102.95 MPa. Furthermore, the brazed shear strength of about 100 MPa can be achieved even for large clearances of 0.011–0.015 mm between the cylinder and the sleeve at one side.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kalinin, G.M.; Abramov, V.Y.; Gervash, A.A.; Zolotarev, V.B.; Krestnikov, N.S.; Mazul, I.V.; Strebkov, Y.S.; Fabritsiev, S.A. Development of fabrication technology and investigation of properties of steel-to-bronze joints suggested for ITER HHF components. J. Nucl. Mater. 2009, 386, 927–930. [Google Scholar] [CrossRef]

- Khirwadkar, S.S.; Singh, K.P.; Patil, Y.; Khan, M.S.; Buch, J.J.U.; Patel, A.; Tripathi, S.; Jaman, P.M.; Rangaraj, L.; Divakar, C. Fabrication and characterization of tungsten and graphite based PFC for divertor target elements of ITER like tokamak application. Fusion Eng. Des. 2011, 86, 1736–1740. [Google Scholar] [CrossRef]

- Kupriyanov, I.B.; Roedig, M.; Nikolaev, G.N.; Kurbatova, L.A.; Linke, J.; Gervash, A.A.; Giniyatulin, R.N.; Podkovyrov, V.L.; Muzichenko, A.D.; Khimchenko, L. Recent results on high thermal energy load testing of beryllium for ITER first wall application. Phys. Scr. 2011, 145, 014063. [Google Scholar] [CrossRef]

- Bisio, M.; Branca, V.; Di Marco, M.; Federici, A.; Grattarola, M.; Gualco, G.; Guarnone, P.; Luconi, U.; Merola, M.; Ozzano, C.; et al. Manufacturing and testing in reactor relevant conditions of brazed plasma facing components of the ITER divertor. Fusion Eng. Des. 2005, 75, 277–283. [Google Scholar] [CrossRef]

- Casalegno, V.; Salvo, M.; Murdaca, S.; Ferraris, M. One-step brazing process for CFC monoblock joints and mechanical testing. J. Nucl. Mater. 2009, 393, 300–305. [Google Scholar] [CrossRef]

- Kaya, Y.; Kahraman, N.; Durgutlu, A.; Gülenç, B. A novel approach to diffusion bonding of copper to stainless steel. Proc. Inst. Mech. Eng. Part B 2011, 226, 478–484. [Google Scholar] [CrossRef]

- Bisadi, H.; Rasaee, S.; Fotoohi, Y. Studying of tool rotation speed on mechanical properties of copper–Al5083 butt joint welded by friction stir welding. Proc. Inst. Mech. Eng. Part B 2014, 229, 1734–1741. [Google Scholar] [CrossRef]

- Qiao, F.; Cheng, K.; Wang, L.; Guo, L. An experimental investigation on the dissimilar joining of AA6061 and 1Cr18Ni9Ti by refill friction stir spot welding and its mechanical properties. Proc. Inst. Mech. Eng. Part B 2015, 230, 779–785. [Google Scholar] [CrossRef]

- Shanjeevi, C.; Kumar, S.S.; Sathiya, P. Multi-objective optimization of friction welding parameters in AISI 304L austenitic stainless steel and copper joints. Proc. Inst. Mech. Eng. Part B 2014, 230, 449–457. [Google Scholar] [CrossRef]

- Elyasi, M.; Derazkola, H.A.; Hosseinzadeh, M. Investigations of tool tilt angle on properties friction stir welding of A441 AISI to AA1100 aluminium. Proc. Inst. Mech. Eng. Part B 2016, 230, 1234–1241. [Google Scholar] [CrossRef]

- Ren, G.; Collins, M.N. The effects of antimony additions on microstructures, thermal and mechanical properties of Sn-8Zn-3Bi alloys. Mater. Des. 2017, 119, 133–140. [Google Scholar] [CrossRef]

- Collins, M.N.; Punch, J.; Coyle, R.; Reid, M.; Popowich, R.; Read, P.; Fleming, D. Thermal fatigue and failure analysis of SnAgCu solder alloys with minor Pb additions. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 1594–1600. [Google Scholar] [CrossRef]

- Coyle, R.; Osenbach, J.; Collins, M.N.; McCormick, H.; Read, P.; Fleming, D.; Popowich, R.; Punch, J.; Reid, M.; Kummerl, S. Phenomenological study of the effect of microstructural evolution on the thermal fatigue resistance of Pb-free solder joints. IEEE Trans. Compon. Packag. Manuf. Technol. 2011, 1, 1583–1593. [Google Scholar] [CrossRef]

- Ntasi, A.; Al Jabbari, Y.S.; Silikas, N.; Al Taweel, S.M.; Zinelis, S. Metallurgical characterization of experimental Ag-based soldering alloys. Saudi Dent. J. 2014, 26, 139–144. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Wang, Y.; Man, Y.; Yu, Q.; Huang, Y. Interfacial microstructure evolution and shear behavior of Au–20Sn/(Sn)Cu solder joints bonded at 250 °C. Mater. Sci. Eng. A 2016, 651, 626–635. [Google Scholar] [CrossRef]

