The Effect of Creep Aging on the Fatigue Fracture Behavior of 2524 Aluminum Alloy

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties

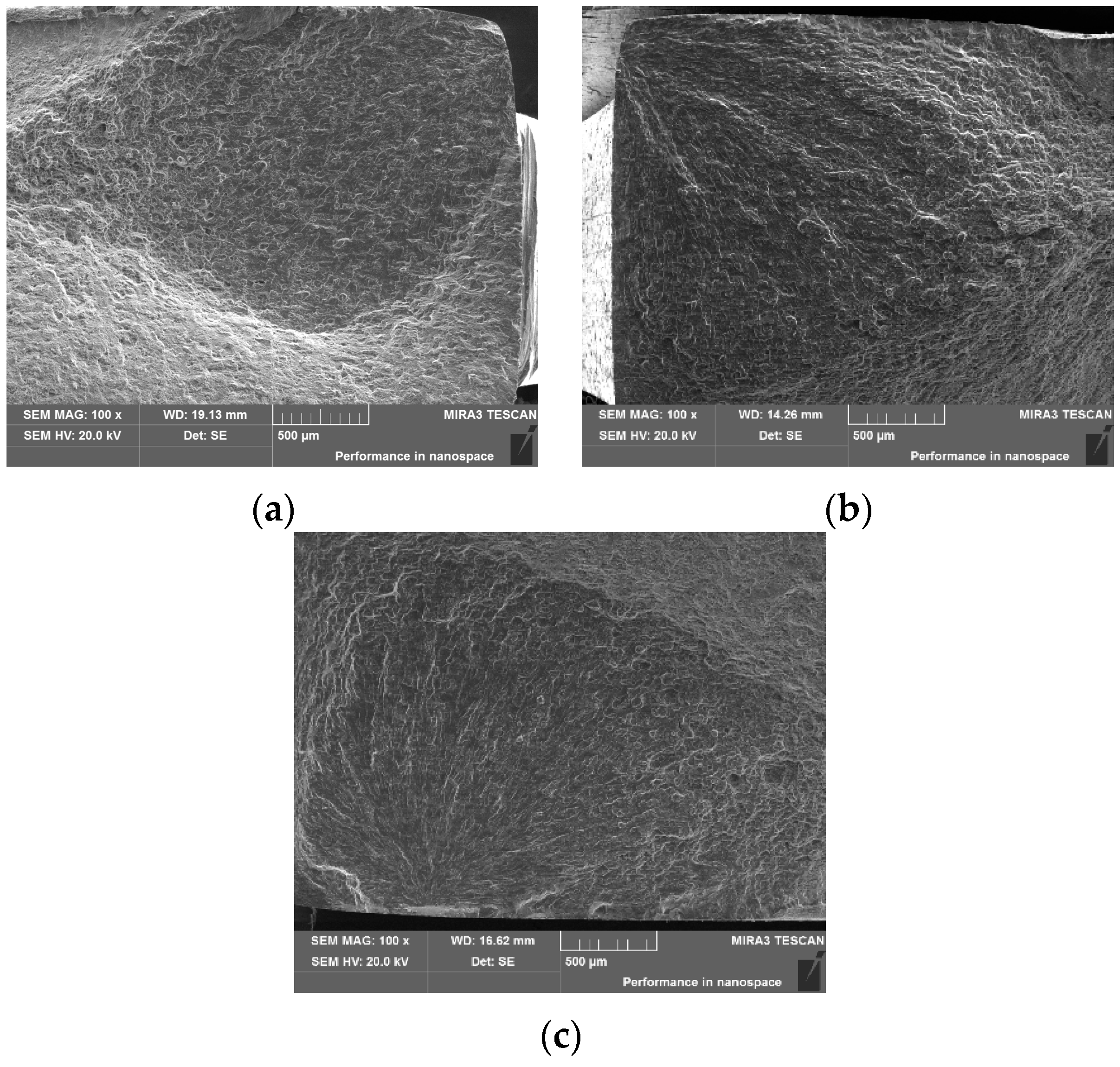

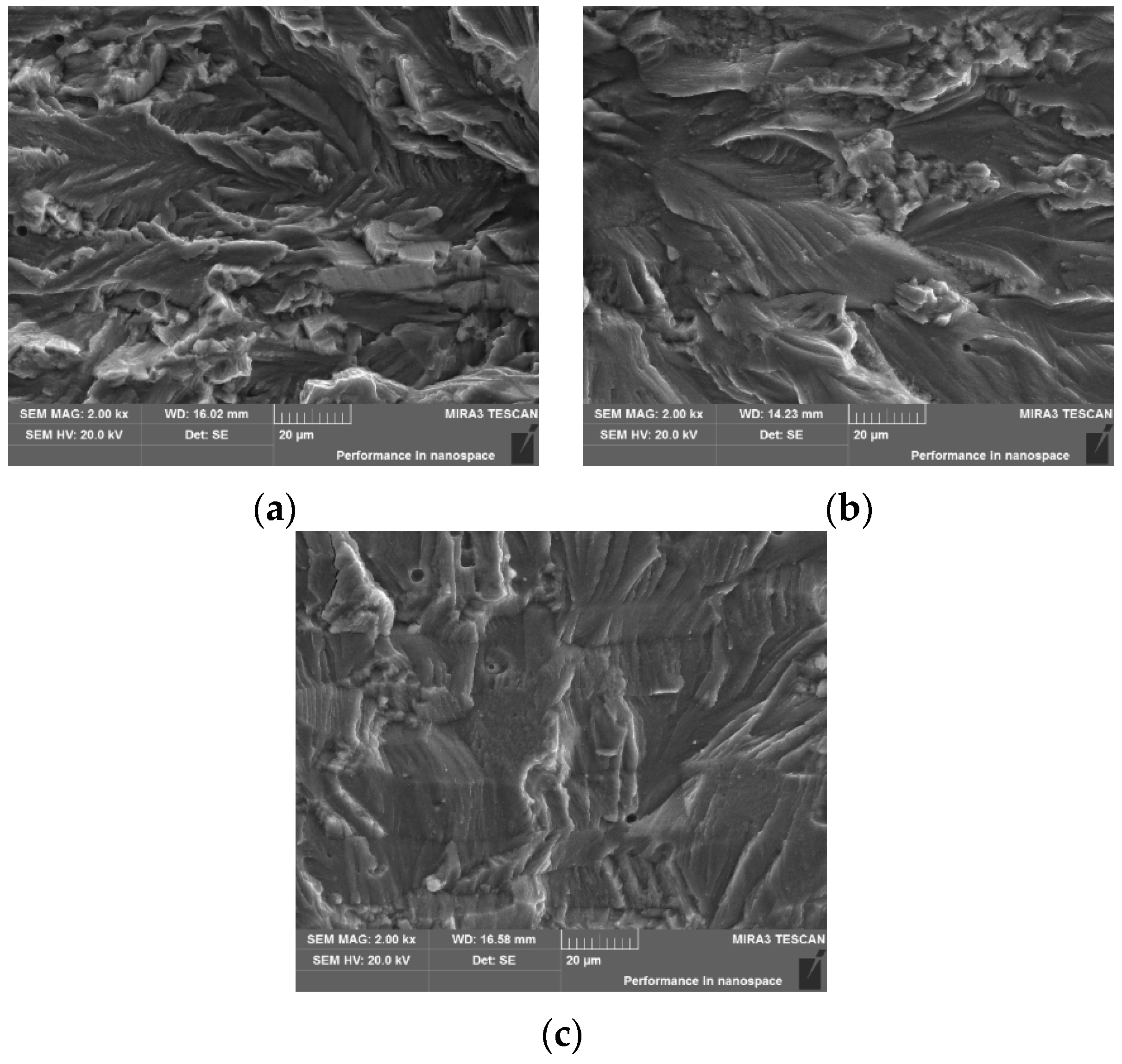

3.2. Fatigue Fracture Analysis

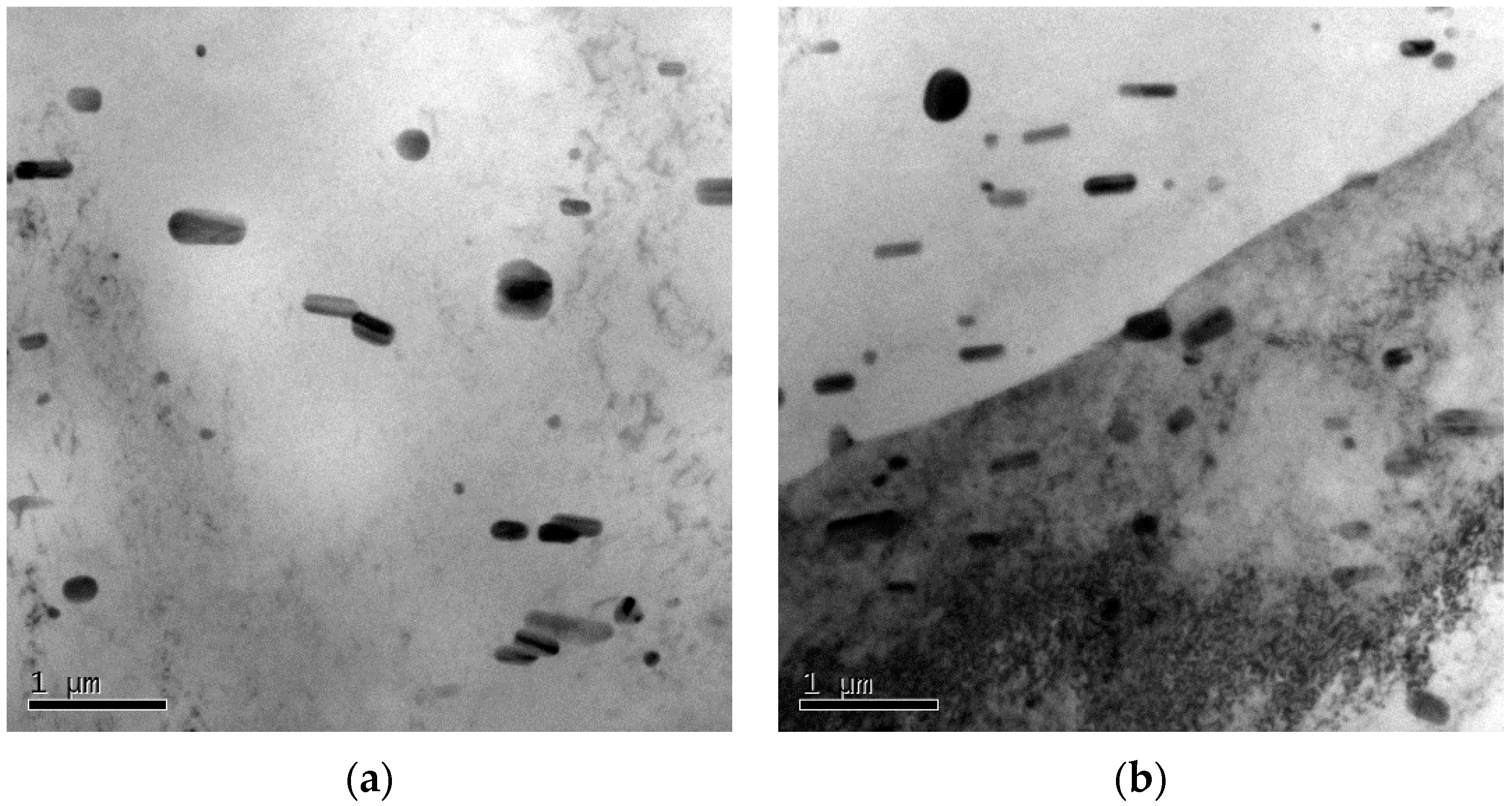

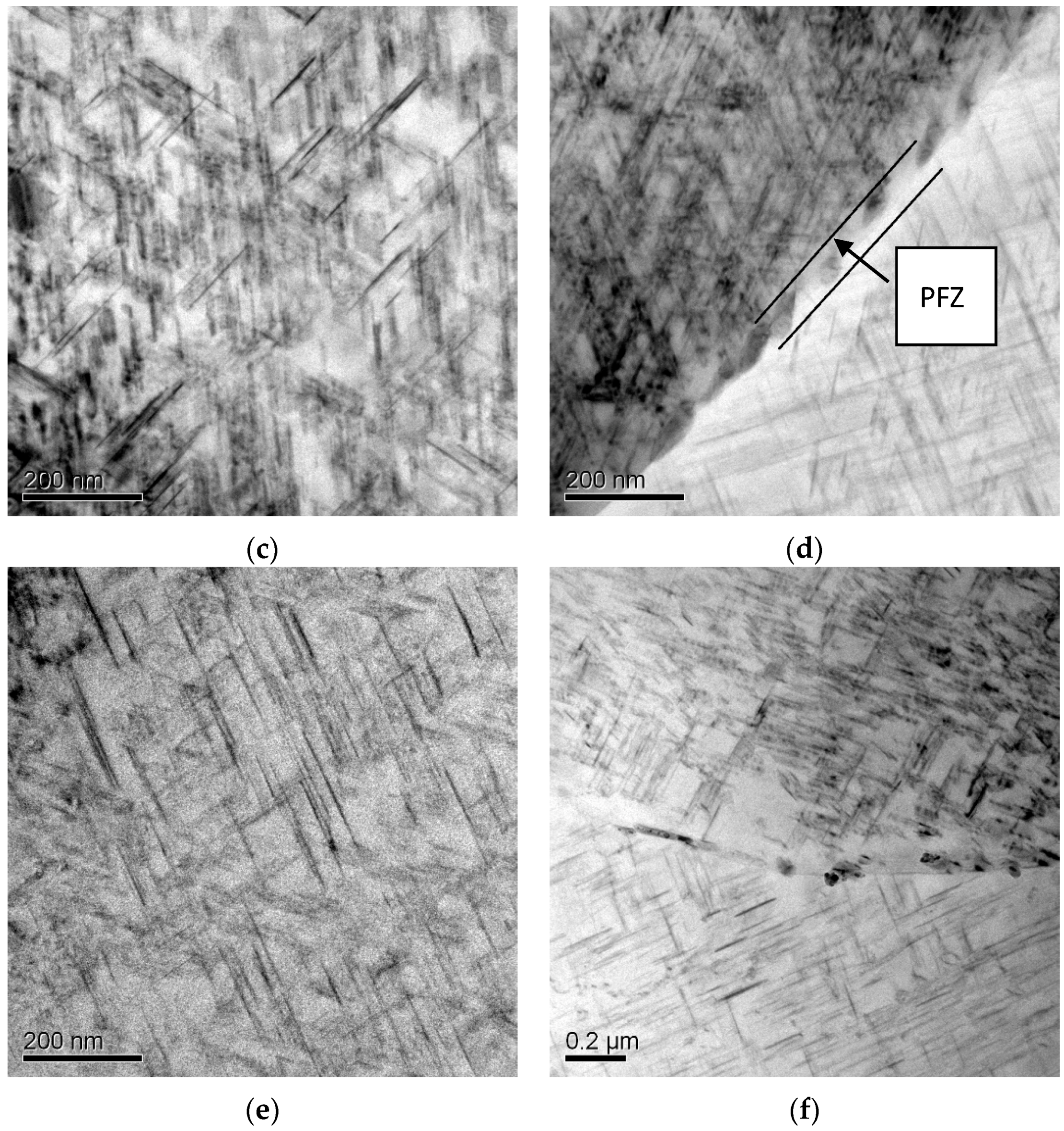

3.3. Microstructure

3.4. Discussion

4. Conclusions

- (1)

- Mechanical performance of samples after artificial aging and creep aging has enjoyed significant improvement over that of the T3 alloy. Fatigue life