The Influence of Deoxidation Practice on the As-Cast Grain Size of Austenitic Manganese Steels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Melting and Casting Process

2.3. Material Characterization

2.4. Thermodynamic Equilibrium Calculations

3. Results and Discussion

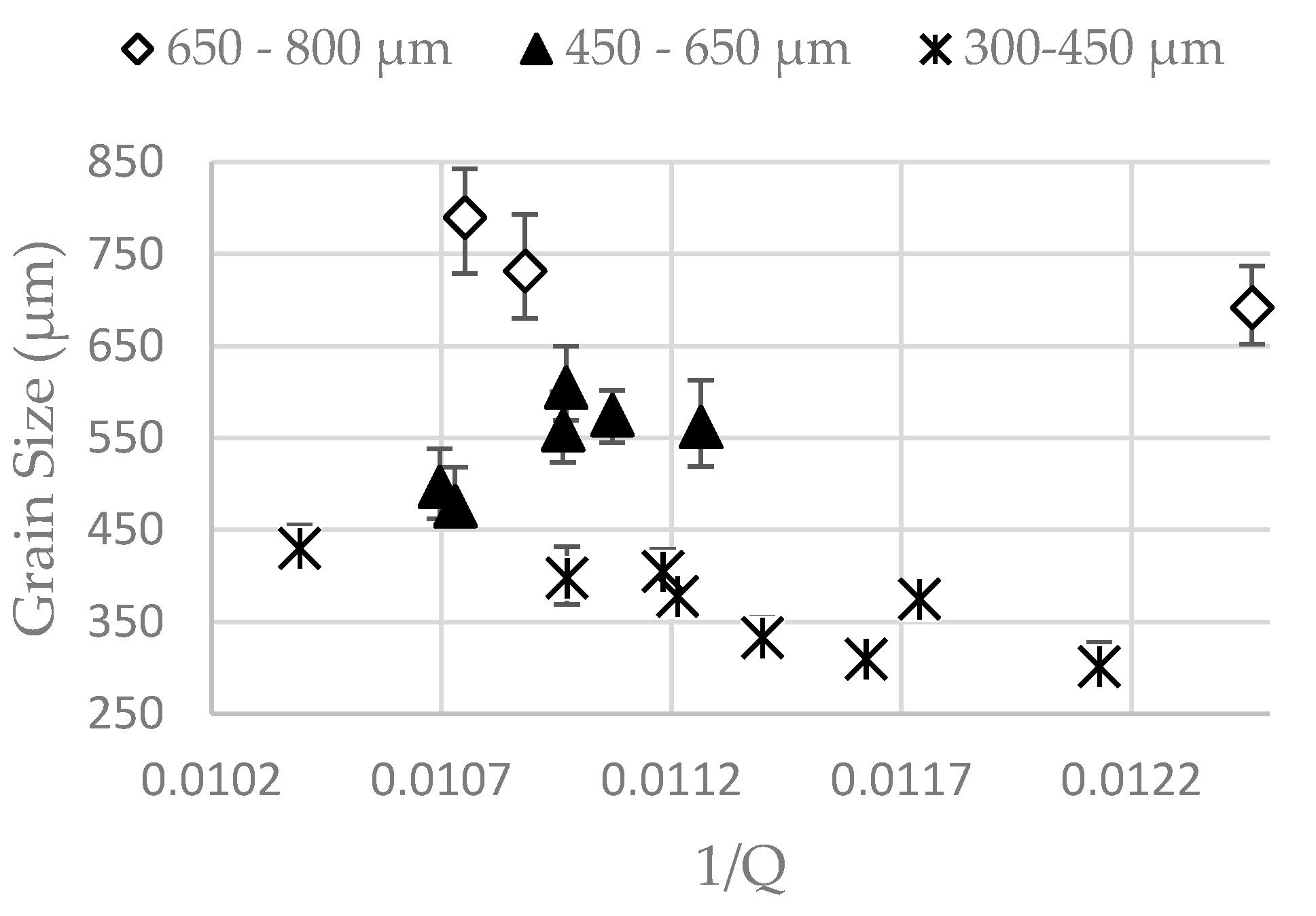

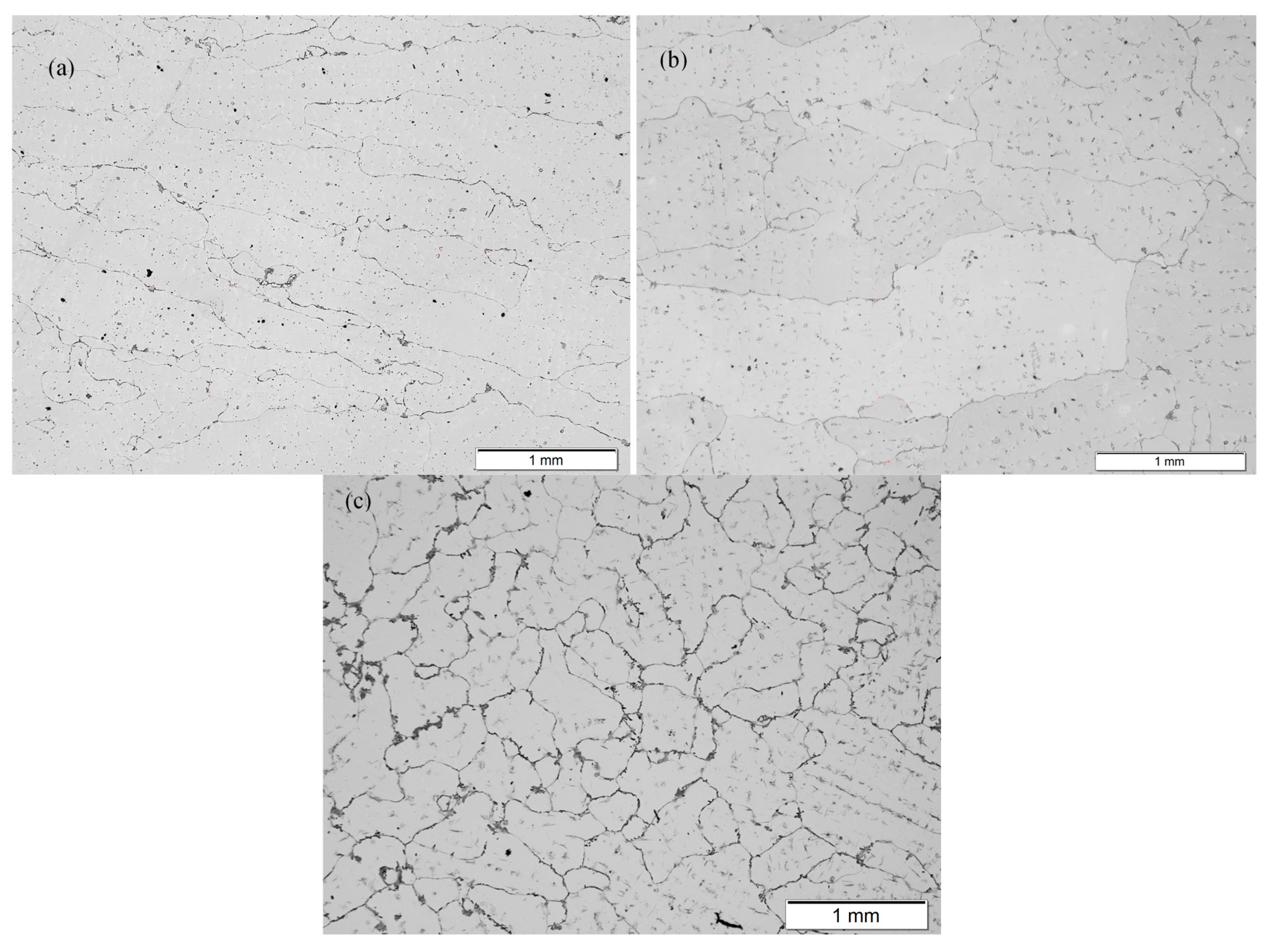

3.1. Grain Size and Microstructure

