Surface Characteristics and Fatigue Behavior of Gradient Nano-Structured Magnesium Alloy

Abstract

:1. Introduction

2. Material and Experiments

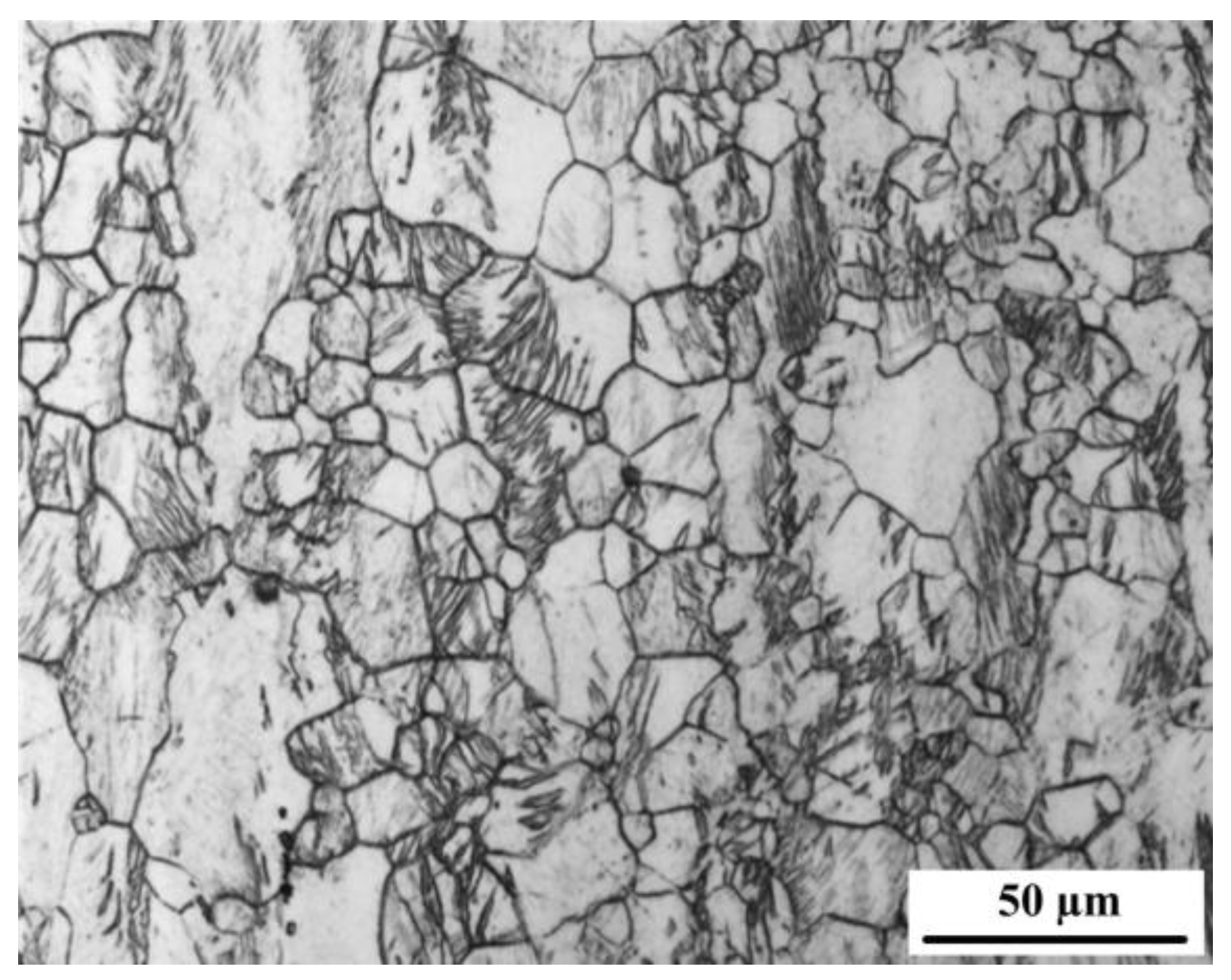

2.1. Material

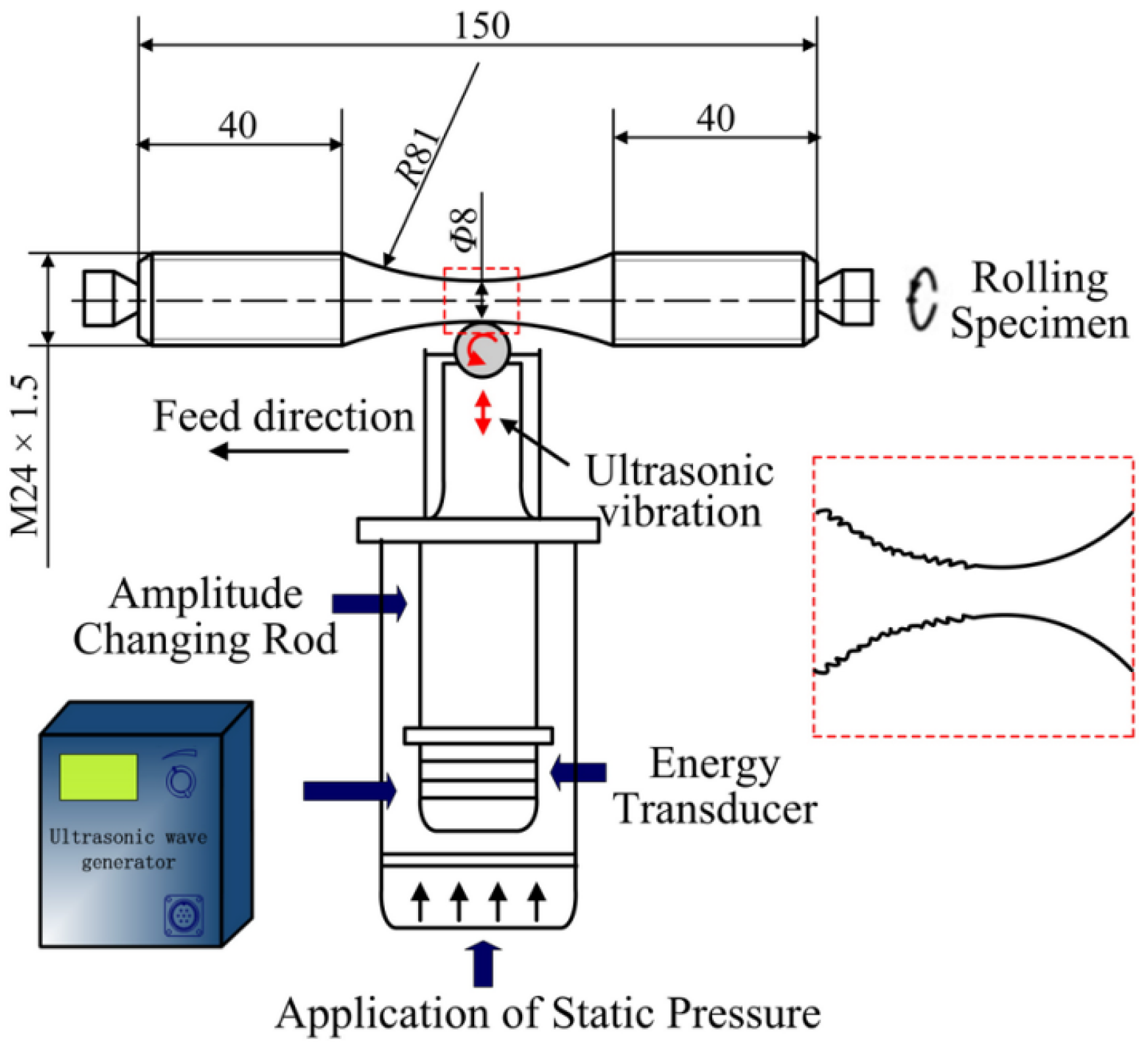

2.2. Fatigue Specimen and HFIR Treatment

2.3. Microstructure Observation

2.4. Surface Roughness, Microhardness and Residual Stress Measurements

3. Results and Discussion

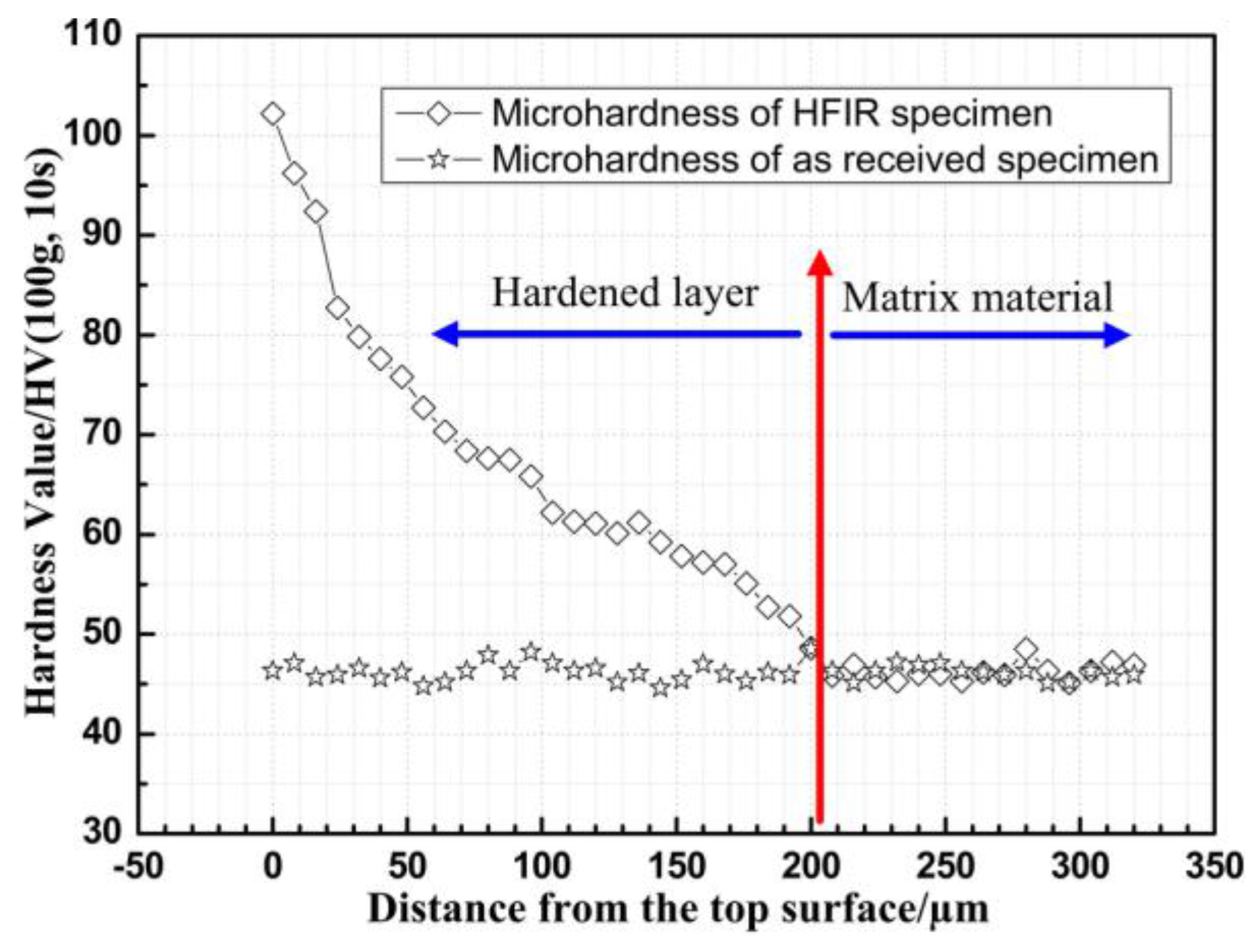

3.1. Microstructure and Microhardness Distribution of the Work-Hardened Layer

3.2. Discussion of Surface Strengthening Mechanism

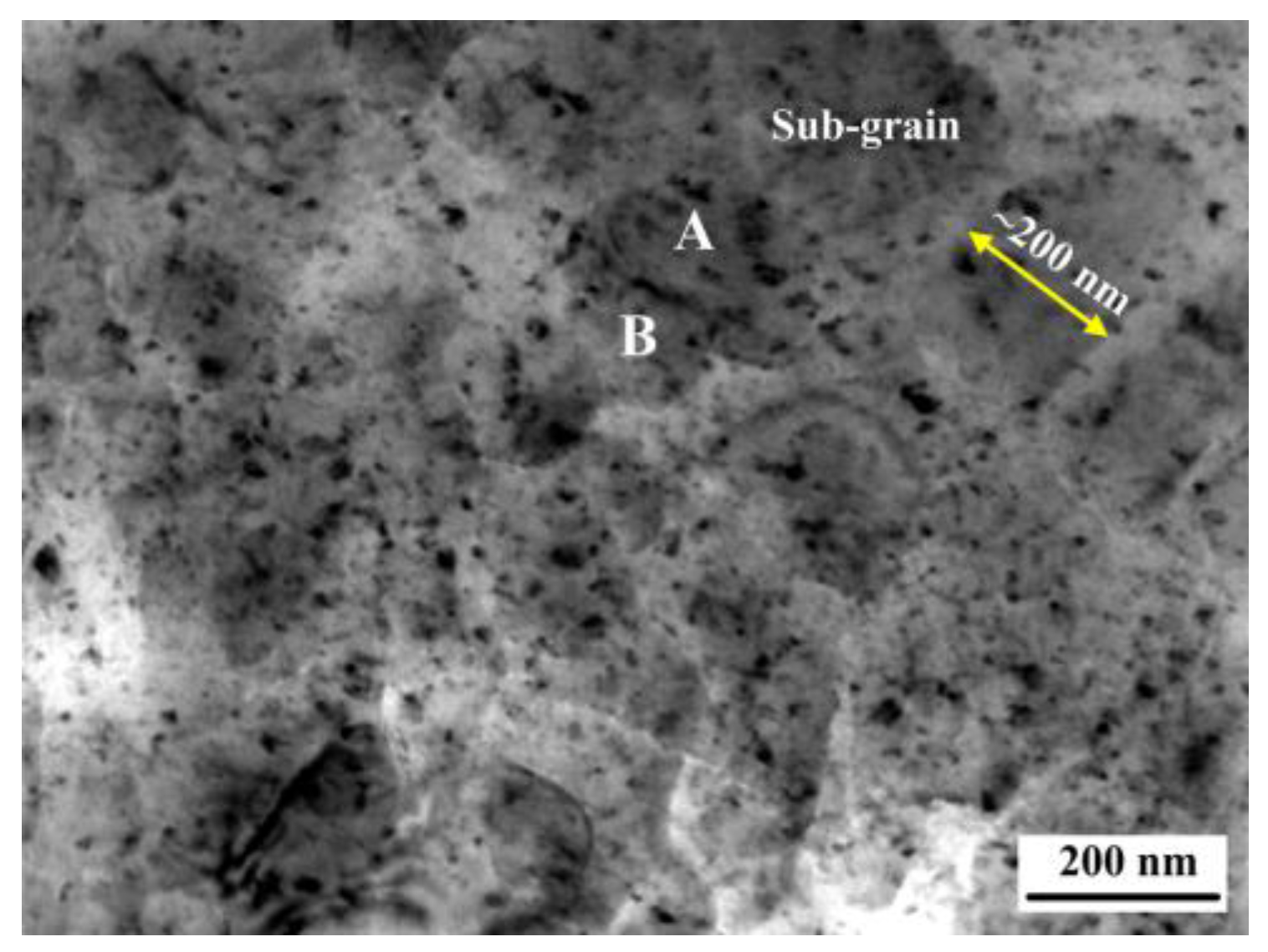

