Study of Surface Metallization of Polyimide Film and Interfacial Characterization

Abstract

:1. Introduction

2. Experimental Procedures

2.1. Materials

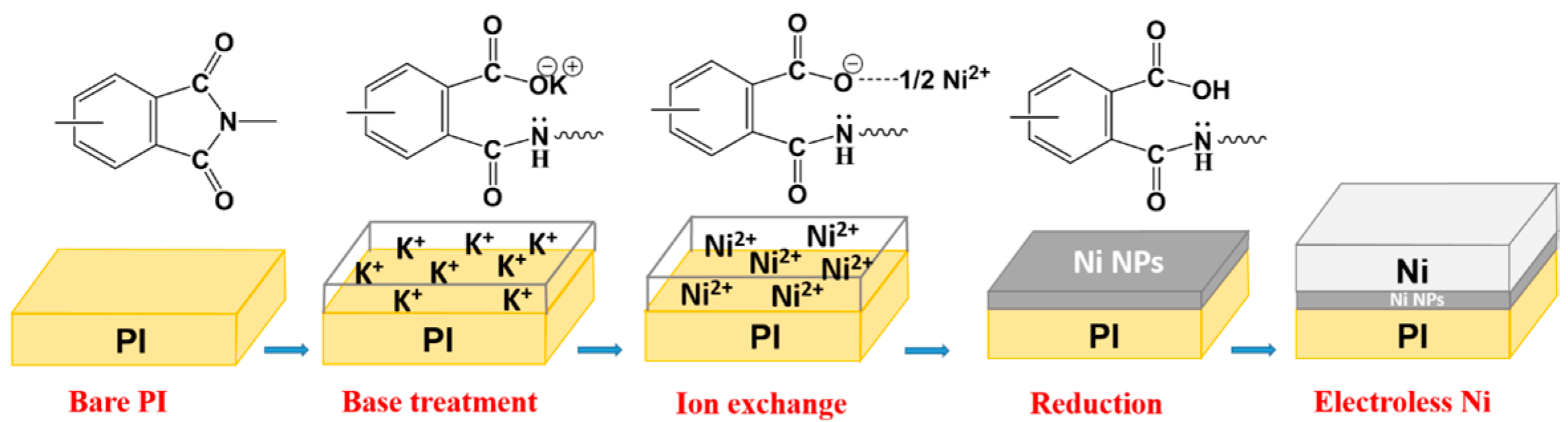

2.2. Metallization Process of PI

2.3. Characterization

2.3.1. Imide-Ring Opening Reaction and Contact Angle

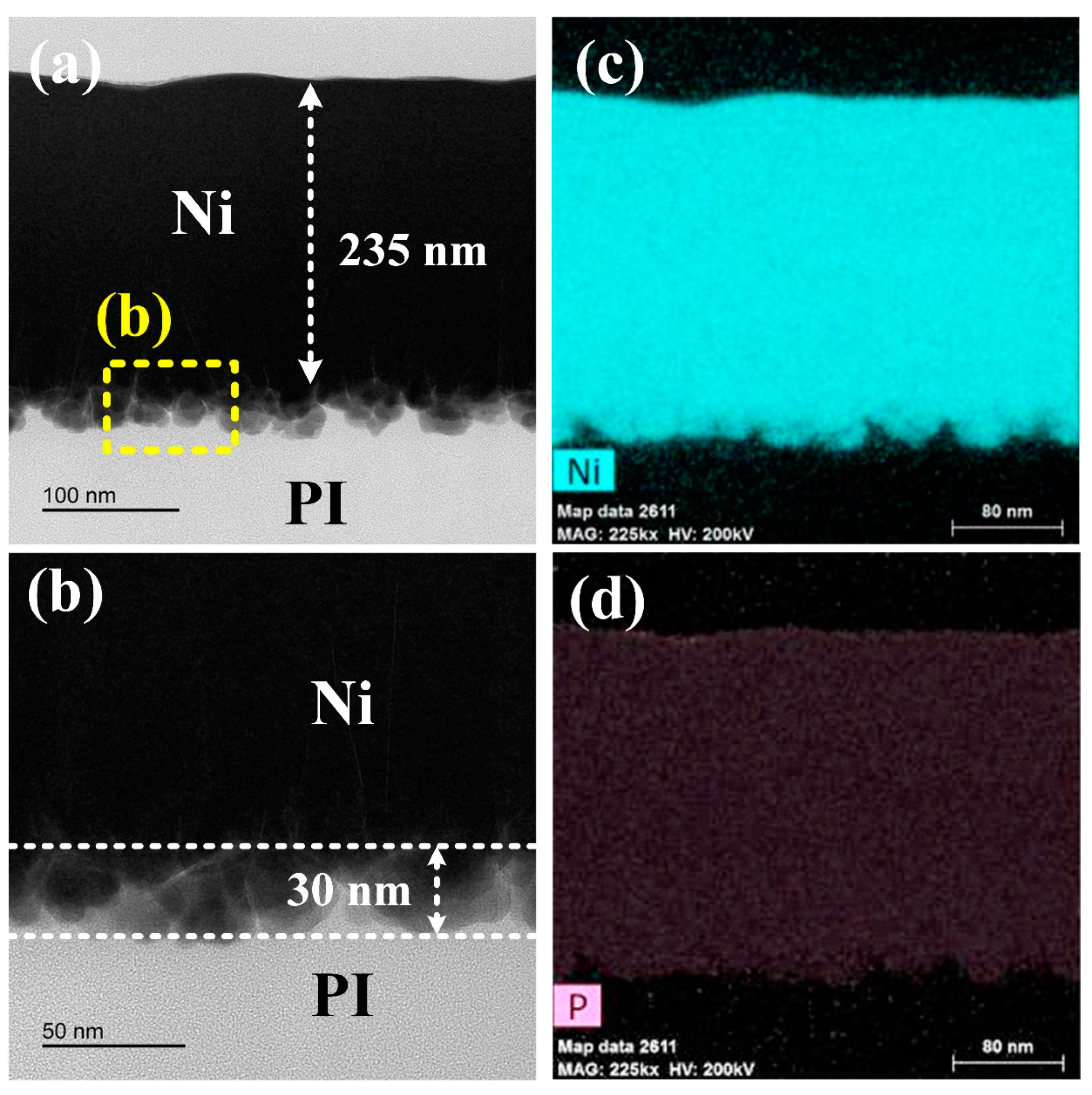

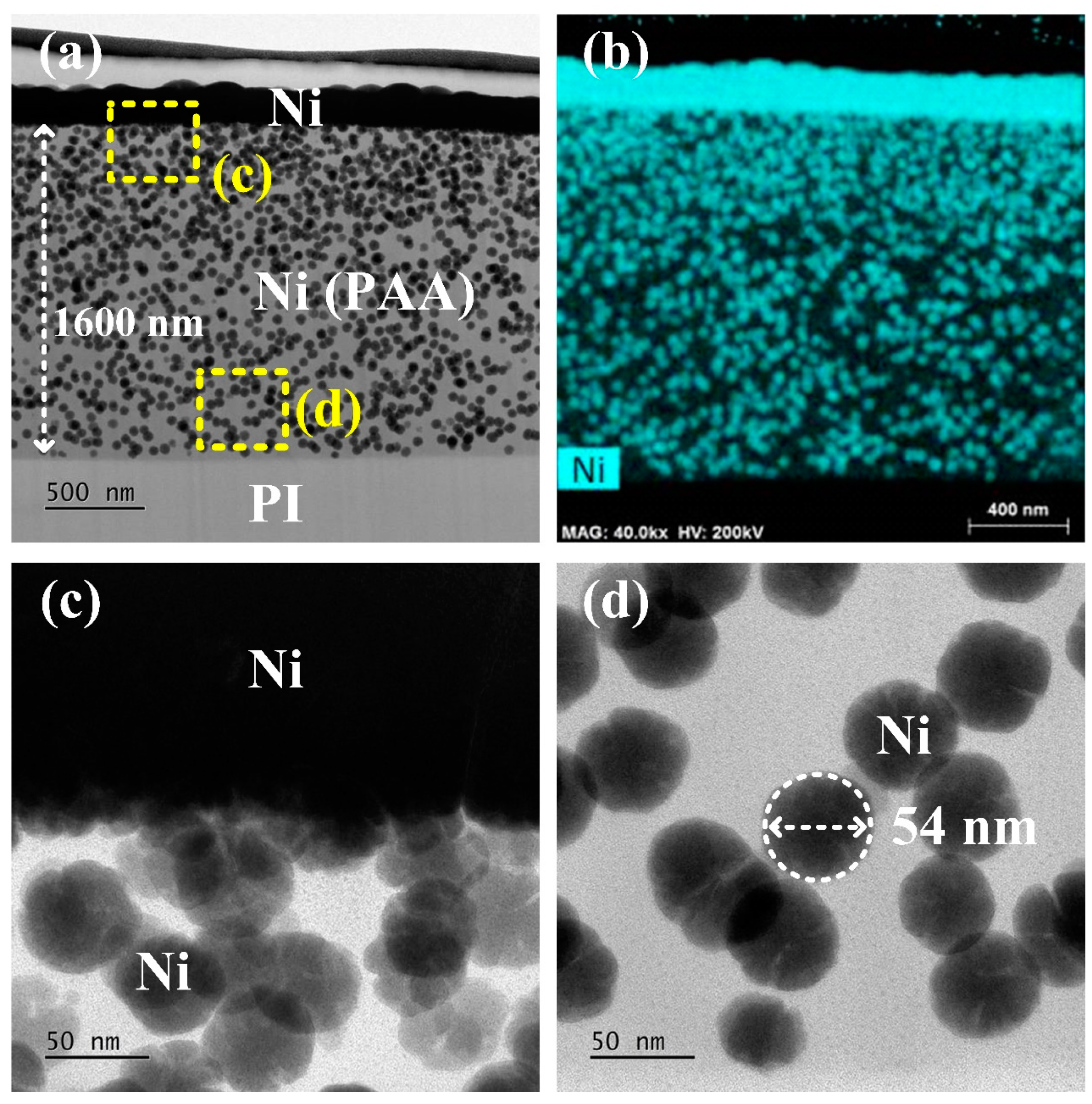

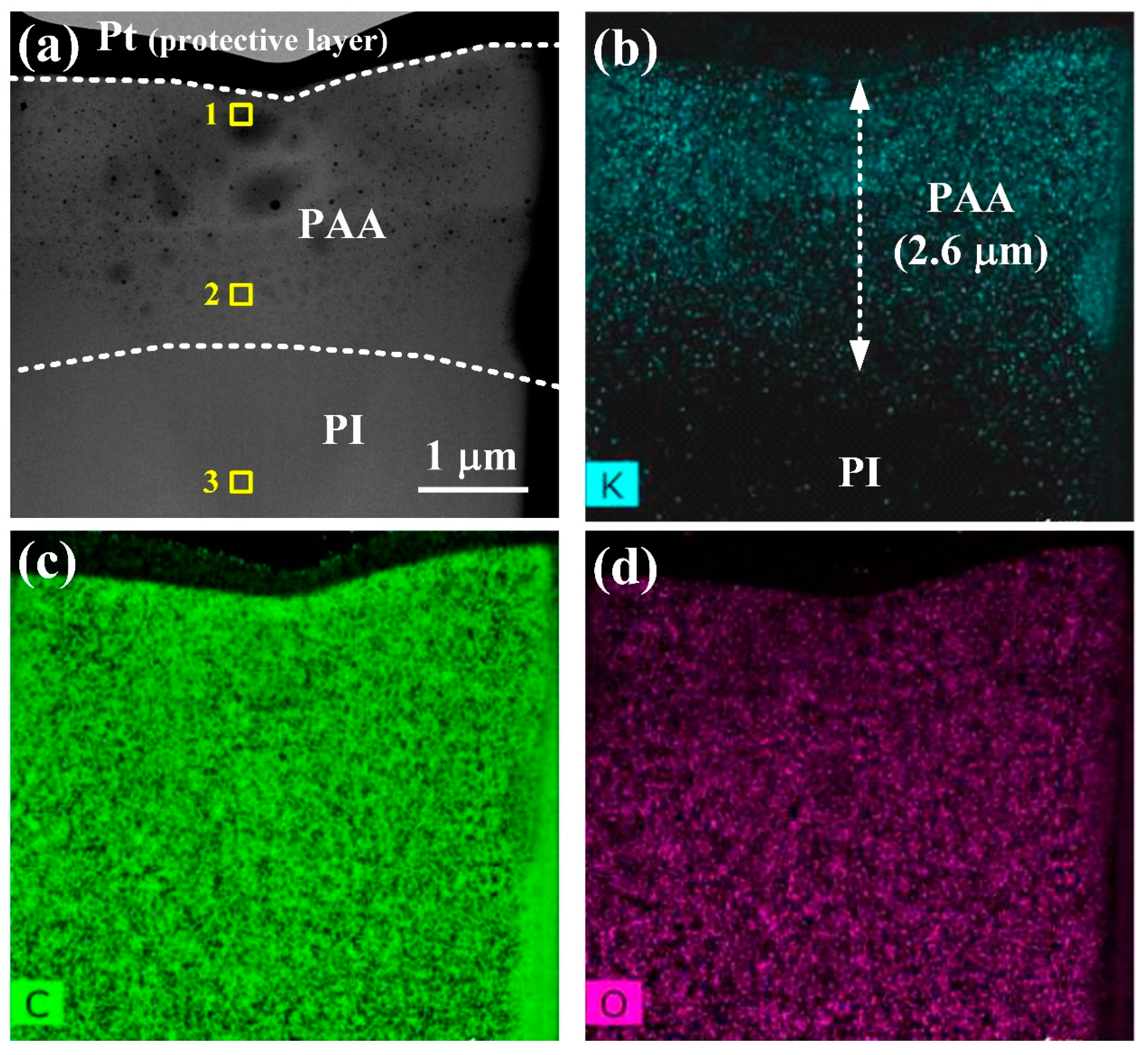

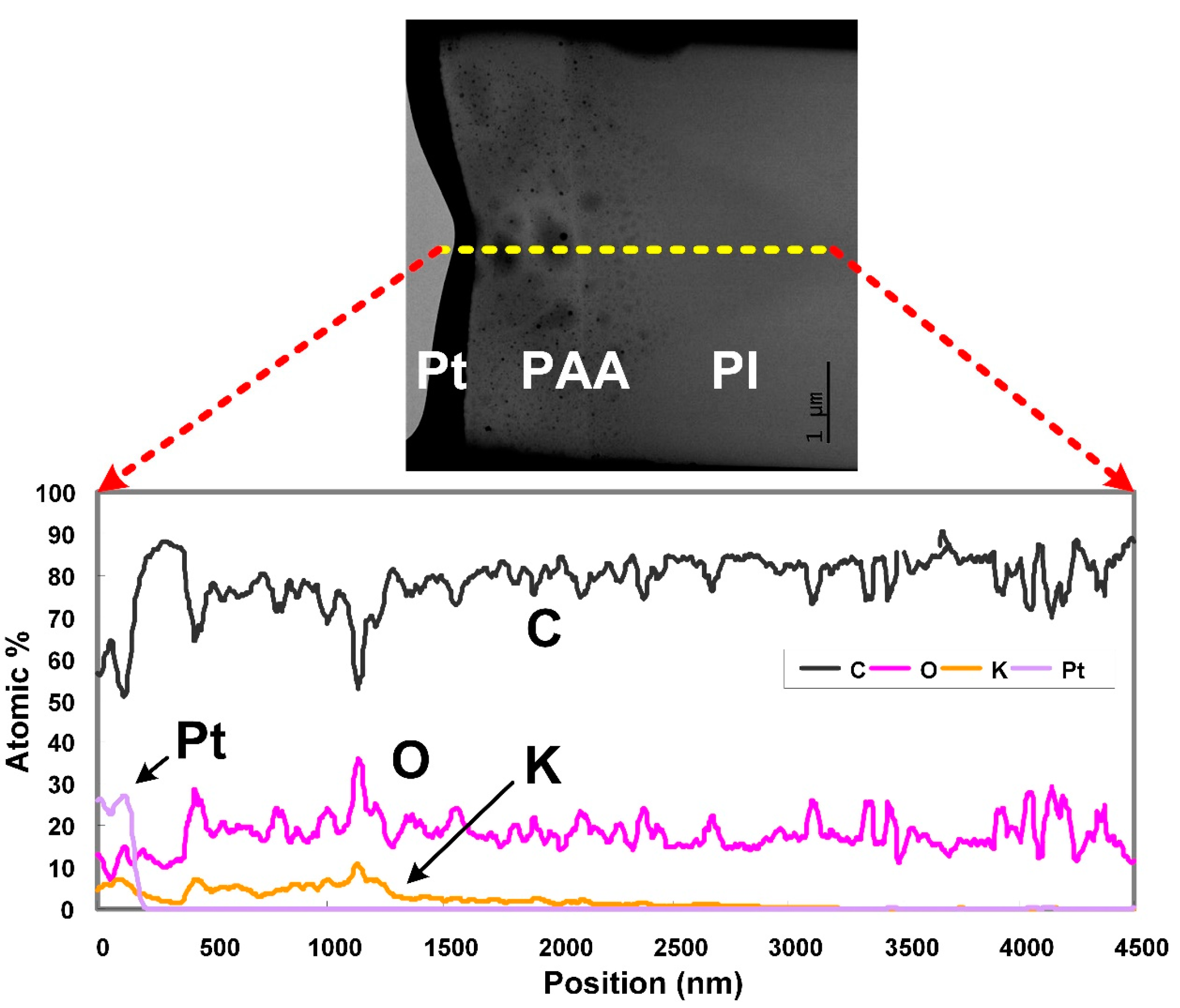

2.3.2. Surface and Cross-Sectional Microstructures of Ni-Metallized PI Film

2.3.3. Peel Strength Test

3. Results and Discussion

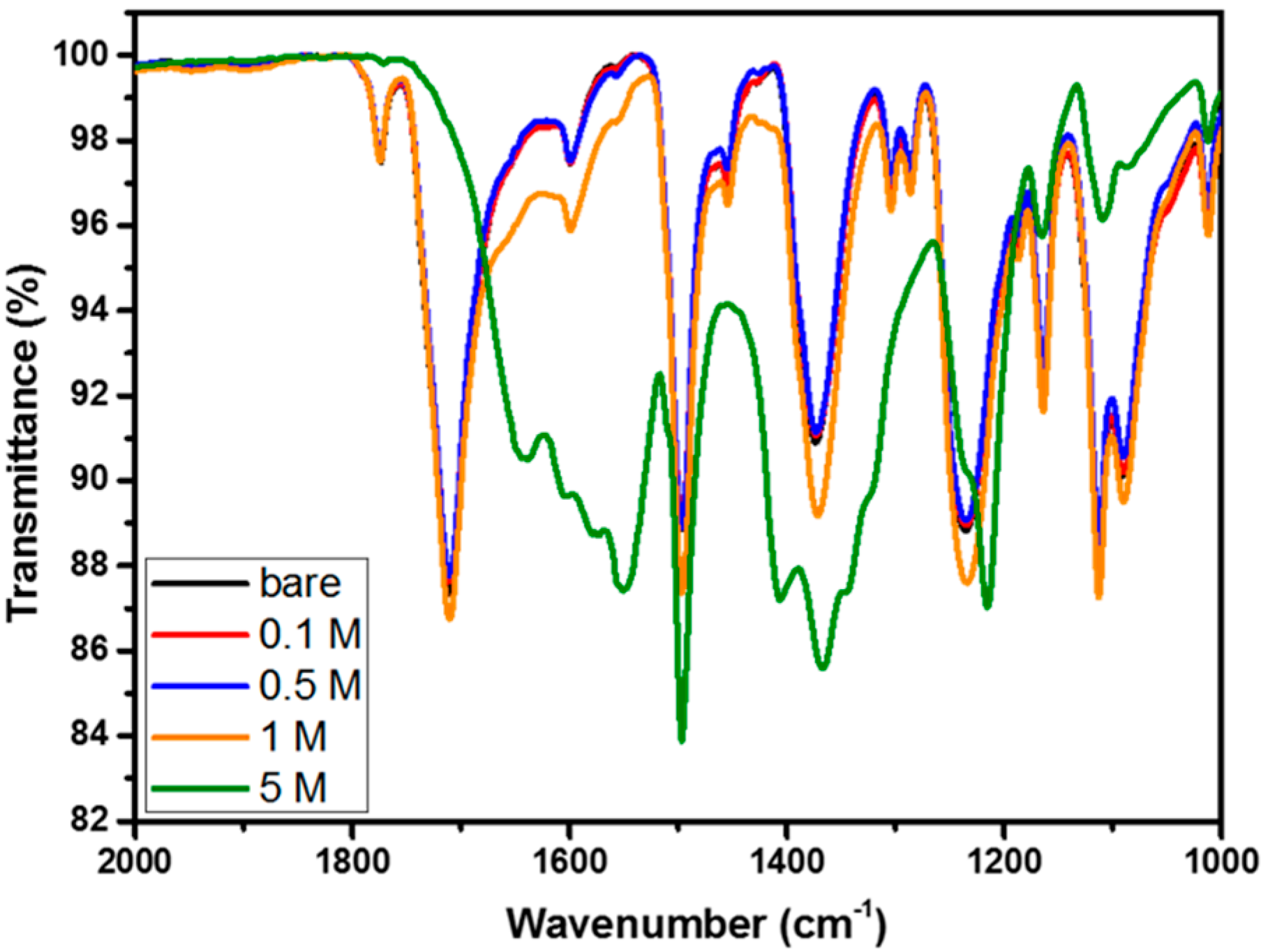

3.1. ATR-FTIR and Contact Angle Analyses of KOH-Treated PI Films

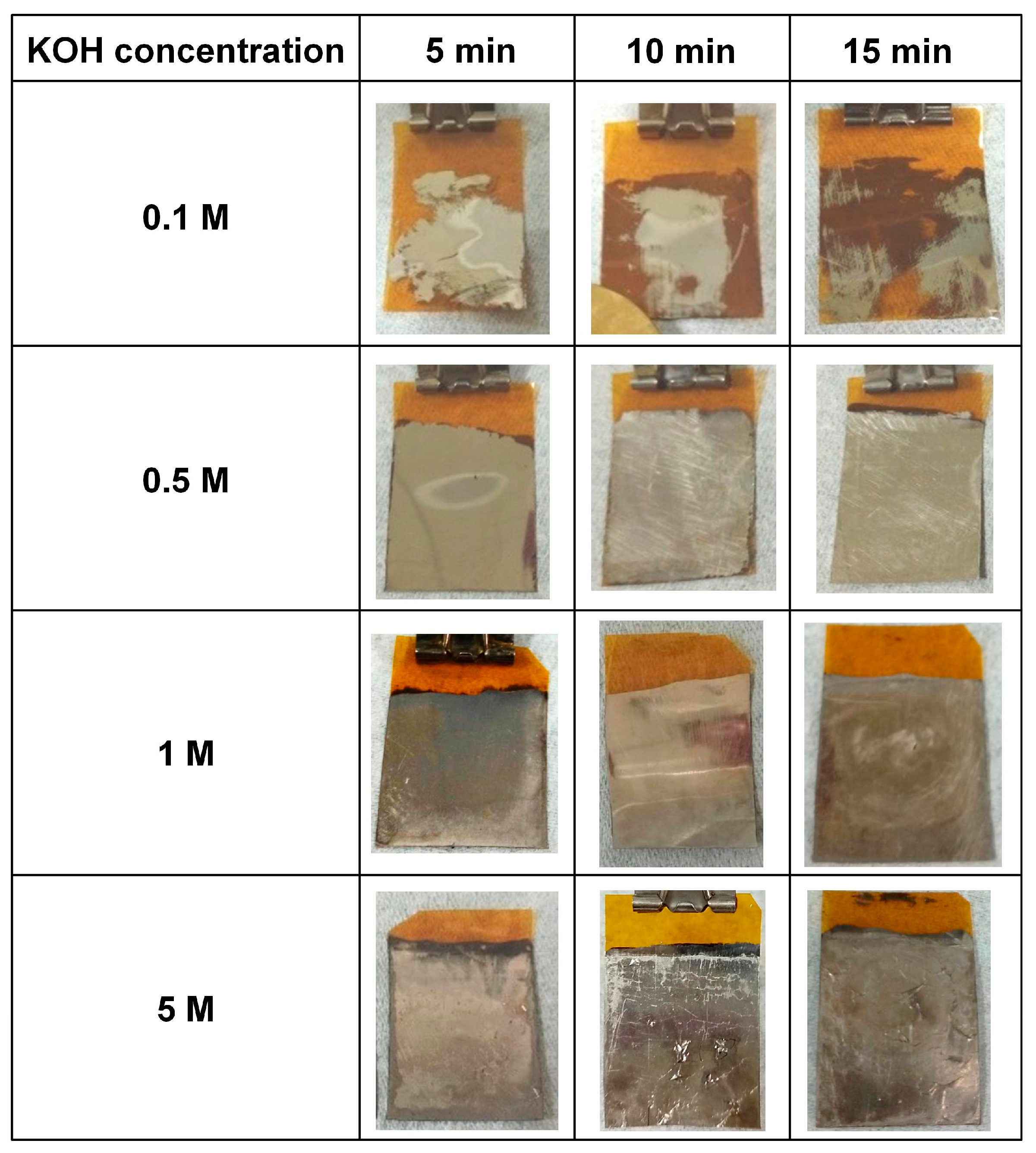