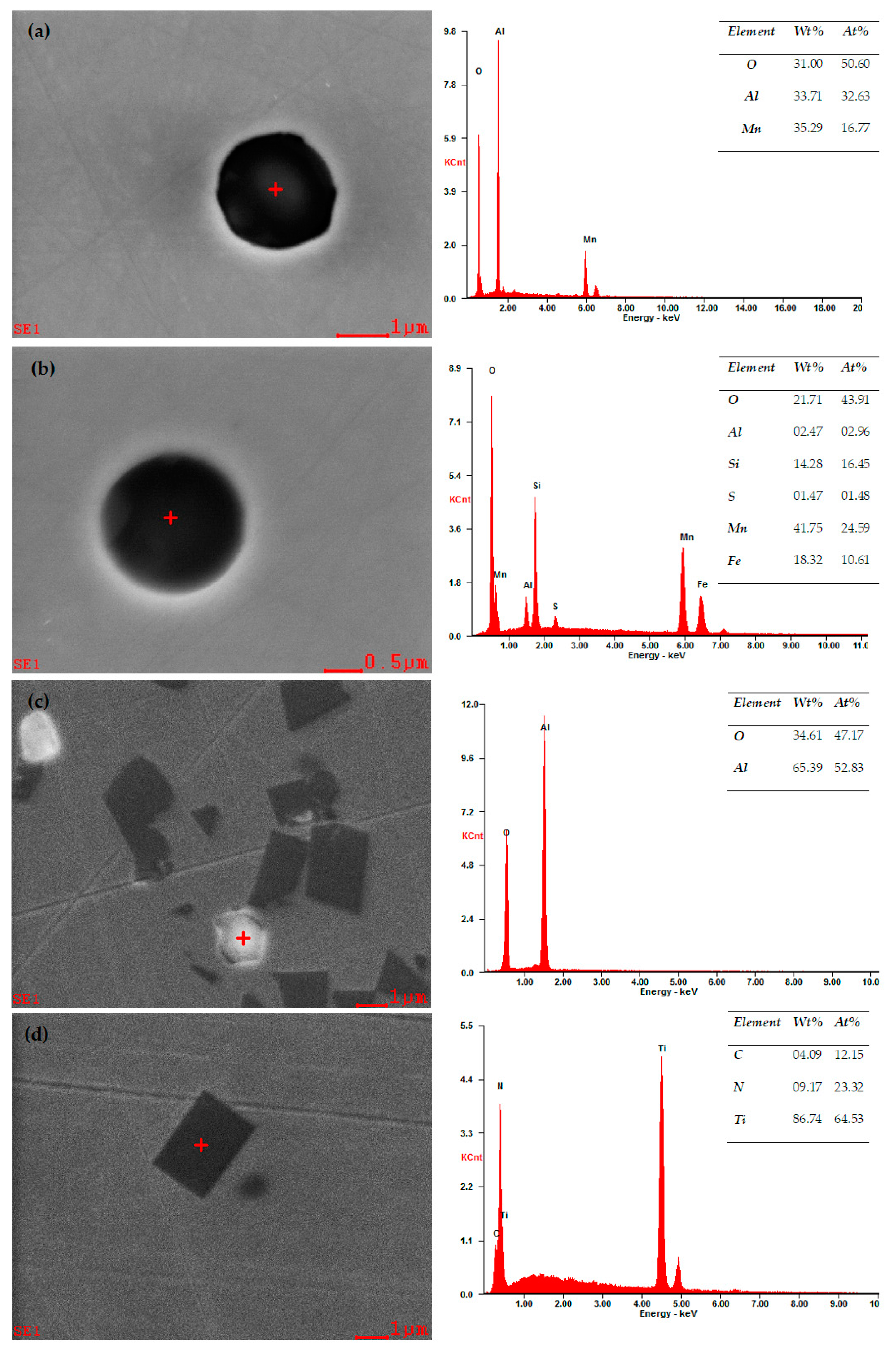

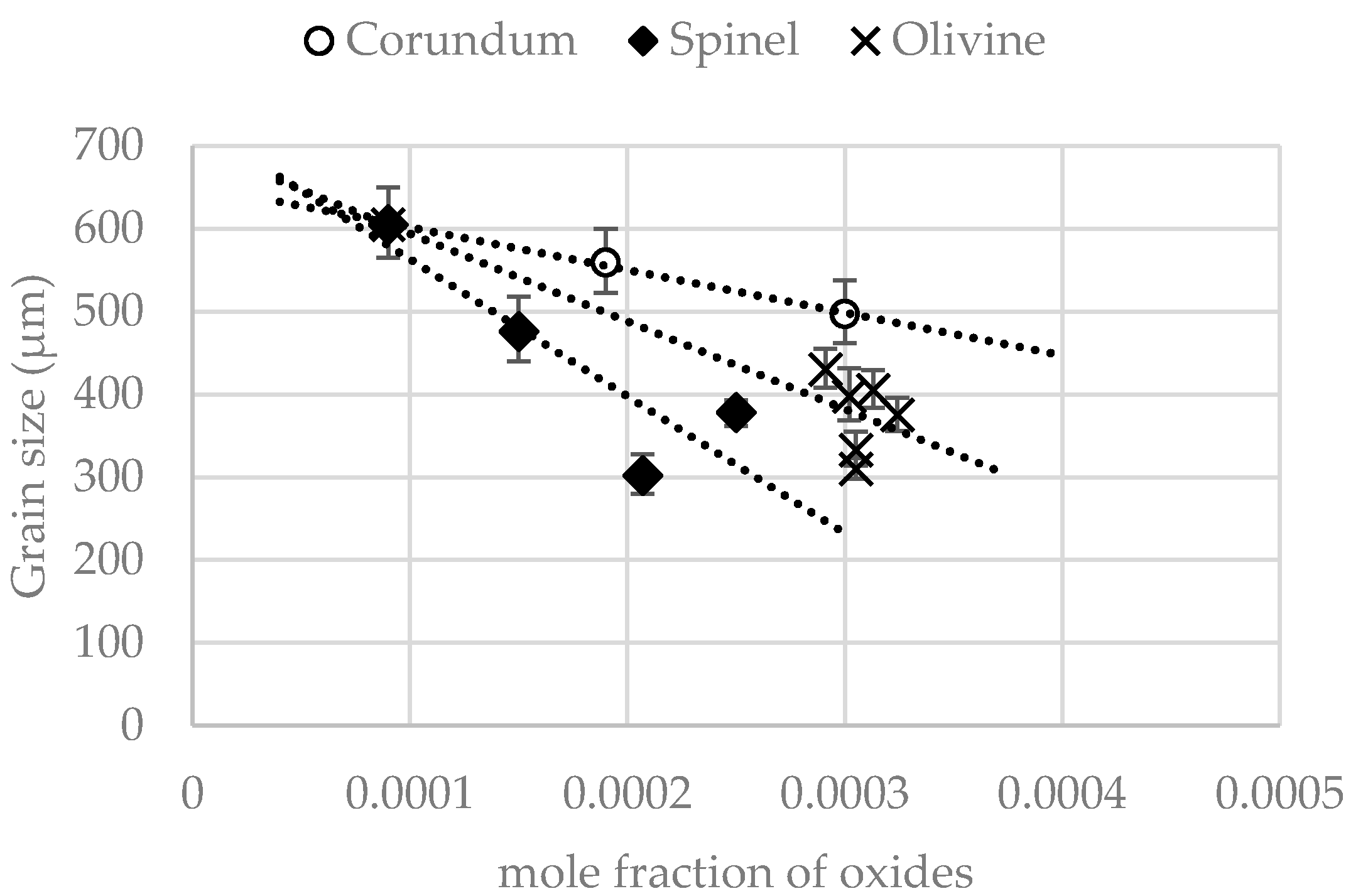

3.2. The Effect of Oxide Particles

3.3. The Effect of Ti(CN) Particles

3.4. The Effect of Deoxidation Practice

4. Conclusions

- Grain size increased as the mole fraction of oxides increased.

- Amongst the oxide particles, spinel particles presented the best potency to nucleate austenitic grains, followed by olivine and finally corundum particles.

