Microstructure, Residual Stress, Corrosion and Wear Resistance of Vacuum Annealed TiCN/TiN/Ti Films Deposited on AZ31

Abstract

:1. Introduction

2. Experimental Section

2.1. Sample Deposition

2.2. Microstructure and Residual Stress

2.3. Composition, Thickness and Property

3. Results and Discussion

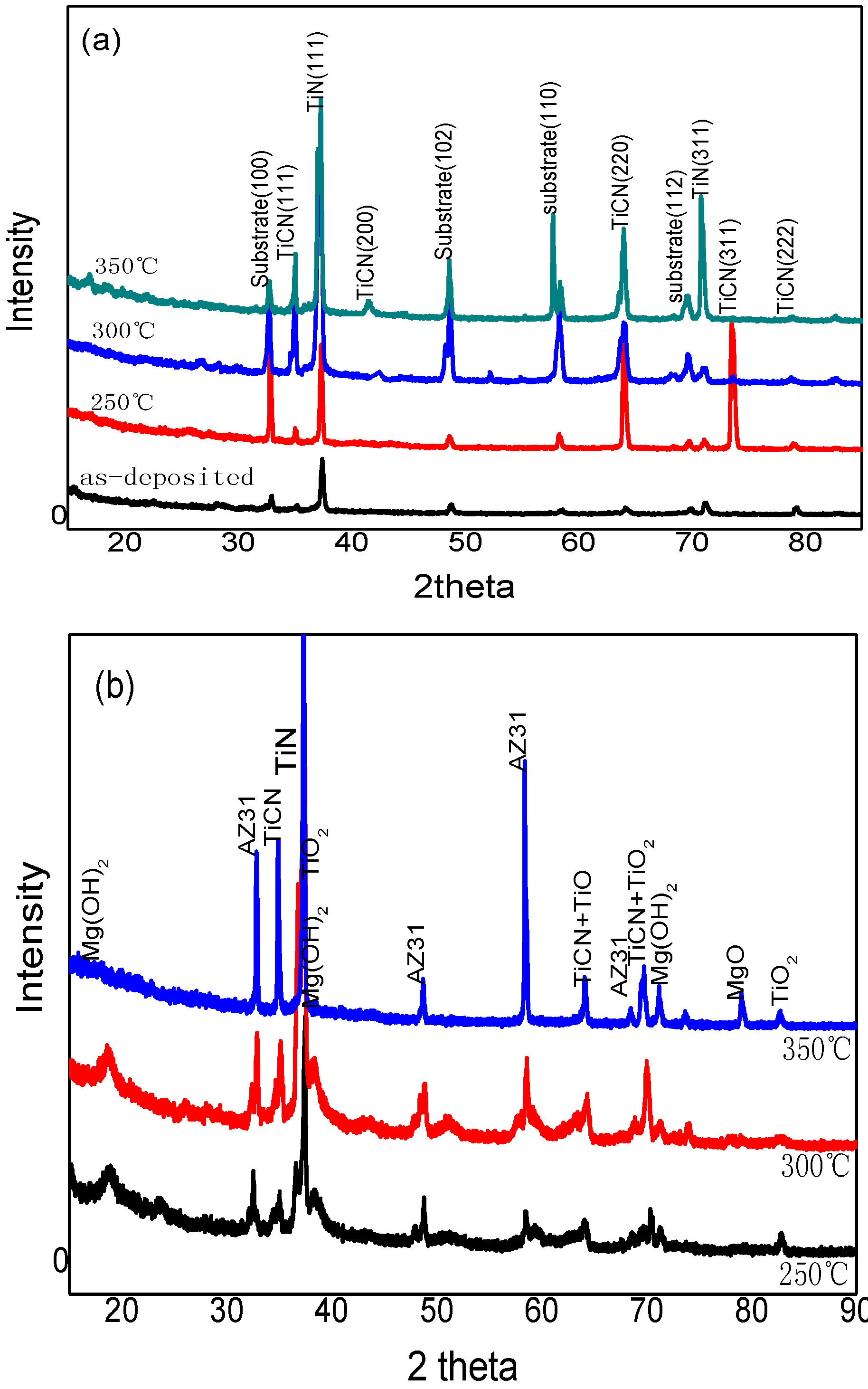

3.1. Microstructure