3.2.1. The 160-μm Deformed Layer from the Top Surface

3.2.2. The 80-μm Deformed Layer from the Top Surface

3.2.3. The Top Surface after HFIR Treatment

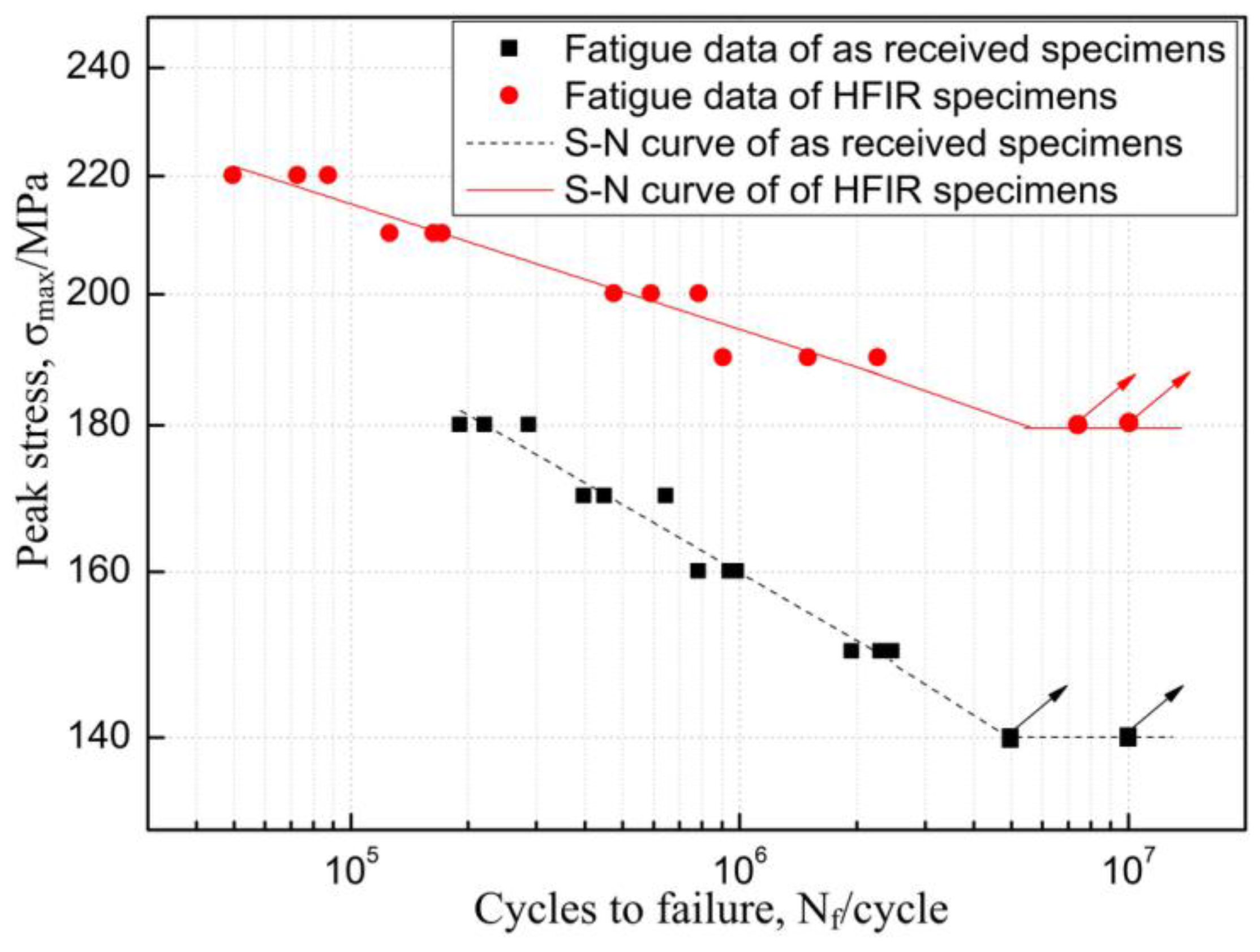

3.3. S-N Curves

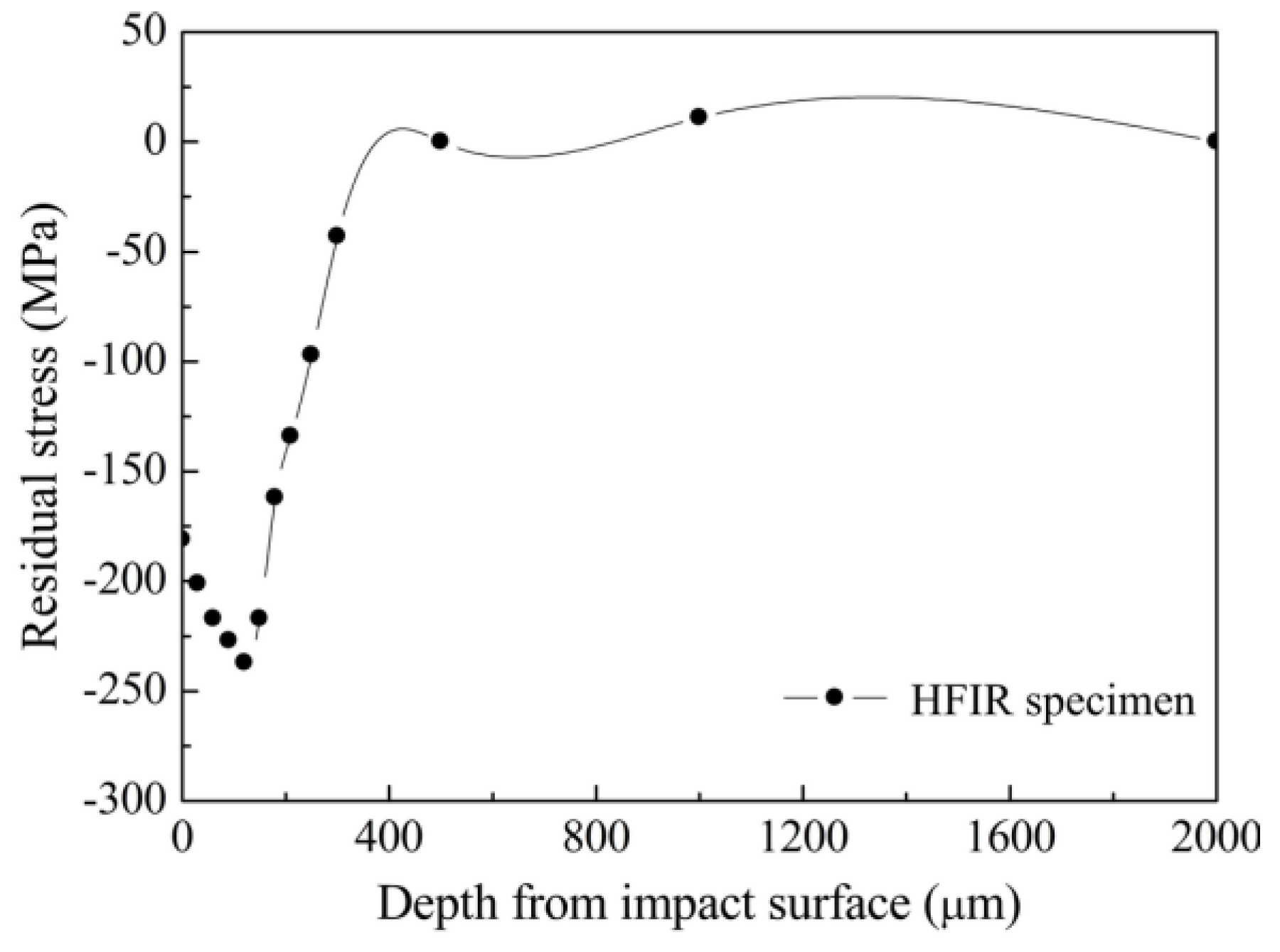

3.4. Discussion of Fatigue Life Improvement

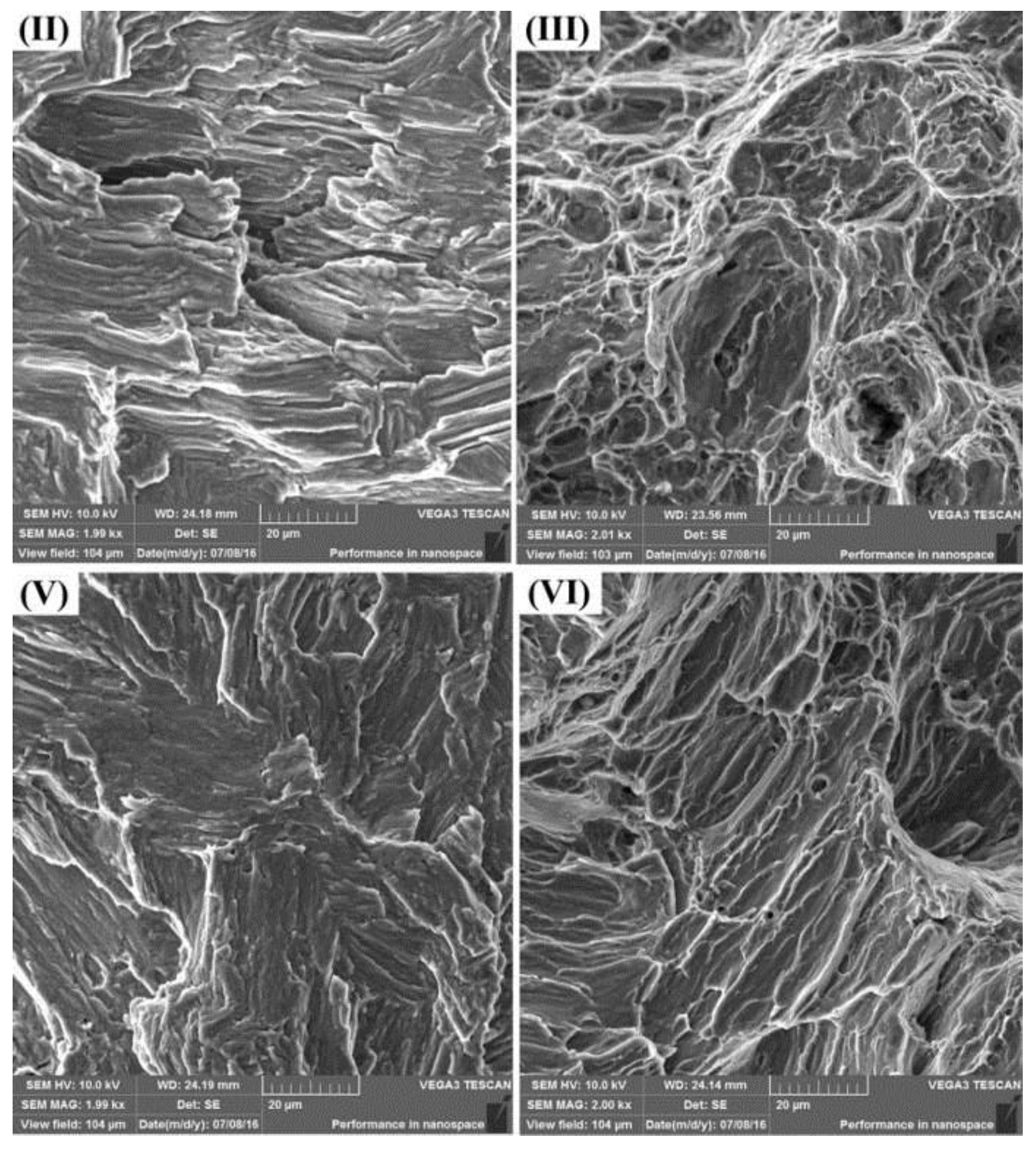

3.5. Fatigue Fracture Process

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Asgari, H.; Szpunar, J.A.; Odeshi, A.G.; Zeng, L.J.; Olsson, E. Experimental and simulation analysis of texture formation and deformation mechanism of rolled AZ31B magnesium alloy under dynamic loading. Mater. Sci. Eng. A 2014, 618, 310–322. [Google Scholar] [CrossRef]