of the alloy through creep aging has also enjoyed improvement over that of the T3 alloy, and the fatigue life of samples after artificial aging treatment drops.

- (2)

- The fatigue fracture morphology of samples in three states is divided into the fatigue source area, the fatigue crack expansion area, and the instant fracture area. Among them, the morphological difference of the fatigue crack expansion area is the largest, fatigue striation of the creep aging alloy is relatively narrow, and there are micro cracks appearing at the fatigue striation of the artificial aging alloy.

- (3)

- All samples treated by artificial aging and creep aging precipitate S′ phases, about 60-nm PFZ appears at the crystal boundary of the samples treated by artificial aging, and the PFZ of the samples treated by creep aging is narrow or even absent.

- (4)

- Transgranular phase precipitation can improve the anti-plastic deformation ability of materials, hence raising the fatigue life of alloy. The presence of rough second phases and PFZ at the crystal boundary is likely to make the alloy crack at the boundary, lowering its fatigue life.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zeng, Y.; Huang, X. Forming Technologies of Large Integral Panel. Acta Aeronaut. ET Astronaut. Sin. 2008, 3, 721–727. [Google Scholar]

- Zhan, L.; Lin, J.; Dean, T.A. A review of the development of creep age forming: Experimentation, modelling and applications. Int. J. Mach. Tools Manuf. 2011, 51, 1–17. [Google Scholar] [CrossRef]

- Holman, M.C. Autoclave age forming large aluminum aircraft panels. J. Mech. Work. Technol. 1989, 20, 477–488. [Google Scholar] [CrossRef]