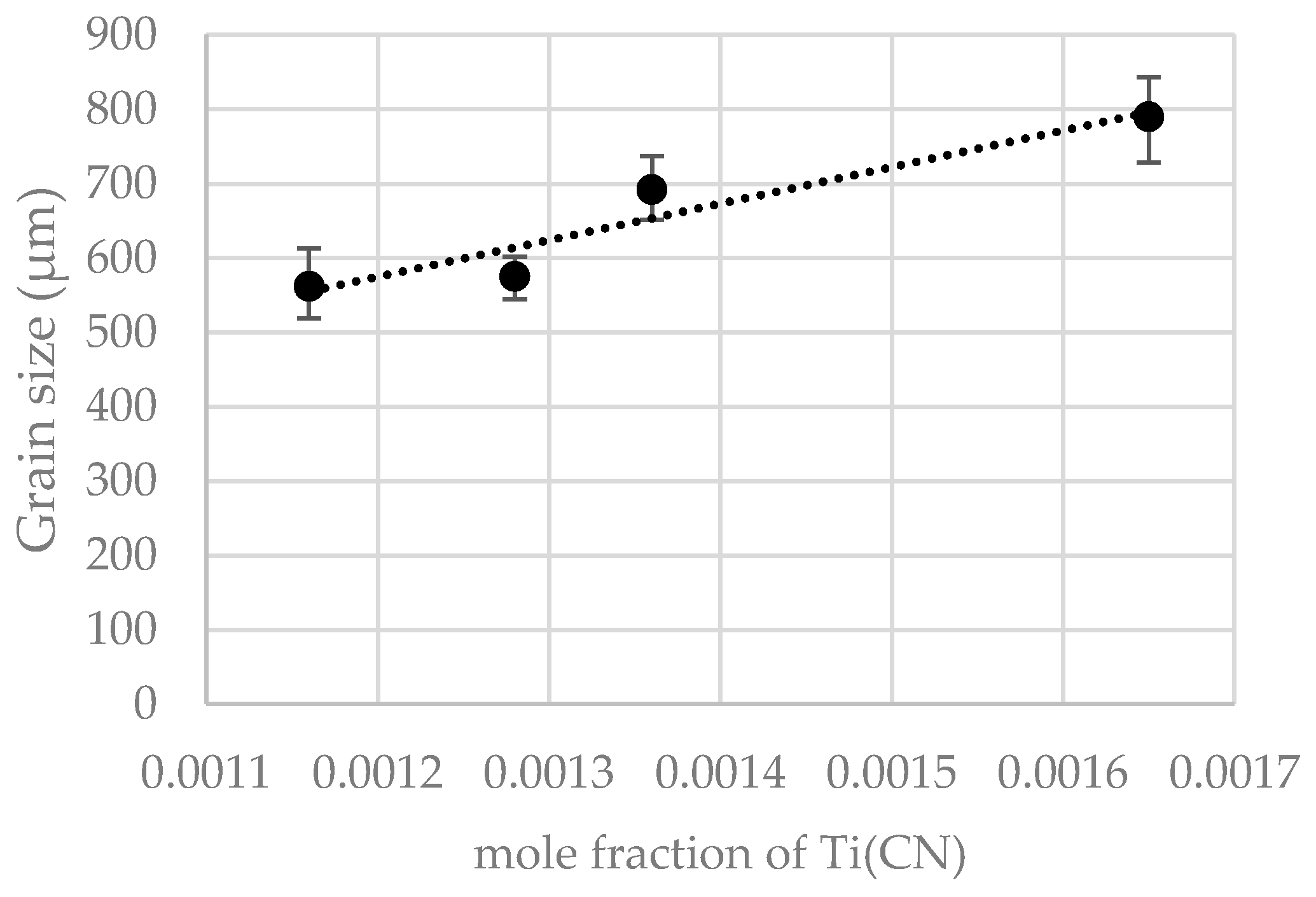

- Ti(CN) particles were not effective as nucleation agents for austenitic grains.

- Under a similar mole fraction of oxides, an increasing mole fraction of Ti(CN) resulted in an increasing grain size. Ti(CN) precipitates on oxide particles in temperatures between the liquidus temperature of steel and the precipitation temperature of oxides; thus, the availability of free oxide particles for austenitic grains to nucleate on is decreased.

- Experimental results on the potency of particles are in good agreement with planar disregistry predictions.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Borse, S.; Mangulkar, Y. Review on grey cast iron inoculation. Int. J. Innov. Res. Sci. Eng. Technol. 2014, 3, 30–36. [Google Scholar]

- Bramfitt, B.L. The effect of carbide and nitride additions on heterogeneous nucleation behavior of liquid iron. Metall. Trans. 1970, 1, 1987–1995. [Google Scholar] [CrossRef]

- StJohn, D.H.; Qian, M.; Easton, M.A.; Cao, P. The interdependence theory: The relationship between grain formation and nucleant selection. Acta Mater. 2011, 59, 4907–4921. [Google Scholar] [CrossRef]

- Haakonsen, F.; Solberg, J.K.; Klevan, O.S.; van der Eijk, C. Grain refinement of austenitic manganese steels. AISTech 2011 Proc. 2011, 2, 764–771. [Google Scholar]