- Li, Z.M.; Wang, Q.G.; Luo, A.A.; Fu, P.H.; Peng, L.M. Fatigue strength dependence on the ultimate tensile strength and microhardness in magnesium alloys. Int J. Fatigue 2015, 80, 468–476. [Google Scholar] [CrossRef]

- Dogan, E.; Vaughan, M.W.; Wang, S.J.; Karaman, I.; Proust, G. Role of starting texture and deformation modes on low-temperature shear formability and shear localization of Mg-3Al-1Zn alloy. Acta Mater. 2015, 89, 408–422. [Google Scholar] [CrossRef]

- Karimi, A.; Amini, S. Steel 7225 surface ultrafine structure and improvement of its mechanical properties using surface nanocrystallization technology by ultrasonic impact. Int. J. Adv. Manuf. Technol. 2016, 83, 1127–1134. [Google Scholar] [CrossRef]

- Manafi, B.; Saeidi, M. Development of a novel severe plastic deformation method: Friction stir equal channel angular pressing. Int. J. Adv. Manuf. Technol. 2016, 86, 1367–1374. [Google Scholar] [CrossRef]

- Sun, H.Q.; Shi, Y.N.; Zhang, M.X.; Lu, K. Plastic strain-induced grain refinement in the nanometer scale in a Mg alloy. Acta Mater. 2007, 55, 975–982. [Google Scholar] [CrossRef]

- Trško, L.; Bokůvka, O.; Novýa, F.; Guagliano, M. Effect of severe shot peening on ultra-high-cycle fatigue of a low-alloy steel. Mater. Des. 2014, 57, 103–113. [Google Scholar] [CrossRef]