- Levers, A.; Prior, A. Finite element analysis of shot peening. J. Mater. Process. Technol. 1998, 80–81, 304–308. [Google Scholar] [CrossRef]

- Zhan, L.; Lin, J.; Dean, T.A.; Huang, M. Experimental studies and constitutive modelling of the hardening of aluminium alloy 7055 under creep age forming conditions. Int. J. Mech. Sci. 2011, 53, 595–605. [Google Scholar] [CrossRef]

- Hargarter, H.; Lyttle, M.T.; Starke, E.A. Effects of preferentially aligned precipitates on plastic anisotropy in Al-Cu-Mg-Ag and Al-Cu alloys. Mater. Sci. Eng. A 1998, 257, 87–99. [Google Scholar] [CrossRef]

- Zhan, L.; Li, Y.; Huang, M. Microstructures and properties of 2124 alloy creep ageing under stress. J. Cent. South Univ. Sci. Technol. 2012, 3, 926–931. [Google Scholar]

- Chen, Y.; Deng, Y.; Wan, L.; Jin, K.; Xiao, Z. Microstructure and Properties of 7050 Aluminum Alloy Sheet During creep Aging. J. Mater. Eng. 2012, 1, 71–76. [Google Scholar]

- Zabett, A.; Plumtree, A. Microstructural effects on the small fatigue crack behavior of an aluminum alloy plate. Fatigue Fract. Eng. Mater. Struct. 1995, 18, 801–809. [Google Scholar] [CrossRef]

- Carter, R.D.; Lee, E.W.; Starke, E.A.; Beevers, C.J. The effect of microstructure and environment on fatigue crack closure of 7475 aluminum alloy. Metall. Mater. Trans. A 1984, 15, 555–563. [Google Scholar] [CrossRef]

- Bray, G.H.; Glazov, M.; Rioj, R.J.; Lib, D.; Gangloffb, R.P. Effect of artificial aging on the fatigue crack propagation resistance of 2000 series aluminum alloys. Int. J. Fatigue 2001, 23, 265–276. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Chen, W. Application of advanced aluminum alloys in A380 structures. Aviat. Maint. Eng. 2005, 2, 40–41. [Google Scholar]

- Shu, D. Mechanical Properties of Engineering Materials, 1st ed.; Machinery Industry Press: Beijing, China, 2007. [Google Scholar]

- Cheng, S.; Zhao, Y.H.; Zhu, Y.T.; Ma, E. Optimizing the strength and ductility of fine structured 2024 Al alloy by nano-precipitation. Acta Mater. 2007, 55, 5822–5832. [Google Scholar] [CrossRef]

- Liu, Z.; Li, Y.; Liu, Y.; Xia, Q. Development of Al-Cu-Mg-Ag alloys. Chin. J. Nonferr. Met. 2007, 12, 1905–1915. [Google Scholar]

- Wang, S.C.; Starink, M.J. Precipitates and intermetallic phases in precipitation hardening Al-Cu-Mg-(Li) based alloys. Int. Mater. Rev. 2013, 50, 193–215. [Google Scholar] [CrossRef]

| Sample | Tensile Strength/MPa | Yield Strength/MPa | Elongation/% |

|---|---|---|---|

| T3 | 477.65 | 339.72 | 18.53 |

| AA | 490.22 | 439.39 | 8.25 |

| CA | 503.17 | 462.17 | 8.56 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, W.; Zhan, L.; Liu, L.; Xu, Y. The Effect of Creep Aging on the Fatigue Fracture Behavior of 2524 Aluminum Alloy. Metals 2016, 6, 215. https://doi.org/10.3390/met6090215

Li W, Zhan L, Liu L, Xu Y. The Effect of Creep Aging on the Fatigue Fracture Behavior of 2524 Aluminum Alloy. Metals. 2016; 6(9):215. https://doi.org/10.3390/met6090215

Chicago/Turabian StyleLi, Wenke, Lihua Zhan, Lingfeng Liu, and Yongqian Xu. 2016. "The Effect of Creep Aging on the Fatigue Fracture Behavior of 2524 Aluminum Alloy" Metals 6, no. 9: 215. https://doi.org/10.3390/met6090215

APA StyleLi, W., Zhan, L., Liu, L., & Xu, Y. (2016). The Effect of Creep Aging on the Fatigue Fracture Behavior of 2524 Aluminum Alloy. Metals, 6(9), 215. https://doi.org/10.3390/met6090215