- Lekakh, S.N.; Ge, J.; Richards, V.; O’Malley, R.; TerBush, J.R. Optimization of melt treatment for austenitic steel grain refinement. Metall. Mater. Trans. B 2017, 48, 406–419. [Google Scholar] [CrossRef]

- Siafakas, D.; Matsushita, T.; Lauenstein, Å. Particles precipitation in Ti- and Al-deoxidized hadfield steels. Steel Res. Int. 2016, 87, 1344–1355. [Google Scholar] [CrossRef]

- Siafakas, D.; Matsushita, T.; Lauenstein, Å.; Ekerot, S.; Jarfors, A.E.W. A particle population analysis in Ti- and Al-Deoxidized Hadfield steels. Int. J. Cast Met. Res. 2017. submitted. [Google Scholar]

- ASTM A128/A128M-93. Standard Specification for Steel Castings, Austenitic Manganese; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- SIS 112132. Blank for Cast Steel Test Piece; Swedish Standards Institute (S.I.S.): Stockholm, Sweden, 1968. [Google Scholar]

- ASTM E112-13. Standard Test Methods for Determining Average Grain Size; ASTM International: West Conshohocken, PA, USA, 2013. [Google Scholar]

- Turkdogan, E.T. Deoxidation of steel. J. Iron Steel Inst. 1972, 210, 21–36. [Google Scholar]

- Andersson, J.O.H.; Höglund, T.L.; Shi, P.F. Thermo-Calc and DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Schneider, J.M.; Voevodin, A.; Rebholz, C.; Matthews, A.; Hogg, J.H.C.; Lewis, D.B.; Ives, M. X-Ray diffraction investigations of magnetron sputtered TiCN coatings. Surf. Coat. Technol. 1995, 74, 312–319. [Google Scholar] [CrossRef]

- Takei, H. Czochralski growth of Mn2SiO4 (tephroite) single crystal and its properties. J. Cryst. Growth 1976, 34, 125–131. [Google Scholar] [CrossRef]

- Spinel. Available online: https://www.mindat.org/min-3729.html (accessed on 3 April 2017).

- Corundum. Available online: https://www.mindat.org/min-1136.html (accessed on 3 April 2017).

| C wt % | Mn wt % | Si wt % | P wt % |

|---|---|---|---|

| 1.05–1.35 | 11.0 min | 1.0 max | 0.07 max |

| Composition (wt %) | C | Si | Mn | Cr | S | Al | Ti | N | O | P |

|---|---|---|---|---|---|---|---|---|---|---|

| Untreated reference material | ||||||||||

| S1 | 1.24 | 0.4 | 12 | 1.45 | 0.0006 | 0.005 | 0.01 | 0.075 | 0.0059 | 0.06 |

| S2 | 1.21 | 0.16 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| S3 | 1.21 | 0.26 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| S4 | 1.21 | 0.46 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| S5 | 1.21 | 0.66 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| S6 | 1.21 | 0.86 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| S7 | 1.21 | 1.46 | 11.78 | 1.52 | 0.0006 | 0.0006 | 0.01 | 0.012 | 0.0067 | 0.04 |

| Deoxidation by addition of 0.1 wt % Al | ||||||||||

| S8 | 1.28 | 0.45 | 13.4 | 1.15 | 0.0006 | 0.011 | 0.03 | 0.035 | 0.0056 | 0.06 |

| S9 | 1.24 | 0.54 | 12.73 | 1.29 | 0.002 | 0.013 | 0.023 | 0.03 | 0.0037 | 0.055 |

| Deoxidation by addition of 0.15 wt % Ti | ||||||||||

| S10 | 1.22 | 0.56 | 11.49 | 1.44 | 0.0006 | 0.0009 | 0.095 | 0.025 | 0.0058 | 0.039 |

| S11 | 1.06 | 0.65 | 11.33 | 1.53 | 0.002 | 0.001 | 0.12 | 0.024 | 0.0060 | 0.039 |

| Deoxidation by addition of 0.1 wt % Al and 0.15 wt % Ti | ||||||||||

| S12 | 1.26 | 0.4 | 12 | 1.45 | 0.0006 | 0.005 | 0.06 | 0.1 | 0.0058 | 0.058 |

| S13 | 1.28 | 0.49 | 12.68 | 1.33 | 0.0006 | 0.012 | 0.1 | 0.034 | 0.0046 | 0.06 |

| S14 | 1.23 | 0.47 | 14.25 | 1.36 | 0.0006 | 0.001 | 0.056 | 0.054 | 0.0035 | 0.059 |

| S15 | 1.25 | 0.5 | 12.47 | 1.37 | 0.0006 | 0.002 | 0.036 | 0.082 | 0.0030 | 0.056 |

| Deoxidation by addition of 0.1 wt % Al and 0.15 wt % Ti (45 min holding in furnace after casting) | ||||||||||