- Fernández-Pariente, I.; Bagherifard, S.; Guagliano, M.; Ghelichi, R. Fatigue behavior of nitrided and shot peened steel with artificial small surface defects. Eng. Fract. Mech. 2013, 103, 2–9. [Google Scholar] [CrossRef]

- Bagheri, S.; Guagliano, M. Review of shot peening processes to obtain nanocrystalline surfaces in metal alloys. Surf. Eng. 2009, 25, 3–14. [Google Scholar] [CrossRef]

- Gao, Y.K. Influence of shot peening on tension-tension fatigue property of two high strength Ti alloys. Surf. Eng. 2006, 22, 299–303. [Google Scholar] [CrossRef]

- Gao, Y.; Lu, F.; Yao, M. Influence of mechanical surface treatments on fatigue property of 30CrMnSiNi2A steel. Surf. Eng. 2005, 21, 325–328. [Google Scholar] [CrossRef]

- Arakawa, J.; Kakuta, M.; Hayashi, Y.; Tanegashima, R.; Akebono, H.; Kato, M.; Sugeta, A. Fatigue strength of USP treated ASTM CA6NM for hydraulic turbine runner. Surf. Eng. 2014, 30, 662–669. [Google Scholar] [CrossRef]

- Bagherifard, S.; Fernandez-Pariente, I.; Ghelichi, R.; Guagliano, M. Effect of severe shot peening on microstructure and fatigue strength of cast iron. Int. J. Fatigue 2014, 65, 64–70. [Google Scholar] [CrossRef]

- Malaki, M.; Ding, H.T. A review of ultrasonic peening treatment. Mater. Des. 2015, 87, 1072–1086. [Google Scholar] [CrossRef]

- Tsai, W.Y.; Huang, J.C.; Gao, Y.J.; Chung, Y.L.; Huang, G.R. Relationship between microstructure and properties for ultrasonic surface mechanical attrition treatment. Scr. Mater. 2015, 103, 45–48. [Google Scholar] [CrossRef]

- Moering, J.; Ma, X.L.; Chen, G.Z.; Miao, P.F.; Li, G.Z.; Qian, G.; Mathaudhu, S.; Zhu, Y.T. The role of shear strain on texture and microstructural gradients in low carbon steel processed by Surface Mechanical Attrition Treatment. Scr. Mater. 2015, 108, 100–103. [Google Scholar] [CrossRef]