- Yoon, J.-W.; Jung, S.-B. Investigation of interfacial reaction between Au–Sn solder and Kovar for hermetic sealing application. Microelectron. Eng. 2007, 84, 2634–2639. [Google Scholar] [CrossRef]

- Nowacki, J.; Danielewski, M.; Filipek, R. Brazed joints evaluation and computer modelling of mass transport in multi-component systems in the Au-Ni solder-14-5 PH joints. J. Mater. Proc. Technol. 2004, 157, 213–220. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, T.; Liu, W.; Huang, Y.; Tang, S.; Wang, Y. Interfacial microstructure evolution and shear behavior of Au-12Ge/Ni solder joints during isothermal aging. J. Mater. Sci. Mater. Electron. 2017, 28, 3685–3694. [Google Scholar] [CrossRef]

- Lang, F.Q.; Yamaguchi, H.; Nakagawa, H.; Sato, H. Solid-state interfacial reaction between eutectic Au-Ge solder and Cu/Ni(P)/Au metalized ceramic substrate and its suppression. J. Mater. Sci. Technol. 2015, 31, 445–452. [Google Scholar] [CrossRef]

- Chidambaram, V.; Hald, J.; Hattel, J. Development of Au-Ge based candidate alloys as an alternative to high-lead content solders. J Alloys Compd. 2010, 490, 170–179. [Google Scholar] [CrossRef]

- Lau, F.L.; Made, R.I.; Putra, W.N.; Lim, J.Z.; Nachiappan, V.C.; Aw, J.L.; Gan, C.L. Electrical behavior of Au-Ge eutectic solder under aging for solder bump application in high temperature electronics. Microelectron. Reliab. 2013, 53, 1581–1586. [Google Scholar] [CrossRef]

- Weyrich, N.; Jin, S.; Duarte, L.I.; Leinenbach, C. Joining of Cu, Ni, and Ti using Au-Ge-based high-temperature solder alloys. J. Mater. Eng. Perform. 2014, 23, 1585–1592. [Google Scholar] [CrossRef]

| Temperature/°C | 1# | 2# | 3# | 4# | 5# | 6# | Average Shear Strength/MPa | Standard Deviations |

|---|---|---|---|---|---|---|---|---|

| 500 | 83.1 | 84.4 | 86.5 | 81.8 | 78.4 | 74.9 | 81.52 | 4.22 |

| 535 | 85.3 | 92.7 | 87.5 | 84.2 | 83.9 | 88.7 | 87.05 | 3.35 |

| 550 | 52.7 | 43.8 | 50.2 | 48.6 | 53.1 | 47.9 | 49.38 | 3.45 |

| Holding Time/min | 1# | 2# | 3# | 4# | 5# | 6# | Average Shear Strength/MPa | Standard Deviations |

|---|---|---|---|---|---|---|---|---|

| 10 | 85.3 | 92.7 | 87.5 | 84.2 | 83.9 | 88.7 | 87.05 | 3.35 |

| 20 | 66.6 | 69.9 | 64.7 | 68.2 | 74.8 | 69.2 | 68.90 | 3.44 |

| 30 | 58.4 | 57.9 | 57.4 | 61.8 | 60.2 | 57.6 | 58.88 | 1.75 |

| 1# | 2# | 3# | 4# | 5# | 6# | Average Shear Strength/MPa | Standard Deviations |

|---|---|---|---|---|---|---|---|

| 102.2 | 105.7 | 102.5 | 100.3 | 101.9 | 105.1 | 102.95 | 2.05 |

| Sample | 1# | 2# | 3# | 4# | 5# | 6# | 7# | 8# | 9# | 10# | 11# | 12# | Average |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Clearance/mm | 0.011 | 0.013 | 0.010 | 0.014 | 0.015 | 0.012 | 0.012 | 0.011 | 0.014 | 0.013 | 0.013 | 0.015 | 0.01275 |

| Shear strength/MPa | 102.3 | 103.1 | 98.8 | 99.6 | 105.3 | 102.7 | 105.3 | 103.6 | 104.2 | 101.8 | 103.1 | 104.2 | 102.83 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Yi, Y.; He, D.; Lai, R. Interfacial Microstructure and Shear Strength of Brazed Cu-Cr-Zr Alloy Cylinder and Cylindrical Hole by Au Based Solder. Metals 2017, 7, 247. https://doi.org/10.3390/met7070247

Li Z, Yi Y, He D, Lai R. Interfacial Microstructure and Shear Strength of Brazed Cu-Cr-Zr Alloy Cylinder and Cylindrical Hole by Au Based Solder. Metals. 2017; 7(7):247. https://doi.org/10.3390/met7070247

Chicago/Turabian StyleLi, Zaihua, Youping Yi, Diqiu He, and Ruilin Lai. 2017. "Interfacial Microstructure and Shear Strength of Brazed Cu-Cr-Zr Alloy Cylinder and Cylindrical Hole by Au Based Solder" Metals 7, no. 7: 247. https://doi.org/10.3390/met7070247