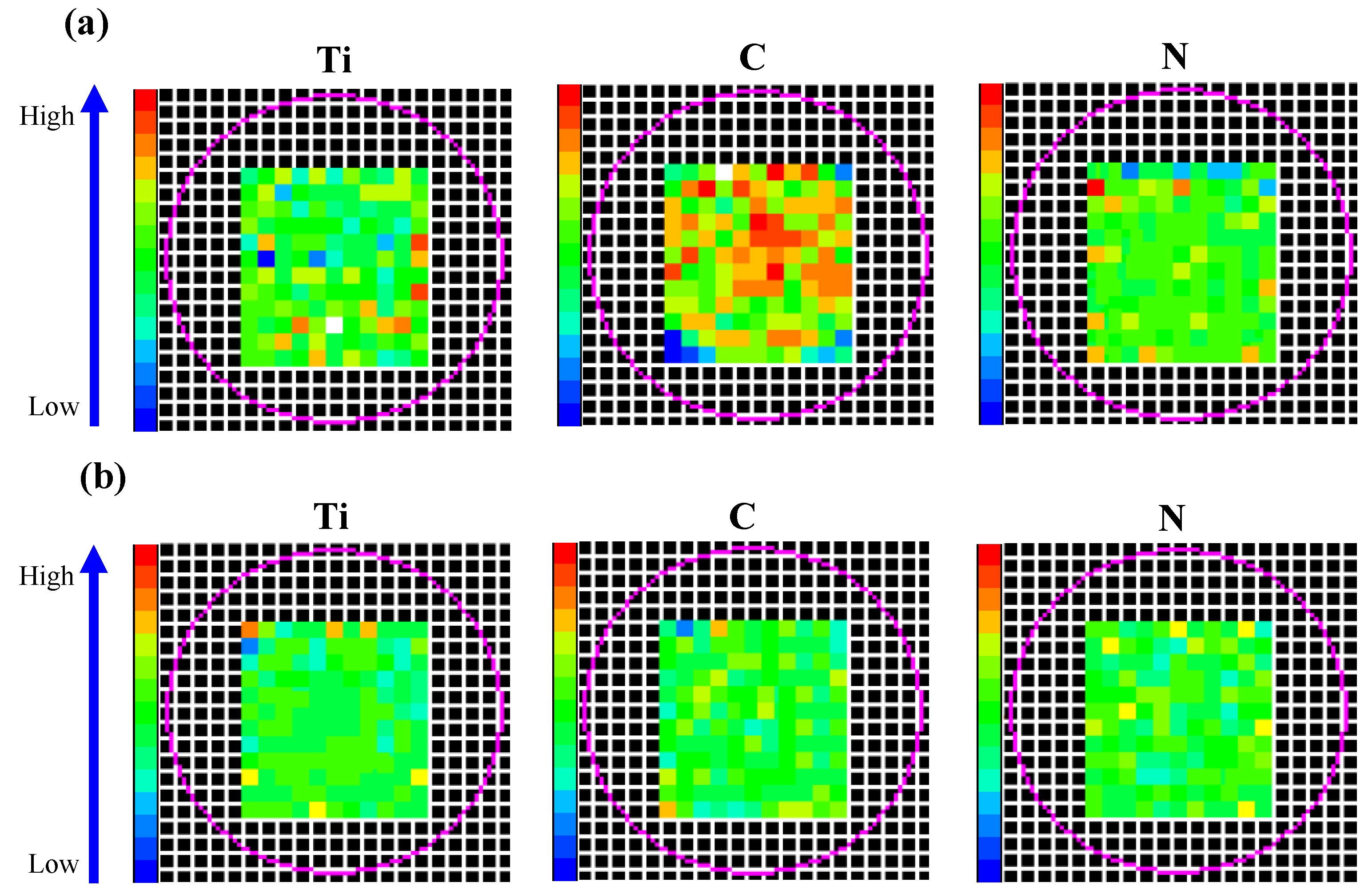

3.2. Composition and Thickness

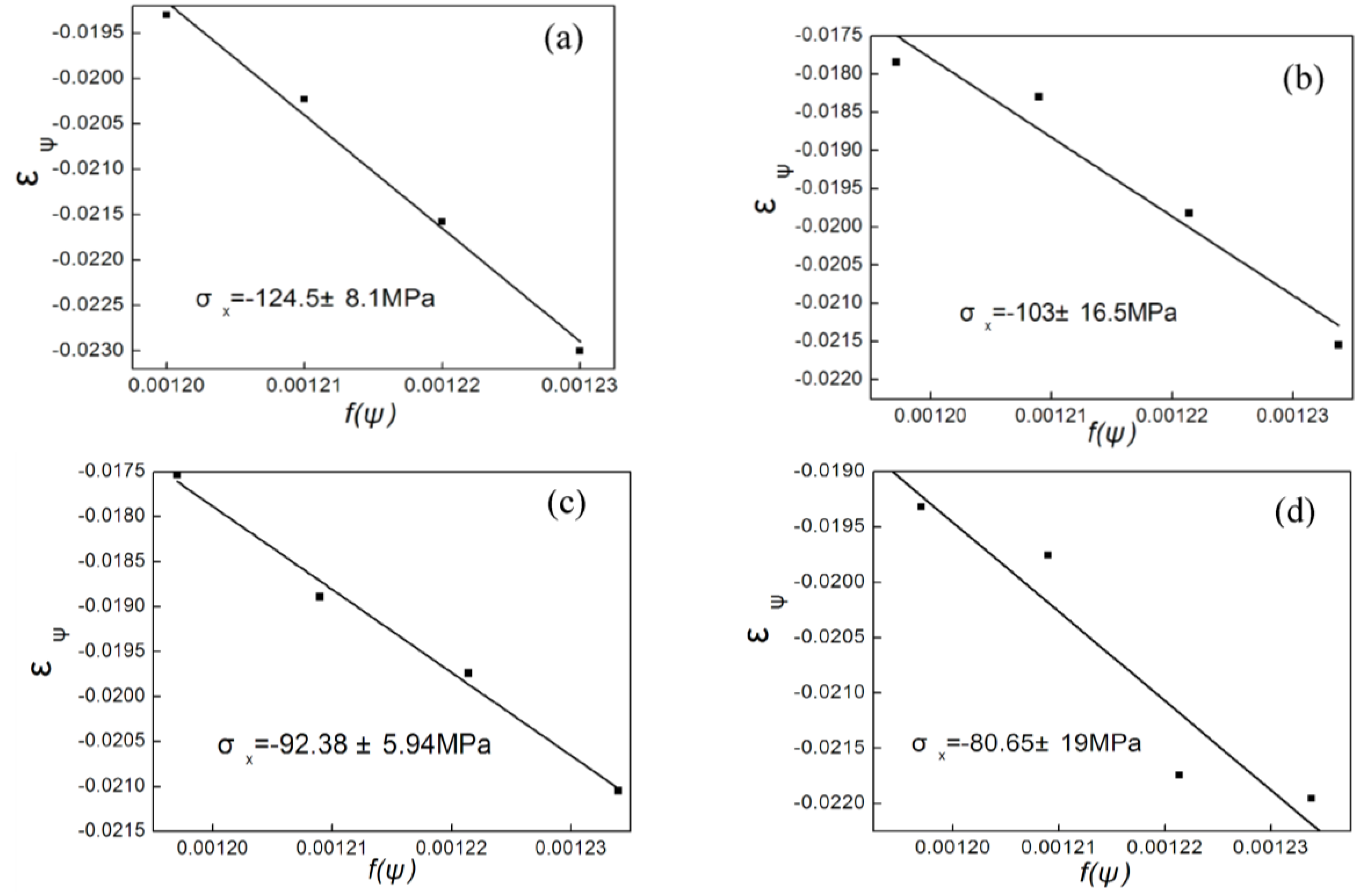

3.3. Residual Stress

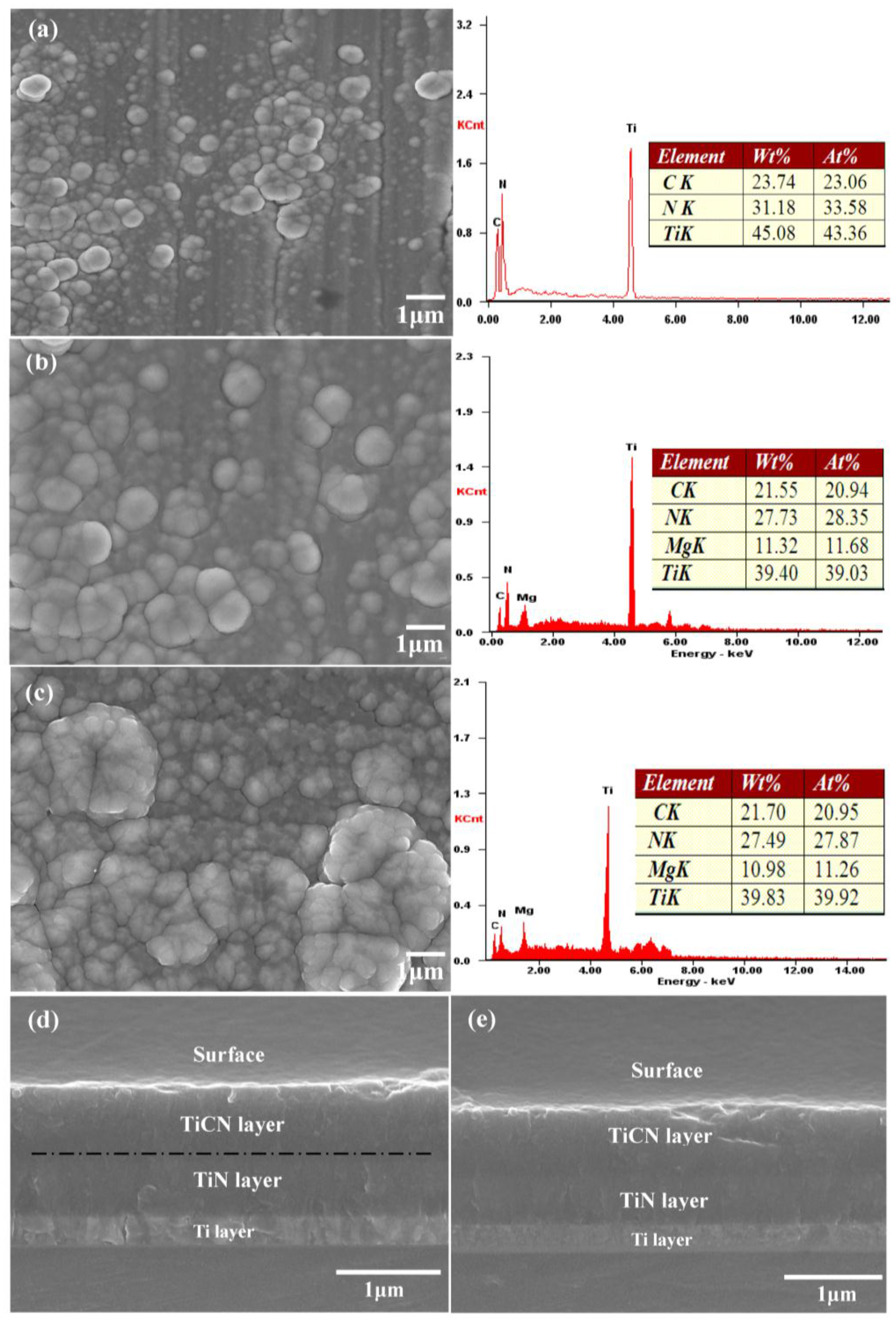