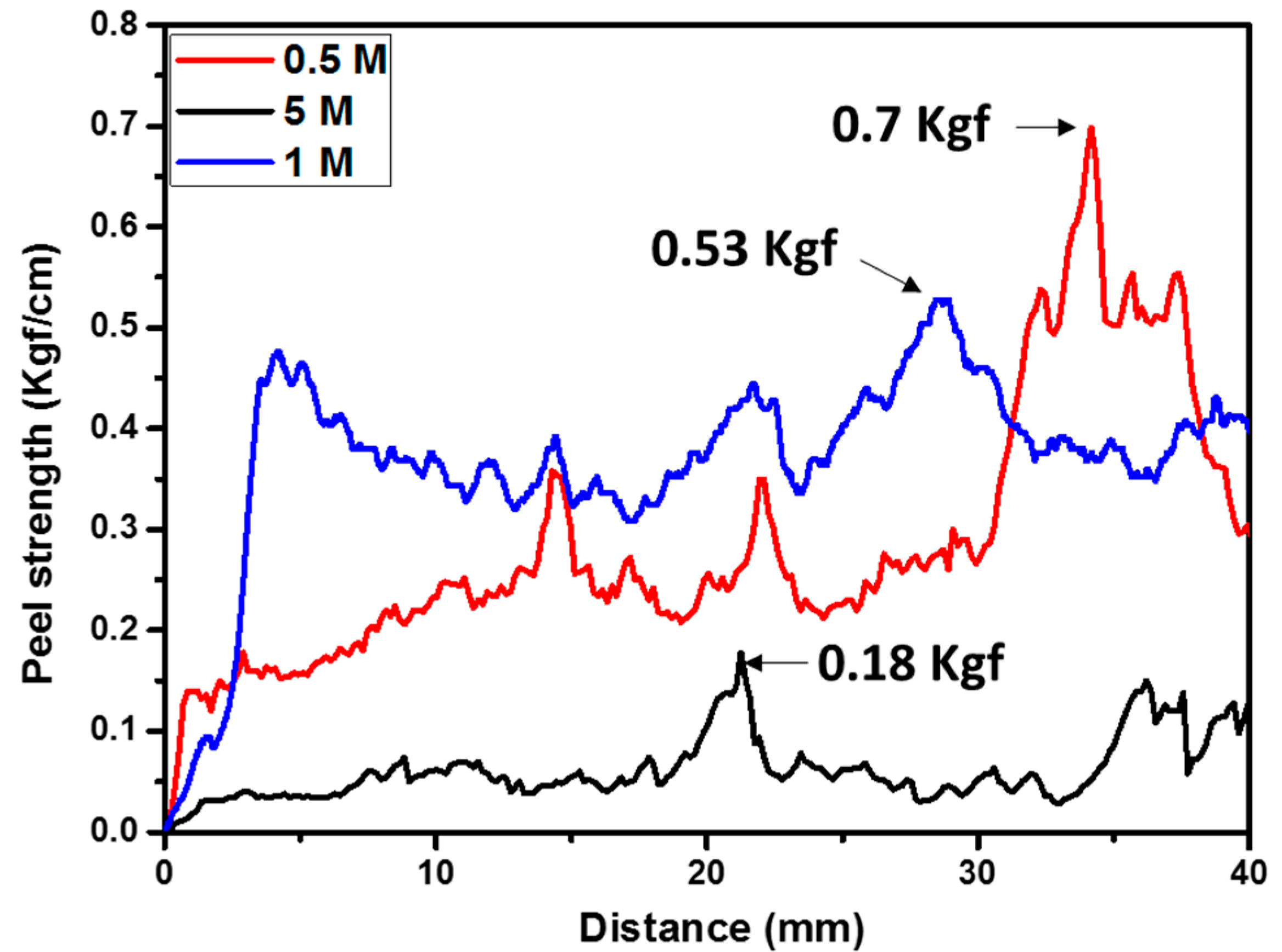

3.2. Surface Metallization of PI Film

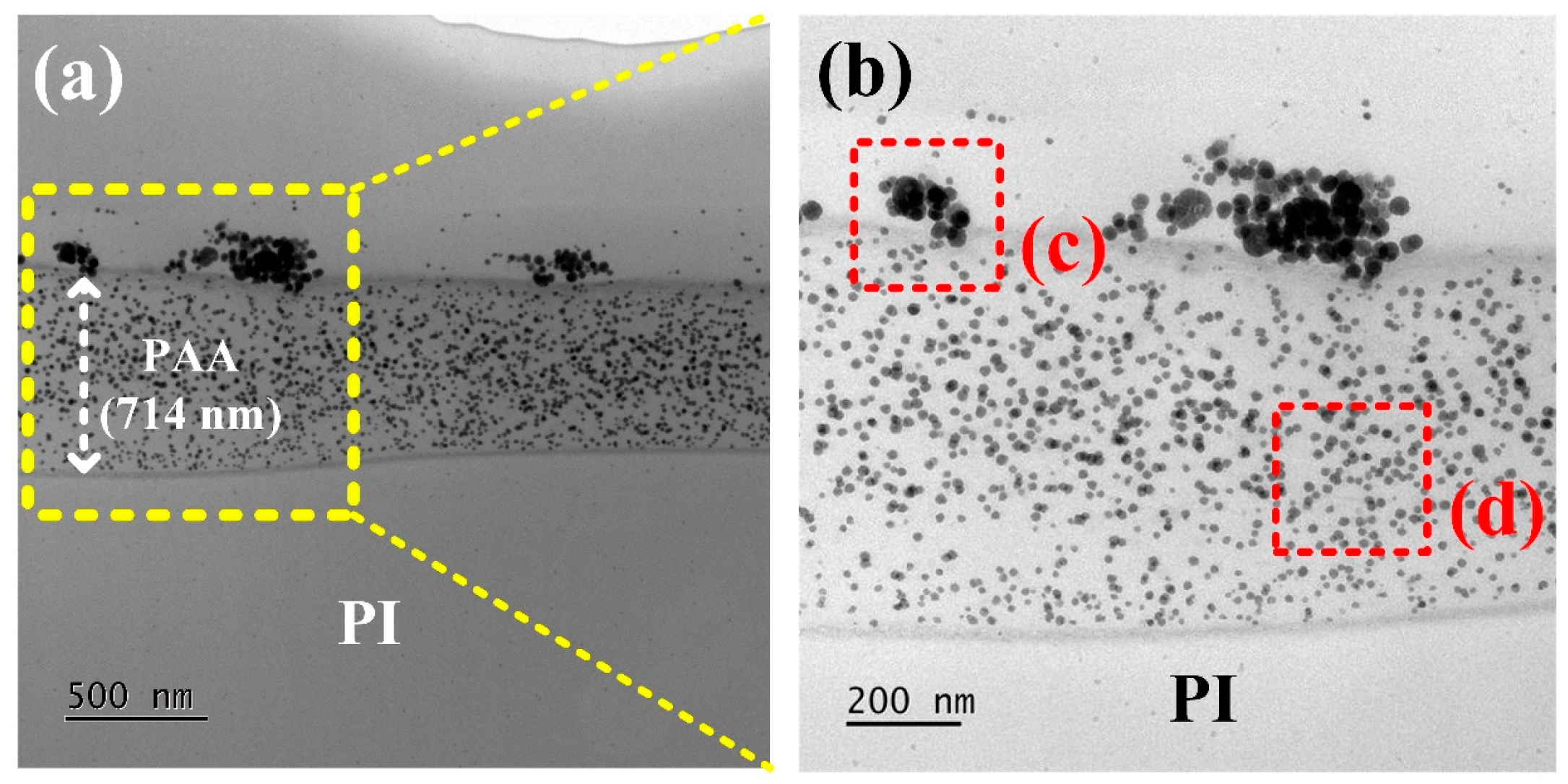

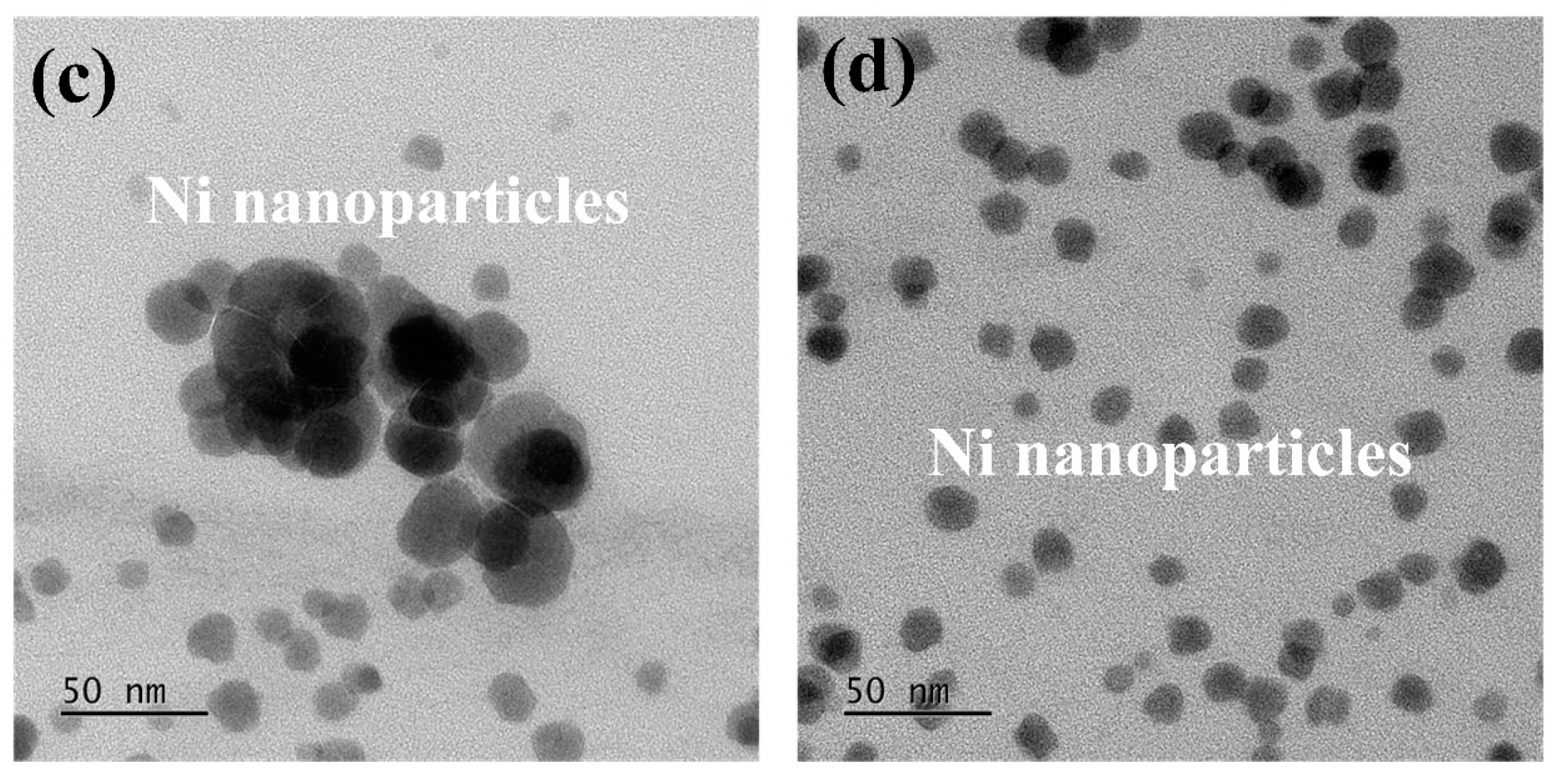

3.3. Cross-Sectional Characterization of Metallized PI Film

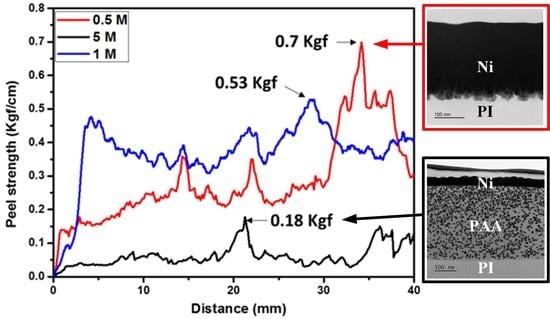

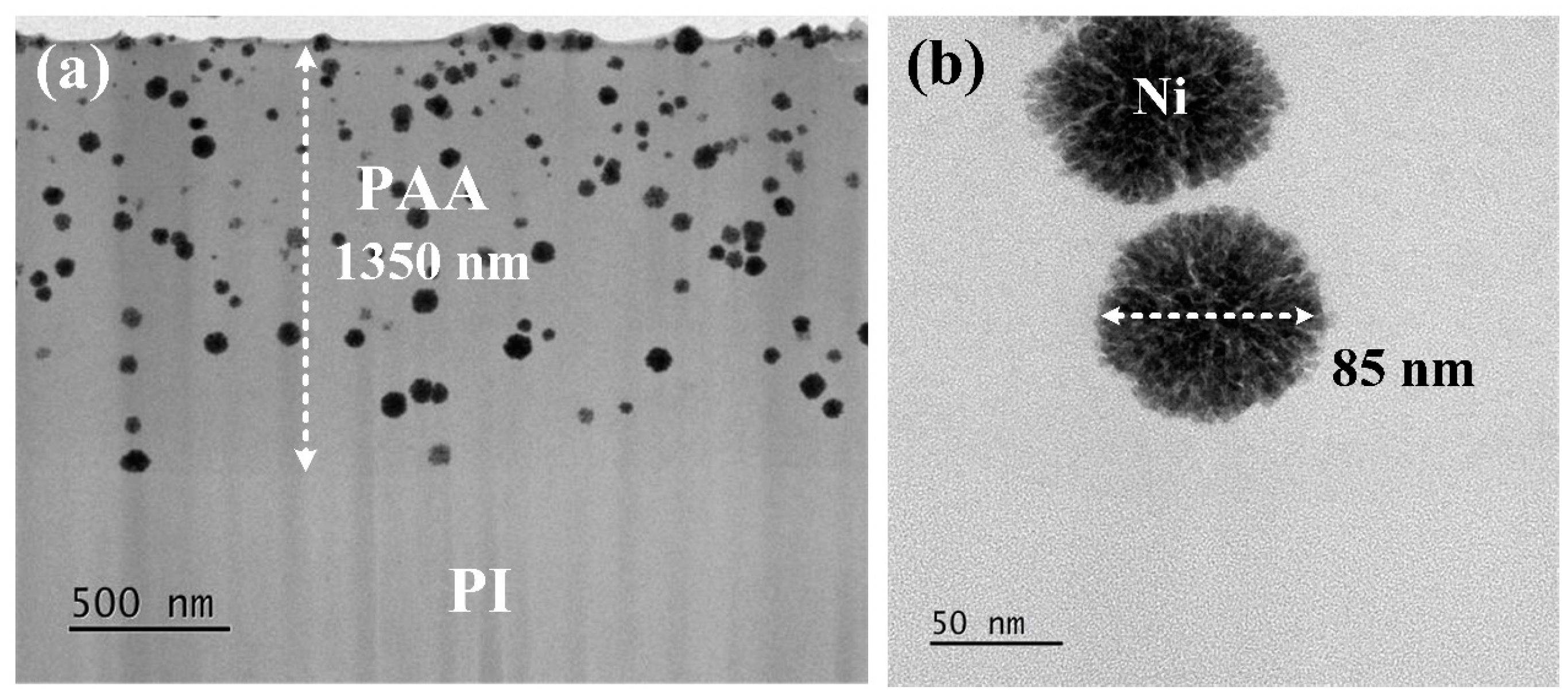

3.4. Pull-Off Examination of Metallized Layer on PI Film

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Dow, W.P.; Liao, G.L.; Huang, S.E.; Chen, S.W. Modification of Cu nanoparticles with a disulfide for polyimide metallization. J. Mater. Chem. 2010, 20, 3600–3609. [Google Scholar] [CrossRef]

- Park, S.C.; Min, K.J.; Lee, K.H.; Jeong, Y.; Park, Y.B. Effect of annealing on the interfacial adhesion energy between electroless-plated Ni and polyimide. Met. Mater. Int. 2011, 17, 111–115. [Google Scholar] [CrossRef]