| S16 | 1.25 | 0.55 | 13.82 | 1.37 | 0.002 | 0.003 | 0.11 | 0.027 | 0.0028 | 0.063 |

| S17 | 1.08 | 0.59 | 12.65 | 1.43 | 0.0006 | 0.002 | 0.097 | 0.06 | 0.0043 | 0.056 |

| Sample ID | GS (μm) | 1/Q | Ti(CN) Mole Fraction | Olivine Mole Fraction | Spinel Mole Fraction | Corundum Mole Fraction | Total Oxide Mole Fraction |

|---|---|---|---|---|---|---|---|

| Untreated reference material | |||||||

| S1 | 378 | 0.01121 | 0.0002 | 0 | 0.00025 | 0 | 0.000250 |

| S2 | 375 | 0.01174 | 0 | 0.00024 | 0.00003 | 0.000054 | 0.000324 |

| S3 | 310 | 0.01162 | 0 | 0.00027 | 0.000035 | 0 | 0.000305 |

| S4 | 333 | 0.01140 | 0 | 0.00027 | 0.000035 | 0 | 0.000305 |

| S5 | 405 | 0.01118 | 0 | 0.00028 | 0.000033 | 0 | 0.000313 |

| S6 | 398 | 0.01000 | 0 | 0.00027 | 0.000032 | 0 | 0.000302 |

| S7 | 430 | 0.01039 | 0 | 0.00026 | 0.000031 | 0 | 0.000291 |

| Deoxidation by 0.1 wt % Al | |||||||

| S8 | 497 | 0.01070 | 0.00038 | 0 | 0 | 0.0003 | 0.000300 |

| S9 | 559 | 0.01100 | 0.00019 | 0 | 0 | 0.00019 | 0.000190 |

| Deoxidation by 0.15 wt % Ti | |||||||

| S10 | 562 | 0.01126 | 0.00116 | 0 | 0 | 0.00029 | 0.000290 |

| S11 | 692 | 0.01246 | 0.00136 | 0 | 0 | 0.00032 | 0.000320 |

| Deoxidation by 0.1 wt % Al and 0.15 wt % Ti | |||||||

| S12 | 575 | 0.01107 | 0.00128 | 0 | 0.00011 | 0.00011 | 0.000220 |

| S13 | 790 | 0.01075 | 0.00165 | 0 | 0 | 0.00025 | 0.000250 |

| S14 | 732 | 0.01088 | 0.00103 | 0.00011 | 0.000065 | 0 | 0.000175 |

| S15 | 605 | 0.01097 | 0.00060 | 0 | 0.000090 | 0 | 0.000090 |

| Deoxidation by 0.1 wt % Al and 0.15 wt % Ti (45 min holding in furnace after casting) | |||||||

| S16 | 476 | 0.01073 | 0.00160 | 0 | 0.00015 | 0 | 0.000150 |

| S17 | 302 | 0.01213 | 0.00188 | 0.000077 | 0.00013 | 0 | 0.000207 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Siafakas, D.; Matsushita, T.; Lauenstein, Å.; Ekengård, J.; Jarfors, A.E.W. The Influence of Deoxidation Practice on the As-Cast Grain Size of Austenitic Manganese Steels. Metals 2017, 7, 186. https://doi.org/10.3390/met7060186

Siafakas D, Matsushita T, Lauenstein Å, Ekengård J, Jarfors AEW. The Influence of Deoxidation Practice on the As-Cast Grain Size of Austenitic Manganese Steels. Metals. 2017; 7(6):186. https://doi.org/10.3390/met7060186

Chicago/Turabian StyleSiafakas, Dimitrios, Taishi Matsushita, Åsa Lauenstein, Johan Ekengård, and Anders E. W. Jarfors. 2017. "The Influence of Deoxidation Practice on the As-Cast Grain Size of Austenitic Manganese Steels" Metals 7, no. 6: 186. https://doi.org/10.3390/met7060186