3.4. Morphology and EDS Analysis

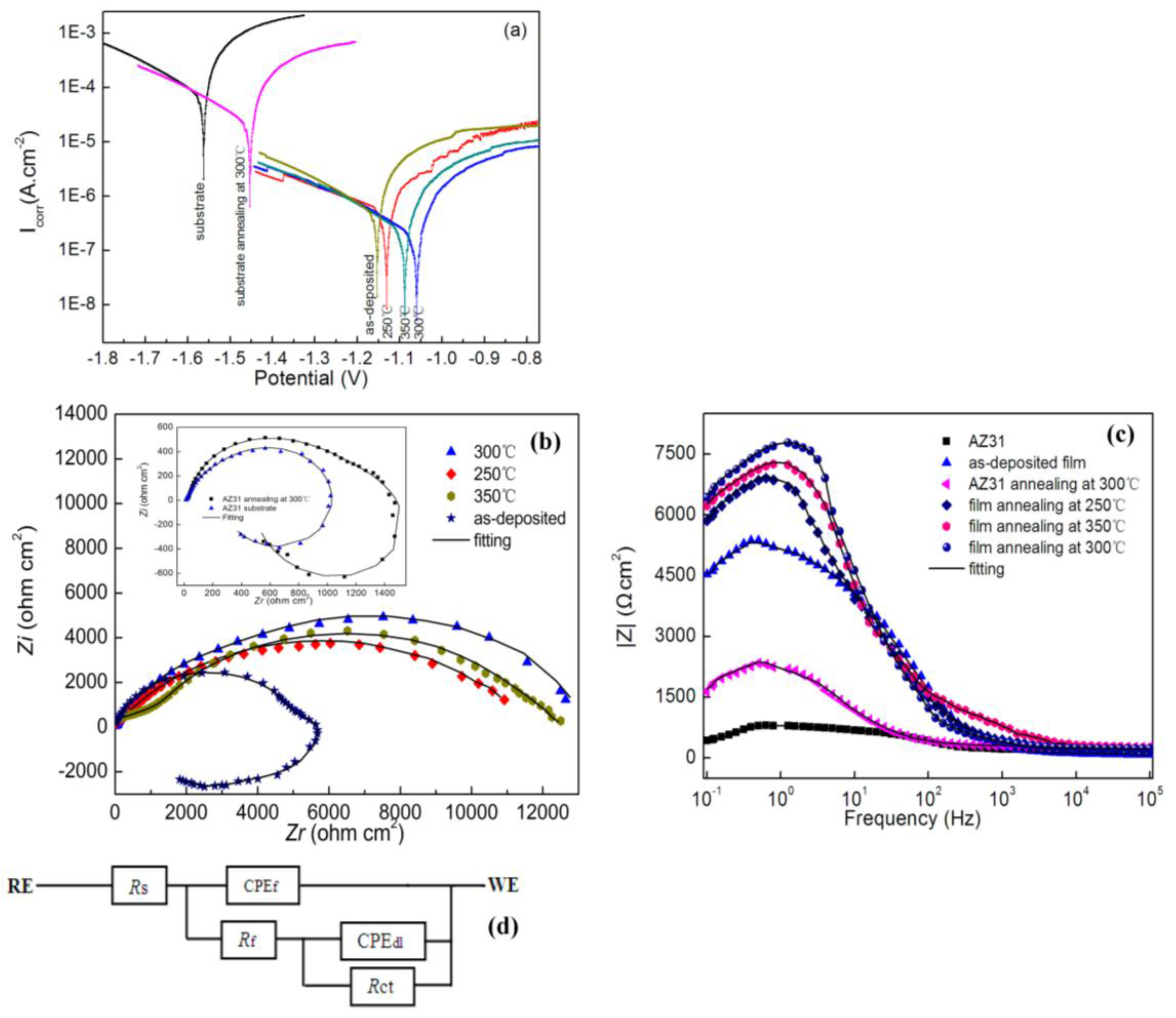

3.5. Corrosion Behavior

3.6. Tribological Behavior

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of interest

References

- Altun, H.; Sen, S. The effect of PVD coatings on the corrosion behaviour of AZ91 magnesium alloy. Mater. Des. 2006, 27, 1174. [Google Scholar] [CrossRef]