- Suh, S.W.; Kim, J.J.; Kim, S.H.; Park, B.K. Effect of PI film surface on printing of Pd(II) catalytic ink for electroless copper plating in the printed electronics. J. Ind. Eng. Chem. 2012, 18, 290–294. [Google Scholar] [CrossRef]

- Shen, F.Y.; Huang, S.E.; Dow, W.-P. Silver Metallization of Polyimide Surfaces Using Environmentally Friendly Reducing Agents. ECS Electrochem. Lett. 2013, 2, D45–D48. [Google Scholar] [CrossRef]

- Giovangrandi, L.; Gilchrist, K.H.; Whittington, R.H.; Kovacs, G.T. Low-cost microelectrode array with integrated heater for extracellular recording of cardiomyocyte cultures using commercial flexible printed circuit technology. Sens. Actuators B Chem. 2006, 113, 545–554. [Google Scholar] [CrossRef]

- Ng, J.H.G.; Desmulliez, M.P.Y.; Lamponi, M.; Moffat, B.G.; McCarthy, A.; Suyal, H.; Walker, A.C.; Prior, K.A.; Hand, D.P. A direct-writing approach to the micro-patterning of copper onto polyimide. Circuit World 2009, 35, 3–17. [Google Scholar] [CrossRef]

- Fjelstad, J. Flexible circuit materials. Circuit World 2008, 34, 19–24. [Google Scholar] [CrossRef]

- Yang, S.; Wu, D.; Qi, S.; Cui, G.; Jin, R.; Wu, Z. Fabrication of highly reflective and conductive double-surface-silvered layers embedded on polymeric films through all-wet process at room temperature. J. Phys. Chem. B 2009, 113, 9694–9701. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Park, Y.J.; Choi, J.H.; Han, H.S.; Hong, Y.T. Surface modification of polyimide film by coupling reaction for copper metallization. J. Ind. Eng. Chem. 2009, 15, 23–30. [Google Scholar] [CrossRef]

- Akamatsu, K.; Ikeda, S.; Nawafune, H.; Deki, S. Surface modification-based synthesis and microstructural tuning of nanocomposite layers: Monodispersed copper nanoparticles in polyimide resins. Chem. Mater. 2003, 15, 2488–2491. [Google Scholar] [CrossRef]

- Akamatsu, K.; Ikeda, S.; Nawafune, H. Site-selective direct silver metallization on surface-modified polyimide layers. Langmuir 2003, 19, 10366–10371. [Google Scholar] [CrossRef]

- Ho, S.M.; Wanc, T.H.; Chen, H.L.; Chen, K.M.; Man, S.M.; Hung, A. Metallization of polyimide film by wet process. J. Appl. Polym. Sci. 1994, 51, 1373–1380. [Google Scholar] [CrossRef]

- Akamatsu, K.; Ikeda, S.; Nawafune, H.; Yanagimoto, H. Direct patterning of copper on polyimide using ion exchangeable surface templates generated by site-selective surface modification. J. Am. Chem. Soc. 2004, 126, 10822–10823. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Xu, Z.; Wu, D.; Wu, Z.; Hu, T.S. Systematic synthesis of polyimide@ inorganics core–shell microspheres via ion-exchange and interfacial reaction. Mater. Lett. 2016, 177, 30–33. [Google Scholar] [CrossRef]

- Ran, J.; Zhang, J.; Yao, W.; Wei, Y. Properties of Cu film and Ti/Cu film on polyimide prepared by ion beam techniques. Appl. Surf. Sci. 2010, 256, 7010–7017. [Google Scholar] [CrossRef]

- Stephans, L.E.; Myles, A.; Thomas, R.R. Kinetics of alkaline hydrolysis of a polyimide surface. Langmuir 2000, 16, 4706–4710. [Google Scholar] [CrossRef]

- Cho, S.-J.; Shrestha, S.P.; Boo, J.-H. Surface treatment for Cu metallization on polyimide film by atmospheric pressure dielectric barrier discharge plasma system. Curr. Appl. Phys. 2011, 11, S135–S139. [Google Scholar] [CrossRef]

- Wu, H.; Susanto, A.; Lian, K. Thin and flexible Ni-P based current collectors developed by electroless deposition for energy storage devices. Appl. Surf. Sci. 2017, 394, 63–69. [Google Scholar] [CrossRef]

- Liao, B.; Wu, X.Y.; Zhang, X.; Liang, H.; Zhang, H.-X. The study of polyimide modified by Ni plasma and its adhesion to Cu films. Nucl. Instrum. Methods Phys. Res. Sec. B 2013, 307, 580–585. [Google Scholar] [CrossRef]