- Pu, Z.; Yang, S.; Song, G.L.; Dillon, O.W., Jr.; Puleo, D.A.; Jawahir, I.S. Ultrafine-grained surface layer on Mg-Al-Zn alloy produced by cryogenic burnishing for enhanced corrosion resistance. Scr. Mater. 2011, 65, 520–523. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, X.H.; Wang, D.P. Determination of the plastic properties of materials treated by ultrasonic surface rolling process through instrumented indentation. Mater. Sci. Eng. A 2014, 600, 21–31. [Google Scholar] [CrossRef]

- Wang, T.; Wang, D.P.; Liu, G. Investigations on the nanocrystallization of 40Cr using ultrasonic surface rolling processing. Appl. Surf. Sci. 2008, 255, 1824–1829. [Google Scholar]

- Liu, Y.; Zhao, X.H.; Wang, D.P. Effective FE model to predict surface layer characteristics of ultrasonic surface rolling with experimental validation. Mater. Sci. Technol. 2014, 30, 627–636. [Google Scholar] [CrossRef]

- Tan, J.C.; Tan, M.J. Dynamic continuous recrystallization characteristics in two stage deformation of Mg-3Al-1Zn alloy sheet. Mater. Sci. Eng. A 2003, 339, 124–132. [Google Scholar] [CrossRef]

- Myshlyaev, M.M.; McQueen, H.J.; Mwembela, A.; Konopleva, E. Twinning, dynamic recovery and recrystallization in hot worked Mg-Al-Zn alloy. Mater. Sci. Eng. A 2002, 337, 121–133. [Google Scholar] [CrossRef]

- Eddahbi, M.; del Valle, J.A.; Pérez-Prado, M.T.; Ruano, O.A. Comparison of the microstructure and thermal stability of an AZ31 alloy processed by ECAP and large strain hot rolling. Mater. Sci, Eng. A 2005, 410, 308–311. [Google Scholar] [CrossRef]

- Galiyev, A.; Kaibyshev, R.; Gottstein, G. Correlation of plastic deformation and dynamic recrystallization in magnesium alloy ZK60. Acta Mater. 2001, 49, 1199–1207. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Li, D.; Chen, H.N.; Xu, H. The effect of nanostructured surface layer on the fatigue behaviors of a carbon steel. Appl. Surf. Sci. 2009, 255, 3811–3816. [Google Scholar] [CrossRef]

- De los Rios, E.R.; Trull, M.; Levers, A. Modelling fatigue crack growth in shot-peened components of Al 2024-T351. Fatigue Fract. Eng. Mater. Struct. 2000, 23, 709–716. [Google Scholar] [CrossRef]

- McDowell, D.L.; Dunne, F.P.E. Microstructure-sensitive computational modeling of fatigue crack formation. Int. J. Fatigue 2010, 32, 1521–1542. [Google Scholar] [CrossRef]

- Zhu, S.P.; Lei, Q.; Huang, H.Z.; Yang, Y.J.; Peng, W.W. Mean stress effect correction in strain energy-based fatigue life prediction of metals. Int. J. Damage Mech. 2016. [Google Scholar] [CrossRef]

- Eichlseder, W. Fatigue analysis by local stress concept based on finite elementsresults. Comput. Struct. 2002, 80, 2109–2113. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Application of different fatigue strength criteria on shot peenednotched parts. Part 2: Nominal and local stress approaches. Appl. Surf. Sci. 2014, 289, 173–179. [Google Scholar] [CrossRef]

- Bagherifard, S.; Colombo, C.; Guagliano, M. Application of different fatigue strength criteria to shot peenednotched components. Part 1: Fracture Mechanics based approaches. Appl. Surf. Sci. 2014, 289, 180–187. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, X.; Zhang, Y.; Liu, Y. Surface Characteristics and Fatigue Behavior of Gradient Nano-Structured Magnesium Alloy. Metals 2017, 7, 62. https://doi.org/10.3390/met7020062

Zhao X, Zhang Y, Liu Y. Surface Characteristics and Fatigue Behavior of Gradient Nano-Structured Magnesium Alloy. Metals. 2017; 7(2):62. https://doi.org/10.3390/met7020062

Chicago/Turabian StyleZhao, Xiaohui, Yanjun Zhang, and Yu Liu. 2017. "Surface Characteristics and Fatigue Behavior of Gradient Nano-Structured Magnesium Alloy" Metals 7, no. 2: 62. https://doi.org/10.3390/met7020062