- Wu, G.S.; Wang, X.M.; Ding, K.J.; Zhou, Y.Y.; Zeng, X.Q. Corrosion behavior of Ti-Al-N/Ti-Al duplex coating on AZ31 magnesium alloy in NaCl aqueous solution. Mater. Charact. 2009, 60, 803–807. [Google Scholar] [CrossRef]

- Yao, X.H.; Tian, L.H.; Zhang, Y.; Ma, Y.; Tang, B. Adhesion and Wear Properties of Cr-N Coatings on Magnesium Alloy by Unbalanced Magnetron Sputtering. Rare Met. Mater. Eng. 2013, 42, 589. [Google Scholar]

- Zhang, Y.; Yan, C.; Wang, F.; Lou, H.; Cao, C. Study on the environmentally friendly anodizing of AZ91D magnesium alloy. Surf. Coat. Technol. 2002, 161, 36–43. [Google Scholar] [CrossRef]

- Niu, L.; Chang, S.; Tong, X.; Li, G.; Shi, Z. Analysis of characteristics of vanadate conversion coating on the surface of magnesium alloy. J. Alloy. Compd. 2014, 617, 214–218. [Google Scholar] [CrossRef]

- Shan, L.; Wang, Y.X.; Li, J.L.; Li, H.; Wu, X.D.; Chen, J.M. Tribological behaviours of PVD TiN and TiCN coatings in artificial seawater. Surf. Coat. Technol. 2013, 226, 40. [Google Scholar] [CrossRef]

- Yan, Y.; Zheng, Y.; Yu, H.; Pu, H. Research Development of the Preparation Technology of Titanium Carbonitride Coating. Mater. Rev. 2007, 21, 55. [Google Scholar]

- Wang, L.; Dong, S.; You, J.; Yu, L.; Li, X.; Xu, J. Microstructure and microhardness of TiCN and TiN/TiCN multilayer films. Trans. Mater. Heat Treat. 2010, 31, 113. [Google Scholar]

- Cheng, G.A.; Han, D.Y.; Liang, C.L.; Wu, X.L.; Zheng, R.T. Influence of residual stress on mechanical properties of TiAlN thin films. Surf. Coat. Technol. 2013, 228, S329. [Google Scholar] [CrossRef]

- Sanjeev, K.S.; Deuk, Y.K. Abnormal residual stress in nanostructured Al thin films grown on Ti/glass substrates. Curr. Appl. Phys. 2013, 13, 1875. [Google Scholar]

- Li, M.; Cheng, Y.; Zheng, Y.F.; Zhang, X.; Xi, T.F.; Wei, S.C. Surface characteristics and corrosion behaviour of WE43 magnesium alloy coated by SiC film. Appl. Surf. Sci. 2012, 258, 3075. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, C.; Song, L.; Zeng, R.; Li, S.; Cui, H. Fabrication of the Superhydrophobic Surface on Magnesium Alloy and Its Corrosion Resistance. J. Mater. Sci. Technol. 2015, 31, 1139–1143. [Google Scholar] [CrossRef]

- Liu, H.; Xu, Q.; Zhang, X.; Wang, C.; Tang, B. Residual stress analysis of TiN film fabricated by plasma immersion ion implantation and deposition process. Nucl. Instrum. Methods Phys. Res. B 2013, 297, 1–3. [Google Scholar] [CrossRef]

- Chen, Z.; Prud’homme, N.; Wang, B.; Ji, V. Residual stress gradient analysis with GIXRD on ZrO2 thin films deposited by MOCVD. Surf. Coat. Technol. 2011, 206, 405–407. [Google Scholar] [CrossRef]

- Li, M.; Zhuang, M.; Yin, K.; Wang, J. Residual stress analysis on the Ti-bioglass coatings produced by high velocity flame spraying. Trans. China Weld. Inst. 2009, 30, 66. [Google Scholar]