- Papadopoulou, E.L.; Morselli, D.; Prato, M.; Barcellona, A.; Athanassiou, A.; Bayer, I.S. An efficient pure polyimide ammonia sensor. J. Mater. Chem. C 2016, 4, 7790–7797. [Google Scholar] [CrossRef]

- Putz, B.; Schoeppner, R.L.; Glushko, O.; Bahr, D.F.; Cordill, M.J. Improved electro-mechanical performance of gold films on polyimide without adhesion layers. Scr. Mater. 2015, 102, 23–26. [Google Scholar] [CrossRef] [PubMed]

- Woo, T.G.; Park, I.S.; Jung, K.H.; Jeon, W.Y.; Seol, K.W. Effect of RF sputtering power on the adhesion of Ni thin film to polyimide. Electron. Mater. Lett. 2011, 7, 353–358. [Google Scholar] [CrossRef]

- Kotnur, V.; Tichelaar, F.; Janssen, G. Sputter deposited Ni–Ti thin films on polyimide substrate. Surf. Coat. Technol. 2013, 222, 44–47. [Google Scholar] [CrossRef]

- Matsubara, H.; Yonekawa, T.; Ishino, Y.; Saito, N.; Nishiyama, H.; Inoue, Y. The observation of the nucleation and growth of electrolessly plated nickel deposited from different bath pH by TEM and QCM method. Electrochim. Acta 2006, 52, 402–407. [Google Scholar] [CrossRef]

- Mu, S.; Wu, D.; Wang, Y.; Wu, Z.; Yang, X.; Yang, W. Fabrication of nickel oxide nanocomposite layer on a flexible polyimide substrate via ion exchange technique. ACS Appl. Mater. Interfaces 2009, 2, 111–118. [Google Scholar] [CrossRef] [PubMed]

- Thomas, R.R. Wetting kinetics of modified polyimide surfaces: Interactions with polar solvents. J. Colloid Interface Sci. 2004, 279, 515–522. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Lu, Q.; Qian, X.; Zhu, Z.; Yin, J. Preparation of surface bound silver nanoparticles on polyimide by surface modification method and its application on electroless metal deposition. Appl. Surf. Sci. 2004, 233, 299–306. [Google Scholar] [CrossRef]

- Ikeda, S.; Yanagimoto, H.; Akamatsu, K.; Nawafune, H. Copper/Polyimide Heterojunctions: Controlling Interfacial Structures Through an Additive-Based, All-Wet Chemical Process Using Ion-Doped Precursors. Adv. Funct. Mater. 2007, 17, 889–897. [Google Scholar] [CrossRef]

- Akamatsu, K.; Nakahashi, K.; Ikeda, S.; Nawafune, H. Fabrication and structural characterization of nanocomposites consisting of Ni nanoparticles dispersed in polyimide films. Eur. Phys. J. D 2003, 24, 377–380. [Google Scholar] [CrossRef]

- Hsiao, Y.-S.; Whang, W.-T.; Wu, S.-C.; Chuang, K.-R. Chemical formation of palladium-free surface-nickelized polyimide film for flexible electronics. Thin Solid Films 2008, 516, 4258–4266. [Google Scholar] [CrossRef]

- Cherng, S.-J.; Chen, C.-M.; Dow, W.-P.; Lin, C.-H.; Chen, S.-W. Chemical deposition of Ni/Pt Bi-layer on polyimide film as flexible counterelectrodes for dye-sensitized solar cells. Electrochem. Solid State Lett. 2011, 14, P13–P15. [Google Scholar] [CrossRef]

- Akamatsu, K.; Shinkai, H.; Ikeda, S.; Adachi, S.; Nawafune, H.; Tomita, S. Controlling interparticle spacing among metal nanoparticles through metal-catalyzed decomposition of surrounding polymer matrix. J. Am. Chem. Soc. 2005, 127, 7980–7981. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Lu, Q.; Zhao, Y. Laser-induced site-selective silver seeding on polyimide for electroless copper plating. Appl. Surf. Sci. 2006, 253, 1573–1580. [Google Scholar] [CrossRef]

- Ikeda, S.; Akamatsu, K.; Nawafune, H.; Nishino, T.; Deki, S. Formation and growth of copper nanoparticles from ion-doped precursor polyimide layers. J. Phys. Chem. B 2004, 108, 15599–15607. [Google Scholar] [CrossRef]

- Li, L.; Ma, Y.; Gao, G.; Wang, H.; Yang, X.; Xie, J.; Wang, W. Pretreatment and deposition process of electroless Ni plating on polyimide film for electronic field applications. Colloids Surf. A 2015, 477, 42–48. [Google Scholar] [CrossRef]

- Lai, K.C.; Wu, P.Y.; Chen, C.M.; Wei, T.C.; Wu, C.H.; Feng, S.P. Interfacial characterizations of a nickel-phosphorus layer electrolessly deposited on a silane compound-modified silicon wafer under thermal annealing. J. Electron. Mater. 2016, 45, 4813–4822. [Google Scholar] [CrossRef]

| KOH (M) | Transmittance (%) | Transmittance/Absorbance | A1720/A1500 | Relative Surface Imide Content (%) | Contact Angle (°) | ||

|---|---|---|---|---|---|---|---|

| 1720 cm−1 | 1500 cm−1 | 1720 cm−1 | 1500 cm−1 | ||||

| 0 | 87.35 | 88.85 | 0.8735/0.0587 | 0.8885/0.0513 | 1.144 | 100 | 80.06 |

| 0.1 | 87.63 | 89.04 | 0.8763/0.0573 | 0.8904/0.0504 | 1.137 | 99.39 | 55.55 |

| 0.5 | 87.75 | 88.89 | 0.8775/0.0568 | 0.8889/0.0511 | 1.112 | 97.20 | 28.81 |

| 1 | 86.75 | 87.36 | 0.8675/0.0617 | 0.8736/0.0587 | 1.051 | 91.87 | 22.03 |

| 5 | 98.35 | 83.88 | 0.9835/0.0072 | 0.8388/0.0763 | 0.094 | 8.22 | 20.74 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, P.-Y.; Lin, C.-H.; Chen, C.-M. Study of Surface Metallization of Polyimide Film and Interfacial Characterization. Metals 2017, 7, 189. https://doi.org/10.3390/met7060189

Wu P-Y, Lin C-H, Chen C-M. Study of Surface Metallization of Polyimide Film and Interfacial Characterization. Metals. 2017; 7(6):189. https://doi.org/10.3390/met7060189

Chicago/Turabian StyleWu, Pei-Yu, Ching-Hsuan Lin, and Chih-Ming Chen. 2017. "Study of Surface Metallization of Polyimide Film and Interfacial Characterization" Metals 7, no. 6: 189. https://doi.org/10.3390/met7060189