- Li, H.; Wang, Q.; Zhuang, M.; Wu, J. Characterization and residual stress analysis of TiN/TiCN films on AZ31 magnesium alloy by PVD. Vacuum 2015, 112, 66–69. [Google Scholar] [CrossRef]

- Li, H.; Li, M.; Han, T.; Sun, J.; Wang, J. Elemental distribution in weld metal of low alloy steel during TIG welding. Trans. China Weld. Inst. 2014, 35, 91–92. [Google Scholar]

- Meng, G.; Li, Y.; Shao, Y.; Zhang, T.; Wang, Y.; Wang, F.; Cheng, X.; Dong, C.; Li, X. Effect of Microstructures on Corrosion Behavior of Nickel Coatings: (II) Competitive Effect of Grain Size and Twins Density on Corrosion Behavior. J. Mater. Sci. Technol. 2016, 32, 465–469. [Google Scholar] [CrossRef]

- Lu, Y.; Dong, J.; Ke, W. Effects of Cl− Ions on the Corrosion Behaviour of Low Alloy Steel in Deaerated Bicarbonate Solutions. J. Mater. Sci. Technol. 2016, 32, 341–348. [Google Scholar] [CrossRef]

- Hollstein, F.; Wiedemann, R.; Scholz, J. Characteristics of PVD-coatings on AZ31hp magnesium alloys. Surf. Coat. Technol. 2003, 162, 261–268. [Google Scholar] [CrossRef]

| Temperature (°C) | Element Contents | Thickness (μm) | ||

|---|---|---|---|---|

| Ti | N | C | ||

| As-deposited | 46.2634 | 30.7397 | 22.9969 | 1.75 |

| 250 | 48.2358 | 28.2041 | 23.5601 | 1.77 |

| 300 | 47.9233 | 28.8855 | 23.1912 | 1.79 |

| 350 | 48.0995 | 28.5277 | 23.3728 | 1.83 |

| Samples | Corrosion Potential Ecorr (V) | Current Density Icorr (A·cm−2) |

|---|---|---|

| Uncoated AZ31 | −1.562 | 8.15 × 10−4 |

| Annealing AZ31 | −1.448 | 1.03 × 10−4 |

| Deposited film | −1.151 | 7.65 × 10−7 |

| 250 °C film | −1.138 | 6.42 × 10−7 |

| 300 °C film | −1.062 | 4.69 × 10−7 |

| 350 °C film | −1.084 | 6.08 × 10−7 |

| Samples | Rs (ohm·cm2) | CPEf (cm−2·s−n·Ω) | n | Rct (ohm·cm2) | CPEdl (cm−2·s−n·Ω) | Rf (ohm·cm2) |

|---|---|---|---|---|---|---|

| 250 °C | 88.63 | 4.58 × 10−6 | 0.79 | 5164 | 3.76 × 10−5 | 898 |

| 300 °C | 95.35 | 2.05 × 10−6 | 0.79 | 5859 | 1.35 × 10−5 | 1156 |

| 350 °C | 99.84 | 4.19 × 10−6 | 0.78 | 5362 | 3.42 × 10−5 | 1009 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Rong, S.; Sun, P.; Wang, Q. Microstructure, Residual Stress, Corrosion and Wear Resistance of Vacuum Annealed TiCN/TiN/Ti Films Deposited on AZ31. Metals 2017, 7, 5. https://doi.org/10.3390/met7010005

Li H, Rong S, Sun P, Wang Q. Microstructure, Residual Stress, Corrosion and Wear Resistance of Vacuum Annealed TiCN/TiN/Ti Films Deposited on AZ31. Metals. 2017; 7(1):5. https://doi.org/10.3390/met7010005

Chicago/Turabian StyleLi, Haitao, Shoufan Rong, Pengfei Sun, and Qiang Wang. 2017. "Microstructure, Residual Stress, Corrosion and Wear Resistance of Vacuum Annealed TiCN/TiN/Ti Films Deposited on AZ31" Metals 7, no. 1: 5. https://doi.org/10.3390/met7010005